Unibor Airbor 2 User Manual

Operating instructiOns

To help you get the best possible

performance from your new Airbor 2

Magnetic Drilling Machine, this guide

contains simple, sensible pointers for the

safe, effective and long term use of the

equipment.

• Please read it carefully, together

with the motor manual and the Guide

to Good Drilling, BEFORE using the

machine, taking especial notice of the

sections relating to the Air Motor.

• ENSURE that you have observed all

the general, local and specific safety

procedures, PARTICULARLY those

relating to the environment in which you

will be using the machine.

2010

editiOn

A Nitto Kohki Company

www.unibor.com

43, Catley Road,

Darnall,

Sheffield S9 5JF.

England.

Tel: (0114) 291 1000

Fax: (0114) 242 5905

e-mail: sales@udce.co.uk

Operating instructiOns

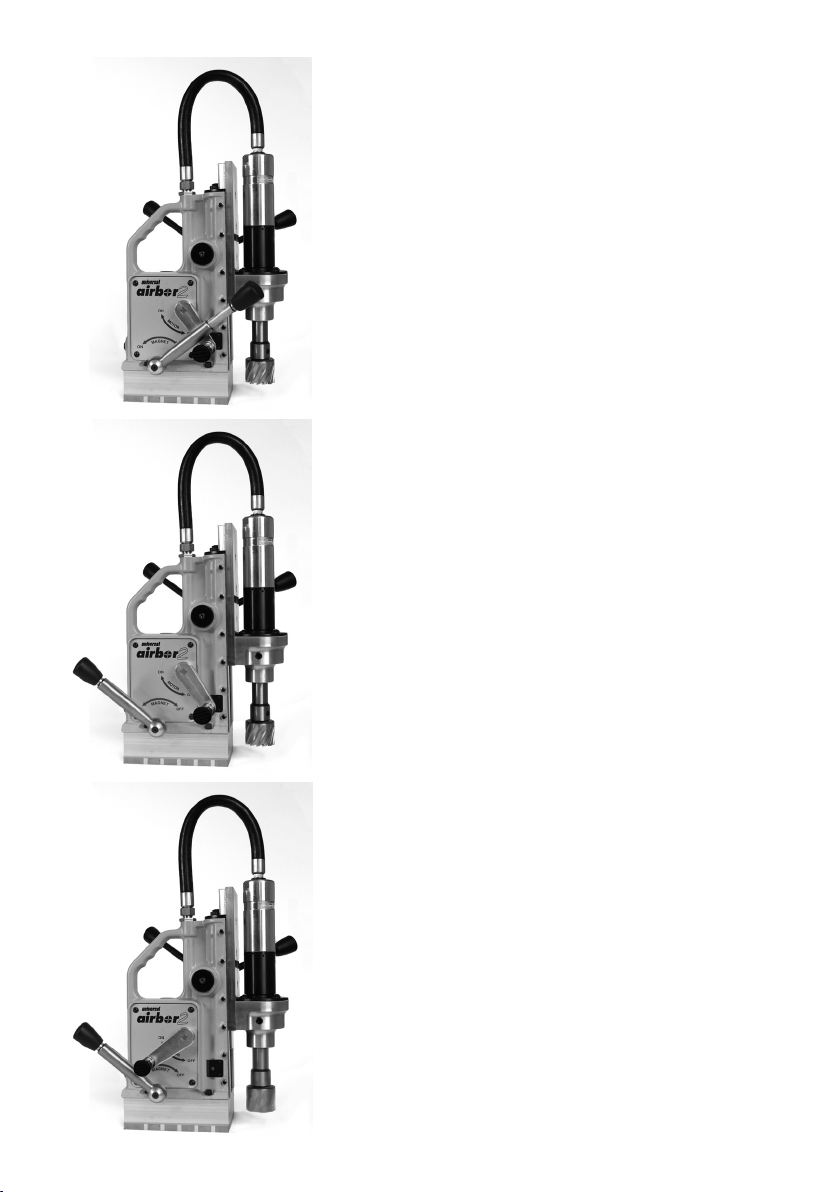

The Airbor 2 requires clean, dry lubricated air at a

maximum pressure of 6.2 bar (620kPa/90 psi) .

The air supply should always be turned off and

disconnected before installing or removing any accessory

on this machine.

Connect the chosen coolant delivery system to the arbor.

To commence drilling, place the machine in the correct

drilling postion. To activate the magnet, extend the

telescopic magnet handle for more leverage, and pull it to

the left.

Re-check the unit is correctly positioned for the hole to be

cut, and close the magnet handle extension.

To start the motor, disengage the motor lever locking pin by

pulling the handle on motor actuating lever, then move the

handle to the left. The motor will start.

While the motor is running, the magnet cannot be

disengaged.

When the cut is complete, stop the motor by moving the

lever to the right

Loading...

Loading...