Unibor HUW150 User Manual [en, de, fr]

A GUIDE TO

2010 EDITION

GOOD DRILLING

To get the best possible performance from your new

Magnetic Drilling Machine, please read this carefully

BEFORE using the drill.

&

GUIDE POUR UN

BON CAROTTAGE

Pour obtenir les meilleures

performances de votre

Perceuse Magnétique

veuillez lire attentivement

ce gu id e AVA NT de

l’utiliser.

$

RICHTLINIEN ZUM

GUTEN BOHREN

Lesen Sie bitte diese

Richtlinien VOR der Arbeit

mit dem Bohrer sorgfältig,

damit Sie die bestmögliche

Leistung aus Ihrer neuen

Magn e tb oh r ma schi n e

herausholen können.

,

.,

PRAKTISCHE

RICHTLIJNEN VOOR

GOED BOREN

Om m et u w ni eu we

magnetische boormachine

d e b e s t m o g e l i j k e

resultaten te verkrijgen

is het belangrijk dat deze

richtlijnen goed worden

gelezen VOORDAT de

b o o r m a c h i n e wo r d t

gebruikt.

1

BEFORE YOU START

3. The Broach Cutting Concept

4. Material and Cutting speeds

5. Feeds and Speeds

6. Safety & Maintenance

8. Fitting Safety Guards

9. Fitting Cutters

10. Starting the Cut

11. Reversing Option

12. Warranty

To help you get the best possible

performance from your new Magnetic

Drilling Machine, this guide contains

simple, sensible pointers for the safe,

effective and long term use of the

equipment. Please read it carefully

before using the drill.

• Ensure that you have observed

all the general and specific safety

procedures.

FRANÇAIS AVANT DE DEMARRER

13. Le Concept du Carottage

14. Matérieux et vitesses de coupes

15. Avances et Vitesses

16. Sécurité et Maintenance

18. Fixation du carter de sécurit

19. Montage de la Fraise

20. Demarrage du Perçage

21. Option sens rotation invers

22. Certificat de Garantie

é

é

Afin de vous aider à obtenir les meilleures

performances de votre nouvelle Perceuse

Magnétique, ce guide contient d’une

maniére compréhensive les informations

de sécurité pour l’utilisation à long

terme de votre machine.

AVANT d’utiliser cette perçeuse,

ASSUREZ VOUS d’avoir enregistré les

instructions générales et les conditions

de sécurité.

DEUTSCH VOR ARBEITSBEGINN

23. Das Kernbohrkonzept

24. Werkstoff und Schnittgeschwindigkeiten

25. Vorschub und Geschwindigkeiten

26. Sicherheits und Wartungsanleitung

28. Montage der Schutzvorrichtung

29. Montage des Kernbohrers

30. Anbohren

31. Umsteueroption

32. Garantieantrag

Um Si e dazu zu befähigen, di e

bestmögliche Leistung aus Ihrer neuen

Magnetbohrmaschine herauszuholen,

enthalten diese Richtlinien einfache,

vernünftige Hinweise zum sicheren,

wirksamen und ständigen Gebrauch

des Geräts. Lesen Sie sie also VOR der

Arbeit mit dem Bohrer sorgfältig.

• BEACHTEN Sie alle allgemeinen und

spezifischen Sicherheitshinweise.

NEDERLANDS VOOR U BEGINT

33. Het Kernboor Concept

34. Boorsnelheden

35. Voedingen en Toerentallen

36. Veiligheid en Onderhoud

38. Plaatsen van de Beschermkap

39. Plaatsen van de Kernboor

40. Beginnen met Boren

41.

Draaien van de motor in tegengestelde Richting

42. Garantie Registratie

2

Om u te helpen de best mogelijke resultaten

te verkrijgen met uw nieuwe magnetische

boormachine, zijn in deze richtlijnen eenvoudige

en doelmatige aanwijzingen opgenomen

waarmee de uitrusting lange tijd veilig en

effectief kan worden gebruikt. U wordt

verzocht deze richtlijnen goed door te lezen

VOORDAT de boormachine wordt gebruikt.

• ZORG ERVOOR dat u alle algemene en

specifieke veiligheidsprocedures in acht heeft

genomen.

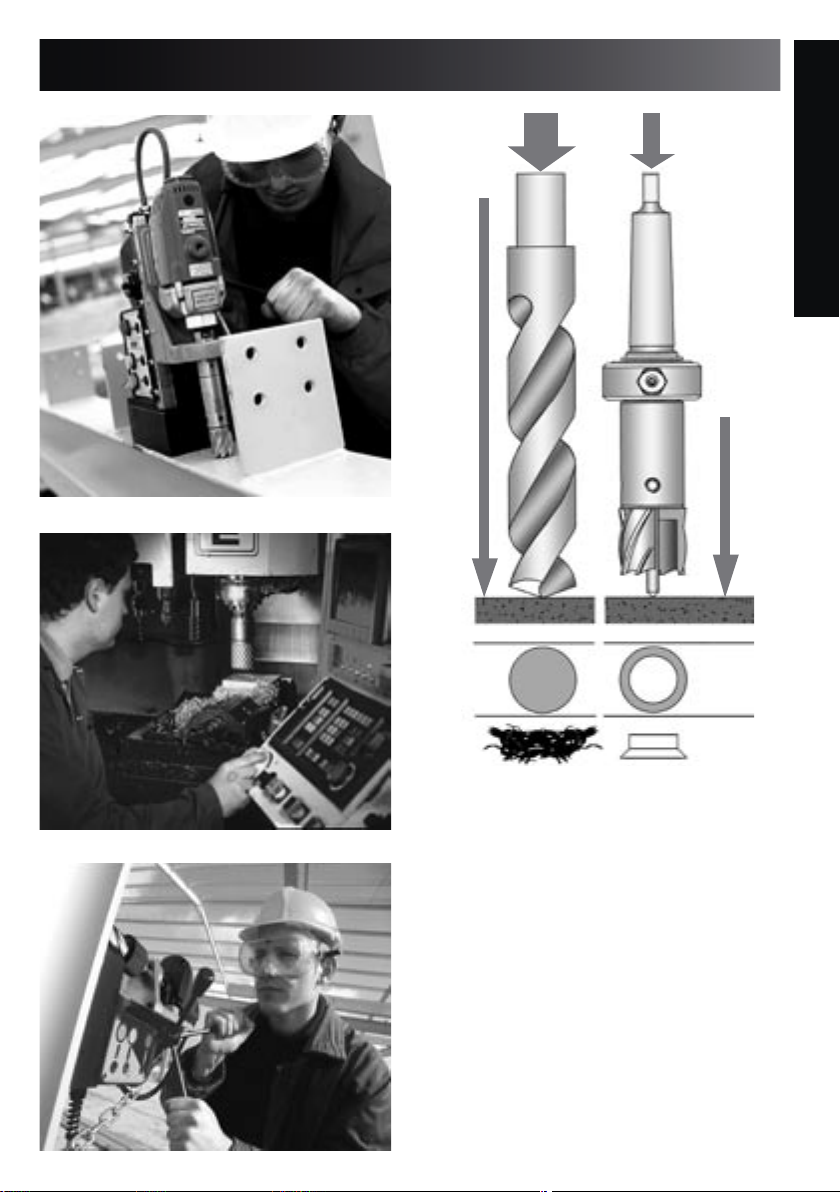

THE BROACH CUTTING CONCEPT

Power

required

Cutting Time

ENGLISH

Cutting Time

Material

removed

If you are unfamiliar with the use of

annular (or broaching) cutters, take a few minutes

to read this guide - you will benefit from the

better performance and longer life of the tool if

you understand the concept.

Annular cutters only cut material at the

periphery of the hole, rather than converting the

entire hole to shavings. As a result the time and

energy required to make the hole is lower than

for a traditional twist drill.

The broaching capacity of a machine

is therefore greater than the twist drill capacity.

The slug ejected after the cut also has a higher

scrap value than shavings.

3

ENGLISH

MATERIAL AND CUTTING SPEEDS

• The ease with which material can be drilled

is dependant on several factors including

tensile strength and abrasion resistance.

Whilst hardness and/or strength is the usual

criterion, wide variations in machinability can

exist among material showing similar physical

properties.

• The cutting conditions can be dependent upon

requirements for tool life and surface finish and

further restricted by the rigidity of the tool and

work piece, lubrication and machine power

available.

• The harder the material the lower the cutting

speed. Some materials of low hardness contain

abrasive constituents leading to rapid cutting

edge wear at high speeds. Feed rates are

governed by rigidity of set up, volume of material

to be removed, surface finish and available

machine power.

• It is preferable to set and maintain a constant

surface speed (RPM) for a given material and

vary the feed rate within defined limits.

• Machine feed is measured in inches or millimetres

per minute and is the product of RPM x number

of teeth in the cutter x feed per tooth. Too light

or excessively high feed rates will both cause

premature cutter failure. Heavy feeds on hard

materials will cause chipping of the cutting edge

and excessive heat generation.

• Slender and long shanked cutters are restricted

in feed rate due to deflection, and wherever

possible the largest and most robust tool must

be used. This is important for harder materials.

Steel up to 400 HB is the potential limit for

conventional M2 HSS tools.

Above 300 HB, cobalt alloy cutters should be

considered for increased tool life. In softer

grades of material, cobalt alloy cutters may give

increased output by increasing speeds and feed

rates by up to 50%. Tungsten Carbide cutters

permit surface speeds and feed rates up to twice

those for standard cutters.

4

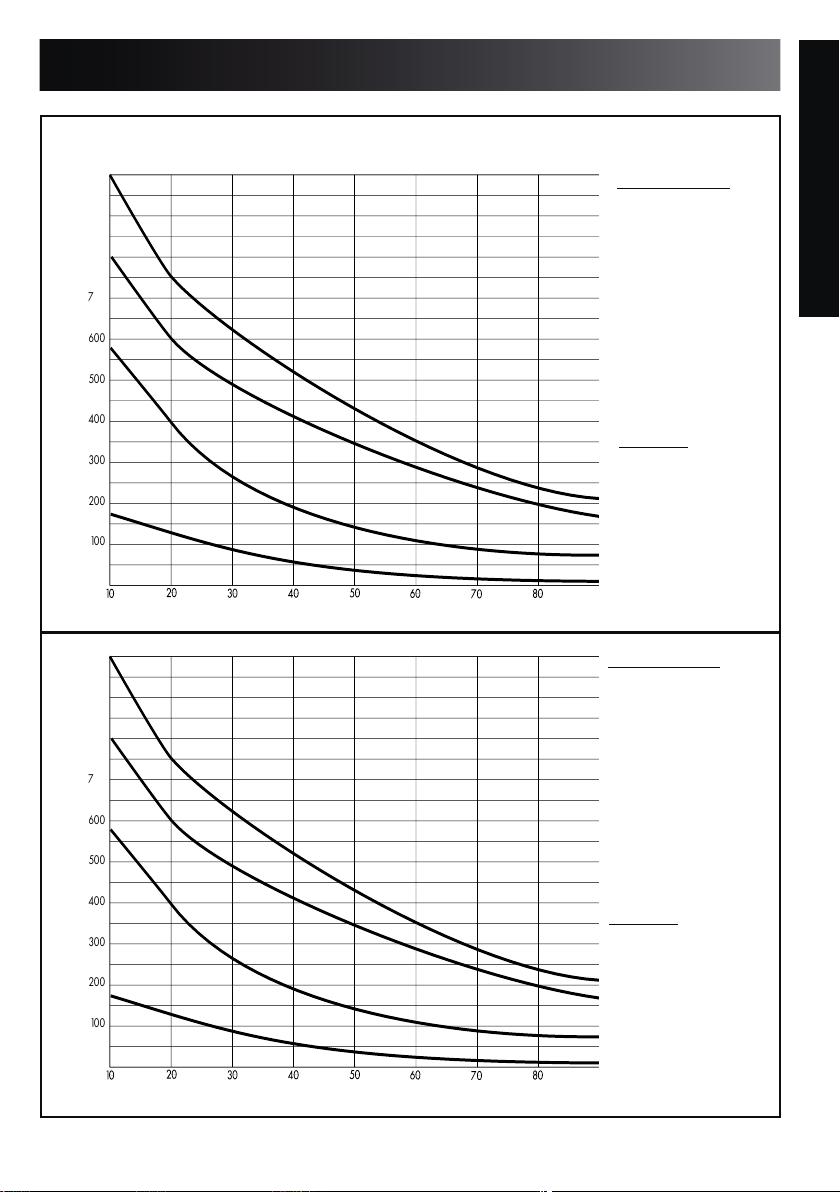

FEEDS AND SPEEDS

CUTTING SPEEDS Suggested speed rates for varying cutter sizes/materials

TOOL FEED RATE

(Metric)

MATERIAL

Fee d rat e

A L U MI N IU M - 6 0

B R A SS - 4 5

( mm /min)

ENGLISH

Speed (RPM)

Speed (RPM)

Cutter Diameter (mm)

Cutter Diameter (inches)

MILD S TE EL - 24

HI TEN SIL E STEEL - 9

TOOL FEED RATE

(Imperial)

MATERIAL

Fee d r ate

ALUMINIUM -

BRASS -

MILD STEEL -

HI TENSILE STEEL -

(in ches /mi n)

23/

13/

4

1 ”

3

/8 “

“

8

“

PLEASE NOTE: These figures are quoted as a starting point. Actual performance will be dictated by material

type, thickness and hardness, application and cutter condition.

5

GENERAL SAFETY INSTRUCTIONS

ENGLISH

1. KNOW YOUR POWER TOOL

Read and understand the owner’s manual and

labels fixed to the tool. Learn its application

and limitations as well as the potential

hazards .

2. EARTH ALL TOOLS

Ensure that (where applicable) suitable

earthed cords and plugs are used and

correctly connected.

3. KEEP GUARDS IN PLACE (where applicable)

-in working order, and correct adjustment and

alignment.

4. R EM OVE ADJUSTIN G KEYS A ND

WRENCHES.

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

5. KEEP WORK AREA CLEAN

Clutte re d a re as a nd b enches invite

accidents.

Floor must not be slippery due to oils, or

dust.

6. AVOID DANGEROUS ENVIRONMENT

Don’t use power tools in damp or wet

locations or expose them to rain. Keep

work area well lighted. Provide adequate

surrounding work space.

7. MAKE WORKSHOP SAFE

.-use padlocks, master switches, remove

keys. Visitors should be a safe distance from

work area

8. DON’T FORCE TOOL

It will do the job better and more safely at

the rate for which it was designed.

9 .USE CORRECT TOOL

Don’t force tool or attachment to do a job it

was not designed for.

10. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties

or jewellery (rings, wristwatches) to get

caught in moving parts. NONSLIP footwear

is recommended.

Wear protective hair covering to contain long

hair. Roll long sleeves above the elbow.

11 . U SE S AF ET Y G OG GL ES ( Hea d

Protection)

Wear approved safety goggles at all times.

Everyday eyeglasses only have impact

resistant lens, they are NOT safety glasses.

Also, use face or dust mask if cutting operation

is dusty, and ear protectors during extended

periods of operation.

12. SECURE WORK

Use clamps or a vice to hold work when

practical. It’s safer and frees both hands to

operate tool.

13. DON’T OVERREACH

Keep proper footing and balance at all

times.

14. MAINTAIN TOOLS WITH CARE.

Keep tools sharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS

Before servicing; when changing accessories

such as cutters, etc.

16. USE RECOMMENDED ACCESSORIES

Consult owners manual for recommended

accessories. Follow the instructions that

accompany the accessories. The use of

improper accessories may cause hazards.

17. CHECK DAMAGED PARTS

Before further use of the tool, a guard

or other part that is damaged should be

carefully checked to ensure that it will

operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect operation. A guard or other part that

is damaged should be properly repaired or

replaced.

18. N EV ER L EAVE TOOL RUNNING

UNATTENDED.

Turn power off. Don’t leave tool until it comes

to a complete stop.

6

MAGNETIC DRILL SAFETY INSTRUCTIONS

• Always inspect the whole unit before use.

• Regular maintenance is essential - check

nuts, screws etc. for tightness before each

use.

• Check cable and plug for damage.

• Never use blunt or damaged cutters.

• Never use a larger diameter cutter than

specified for the machine

• Always use the safety guards (where

fitted).

• Always wear goggles and gloves

• Secure the unit with the safety strap before

drilling.

• Always disconnect from the power source

before changing cutters or working on the

machine.

• Remove rings, watches, ties etc. that could

tangle in the moving parts.

• Keep the unit and workpiece as clear of dirt

and shavings as possible.

• On swivel machines, ensure that the swivel

base is locked in the required position.

• Do not attempt to change speed while the

drill is running.

• Only use accessories recommended by the

manufacturer.

• Never modify the tool in any way.

IMPORTANT MESSAGE

TO PREVENT DAMAGE TO THE CIRCUITRY,

NEVER USE ELECTROMAGNETIC DRILLING

MACHINES AND WELDING EQUIPMENT ON

THE SAME MATERIAL SIMULTANEOUSLY

MAINTENANCE INSTRUCTIONS

• Occasionally apply a few drops of oil to

the rack toothing.

• The bearings of the feed shaft are selflubricating and must not be greased

• Grease the sliding surface of the carriage

with MOLYCOTE grease.

• When not in use or being transported the

unit should be kept in the case supplied.

• After use ensure unit is clean of swarf and

dirt.

• Parts that are worn or damaged should

be replaced immediatley with genuine

manufacturer’s replacements.

• Ensure all cutting edges are sharp when

in operation. Using blunt cutting tools may

lead to an overload of the motor.

• After every 30 minutes running, it is

recommended that the machine is laid on

its side to permit grease to run across the

gear train.

• After repeated use, the cradle may

become loose. This is remedied by adjusting

the tension screws on the side of the body.

Put 2.5mm Allen Key into head of cradle

retaining nuts, using 8mm Spanner undo the

locking nuts anti-clockwise, holding the

Allen key without moving grub screws.

Using the Allen Key gently tighten screws

in series until the cradle moves freely in

the slide but does not allow the motor to

wobble.

When adjustment is complete re-tighten

locking nuts clockwise, ensuring the

grub screws do not move from their new

positions.

ENGLISH

7

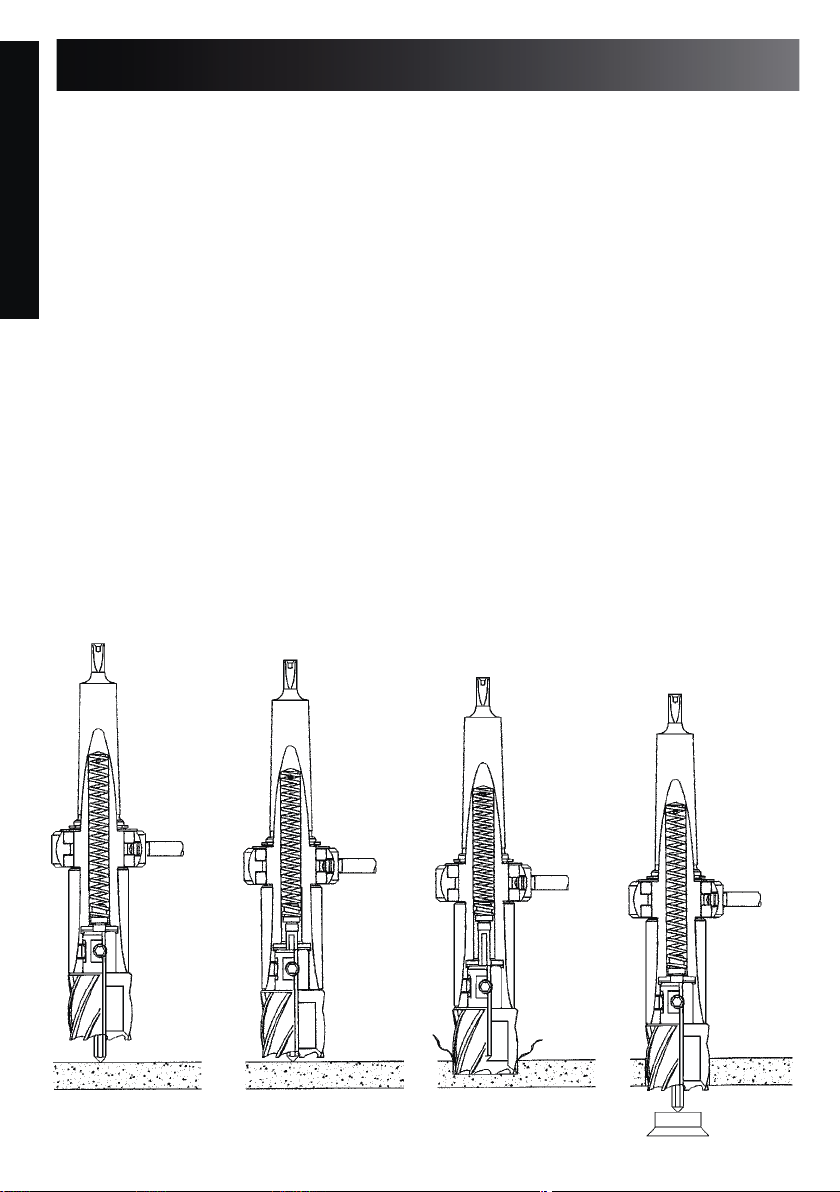

FITTING THE SAFETY GUARD

ENGLISH

DRILL GUARD INSTRUCTIONS

Ensure drill unit is isolated from power supply.

TYPE 1 - This type uses a single screw to fix the

guard to the drill.

Fit guard to drill in position shown in fig. 1.

Secure the guard to drill with the screw supplied.

DO NOT overtighten the fixing screw, this should

be loose enough to allow the guard to rise when

required. Lower the guard to drilling surface.

When drilling, the guard should always be in

contact with the surface being drilled. As the

drill is lowered, the guard will rise in relation

to the drill.

Fig. 1

TYPE 2 - This type uses two screws to support the

guard in position, one either side of the drill.

If necessary press the plastic guard guides into

their locating holes on ether side of the motor

cradle

Fit guard to drill as shown in fig 2.

Secure guard to drill with screws and washers

supplied. DO NOT overtighten the fixing screws,

these should be loose enough to allow the guard

to rise when required. Lower guard to drilling

surface.

When drilling, the guard should always be in

contact with the surface being drilled. As the

drill is lowered, the guard will rise in relation

to the drill.

Fig. 2

FITTING THE CUTTER (STANDARD ARBOR)

Fig. 3

8

Fig. 4

FITTING THE CUTTER (QUICKHITCH ARBOR)

E

NSURE POWER IS OFF BEFORE WORKING ON THE MACHINE

Insertion of pilot pin

• The pilot pin is used to both centre the cutter and to eject

the slug on completion of the cut. It has a flat side to allow

coolant to run down to reach the centre of the cut where the

heat is greatest. Slide the pin through the hole in the centre

of the cutter shank.

FITTING THE CUTTER

• With a standard arbor, two grub screws secure the cutter in

Fig. 5

Fig. 6

Fig. 7

the arbor. The cutter shank has two flats that must be aligned

with the grub screws in the arbor (fig. 3). Insert the cutter shank

into the arbor. The screws must be tightened evenly (using

the 5mm Allen key supplied) so that the cutter is prevented

from moving (fig. 4).

• Machines fitted with the Quickhitch™ arbor will accept

any cutter with a 19mm diameter shank having one or more

flats.

To fit a cutter, align it below the Quickhitch™ and twist the

arbor sleeve clockwise against its spring and hold, Fig. 5.

Insert shank of cutter into arbor, push it home and release

the sleeve, Fig.6.

Twist the cutter in the arbor to ensure the flat is engaged in

the locking mechanism, Fig.7.

Turn the sleeve fully anti-clockwise to complete the locking

operation’ Fig.8.

To remove the cutter, simply twist the sleeve clockwise

against the spring, the cutter will be ejected.

Mark the position of the hole

• Make sure the workpiece is clean and flat and position the

machine with the pilot over the centre of the hole to be cut.

FIT THE SAFETY STRAP.

Applying Coolant

• Cutting oil ensures longer cutter life and enables the slug

to be ejected cleanly. A 500 ml bottle is included with

every machine.

• On machines with a coolant system, oil will be automatically

delivered to the cutter when the cut commences

• On machines with an internal oil arbor, fill the reservoir in

the arbor through the small holes at the top.

• When cutting on vertical surfaces or upside down, cutting

paste, gel or foam is recommended. It is best applied inside

the cutter before drilling.

Fig. 8

N.B. Safety strap and guards have been omitted from the photo’s.

9

ENGLISH

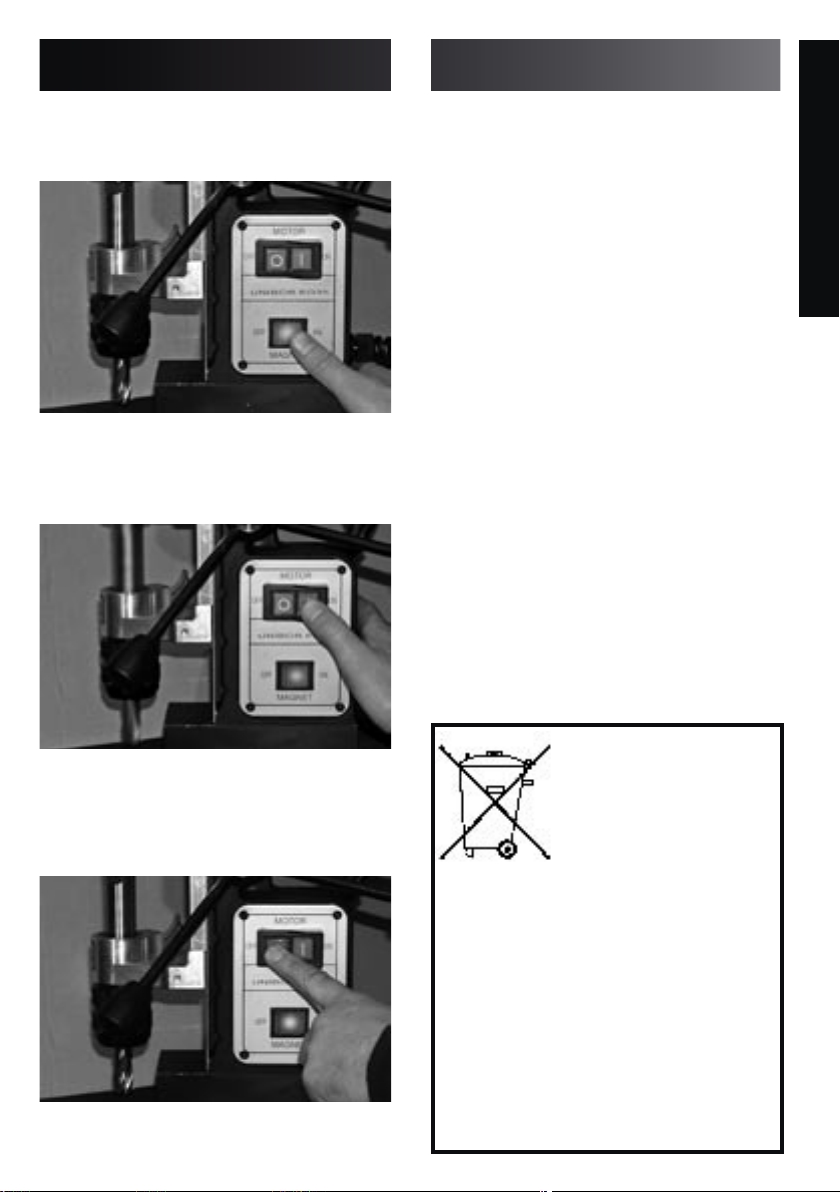

STARTING THE CUT (ELECTRONIC PANEL)

Fig. 9

Fig. 10

Fig. 11

• Plug the machine into the power socket and the red LED on

the electronic control panel will flash.

• To POWER UP THE MACHINE, press and release the red

button Fig. 9

• To ENERGISE THE MAGNET, press and release the yellow

button - the yellow LED will light Fig. 10 .

RECHECK the pilot is still centred on the hole position energising the magnet can sometimes cause the unit to move

slightly from the centre mark, reposition if necessary.

• The magnet will hold on all ferrous materials from a

minimum of 6mm (1/4”) thickness.

STARTING THE CUT

• ALWAYS lower the safety guard.

• START THE MOTOR by pressing and releasing the green button

- the green LED will light Fig. 11 .

• Wind the cutter gently down to the surface of the work

and apply light pressure until the cutter has made the initial

groove in the surface. Increase the pressure until the motor

is loaded Fig. 12.

• Maintain steady pressure throughout the rest of the cut.

Too much pressure will not speed the cut, it will reduce the

life of the cutter and may cause damage to the motor. If the

shavings become blue add more oil.

•

TO STOP THE MOTOR,

•

If the cutter jams in the workpiece,

raise the cutter out of the workpiece before re-starting.

• If the power is interrupted during the cut, the machine must

be reset before the motor will restart.

• At the end of the cut, the slug will be ejected. Withdraw the

cutter from the work piece and stop the motor.

• To disengage the magnet, press and release the yellow button

- the magnet will not disengage immediately, there will be a

3 second delay before the magnet disengages along with a

continuous beep.

Incorrect start up or shut down sequence:-

• A single beep will be heard for all operations carried out in

the correct sequence. A continuous beep will sound for any

incorrect sequence.

• Neither drill nor magnet can be operated until red power

button is activated.

• When the red power button is activated, the motor will not

run until the magnet is activated.

PRESS

&

RELEASE GREEN BUTTON

STOP THE MOTOR

.

and gently

10

Fig. 12

N.B. Safety strap and guards have been omitted from the photo’s.

(MECHANICAL PANEL)

REVERSING OPTION

• Plug the machine into the power socket.

• To POWER UP TH E MACHINE/EN ERGI SE THE

MAGNET, press the red rocker switch Fig. 13

Fig. 13

RECHECK the pilot is still centred.

STARTING THE CUT

• ALWAYS lower the safety guard.

• S

TART THE MOTOR

- press the green button Fig. 14 .

REVERSING OPTION (electronic panel only)

Machines fitted with the optional Reverse Drilling

Controller are operated as shown below.

• Power up the drill & energise the magnet as

before

• TO DRILL FORWARDS, press and release the green

button quickly - the green LED will light.

• TO STOP THE MOTOR, press and release the

green button.

• TO DRILL IN REVERSE, press and hold the green

button, wait for the beep, then release the button

- the green LED will flash (the pause is to ensure

the motor has stopped), the motor will then start

in reverse.

• TO STOP THE MOTOR, press and release the

green button.

The Green LED indicates as follows:ON - Drilling forwards

FLASHING - Drill in Reverse

REVERSING OPTION (mechanical panel only)

• Power up the drill & energise the magnet as

before

• S

TART THE MOTOR

• TO DRILL IN REVERSE - move the toggle switch to

the centre position, wait for the motor to

stop, then move the toggle switch to ‘Reverse’

and the motor will run in reverse.

- press the green button

ENGLISH

Fig. 14

• Proceed with the cut as detailed opposite

•

TO STOP THE MOTOR,

• At the end of the cut, the slug will be ejected.

Withdraw the cutter from the work piece and stop

the motor.

Fig. 15

PRESS THE RED MOTOR BUTTON

Fig. 15

•

TO DISENGAGE THE MAGNET

rocker switch.

, press the red

RECYCLING

Do not dispose of

.

electrical equipment

t o g e t h e r w i t h

house h old wast e

material!

In observance of European Directive 2002/96/

EC on waste electrical and electronic equipment

and its implementation in accordance with

national law, electric equi pment that has

reached the end of its life must be collected

separately and returned to an environmentally

compatible recycling facility.

WEEE Compliance Certificate:- on request

All magnetic drilling systems are full y

compliant with ROHS regulations.

11

EU DECLARATION OF CONFORMITY

ENGLISH

EC Declaration of Conformity

We hereby certify that the machine described below:-

1. TYPE : Electro Magnetic Drilling Machine

2. MODEL No: . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. . .. .. . ..

3. SERIAL No . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. . .. .. . ..

These power tools have been designed in compliance with:

2006/42/EC, 2004/108/EC, EN 55014-1, EN 55014-2,

EN 55022, EN 61029, EN 61000-3-2 & EN 61000-3-3.

and with the essential Health & Safety requ ireme nts.

Signed: . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. . .. .. . .. E. Kaibuchi (Director)

WARRANTY REGISTRATION

Certificate No. EC/MT

Th is machine is guaran teed against any faulty

components or workmanship for a period of 6 calendar

months from the date of purchase provided that:

1. The guarantee card is completed and returned to

the address below within ten days from the date

of purchase.

2. Any defects are, in the opinion of the warrantor,

due to faulty manufacture and are not caused by

misuse, tampering or attempted operation at other

than the voltage specified on the name plate of the

machine.

3. This guarantee does not cover repairs carried out

by unauthorised persons or defects due to fair

wear and tear.

4. We reserve the right to charge labour, packing

and carriage costs incurred in servicing any item

returned.

5. Machines for repair under our guarantee terms must

be returned to:

REPAIR WORKSHOP

PO Box 445

Sheffield, England

S9 5YS

6. If it is necessary to return this machine for repair,

please use the original packaging if possible and

quote the guarantee card number.

7. The warrantor cannot be held responsible for

damage or loss (however caused) to machines in

transit.

8. Please complete the date of purchase prior to

forwarding Guarantee Registration.

9. Retain this portion for evidence of your purchase

which must be subm itted in th e event of any

guarantee claim.

THIS GUARANTEE DOES NOT INVALIDATE YOUR STATUTORY RIGHTS.

Model No. ... .. .. .. ... .... .... .... .... .. .. .. Purchased from ..............................

Serial No. .................................. Date of purchase ............................

UNIVERSAL DRILLING & CUTTING EQUIPMENT LTD.

(USA)

Lombard IL. 60148

USA

12

(UK)

43 Catley Road

Sheffield S9 5JF

United Kingdom.

(Europe)

Dalweg 1 (Pinnepot II)

3233 KK Oostvoorne

The Netherlands

974 North DuPage Ave

LE CONCEPT DE CAROTTAGE

Puissance

Temps de coupe

requise

Temps de coupe

FRANÇAIS

Matière

enlevée

Si vous n’êtes pas familiarisé avec la

coupe par carottage, accordez quelques minutes,

pour la lecture de ce guide. En comprenant

le concept de ce genre de perçage vous

augmenterez performances et longévité des

outils. La fraise à carotter coupe le matériau

à la périphérie du trou, au lieu d’enlever toute

la matière comprise dans son diamètre. Il en

résulte une réduction de temps d’usinage et

d’énergie par rapport au perçage avec un foret

hélicoïdal. Avec le carottage, la quantité de

matière enlevée étant très réduite, la capacité

de perçage pour une même machine est bien

supérieure à celle obtenue avec les forets

hélicoïdaux.La valeur de la débouchure est plus

importante que celle des copeaux des forets

hélicoïdaux.

13

MATIERES ET VITESSES DE COUPES

* La facilité de perçage dépend de plusieurs

paramètres dont la dureté de la matière et

sa résistance à l’abrasion. Si dureté et / ou

résistance sont les critères habituels d’un

matériau, il y a trés souvent des différences

importantes pour une même matière.

* Les conditions de coupe peuvent aussi

dépendre des critères suivants: durée de

vie des outils, finition de la surface, rigidité

de l’outil, lubrification, puissance disponible

FRANÇAIS

de la machine.

* Plus la matière est dure, plus la vitesse de

coupe est faible. A grande vitesse certaines

matières de faible dureté mais contenant

des composants abrasifs émoussent les

arêtes coupantes des outils. L’avance doit

tenir compte de la rigidité de l’ensemble, du

volume de matière à enlever, de l’état de

surface désiré et de la puissance machine.

* Il est préférable de régler et maintenir une

vitesse constante pour une même matière

et faire varier l’avance dans les limites

définies.

* L’avance de l’outil, en millimètres/mn ou en

pouces/mn, est le produit de la vitesse par

le nombre de dents de la fraise et l’avance

par dent.Avec une avance trop faible ou trop

importante l’outil est plus vite détérioré. Dans

le cas de matière dure, l’ avance trop grande

écaille les arêtes de coupe tout en créant un

échauffement exagéré.

* Les outils et porte outils longs et étroits ne

supportent pas des avances importantes du

fait de la flexion. Dans la mesure du possible

utiliser les dimensions maximum en diamétre,

ceci est important pour les matières dures.

L’acier de 400 HB est la limite pour les outils

conventionnels en M2 HSS. Au dessus de 300

HB, les alliages au cobalt sont recommandés

pour augmenter la vie des outils. Pour l’ acier

moins dur l’alliage avec le cobalt peut

améliorer les performances en augmentant

vitesse et avance jusqu’à 50%.

14

Loading...

Loading...