Page 1

Operating and mounting manual (translation)

EV / EVF

Operating and mounting manual

Safety shut off valve solenoid valve

EV / EVF

Contents

1.0 General Remarks

1.1 Valve data

1.2 Application

2.0 Danger Notices

2.1 Safety terms

2.2 Safety notice

2.3 Qualified staff

2.4 Unauthorized modification and spare part production

2.5 Unauthorized operation

2.6 Safety information for the use in explosion-prone areas guideline 94/9/EC

3.0 Handling

3.1 Transport

3.2 Storage

3.3 Handling before mounting

4.0 Product Description

4.1 Function

4.2 Technical data

4.3 Marking

5.0 Installation

5.1 Warning of dangers during installation, operation and maintenance

5.2 Installation

6.0 Operation

6.1 Commissioning

6.2 Shutting down

6.3 Maintenance

6.4 Putting back into operating

7.0 Troubleshooting

7.1 Detection of defects

7.2 Troubleshooting plan

8.0 Dismantling of the Valve

8.1 Replacement of wear parts

9.0 Warranty

10.0 Explanations on Codes and Directives

11.0 Drawing

11.1 Sectional drawing

11.2 View drawing

11.3 List of parts

12.0 Declaration of Conformity

_______________________________________________________________________________________________________

220.100.091-05 Page 1 /21 Version: 06/2017

TM 4474

Page 2

Operating and mounting manual (translation)

EV / EVF

1.0 General Remarks

This operating manual includes instructions to assemble and operate the valve in the prescribed and

safe way. Additionally, the adeqaute operating instructions of each special solenoid drive must

be considered.

Series MG... 220.000.038

Series MG...X 220.000.040

Series MG…Xme 220.000.039

If any difficulties appear that can not be solved by means of the operation instructions, further

information may be demanded from the manufacturer.

This operating manual is in accordance with the relevant valid EN safety standards and the valid

prescriptions and rules of the Federal Republic of Germany.

If the solenoids are used abroad of the FRG, the operator and/or the person who is responsible for the

plant concept must take care that the valid national rules are met. The manufacturer reserves the right

of any technical change and improvement. The use of these operating instructions suppose the

qualification of the user according to paragraph 2.3 “qualified staff”.

The operating staff must be trained in accordance with the operating instructions. The operating

manual must always be available at the location where used.

1.1 Valve data

Manufacturer:

UNI Geräte E. Mangelmann

Elektrotechnische Fabrik GmbH

Holtumsweg 13

D-47652 Weeze

Telefon: +49 (0) 2837/9134-0

Fax: +49 (0) 2837/1444

E-Mail: info@uni-geraete.de

Homepage: www.uni-geraete.de

Designation

Directly functioning, currentless closed, spring safety shut off valve with magnet drive.

Type test acc. to DIN EN 264

Working pressure: 5 EV(F) 5bar

10 EV(F) 10bar

25 EV(F) 25bar

40 EV(F) 40bar

Ambient temperature: -10°C to + 60°C (263K to 333K)

Medium temperature: EV -10°C bis + 140°C (263K bis 413K)

EVF -10°C bis + 200° C (263K bis 473K)

Working pressure: 100-EVF 5 / 7 16bar

Medium temperature: -20°C to + 60°C (253K to 333K)

Ambient temperature: -20°C to + 60°C (253K to 333K)

Fitting position: vertical drive ± 5°, with order supplement „W“ vertical or

horizontal.

Working pressure: 100-EVF 10N 100bar

Medium temperature: -10°C to + 60°C (263K to 333K)

Ambient temperature: -10°C to + 60°C (263K to 333K)

Fitting position: vertical drive

Switching cycles: see operating instructions solenoid drive

_______________________________________________________________________________________________________

220.100.091-05 Page 2 /21 Version: 06/2017

TM 4474

Page 3

Operating and mounting manual (translation)

EV / EVF

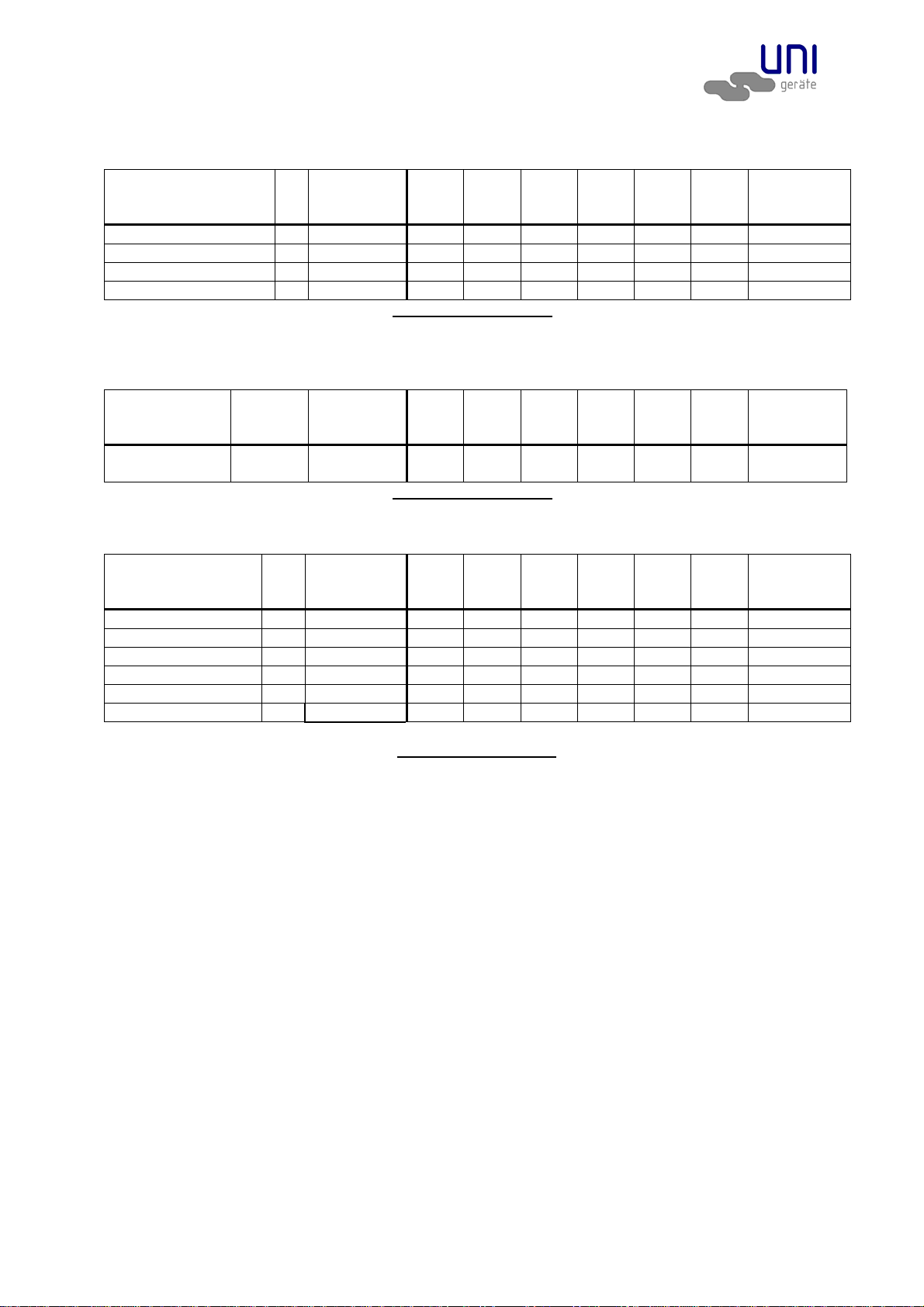

Flange connection measures acc. to DIN EN 1092-2 / ANSI

Flange DN

Flange ANSI

PN TÜV-

Report-no.

15

(5N)

1/2

20

(7N)

3/4

25

(10N)

1

32

(12N)

1 1/4

40

(15N)

1 1/2

50

(20N)

2

Test

Pressure

(*) PT

5 EV..NÜ..92/93 25 S7/99 X X X O O O PT 16

10 EV..NÜ..92/93 40 S7/99 X X X O O - PT 25

25 EV..NÜ..92/93(#) 40 S7/99 X X X O O - PT 40

40 EV..NÜ..92/93 40 S7/99 X X X O - - PT 40

(*) Test pressure to perform leakage test "No FUNCTION TEST"

X Type test acc., O Acceptance test certificate 3.2 possible, - not available,

(#) For liquefied gas in its liquid form according to DIN 32725

Threaded connection dimension at DIN ISO 228-1

Connection G PN

Class

TÜV-

Report-no.

1/2

(5)

3/4

(7) 1 (10)

1 1/4

(12)

1 1/2

(15) 2 (20)

Test

pressure

(*) PT

100-EVF...

100

900/1500

- O O - - - -

PT 100

(*) Test pressure to perform leakage test "No FUNCTION TEST"

X Type test acc., O Acceptance test certificate 3.2 possible, - not available,

Flange connection measures acc. to DIN EN 1092-2 / ANSI

Flange DN

Flange ANSI

PN TÜV-

Report-no.

15

(5N)

1/2

20

(7N)

3/4

25

(10N)

1

32

(12N)

1 1/4

40

(15N)

1 1/2

50

(20N)

2

Test

Pressure

(*) PT

5 EVF..NÜ..92/93 40 S8/99 X X X O O O PT 16

10 EVF..NÜ..92/93 40 S8/99 X X X O O - PT 25

25 EVF..NÜ..92/93 40 S8/99 X X X O O - PT 40

40 EVF..NÜ..92/93 40 S8/99 X X X O - - PT 40

40 EVF..NH.Ü.. 40 S8/99 X X X - - - PT 40

100 EVF..N.. 100 - - - O(**) - - - PT 100

(**) Passage 12mm

(*) Test pressure to perform leakage test "No FUNCTION TEST"

X Type test acc., O Acceptance test certificate 3.2 possible, - not available,

Voltage: VDC 12 – 440 (–15% bis +10%)

VAC 24 – 500 (–15% bis +10%)

Protection type: IP54 or IP65

Frequency: 40 – 60 Hz

Power: 10 – 4000W

Details to the electrical data can be found on the type signand the adeqaute operating instructions of

the solenoid valves.

1.2 Application

The UNI Geräte solenoid valve EV and EVF are used as automatic safety shut-off valves to secure, to

limit, shut-off and release Liquid gas heating installation and in steam boiler plant.

Qualified for fuel oil EL, M (EV) according to DIN 51603 and for liquid gas to DIN 61522 in liquid state

and other liquids having a viscosity rate up to 75mm²/s and for fuel oil S (EVF).

If used in other cases, the operator must carefully check if construction/design of valve, accessories

and materials are suitable for the new application. The range of application is subject to the

responsibility of the plant planner. The service life of the valve is 20 years.

_______________________________________________________________________________________________________

220.100.091-05 Page 3 /21 Version: 06/2017

TM 4474

Page 4

Operating and mounting manual (translation)

EV / EVF

2.0 Danger Notices

2.1 Safety terms

The signal terms DANGER, CAUTION und NOTICE are used in this operating manual in case of

notices concerning special dangers, or for unusal information requiring a special marking.

DANGER! means that in case of non-observance there is danger to life and/or

considerable damage.

CAUTION! means that in case of non-observance there is danger of injury and/or

damage.

NOTICE! means that attention is drawn to technical correlations/connections.

Observance of other, not especially marked notices concerning transport, assembly, operation and

maintenance and other data (in the operating manual, product documentation and at the unit itself) is

also essential, in order to avoid disturbances that might affect direct or indirect damage to property or

injury to persons.

2.2 Safety notice

Non observance of safety instructions can lead to loss of any claim for damages.

Non observance can lead to the following mentioned dangers:

Failure of important functions of the valve/plant

Endangering of persons by electrical or mechanical influences.

Protection against accidental contact for moving parts may not be removed as long as the

valve is in operation.

Leakage of dangerous media (e.g. explosive, toxic, hot) must be removed in the way that

there is no danger for persons or environment. Laws and regulations must be observed.

2.3 Qualified staff

These are persons who are familiar with erection, assembly, starting, operation and maintenance of

the product and who have special qualifications acc. to their activities and functions, e.g.:

Instruction and obligation to carry out and meet all regional and in-house orders and

requirements.

Education or instruction according to the safety engineering standards in use and

maintenance of adequate safety and working protection equipment.

Training in first aid.

2.4 Unauthorized modification and spare part production

Modification or changes of the valve are only allowed after agreement of the manufacturer. Original

drawings and accessories authorized by the manufacturer are for safety purposes. The use of other

parts or unauthorized changes at the valve by third persons may cancel and abolish the

manufacturere’s liability for resulting consequences.

2.5 Unauthorized operation

Operational reliability of the delivered valve is only guaranteed in case of determined use in

accordance to paragraph 1 of the operating manual. The application limits mentioned on the type

sign may on no account be exceeded.

2.6 Safety information for the use in explosion-prone areas guideline 2014/34/EU

The temperature of the medium must not exceed the respective temperature class, and

respectively, the respective maximum permitted medium temperature as per operation

guideline.

If the valve is heated (e.g. heating jacket), care must be taken, that the specified temperature

class is kept in the time.

_______________________________________________________________________________________________________

220.100.091-05 Page 4 /21 Version: 06/2017

TM 4474

Page 5

Operating and mounting manual (translation)

EV / EVF

The valve must be connected to the ground.

In the case most simple this can be realized via pipe screws by means of tooth disc.

Otherwise the connection to the ground must be implemented by other measures e.g. cable

links.

Control valves, electrical and electrical/mechanical drives as well as sensors must undergo a

separate conformity check as per ATEX. In doing so the respective safety and explosion

protection information in the operation instructions are to taken into special consideration.

Any modifications whatsoever to the valve are not allowed. The ATEX approval is void with

immediate effect if the valve is modified without prior authorisation (even including painting).

UNI-Geräte GmbH must be consulted before any modifications are made.

Furthermore we point out the guideline 95/C332/06(ATEX 118a), which include the minimum

regulations for the improvement of the health-related situation and the safety of the employees, who

might be jeopardized by an explosive atmosphere.

3.0 Handling

3.1 Transport

For any transport works, the generally recognised technical rules and standards as well as rules for

prevention of accidents must be observed.

In case of transport, storage and stopping, the flange protection caps must be mounted at both valve

flanges.

The goods to be transported must be carefully treated. During transport, the valve must be protected

against strokes, impacts or vibration. The coat of lacquer may not be damaged. Transport temperature

is –20°C up to +60°C.

Never transport the valve at screwed cable glands, appliance plugs or add-on units. The valve

can be transported at ring nuts, flange borings or by means of a belt under the solenoid drive.

Transport the valve in a case or on a pallet with smooth base and put it softly on plain floor. Never put

the valve on limit switch box.

The goods must be checked on completeness and transport damage. See also section 9.0

3.2 Storage

If the valve is not installed immediately after delivery, it must be stored properly.

Storage temperature -20°C up to +60°C, dry and clean.

The lacquering protects against corrosion in neutral dry atmosphere. Do not damage colour.

In humid rooms, a drying agent or a heating resp. is necessary because of condensation of

water.

Requirements according to DIN 7716 (products made of caoutchouc and rubber) must be met.

3.3 Handling before mounting

In case of valve with protection caps, they must be removed before being mounted!

Protect against atmospheric influences such as humidity.

Appropriate treatment protects against damage.

4.0 Product Description

The UNI-Geräte solenoid valves of the series EV and EVF are directly controlled currentless closed

shut-off valves with fast shut-off function as per DIN EN 264 (liquid gas in liquid gas phase as per DIN

51622) with solenoid valve.

Sectional drawing 11.1 Fig. in Fig. 1 and 6 shows the valve construction.

_______________________________________________________________________________________________________

220.100.091-05 Page 5 /21 Version: 06/2017

TM 4474

Page 6

Operating and mounting manual (translation)

1)

1)

EV / EVF

4.1 Function

On switching on of the solenoid drive (800) the solenoid core (207) is pulled against the upper part of

housing (106). The pressure spring (503) is further prestressed and the valve disk (200) opens the

valve cross section. The valve is open.

On shutting off, supply interruption or supply failure the valve closes to the solenoid drive. The valve

disk (200) closes due to the pre-stress of the pressure spring (5 03). The valve is closed.

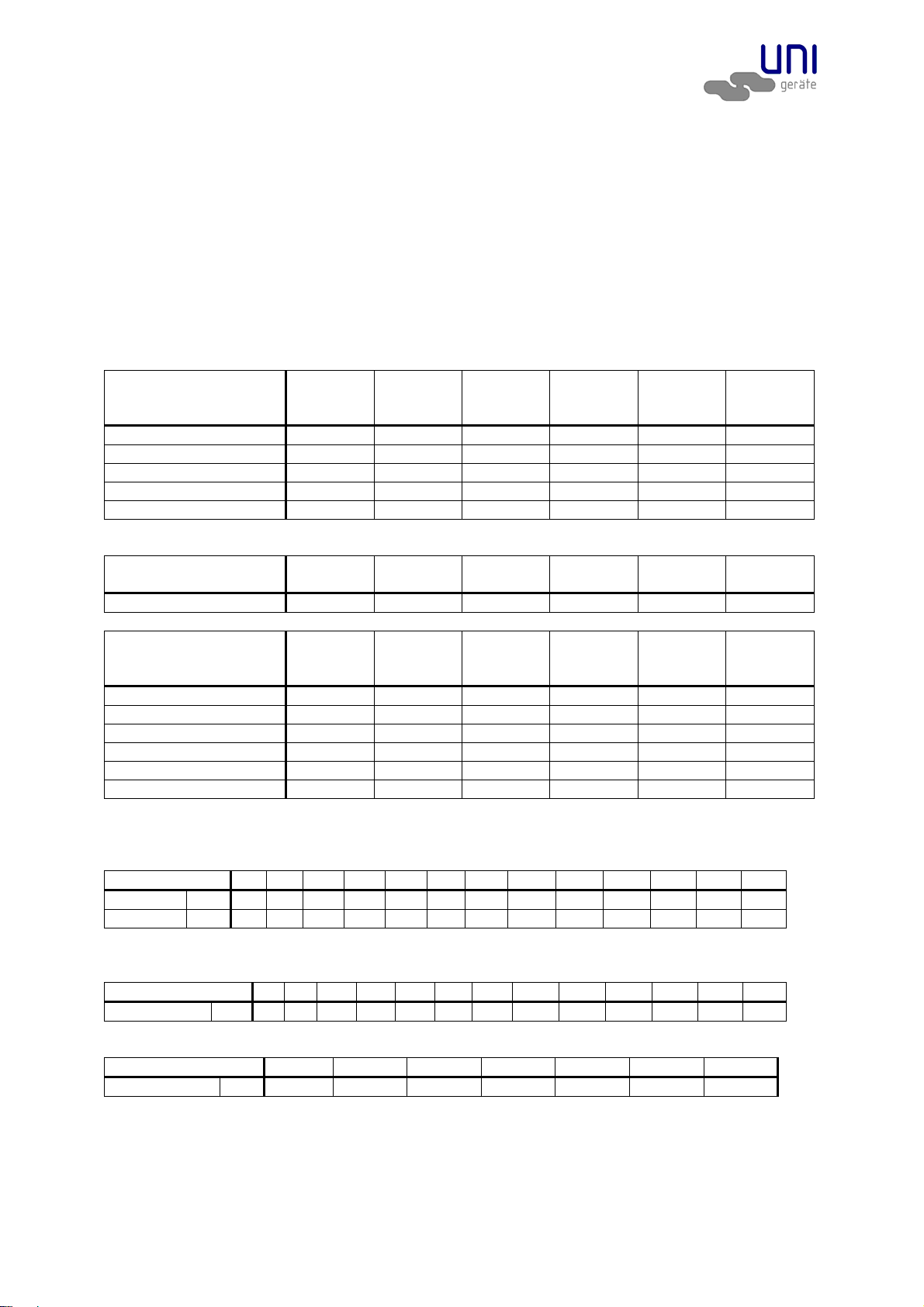

4.2 Technical data

Opening times: 0,3 – 0,7s , depends upon nominal width

Closing times: 1s

Solenoid –drive types MG...

Flange DN

Flange ANSI

5 EV...NÜ..92/93

10 EV...NÜ..92/93

25 EV...NÜA..92/93

25 EV…NÜA..92/93(#)

40 EV...NÜA..92/93

(#) For liquefied gas in its liquid

Connection G

ANSI

100-EVF....

Flange DN

Flange ANSI

5 EVF...NÜ..92/93

10 EVF...NÜ..92/93

25 EVF...NÜA..92/93

40 EVF...NÜA..92/93

40 EVF...NH.Ü..

100 EVF…N..

Drive types with “A” consist of pickup and holding winding

Max. valve loading by pipe power

The indicated moments may not work longer than 10s.

DN 8 10 15 20 25 32 40 50 65 80 100 125 150

Torsion Nm

Bending Nm

1)

Not valid in case of valves with flanges

80 35 50 86 125 160 200 250

35 70 105 225 340 475 610 1100 1600 2400 5000 6000 7600

Starting torque, pipe screws greased

DN 8 10 15 20 25 32 40 50 65 80 100 125 150

Torque Nm

20 30 30 30 30 50 50 50 50 50 80 160 160

Starting torque, product screws and nuts greased

Screw M6 M8 M10 M12 M16 M20 M24

Torque Nm

4.3 Marking

The type sign on the solenoid drive has the following information:

Fabricator

Valve type, nominal width, pressure and temperature indication, fitting position

Year of construction/ production no.

_______________________________________________________________________________________________________

220.100.091-05 Page 6 /21 Version: 06/2017

TM 4474

15

(5N)

1/2

014 014 016 018 019A5 019A2

016 016 019A5 018A2 019A1 016A1 016A1 018A2 019A2 019A3 018A1 018A1 019A1 - - 019A1 019A1 019A2 020A2 - -

1/2

(5)

019A5 019A5 - - - -

15

(5N)

1/2

014 014 016 019A5 019A5 019A2

016 016 019A5 018A2 019A1 016A1 016A1 018A2 019A2 019A3 019A1 019A1 019A2 020A2 - 019A1 019A1 019A2 - - -

- - 019A5 - - -

20

(7N)

3/4

3/4

(7)

20

(7N)

3/4

25

(10N)

1

1

(10)

25

(10N)

1

32

(12N)

1 1/4

1 1/4

(12)

32

(12N)

1 1/4

3251)400

40

(15N)

1 1/2

1 1/2

(15)

40

(15N)

1 1/2

50

(20N)

2

2

(20)

50

(20N)

2

- - -

5 11 22 39 70 110 150

Page 7

Operating and mounting manual (translation)

EV / EVF

TÜV-report-no:

Valve class and valve group acc. to DIN EN 264

CE-sign and no. of relevant location to 2014/68/EU

Fluid group and test pressure PT to 2014/68/EU

Solenoid drive type

Electr. performance

Voltage

Frequency

Protection type

When using solenoid drives for x-protection zone 1 refer to information in the valid operating

instructions.

Refer also to section 10.0.

5.0 Installation

5.1 Warning of dangers during installation, operation and maintenance

DANGER!

Safe operation of the valve can only be guaranteed if it is installed, commissioned

and maintained by qualified personnel (see point 2.3 “Qualified staff“) correctly and

in observance of the warnings in this operating manual. Apart from that, the

operation safety order and the qualified use of tools and protection equipment must

be guaranteed. The operating instructions for the valve must be observed during all

work on or with the valve. Failure to observe these instructions may result in injury

or in damage to the valve or other installations.

When the valve is used as a final sealing element, a safety precaution e.g. blanking disc, blind flange,

etc., in accordance with the code of practice of the German Technical and Scientific Association for

Gas and Water (DVGW) is recommended during all repair work.

5.2 Installation

Apart from the general installation guidelines, the following points should be observed:

NOTICE!

Remove the flange covers.

The inside of the valve and the pipeline must be free from foreign particles.

Observe the installation position in relation to the flow direction, see markings

on the valve.

Centre gaskets between the flanges.

The connecting flanges must be aligned.

Ensure that none of the components is strained during installation.

The valve must not be used as a fixed point; it is supported by the pipework

system.

Protect valves from soiling, particularly during construction work.

Thermal expansion of the pipework must be equalized using compensators.

The valve can be installed with upright but not suspended solenoid drive. Valves with order suffix “W”

in the type designation can be installed with horizontal solenoid drive.

NOTICE!

Please observe the solenoid drive operating instructions (BTA).

6.0 Operation

DANGER!

Before commissioning a new installation or before starting up an installation again

after repairs or modifications, ensure:

The proper completion of all installation and assembly work!

Commissioning only by “qualified staff” (see point 2.3).

Installation or repair of existing guards and protection equipment.

_______________________________________________________________________________________________________

220.100.091-05 Page 7 /21 Version: 06/2017

TM 4474

Page 8

Operating and mounting manual (translation)

EV / EVF

6.1 Commissioning

Before commissioning, check the data on material, pressure, temperature and flow direction

with the layout plan of the pipework system.

Depending on the field of application, the local regulations have to be observed, e.g. the

operation safety order.

Residues in the pipework and the valve (dirt, weld beads, etc.) will inevitably result in leaks.

Leakage inspection of the installed valve.

6.2 Shutting down

Depending on the field of application, the local regulations have to be observed, e.g. the

operation safety order.

6.3 Maintenance

Solenoid valves have to be checked at regular intervals for proper function and internal leak tightness.

The intervals for regular inspections have to be defined by the operator according to the operating

conditions. UNI-Geräte recommends an internal visual inspection once a year and an overhaul of the

valve after 2 years or after the following number of switching cycles at the latest:

Application

DN ≤ 25 ≤ DN 80 ≤ DN 150 > DN 150

temperature

≤ 25°C

> 25°C

150 000 75 000 25 000 20 000

50 000 25 000 25 000 5 000

6.4 Putting back into operation

When putting a valve back into operation, ensure that all the necessary steps described in section 5.2

(Installation) and section 6.1 (Commissioning) are repeated.

7.0 Troubleshooting

7.1 Detection of defects

DANGER!

Be sure to observe the safety instructions during troubleshooting.

If the malfunctions cannot be remedied using the following “Troubleshooting plan (7.2)” please

contact the manufacturer.

In the event of faults in the function or operating behaviour of the valve, check whether the installation

work was carried out and completed as described in this operating manual.

Depending on the field of application, the operation safety order must be observed.

Check the data on material, pressure, temperature, voltage and flow direction with the layout plan of

the pipework system. In addition, check whether the operating conditions correspond to the technical

data in the data sheet or on the rating plate.

7.2 Troubleshooting plan

Malfunction Possible causes Remedy

No flow Valve does not open Switch on solenoid drive (800)

Check operating voltage

Working pressure too high Compare working pressure with the data

on the rating plate

Flange covers were not removed Remove flange covers

Low flow rate Clogging in the pipework system Check pipework system

Valve leaking at seat,

no internal tightness

Valve seat gasket (400) or valve seat

(100) damaged by external particles

See section 8 or replace valve

No external tightness Gaskets damaged See section 8 or replace valve

_______________________________________________________________________________________________________

220.100.091-05 Page 8 /21 Version: 06/2017

TM 4474

Page 9

Operating and mounting manual (translation)

EV / EVF

Malfunction Possible causes Remedy

Valve does not close Connected voltage too high Check whether there is residual voltage,

see section 4.1

Flange fracture (valve/

pipework)

Screws not tightened uniformly, mating

flanges not aligned

Align pipework.

Install new valve

NOTICE!

Observe section 10.0 before all installation and repair work!

Observe section 6.4 when putting the valve back into operation!

8.0 Dismantling of the Valve

In addition to the general installation guidelines and the operation safety order, the following points

must also be observed:

DANGER!

Depressurised pipework system

Cooled medium

Emptied installation

Vent pipework systems containing corrosive, inflammable, aggressive or toxic

media

Have dismantling work carried out only by qualified staff (see point 2.3)

8.1 Replacement of wear parts

Shut down the valve as described in section 6.2.

Fig. 1 100-EVF…. G1/2, G3/4

Fig. 5 100-EVF..N.. DN25

Fig. 6 40-EVF..NH... (DN15, DN25)

De-installation of the limit switch mounting

Switch limit switch (803) to zero-potential. Open limit switch housing (120). Loosen hexagon nut

(901/2) and screw it off and remove it together with switch actuator (513) from the limit switch spindle

(243). Loosen hexagon nut (901/3) and remove it. Take off the limit switch housing (120) with terminal

box (716) from the limit switch connection piece (246). Remove connecting piece limit switch (246)

from solenoid housing (800).

Replace the solenoid valve

Switch off and dismantle the solenoid drive as described in the operating manual of the solenoid drive.

DANGER!

After continuous operation, the solenoid drive may be hot! Danger of burns!

During the visual inspection, pay attention to the following points:

1. Damage to the valve seat (100).

2. Damage to the valve disc sealing (400)

3. Wear of the guide rings (206)

In case of damage to the valve seat, replace the whole magnetic valve.

If the sealing element becomes damaged the spare parts kit should be used.

Loosen the setscrew (941). Loosen the upper part of housing (106) by turning to

the right and screwing it off.

_______________________________________________________________________________________________________

220.100.091-05 Page 9 /21 Version: 06/2017

TM 4474

Page 10

Operating and mounting manual (translation)

EV / EVF

NOTICE!

The complete upper part of housing (106) is under spring power.

Remove spring bolt (210) with pressure spring (503) from the solenoid core (207).

Release safety bolt (902/2) and remove it from the valve pin (214). Put the solenoid

core (207) complete with valve pin (214) and dust guard membrane (407) onto a

clear surface.

Loosen cylinder screw (910/2) and pull off the limit switch actuator (513) from the

valve spindle (205) and remove it.

Loosen hex. nut (901/3) and remove it with limit switch consoles (512); remove

limit switches (803) as well.

NOTICE!

Before doing so disconnect limit switch pos. 803.

Fig. 2 5/10/25/40-EV …NÜ… (lip ring sealing)

Loosen cylinder screws (910/1) and remove them with the lock washers (905/1).

Remove spacer (110).

Lift the complete parts (115; 200/1; 201; 205; 212; 249; 902/1; 912 und 950) out of

the valve housing (100). Pull of the guiding parts (115; 212; 249) from the valve

spindle (205).

Remove split-pin (912) and pull out safety bolt (902/1).

NOTICE!

The ball (950) falls out.

Remove the complete valve disk (200/1).

Fig. 3 5/10/25/40-EVF …NÜ.. (sealing of expansion bellows)

Fig. 4 5/10/25/40-EVF …NÜ.. (sealing of expansion bellows)

Drive spring dowel sleeve (943) out of torsion protection (227).

Loosen cylinder screws (910/1) and remove them with the lock washers (905/1).

Lift off spacer (110).

Only by Fig. 3

Lift the complete parts (200/2; 201; 205; 227; 400; 504, 507, 902/1, 912 und 950)

out of the valve housing (100). Pull the torsion protection (227) off the valve spindle

(205).

Only by Fig. 4

Lift the complete parts (200/3; 205; 227; 504, 507, 902/1, 912 und 950) out of the

valve housing (100). Pull the torsion protection (227) off the valve spindle (205).

Remove split-pin (912) and pull out the safety bolt (902/1)n.

NOTICE!

The ball falls out (950).

Lift off the complete valve disk (200/2 or 200/3).

All parts marked as wear and tear parts are to be replaced. In case of damages at

the valve disk sealing (400) the valve disk (200/1, 200/2) is to be replaced

completely. In case of damages and drag lines at the valve disk (200/3) the latter is

to be replaced completely. In case of cracks and pressure marks at the expansion

bellows (504) the latter is to be completely removed including the expansion

bellows piece (507).

NOTICE!

Before installation O-rings (403/X), gaskets (402/X), lip rings (404/X) and in case of

sealing metal against metal the packing (406) are to be replaced.

_______________________________________________________________________________________________________

220.100.091-05 Page 10 /21 Version: 06/2017

TM 4474

Page 11

Operating and mounting manual (translation)

EV / EVF

NOTICE!

For special application such as for oxygen use only the approved Lubricants

Assemble the valve in the reverse order to the dismantling.

CAUTION!

Install wear parts carefully and properly and do not damage them during assembly.

Examine the valve for internal and external leaks and finally carry out a function test.

9.0 Warranty

Scope and period of the warranty is specified in the edition of the “General Terms of Business of the

UNI-Geräte E. Mangelmann Elektrotechnische Fabrik GmbH” valid at the time of delivery or else in the

purchase agreement.

We warranty that the valve is free from faults in line with the state of the art and for the confirmed field

of application.

No warranty claims will be accepted for damage resulting from improper use or failure to observe

these operating and installation instructions, the statutory accident prevention regulations, the EN, DIN

and VDE standards and other codes and regulations.

Warranty claims will also not be accepted for damage occurring during operation due to operating

conditions deviating from those specified in the data sheet or in other agreements.

Justified complaints will be remedied by reworking by us or specialist companies authori sed b y us.

Claims going beyond the scope of the warranty will not be accepted. The customer shall have no right

to the supply of a replacement valve.

Maintenance work, installation of parts from other manufacturers, any modifications to the design and

natural wear are not covered by the warranty.

Transport damage must be reported not to us but without delay to your responsible goods handling

company, the railway company or the shipping agent as otherwise all claims for damages against

these companies will be voided.

10.0 Explanations on Codes and Directives

The Council of the European Community has passed common guidelines for the free exchange of

goods within the Community; these guidelines determines a minimum of requirements for safety and

protection of health. The type test confirms that products correspond to the EC guidelines, i.e. are in

conformity with the relevant, especially harmonized standards. The directives DIN EN 264 refer to oil

solenoid valve (mechanical part).

Notes concerning directives DIN EN 264:

The valves must be developed, manufactured and checked under observation of standard DIN EN

264. This is proven by the type test.

Notes on Directive 2014/68/EU (Pressure Equipment Directive, DGRL):

It has been conformed that the quality assurance in design control, manufacture and final acceptance

of the manufacturer, UNI-Geräte E. Mangelmann Elektrotechnische Fabrik GmbH, satisfy the requirements of 2014/68/EU Article 14 Module H. The gas solenoid valves comply with the fundamental

requirements of Directive 2014/68/EU. Valves in according to Article 1 Paragraph 2,f,v or Article 4

paragraph 3 are not allowed to have the CE Mark in according to Article 18.

_______________________________________________________________________________________________________

220.100.091-05 Page 11 /21 Version: 06/2017

TM 4474

Page 12

Operating and mounting manual (translation)

EV / EVF

Note concerning ex-guideline 2014/34/EU (explosion guideline ATEX):

The product is not subject to guideline 214/34/EU, since due to the loads occurring during practical

operation, there is no effective source of ignition even in case of an error case to be assumed. This

also applies to spring loaded components in gas-filled rooms. In case of electric drives, sensors or

other electric components the application as per 2014/34/EU is to be checked separately.

11.0 Drawing

11.1 Fig. 1 100-EVF… (G1/2 – G3/4)

097

716

403/3

246

403/3

243

106

800

219/4

210

219/3

503

207

943

206

509

908

901/1

214

219/2

900/3

948

219/1

108/2

504

966

404/1

403/2

403/1

948

900/2

100

403/1

403/2

504

108/1

116.001.50

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 12 /21 Version: 06/2017

TM 4474

6

404/1

966

948

900/1

Page 13

Operating and mounting manual (translation)

EV / EVF

Fig. 2 5/10/25/40-EV …NÜ…

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 13 /21 Version: 06/2017

TM 4474

Page 14

Operating and mounting manual (translation)

EV / EVF

Fig. 3 5/10/25/40-EVF …NÜ..

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 14 /21 Version: 06/2017

TM 4474

Page 15

Operating and mounting manual (translation)

EV / EVF

Fig. 4 5/10/25/40-EVF …NÜ.. (metal-of-metal sealing)

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 15 /21 Version: 06/2017

TM 4474

Page 16

Operating and mounting manual (translation)

EV / EVF

Fig. 5 100-EVF..N.. (DN25)

097

716

403/3

246

403/3

243

210

219/3

219/2

503

207

908

941

509

106

108/2

110/1

504

403/2

800

206

901/1

214

219/1

218

966

404/1

403/1

948

900/2

100

900/2

948

900/1

948

403/2

504

403/1

404/1

948

900/1

966

110/2

948

900/2

108/1

116.001.505

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 16 /21 Version: 06/2017

TM 4474

Page 17

Operating and mounting manual (translation)

EV / EVF

Fig. 6 40-EVF..NH.. (DN15, DN25)

= Spare Parts

_______________________________________________________________________________________________________

220.100.091-05 Page 17 /21 Version: 06/2017

TM 4474

Page 18

Operating and mounting manual (translation)

EV / EVF

11.2 View drawing

Fig. 1 100-EVF….(G1/2 – G3/4) Fig. 2 5/10/25/40-EV(F)…N.. (DN15 – DN50)

C

´

B

/

B

A

D

Fig. 5 100-EVF..N.. (DN25) Fig. 6 40-EVF…NH..(DN15, DN25)

C

´

B

/

B

D

A

11.3 List of parts

Pos./ Item Stück/ Qty. Benennung Description

097 1 Endschalteranbau Limit switch mounting

100 1 Ventilgehäuse Valve chamber

106 1 Gehäuseoberteil Upper part of housing

108/x 1 Gehäuseflansch Housing flange

110/x 1 Distanzstück Spacer

115 1 Dichtplatte Sealing board

200/1 1 Ventilteller Valve disk

Pos./ Item Stück/ Qty. Benennung Description

200/2 1 Ventilteller Valve disk

200/3 1 Ventilteller Valve disk

201 1 Tellerscheibe Disc plate

_______________________________________________________________________________________________________

220.100.091-05 Page 18 /21 Version: 06/2017

TM 4474

Page 19

Operating and mounting manual (translation)

EV / EVF

205 1 Ventilspindel Valve spindle

206 2 Führungsring Guide ring

207 1 Magnetkern Solenoid core

209 1 Abwurfbolzen Discharge bolt

210 1/3/4 Federbolzen Spring bolt

212 1 Spindelführung Spindle guide

214 1 Ventilstift Valve pin

218 1 Zweiteiliger Ring Two-piece ring

219/x 1 Spindelmutter Spindle nut

227 1 Verdrehschutz Torsion protection

243 1 Endschalterspindel Limit switch spindle

246 1 Verbindungsstück Endschalter Conncetion piece limit switch

249 1 Endschalter Konsolenhalter Limit switch console owner

400 1 Ventiltellerdichtung Valve disc sealing

402/1 1 Flachdichtung Gasket

402/2 1 Flachdichtung Gasket

402/3 1 Flachdichtung Gasket

403/1 1 O-Ring O-ring

403/2 1 O-Ring O-ring

403/3 1 O-Ring O-ring

404/1 2 Lippenring Lip-ring

404/2 1 Lippenring Lip-ring

405 1 Abstreifring Scraper ring

406 2 Packung Packing

407 1 Staubschutzmembrane Dust guard membrane

503 1/3/4 Druckfeder Pressure spring

504 1 Faltenbalg Expansion bellows

507 1 Faltenbalgstück Expansion bellows piece

509 1 Distanzring Distance ring

512 1/2 Endschalterkonsole Limit switch console

513 1/2 Endschalterbetätigung Switch actuator

716 1 Klemmkasten Terminal box

800 1 Magnet-Antrieb Solenoid drive

803 1/2 Endschalter Limit switch

900/x 12/20 Sechskantschraube Hex. head screw

901/1 1/2/4 Sechskantmutter Hex. nut

901/2 1 Sechskantmutter Hex. nut

901/3 1 Sechskantmutter Hex. nut

902/1 1 Bolzen Bolt

902/2 1 Bolzen Bolt

905/1 4 Federring Lock washer

905/2 2/4 Federring Lock washer

908 1 Sicherungsblech Safety plate

910/1 4 Zylinderschraube Cylinder screw

910/2 1/2 Zylinderschraube Cylinder screw

910/3 2/4 Zylinderschraube Cylinder screw

912 1 Splint Split-pin

941 1 Gewindestift Setscrew

943 1 Spannstift Spring dowel sleeve

948 12/20 Nordlockscheibe Nordlock washer

949 1 SL-Sicherung SL-retainer

950 1 Kugel Ball

966 1 DU-Buchse DU-liner

Wearing parts

Version Fig. Type Spare parts

Threaded

version

_______________________________________________________________________________________________________

220.100.091-05 Page 19 /21 Version: 06/2017

TM 4474

Fig.1 100-EVF…(G1/2, G3/4) Solenoid drive (800)

Page 20

Operating and mounting manual (translation)

EV / EVF

Flange

version

Fig.2 5/10/25/40-EV 5/7/10N

Fig.3 5/10/25/40-EVF 5/7/10N Spare part kit, Solenoid dri v e (800)

Fig.4 5/10/25/40-EVF 5/7/10N

Spare part kit, Solenoid drive (800)

Spare part kit, metal-of-metal sealing

Solenoid drive (800)

Fig.5 100-EVF..N.. (DN25) Solenoid drive (800)

Fig.6 40-EVF..NH.. (DN15, DN25) Solenoid drive (800)

Dimension with standard solenoid drive

Connection G Dimension

Installation length A

100-EVF.... B

B`

ØC

D

1/2

(5)

95 95 - - - -

572 572 - - - 722 722 - - - 194 194 - - - 111 111 - - - -

3/4

(7)

1

(10)

1 1/4

(12)

1 1/2

(15)

(20)

Flange DN Dimension 15

(5N)

Installation length A (*)

Flange ANSI Dimension 1/2" 3/4" 1” 11/4” 11/2” 2”

5-EV..NÜ..92/93 B

B`

ØC

10-EV..NÜ..92/93 B

B`

ØC

25-EV..NÜ..92/93 B

B`

ØC

40-EV..NÜ..92/93 B

B`

ØC

5-EVF..NÜ..92/93 B

B`

ØC

10-EVF..NÜ..92/93 B

B`

ØC

25-EVF..NÜ..92/93 B

B`

ØC

40-EVF..NÜ..92/93 B

B`

ØC

40-EVF…NH.Ü…. B

B`

ØC

Flange DN

Flange ANSI

Installation length A

100-EVF…N.. B

(#) VG-chamber PN100

A = Dimension at DIN (resp. flanges ANSI and dimension DIN or flanges and dimens ion at DIN)

(*) = Dimension at ANSI 150lbs (see data sheet on our website armature installation lenght

225 100 026)

B` = Dimension for removing the solenoid drive

Dimension 15

B`

ØC

D

130 150 160 180 200 230

447 447 447 478 478 488

565 565 578 628 628 638

153 153 153 194 194 194

447 447 470 478 478 578 578 620 628 628 153 153 194 194 194 447 447 470 478 478 578 578 620 628 628 153 153 194 194 194 -

470 470 470 511 - 620 620 620 691 - 194 194 194 230 - -

466 466 466 498 498 508

583 583 597 648 648 658

153 153 153 194 194 194

466 466 490 498 498 597 597 640 648 648 153 153 194 194 194 -

466 466 490 498 498 597 597 640 648 648 153 153 194 194 194 490 490 490 531 - 640 640 640 711 - 194 194 194 230 - -

583 583 583 - - 740 740 740 - - 194 194 194 - - -

(5N)

1/2

- - 230(#) - - -

- - 629 - - -

- - 779 - - -

- - 194 - - -

- - 189 - - -

20

(7N)

20

(7N)

3/4

25

(10N)

25

(10N)

1

32

(12N)

32

(12N)

1 1/4

40

(15N)

40

(15N)

1 1/2

50

(20N)

50

(20N)

2

2

_______________________________________________________________________________________________________

220.100.091-05 Page 20 /21 Version: 06/2017

TM 4474

Page 21

Operating and mounting manual (translation)

EV / EVF

12.0 Declaration of Conformity

_______________________________________________________________________________________________________

220.100.091-05 Page 21 /21 Version: 06/2017

TM 4474

Loading...

Loading...