Page 1

Table of Contents

Preface

Introduction ........................................................................................................xi

PowerColor ColorSync Separator ........................................................................xi

PowerColor Press Edition ..................................................................................xii

How to Use This Manual ..................................................................................xiii

Typographical Conventions ..............................................................................xiii

Related Documentation ....................................................................................xiii

Chapter 1: Installation

Configuration Requirements ............................................................................1-1

Host Computer ............................................................................................1-1

Scanner ........................................................................................................1-1

Setting Up and Installing PowerColor..............................................................1-2

Installing on an Apple Macintosh..............................................................1-2

Configuring Your Monitor for PowerColor............................................1-2

Installing the PowerColor Software ......................................................1-3

Assigning Memory to PowerColor..........................................................1-5

Installing on a Windows PC........................................................................1-6

Configuring Your Display ......................................................................1-6

Installing the PowerColor Software ......................................................1-6

Table of Contents iii

Page 2

Chapter 2: Getting Acquainted

Overview of the Scanning Process ....................................................................2-2

Launching PowerColor ....................................................................................2-2

Setting Preferences ............................................................................................2-3

Changing Screen Gamma ................................................................................2-6

Making an Overview..........................................................................................2-7

Image Selection Tools ......................................................................................2-8

Creating Regions ..............................................................................................2-9

Images and Memory..................................................................................2-10

Region Names............................................................................................2-11

Working with Regions ....................................................................................2-12

Activating Regions ....................................................................................2-12

Adjusting the Queue Manager Window ....................................................2-13

Manipulating Regions in the Queue Manager ........................................2-14

Saving the Queues ....................................................................................2-14

Previewing Regions....................................................................................2-15

Dynamic Operations in the Queue Manager............................................2-16

Transforming Images................................................................................2-16

Viewing an Image in Detail ......................................................................2-17

Updating Images ............................................................................................2-18

Updating Automatically ............................................................................2-18

Updating Manually....................................................................................2-18

Saving and Recalling Settings........................................................................2-19

iv PowerColor User Guide

Page 3

Chapter 3: Correcting Images with

PowerColor Photo/RGB Mode

Using the RGB Probe ........................................................................................3-2

RGB Probe Window Configurations............................................................3-2

Setting Highlight and Shadow..........................................................................3-4

Using the Gray Eyedropper..........................................................................3-7

Adjusting Tonal Range in Basic Mode ............................................................3-8

Adjusting Tonal Range in Expert Mode..........................................................3-10

Using the RGB Controls ..................................................................................3-12

Adjusting Colors ........................................................................................3-12

Correcting Colors..................................................................................3-13

Manipulating the Histograms ............................................................3-14

Using the ColorSync Profiles ..........................................................................3-15

Storing ColorSync Profiles ..................................................................3-15

Using Profiles ......................................................................................3-16

Table of Contents v

Page 4

Chapter 4: Correcting Images with

PowerColor Press/CMYK:

Production Mode

Understanding the CMYK Probe........................................................................4-1

Probe Location ............................................................................................4-1

Displaying Density Values............................................................................4-2

Displaying Color Plates................................................................................4-2

CMYK Values Before and After Corrections..................................................4-2

Selecting Fixed Reference Points ................................................................4-3

Using Production Color Controls......................................................................4-4

Production Mode Workflow ........................................................................4-4

Setting Highlight and Shadow Points ..............................................................4-6

Setting Dot Limits..............................................................................................4-9

Setting an Image’s Tone..................................................................................4-10

Adjusting Color in Tone Regions ........................................................4-10

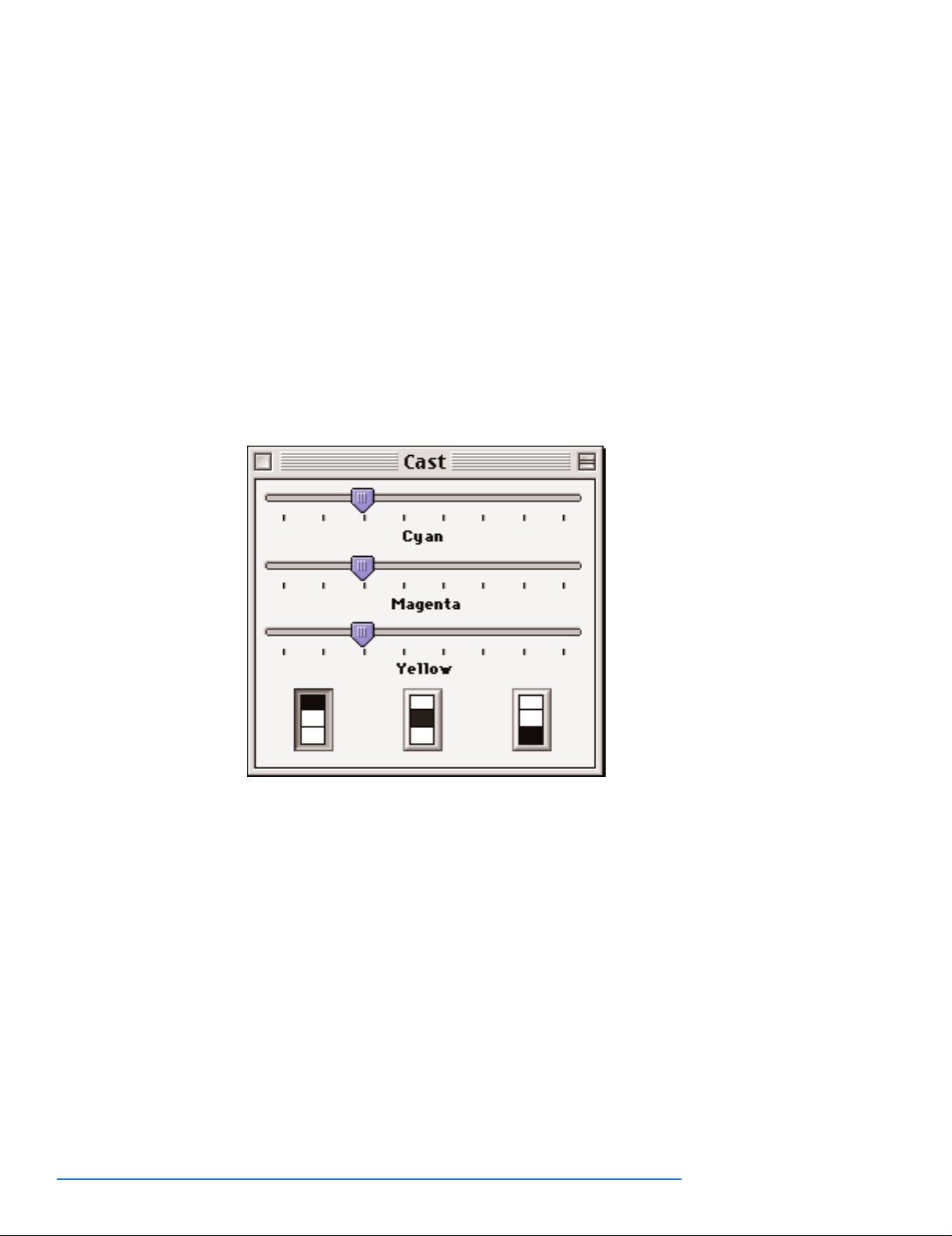

Correcting Color Casts..........................................................................4-10

Setting Multiple Gray Points................................................................4-11

Making Selective Color Corrections................................................................4-12

Selecting Colors to be Corrected ..........................................................4-12

Using the Sliders to Correct Individual Colors....................................4-13

vi PowerColor User Guide

Page 5

Chapter 5: Correcting Images with

PowerColor Press/CMYK:

Expert Mode

Calibrating PowerColor Press ..........................................................................5-1

Understanding Calibration..........................................................................5-1

Preparing the Target for Output..................................................................5-2

Setting Up the Gray Balance ............................................................................5-5

Editing the Gray Balance Table ..................................................................5-6

Controlling Dot Gain ........................................................................................5-7

Setting Dot Gain ..........................................................................................5-7

Using Tone Controls........................................................................................5-10

Removing Color Casts..........................................................................5-10

Tone Curves..........................................................................................5-11

Using the Gray Eyedropper ..................................................................5-12

Setting Highlight and Shadow Points ............................................................5-13

Automatically ......................................................................................5-13

Manually ..............................................................................................5-13

Using Gradation Controls ..............................................................................5-16

Understanding Gradation..........................................................................5-17

Working with Gradation Curves................................................................5-20

Using Negative Slope Detection ................................................................5-21

Working with the Gradation Table............................................................5-22

Determining Black Generation ................................................................5-23

Table of Contents vii

Page 6

Chapter 6: Unsharp Masking

Applying Unsharp Masking ..............................................................................6-1

Controlling USM in Tonal Regions ............................................................6-2

Manually Adjusting the Region Control Bars ......................................6-4

Controlling Edges between Tonal Regions............................................6-4

Using the Unsharp Masking Curve ............................................................6-5

Applying Descreening........................................................................................6-6

Descreening options ....................................................................................6-6

Customizing the Descreening Function......................................................6-7

Chapter 7: Scanning Images to Disk

Reviewing Scan Settings ..................................................................................7-1

Checking Toolbar Parameters ....................................................................7-2

Scan Type................................................................................................7-3

Scan Mode ..............................................................................................7-3

Line Screen ............................................................................................7-4

Sampling ................................................................................................7-4

Using the Resolution Lock Tool ............................................................7-4

File Size ..................................................................................................7-4

Width and Height ..................................................................................7-4

Scale........................................................................................................7-5

Naming Final Scans ....................................................................................7-5

Performing Final Scans ....................................................................................7-6

Scanning Images Individually....................................................................7-6

Batch Scanning All Images ........................................................................7-6

Pausing or Stopping the Scanning Process................................................7-6

Chapter 8: Tips and Tricks

Tips and Tricks ..................................................................................................8-1

viii PowerColor User Guide

Page 7

Preface

Page 8

Page 9

Introduction

PowerColor is a powerful scanning software package for the UMAX Technologies,

Inc. scanner. With its many flexible features, PowerColor enables you to perform

complex color corrections and to make professional RGB or CMYK color separations from your scanned images quickly and easily.

Because it manipulates 16-bits per channel color data directly on the host computer, PowerColor gives you the opportunity to preview changes during the initial

scanning process without additional prescanning. PowerColor also provides

instant CMYK feedback on your image transformations, so you can see the results

of your changes immediately.

For performing CMYK separations, PowerColor offers the ease and automation of

ICC profiles with our ColorSync Separator, as well as high level control with the

PowerColor Conventional Separator.

PowerColor and ColorSync (Macintosh)

The Macintosh version of PowerColor is fully ICC compatible with the use of 16bits per channel input, output, and display profiles. Output profiles can be either

RGB or CMYK, allowing for flexible color matching for a wide variety of output

devices.

Preface xi

Page 10

PowerColor includes the following features:

• Multiple, independent scan regions

• Color, range, and gradation control for individual scan regions

• Image manipulation tools, including rotation, cropping, and unsharp

masking

• Flexibility in setting lpi, dpi, size, and scale for individual scan regions

• Scanning to commonly used file formats

• Use of standard ColorSync ICC profiles (Macintosh only)

PowerColor Press

PowerColor Press is a high-end CMYK separator based on a density-to-dot color

engine. This software is intended for use by those who understand the concepts

behind color separation and reproduction as they relate to offset printing.

PowerColor Press offers sophisticated, advanced features for creating high-end

color separations, including:

• Selective color correction

• Automatic adjustments for wanted and unwanted colors

• Two operation modes for general production and expert work

• Input/output three-color and four-color density range gradation control

• Cast correction with diffused highlight and shadow settings

• UCR/GCR gradation control

• User definable dot gain

• User definable gray balance

xii PowerColor User Guide

Page 11

How to Use This Manual

This manual explains how to install PowerColor and guides you through the

functions of the software. It contains all the information you need to begin using

PowerColor with your scanner. Once you have installed the software, this manual

will help you understand the process and tools for scanning, color correction, and

image manipulation.

Typographical Conventions

The following typographical conventions are used throughout this guide:

Menus and menu options, dialog box selections, on-screen messages, and keyboard keys appear in bold: e.g. Manual Update, Preview, etc.

Note: Notes provide useful information about

the current topic.

Related Documentation

This guide assumes that you are familiar with the Macintosh or Microsoft

Windows interface and operating system. For detailed information on your computer and its interface, refer to your computer’s installation guide. For details on

using your scanner, refer to the Umax Technologies, Inc. Installation and

Operation Manual provided with your scanner.

Preface xiii

Page 12

Page 13

Installation

1

1

Page 14

Page 15

his chapter describes the configuration requirements for PowerColor and

T

guides you through the software installation process for both the Macintosh

and Windows platforms.

Configuration Requirements

Before installing PowerColor, make sure your system meets the minimum configuration requirements indicated below.

Host Computer

In order to take full advantage of the PowerColor software,

your host computer must meet the following minimum requirements:

Macintosh

®

• Macintosh

sor installed

• 24-bit color display adapter

PowerPC 8100 computer or better with floating point coproces-

• 17" or larger high-resolution monitor (1024 x 768 dpi)

• 64 MB RAM available (128 MB recommended)

• System 7.5 or higher

Windows PC

• Pentium class computer running at 266 megahertz or above

• 24-bit color display adapter

• 17” or larger high-resolution monitor (1024 x 768 dpi)

• 32 MB RAM available (64 MB recommended)

• Windows NT 4.x or Windows 95/98

Scanner

PowerColor works with the UMAX Technologies, Inc. series of scanners.

For details on connecting your scanner to your host computer, refer to your

scanner’s user guide.

Chapter 1: Installation 1-1

Page 16

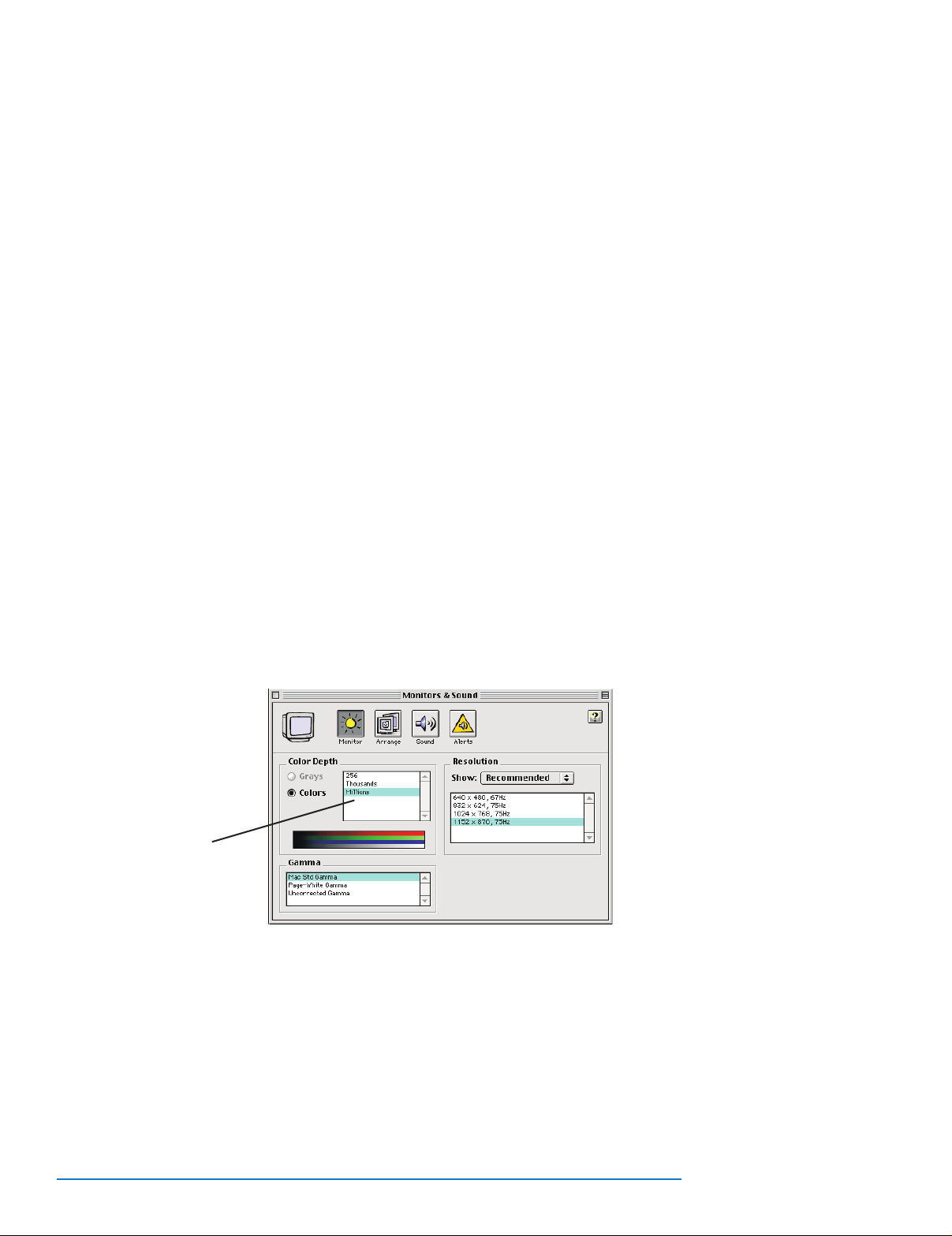

Figure 1–1

Monitors control

panel.

➀

–Millions setting.

Setting Up and Installing PowerColor on

an Apple Macintosh

This section gives instructions for installing PowerColor on an Apple Macintosh

computer. For installation on a computer running Microsoft Windows, turn to

page 1-6.

Configuring Your Monitor for PowerColor

PowerColor Needs to run in 24 or 32 bit color mode. To configure your monitor

for PowerColor, follow the steps below:

1. Open Control Panels in the Apple menu.

2. Open the Monitors control panel and set your monitor to millions of colors

(see Figure 1–1).

➀

1-2 PowerColor User Guide

Page 17

Figure 1–2

PowerColor installer

splash screen

Installing the PowerColor Software

To install the PowerColor software, proceed as follows:

1. Insert the PowerColor CD into your CD-ROM drive and double-click on the

Installer icon.

2. Click on Continue... in the PowerColor installer splash screen.

Chapter 1: Installation 1-3

Page 18

Figure 1–3

Installation destination window

3. Read and adhere to License Agreement. Click the agree button to continue.

4. Click the box next to Standard to install the Application and ColorSync

Profiles. If you choose to install just one component, click on the arrow to

the left of the box for separate component installation options. After selecting your installation options, click the install button to continue.

5. If you want to change the location in which PowerColor will be installed,

follow these steps:

• Click on the Install Location drop down menu.

• Choose Select Folder in the drop down menu.

• In the destination window that appears, select the destination disk and

folder of your choice for PowerColor.

Note: To install PowerColor, you must have at

least 10 megabytes of free hard drive space.

• Highlight the folder where PowerColor will reside and click on Install.

6. Follow the screen prompts to complete installation and exit the installer

Installation of your PowerColor software is now complete.

1-4 PowerColor User Guide

Page 19

Figure 1–4

PowerColor Get Info

dialog box

Note: If you are reinstalling or upgrading from a

previous version of PowerColor, before launching the application, delete all PowerColor

Preferences files (located in the Preferences

folder within the System Folder). PowerColor

will create a new preferences file the first time

you launch it.

Assigning Memory to PowerColor

To increase the amount of memory assigned to PowerColor, proceed as follows:

1. Select the PowerColor application icon in the PowerColor folder and choose

Get Info from the File menu (+I).

2. In the PowerColor Info dialog box that appears, under Memory

Requirements make sure the Preferred size is set to at least 32 MB. If possible, increase the RAM for PowerColor to 64 MB.

3. Close the PowerColor Info dialog box.

Chapter 1: Installation 1-5

Page 20

Setting Up and Installing PowerColor on

an Windows NT and Windows 95/98

This section gives instructions for installing PowerColor on a PC running

Microsoft Windows 95, 98 or Windows NT. For installation on an Apple

Macintosh, turn to page 1-2.

Configuring your display for PowerColor

PowerColor needs to run in 24 or 32 bit color depth. To configure your display

settings for PowerColor, do the following:

1. Right click on a clear area of your Windows desktop. Choose Properties from

the pop-up window that appears.

2. The Windows Display Properties window will appear. Choose the Settings Tab.

3. In the Color Palette section of the Settings window, choose 24 bit or 32 bit color.

Installing PowerColor

To install the PowerColor software, proceed as follows:

1. Insert the PowerColor CD into your drive and double-click on the Setup icon.

2. The PowerColor installer will launch. You will be asked to specify the location

3. After you have selected the install location, click OK to have the software

1-6 PowerColor User Guide

in which PowerColor should be installed. Use the standard Windows dialog

box to specify a location, or use the default location of:

c:\Program Files\PowerColor

installed to the specified directory.

Page 21

Getting Acquainted

2

2

Page 22

Page 23

owerColor provides a powerful and flexible software interface between your

P

Computer and UMAX Technologies, Inc. scanner. The software offers a wide

array of professional scanning and image manipulation tools with all the convenience and user friendliness of the standard Macintosh or Microsoft Windows

interface, including drop-down menus, multiple windows, point-and-click controls, and keyboard shortcuts.

This chapter covers the following topics:

• Overview of the scanning process

• Launching PowerColor

• Setting Preferences

• Changing Screen Gamma

• Making an Overview

• Image Selection Tools

• Creating Regions

• Working with Regions

• Updating Images

• Saving and Recalling Settings

For details on correcting scanned images, see Chapters 3–6. How to use the

Queue Manager and scan images to disk is discussed in Chapter 7.

Chapter 2: Getting Acquainted 2-1

Page 24

Overview of the Scanning Process

Preparing scans with PowerColor is a simple process with many tools for an efficient and organized workflow. Summarized below are the basic steps in the

PowerColor process:

1. Generate an overview scan of the entire scanning bed:

2. Define regions as desired and add them to the Queue Manager.

3. Select an image from the Queue Manager and perform the desired image

corrections while verifying the results visually and numerically on-screen.

4. Scan the final images to disk using the desired output and file formats.

Launching PowerColor

To launch the application, double-click on the PowerColor icon in the

PowerColor folder, or, if using Windows, click on your Windows Start menu, then

choose PowerColor from withn the UMAX program group. When the application

opens, the menu bar, blank Overview window, Queue Manager, Control Bar and

Toolbar are displayed (see Figure 2–1). These are the tools with which you can

access all of PowerColor’s commands and functions.

Figure 2–1

PowerColor menus:

Toolbar, Control Bar

and Queue Manager

2-2 PowerColor User Guide

Page 25

Figure 2–2a

Preferences window,

General components

Setting Preferences

Before you begin scanning, check PowerColor’s preferences to be sure the options

you need will be available.

Preferences are set in the Preferences window (see Figure 2–2). To open this

window, select Preferences from the Edit menu.

The components of the Preferences, General window, are defined as follows:

• Application: The static fields in this section describe the software revision

number and type of encryption (if any). This area is also used to toggle

between the ColorSync and PowerColor Press by selecting the desired radio

button.

• PowerColor Photo : This section allows you to set the mode of operation as

well as the type of information to be displayed in the expert tone graph.

• PowerColor Press: This section allows you to set the type of separation tools

to be used with PowerColor Press. Production mode provides an “all-in-one”

color correction window suitable for most general scanning work. In Expert

mode, all of PowerColor’s sophisticated image correction features are available separately.

• Default Save Directory: Allows navigation to volumes mounted on

workstation or available network or servers.

• Prompt Before Adding to Queue: toggles a prompt before file names are

added to the queue for final scan.

Chapter 2: Getting Acquainted 2-3

Page 26

Figure 2–2b

Preferences window,

Other components

• Periodically Save Queue: allows you to designate whether PowerColor will

automatically save the current queue at the interval specified in the Saving

Interval Field.

The components of the Other tab in the Preferences Window are defined as follows:

• Overview: This section controls how images are viewed on screen during the

scanning and color correction process. The Resolution setting defines the

desired resolution of the overview scan. The default value is 50 dpi. Higher

resolutions provide greater detail in the image window, but also require considerably more RAM (as reflected in the non-editable Buffer Size field). If

you have over 64 MB of RAM available for PowerColor, setting the resolution to 75 or 100 increases the default resolution in the region windows,

which may save you from having to perform a preview scan for each region.

The Preview Size setting defines the dimensions of the image window. The

default size is 512 pixels.

• Units: sets the units of measure for the entire application. The default setting

is Inches.

• Probe Size: sets the size of the area sampled by the probe. 1x1 samples a sin-

gle pixel; 3x3 samples the eight pixels surrounding the cursor location; 5x5

samples the 24 pixels surrounding the cursor location.

2-4 PowerColor User Guide

Page 27

Interpolation: PowerColor provides the following interpolation modes:

– Bi-Cubic: weighted average of a region of pixels around the target pixel

(default mode). This type of interpolation provides high quality for continuous tone images when scaled to a resolution higher than that of the

scanner.

– Bi-linear: weighted average of adjacent pixels. This setting provides high

quality with better performance than Bi-Cubic, but may cause unwanted patterns in some images.

– Nearest neighbor: interpolation by pixel replication (should only be

used for line art).

– Maximum Optical Resolution: This feature allows PowerColor to set a

maximum optical scanning resolution for certain film types. Any resolution above this value will be interpolated. This is very helpful when

scanning noisy or grainy originals that need to be enlarged beyond the

quality of the original.

Note: The preferences you select, as well as all

window positions and contents, are saved by

PowerColor when the application is closed. The

next time you launch PowerColor, they will be

restored.

Note: Changes made in the preference window

do not require the PowerColor application to be

restarted to take effect.

Chapter 2: Getting Acquainted 2-5

Page 28

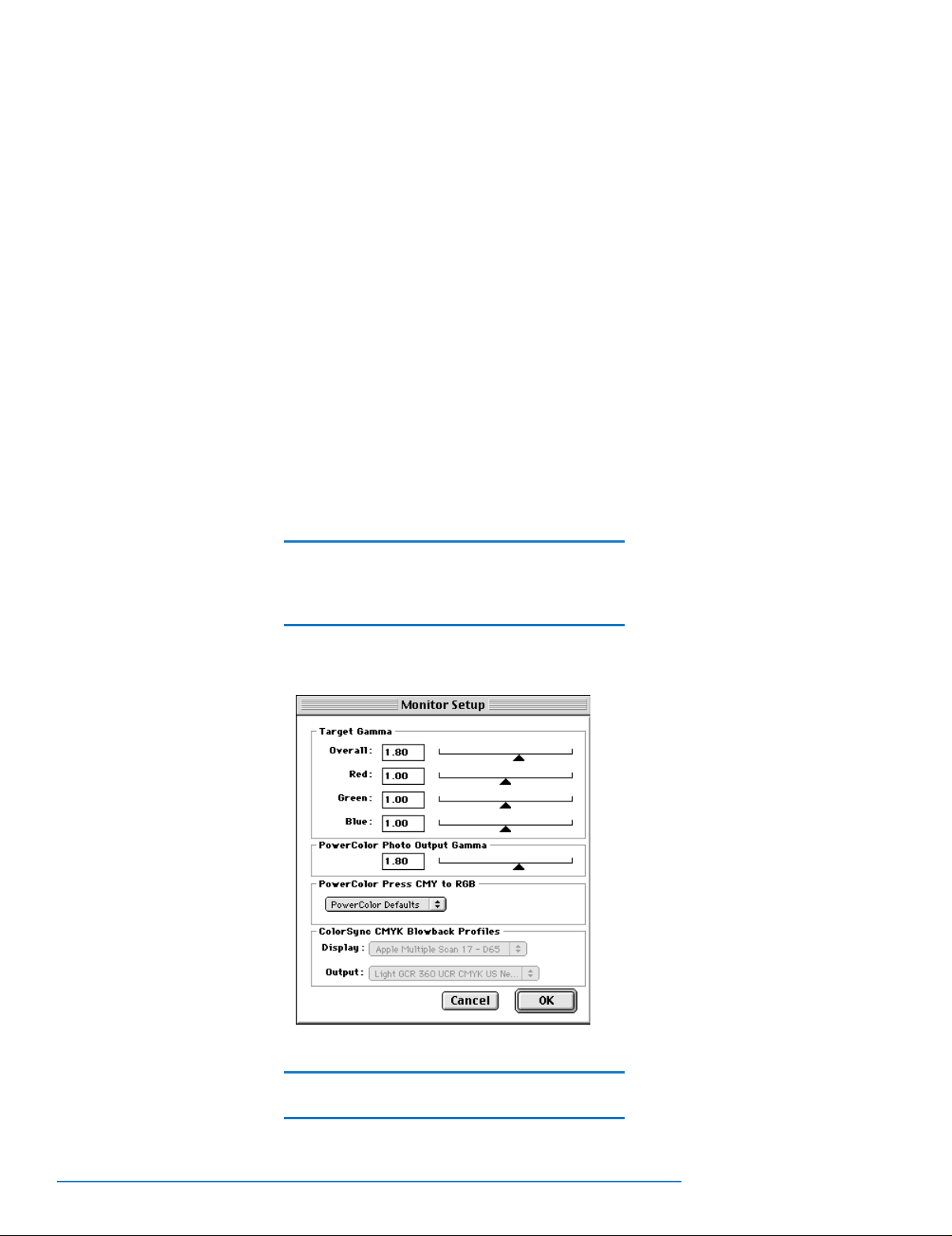

Changing Screen Gamma

PowerColor’s Monitor Setup option in the Edit menu (see Figure 2–3) allows you

to specify the gamma values of your monitor, as well as the CMY-to-RGB tables

used by PowerColor Press to display the “blowback” of your CMYK output.

By default, PowerColor assumes a monitor gamma value of 1.8. If you have

changed your monitor’s gamma, enter the new gamma value in the Monitor

Setup window. PowerColor then adjusts its previews to look the same regardless of

any monitor gamma

(in the range of 0.2 to 5.0)

Note: PowerColor does not adjust the gamma

value of your monitor. It merely adjusts its previews to look the same regardless of different

gamma settings.

You can choose between the PowerColor default blowback tables, or you can

Figure 2–3

Monitor Setup

window

select ColorSync and load your own monitor and output CMYK profile.

Note: PowerColor only uses ICC tables for the

monitor preview in Separator Mode.

2-6 PowerColor User Guide

Page 29

Making an Overview

Before working with images, the contents of the scanning surface must be

scanned into the Overview window. To do so, proceed as follows:

1. Mount the original(s) on your scanner.

2. Select the Scan Type in the toolbar as follows:

• Transmissive: color or black-and-white transparencies.

• Transmissive Negative: negative transparencies.

• Reflective: color or black-and-white photographs or prints.

3. Click on the Preview button ( ) in the toolbar or the Preview button

( ) below the blank first image in the Queue Manager.

Your scanner now produces a low-resolution overview scan of the entire

scanning surface.

Note: To stop an overview scan once the desired

portion of the scanning surface has been

scanned: on a Macintosh press + . (period), if

using Windows, hit the Escape (ESC) key.

Note: If you are scanning all the images in the

Queue Manager using the same line screen,

sampling, and scale values, set up the Overview

with the desired values. All images subsequently added to the queue will reflect those changes.

Chapter 2: Getting Acquainted 2-7

Page 30

Image Selection Tools

Once you have produced an Overview, PowerColor’s image selection tools, located in the

Control Bar, allows you to define and work with regions for detailed color correction

work. This section describes how to use these tools.

Note: For Macintosh users, enabling the Macintosh

Balloon Help will cause the name and function of

each button to be displayed as the cursor passes

over it.

Image Selection Tools

Probe Region: The Probe (or Pointer) tool is used to select items and to move around the

image to sample pixels. The tool deselects the Crop and Zoom tools.

Zoom: Click on the image with the Zoom tool to enlarge the image for more precise examination of a region. If necessary, resize the image window to accommodate the new view. The magnification is shown at the bottom left-hand corner of the image window. To reduce the view again, hold

down the Option key (Macintosh) or Control key (Windows) while clicking on the image with the

Zoom tool. Note: The point where the Zoom tool is clicked becomes the new center of the image in

the window.

Crop Region: Use the Crop tool to select a portion of the image, for example to cut out the

clack edges of a film frame or tape used to hold images on the scanning surface.

Auto Range: Automatically adjusts the tonal range, setting the highlight and shadow points.

Pick Neutral Point: Uniquely selects multiple gray points in an image by holding down the

Option key (Macintosh) or Control key (Windows) and clicking on quarter, mid, and three quarter

tone values.

Highlight Value Shadow Value: Automatic values for each image highlight and

shadow range are made with both buttons selected (default setting). Deselecting either button will

result in a new auto range without the deselected value. Edit/Undo, from Main Menu reverts to last

values.

Refresh: With automatic updating off, click on the Refresh key to update the active region

with all changes since the last update

2-8 PowerColor User Guide

.

Page 31

Figure 2–4

Region Window

Regions

The purpose of the region window is to define areas from the overview that will

be scanned to image files, and to correct them in higher resolution than the

overview. Each region window has the following components:

• History : Each region can be cropped, rotated, and color corrected indepen-

dently of all other regions. Each region also carries its own history list of all

actions taken by the user on that region. You can scroll the history list by

selecting the “H” icon at the bottom of the region window (Macintosh version) or on the Toolbar (Windows version). This list can be used to undo

and redo to any point in the history.

• Duplicate: At any time during the correction process the active region can be

duplicated for side by side comparison. This duplicate view is static except

for its history list, which can be used to compare views at any correction

step.

Chapter 2: Getting Acquainted 2-9

Page 32

Creating Regions

There are two ways to create regions: from the cropped overview, or by opening a

TIFF file from disk.

1. Creating a region from a TIFF file

To create a region from a TIFF file on your hard drive, choose Open from the file

menu and choose the desired TIFF file. The file will open into a new region window.

2. Creating a region from the Overview

Once you have cropped the desired portion in the Overview, double click the

selected area to assign it to a region. You can also click on the Add Region button ( ) from the Queue Manager.

Images and Memory

The amount of memory (RAM) required for a region varies depending on the

Overview resolution (selected in the Preferences window) and the size of the

region. You can create as many regions as the amount of RAM assigned to the

PowerColor application allows. (The minimum and default application RAM is

32 MB, 64 MB of RAM is recommended.) If you exceed the amount of memory

allocated to the application, the following warning dialog appears:

Figure 2–4

Out of Memory

warning

If this dialog box appears, you can:

1. Quit the application and assign more RAM to PowerColor, (Macintosh only)

2. Final scan the regions you have already created, and/or

3. Delete unneeded regions. For more information on final scanning or deleting

regions, see Chapter 7.

2-10 PowerColor User Guide

Page 33

Note: Macintosh users: To check the current

memory setting for PowerColor on a Macintosh,

Select About this Macintosh in the Apple menu.

Region Names

PowerColor names regions by default according to the order

in which they are created. The default name assigned to

a region is based on the following scheme:

Region-X : scan####

where

X = the region number in the order of its placement in the

Queue Manager.

#### = an arbitrary sequential number.

Your regions may represent separate originals for different jobs, or different areas

from within the same piece of art. When you prepare your final scans, it is helpful to follow a naming convention for your regions that makes sense in your

production environment (for example, by job, client, date, etc.). To change the

name of a selected region, press +S or select Save from the File menu.

Note: For more information about naming

regions, see

Naming Final Scans

Chapter 2: Getting Acquainted 2-11

in Chapter 7.

Page 34

Working with Regions

Regions created using the Add Region button are placed into PowerColor’s Queue

Manager. The Queue Manager. is a highly flexible tool designed to organize your

work with regions. Use the Queue Manager. to:

• Activate a region

• Preview regions

• Rearrange the order of the regions

• Scan regions to disk

• Add a region

• Delete a region or all regions

• View the progress of a scan

• Switch between detail view and full preview

This section explains how to manipulate regions using the Queue Manager.

Scanning to disk is discussed in Chapter 7.

Activating Regions

To activate a region, double-click on its image in the Queue Manager. The

selected region is then framed in red, the region number is displayed in the

Region field, and the image data is shown in the appropriate fields in the toolbar.

A 1:1 view of the image is displayed in the image window. Color correction work

can now be performed on the image.

2-12 PowerColor User Guide

Note: Before making color corrections, make

sure the region you want to work on is active.

Page 35

Adjusting the Queue Manager Window

The Queue Manager window can be manipulated using standard Macintosh or

Windows tools:

• To close the window, click on the close box in the upper left-hand corner (to

reopen it, select Queue Manager from the Window menu. or press +M on

a Macintosh, or Control+M on a Windows PC).

• To expand the window to its full size, click on the window resize box.

• To resize the Queue Manager window to a custom size, click and drag the

resize button in the bottom right-hand corner. on a Mac, or click and drag

any corner on a Windows PC.

• To scroll through the images in the Queue Manager, use the standard scroll

bar at the bottom of the window.

• To move the Queue Manager window to another location on screen, click

and drag the title bar.

Chapter 2: Getting Acquainted 2-13

Page 36

Manipulating Regions in the Queue Manager

The regions in the Queue Manager can be rearranged or deleted any time, even

while scanning is in progress.

To rearrange the order of the regions in the Queue Manager, click and drag the

region to the desired location in the queue.

Note: The Overview can not be moved in this

manner.

To delete a region, use one of the following tools:

Cut: To delete a single region from the queue, activate the region by

double-clicking on it (a red frame appears around it) and click on the

black Cut button in the Queue Manager to delete the region.

Cut All: To delete all regions from the queue, click on the red Cut All

button in the Queue Manager

Saving the Queue

To save the contents of the current queue manager choose Save Queue from the

file menu. In the dialog box that appears assign a name for the queue, then

click OK to have it saved to disk. This option is useful for preserving your work in

the event of a crash, or for production environments in which drums need to be

set up for later scanning.

2-14 PowerColor User Guide

Page 37

Previewing Regions

Before manipulating and correcting regions, the image should generally be

previewed.

Note: Although previewing an image is not

absolutely necessary, it improves the accuracy of

the Probe values and provides a higher resolution

image for image correction work. Without a preview scan your Probe values may not be accurate

due to the dithering of the low resolution image.

Preview: To preview a single region, click on the Preview button ( )

under the desired image in the Queue Manager. During scanning the

region’s Preview button appears red, green, and blue. Once the preview

is complete, the button turns all red.

Preview All: PowerColor’s Preview All button allows you to batch

preview all the regions in the Queue Manager with a single click. This can

be done even if there are different types of originals in the scanning area

(reflective, positive transparencies, or negative transparencies).

Once you have defined and added multiple regions with the PowerColor

tools, click on the Preview All button. The scanner then scans each region

in succession.

To preview only certain regions in the Queue Manager, click on the

white Preview button under each desired image. The regions are then

scanned in order.

Chapter 2: Getting Acquainted 2-15

Page 38

Dynamic Operations in the Queue Manager

The Queue Manager is a multitasking tool. While a region

is being previewed or final scanned, other regions can be added, deleted, or

rearranged in the Queue Manager. Color correction work can also be performed

on a region in the queue, whether or not scanning is in progress.

The queue may also be interrupted during scanning using the Active/Pause icon

on the right-hand side under the Overview in the Queue Manager. Clicking on

this icon toggles the scanning process on ( ) or off ( ).

Transforming Images

To make your work with regions easier, PowerColor also includes the tools shown

below to transform images. The tools can also be selected from the Transform

menu.

Note: The image transformation tools can only

be used in a region, not in the Overview.

Rotate Left: rotates the image in a region 90° counterclockwise.

2-16 PowerColor User Guide

Rotate Right: rotates the image in a region 90° clockwise.

Flip Horizontally: flips the image horizontally, along the vertical axis.

Flip Vertically: flips the image vertically, along the horizontal axis.

Page 39

Viewing an Image in Detail

PowerColor’s Detail feature is used to scan a small area of a region at the final

scan output resolution. This feature is helpful for examining an image in precise

detail.

To use the Detail feature, proceed as follows:

1. Activate the region in which you want to perform

a detail scan by double-clicking on it in the Queue Manager.

2. Select Detail in the Region menu or click on the Pick Detail Point button

( ) in the Control bar. The cursor becomes a cross-hair.

3. Click on the center of the desired area of the image to

be viewed in detail.

The scanner now performs a detail scan of predefined dimensions around

the point you selected using the scanning parameters indicated in the fields

in the toolbar (size, scale, line screen, etc.).

Once the detail scan is complete, you can switch between the detail view (as indicated in the title bar of the image window) and normal preview by toggling the

Detail checkbox in the Queue Manager.

Note: The purpose of the detail scan is to view

a small area of interest at the final output resolution. Before performing a detail scan remember to setup the output parameters for the

image in the geometry window.

Chapter 2: Getting Acquainted 2-17

Page 40

Updating Images

Whenever you make changes in a prescanned image or scanning parameters, the

image can be updated in the Region window so you can visually gauge the effect

of the changes. Image updating is performed in two ways: automatically and

manually.

Updating Automatically

If you want the image window to be updated automatically, choose Auto Update

On from the Preferences menu. The image is then updated every time you make

a change. To turn off automatic updating, choose Auto Update Off.

Automatic updating is helpful in visually tracking changes incrementally.

However, it can add production time due to the time needed to refresh the screen

image after every adjustment.

Updating Manually

With automatic updating off, click on the Manual Update button ( ) in the

toolbar (or in any window where it appears) to update the active region with all

changes since the last update. You can also use the keyboard shortcut +K..

When the update is completed, the Command field at the top of the toolbar indicates Updating… Done.

The manual update feature is particularly useful if you are a more experienced

scanner operator and only need to check the image window from time to time.

2-18 PowerColor User Guide

Note: If you are using the manual update feature, the image window’s display is updated

only when you click on the Manual Update button.

Page 41

Figure 2–5

Settings menu.

Saving and Recalling Settings

During your color correction work, you may decide to save the changes you have

made for future applications. You may also wish to use other predefined settings,

or even start over. PowerColor gives you the option of saving and recalling default

or previously saved settings for one or all of the parameters you have changed, or

resetting the parameters to those in the original prescan.

To use this feature, select one of the options in the Settings menu,

Save: This option allows you to save custom correction settings. After

adjusting the settings you want to save, click on the Save button or

select Save in the Settings menu. In the dialog window that appears

(see Figure 2–6) check off the settings you want to save.

In the standard file dialog that appears next, name the settings file and

choose where it will be stored. The settings can now be recalled any

time using the Recall feature (see below).

Note: Only the settings you check off are saved.

Chapter 2: Getting Acquainted 2-19

Page 42

Figure 2–6

Settings window

Recall: This option recalls a previously saved settings file. PowerColor

comes with a number of preset files for your convenience, or you may

recall a settings file you created. After you select Recall, a standard file

dialog appears for you to select the settings file to be recalled.

Save Default: Use this option to store your own custom default settings.

Note: The Save Default option overwrites

PowerColor’s default settings. Once

PowerColor’s defaults have been overwritten,

they cannot be recalled. If you use certain settings regularly, save those settings in a separate

file and recall them as needed. See Save and

Recall above for more information about these

options.

2-20 PowerColor User Guide

When you select Save Default, a dialog window similar to the one

shown in Figure 2–6 appears where you can check off the settings to be

saved as defaults.

Note: Only the settings you check off are saved

as defaults.

Page 43

Recall Default: This option brings up a dialog window similar to the

one shown in Figure 2–6 where you can select the specific default settings to be recalled by clicking on the appropriate checkboxes. Click on

OK to recall the settings.

Linearize: This option will reset tone and gradation curves to linear

values. For other settings it will remove any correction made to the

tool. For example, gray balance would become equal percentages for

all inks.

Reset to Factory Defaults: This option will reload the original defaults

that may have been saved over at some time.

Note: In some cases, PowerColor grays out settings in the Recall Default and Reset dialog windows. The grayed out items are values which

have not been saved.

Chapter 2: Getting Acquainted 2-21

Page 44

Page 45

3

3

Correcting Images with

PowerColor Photo/RGB Mode

Page 46

Page 47

owerColor offers many powerful features that allow you to correct your pres-

P

canned images before the final scan is made. For those who prefer to work in

RGB color space, PowerColor provides fast and efficient tools to make image corrections.

This chapter explains how to use the RGB tools and covers the following topics:

• Using the RGB Probe

• Using the RGB Controls in Basic Mode

• Using the RGB Controls in Expert Mode

The Photo mode is selected in the Preferences window (see Setting Preferences in

Chapter 2 for more information).

For information on working in the CMYK color space with PowerColor, refer to

Chapters 4 and 5. For details on using PowerColor’s descreening and unsharp

masking features , see Chapter 6.

Chapter 3: Correcting Images in the RGB Color Space 3-1

Page 48

Using the RGB Probe

The most important tool in correcting images is the Probe. This window tracks

your corrections by displaying the RGB values. To view the RGB Probe, select

Probe in the Window drop down menu (Or press +P on a Macintosh,

Control+P if using Windows). As you pass your cursor over the Overview or a

region window, the Probe shows the values for the pixel(s) at the current cursor

position.

The RGB Probe window is a static display. Its appearance depends on the Scan

Mode you select in the Control Bar (see next section). However, the Probe always

shows the X/Y coordinates of the current cursor position (Probe Location) and

the original and output optical density values (Densities) for the selected pixel(s).

RGB Probe Window Configurations

When scanning in RGB mode, the RGB Probe displays the RGB reflectance values

(RGB Pixel Values) for the selected pixel(s) (see Figure 3–1).

Figure 3–1

RGB Probe in RGB

mode

3-2 PowerColor User Guide

Page 49

Figure 3–2

RGB Probe in Gray

mode

If the image is in a grayscale scan mode (one of the Gray options), the RGB

Probe shows the reflectance value (Pixel) and dot percentage (Dot) for the selected pixel both before and after correction (see Figure 3–2).

When scanning line art (the Scan Mode is set to one of the Line options), the

Line Art Pixel Value field in the RGB Probe shows whether the selected pixel is

black (0) or white (1) both before and after correction (see Figure 3–3).

Figure 3–3

RGB Probe in Line

mode

Note: When probing images in line art or grayscale mode, set the Probe Size in the Preferences window to 1x1 to avoid false readings.

Chapter 3: Correcting Images in the RGB Color Space 3-3

Page 50

Setting Highlight and Shadow

The most important aspect of setting up a scan is defining where to place the

highlight and shadow point. PowerColor has an automatic as well as a manual

means for accomplishing this task.

Note: There are two types of highlights:

“Specular” highlights are areas that contain no

color, while “diffused” highlights contain a minimum amount of color. All densities less than

the diffused highlight slope to white at a 45º

angle. When setting Highlight and Shadow

points, PowerColor uses the values within the

Diffused Highlight and Shadow area of the Tone

and Cast window.

Setting the Input Range automatically with Auto Range

In the Control bar you will find the Auto Range Icon. By selecting this tool, an

Auto Range will be performed on the active region. The Highlight and Shadow

point will be set to the RGB values shown in the Diffused Highlight and Shadow

fields at the bottom of the Tone and Cast Window. Also, these points will be

marked in your image by sticky densitometers.

How Auto Range determines Highlight and Shadow points

After the software has evaluated the image data it will make a series of decisions

as to where it will set the Highlight and Shadow point.

• Auto Range looks only at the densities of the image data that falls within the

current Region Crop. This is important to know because if you leave film

edge or an area beyond the image edge in your crop, the software will

include that data in its decision.

• The Highlight and Shadow points will not be set at the extreme minimum

and maximum, but at a percentage inside of the min and max. The reason

for this is to avoid setting the points on dust or scratches on the film.

• Due to the use of a catch light, data is never clipped, regardless of where the

highlight and shadow is set. (We will explain this later on with a discussion

of the Diffused Highlight.)

• PowerColor searches for densities that are closest to neutral (equal).

3-4 PowerColor User Guide

Page 51

Setting the Input Range Manually

In both Basic and Expert mode, there are two methods of manually setting the

Input Range:

1. Select the Histograms tab from the Photo RGB Window. You can use the fields

at the bottom of the Input Histogram to enter the Highlight and Shadow densities, or move the two arrows at the bottom of the Histogram graph. Changing the

RGB Histogram will affect all channels equally. To set each channel separately,

select the appropriate channel from the drop down window and adjust the

Highlight and Shadow points.

Note: In expert mode, any changes to the

Histograms will be shown in the position of the

RGB tone curves.

2. First, perform an Auto Range by clicking on the Auto Range icon within the

Control Bar. Next, select the Pointed cursor from the Control Bar, then click on

the diamond shaped Highlight (white) and Shadow (black) densitometers within

the region, and move them to the desired locations.

Changing the Diffused Highlight and Shadow Point : An Example

It is very important to understand the interaction between the diffused highlight

and shadow point in the image, the diffused highlight and shadow RGB fields in

the Tone and Cast menu, and the highlight and shadow cast correction setting in

the Tone and Cast menu. One will always affect the other.

• The sticky densitometers reflect the exact points of interest.

• The Highlight and Shadow RGB fields control the values those points will

inherit.

• The Cast settings influence how the RGB values react to one another when a

new value is typed into one of the fields or when you select a different cast

setting.

For this example, an IT8 target is used, although a similar target containing a

gray wedge would work as well.

Chapter 3: Correcting Images in the RGB Color Space 3-5

Page 52

The bottom of the target contains 22 steps of gray bordered by paper white and

black. Let’s refer to paper white as a specular highlight (any point that should

contain no color) and black as our shadow point.

By selecting the pointed cursor from the Control bar, you can pick up the highlight sticky densitometer and drag it to a new location. First, place the highlight

densitometer on the specular highlight. This will cause that area to become our

point of interest and reflect the values in the RGB Highlight fields from the Tone

and Cast Window.

We will now work with the Highlight fields in the Tone and Cast Window. First,

make sure the Highlight and Shadow Cast Correction is set to full. In the Red

field next to the Diffused Highlight label type in “255” and hit Enter. Notice that

both the Green and Blue values changed automatically. This is because the Cast

Correction setting is on Full--The color computer will always keep the RGB values adjusted based on the Cast setting. You have now made the paper white

patch a specular highlight.

For the Shadow point, take the Shadow sticky densitometer and place it on the

Black patch. In the Red field next to the Shadow label type 0. The black patch

will now become the absolute shadow point.

Of course, setting the input range would be a piece of cake if you only have to

scan IT8’s. Unfortunately, in the real world, not all images have perfect specular

highlights and absolute shadow points. But that’s OK, because PowerColor was

designed for the real world.

The next example is closer to the challenges of everyday scanning: Again, lets

use the bottom of the IT8, but this time we are going to throw out every patch

except #3 and #20. Now patch #3 may exist in an image as a linen table cloth,

pearl necklace, shirt, or countless other objects and materials. The point is that it

is identifiable in the image, and we either know, were told, or have to make an

assumption as to how it should reproduce on paper.

Lets start with knowing that patch #3 should be neutral and the red value should

be 240. Take the Highlight sticky densitometer and place it on patch #3. In the

Red field type in 240 and hit Enter. You have just set a Diffused Highlight and,

because the red value is less than 255, the Catch Light is automatically activated.

Now move the Shadow sticky densitometer to patch #20 and in the Red field next

to the Shadow label, type 10 and hit Enter.

3-6 PowerColor User Guide

Page 53

Note: Highlight and Shadow points don’t need

to be at the extreme ends of a histogram, even

though most of us are taught to think that way.

In fact, the highlight and shadow points don’t

even need to be neutral and in many images

you will need to leave a cast in these points.

Now, change the Highlight Cast correction setting to Half. The color computer

will automatically calculate and keep half of the original cast. Change the cast

setting to None. The Highlight point will now keep 100% of its original cast. Set

the cast setting to Manual and you can now control the Highlight point to any

values that you desire. This of course works identically for the Shadow Cast.

Using the Gray Eyedropper

The gray eyedropper is unique in that it can set multiple points. Gray points are

made up from the quarter tone, midtone, and three-quarter tone regions. On a

Mac, to select multiple points, hold down the Option key (Macintosh) or Control

key (Windows) while selecting each point. Before you select the last point, release

the Option or Control key and click on the point. The tool is then deselected automatically.

Chapter 3: Correcting Images in the RGB Color Space 3-7

Page 54

Tone and Cast

PowerColor gives users two options for working with Tone and Cast--Basic and

Expert modes.

• The Basic Mode uses sliders for correction instead of curves. These sliders

are easy to use, yet give good control over image editing features.

• The Expert mode gives access to curves for more advanced adjustment of the

tonal settings.

To change the current mode, select Preferences from the Edit Menu, then choose

the desired setting within the General section of the Preferences Window.

Adjust Tone and Cast - Basic Mode

Figure 3–5

Basic Mode Sliders

Adjusting Tone and Cast in Basic Mode

• Brightness: Controls the lightness and darkness of the image. Usually

referred to a the midtone point on a gradation curve.

3-8 PowerColor User Guide

Page 55

• Contrast: Controls how fast the transition is between light and dark pixels.

On a gradation curve this would be the correlation between the quarter

tones and three quarter tones.

• Saturation: The amount of chromanence present in all hues. Zero percent

saturation would yield a black and white image.

Chapter 3: Correcting Images in the RGB Color Space 3-9

Page 56

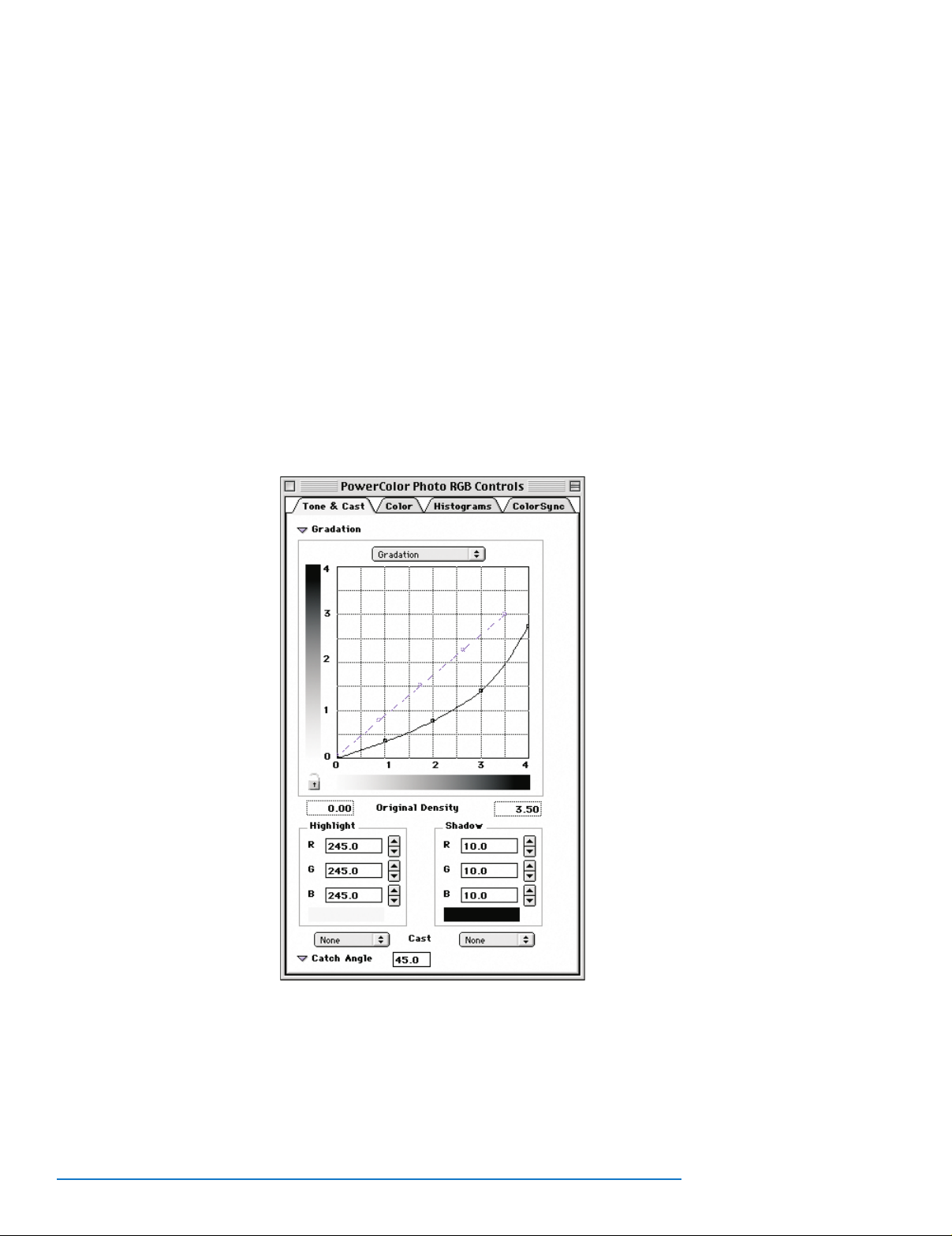

Figure 3–5

Tone & Cast option in the

RGB Control window

Adjusting Tone and Gradation - Expert Mode

The purpose of the tone curves is to define what is neutral by removing unwanted casts. The

purpose of the gradation curve is to specify tone compression and contrast. Therefore, color correction should be performed only in the Selective Color window, where neutrals and hues are

treated separately. To adjust neutral tones, use Tone & Cast; to correct hues, use Selective Color.

3-10 PowerColor User Guide

Page 57

The gradation curve (black) defines how tone compression is handled. The horizontal axis shows the input density while the vertical axis displays the output

density.

The points (called “anchor points”) are located, from left to right, at the following values: highlights, quarter tones, midtones, three-quarter tones, and shadows.

By selecting an anchor point and dragging it up or down, you can alter the gradation value for that point.

The lock icon at the bottom left corner of the grid is open by default. By clicking

on it, you can lock the anchor points on the curve. This allows you to move the

points individually without affecting the others. Locking anchor points is useful

for fine-tuning the gradation curve.

Note: Adjustments in the gradation curve

change the input-to-output tonal compression.

For example, moving the three-quarter tone

point down expands the shadow area of the

image by starting the three-quarter tone range

at a lower optical density.

Note: Every original, film or print, has a specific

density range which defines the points where

the image data starts and ends. This density

range is measured on an optical density scale of

0 (lowest) to 4 (highest).

The “output density range” is usually set to different values than the input range.

The default output density value is 2.7, the maximum density monitors are capable of displaying. Knowing the density range of your intended output device and

entering that value in the RGB Control window helps optimize the quality of the

final image.

Note: If you are unsure of which value to use,

keep the value 2.7. If your output device is a

film recorder, values of 3.0 or higher may be

advisable.

Chapter 3: Correcting Images in the RGB Color Space 3-11

Page 58

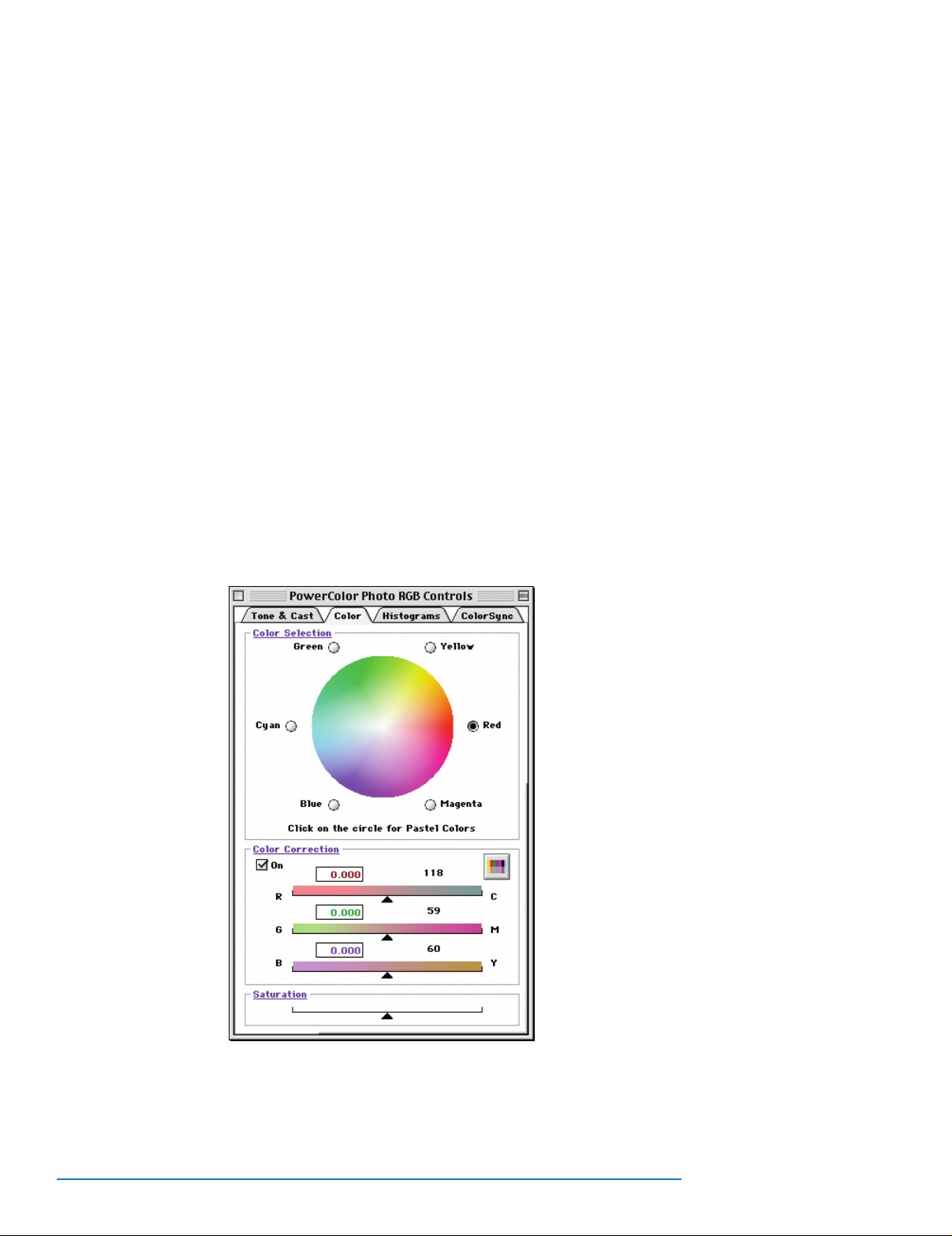

Using PowerColor Photo Controls

Adjusting Colors

The Color option in the RGB Control window (see Figure 3–4) provides control

over high chroma (saturated) and low chroma (pastel) in all primary and secondary colors independently.

Use the Color Selection color wheel to select the individual color to be corrected.

You can also click on any area of the image and PowerColor automatically

detects the selected pixel’s high value and whether it is a pastel or saturated color.

To toggle between the high and low chroma colors, click on the color wheel. This

toggle feature allows you to make changes in the darker or lighter colors without

affecting the other.

Figure 3–4

Color option in the

RGB Control window

3-12 PowerColor User Guide

Page 59

Correcting Colors

The checkbox in the Color Correction section of the RGB Control window toggles

selective color on or off. The default mode is On.

Note: The Color Correction checkbox should

always be checked.

The sliders in the Color Correction section allow you to perform color correction

in the three separate color channels. To do so, proceed as follows:

1. Select the hue to adjust by clicking on the color wheel.

2. Click on the radio button of the desired color.

Note: Steps 1 and 2 above can be combined by

selecting a point in the image, which automatically selects the proper hue and color.

3. Adjust the sliders to add or remove color(s) in a channel. Remember that

small movements in either direction can have strong effects.

Note: The boxes in each slider show arbitrary

reference numbers for your convenience. The

numbers to the right of the boxes show the RGB

values after the change.

4. Click on the Manual Update button in the window to check the results of

each change (or turn on automatic updating by clicking on the Auto Update

On button located in the Preferences Window).

The Before and After sections of the Probe provide real-time feedback for your

changes.

Chapter 3: Correcting Images in the RGB Color Space 3-13

Page 60

Figure 3–6

Histograms option in

the RGB Control window

Manipulating the Histograms

Manipulating the image’s histograms is a quick and powerful method of of setting its tonal range. To do so, click on Histograms in the RGB Control window

(see Figure 3–6).

The window displays the input density histogram and the output reflectance histogram. The input histogram can be adjusted to show all three RGB channels

together or each channel individually. To adjust the limits, slide the white slider

(highlight) and/or black slider (shadow) to the desired position.

The Output Reflectance histogram is a static display that cannot be adjusted. It is

designed to show how your adjustments will affect the image when output.

Note: Minor adjustments to histograms have

strong results. Move the sliders in small increments to avoid distorting your range values

excessively. (Remember to update the image

regularly to view your changes.)

3-14 PowerColor User Guide

Page 61

The ColorSync Separator (Macintosh Only)

The ColorSync window appears when you select ColorSync in the RGB Control

window (see Figure 3–7). Please note that this feature is available only for the

Apple Macintosh version of PowerColor.

The ColorSync window allows you to choose ColorSync ICC profiles. These profiles

will be applied to separations done if Photo is the specified separator in the

Preferences window (See Chapter 2-3).

Using the ColorSync Separator

In order to use a ColorSync profile, it must be in the ColorSync Profiles folder

within the System Folder of the Macintosh.

You can choose to open profiles for calibrating your output to a specific printer, as

well as input profiles for reflective or transparency scanning. These profiles will

automatically be applied to images scanned into CMYK colorspace.You can also

specify a screen monitor profile to provide an accurate “blow back” of your

images.

Chapter 3: Correcting Images in the RGB Color Space 3-15

Page 62

To choose a profile, click on the appropriate button within the ColorSync Window.

In the file dialog box that appears, choose the desired profile.

Note: ColorSync must be active on your system in order to use ColorSync profiles

Note: ColorSync must be active on your system

in order to use ColorSync profiles.

Tagging profiles to scanned images

The Store ColorSync Profiles in Saved Images check box at the bottom of the

ColorSync Window allows the user to tag the current profiles to final scanned

images. This feature is only available with the TIFF format. When using this

feature, the output file is not processed with the profiles, which allows further

correction “downstream” with different profiles, and also allows others to view

the file as you did.

3-16 PowerColor User Guide

Page 63

4

4

Correcting Images with

PowerColor Press/CMYK:

Production Mode

Page 64

Page 65

owerColor’s selective separator offers two color control modes for image cor-

P

rection work in the CMYK color space: Production and Expert. The Expert

color control mode is discussed in Chapter 5.

This chapter explains how to use Production mode and covers the following

topics:

• Understanding the CMYK Probe

• Using Production Color Controls

• Making Selective Color Corrections

The Production mode is selected in the Preferences window (see Setting

Preferences in Chapter 2 for more information).

Chapter 4: Color Correction in the CMYK Color Space: Production Mode

Page 66

Page 67

Figure 4–1

CMYK Probe window

Understanding the CMYK Probe

The CMYK Probe window (see Figure 4–1) is opened by selecting Probe from the

Tool menu or pressing +P (Macintosh) or Control + P (Windows).

The Probe is a static display of numerical information used as a guide in making

color correction changes. It is a valuable tool and should always be used in conjunction with the screen display. This section explains how to understand and use

the Probe.

Probe Location

This section of the CMYK Probe window shows the cursor’s X/Y coordinates at the

current location.

Chapter 4: Color Correction in the CMYK Color Space: Production Mode 4-1

Page 68

Displaying Density Values

The Densities table can be toggled open or closed with the blue triangle. It displays the RGB densities as read from the scanner (Original), after color correction (Reproduction), and when output after tone compression (Output).

Displaying Color Plates

The Probe allows you to select the color separations or combination of separations you would like to view in the image window as follows:

• The Four Plates button ( ) shows all four process colors together in the

image window (press +0 on a Macintosh or Control + 0 in Windows).

• The Cyan button ( ) shows only the Cyan plate in the image window

(press +1 on a Macintosh or Control + 1 in Windows).

• The Magenta button ( ) shows only the Magenta plate in the image

window (press +2 on a Macintosh or Control + 2 in Windows).

• The Yellow button ( ) shows only the Yellow plate in the image window

(press +3 on a Macintosh or Control + 3 in Windows).

• The Black button ( ) shows only the Black plate in the image window

(press +4 on a Macintosh or Control + 4 in Windows).

CMYK Values Before and After Corrections

The section below the Color Plates shows the CMYK values of the current cursor

location before and after changes, both in color swatches and in terms of dot

percentages.

Note: As you sample the image, you can

“mark” a location for image correction by simply clicking with your mouse. The CMYK values

for that location are then entered in the CMYK

Selective Color window (see below for details)

and remain there until you click on another

location in the image window. After a location is

marked, the cursor can still be used to sample

other parts of the image.

4-2 PowerColor User Guide

Page 69

Selecting Fixed Reference Points

The Static Probes section at the bottom of the CMYK Probe can be toggled open

or closed by clicking on the blue triangle. It allows you to select up to three fixed

points in the image which you can use to monitor important tonal ranges as you

correct the image.

To select a point, click on the 1, 2, or 3 button and click on the desired location

in the image. The location is flagged with the number, and the colors and dot

percentage values for that point before and after any changes are displayed in the

Probe.

Note: New static points can be selected at any

time using the above procedure, but the points

cannot be moved or deleted.

Chapter 4: Color Correction in the CMYK Color Space: Production Mode 4-3

Page 70

Using Production Color Controls

PowerColor’s CMYK Production mode is designed to combine the most common

tools for color correction work in a single dialog window. This allows you to work

more efficiently, gain a better overview of all adjustments, and use window space

economically. For more detailed and precise color controls in the CMYK color

space, or to build custom tables, use the Expert mode (see Chapter 5).

Note: Changes made in Production mode are

reflected in the individual controls in Expert

mode and vice versa.

To use the Production mode, select Production as PowerColor Press Mode in the

Preferences window (see Setting Preferences in Chapter 2 for more details). Open

the Production Controls window by selecting Production Controls in the

Correction menu.

Production Mode Workflow

PowerColor’s Production mode was designed to allow for fast setup and correction

of scans through the use of predefined tables. Color correction tables are made up

of six components: Grey Balance, Dot Gain, Gradation, Tone, USM, and Selective

Colors. Selective colors are corrected in the CMYK Selective Color window (see

next section).

4-4 PowerColor User Guide

Page 71

Figure 4-2

CMYK Production

Controls

Using Production Controls

The Production Controls window is broken into three major sections.

• Tools to set highlight and shadow points

• Pop-up menus for dot limits, settings and cast

• Slider controls for brightness, contrast, and saturation

Although there is no set workflow that needs to be followed when correcting an

image, for this manual we will assume a more traditional work-flow as follows:

• Set highlight and shadow points

• Set cast correction settings

• Adjust brightness and contrast

• Adjust dot limits

• Adjust selective colors

• Adjust USM

For this section of the manual we only cover the topics associated with the

Production Controls window. Selective color will be covered later in chapter 4.

USM will be covered in chapter 6.

Chapter 4: Color Correction in the CMYK Color Space: Production Mode 4-5

Page 72

Setting Highlight and Shadow

The most important aspect of setting up a scan is defining where to place the

highlight and shadow point. PowerColor has an automatic as well as a manual

means for accomplishing this task.

Note: There are two types of highlights:

“Specular” highlights are areas that contain no

dot percentage of any ink, while “diffused”

highlights contain a minimum dot percentage.

All densities less than the diffused highlight

slope to a 0% dot at a 45º angle. When setting

Highlight and Shadow points, PowerColor uses

the values within the Diffused Highlight and

Shadow area of the Production Controls

Window.

Setting the Input Range automatically with Auto Range

In the Production Controls Window you will find the Auto Range Icon ( ).

By selecting this tool, an Auto Range will be performed on the active region. The

Highlight and Shadow point will be set to the values shown in the Diffused

Highlight and Shadow fields within the Productions Control Window. Also, these

points will be marked in your image by sticky densitometers.

How Auto Range determines Highlight and Shadow points

After the software has evaluated the image data it will make a series of decisions

as to where it will set the Highlight and Shadow point.

• Auto Range looks only at the densities of the image data that falls within the

current Region Crop. This is important to know because if you leave film

edge or an area beyond the image edge in your crop, the software will

include that data in its decision.

• The Highlight and Shadow points will not be set at the extreme minimum

and maximum, but at a percentage inside of the min and max. The reason

for this is to avoid setting the points on dust or scratches on the film.

• Due to the use of a catch light, data is never clipped, regardless of where the

highlight and shadow is set. (We will explain this later on with a discussion

of the Diffused Highlight.)

• PowerColor searches for densities that are closest to neutral (equal).

4-6 PowerColor User Guide

Page 73

Setting the Input Range Manually

To set the Input Range Manually when using the Production Controls, first, perform an Auto Range by clicking on the Auto Range icon within the Control bar.

Next, select the Pointed cursor from the Control bar, then click on the diamond

shaped Highlight (white) and Shadow (black) densitometers within the region,

and move them to the desired locations.

Changing the Diffused Highlight and Shadow Point : An Example

It is very important to understand the interaction between the diffused highlight

and shadow point in the image, the diffused highlight and shadow fields in the

Production Controls, and the highlight and shadow cast correction setting in the

Production Controls. One will always affect the other.

• The sticky densitometers reflect the exact points of interest.

• The Highlight and Shadow fields within the Production Controls control the

values those points will inherit.

• The Cast settings influence how the values react to one another when a new

value is typed into one of the fields or when you select a different cast setting.

For this example, an IT8 target is used, although a similar target containing

a gray wedge would work as well.

The bottom of the target contains 22 steps of gray bordered by paper white and

black. Let’s refer to paper white as a specular highlight (any point that should

contain no color) and black as our shadow point.