unGer Hydro Power DI12 Series, Hydro Power DI24 Series, Hydro Power DI48 Series Installation & Operating Instructions Manual

Quality Tools for Smart Cleaning

ENGLISHDEUTSCH

NEDERLANDS

DI12x DI24x DI48x

1

DI Ion exchange resin filter

DI Ionentauscher-Harzfilter

DI Ionen-uitwisselaar-harsfilter

Status: 03/2016

INSTALLATION & OPERATING INSTRUCTIONS

MONTAGE & BEDIENUNGSANLEITUNG

INSTALLATION OG DRIFTSVEJLEDNING

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

2

HydroPower DI

Table of contents

Introduction ...................................................................................................... 3

1. Safety regulations ......................................................................................... 4

1.1 General .............................................................................................................. 4

1.2 Intended use ...................................................................................................... 4

1.3 Operating temperatures, pressures and connections .....................................4

1.4 Conversions and modifications to the device ................................................... 4

1.5. Attention (General hazards) ............................................................................. 5

2. Shipping & Packing ....................................................................................... 6

2.1 Receiving inspection of QuickChange resin bags .............................................6

2.2 Receiving inspection of entire unit ...................................................................6

2.3 Claims ............................................................................................................... 6

3. System Overview........................................................................................... 7

4. Installation and start-up ............................................................................... 9

4.1 New Machine Set up ......................................................................................... 9

4.2 Start-up ............................................................................................................. 9

4.3 During operation ............................................................................................. 10

5. EcoFlo - The Water Flow Optimizer ............................................................. 11

6. Resin Change .............................................................................................. 12

6.1 Capacity ........................................................................................................... 13

6.2 Resin Change: QuickChange resin bags (recommended) .............................. 13

6.3 Resin Change: loose resin .............................................................................. 14

7. Technical Data ............................................................................................. 14

7.1 Warnings .........................................................................................................14

7.2 Tips .................................................................................................................. 14

8. Spare Parts ................................................................................................. 15

Quality Tools for Smart Cleaning

ENGLISH

3

HydroPower DI

Introduction

Introduction

When choosing Unger complete desalination as water treatment system,

you have decided in favour of a high-quality product.

Complete desalination is based on the principle of ion exchange.

The minerals responsible for producing hardness and the conductivity (TDS value) are

removed from the water.

The application of this treatment filter has the following advantages:

• A water fed pole and a brush are all that is needed for glass cleaning.

• Prior to system installation and start-up it is essential that you observe

the safety regulations and instructions for installation and maintenance

contained in these instructions.

• The manufacturer is not liable for the function of the device:

• When handling is not in compliance with regular use.

• When used for applications not mentioned in the manual

(use other than intended),

• When failing to comply with safety regulations.

There is a risk of damage to the treatment filter if:

• Operating and installation errors.

• Wrong usage of loose resin (Overfill, expansion of resin)

• Vessel is opened incorrectly

• Replacing spare parts that are not included in the official Unger

spare parts pricelist.

• Performing unauthorised modifications to the design.

• Non-compliance with safety regulations (e.g. anti-freeze protection).

• Use of chemical additives.

• Insufficient maintenance.

All maintenance and repairs are to be performed by a specialist.

Use only original spare parts by Unger (according to spare parts list).

For all inquiries and spare parts orders it is important to provide detailed

information on the device.

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

4

1. Safety regulations

1.1 General

Please observe the applicable rules and regulations, as well as the effective accident

prevention regulations. Unger is not liable for any occurring water damage.

Make sure that the area of application has sufficient water drainage.

Close feed valve in case of prolonged shut-down times (e.g. weekends).

Transportation: Ensure nLite

®

HydroPowerDI tanks and cart models are properly

secured to trailer, van or truck bed.

The window cleaning contractor shall meet all applicable local, state/provincial, federal

licensing and registration requirements. He also shall strictly adhere to all applicable

local, state/provincial and federal labour laws and safety codes and standards.

1.2 Intended use

This device may cause danger if it is improperly installed, not regularly maintained or

not used as intended. Use this device only for water treatment to reach an optimal water

quality for glass cleaning. Any other use, especially water treatment for food production

(e.g. beverages) is considered as non-intended and not allowed.

When operating with a tap waterIine, it must be assured that the connected watertap is

equipped with a rebound valve to prevent water flowing back into drink water line!

When operating with water other than from drinking water system, e.g. from a well, a

water analysis must be performed prior to application to determine if the water is

suitable. Excess impurities in the water may have an adverse effect on system

performance and cleaning result.

1.3 Operating temperatures, pressures and connections

The system must be protected against frost. The temperatures in the service room must

be at least 4°C. The water temperature may not exceed 30°C, and maximum operating

pressure is 8 bar.

Depending on the composition of the raw water, the treated water is more or less

aggressive. Thus, the parts getting in contact with the treated water must be made of

suitable material.

1.4 Conversions and modifications to the device

Due to safety reasons, unauthorised modifications are not allowed. Original parts and

accessories are specifically designed for this device. Any liability by the manufacturer for

damages resulting from modifications to the device or from using parts other than

original parts is excluded.

HydroPower DI

Safety regulations

Quality Tools for Smart Cleaning

ENGLISH

5

HydroPower DI

General hazards

Contents under pressure can cause severe

injury or death from tank rupture.

When starting system:

•Checksystemforcracks.

•Besurecoverisinlockedposition.

•Donotexceedpressureof116psi(8Bar).

•Keepdischargelineopenandholdyellowle-

ver down to remove trapped air from system.

•Foruseonlywithdrinkingwater

Before servicing system:

•Shutoffdrinkingwatersupplyandopen

waterfed pole tubing discharge line.

•Disconnectwatersupplyandallowtank

to drain.

DANGER

!

Spilled resin is a slipping hazard.

Clean up spilled resin immediately.

WARNING

!

Resin can cause skin irritation.

Avoid skin contact.

Wash hands thoroughly after use.

Can cause eye irritation.

Avoid eye contact.

Wear safety goggles.

In case of eye contact, immediately

flush eyes thoroughly with clean

water. Consult doctor if symptoms

persist.

CAUTION

!

STORAGE: Do not store

resin in open or unlabelled

containers. Store in a cool

(15°F to 100°F), dry place.

DISPOSAL: Dispose of in

accordance with

applicable federal, state/

provincial, and local

regulations.

All nLite

®

HydroPower DI

units require the use of

mixed bed ion exchange

resin (commonly referred

to as de-ionizing resin).

This resin will require

replacement and handling.

1.5 Attention (General hazards)

Purified water is delivered to the waterfed pole by flexible hose from the

HydroPowerDI system. This introduces a risk of tripping both to worker and

general public. Identify work area with appropriate signage.

Any surface that becomes wet must be identified with appropriate signage to direct

pedestrians and workers away from work area. During wintertime, it is important to avoid

water pooling, which could freeze, creating a dangerous slip hazard.

General hazards associated with the use of water fed poles and deionization equipment1:

•Triphazardtothegeneralpublicwhenusingtrailinghoses.

•Sliphazardpresentedfromwetpathways.

•Sliphazardforoperatorwhenconcentratingonwork.

•Fallsfromheightwhenworkingonatroofs.

•Electrocutionfrompolescomingintocontactwithoverheadpowersource.

•Injuriestoothersfromfallingpolesorfabricofthebuildingthatmaybedislodged.

•Injurytoothersfromfallingpolescausedbyincorrecthandlingorfailureofpole.

•Injurythroughincorrectmanualhandlingofpolesandotherequipment.

•Spreadoflegionelladiseasethroughpoormaintenanceofsystem.

•Hazardsfromcarryingtanks,systemsandequipmentthatareoverloaded,unstable,

unsecured or incorrectly installed within a vehicle.

1. British Window Cleaning Academy (BWCA): Safety in window cleaning using waterfed pole systems

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

6

2. Shipping & Packing

2.1 Receiving inspection of QuickChange resin bags

Unger QuickChange resin bags are carefully checked and packed prior to dispatch.

However, damages caused by shipment cannot be ruled out.

Check packing for exterior damage while delivering person is still present.

2.2 Receiving inspection of entire unit

• Check device for completeness based on illustration (page 8).

Based on your ordered part number following parts my be optional:

TDS-meter (5), Cart (9), Wheels (10)

• Visual inspection of device for shipping damages.

2.3 Claims

Have delivering person confirm any damages to the packing.

Save packing and shipping carton for possible return.

Reports of shipping damages that have not been confirmed by the transport company cannot

be accepted.

Damage detected only after start-up must be reported to the dealer without undue delay, at

the latest, however, 6 months after purchase.

The dealer‘s invoice is absolutely necessary to confirm the date of purchase.

In addition, the general terms and conditions of Unger apply.

HydroPower DI

Shipping & Packing

Quality Tools for Smart Cleaning

ENGLISH

7

3. System Overview

Pure Water is water in its purest form, physically processed to

remove the minerals that would otherwise lead to limescale spots

and streaks. Such impurities are referred to as TDS (Total Dissolved

Solids) and are measured in ppm (parts per million). The water is

considered 100 % demineralised (pure) when its TDS is measured at

0 ppm, whilst the 180 ppm is considered as average water hardness.

The new HydroPower DI offer you a bundle of great

benefits, delivered through innovative features:

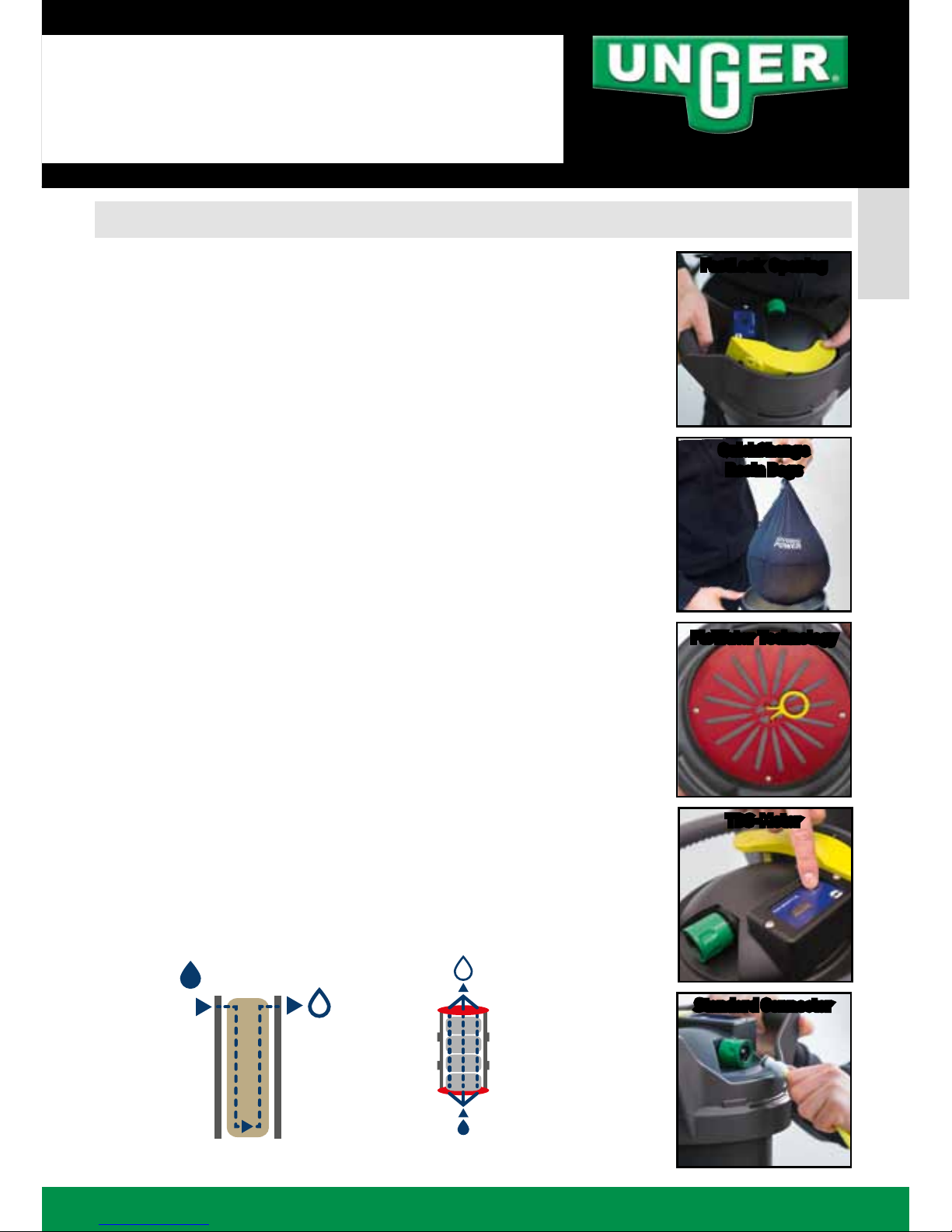

Fast Lock Opening

The new HydroPower DI offers an easy & quick opening of the vessel

with a big yellow lever. This includes a pressure valve, so pressure

can be released easily before opening. In one movement you can

press and turn the lid and open the full diameter of the vessel.

QuickChange Resin Bags

Pre-packed resin bags save time and simplify resin change process

- no more time-consuming, inconvenient filling up of narrow vessels

and no more spilled, wasted resin. Resin change process as simple

as coffee pad change in a coffee machine - simple removed the used

bag and insert a new one! Each bag is made from a waterpermeable material and contains a pre-proportioned amount of

Unger High Capacity Premium Grade Virgin Mixed Bed resin.

FloWater Technology

Innovative flow distribution design means that that you produce

much more pure water from a single resin refill compared to

previous generation of DI filters. Reduced operational cost through

less frequent resin replacement. Less waste, less time spent on

changing resin.

Standard DI Filter

(e.g. UNGER DI400)

NEW

HYDRO POWER Filter

HIGHER EFFICIENCY

HydroPower DI

System Overview

FastLock Opening

QuickChange

Resin Bags

FloWater Technology

TDS-Meter

Standard Connector

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

5

2

3

4

1

2

6

7

9

10

8

4 4

8

HydroPower DI

Installation & Start up

1. Water IN connection

2. Water OUT connection

3. FastLock opening lever

to release pressure off the

vessel and to open the vessel

4. Handles to carry and open

the vessel.

5. TDS-Meter

to check the water quality

6. Vessel

7. QuickChange Resin Bag(s)

8. Water IN valve

(packed to box)

9. Cart (optional)

10. Set of wheels (optional for

non-cart versions)

Quality Tools for Smart Cleaning

ENGLISH

9

4. Installation and start-up

4.1 New Machine Set-Up

• Unpack unit:

Inspect HydroPower DI system and all components. Read warnings and

operating manual.

Inspection & Scope of Delivery: Refer to illustration; perform visual inspection and

take inventory of the following items that should be shipped with the system, then test

system for functionality:

a. TDS Meter functional (powers on/off)

b. Fast Lock lever (yellow) – Depress lever, rotate in clockwise direction and

remove top cap assembly.

c. QuickChange Resin Bag(s) installed in unit.

i. DI120 series – One Bag

ii. DI240 series – Two Bags

iii. DI480 series – Four Bags

d. Trolley, wheels and tank clamp system (optional).

• Water supply connection

• The inflowing water must comply with the applicable local Drinking Water

Ordinance.

• It must be assured that the connected watertap is equipped with a rebound valve

to prevent water flowing back into drink water line.

• Inflowing water temperature max. 30°C

• Temperature on site 4° to 40°C; not in immediate vicinity of heater.

• Do not install in the immediate vicinity of heat sources or in direct sun.

• Depending on the composition of the raw water, the treated water is more or less

aggressive. Thus, the parts getting in contact with the treated water must be

made of suitable material (e.g. glass, plastic or aluminium). Copper and other

non-ferrous metals are not suitable.

4.2 Start-up

1. Locate jobsite drinking water supply.

2. Before window cleaning can begin, the system must be connected to a drinking water

supply (1). If well water system is source, it is recommended water quality analysis be

performed prior to application.

3. Unger recommends testing the onsite water supply for TDS (total dissolved solids) (5)

prior to working. Higher TDS levels reduce the DI system‘s capacity. Conversely, lower

TDS levels will increase the amount of water the system is able to produce.

4. Inspect system – ensure Unger’s QuickChange resin bag(s) (7) are properly

installed, with zip-tie facing up and the sewing in parallel to the vessel ledge.

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

A

B

C

10

HydroPower DI

Start up & Operation

a. NOTE: The performance of HydroPower DI is optimized for the usage with Quick-

Change Resin Bags, but it can also be filled with loose resin.

b. Unger’s pre-measured replacement QuickChange resin bags are designed to allow a

controlled resin expansion within a designed safety limit.

5. Set up system in upright position. Choose a stable onsite location;

best to locate near work area.

6. Connect hoses to system (tap water (1) and waterfed pole tubing (2),

(fig. A).

7. Ensure all waterfed pole on/off valves are in “OPEN” position.

8. Turn on tap water supply slowly.

9. Inspect system as it pressurizes and begins producing pure water.

Keep discharge line open and hold down yellow lever (3) to remove

trapped air from system (fig. B). Use only with drinking water.

10. Turn on TDS meter (5) and inspect pure water quality (fig. C).

For first time use, the TDS meter should read 000.

Stop use when TDS meter reads 010 ppm and change resin.

Adjust flow at waterfed pole brush head by:

a. Tap water valve or

b. Waterfed pole control (on/off) valve.

11. You are ready to start cleaning.

4.3 During operation

1. Periodically inspect the HydroPower DI system during use. Ensure hoses are proper-

ly attached. Inspect system for leaks and proper fit of top cap assembly.

2. Take care when working to ensure there is enough slack in waterfed pole tubing.

This tubing is connected to the top of the unit, and excessive tugging may cause the

system to tip over.

3. Drinking water flows into the system’s lower connection port via tap pressure and

flows upwards through the HydroPower DI vessel. Pure Water exits through the top

connection. When plumbing line pressures fall below 3 bar (44psi),

a reduction in flow rates will be noticeable.

4. Use the included water valve on Water IN valve (8) to regulate the water stream

inside the HydroPower DI.

Quality Tools for Smart Cleaning

ENGLISH

11

HydroPower DI

EcoFlo-Water Flow Optimizer

5. EcoFlo - Water Flow Optimizer

Depending on the pressure of the incoming water supply, using the HydroPower EcoFlo

insert allows you to restrict the water flow to an optimum level of between 120 – 150 L per

hour, which is ideal for regular glass cleaning. Optimising the water flow in this way allows

you to use less pure water, extending the lifetime and performance of a single resin refill in

the HydroPower DI Filters by at least 20%, without compromising the quality of your work.

• Automatically reduces the water flow – see table below for details.

• Fits any industry standard valves.

• Can be fitted, removed or replaced inside the water flow valve in seconds – simple.

• Compatible with all HydroPower DI Filters, regardless of size.

• NOTE: By reducing the flow it will take longer to fill a pure water

vessel / storage tank when using EcoFlo.

To speed up the filling process you should

remove the EcoFlo insert from the valve.

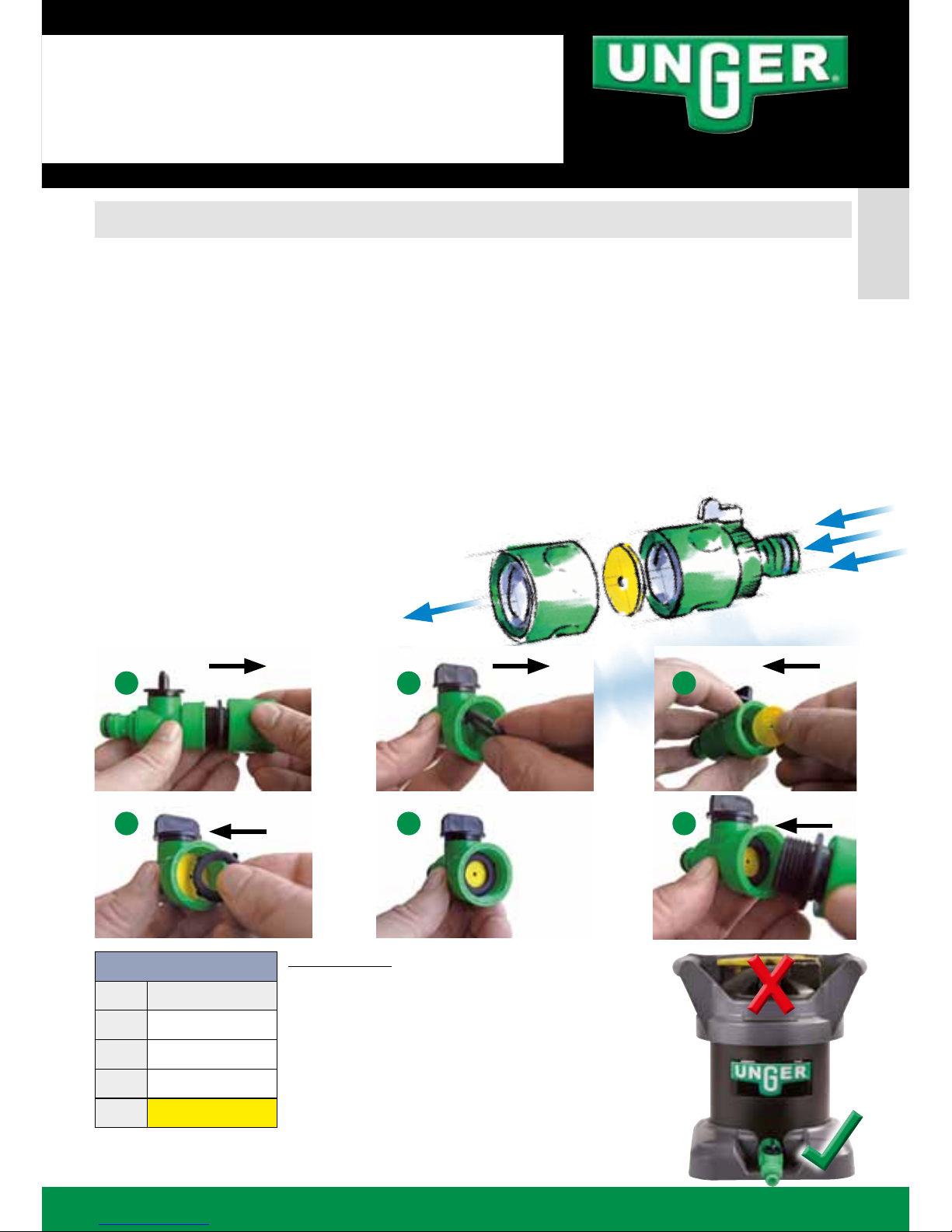

HOW TO FIT THE ECOFLO:

1

2 3

4 5 6

!

O-Ring must

be positioned

AFTER the

EcoFlo!

ATTENTION:

EcoFlo must be inserted into the Incoming

Water Valve (Inlet) only, located at the

bottom of the filter.

Inserting EcoFlo into the Outgoing Water Valve

(Outlet) may result in a build up of pressure inside the

filter vessel, potentially causing damage to the unit.

Do not use the EcoFlo when then pressure of

the incoming water is below 3 Bar.

Order your free EcoFlo:

PRESSURE

Bar

Output* with EcoFlo

6

180 L/hour

5

150 L/hour

4

120 L/hour

3

Do not use EcoFlo!

* Pure Water Output at the brush

with EcoFlo and with Pole

Hose, 25 m

EU: www.ungerglobal.com/ecoflo

UK: www.ungerglobal.com/uk/free-ecoflo

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

D

E

F

F2

G

H

12

HydroPower DI

Resin Change

6. Resin Change

6.1 Capacity

Since the DI resin filter is used at different filling points with various degrees of

hardness, the available quantity of completely desalinated water differs.

The conductivity measurement is used to monitor water quality.

If a conductivity measurement indicates a value of > 10 ppm, the resin is depleted.

The QuickChange resin bag or the loose resin must be replaced.

Raw water quality can be determined in various ways.

a) Information from responsible water works (indication of overall hardness).

b) By measuring the mineral content with Unger TDS-Meter (5).

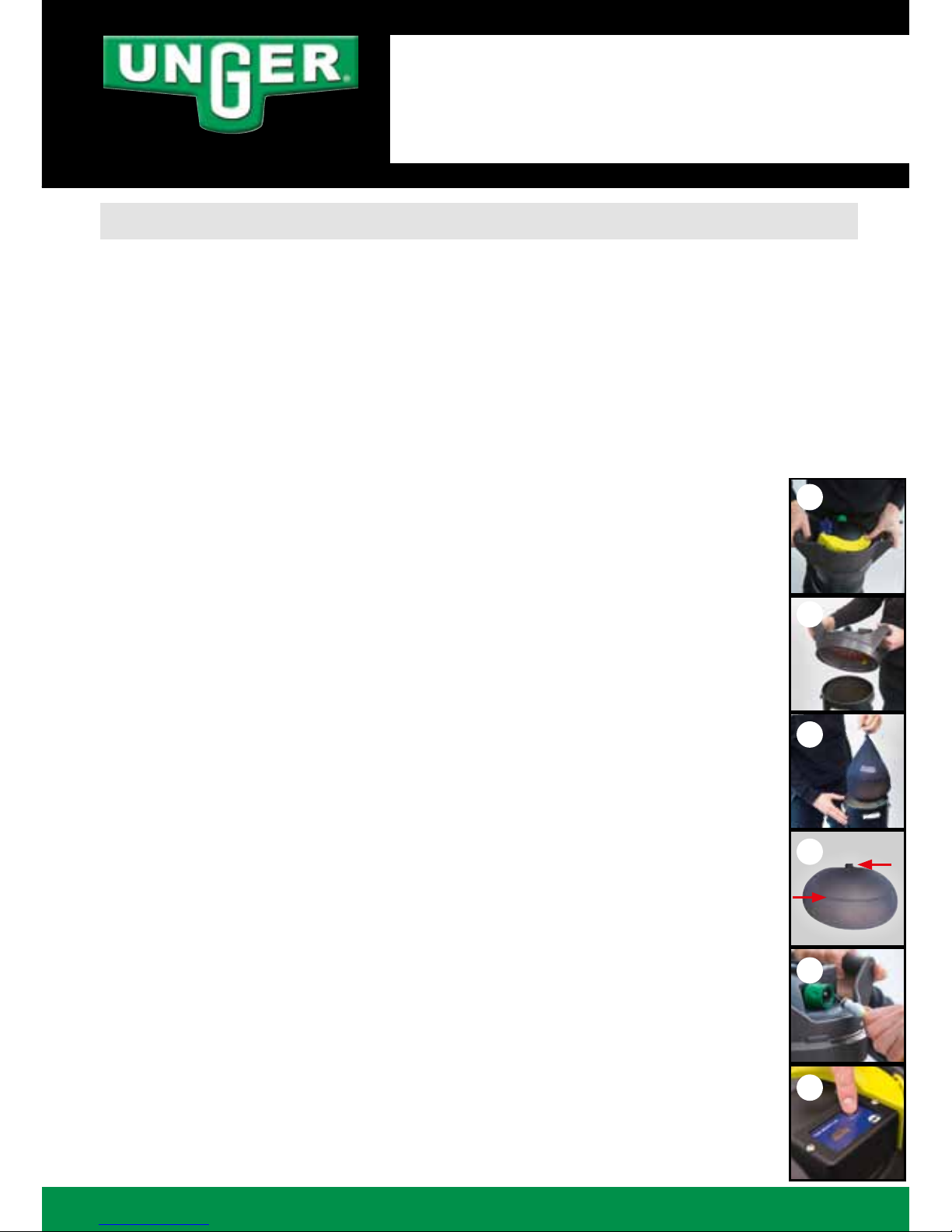

6.2 Resin Change - QuickChange resin bags

Unger’s pre-measured replacement QuickChange resin bags are designed

to allow a controlled resin expansion within a designed safety limit.

1. SHUT OFF TAP WATER SUPPLY VALVE

a. Shut off tap water supply and open pole tubing discharge line.

b. Disconnect feed tap water line and allow system to drain.

2. REMOVE TOP CAP ASSEMBLY:

a. Press yellow FastLock Opening lever (3) (fig. D) to to get pressure

out of the vessel, fix the base unit with your feet, press the top cap

slightly down and use a counter-clockwise 1/8 turn to release top cap

assembly; remove and set aside (fig. E).

b. Open all valves to facilitate the removal of the bags.

c. Reach into housing and remove exhausted resin bag(s) by hand (fig. F);

discard according to local regulations.

3. REPLACE RESIN BAG

a. Install new resin bag(s) by hand (fig. F) – be sure to seat bags with

zip-tie facing up and sewing in parallel to vessel ledge (fig. F2).

Otherwise resin capacity will not completely be used and ppm value is

too high.

b. Inspect system head assembly: O-ring and FloWater distribution

filter are in good condition. Re-coat o-ring with silicone lubricant only.

c. Re-install DI System head assembly, press it slightly, then turn it 1/8

clockwise while fixing the base unit with your feet.

d. System is ready to be operated.

4. RECONNECT WATERFED POLE TUBING (fig. G)

a. Turn “ON“ water supply at tap.

b. Inspect system as it pressurizes.

c. Keep discharge line open and hold down yellow lever (3) to remove

trapped air from system.

5. TEST SYSTEM TDS (fig. H)

Quality Tools for Smart Cleaning

I

J

K

L

M

ENGLISH

13

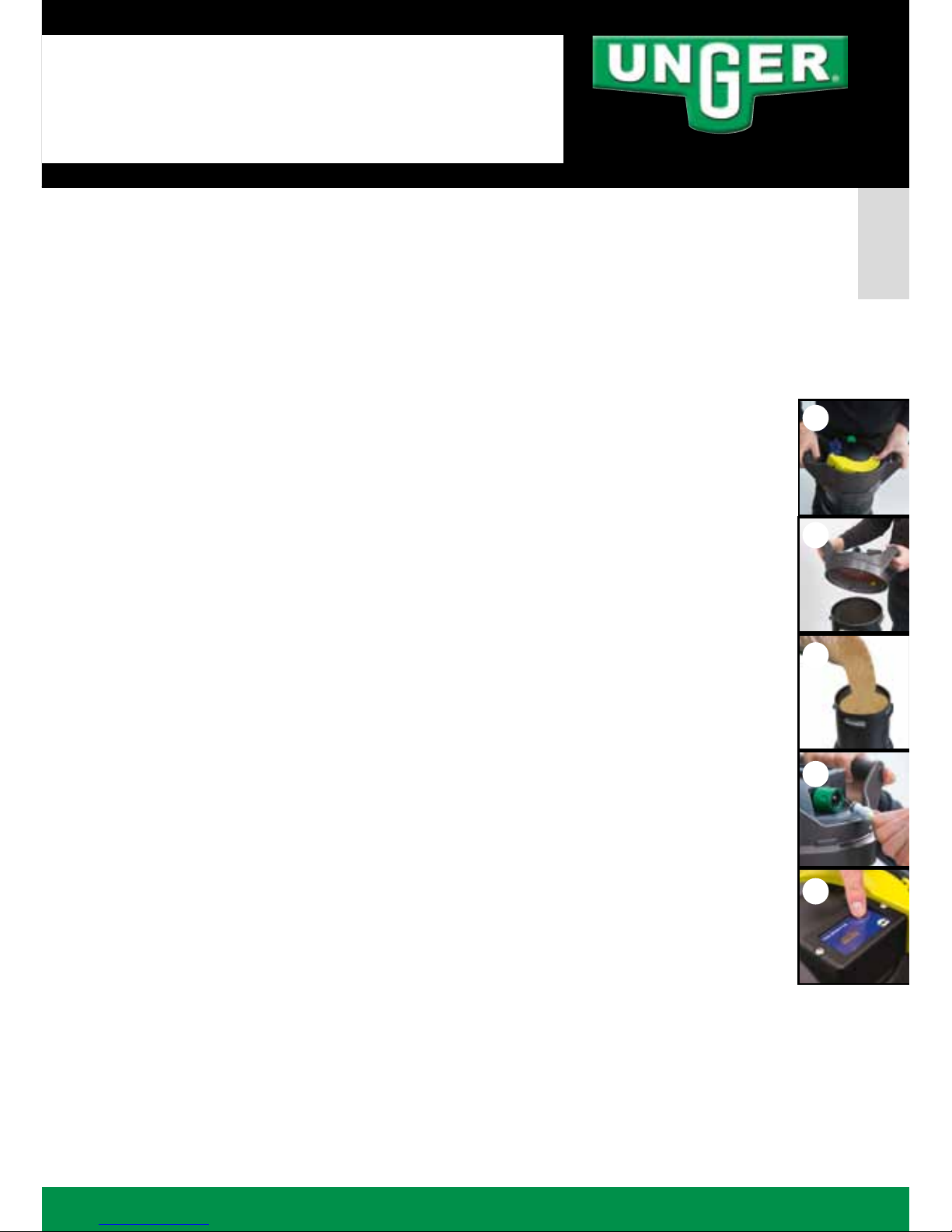

6.3 Resin Change - loose resin

NOTE: Pay attention to not overfill the vessel. Only use new, saturated wet resin. Never use

dry resin as this will expand a lot and can damage the system.

1. SHUT OFF TAP WATER SUPPLY VALVE

a. Shut off tap water supply and open pole tubing discharge line.

b. Disconnect feeding tap water line and allow system to drain.

2. REMOVE TOP CAP ASSEMBLY:

a. Press yellow FastLock Opening lever (3) to get pressure out of the vessel,

(fig. I) fix the base unit with your feet, press the top cap

slightly down and use a counter-clockwise 1/8 turn to release top cap

assembly; remove and set aside (fig. J).

b. Empty the resin out of the vessel by tipping it over or by using a small

shovel; discard according to local regulations.

3. REPLACE RESIN

a. Fill with new resin out of a bag (fig. K). Pay attention to not overfill the vessel.

Only use new, saturated wet resin. Never use dry resin as this will expand

a lot and can damage the system.

b. Only fill with the following quantities into the vessel:

Small system: max. 6,25l wet resin

Medium system: max.12,5l wet resin

Big system: max. 25l wet resin

1 cm from the top of the resin to the ledge of the vessel

must stay unfilled to prevent damage.

c. Inspect system head assembly: O-ring and FloWater distribution

filter are in good condition. Re-coat O-ring with silicone lubricant only.

Pay attention that no resin beads are in the screwing mechanism.

d. Re-install DI System head assembly, press it slightly, then turn it 1/8

clockwise while fixing the base unit with your feet.

e. System is ready to be operated.

4. RECONNECT WATERFED POLE TUBING (fig. L)

a. Turn “ON“ water supply at tap.

b. Inspect system as it pressurizes.

c. Keep discharge line open and hold down yellow lever (3) to remove

trapped air from system.

5. TEST SYSTEM TDS (fig. M)

ATTENTION: Spilled resin is a slipping hazard. Clean up spilled resin immediately.

HydroPower DI

Resin Change

Quality Tools for Smart Cleaning

www.ungerglobal.com/hydropower

14

HydroPower DI

Technical Data

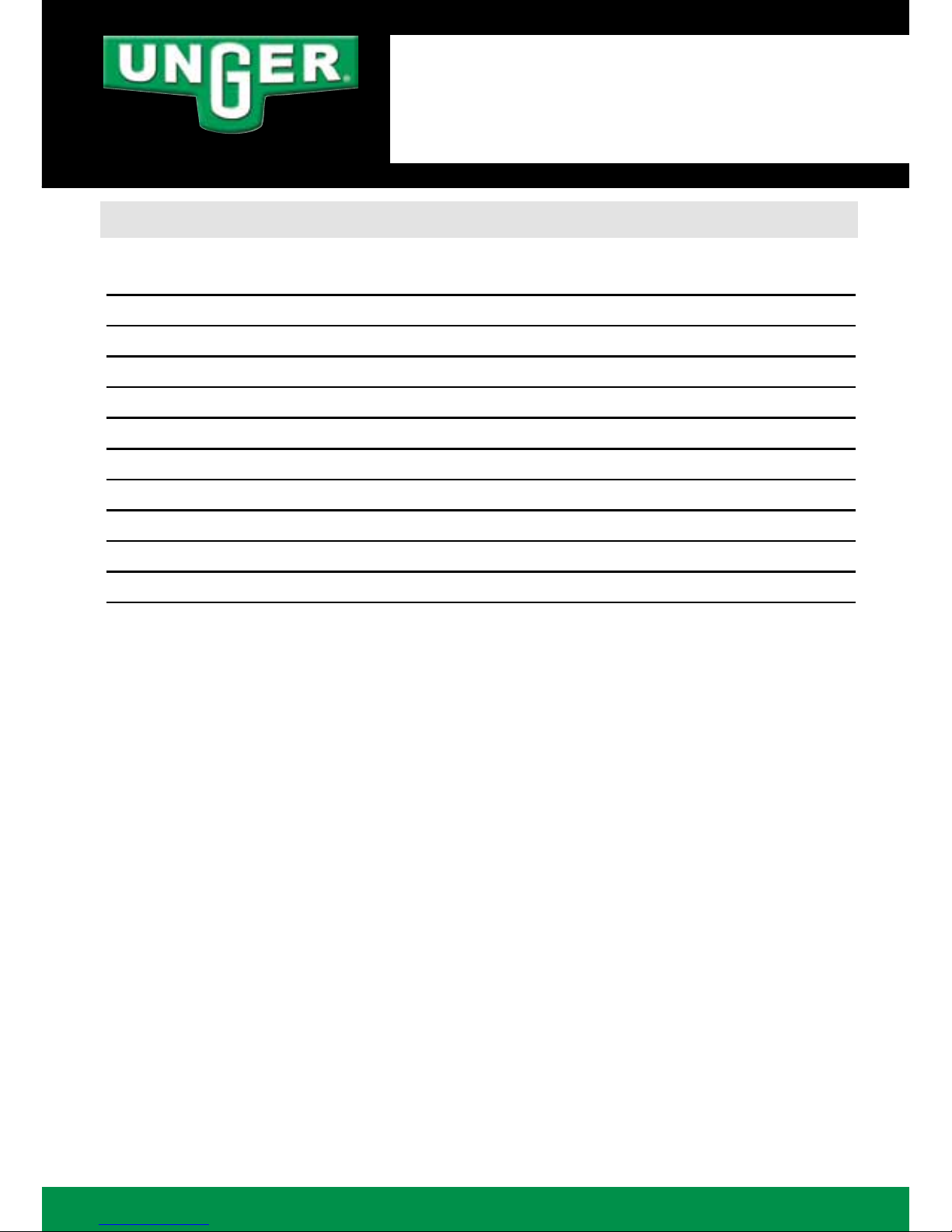

7. Technical Data

* These values are based on the „DIxxT“ variation, including resin bags, TDS-meter, excluding wheels

or cart. For variation „C“ with cart please consider following values:

Size incl. wheels (WxDxH): 55 x 108 x 67 cm. Weight (cart): 12,30 kg.

WARNINGS: Read Before Using!

• Do not drink the water produced by this system. Water produced by the

HydroPower DI system is too pure and will rob the body of vital minerals and nutrients

if imbibed in quantity.

• Prior to opening vessel housings, turn off water and relieve pressure in hose.

Press the yellow FastLock Opening lever on top to get pressure out of the

housings.

• If you use the QuickChange resin bags (recommended), pay attention on correct

position (be sure to seat bags with zip-tie facing up and sewing in parallel to vessel

ledge.

• If you use loose resin, pay attention on correct filling and prevent overfilling.

• After a longer non-usage period, flash the filter thoroughly so that only fresh water is

in.

TIPS:

•

Clean highest windows first. Start at the top of each window and clean using vertical strokes with moderate speed.

•

DI Systems eliminate spotting so when you are finished cleaning, let the surfaces air dry - no need to wipe.

(NOTE: First time cleaning with pure water may necessitate washing windows twice for maximum results.

Factor DI12T DI24T DI48T

Shipping weight incl resin* 11 kg 20 kg 35 kg

Max. recommended power (l/min.) 6 10 20

Height* 35 cm 59 cm 116 cm

Inner Diameter 20 20 20

Dimension of base 28 x 30cm 28 x 30cm 28 x 30cm

QuickChange Resin Bags 1 2 4

Max. fill with loose resin 6,25 l 12,5 l 25 l

Max. permanent pressure (bar) 8 8 8

Max. water temp. (°C) 30 30 30

Min. water temp. (°C) 2 2 2

Loading...

Loading...