Unibor UA5000 Autofeed User Manual

1

The UA5000

Autofeed

machine

is part of

the

range of

specialist

engineering

products.

UA5000 AUTOFEED

DRILLING SYSTEM

OPERATING INSTRUCTIONS

(A Nitto Kohki Company )

To get the best possible

performance from your

new Magnetic Drilling

Machine, please read

this carefully

BEFORE using

the drill.

FOR THE

2

3

2

BEFORE STARTING

(A Nitto Kohki Company )

Read these instructions carefully before

operating, maintaining or servicing this

tool.

Please keep these instructions in a safe

accessible place.

Read to fully understand and observe

the following safety precautions and

warnings. Careless or improper use of

this equipment may result in serious or

fatal injury.

Always wear eye, head and ear

protection equipment, when using this

tool.

WARNING! Indicates instant possibility

of severe personal injury or loss of life,

if instructions are not followed.

CAUTION! Indications a possibility of

personal injury or equipment damage, if

instructions are not followed.

OPERATOR SAFETY

• Always read the instructions carefully so as to

avoid any injury or damage when unfamiliar with

this equipment.

• Always wear a safety face shield or goggles.

• Wear ear defenders when using this equipment.

• Always wear heavy clothing, boots and gloves.

Do not wear loose clothing, short pants, sandals

etc. and ensure that long hair is tied up above

shoulder length.

• Do not operate this equipment when tired,

ill or under the influence of alcohol, drugs or

medication

• Never allow an inexperienced person operate

this equipment.

• Never operate the equipment in damp, or water

logged area.

• Keep all carry handles and levers free from oil.

• Keep hands away from the cutter when it is

rotating. Ensure that it has stopped rotating and

is disconnected from the power source before

touching the cutter.

• Do not attempt to gain access into the electrical

panel. There is risk of electrical shock.

• Never use a larger diameter cutter than

specified for use with this equipment.

• Do not attempt to connect the equipment to a

power source other than that specified by the

manufacturer.

• Ensure that the cutter being used is sharp and

free from damage.

T

OOL SAFETY

• Inspect the entire piece of equipment before

use.

• Replace damaged components, lubricate

where necessary and ensure that all fasteners

are secure.

• Always use a safety chain to secure the

equipment when it is being used above the

ground.• Use only accessories that have been

recommended by the manufacturer. Failure to do

so could result in damage to the tool and may

invalidate the warranty.

WARNING!

Never modify the tooling any way. Do not use

your equipment for any job other than for which

it is intended.

M

AINTENANCE SAFETY

• Maintain according to the manufacturers

recommended procedures.

• Disconnect the equipment from the power

source before attempting any maintenance.

• Use only genuine replacement components as

recommended by the manufacturer.

T

RANSPORT AND STORAGE

• Before moving the tool, ensure that the cutter

has stopped rotating.

• Carry the tool with the cutter pointing away

from the body to avoid laceration.

• After use, clean the equipment and it’s

accessories and store in a dry place.

• Store the equipment along with the maintenance

tools in its correct carrying case when not in use.

Page 3.

Warnings and Safety Instructions

Page 4.

Broach Cutting Concept & Technical overview

Page 5.

Machine Parts & Electronic Functions

Page 6.

Preparation & Drilling

Page 7.

Manual Feed & Autofeed

Page 8.

Parts Explosion Diagram

Page 9.

Parts List

Page 10.

Maintenance and recycling

Page 11.

EU Declaration of Conformity

43, Catley Road,

Darnall, Sheffield

S9 5JF. England.

Tel: (0114) 291 1000

Fax: (0114) 242 5905

Website- http://www.unibor.com

e-mail: sales@udce.co.uk

CONTENTS

INTRODUCTION

Congratulations on the purchase

of your new, lightweight, autofeed

multi-purpose magnetic base drill.

This is a high quality product with

unique features that make it the

perfect solution for your hole drilling

requirements.

4

5

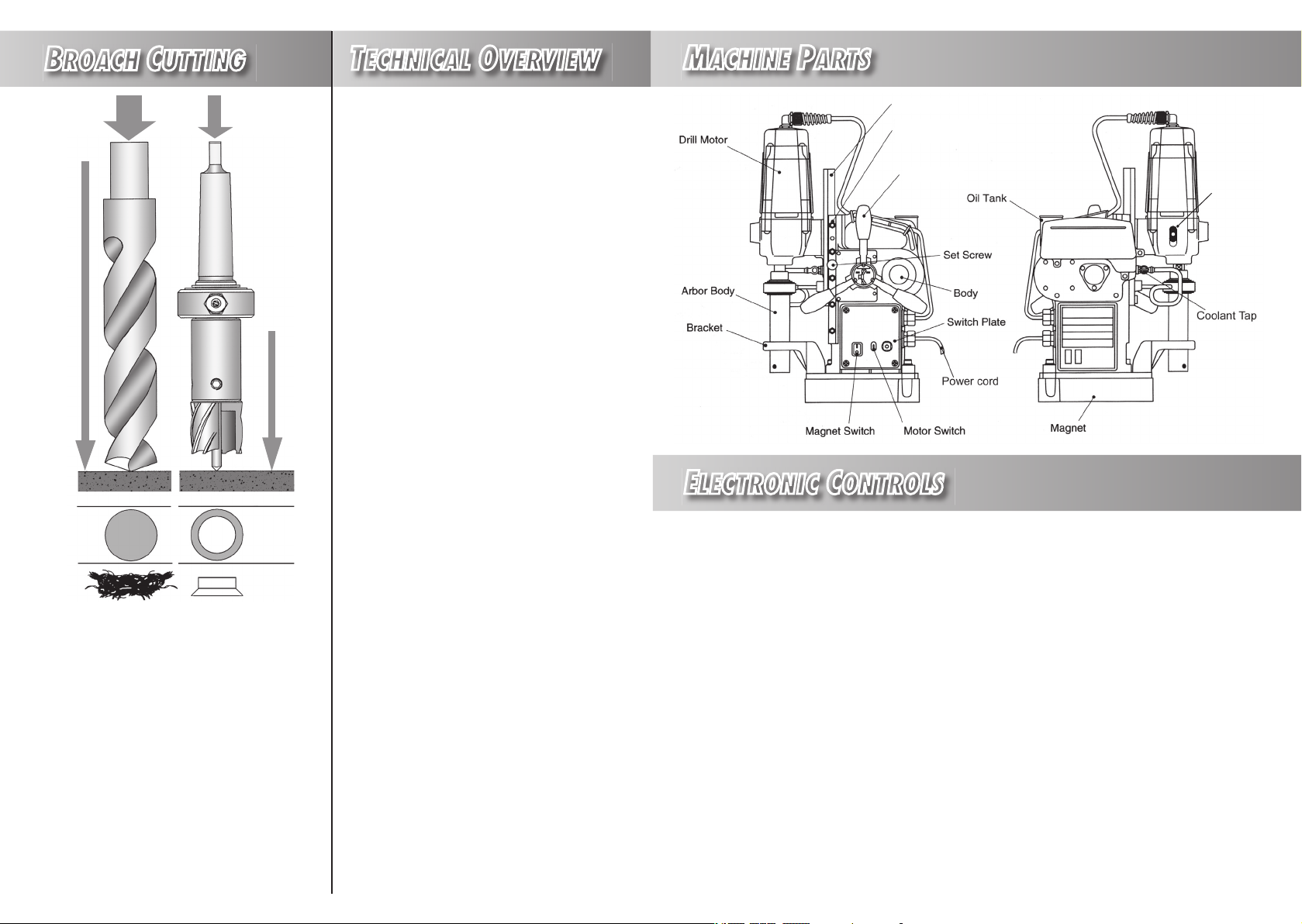

If you are unfamiliar with the use of annular

(or broaching) cutters, read this guide - you will

benefit from the better performance and longer

life of the tool if you understand the concept.

Annular cutters only cut material at the

periphery of the hole leaving a solid ‘slug’ at

the centre which is ejected at the end of the cut,

rather than converting the entire hole to shavings.

As a result, the time and energy required to make

the hole is lower than for a traditional twist

drill.

The broaching capacity of a machine is

therefore greater than the twist drill capacity.

The slug ejected after the cut also has a higher

scrap value than shavings.

The benefits in terms of productivity can be

as much as double.

Power

required

Material

removed

Cutting Time

Cutting Time

ELECTRONIC CONTROLS

LOAD DETECTOR

If there is an overload during drilling, the

following functions are automatically activated.

The load detector may not function properly if

the power supply is an engine generator or the

supply voltage is too high or too low.

A

UTOMATIC FEED CONTROL FUNCTION

This system automatically controls the feed

rate where several seconds after start-up of the

drilling it automatically slows down the feed

and then the rate varies depending on the load

on the motor. The feed rate is also automatically

regulated according to the cutter diameter.

OVERLOAD STOP FUNCTION

Both the drilling and feeding operations stop

automatically whenever there is an excessive

load on the motor, preventing the motor and

cutter from breaking. If the cutter is dull, however,

breakage may be inevitable.

C

YCLE STOP FUNCTION

After the cut has finished, a detector responds to

the reduction in load and both the drill and the

feed motor automatically stop.

MACHINE PARTS

Capstan

Speed

change

switch

LIMIT SWITCH FUNCTION

Even if the automatic stop function fails at the end

of drilling, allowing the drill motor to continue

downward feed, the limit switch stops both the

drilling and feed when the stroke reaches its

lower limit.

S

IDE SLIP DETECTION FUNCTION

If the magnet slides off while drilling, the drill

motor and the feed will stop.

R

ESTART PREVENTION FUNCTION

• When a power failure occurrs while the tool

is being used, the restart prevention function

operates when the power is restored.

• Even when the drill stops during operation

because of the interruption or accid ental

unplugging of the power supply, and the power

supply then resumes, the indicator lamps are lit

and the magnet regains its attracting power, but

the drill motor will not rotate.

• To resume work, set the magnet switch to On

and then the motor switch to On, and the drill

motor will start.

BROACH CUTTING

Cradle slide

Cradle slide

adjustment screws

Cutter capacity - 12 - 50mm (HSS)

No load speeds - 350/650 rpm

Power consumption - 1150w

Clamping force - 720kg

Size (L/W/H) - 330 x 268 x 565mm

Weight - 21 kg

Voltage - 240v

ALSO INCLUDES: Warranty, Carrying case,

Allen keys, Safety strap, Cutting Oil

• The easy to use and rugged design makes the

UA5000 a cost effective solution to drilling

clean, accurately positioned holes.

• Powered by a variable speed Eibenstock UNI

II motor.

• Automatic load sensing cutter feed.

MAIN FUNCTIONS

1. Slow start

The feed motor rotates slowly before cutting

starts for cutter protection and ease of

centring.

2. Auto feed speed adjustment

The feeding speed is automatically adjusted

depending on the size of cutter used.

3. Auto-return

The drill motor rises quickly when cutting is

completed and stops at its original retracted

position.

4. Auto-stop

The drill motor stops to avoid breakage of the

cutter when the force required to cut reaches a

predetermined amount. The drill motor will stop

if the magnet base moves during cutting.

5. Non-accidental-start

The machine must be reset if the power supply

is lost during operation. The switch must be

manually set to off and then back to on to reset.

TECHNICAL OVERVIEW

Loading...

Loading...