Page 1

Remote UV lamp model shown here,

including Internal Bracket / Light Shield Kit

Homeowner / User Guide

1-866-GO-UV-AIR (468-8247)

ultravation.com

DC-0H-0232

Thank you for purchasing an Ultravation

Professional Indoor Air Quality Product

Package Contents:

• UMX/UME Electrical Housing

• Ten 3/4 inch 5/16 self-tapping

screws

• UVC warning label

• Warranty card

• Remote mount Viewport label

• Remote mount Viewport

• Two wire nuts (for 24V systems)

• Light Shield (24V systems,

one for each lamp)

• Four T3 lamp mounting screws

(remote lamp models)

Options

Refresh™ PCO (Photocatalytic Oxidation)

• Whole house odor reduction module

w/gasket

• Four 3/4 inch 5/16 self-tapping sheet

metal screws

UMX/UME- 1224T, 1200T, 1000T3

• One 12" T3 UVC lamp

• One T3 lamp mounting gasket

UMX/UME- 12242T, 1202T, 2000T3

• Two 12" T3 UVC lamps

• Two T3 lamp mounting gaskets

UMX/UME- 1924T, 1900T, 1036T3

• One 17" T3 UVC lamp

• One T3 lamp mounting gasket

UMX/UME- 19242T, 1902T, 2036T3

• Two 17" T3 UVC lamps

• Two T3 lamp mounting gaskets

ILS (Internal Light Shield) – 1 Per Lamp

• One lamp clip

• One heavy duty mounting magnet

• Associated hardware

®

Introduction

Ultravation manufactures several configurations of ultraviolet (UV) disinfection products

to meet any installation criteria. UltraMAX™ two-lamp UV systems are designed to treat

up to a 5 ton HVAC system or cover 3,500 sq ft.

Ultravation® UltraMAX™ products have been designed for peak performance in the cool

temperatures of the supply plenum of an HVAC system.

We suggest mounting the UV lamps and optional Re-Fresh™ Odor reduction module on

the exit or supply side of the HVAC system and before the ductwork branches off.

Installing UV equipment in the HVAC system return may degrade the media filter and/or

collect dirt particles on the UV lamp glass gradually decreasing performance. If there is

obvious microbial growth in the return duct, then installing the UV system (or a second

system) in the return can be the best solution.

However, caution must be taken to ensure that no light from the UV lamp(s)

can come in contact with any installed media filters or can be seen from

outside the HVAC system when it is running. Remember: DO NOT look at UV

light without proper eye protection.

Ultravation’s exclusive Re-Fresh™ Odor Reduction Module (optional) performs

continuous photocatalytic air processing, constantly reducing or eliminating hundreds of

common VOC odors while enhancing the germicidal effect of the system resulting in

clean, fresh, breathable air.

UltraMAX UV systems produce no ozone. No harmful by-products or off-gassing takes

place in the sterilization process or the photocatalytic process.

If you need help or have questions call our toll free help line:

1-866-GO-UV-AIR (468-8247) • 9:00 AM – 5:00 PM EST

SAFETY PRECAUTIONS:

It is recommended that this unit be installed and maintained by a trained technician:

WARNING: UV Hazard. Always protect eyes from ultraviolet light. NEVER

look at UV lamps in operation. Unplug or disconnect power before

replacing lamps or servicing.

WARNING: Severe eye damage or temporary blinding may occur.

WARNING: DO NOT operate outside of air handler. Mount lamp base

to duct first.

WARNING: No openings in HVAC system are allowed which would give

direct line-of-sight to the UV light.

In the event of accidental breakage or replacement of the ultraviolet lamp, please

ensure that the lamp is disposed of in accordance with local and state environmental laws regarding fluorescent lamps containing mercury.

Notice: All wiring inside air handling system in direct line of site of the UV lamp must

be shielded with aluminum foil tape or equivalent non-combustible material. When

installing this unit, select a mounting location that prevents ultraviolet light exposure

to plastic non UV-rated flexible duct liner or other plastic components with unknown

resistance to ultraviolet light. Ultraviolet light may cause color shift or structural

degradation of plastic HVAC components. If installing where UV light can directly

contact fiberglass duct board, contact manufacturer of fiberglass product for advice

on UV rating. If unknown, install metal sheathing or foil tape to completely protect

fiberglass duct board from UV light exposure.

Important information about UV lamp replacements:

Replace UV lamps each year in order to maintain optimum effectiveness in the reduction of pathogens such as bacteria, viruses and microscopic mold. Lamps operating

after a period of two years do not provide adequate reduction of pathogens and

must be replaced. Lamps operating beyond 18,000 hours (two years) draw excessive

electrical current which may result in damage to the UV system. If UV lamp(s) have

been operating for more than two years, the system must be turned off until replacement lamp(s) are installed. Failure to do so may void the warranty.

Lamp Replacement Chart

Use this chart to determine lamp replacement number

System Model Description Replacement Part Number

UME/UMX 1224T, 12424T,

1200T, 1202T, 1000T3, 2000T3 12" T3 UV Lamp ASIH1001

UME/UMX 1924T,19424T,1900T,

1902T, 1036T3, 2036T3 17" T3 UV Lamp ASIH1003

Refresh™ PCO Option Module Odor Reduction, Universal Fit 94-004

Please contact your local dealer or HVAC contractor for replacement lamps.

Warranty

Ultravation warrants this product against any defects in material or workmanship

for a period of ten years after date of consumer purchase, with the exception of the

ultraviolet lamp(s), which are warranted for a period of one year after date of consumer

purchase.

This warranty does not include damage to the unit from accident, misuse or improper

installation.

If this product should become defective during the warranty period, Ultravation will

elect to repair or replace the product free of charge. Ultravation will return repaired or

replaced warranted products pre-paid to the customer, provided that the product was

delivered pre-paid.

Ultravation shall have no responsibilities for charges incurred by the customer for

installation or removal of warranted items. Liability is limited only to the replacement or

repair of this product.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. All returns must be accompanied by a return authorization number, which may be obtained by contacting Ultravation, Inc.

Ultravation, Inc.

P.O. Box 165, 212 Ideal Way, Poultney, Vermont 05764

Phone: 1-866-GO-UV-AIR (468-8247) • Fax: 802-287-9203

www.ultravation.com • info@ultravation.com

Copyright © 2008-2012 Ultravation Inc.

UL Listed. The health aspects associated with the use of this

product and its ability to aid in disinfection of environmental

air have not been investigated by UL.

5TA2

Ultravation’s T3™ system is protected by US patents 6,809,326B2 and 6,838,057B2 • Copyright © Ultravation, Inc. All rights reserved.

Ultravation.com

Page 2

Installation

Installation steps for remote lamp mounting, remote lamp replacement, and

external mounting of power supply:

1. Remove the cover from the electronic housing.

2. Determine a suitable location to install unit housing. Mounting location should be of

sufficient strength as to support the unit, otherwise reinforcement of the ductwork

may be necessary. Fasten unit in place with two self-tapping screws (supplied).

3. Re-fasten housing cover to the power supply.

UV Lamp Installation:

1. Select location for UV lamp module, drill a 1" hole for each lamp. Fasten mounting

plate over drilled hole with screws provided.

2. Insert UV lamp module into 1" opening. Attach to mounting plate with the two

provided self-tapping screws.

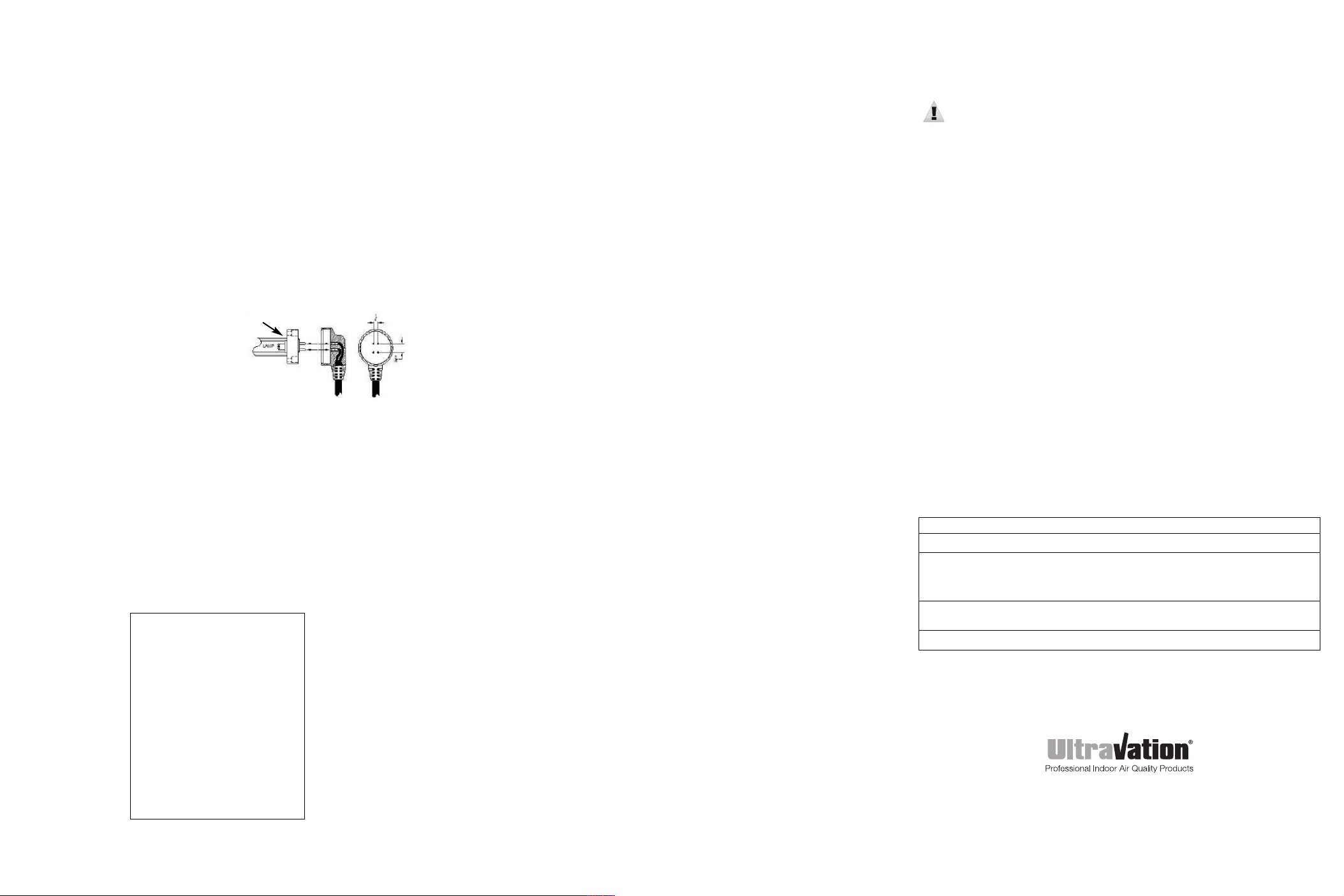

3. Plug the lamp connector onto the installed UV lamp assembly. Be sure the four pinholes are orientated properly to the four mating pins of the lamp (see

diagram, below).

4. Connect full time power to unit. (The UV system should be powered constantly, not

cycled with HVAC system power).

IMPORTANT: T3 Lamp Connection

Lamp pins are in a rectangular pattern (NOT

square). The plug can be connected to the

lamp in either of the two ways that match

the pin pattern. The T3 UV lamp assembly

can be removed independently, simply by

removing the two screws in the lamp base.

ELECTRICAL POWER CONNECTION 24VAC UNITS

All 24 volt UV equipment for HVAC systems (regardless of manufacturer) must be

installed using a separate, dedicated minimum 40VA transformer to avoid the possibilty

of voiding UL certification of the HVAC system.

This product is equipped with a 1.75 amp in-line fuse for both surge and electrical arc

protection. Replace only with AGC 1.75 AMP (2 AMP max) fuse (available from

Ultravation or authorized distributor, part number EL-PP-0001). Failure to do so will

defeat the design and void the warranty.

For installation of integrated

lamp models follow

illustration on supplied template

DC-IH-3333

Lamp assembly

Installation options for Internal Bracket/Light Shield (ILS)

The Internal Bracket/Light Shield (optional some models) is a versatile kit that can be

used for mounting the UVC lamp(s) completely inside the HVAC system via a screw

mount or using the heavy duty magnet for even easier mounting. It can also serve as a

light shield to block the intense UVC energy from breaking down non metallic

materials such as filters, or to prevent UVC energy from escaping through air return

grills. For the full range of configurations see accompanying installation option sheet

DC-IH-3334.

Installation steps for optional exclusive Refresh™ PCO Odor Reduction Module:

1. Find a location adjacent to the UV lamps to mount the PCO module. Activation of

the PCO module requires UV light shining on its surface. It can be mounted within

inches of the UV lamp or if necessary it can be within 2 ft. of direct UV light source

and still function.

2. Drill one 2 1/2" diameter hole at the desired location. Fasten the base plate of the

module to the duct or air handler with the four supplied screws.

3. The PCO module measures 14 3/4" inches long by 2 1/2" diameter. The surface

area of the module relates directly to the amount of VOCs it can break down. If

necessary the module can be trimmed to a shorter length to accommodate installation. For additional effectiveness, install additional PCO modules in the area of the

UV lights, thereby increasing the airborne bacteria disinfection rate and the removal

of VOC odors. PCO modules may be installed completely inside the HVAC system.

Installation steps for UV Viewport

1. Find a location on the air handler or ductwork that will be in direct line of sight to

the UV lamps where a 3/8" inch hole can be safely drilled.

2. Affix the UV Viewport label to air handler or ductwork.

3. Drill the hole through air handler or ductwork using the label as a template.

4. Insert and press in the UV Viewport until it snaps into place.

5. The Viewport glows blue when the lamp(s) are operational (but does not allow actual

UVC light to pass through it).

Maintenance

Never perform maintenance on the UV unit without disconnecting power.

Typical maintenance consists of replacement of the ultraviolet (UV) lamps. UV lamps

undergo a photochemical process during operation. This slowly reduces the amount

of UV light generated to disinfect the air and surfaces. For optimum air stream disinfection UV lamps should be replaced on an annual basis. For surface disinfection,

lamp replacement should be performed no later than every two years.

When installing new lamps, ensure that the lamp glass is free from any fingerprints or

debris, as this may alter the path of the UV energy. Use rubbing alcohol and a dry

cloth to remove any surface contamination.

Troubleshooting

Ultravation® air disinfection equipment is designed to provide many years of trouble

free operation. In the unlikely event of a problem, please contact your local HVAC

professional or Ultravation directly. Before calling for service, you should have the

model number, serial number, and purchase date. The model and serial number are

located on an end panel of the base unit.

Please note: It is a normal characteristic of all UV lamps to blacken around the

filaments of the lamp. This does not signify the lamp is defective or not emitting

ultraviolet light. A UV lamp is defective only if it will not light. UV lamps that operate

do not qualify for warranty coverage.

If you are troubleshooting the unit, please check the following:

• The electronic circuit of a 2-lamp system only operates when both lamps are on.

• Verify the unit has power (24VAC or 120V - 240V depending on installation).

• Be sure the power switch is in the ON position.

• Verify if in fact the UV lamps are ON or OFF.

• Check that lamps are securely plugged into their sockets.

• Press the unit reset. If the unit and the unit does not reset, wait 5 minutes before

trying again.

continued …

Troubleshooting, continued

• Verify that the in-line surge protection fuse is still functional. If needed, replace only

with an AGC 1.75 AMP (2 AMP max) fuse.

• Determine what signal, if any, the UV Lamp Monitor LED is emitting. (See the

UVLampMonitor chart below.)

Remember: DO NOT look at UV light without proper eye protection.

Note: If just one UVC lamp of a 2-lamp system operates, make sure the lamp

connection is correct (see T3 connection illustration at left).

Note: A flashing red every 1 second and a beep every 1 second does not necessarily

mean the lamps are defective or no longer emitting UV, it is sensing that the lamp or

lamps in the unit are not on. This could be caused by other factors. In this case, a

service technician should be contacted.

Lamp Replacement and Reset Procedure

See “UV Lamp Installation” for replacement procedure.

Note: When replacing lamps disconnect power to the unit first.

After the lamps are in place, complete steps 1-4 below to reset the service indicator

light to 0. For optimum air stream disinfection it is recommended that the UV-C

lamp(s) be replaced on an annual basis.

Setting the Service Indicator Light (FOR UMX SERIES ONLY):

We recommend that a certified technician perform this operation. (For integrated lamp

UMX models the cover must be removed and power left on – the reset switch is inside

the unit.)

1. To set or reset the annual service indicator the unit must have power connected.

2. Press down and hold the square yellow RESET button (hold down for 10 sec.). It is

located below LED Viewport on the end of the electrical housing. The LED turns

GREEN while the button is depressed.

3. Release the square yellow RESET button. The LED will now glow green

continuously indicating the reset procedure was successful.

There are NO user serviceable parts inside. Refer servicing to qualified service personnel.

UVLampMonitor (UMX Models Only)

The below chart indicates how to interpret UVLampMonitor status

LED Color Audible Alarm Unit Status

Green No sound OK

Solid Red No Sound Replace lamp within 30 days

Flashing Red 3 min Lamp(s) has exceeded 1 year of operation

(5 secs) beep interval Replace lamp(s) and reset alarm

Pulsing Red (1 sec) 1 sec beep interval Lamp(s) are not operating (verify if possible)

Reset lamp service indicator

Occurs after approximately

11 months of service

Ultravation.com

DC-0H-0232

Loading...

Loading...