Unical modulex 360, modulex 540, modulex 630, modulex 450 Installation, Use And Maintenance Manual

Page 1

MODULEX

360 - 450

540 - 630

MODULAR CONDENSING

BOILER

00332210 - 2nd edition - 09/05

INSTALLATION, USE AND

MAINTENANCE

GB

Page 2

IMPORTANT

This INSTRUCTION MANUAL, which is an integr al and indispensable part of the product, must be handed over to the user b y the plumbers and

must be kept in a safe place for future reference. The manual m ust be handed ov er with the boiler should it be sold or transf erred.

This boiler must be used for the purposes for which it has been designed. Any other use shall be considered incorrect and therefore

dangerous.

The boiler must be installed in compliance with applicable laws and standards and according to the manufacturer’s instructions given in this

manual. Incorrect installation ma y cause injury to persons and/or animals and damage to property. The manufacturer shall not be held liab le for any

such injury and/or damage.

Damage and/or injury caused by incorrect installation or use and/or damage and/or injury due to non-observance of the manufacturer’ s instructions

shall relieve UNICAL from any and all contractual and e xtracontractual liability.

Before installing the boiler, check that the technical data corresponds to requirements f or its correct use in the system.

Check that the boiler is intact and that it has not been damaged during transport and handling. Do not install equipment which is patently damaged

and/or faulty.

Do not obstruct the air suction and/or heat dissipation grates.

Only original accessories must be used for all boilers supplied with optionals or kits (including electrical ones).

Dispose of the packaging with care as all the materials can be recycled. The packaging must therefore be sent to specific waste management

sites.

Keep the packaging out of the reach of children as it may represent a choking and suff ocation hazard.

In the event of failure and/or faulty functioning, switch off the boiler. Do not attempt to mak e repairs: contact qualified technicians.

Original parts must be used for all repairs to the boiler.

Non-observance of the above requirement may jeopardize the saf ety of the boilers and expose people, animals and property to danger.

To guarantee efficiency and correct functioning of the equipment it is legally binding to service the boilers once a year according to

the schedule indicated in the relative section of this manual.

In the event of long periods of inactivity of the boiler , disconnect it from the po wer mains and close the gas tap (W arning! In this case the boiler’ s

electronic anti-freeze function will not be operative).

Should there be a risk of freezing, add anti-freeze: it is not advisable to empty the system as this may result in damage; use specific anti-freeze

products suitable for multi-metal heating systems.

N.B.

For boilers which use gaseous fuel, if you smell gas:

- do not turn on or off electrical switches and do not turn on electrical appliances;

- do not ignite flames and do not smoke;

- close the main gas tap;

- open doors and windows;

- contact a Service Centre, qualified installer or the gas supply company.

Never use flames to detect gas leaks.

WARNING

This boiler has been built for installation in the country indicated on the technical data plate: installation in any other country may be a source

of danger for people, animals and property.

Read the warranty conditions and clauses on the warranty certificate attached to the boiler with care.

2

Page 3

DAT A PLA TE

®

1

2

15

17

19

G20

2H

G20

2E

G30/G31

3+

G30 - 31

3B/P

G31

3P

1 = P.I.N. code

2 = Boiler type (only for condensing boiler)

3 = (S.N°) Serial Nr.

4 = Manufacture Date

5 = Model

6 = Appliance type

7 = Elettrical supply

8 = Maximum absorbed power - Insulation

protection

3

9

12

20 - 25

20

28-30/37

30 - 50

37 - 50

4

/

6

16

18

mbar

mbar

mbar

mbar

mbar

IT ES IE

PT GR

TR HR

CZ SK

HU

SI

GB

CN RU RO

LV E E LT

7

10

13

20

II 2H3+

II 2H3+

II 2H3B/P

II 2H3P

II 2HS 3B/P

II 2E3P

II 2H3P

I 2H

I 2H

9 = (Pn) Nominal Output

10 = (Pcond) Condensing Nominal Output

(only for condensing boiler)

11 = (D) Specific flow rate EN 625

12 = (Qn) Nominal heat input

13 = (Qnw) Nominal heat input for D.H.W.

system if there are different out puts

between the C.H. and D.H.W . circuits

14 = (NOx) NOx Class

5

20 ; 28-30/37 mbar

20 ; 28-30/37 mbar

20 ; 50 mbar

18 ; 50 mbar

25 ; 30 mbar

20 ; 50 mbar

20 ; 37 mbar

20 mbar

20 mbar

21

8

11

14

15 = (PMS) Max pressure C.H. system

16 = (T max) Max T emperature C.H. system

17 = (PMW) Max pressure D.H.W . system

18 = (T max) Temperature D.H.W. system

19 = Adjusted for gas type X

20 = Countr y of destination, Gas category,

Supply pressure

21 = Side for national brand

3

Page 4

1

TECHNICAL FEA TURES

AND DIMENSIONS........................................................... pag. 6

1.1 T echnical F eatures .................................................................. pag. 6

1.2 Dimensions .............................................................................. pag. 7

1.3 T echnical Data and Main Components.................................... pag. 9

1.4 Side View................................................................................. pag. 10

2

INSTRUCTIONS FOR INST ALLERS ................. pag. 11

2.1 Instructions for installation...................................................... pag. 11

2.2 Installation ............................................................................... pag. 11

2.2.1 Packing....................................................................... pag. 11

2.2.2 Boiler Location inside a Heat Power Plant................. pag. 13

2.2.3 Boiler Connection ....................................................... pag. 13

2.2.4 Connection to Chimney .............................................. pag. 1 3

2.2.5 Notes on Condensate Drain ....................................... pag. 1 4

2.3 Types of Heating Systems ...................................................... pag. 15

2.3.1 C.H. System Air Vent.................................................. pag. 16

2.3.2 Boiler and System Filling-up & Draining .................... pag. 16

2.3.3 Max Allowable Working Pressure............................... pag. 17

2.3.4 Safety Valv e ............................................................... pag. 17

2.3.5 Gas Mains .................................................................. pag. 17

2.3.6 Hydraulic Compensator or Open Manifold ................. pag. 17

2.3.7 Filter ........................................................................... pag. 18

2.3.8 Ball Valv es.................................................................. pag. 18

2.3.9 Feeding Water Quality ................................................ pag. 18

2.3.10 Boiler Antifrost Protection .......................................... pag. 18

2.3.11 Min. Water Flow Rate.................................................. pag. 19

2.4 Boiler Operation....................................................................... pag. 19

2.4.1 General Description .................................................... pag. 2 0

2.4.2 Ignition Sequence....................................................... pag. 21

2.4.3 Supplementary Board ................................................. pag. 2 2

2.4.4 Domestic Hot Water (DHW) Mode Operation ............. pag. 2 3

2.5 Boiler Operation in case of technical intervention .................. pag. 23

2.6 Electric Connections ............................................................... pag. 24

2.6.1 Power Supply .............................................................. pag. 25

2.6.1 Wiring Diagram ........................................................... pag. 25

2.6.2 Electric Connection to Ignition PCB........................... pag. 26

2.6.3 Electric Connection to the Room Thermostat ............ pag. 26

2.6.4 DHW Storage T ank ..................................................... pag. 27

MODULAR BOILER DRIVE (MBD)

OPERATION.......................................................................... pag. 28

3

4

3.1 General Description ................................................................. pag. 28

3.2 Operation and display instructions.......................................... pag. 28

3.2.1 “Mode” Ke y.............................................................. pag. 29

3.2.2 “Step” Ke y ............................................................... pag. 2 9

3.2.3 “+ / -“ Key................................................................ pag. 29

3.2.4 “Store” Ke y .............................................................. pag. 29

3.2.5 Service Code .......................................................... pag. 29

3.2.6 Programming Access Procedure ........................... pag. 30

3.2.7 “Stand-by” Key........................................................ pag. 32

Page 5

3.2.8 “Parameter” Mode ................................................... pag. 32

3.2.8.1 Installer and User programmable Operation

Parameters............................................... pag. 32

3.2.8.2 Installer programmable Operation

3.2.9 “Data” Mode ............................................................ pag. 34

3.2.9.1 Installer and User programmable

3.2.9.2 Installer programmable parameters

3.2.10 “T est” Mode ............................................................. pag. 35

3.2.11 “Operation Time” Mode ........................................... pag. 35

3.3 Heating Mode Operation.......................................................... pag. 36

3.3.1 Heating Mode Operation by Room Thermostat............. pag. 36

3.3.2 Heating Mode Operation by Outer Sensor.................... pag. 36

3.3.3 Heating Mode Operation by Outer Compensator.......... pag. 37

3.4 DHW Mode Operation. ............................................................. pag. 37

3.4.1 DHW Mode Operation by Storage Tank NTC Sensor ... pag. 37

3.4.2 DHW Mode Operation by Storage Tank Thermostat ..... pag. 37

3.5 Burner Pressure Adjustment T est ........................................... pag. 38

Parameters by previously entering

the service code ...................................... pag. 33

parameters ............................................... pag. 34

by previously entering the

service code............................................. pag. 34

4

5

ERRORS ................................................................. pag. 3 9

4.1 Blank Display ................................................................. pag. 3 9

4.2 The Boiler doesn’t fulfill the DHW Production Request. ......... pag. 39

4.3 Ignition Anomalies ................................................................. pag. 3 9

4.4 Block Errors ................................................................. pag. 3 9

4.5 Error Codes ................................................................. pag. 4 0

4.5.1 Error Codes by Alarm.................................................... pag. 40

4.5.2 Error Codes related to local temperatures .................... pag. 40

4.5.3 Error Codes related to gas pressure, MBD ,

AM-4 and AM-5 ............................................................ pag. 4 1

4.5.4 Error Codes related to global temperatures .................. pag. 41

MAINTENANCE .................................................. pag. 4 2

5.1 Main Features .................................................. pag. 4 2

5.2 Siphon Cleaning .................................................. pag. 4 2

5

Page 6

1

GENERAL DESCRIPTION

1.1 - TECHNICAL /

FEATURES

- MODULEX is a compact, gas fired,

Low NO

up by one sectional boiler body (so

called

separately or in cascade.

This heat module consists of two or

more thermal elements (from 4 to 7),

which cannot be separated from

each other, being under the same

protecting casing. These thermal elements are connected to a single

smoke exhaust manifold and are

controlled by a single microprocessor which manages completely the

temperatures from the point of view,

both operational and safety.

- If, for instance, one of the thermal

elements whose the boiler is composed, goes out of order, the other

thermal elements continue to supply their output. It is nearly impossible the boiler go completely out of

order.

- MODULEX has been examined ac-

cording the following European directives:

- (GAD) Gas Appliances Directive

- (BED) Boiler Efficiency Directive

by CERTIGAZ, under the No .

1312BP4012, for type B23 operation,

i.e. the boiler can be connected to a

traditional natural draught chimney,

and for operation in category I

–20 mbar).

It also conforms to the following European directives:

- EMC (Electro Magnetic Compatibi-

lity) Directive No. 89/336 CEE

- L VD (Low V oltage Directiv e)

- Machines Directive

- The boiler body, made by sections

of cast aluminium/magnesium/silicium alloy, is conceived to recover

the sensible and the latent heat of

the combustion gases, thus allowing to reach an efficiency of

109% on the N.C.V.

- Each thermal element, composed of

a combustion chamber with burner,

modulating fan with control pressure switch, gas valve, ignition device, flame control, NTC sensor for lo-

6

, condensing boiler, made

x

heat module

No. 73/23 CEE

No. 89/392 CEE

), set to operate

No. 90/396 CEE

No. 92/42 CEE

2H

(G20

cal temperature control and safety

thermostat, can deliver an output

between a maximum of 90 kW and a

minimum of 22 kW .

4

360

5

450

6

540

7

630

- Each single boiler is equipped with

NTC sensors for global temperature control on the flow and return manifolds.

- Total premix modulating burner

equipped with metallic sponge radiation burner.

Premix in the pre-combustion chamber. Automatic no return diaphragm

for separation from combustion

chamber.

- Combustion air suction/feeding system from the boiler house

- Possible cascade installation of 2 or

more MODULEX

- Heating Operation: setting of instantaneous output by a main microprocessor, with a comparison parameters pre-setting between the requested temperature (or calculated by

the outer compensator) and the global flow temperature.

- Logic of operation:

A) Output sharing on as many modules as possible at min. load (down

to 22 kW) for the max. efficiency.

B) Automatic operation hour splitting-up system for each module to

guarantee the best homogeneous

use.

C) DHW production by a priority sensor which, thanks to the dedicated

electronic board, drives a special

loading pump or a 3-way diverting

valve for the preparation of a storage tank with the possibility of presetting the D.H.W. circuit output, up

to maximum 360 kW .

D) Output check of each module for

any calibration and/or assistance by

secret access code.

- Control panel with alphanumeric display, programming keys, reset and

hydrometer .

- Displays: global flow/return temperature, DHW temperature, external tem-

60

75 l/h

90 l/h

105 l/h

perature.

- Adjustments: flow temperature, fan

speed, max/min. output percentage.

- Access to all testing/programming

parameters of each module: operation

test, operation time, boiler anti-frost

protection from 7°C, pump’s anti-

blocking system.

- Integral easily removable panel set

l/h

(painted steel panels).

- Condensate collecting tank equip-

ped with drain siphon and stainless steel smoke chamber.

- Built-in air vent.

- Weights and dimensions are limi-

ted (see table at par. 1.2).

Page 7

1.2 - DIMENSION

MODULEX 360

Øi D

L.H. SIDE VIEW

B

A

ATTENTION

CHIMNEY

CONNECTION

INDIFFERENT

POSITION FROM THE

ONE SHOWN ARE

S

NOT ALLOWED.

C

110

UPPER VIEW

666

FRONT VIEW

576

1243

T

E

E

P

R

E

E

D

S

T

O

O

T

E

S

M

R

S

REAR VIEW

474

920

®

446

171

398

G

206

M

H

1372

232

R

974

124

MODULEX

Dimension

No. of Modules

Height mm

Width ''L'' net mm

Width with packaging mm

Depth ''C'' mm

Depth ''A'' mm

Depth ''B'' mm

Depth with packaging mm

Net weight kg

Gross weight kg

Connections

Gas mm

C.H. system Flow M mm

C.H. system Retur n R mm

Chimney connection ''D'' mm

Chimney width ''H'' mm

Condensate drain diameter mm

474

fig. 1-a

360

4

1372

920

1020

1530

985

390

1200

430

496

DN50 PN 10/16

DN80 PN 10/16

DN80 PN 10/16

250

615

40

7

Page 8

MODULEX 450 - 540 - 630

R.H. SIDE VIEW

G

F

=

UPPER VIEW

124

124

110

666

232

474

ATTENTION

CHIMNEY

CONNECTION

INDIFFERENT

POSITION FROM THE

ONE SHOWN ARE

NOT ALLOWED.

Øi D

206

1243

576

E

P

R

E

T

O

T

S

S

=

FRONT VIEW

(D) 1520

920

®

T

E

D

E

S

O

E

M

R

REAR VIEW

=

G

M

R

171

(E) 425

398

1372

974

425

600

350

175

H

MODULEX

Dimension

No. of Modules

Height mm

Width ''L'' net mm

Width with packaging mm

Width ''D'' mm

Width ''E'' mm

Depth ''F'' mm

Depth with packaging mm

Net weight kg

Gross weight kg

Connections

Gas mm

C.H. system Flow M mm

C.H. system Retur n R mm

Chimney connection ''D'' mm

Chimney width ''H'' mm

Condensate drain diameter mm

450

1372

920

1020

1520

445

1120

1320

1340

510

584

DN50 PN 10/16

DN80 PN 10/16

DN80 PN 10/16

250

615

40

5

DN50 PN 10/16

DN100 PN 10/16

DN100 PN 10/16

S

540

1372

920

1020

1520

425

1256

1380

1700

620

700

300

720

40

6

DN50 PN 10/16

DN100 PN 10/16

DN100 PN 10/16

fig. 1-b

630

7

1372

920

1020

1520

425

1390

1514

1840

680

778

300

855

40

8

Page 9

1.3 - TECHNICAL DATA

The Technical data plate is placed under the front jacket next to the control

panel.

BOILER TYPE MODULEX

Nominal Heat Input on P.C.I

Minimum Heat Input on P.C.I .

Nominal Output (Tr 60 / Tm 80 °C)

Minimum Output (Tr 60 / Tm 80 °C)

Nominal Output (Tr 30 / Tm 50 °C)

Minimum Output (Tr 30 / Tm 50 °C)

Qn

Qmin

Pn

Pn min

Pcond

Pcond min

kW

kW

kW

kW

kW

kW

Efficiency at max. output (Tr 60 / Tm 80°C) %

Efficiency at min. output (Tr 60 / Tm 80°C) %

Efficiency at max. output (Tr 30 / Tm 50°C) %

Efficiency at min. output (Tr 30 / Tm 50°C) %

Efficiency at 30 % at part load (Tm 50°C) %

Efficiency at 30 % at part load (Tr 30°C) %

Efficiency Class acc. to Directive 92/42 CEE

Efficiency Class acc. to Directive 92/42 CEE (100%) %

Efficiency Class acc. to Directive 92/42 CEE (30%) %

Combustion efficiency at nominal load %

Combustion efficiency at part load %

Stand-by losses (Q min.) %

Stand-by losses (Q nom.) %

Flue gas temperature (min) °C

Flue gas temperature (max) °C

Flue gas mass flow rate (min) kg/h

Flue gas mass flow rate (max) kg/h

Excess of air λ %

(min) %

CO

2

CO2 (max) %

NOX (value according EN 297/A3 + EN 483) mg/kWh

NOX class

Flue losses with burner in operation (min.) %

Flue losses with burner in operation (max) %

Flue losses with burner off %

Min. water flow rate in CH circuit (∆T 20°C) l/h

Minimum pressure in CH circuit bar

Maximum pressure in CH circuit bar

DHW specific flow rate l

Gas Consumption Natural gas G 20 (20 mbar) Qn m

Gas Consumption Natural gas G 20 (20 mbar) Qmin m

3

/h

3

/h

Max. available pressure at the chimney base Pa

Condensate production kg/h

Emissions

CO with 0% of O

in the flue system ppm

2

NOx with 0% of O2 in the flue system ppm

Sound level dBA

Electrical data A

Voltage / Frequency V/Hz

Fuse on main supply A (F)

Max / Min absorbed power W

Insulation degree IP

Standby Consumption W

360

360

22

353,9

21,3

377,60

23,80

98,30

96,82

104,89

108,18

102,0

109,2

98,10

96,65

97,52

97,86

1,0

n.r

42

50

36,6

583,0

24,25

8,9

9,2

62

2,48

2,14

0,2

16237

0,5

73

38,06

2,33

100

22,7÷60

<35

<35

<50

230 / 50

540/41

40

10

4

5

6

-

28,3÷75

230 / 50

4

450

450

22

442,5

21,3

472,0

23,80

98,33

96,82

104,89

108,18

102,0

109,2

98,29

96,94

97,52

97,86

1,0

n.r

42

50

36,6

728,7

24,25

8,9

9,2

62

2,48

2,14

0,2

20296

0,5

88

47,58

2,33

100

<35

<35

<50

675/41

40

10

4

5

6

-

-

230 / 50

4

540

540

22

531,8

21,3

566,4

23,80

98,48

96,82

104,89

108,18

102,0

109,2

98,45

97,18

97,52

97,86

1,0

n.r

42

50

36,6

874,4

24,25

8,9

9,2

62

2,48

2,14

0,2

24355

0,5

103

57,10

2,33

100

34÷90

<35

<35

<50

810/41

40

10

104,89

108,18

4

1020,2

5

28414

6

-

39,7÷105

230 / 50

4

945/41

630

630

22

621,3

21,3

660,8

23,80

98,62

96,82

102,0

109,2

4

98,59

97,38

97,52

97,86

1,0

n.r

42

50

36,6

24,25

8,9

9,2

62

5

2,48

2,14

0,2

0,5

6

118

66,61

-

2,33

-

100

<35

<35

<50

4

40

10

9

Page 10

1.4 - SIDE VIEW WITH MAIN COMPONENTS

FAN

GAS VALVE

GAS PIPE

BURNER

C.H. FLOW

C.H. RE TURN

CONDENSATE

COLLECTING

TRAYSMOKE

MANIFOLD

BOILER FRAME

FILLING-UP

ELBOW

Min. Depth 100 mm

ALUMINIUM/

SILICON HEAT

EXCHANGER

CONDENSATE

DRAIN

SIPHON

150

fig. 2

2.1 - COMPOSITION OF THE

SUPPLY

- Boiler body made of sections of alumi-

nium/magnesium/silicium alloy (5 to 8)

- Premix stainless-steel burner (4 to 7)

- Premixing chamber (8 to 14) with bu-

ilt-in non return valve

- Modulating fan (4 to 7) with air pres-

sure switch control

- Gas valve (2 for each module – from 8

to 14) with separated flame control

device SATRONIC (from 4 to 7)

- NTC sensors for local temperature con-

trol on each boiler section (5 to 8)

- NTC sensor for global flow manifold

10

temperature

- NTC sensor for global return manifold temperature

- High Limit thermostat on each boiler

section (5 to 8)

- Automatic air vent on the flow manifold

- Boiler draining/filling tap on return

manifold

- Minimum gas pressure switch on gas

manifold

- Condensate collecting tray

- Plastic pipe (1m) and fittings for condensate evacuation Ø40

- Smoke chamber terminal, with flue soc-

ket:

Ø 250 mm for models 360 and 450

Ø 300 mm for models 540 and 630

- Integral painted steel casing

- Modulation and control PCB (MBD)

with PC interface

- AM-4 PCB for DHW production and

outdoor temperature sensor

- Supplementary PCB type AM-5 (1 x

mod. 360; 2 x mod. 450 and mod. 540;

3 x mod. 630)

- Electronic card for interface

- Outdoor sensor (into the smoke chamber)

Page 11

2

IINSTRUCTIONS FOR

INSTALLERS

2.1 - INSTRUCTIONS FOR INSTALLATION

The MODULEX boiler is foreseen for the

I

gas category and shall be installed

2H

in compliance with the latest regulations

or rules in force.

2.2 - INSTALLATION

2.2.1 - PACKING

The MODULEX boiler is delivered into a

strong carton box, complete of pallet (in

order to easily transport the boiler up to

the nearest point of installation place. The

procedures for unloading the boiler are

shown into the figure 3.

Remove both straps and finally the cardboard box from above, making sure the

product is intact. The packing elements

(cardboard box, straps, plastic bags,

etc…) shall not be left to children’s

hand since they may be dangerous.

For the pallet removal is necessary to lift

the boiler: it’s necessary to use a jib crane (like shown into the figure 3), in order

to avoid of damage the pressure

switches, gas valves or electric cables.

- Remove the jacket and prepare the

sling with the bands “A” (fig. 3) by taking

care of let the bands pass internally of

flow , return and gas manifolds.

- Bind the bends to the jib; during this

step be particularly careful.

Inside the packing,

on the rear part of the boiler, for Modulex 360 – 450

on the front part of the boiler, for Modulex 540 – 630

you can find the smoke chamber , containing:

- a plastic bag containing:

• 3 gaskets (1 rectangular between

condensate tray and flue terminal, 1

square between flue socket base and

flue terminal and 1 for flue socket Ø

250 or Ø 300 mm according to the

model

• 2 bends + 1 Tee piece + 1 plastic plug,

Ø 40 mm for condensate drain.

• the screws necessary for fixing

- A plate for the jacket closing, only for

models 540-630

- The outdoor sensor

- The siphon pipe for condensate drain

on the L.H. side of the boiler:

- the R.H. side panel connected to the

L.H. side one by a thermoretractable

film.

B

A

DIMENSIONS

modulex 360 1650 1200 1020

modulex 450 1650 1550 1020

modulex 540 1650 1700 1020

modulex 630 1650 1840 1020

on the boiler top:

- a plastic bag containing:

• This instruction manual

• Warranty certificate

• Hydraulic certificate

A

C

B

C

fig. 3

11

Page 12

BOILER UNLOADING AND PACKAGE REMOVAL

1

PALLET REMOVAL

B

A

2

3

4

12

fig. 4

Page 13

2.2.2 - BOILER LOCA TION INSIDE A

BOILER HOUSE

Special attention shall be paid to local regulations and laws about boiler houses and

particularly to the obligation of keeping

minimum clearances and empty space

around the boiler. The installation shall be

in compliance with all latest regulations

and laws about boiler houses, installations

of heating and hot-water systems, ventilation, chimneys capable of evacuating

the flue gases of condensing boilers and

any other applicable requirement.

2.2.3 - BOILER CONNECTION

The boiler Modulex leaves the factory predisposed for the hydraulic and gas connection on the back side of the boiler. The

smoke outlet is placed on the back side

When selecting the position for the

installation of the boiler it has to be

considered that, for the cleaning and

washing operations of the boiler

body , one of the boiler sides must be

accessible for the removal of a special baffle placed under the aluminum

sections.

of the boiler for MODULEX 360; it's placed on the R.H. side of the boiler for MODULEX 450 - 540 - 630.

For the smoke chamber fixing, use the

The boiler can be put on a flat and sufficiently strong base with the same di

mensions as the boiler ones and at least 100mm high (see fig. 5), in order to

assemble the condensate drain siphon.

An alternative to this base may be a

100 mm deep well next to the boiler as

siphon housing (see fig. 2). After installation the boiler shall be

perfectly horizontal and stable, to reduce any possible vibrations or noises.

screws and gaskets included into the instruction bag, and a cross screwdriver at

least 300 mm of length.

2.2.4 - CONNECTION TO THE

CHIMNEY

ATTENTION:

BEFORE ASSEMBLING THE CHIMNEY DUCT IT’S ABSOLUTELY NECESSARY TO SET A SUPPORT UNDER THE SMOKE CHAMBER TERMINAL

Into a condensing boiler, the smokes reach a very low temperature (Max 84°C).

So, it’s necessary that the chimney is

perfectly impermeable to condensation of

combustion products and built with materials corrosion resistant.

The various spigot joints have to be well

sealed and endowed with provided for

2.2.4.1 - MA TERIALS FOR FLUE

PIPES

As material can be used the stainless

steel AISI 316 L or AISI 316 Ti, with a

minimum wall thickness of 0.4 mm, or the

aluminium, with a minimum wall thickness

gaskets, so that to prevent the condensation spillage and the air entry.

For the chimney dimensioning, diameter

and height, it is necessary to make reference to the national and local regulations.

In order to avoid, during the operation, the

ice formation, the temperature of the inside wall in every point of the system for

the combustion products evacuation, for

all of its length, doesn't have to be lower

than 0°C.

For operation in condensing conditions

with the outdoor temperature of project, it

will be therefore necessary the realization of a system of confluent condensation drain, according to the installation

conditions, in the collection box of the

boiler or separated by it.

of 1.5 mm, or the PVDF (Polyvinildimethylfluorure), or the PPS (Simple transparent polypropylene), certified for this

use. Other materials and thicknesses are

also admitted, provided they guarantee at

least equivalent caracteristics.

In case of tubing of an existing chimney

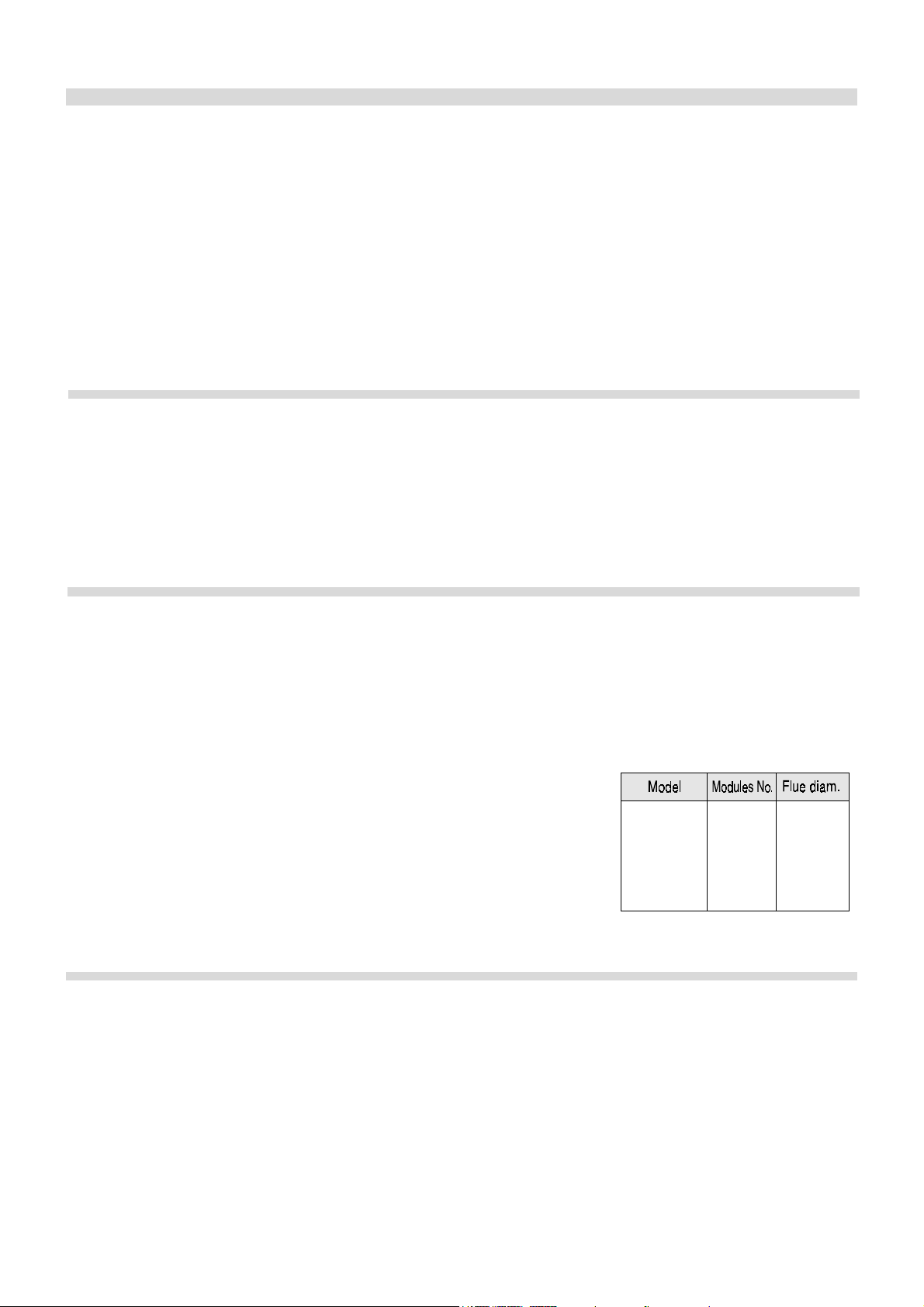

360

450

540

630

the flue pipe has to be of aluminium (min.

thickeness of 1.5 mm) or of stainless

steel (min. thickness of 0,4 mm) and its

connections have to be water proof.

4

5

6

7

250

250

300

300

13

Page 14

2.2.5 NOTES ON CONDENSATE

DRAIN

Avoid the condensate stagnation inside

the combustion products evacuation

system, (for this reason the evacuation

duct must have an inclination toward the

drain of at least 30 mm/m) except the

liquid column, inside the condensate

siphon (which needs to be filled with

water after installation: its minimum

height, when all the fans are in operation, must be at least 25 mm).

In order to avoid ice formation while the

INITIA L SIPHON

FILLING-UP PLUG

0

5

1

BOILER HOUSE

FLOOR

boiler is operating, which can cause the

stop of the boiler, the whole condensate

evacuation system has to be well insulated. It is forbidden to evacuate the condensate through a gutter: risk of ice formation and corrosion.

The condensate, before being evacuated to the sewer , has to be neutralised,

neutralization which can be obtained by

mixing the drain water coming from

washing machines, dish washing ma-

The upper part of the drain

pipe shall not be higher

than the tray bot tom.

chines, etc., which normally have a

basic pH. The connection to the sewer

will be through a visible drain. Given

the high acidity degree (pH 3 to 5) only

plastic materials can be used for the

condensate evacuation pipes. Moreover it must be dimensioned and constructed so as to allow the correct outflow of drains preventing any bottleneck

and any leakage.

0

5

1

* Min. height of the condensate column,

with all fans operating at max. speed,

requested by the EN standards.

2.2.6 - WATER TREATMENT

If the installation needs a water treatment the following conditions are to be

respected:

- the pH, for boilers with aluminium

alloy body, must always be within

6.5 and 8;

2.2.6.1 - REPLACEMENT OF AN EXI-

STING BOILER BY A MODULEX

In case of installation of a MODULEX on

an old C.H. system we recommend to

purge and to rinse properly the whole

system before connecting the new boiler.

To avoid misunderstandings it is sug-

** Min. height of the condensate column,

with all fans operating at max. speed. In

the case it is not possible to create a 100

- all precautions will be taken to avoid

the formation and localisation of oxygen in the water of C.H. systems. For

this reason it will be necessary that

in the C.H. systems using floor radiant

heating, the plastic pipes used are

impermeable to the oxygen;

- in case of utilisation of anti-frost so-

gested to interpose between the boiler

and the system, a plate heat exchanger.

On the contrary , in case of installation of a

MODULEX on a new system we recommend to make a simple water rinse of the

mm basement, install the boiler on the

floor and foresee a min. 100 mm well to

lodge the siphon (see fig. 2).

fig. 5

lutions, their compatibility with aluminium alloy and other components

of the C.H. system has to ascertained.

whole system and to fit a Y filter on the return pipe to the boiler, equipped with gate

valves.

14

Page 15

2.3 - EXAMPLES OF

HEATING SYSTEMS

®

576

1243

E

T

E

P

R

D

E

E

S

O

O

T

T

E

M

R

S

S

The following system figures are to illustrate some, but not all types of heating

systems.

Flow

See fig. 16

1112 13

Return

Filter

Boiler pump

Fig. 6.1 Heating system with one group of radiators.

®

576

1243

T

E

E

E

R

P

S

E

D

O

O

T

T

E

M

S

S

R

Flow

See fig. 16

11

1213

Mixing bottle

Mixing bottle

Heating system

pump

D.H.W. Circuit

1718

See fig. 16

16

Heating circuit

Heating Circuit

Return

Filter

Boiler pump

Fig. 6.2 Installation of a boiler with a mixing bottle and connection to a heating circuit with DHW production (storage tank output< or = boiler

output).

Heating Circuit Heating Circuit

1243

Heating Circuit

®

576

T

E

E

P

E

D

R

S

E

E

O

O

T

T

R

M

S

S

Mixing bottle

Flow

See fig. 16

1112 13

Return

Filter

Boiler pump

Fig. 6.3 Heating system with mixing bottle and flow temperature control by an outer compensator. More radiator groups are

controlled by a dedicated outer compensator. The heating curve of the boiler outer compensator has to be adjusted at 5 K above the

temperature of the radiator group working at the highest temperature.

15

Page 16

1243

Heating C ir cuit

See fig. 16

1617 18

Heating

system pump

D.H.W . Circuit

No ret urn

valve

®

576

T

E

E

E

R

P

S

D

E

O

O

T

E

T

R

M

S

S

Mixing bottle

Flow

See fig. 16

1213

11

Return

Filter

Boiler pump

Fig. 6.4 D.H.W. storage tank with loading pump installed on the secondary circuit, in parallel with the heating circuit.

Note: The Pr pump (heating pump) shall be off while the storage tank pump is running. In this case, the second digit of

parameter A shall be set to 2 (three-way valve).

For the connection of a boiler pump on the primary circuit or of a storage tank loading pump or a three-way valve, convenient

information can be found in the following table, which indicates the terminals supplied with 230 V in the different hypothesis.

Is there any heating demand?

Is there any D.H.W. demand?

YES/ NO YES / NO YES / NO

YES NO YES

YES

NO

NO

NO

D.H.W. priority system

configuration depending on 2

nd

figure of “A Parameter”

230 V - 50 Hz tension

is present at

terminals 16 - 18

230 V - 50 Hz tension

is present at

terminals 11 - 13

(see paragraph 3.2.8.2)

parameter A = x 0

parameter A = x 1

parameter A = x 2

The terminals 11 –13 will be supplied on tension 230 V in the case the pump after running is activated.

nd

2

figure

nd

2

figure

nd

2

figure

YES

NO YES

YES NO NO

NO YES YES

YES

YES

YES

NO *

NO *

NO *

2.3.1 - VENTING OF THE C.H. SYSTEM

An effective air vent shall be foreseen

in the highest point of the system. Inside

2.3.2 - BOILER AND HEA TING

SYSTEM FILLING-UP &

DRAINING

For filling-up the system a filling tap has

to be foreseen on the system return pipe.

The filling-up can also be made through

the draining tap on the boiler return

manifold.

16

the boiler, there is an automatic air vent

on the flow manifold (see fig. 2). This air

In both the cases, an approved hydraulic

disconnection system has to be fitted.

Before connecting the boiler, carefully

rinse out the whole system by running

water .

The boiler is equipped with its own draining tap (see fig. 2 for its position).

Never use such a tap to drain the sys-

vent is foreseen for the boiler , not for

the whole system.

tem, since the system dirt could gather

in the boiler and compromise its operation. The system itself shall be equipped

with its own draining tap , whose size depends on the system capacity . The application of a filter on the return pipe to the

boiler is advisable.

Page 17

2.3.3 - MAX ALLOWABLE WORKING

PRESSURE

The boiler max allowable working pressure is 6 bar, while the min. one is 0,8

bar.

The boiler does not have any special

protection device against water lack,

2.3.4 - SAFETY PRESSURE RELIEF

V AL VE (not supplied)

A safety valve dimensioned for the system capacity and in compliance with

local regulations in force shall be installed

2.3.5 - GAS MAINS

Due to the presence of a min. gas pressure switch, the gas main diameter shall

be calculated carefully. Even though the

since this function is carried out by the

safety thermostats of the modules with

timeliness. However, the installation of

a min. pressure switch as well as its electric connection are foreseen (1/4” con-

on the flow pipe (within 500 mm from the

boiler).

gas valves have their own filter,

UNICAL suggests one further filter easy

to be checked, to be installed on the

nection on the return manifold and electrical in series connection on the min.

gas pressure switch terminals).

gas pipe supply.

2.3 . 6 - HYDRAULIC COMPENSA T OR

OR OPEN MANIFOLD

For the correct operation of the boiler,

the use of an hydraulic compensator is

advisable because it guarantees:

- separation and gathering of circuit dirt

- best air venting

- hydraulic de-coupling of the two

hydraulic circulation circuits.

TABLE FOR THE RECOMMENDED

DIMENSION OF THE HYDRAULIC

COMPENSATOR

BOILER

CIRCUIT

360 kW

360 - 450

450

- 540 - 630 kW

Over

> 630 kW

F

I

L

T

E

R

kW

C.H. FLOW

KVKR

20.000

30.000

50.000

100.000

150.000

200.000

g

200

250

300

400

500

600

1/2’’

100

125

150

200

250

300

D

1/2’’

HV

e

C.H. FLOW

HEATING

g

c

SYSTEM

CIRCUIT

h

1/2’’

100

125

150

200

250

300

200

200

250

250

300

300

HR

b

a

1/2’’

300

300

300

300

400

400

1.000

1.000

1.000

1.500

1.500

1.800

C.H. RETURN

150

1.650

150

1.650

150

1.700

200

2.250

300

2.500

300

2.800

fig. 7

200

200

200

200

200

200

17

Page 18

2.3.7 - FILTER

UNICAL suggests the installation of a Y

filter with two gate valves on the return

pipe so that it can be cleaned if necessary. Such filter shall protect the boiler

2.3.8 - BALL V ALVES

Unical suggests the installation of ball

gate valves on the system flow/return

pipes. In this case the boiler, if necessary, can be disconnected or drained,

without having to drain the whole sys-

2.3.9 - FEEDING W ATER QUALITY

- The system and reinstatement

water chemical-physical features

are fundamental for the boiler correct operation and safety.

- Among the inconveniences caused by feeding water low qualities the most frequent and serious

one is the scale deposit on heat

exchange surfaces.

- Less frequent but not less serious

is the water side corrosion of all

heating circuits surfaces.

- It is known that calcareous scales

reduce heat exchange due to their low heat conductivity, so that

even few mm-thick scales may

cause very dangerous localised

overheating.

from the heating system dirt. Its regular

cleaning has to be foreseen.

tem. A closed expansion vessel, properly dimensioned and equipped with its

safety valve, shall be fitted between the

gate valves and the boiler.

- Water treatment is advisable in the

following cases:

A) high hardness of the available

water (> 20°f)

B) very large heating systems

C) high quantities of reinstatement

water due to leakages or maintenance works

- The use of an inhibitor is advisable to treat feeding waters and to

protect heating systems against

calcareous scales, corrosion and

microbiologic growth. In case of

freezing as well, the use of an antifrost together with the inhibitor is

advisable.

- Qualified companies can provide

boiler de-scaling.

WARNING!

Never intercept safety devices, such

as safety valve and expansion vessel.

- Any system needs water re-filling

because of evaporation, small or

substantial leakages and maintenance. It is then necessary to calculate the water quantity requested to avoid new inconveniences

due to untreated water.

To this purpose, the installation of

a water flow-meter is advisable on

reinstatement pipe.

2.3.10- BOILER ANTIFROST

PROTECTION

Should the flow temperature (measured

at global flow temperature NTC) decrease under 7°C, the system pump is

set up. Should temperature ulteriorly

18

decrease (under 3°C), all modules shall

start at min. output until the return temperature reaches 10°C. Such protection

device is exclusively for the boiler. For

the protection of the whole system, a second anti-frost thermostat is necessary to

switch on the heating system pump.

Page 19

2.3.11 - MINIMUM W ATER FLOW RA TE

A minimum water flow rate, as shown in

the table on the right, is to be guaranteed

through the boiler at any time.

RICIRCULATION PUMP

The recirculation pump shall have a

manometric head able to assure the

water flow rate as per the diagram of fig.

8.

Pumps shall be calculated by installers or technical engineers according

to boiler and system parameters.

8

7,5

7

6,5

6

2

5,5

(mH O)

5

4,5

4

3,5

3

PRESSURE LOSSES

2,5

2

1,5

1

0,5

0

02,5 57,5 10

12,5

kW output

The water side resistance curve of the

boiler is shown in fig. 8.

The pump is not an integral part of the

boiler.

WATE R SIDE

PRESSURE LOSSES

15 17,5

20

22,5 25 27,5 30 32,5

WATER FLOW m³/h

360 450 540 630

30,96 38,70 46,44 54,18

20,64 25,80 30,96

15,48 19,35 23,22

36,12

27,09

It's recommended to choose a circulator with the rate and discharge head

around 2/3 of its charactestic curve.

630

450 540

360

35

37,5 40

45 47,5 50 52,5 55

42,5

fig. 8

2.4 - BOILER OPERATION

The boiler consists of mutually connected combustion chambers; each of them

has its own burner, fan with air pressure switch for control, two gas valves

with ignition and ionisation device.

Each group of these components is

called thermal element.

Max. output of a thermal element is 90 kW .

So, a 630 kW boiler consists of 7 thermal

elements.

Each thermal element has its own temperature sensor NTC - Negative T emperature Coefficient - called local NTC,

which locally checks the flow tempera-

ture of each thermal element.

The flow temperature at the boiler outlet

and the return temperature at the boiler

inlet are controlled by global NTC temperature sensors (see fig. 2).

In case of more heat request by heating

or DHW systems, the boiler starts up and

water will be heated by an aluminium boiler body . Then the boiler pump sends water to the mixing bottle and from here to

the radiators, according to the heating

system choosen.

The combustion air is supplied by fans

and taken in from the boiler room. The

combustion air is then pushed into the

pre-combustion chamber through a diaphragm. Beyond the diaphragm, the air

mixes with gas and such mixture passing through the non-return valve is sent

to the burner. Then, on leaving the burner

surface, the air/gas mixture ignites electrically and the resulting combustion gases, after being transported (and cooled)

through finned tubes, enter the condensate collecting manifold and then are

evacuated through the chimne y .

19

Page 20

2.4.1 - GENERAL DESCRIPTION

When there is an heat request from a

room thermostat or an outer compensator, the Modular Boiler Drive (MBD) calculates the necessary output according

to the difference between the set temperature (or the temperature calculated by

the outer compensator) and the global

flow temperature. The number of thermal

elements (each thermal element represents a maximum output of 90 kW) x

100% determines the maximum output

expressed in %.

When the output has been determined, the

boiler pump (not supplied by Unical) is set

up and the fan of one thermal element is

set in motion at starting speed. The gas

valve opens and ignition is to occur within 5 sec. When the ionisation electrode

detects the flame, the thermal element

starts operating.

Subsequently other thermal elements are

likely to start in the same way . One of the

operation principles for this boiler is letting as many burners as possible operate simultaneously at minimum load to

reach the maximum efficiency .

For example, if a 4 thermal element boiler

is requested to operate at its max output,

this shall be 400% i.e. :

90 kW x 4 thermal elements =

360 kW = 400%.

If it is requested to operate at 200% output, thanks to the output sharing system

on the highest number of thermal elements, each thermal element will operate

at 50% output i.e. :

200% : 4 thermal elements = 50%

equal to a total of 180 kW , that is 45 kW

for each thermal element.

Such principle provides clearly efficiencies much higher than those obtained in

traditional groups of small boilers installed

in cascade.

When the output shared on each thermal

element is less than 22 kW , one thermal

element after the other is automatically

excluded and the remaining output is

shared on thermal elements having the

smallest number of operation hours (by

the automatic operation-time calculating

system).

Modulation, i.e. output reduction, is based

on the difference between the set temperature (or the temperature calculated by

the outer compensator) and the global

flow temperature.

When no ignition occurs, the ignition device puts to lock out position the thermal

element concerned.

1 Thermal element = 90 kW = 100%

4 Thermal elem. = 90 kW x 4 = 360 kW = 400%

4 thermal elements of 90 kW each working

kW

at 50% of the output give = 180 kW = (200%),

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

mod 1

5

0

i.e. 45 kW / thermal element

400% : 360kW = 200% : X

X = (200x360) : 400 = 180 kW

Output shared on 4 thermal elements : total output

output shared on 4 thermal elements

= 180:360 = 0,5 = 50%

% (p.c.i.)

109

107

1 thermal

element

50 % = 45 kW

105

1 thermal

element

100 % = 90 kW

20

22

Efficiency of a thermal element working at full capacity

(90 kW) = 103 % (in condensation)

Efficiency of a thermal element working at reduced capacity

(45 kW) = 107 % (in condesation)

Efficiency of a thermal element working at minimum capacity

(22 kW) = 109 % (in condesation)

All the thermal elements work in parallel at the same output, equalizing,

thus, the C.H. system efficiency to the one of the thermal element.

40 8060

45

90

P

(kW)

20

Page 21

Ignition diagram, for Modulex 630, with 7 burners. (6 are working, 1 is during ignition procedure).

2.4.2 IGNITION SEQUENCE

5 seconds after the switch ON-OFF is

IGNITION SEQUENCE DIAGRAM

ON, the pump is set up together, eventually, with the 3-way valve in the case

of a heat request from the Room Thermostat. The ignition PCB (“CVI” means

Combined Valve and Ignition) is powered on and, after 24 sec, the fan is set in

motion and reaches the starting speed;

it stays in operation making the prepurge of the combustion chamber for

10 sec; in the meanwhile the air pressure switch, actuated by the fan, switches from C-NO (open position) to C-NC

(closed position) allowing the ignition

spark to be obtained and the gas valve

to be opened after 5 to 8 sec allowing

the AIR/GAS mixture. If within the safety

time there is no burner lighting the burner is put definitely in lockout position (the

relevant red push button, on the front panel board, will light).

When heating and/or DHW request ceases, the pump stays in overrun according

to relevant pre-set times. Such sequence

is the same for the other burners without,

quence in their assembling order, but in

their operation hours.

necessarily, keeping the lighting se-

Fig. 9

Fig. 9

21

Page 22

2.4.3 - SUPPLEMENT AR Y BOARD

The Modular Boiler Drive (MBD) in fig.

9, supplied for each boiler by Unical,

manages to check a two-burner group

(2 x 90 = 180 kW). For boilers with output

> 360 kW, 2 or 3 supplementary boards

AM-5 are assembled by the manufacturer, each of them managing to check

up to 2 burners. For example, a boiler

with 5 burners (450 kW) is equipped with

two supplementary boards AM-5.

The supplementary boards have two

small dip-switches, which shall be positioned according to the patterns here

below, regardless the number of supplementary boards AM-5 fitted (such

operation is carried out at the manufacturer’s workshop and will also be done

on site in case of the replacement of a

faulty one).

X1 = CVI supply (ignition PCB)

X2 = CVI supply (ignition PCB)

X3 = 230 V electrical supply from mains

X7 = to MDB by flat cable

AM-5

X3

X1

X2

DIPSWITCH 2

X7

DIPSWITCH 1

Fig 10

Fig. 11-

SUPPLEMENTARY BOARD.

POSITIONING OF THE DIPSWITCHES

O

AM-4

AM-4

F

F

2

1

Thermal element

AM-5

N.1

O

F

F

2

1

Thermal element

AM-5

N.1

O

F

F

2

1

AM-5 and AM-4 boards

positioning

for a MODULEX 360.

Thermal element

AM-5

O

F

F

AM-5 and AM-4 boards

positioning

2

1

N.2

O

F

F

for a MODULEX or 0.450 54

O

F

F

AM-5 and AM-4 boards

2

2

1

1

positioning

for a MODULEX 630

22

AM-4

Thermal element

AM-5

N.1

Thermal element

AM-5

N.2 N.3

Thermal element

AM-5

Page 23

2.4.4 - DOMESTIC HOT W A TER (DHW)

MODE OPERA TION

Each boiler is equipped with an AM-4

board, necessary to control a D.H.W

tank and to receive a 0 - 10V signal from

an outer compensator (se fig. 11). If there

is a heat request, the MBD can control

either a storage tank loading pump or a

3-way diverting valve. So the boiler will

ignite and operate according to what

previously described. The global flow

water temperature, set as standard 20

K higher than the requested DHW temperature, is modulated as well. By using dip-switches, it is possible to limit

the boiler output when working in D.H.W

mode, in order to avoid overheat when

the DHW storage tank absorbed output

is less than the boiler produced one.

DHW production has always priority on

heating. Some examples about hydraulic and electric connections of a hot

water storage tank are shown in the figures 6.1 - 6.2 - 6.4 .

For example:

If we combine a 90 kW storage tank to a

Modulex 360, setting the dip-switch 1 to

“OFF “ and the dip-switch 2 to “OFF”, so

as to adjust the functioning of the number of modules on the basis of the storage tank's requests (one module will function).

If we combine a 180 kW storage tank to

a Modulex 360, setting the dip-switch 1

to “OFF “ and the dip-switch 2 to “ON”,

two modules will function.

If we combine a 270 kW storage tank to

a Modulex 360, setting the dip-switch 1

to “ON “ and the dip-switch 2 to “OFF”,

three modules will function.

If we combine a 360 kW storage tank to

a Modulex 360, setting the dip-switch 1

to “ON “ and the dip-switch 2 to “ON”, four

modules will function.

X1= diverting valve or storage tank

loading pump

X2= outer compensator / D.H.W. tank

NTC

X7= to the MBD by flat cable

AM-4

X1

DIPSWITCH 2

Flue

Temp.

DHW

Tank

NTC

0-10 V

X2

X7

DIPSWITCH 1

Fig 11

IN THE MODULEX BOILERS WITH AN

OUTPUT HIGHER THAN 360 KW

DIPSWITCH CURSOR POSITION

REGULATION

CONFIGURATION

360 kW

O

F

F

2

1

Four modules are

ignited (360 kW )

270 kW 180 kW

O

F

F

2

1

Three modules are

ignited (270 kW )

Two modules are

ignited (180 kW )

In order to guarantee the best D.H.W.

production the dip-switches present

configuration allows a maximum availability up to 360 kW .

90 kW

O

F

F

21

Just one module is

O

F

F

2

1

ignited (90 kW )

2.5 - OPERATION IN CASE

OF TECHNICAL INTERVENTION

For after sale service and test reasons,

any single thermal element or all simultaneously can be kept operating at full

or reduced load. In this way the CO

2

lev-

el can be checked and, if necessary , adjusted at full or reduced load (for any single thermal element or for all simultaneously).

Thanks to this option the search for failures on each thermal element will result easier.

23

Page 24

2.6 - ELECTRIC

CONNECTIONS

The MODULEX electrical connections

are defined in the chapter “Wiring diagram” (paragraph 2.6.1).

For electrical features see appliance data

plate.

The boiler installation needs a supply

of 230 V – 50 Hz – single phase, and

must be workmanlike performed, as foreseen by the local and international electrical rules in force and without the utilisation of adapters, multiple sockets or

extension cords. It is fundamental to

check this safety requirement. If in any

doubt, ask for an accurate control of your

electric system by highly qualified personnel.

UNICAL is not liable for any damage

caused by unproper earthing system.

The gas and water feeding pipes and

the C.H. system pipes cannot be used

as earthing means.

Boiler electric safety is guaranteed only

when it is properly connected to an efficacious earthing system in compliance

with the regulations in force.

The use of any power supplied equip-

ment implies the observance of some fundamental rules, such as:

- do not touch the boiler with any wet

part of your body and/or barefooted;

- do not pull the supply cable;

- do not expose the boiler to sunlight,

rain, etc…;

- keep the boiler away from untrained

people.

The boiler supplying cable shall not be

replaced by the user. In case of any

damage to the cable, stop the boiler

and contact qualified personnel for its

replacement.

For the technical characteristics see the

boiler data plate.

The boiler electrical supply (230 V – 50

Hz – single phase) is to be done directly on the three pole plug A (fig. 12) supplied with the boiler. This boiler is phase

sensitive, it means that Phase and Neu-

tral wires from mains have to be connected to Phase and Neutral terminals

of the three pole plug, otherwise the

boiler will go in lockout position.

It is necessary to fit a double pole switch

on the supply line in an easy accessi-

ble position in order to make quick and

safe the service operations.

WARNING!

230 V cables shall be separated from

24 V ones, using the two plastic conduits supplied within the boiler casing

L.H. side panel.

A

Fig. 12

TABLE OF RESISTANCE OF

NTC1 - NTC2 - NTC3

Relationship between temperature (°C) and

nominal resistance (Ohm) of the sensors

NTC1 - NTC2 - NTC3

Example:

- At 25°C, resistance is

12000 Ohm

- At 90°C, resistance is

1300 Ohm

24

Temperature (°C) resistance (Ohms)

0 35400

10 22500

20 14700

25 12000

30 9835

40 6712

50 4672

60 3311

70 2388

80 1749

90 1300

100 980

110 749

Page 25

2.6.1 - WIRING DIAGRAM

TAN GE NTIA L FAN K IT

BROWN

RED

BROWN

SECURITY

THERMOSTAT

TRANSFOR MATOR

BLUE

RED

BROWN

BLUE

BROWN

BLUE

YEL/GREEN

BROWN

BLUE

RED

HIGH LIMIT

LIMIT GE NERAL

THERM OSTATE

LAMP HIGH

THERMOSTAT GENERAL

BROWN

BLACK

CONDOTTO CAVI 230 V

CONDOTTO CAVI 24 V

00331506

ALIMENTAZIONE

230 V - 50 Hz

Fig. 14

25

Page 26

2.6.2 - WIRING CONNECTIONS OF THE IGNITION ELECTRONIC CARD

Connections detail

to the ignition electronic card

for each modul.

E. ACC.Ignition electrode

E. RIV Ionisation electrode

PR Rest button (on main

board)

LB Lockout warning light

(on main board)

TL High limit thermostat

(local)

PV Fan air pressure

switch

Fig. 15

2.6.3 - ELECTRICAL CONNECTION

TO AN OUTER COMPENSATOR, A ROOM THERMOSTAT

OR AN OUTER TEMPERATURE SENSOR

Outer compensator: connect the com-

pensator 0-10V outlet signal to terminals 9 - 10 of the 20-pole terminal-strip

(see fig. 16). By using this signal it is possible to set a global flow temperature depending on the outdoor temperature.

ON/OFF room thermostat or programmer: it shall be connected to the termi-

nals 5-6 of the 20-pole terminal-strip (see

Note. The terminals 11 – 13 and 16 – 18 must be used to control a 3-way valve or a DHW tank loading pump or a boiler pump through

relays, as shown in the hydraulic schemas of fig. 6.1 to fig. 6.6. NEVER supply directly from these terminals the a.m. devices .

ADDITIONAL

SECURITY

(LOW

OUTSIDE

SENSOR

WATER

PRESSURE)

fig. 16).

Outdoor sensor: supplied as standard,

it must be fitted on an outer wall exposed

to North or North-East, at a minimum

height from floor of 2.5 m. The mounting

in proximity of opening windows and

doors and ventilation grates has to be

avoided. Never fit the outdoor sensor in a

sunny position. It shall be connected to

terminals 3 - 4 of the 20-pole terminal-strip

(see fig. 16).

T o avoid electromagnetic disturbances it is necessary to separate the

external sensor wiring (between

sensor and terminal strip) from the

230 or 400 V harness (a plastic conduit

STORAGE TANK

SENSOR OR

THERMOSTA T

PRIMARY SYSTEM

ON-OFF

PUMP

for 230 or 400 V harness and one for 24

V wiring)

Depending on the outdoor temperature

detected by the sensor the boiler will modulate and adjust the flow temperature according to the programmed heating curve

(see fig. 19).

ON/OFF room thermostat in combination with outdoor sensor: When both

devices are connected as shown here

below, the boiler will modulate and adjust the flow temperature according to

the room and outdoor temperature detected by the two sensors (see fig. 19).

DHW PUMP OR

3-W AY V A LVE

The intervention of the

additional security

provokes the block of the

boiler and error code

is displayed.

26

ROOM THERMOSTAT

AND/OR ON/OFF

TIMER

E26

BMS

CONNECTION

230 V24 V

ALARM SIGNAL

(VOLT FREE CONTACT)

MAIN SUPPLY

FROM THE

FILTER

Fig. 16

Page 27

2.6.4 - DHW STORA GE T ANK

DHW production by an outer storage

tank connected to the boiler can be carried out by an electric diverting valve or

a separated storage tank loading pump

Both devices can be chosen via the control panel push buttons, by selecting the

right parameter A (see paragraph

3.2.8.2, parameter A - 2

nd

digit).

The DHW tank NTC sensor, supplied

as an option, will be connected to the

terminals 7 – 8 of the 20-pole terminalstrip.

ELECTRICAL CONNECTION OF THE THREE WAY VALVE

16

17

18

LN

3-WA Y V AL VE CONNECTION

satisfied

DHW tank

3-contact relay

na

c

nc

Boiler AB

M

B

DHW tank

Line

V.D. Engine

Power

Neutral

A Heating system

WARNING!

There is a 230 V tension between terminals 16 - 18 only when there is a heat

demand by the DHW NTC sensor or by a DHW thermostat; in this case the display

4 XX

will show :

(see 3.2.5).

16

17

18

LN

3-contact re l ay

3-WAY VAL VE CONNECTIO N

not satisfied

DHW tank

na

c

nc

M

B

DHW tank

A Heat ing syste m

Boiler AB

Line

Neutral

V.D. Engine

Power

ELECTRICAL CONNECTION OF A DHW TANK

LOADING PUMP

16

17

18

LN

DHW tank loading pu mp

Tank satisfied

DHW

16

17

18

LN

DHW tank loading pump

DHW

Tank not satisfied

3-contact relay

na

nc

DHW tank

c

Line

Neutral

Pump Engine

Power

3-contact relay

na

nc

DHW tank

c

Line

Neutral

Pump Engine

Power

WARNING!

There is a 230 V tension between terminals 16 - 18 only when there is a heat

demand by the DHW NTC sensor or by a DHW thermostat; in this case the display

will show :

4 XX

(see 3.2.5).

ELECTRICAL CONNECTION OF A BOILER PUMP (OR A DHW LOADING

PUMP IF WITH A 3-WA Y VALVE) Boiler pump or DHW loading pump

11

12

13

LN

CH loading pump/

DHW tank loading pump

3-contact re lay

na

c

nc

Line

Neutral

DHW tank

Pump Engine

Power

11

12

13

LN

CH loading p ump/

DHW tank loading pu mp

3-contact relay

na

c

nc

Line

Neutral

DHW tank

Pump Engine

Power

WARNING!

There is a 230 V tension between terminals 11 - 13 only when there is a heat

demand by the DHW NTC sensor or by a DHW thermostat; in this case the display

4 XX

will show :

(see 3.2.5).

Fig. 17

27

Page 28

3

OPERATION OF THE MAIN PCB, NAMED MBD

(MODULAR BOILER DRIVE)

3.1 - GENERAL

DESCRIPTION

The Standby mode is on 5 sec. after

starting or resetting the boiler. Subsequently the pump is set up for 1 min. If

no heat is requested, this procedure is

Reset buttons for the

Pressure

gauge

1

different thermal element

576

243

P

E

T

S

Step

+ -

performed every 24h (automatic anti-jamming system for boiler pump or re-circulation pump). If a DHW production boiler

does not use a 3-way valve but rather a

On/Off switch

Lockout warning light

T

E

E

D

S

O

E

R

ResetDisplay

T

S

Store

E

R

O

M

Mode

storage tank loading pump, such a pump

is set up for 1 min every 24h if no heat is

requested. In this way the pump will not

jam.

®

Fig. 18

Operation and indications on the display (example with 7 thermal elements)

3.2 - OPERATION AND

DISPLAY

INSTRUCTIONS

The control panel has 5 function keys,

STEP - +/- -STORE - MODE - RESET,

one display, one ON/OFF main switch,

2 to 7 reset buttons with lockout warning light and one pressure gauge. All

different operation modes are displayed by slightly pressing the

mode

key.

If no other keys are pressed within 15

minutes from the last pressing, except

when the

board will go into

playing

Standby

TEST

mode is used, the panel

standby

mode dis-

the global flow temperature.

mode gives information as

shown in par. 3.2.6 concerning the

MODULEX instantaneous operation

phase.

28

Page 29

3.2.1 -

“MODE”

KEY

The default set mode of the boiler is

stand-by

mode. By this mode, the 4digit (letters or figures) display shows

the flow temperature or the operation

state (from 0 to 9 – see par. 3.2.7).

The indication on the display will be:

, where the 1st digit indicates the

number of step (operation state - see

par. 3.2.7) while the 3

rd

and 4th ones the

flow temperature value.

By slightly pressing the

(abbreviation for

mode

parameter

key,

), which is

one of the 6 operation modes (main

menu), is displayed.

By slightly pressing the

mode

key again,

the 4-digit display will show .

3.2.2 -

''STEP''

KEY

Once one mode, among the four modes

mentioned above (i.e. para – data – test

– hour), has been selected by pressing

mode

key, it is possible to choose, by

pressing

step

key, the parameter and

After entering the access code, strictly

reserved to the installer and the service

technicians, it is possible to go into the

extended programming menu and into

the following modes:

and

By slightly pressing the

mode

key again,

the 4-digit display will show .

In this mode it is possible, only by the

installer or service technician, to make

the fine adjustment of the combustion

for the complete boiler or for each single thermal element at high or low output (see par. 3.2.10), acting on the CO

level.

the thermal element (or the whole boiler)

whose values have to be changed or to

be checked.

By slightly pressing the

mode

the 4-digit display will show .

In this mode it is possible to check, only

by the installer or service technician, the

operation time for each b urner. It is also

possible to calculate the total operation

time of the boiler.

2

key again,

3.2.3 - "

+ / -" KEY

Once the values requested have been

entered, it is necessary to store them in

order to make them operative. To this

purpose, press

store

.

3.2.4 - "STORE" KEY

Once the values requested have been

entered, it is necessary to store them in

order to make them operative. To this

purpose, press store.

3.2.5 - SERVICE CODE

The access to some programming parameters is reserved only to service

technicians and, if necessary, to the installer. This access is protected by a

secret service code.

To enter this code proceed in the fol-

In the par. 3.2.6 is shown the procedure

how to get into the extended programming menu.

lowing way:

Keep

mode

and

step

keys pressed simultaneously: C.XX (a random code) is

displayed.

By using the ''+/-'' key, replace this code

with the secret one and, always keep-

ing

mode

and

step

keys pressed, press

store

. When the right code has flashed

once, it has been stored.

After entering the service code, the display reverts to

stand-by

mode.

29

Page 30

3.2.6 - PROGRAMMING ACCESS PROCEDURE

it selects:

- pa r a me t e r s

- data (all/single)

- test (all/single)

x

xx

mode

By pressing

mode

By pressing

mode

By pressing

P

E

T

S

+/- :

it increases

or decreases

the displayed

value

= Stand-by mode Display

By pressing see par 3.2.8

The User has

access to these

three parameters

only (see 3.2.8.1)paragraph

The User has not access

to these parameters.

Only the installer or

service technician can

get access by previously

entering the service code

(see 3.2.8.2)paragraph

By pressing

By pressing

(see paragraph 3.2.9.1)

Single burner (1 to 7) DATA

are not programmable by the

user. Only the Installer can

enter DATA by a service

code (see 3.2.9.2).paragraph

step

By pressing Step,

without any service code.

step

step

All about the burner 1 is applicable to all

other burners (2 to 7).

The parameter number is not displayed.

*

(see the following page)

It displays when

in DATA mode.

It stores when

in PARA mode.

It shows the number of step (from 0 to 9 – see 3.2.7)

It shows the number of the parameter displayed (from 1 to 9 and from A to N)

E

R

O

T

S

They show the regulation value of the displayed parameter.

1

.

0

6

By pressing step

20

.

38

.

4x

9

.

a

nx

.

As above

1

By pressing step

As above

0

By pressing

As above

x.

By pressing

As above

xx.

By pressing step

As above

x

x

By pressing step

As above

x

E

D

O

M

it

chooses

the mode

step

step

By pressing

E

R

Reset

the boiler

paragraph

15

.

0

NOTE: Once the mode has been

selected by the key, the installer can

enter the different parameters by pressing

step

the key. After some minutes

from last pressing one of the 5 keys,

the boiler shall switch to mode .

If, on the contrary, the installer wishes to switch

to the following mode, , press the

mode

.

store

mode

key once again.

.

By pressing

step

.

By pressing

step

As above

.

By pressing

step

As above

.

By pressing

step

*

*

.

.

x

x

x

x

xx

By pressing

store

xx

By pressing

store

xx

By pressing

store

xx

By pressing

store

T

E

S

150.

.

.

.

.

.

.

x

.

xxx

xx

By pressing

store

x