Unical Alkon 09 R 18, Alkon 09 C 18, Alkon 09 R 24, Alkon 09 C 24 User Operating Instructions Manual

Page 1

00333177 -1st edition - 06/2009

ALKON

09

R 18 - C 18

R 24 - C 24

USER’S OPERATING

INSTRUCTIONS

Page 2

2

Contents

1 - SYMBOLS USED IN THIS GUIDE

When reading this guide particular care has to be given to the parts marked with the followings symbols:

NOTE!

Suggestions for the user

WARNING!

Indicates a potentially dangerous

situation for the product and the

environment

DANGER!

Indicates serious danger

for your personal safety

and for your life

2 - CORRECT USE OF THE APPLIANCE

The ALKON appliance has been designed utilizing today’s heating technology and in compliance with the

current safety regulations.

However, following an improper use, dangers could arise for the safety and life of the user or of other

people, or damage could be caused to the appliance or other objects.

The appliance is designed to be used in pumped hot water central heating systems and for domestic hot

water production.

Any other use of this appliance will be considered improper.

UNICAL declines any responsibility for any damages or injuries caused by an improper use; in this case the

risk is completely at the user’s responsibility.

In order to use the appliance according to the scopes it was designed for it is essential to carefully follow

the instructions indicated in this guide.

3 - WATER TREATMENT

• The hardness of the mains water supply conditions the frequency with which the heat exchanger is cleaned.

• In hard water areas where the main water can exceed 15°f total hardness, a scale reducing device is recommended. The choice of this device has to be made taking into consideration the water’s characteristics.

• In order to improve the resistance to lime scale, it is recommended to adjust the domestic hot water temperature as near as possible to the one you really require.

• The use of a modulating room thermostat reduces the dangers of lime scale formation.

• We recommend you to check the state of cleanliness of the domestic hot water heat exchanger at the end of the

first year and subsequently, on the basis of the amount of lime scale found, this period can be extended to two

years.

CONTENTS

1 Symbols used in this guide ....................................................................................................................................................... 2

2 Correct use of the appliance .................................................................................................................................................... 2

3

Water treatment ......................................................................................................................................................................... 2

4

Information to be handed over to the user ............................................................................................................................... 3

5 Safety warnings ......................................................................................................................................................................... 3

6 Operating instructions ............................................................................................................................................................... 4

6.1 Control panel ...................................................................................................................................................................... 4

6.2 Check list before commissioning the boiler ...................................................................................................................... 6

6.3 Boiler operation .................................................................................................................................................................. 6

DHW production ................................................................................................................................................................ 6

CH Mode ............................................................................................................................................................................ 6

Shutting down the boiler .................................................................................................................................................... 6

6.4 Frost protection mode ........................................................................................................................................................ 6

6.5 Eliminating the faults .......................................................................................................................................................... 7

Page 3

3

General information

The user has to be instructed on the use and operation of his heating system, in particular:

• Hand over these instructions to the end user, together with any other literature regarding this appliance, placed

inside the envelope contained in the packaging. The user has to keep these documents in a safe place in

order to always have them at hand for future reference.

• Inform the user on the importance of air vents and of the flue outlet system, stressing the fact that is absolutely

forbidden to make any alterations to the boiler.

• Inform the user how to check the system’s water pressure as well as informing him how to restore the correct

pressure.

• Explain the function of time and temperature controls, thermostats, heating controls and radiators, to ensure

the greatest possible fuel economy.

• Remind the user that, in order to comply to the standards in force, it is necessary to inspect and service the

boiler according to the current codes of practice and according to the schedule indicated in this manual by the

manufacturer.

• If the appliance is sold or transferred to another owner or if the present user moves home and leaves the

appliance installed, ensure yourself that the manual always follows the appliance so that it can be consulted

by the new owner and/or installer.

Failure to follow the instructions indicated in this guide, which is supplied with the boiler, could cause injury

to persons, animals or damage to property. The manufacturer shall not be held liable for any such injury and/

or damage.

4 - INFORMATION TO BE HANDED OVER TO THE USER (BY THE INSTALLER)

5 - SAFETY WARNINGS

WARNING!

The installation, adjustment, and servicing of this appliance must be carried out by a competent person and

installed in accordance with the current standards and regulations. Failure to correctly install this appliance could cause injury to persons, animals or damage to property. The manufacturer shall not be held liable

for any such injury and/or damage.

DANGER!

NEVER try to service or repair the appliance yourself.

All types of servicing or repairs must be carried out by a professionally qualified person, authorized by

UNICAL; UNICAL recommends drawing up a service contract.

Bad or irregular servicing could compromise the safe operation of the appliance, and could cause injury to

persons, animals or damage to property for which UNICAL shall not be held liable.

Alterations to parts connected to the appliance

Do not carry out any alterations to the following parts:

- the boiler

- to the gas, air, water feed pipes and electrical current

- to the flue pipe, safety relief valve and its drainage pipe

- to the constructive components which influence the appliance’s safe operation

Smell of gas

If you smell gas follow these safety indications:

- Do not touch any electrical switches

- Do no smoke

- Do not use the telephone

- Close the On/Off gas service cock

- Open all windows and doors where the gas leakage has occurred

- Inform the gas society or a specialized company

Explosive and easily inflammable substances

Do not use or leave explosive or easily inflammable material (as for example: petrol, paint, paper) in the room

where the appliance has been installed.

Page 4

4

User’s operating instructions

A = Manometer

B = Summer/Winter switch + Heating temperature controller

C = D.H.W. temperature controller

D = Push button for RESET/CALIBRATION/DIAGNOSTICS

E = Display

F = Symbol indicating a heating request

G = Symbol indicating a D.H.W. request

I = Symbol indicating a burner lockout

L = Symbol indicating burner in operation

M = Symbol indicating an error presence

N = Digits indicating boiler temperature or error code

B

D ACE

F

G

L

I

M

N

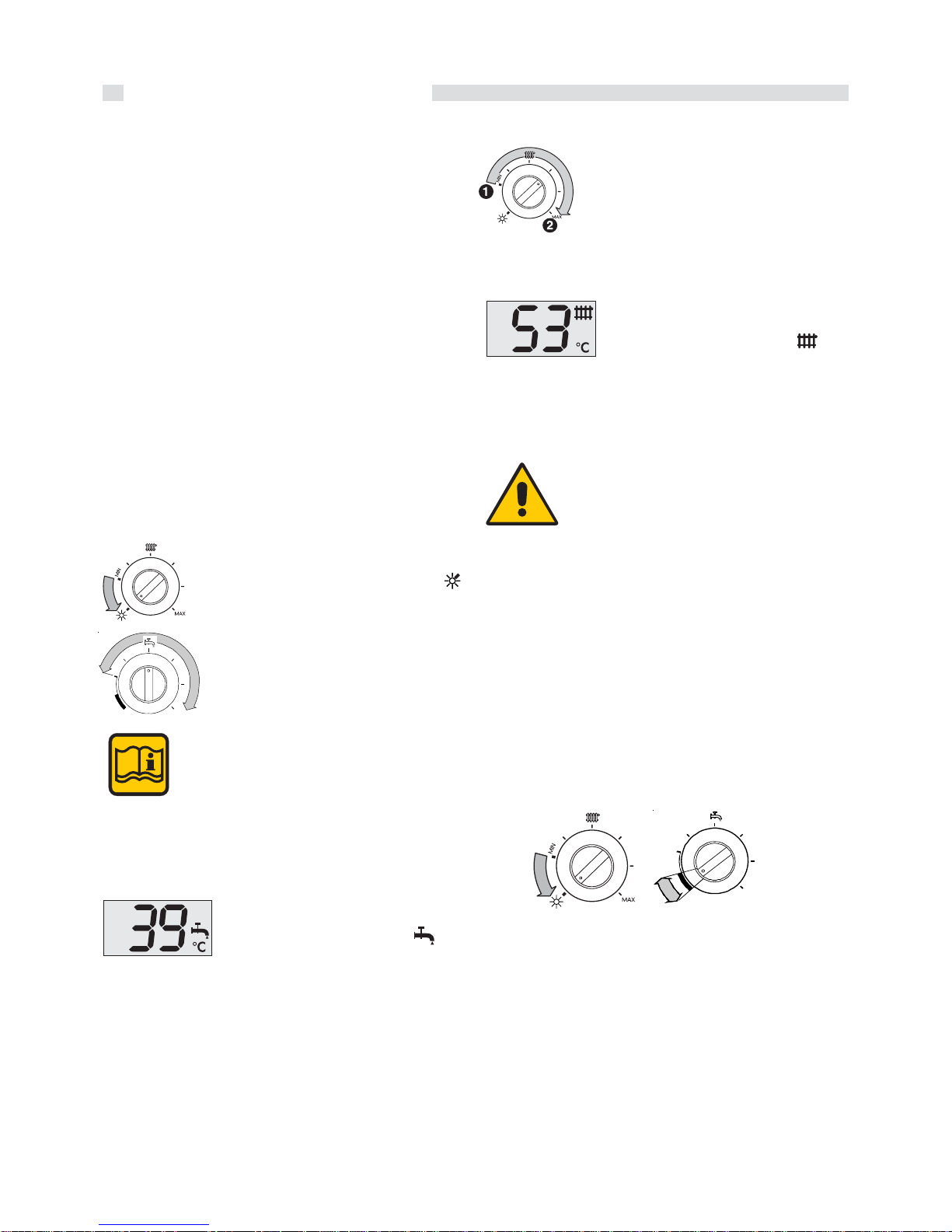

Summer/Winter switch + Heating temperature

controller

Through this knob it is possible to select the

operation mode:

· Summer (D.H.W. production only)

· Winter (Heating and D.H.W. production)

The pointer of the knob in

Summer

position

means that the boiler does not supply any

heating (in any case the anti-frost protection

remains active).

With the pointer of the knob within the range

shown beside, the boiler is in Winter mode

and controls the heating water temperature,

which can be adjusted between a minimum

of 30°C and a maximum of 85°C.

D.H.W temperature controller

In the ALKON R models this function is active only if the boiler

is connected to an external D.H.W. storage tank.

Through this knob it is possible to adjust the

temperature of the D.H.W.

NOTE

In the ALKON R models, not

connected to an external

D.H.W. storage tank, the

pointer of the knob has to be

positioned as shown beside.

With the pointer of the knob within the range

shown beside, the D.H.W. temperature is 38°C.

Function “ECO-COMFORT”

With the pointer of the knob within the range

shown beside, there is the activation of the

function ECO-COMFORT, which assures a

drawing of D.H.W. at 38°C with the best energy

saving.

Function “COMFORT”

The D.H.W. temperature can be adjusted

between a minimum of 38°C and a maximum

of 60°C.

HOLIDAYS

If the boiler is not controlled by a modulating

chrono-thermostat, during Holidays period the

pointer of the knob has to be positioned within

the range shown beside.

°C

®

MAX MAX

M

I

N

MAX

MAX

MAX

MAX

MAX

MAX

6 - OPERATING INSTRUCTIONS

6.1 - CONTROL PANEL

Page 5

5

User’s operating instructions

Operation in Heating mode

The symbol is shown when the boiler receives a

heat request for C.H. If, at the same time, there is

a heat request also for D.H.W. production this

symbol is switched off.

Operation in D.H.W. mode

The symbol is shown when the boiler receives a

heat request for D.H.W. production

Burner Lockout indication

This symbol is shown when the burner is put in

lockout by the burner control, due to:

· Lack of gas

· Lack of ignition

In the first case, in which none ignition took place,

ascertain the gas cock is open.

Fault indication

This symbol is shown when there is a fault within

the boiler.

1) If the fault does not cause the stop of the

boiler operation, to have the error code shown

on the display, it is necessary to press the reset

button (D); in case the boiler is in stand-by the

error code is shown also without pressing the

reset button.

2) If the fault causes the stop of the boiler

operation, the error code is shown flashing on

the display.

Reset button

By pressing this push button, it is possible:

· To restart the boiler after a lockout due to the

burner control, which has lit, on the display, the symbol

.

· To have the error code shown on the display if

the boiler operation was not stopped by this fault.

· To activate the special function for calibration.

· To enter the Service Menu and select the

parameters.

Indication of burner in operation

This symbol indicates the burner is in operation.

The symbol is shown when the boiler receives a

heat request for C.H. or D.H.W. production.

Thermometer

It shows the boiler or the DHW temperature.

If, on the display, the symbol

( ), is

shown,

the temperature is the one of the heating

circuit.

If, on the display, the symbol

( ) is

shown,

the temperature is the one of the DHW

circuit.

Manometer

It shows the water pressure

of the heating circuit; the value of

such pressure has to be equal or higher than

0,8/1 bar(in cold conditions).

If the pressure is below

0,8/1 bar the boiler operation is inhibited and

it is necessary to restore

the correct value acting on the filling cock.

This operation has to be performed when the

heating circuit is cold.

Page 6

6

User’s operating instructions

6.4 - FROST PROTECTION MODE

The boiler is fitted with a frost protection system which will

operate automatically when the system temperature falls below 6°C: the burner is automatically fired and the pump is

energized until the system’s water temperature has risen to

16°C.

If the temperature detected by the CH sensor falls below 2°C,

burner operation is automatically stopped until the temperature has risen to 5°C.

D.H.W. production (Summer mode)

Make sure the selector (B) is in position ( )

Position the D.H.W. temperature adjusting

knob (C) on the desired temperature:

COMFORT between 38 and 60°C, ECOCOMFORT or ECO.

Note:

By adjusting the DHW temperature at a temperature very close to the one actually used

will avoid mixing hot water with cold water,

thus resulting in fuel savings and a significant reduction of lime scale formation.

When opening a D.H.W. tap the boiler will start automatically

in order to supply water at the desired temperature.

During all the phase of D.H.W. drawing,

on the display the actual D.H.W.

temperature and the symbol (

) are

shown.

C.H. mode (Winter mode)

In order to have the boiler operating for C.H.

purposes, the pointer of the knob (B) has to

be positioned between 1 (minimum

temperature) and 2 (maximum

temperature).

If the C.H. installation is equipped with a Room thermostat,

position the pointer of the knob (B) in an intermediate position.

During the operation in C.H. mode, on

the display the actual boiler water

temperature and the symbol ( ) are

shown.

Put out of operation

In order to put completely out of operation the boiler cut the

power supply to the boiler through the external main switch.

In case of long periods of inactive state of the

boiler close also the gas and cold water cocks.

B

C

To activate the anti-frost protection position the pointer of

knobs (B) and (C) as shown below.

MAX

MAX

6.2 - CHECK LIST BEFORE COMMISSIONING

THE BOILER

Before commissioning the appliance it is recommended to

check the following points:

- Check that the On-Off gas valve, positioned upstream of

the boiler, is in the On position.

- Check that any On-Off valves fitted on the flow and return

pipes for servicing purposes are in the On position.

- Check that any On-Off valves fitted on the cold water inlet

for servicing purposes are in the On position.

- Check that the pressure relief valve drainage pipe is con-

nected to the sewage system.

- Check that the boiler is connected to the electrical supply;

the display on the panel board has to be illuminated.

- Check the heating system pressure, indicated by the pres-

sure gauge. For correct operation the pressure should be

between 0,8 and 1 bar (with the pump not running).

If the pressure falls below 0,7 bar restore the correct pressure by regulating the filling valve when the system is cold

and the boiler not operating (refer to paragraph 6.5).

6.3 - BOILER OPERATION

Page 7

7

User’s operating instructions

6.5 - FAULT SOLUTION

When the boiler shows an light anomaly the symbol ( ).

starts flashing on the display, beside the boiler temperature.

When the boiler shows a permanent fault the symbol (

)

starts flashing beside the error code, which has taken the

place of the boiler temperature.

If the fault is a blocking one or if the boiler is in stand-by the

code that identifies the cause is shown instead of the

temperature (for the fault list see paragraph. 5 - “error codes”

of the installation manual).

Error code:

Cause:

The burner’s lock-out device has intervened due to:

- no gas supply (in this case check that the gas service cock

is open

- presence of air in the piping (if it is a new system or after a

long inactivity of the boiler).

Elimination of the fault:

Check that the gas service cock is in the On position and that

the air present in the piping has been vented.

Press the reset key to restore correct boiler operation.

If the cut-off device operates repeatedly (a

maximum of 3 times), causing boiler shutdown, do not try to relight the boiler yourself. Contact your nearest Unical authorized

After Sales Service Centre.

°C

Error code:

Meaning:

Too low water pressure in the C.H. circuit

Elimination of the fault:

Restore the correct pressure value by regulating the boiler’s

filling valve (for correct boiler operation the pressure should

be between 0,8 and 1 bar).

When the correct pressure value has been reached the led

will switch off automatically and normal boiler operation will

be restored.

DANGER!

If the system has to be frequently restored

please contact an authorized Unical After

Sales Service Centre.

WARNING!

This feature will operate only if the electrical

supply to the boiler is On (green Power On led

illuminated).

However, further frost protection can be incorporated by using specific frost protection products, suitable for multi-metal systems. Do not

use anti-frost products for motor vehicles

because they could seriously damage the

water gaskets.

If, for any reason, there is no gas or electrical

supply, the above described frost protection

mode will not be active.

Filling

valve

The user can intervene and restore the

operation of the boiler only in presence of the

following codes:

· LP (boiler water pressure too low)

· — (burner lockout)

With all the other error codes the user is NOT

AUTHORIZED to try to restore the boiler

operation.

He has to address him self to an UNICAL

authorized after sale service.

Page 8

AG S.P.A.

46033 casteldario - mantova - italia - tel. +39 0376 57001 (r.a.) - fax +39 0376 660556

www.unical.ag - info@unical-ag.com

The Unical declines every responsibility for the possible inaccuracies if owed to errors of transcript or press. Also

reserves the right to bring those changes that it will hold necessary to it own products or profits, without jeopardizing its

essential characteristics.

Loading...

Loading...