Page 1

Revision 7 (Feb 2019)

FANTASY MACHINE

USER’S MANUAL

Revision 7(February 2019)

www.ultratec-facet.com

Page 2

Revision 7 (Feb 2019)

TABLE OF CONTENTS

INTRODUCTION

1.0 UNPACKAGING THE UNIT

2.0 AN OVERVIEW

3.0 SETTING UP

3.1 The Machine, 3.2 Install Dial Indicators, 3.3 Install Drip Tank,

3.4 Install Splashguard, 3.5 Install Lamp, 3.6 Install Lateral Stop Arm

4.0 OPERATION

4.1 The Control Panel

4.1.1 Control of Tool-drive Motor

4.1.2 Control of Reciprocation Motor

4.2 Tool-drive Motor position

4.2.1 Moving Tool-drive Motor position

4.3 The Mast

4.3.1 The Mounting Block

4.3.2 Mounting the Mast.

4.3.2.1 Affixing the Rigidizer to the Mast

4.4 Drive Motor Setups

4.4.1 Position 1 - the “Home” position. Aligning the Mast to the unit’s working mechanisms

4.4.2 Position 2 Alignment

4.5 Horizontal Positioning – X, Y, θ

4.5.1 X Positioning.

4.5.2 Y Positioning.

4.5.3 θ Positioning

5.0 TOOLS

5.1 Mounting Tools into the Tool-drive Motor

5.1.1 Cylindrical tools

5.1.2 Slitting Tools

5.2 CUTTING AND POLISHING TOOLS

6.0 CUTTING INFORMATION

Appendix

Page 3

Revision 7 (Feb 2019)

INTRODUCTION

The Ultra Tec Faceting Machine has been manufactured since 1966. It displays Ultra Tec’s approach to

equipment design -- direct, simple, thorough and non-compromising – providing the user with the precision and

repeatability that fine lapidary work requires.

The Fantasy machine was developed at the urging of professional gem cutters. It is based on their “wish list” –

a list that included mechanisms and controls for almost every possible axis of positioning. It started out with a

goal of making advanced positioning controls available for “concave cutting”. When we were done, we found

that the equipment could not only do the enhanced concave cutting originally intended but also something new “Fantasy stones” – essentially, geometric carving – a lapidary art that gives free rein to the imagination of the

user. So—the project became a goal exceeded.

The Fantasy Machine has gone through a period of extensive testing – tweaking – modifying – getting it right.

That period included learning – a learning that continues – but clearly, it was time for the Fantasy machine to be

introduced.

As Fantasy users gain experience – their work will turn increasingly complex. It’s not for kids. It is for lovers of

lapidary, perhaps better said – imaginative lovers of lapidary—it’s an art form. Enjoy it.

ABOUT YOUR FANTASY MACHINE

The Fantasy Machine is a precision device, but not a delicate device. For maintenance, it only needs normal

“wipe-it-down” cleanliness and reasonable care.

Pay attention to safety -- there are tools in multiple motion. In general, these are not sharp cutting tools, but

sometimes are, and are necessarily exposed. So -- treat them with respect.

As with any electro-mechanical device, there can be occasional problems--and if you experience one, re-read

the Owner's manual for the function involved, to assure that you are performing the operation correctly. If you

still experience a problem, communicate with your Ultra Tec representative or with the factory.

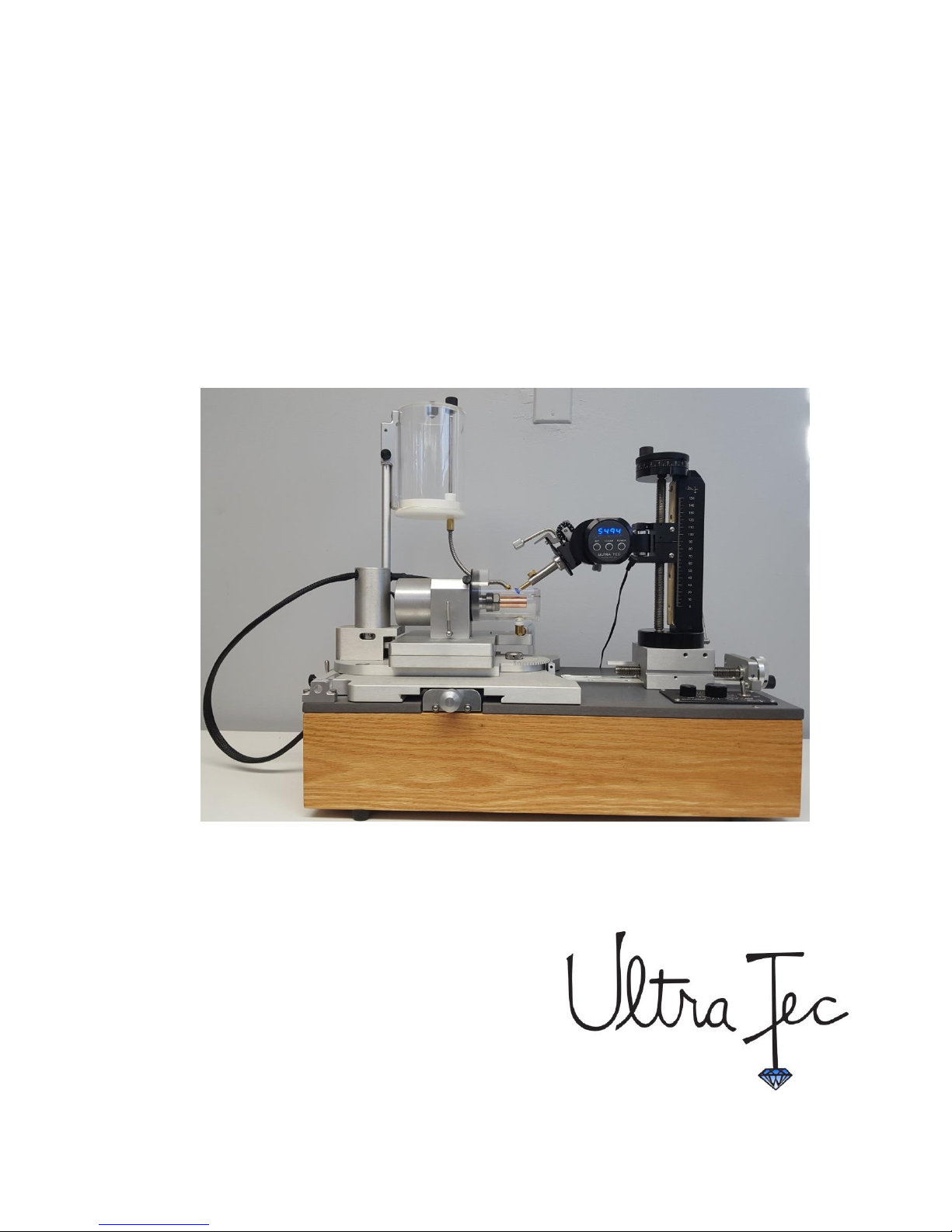

Shown with a Mast mounted – how it will look “in use”.

ABOUT THIS MANUAL

Most Manuals start out by saying “Read this carefully before proceeding”. Our advice is to do what you will

probably do anyhow -- that is, “Browse through this Manual quickly, and then start trying things out – go back to

the Manual if something puzzles you”. Our reason: This is a complex, but very logical machine. As a faceter

you’ll figure out most of it by just looking at it. For many functions it takes longer to go through a verbal

description than it does to just look at it—and try it. Obviously, if something feels “too tight”, or is “jamming”, go

back to the Manual and read the section you need.

Page 4

Revision 7 (Feb 2019)

1.0 UNPACKAGING THE UNIT

The machine comes in protective packaging which you may want to save, along with its box, in the event that

future shipment or storage is necessary. These are the included items:

Please note that the Fantasy Machine is heavy, so you may want someone to help you with lifting it out of its

shipping box. Have a sturdy surface to set it onto.

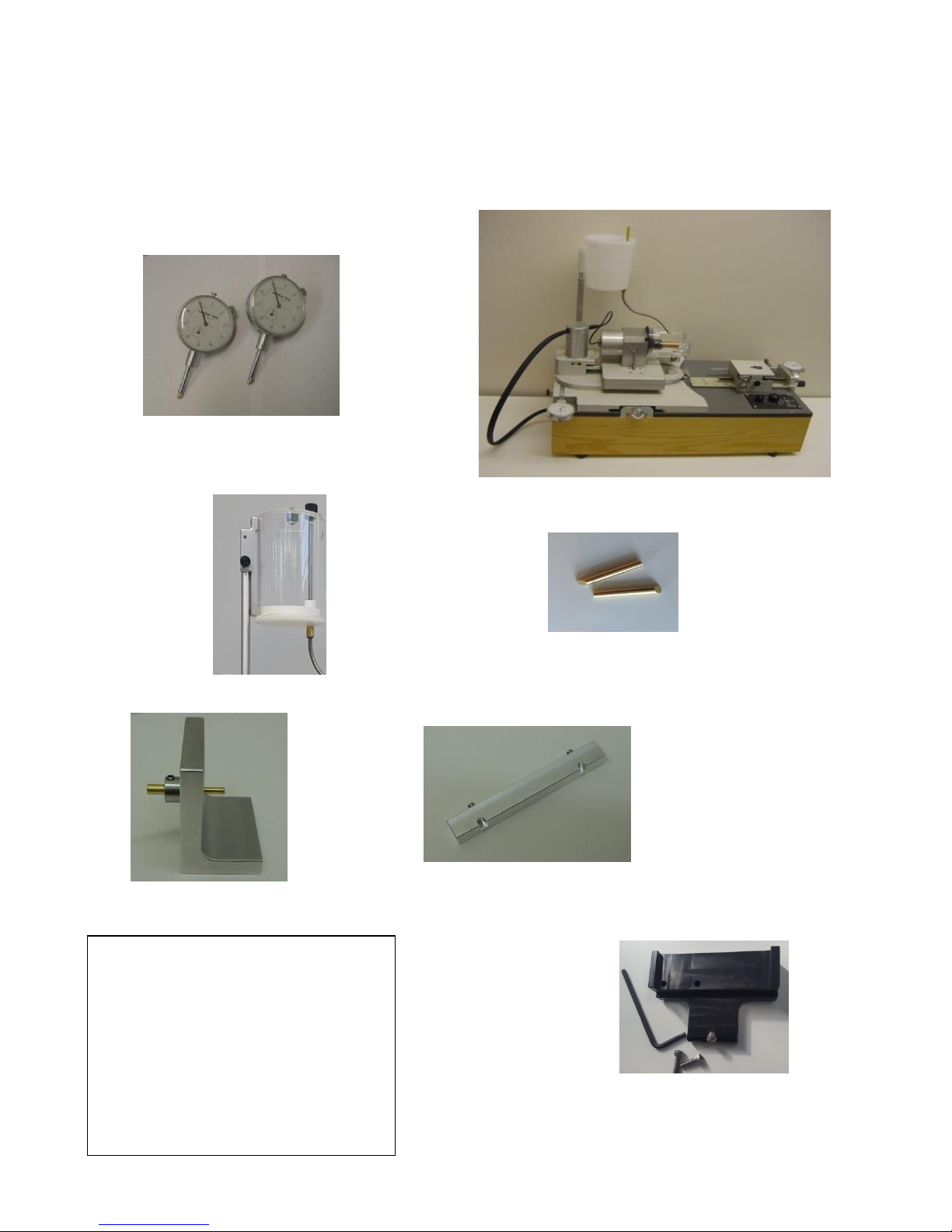

There are not a lot of pieces.

The Base - the basic machine itself →

Two Dial Indicators

Mast Alignment Dops →

Drip Tank

Position 2 Alignment Block

Position 2 Spacer

Lateral Stop Bracket

And, Tool Box that includes:

Cylindrical Tools:

Copper/Maple/Phenolic -diameters

8mm 13 mm, 17 mm;

Slitting Tools: Copper/Phenolic – 90º;

and Adapter Shaft.

ER-16 Collet Set of 10

ER-16 Spanner Wrench.

Page 5

Revision 7 (Feb 2019)

2.0 An Overview

The Fantasy Machine provides multiple axis repeatable positioning for use of cylindrical tools (“mandrels”) and

Slitting tools (disc “grooving” tools).

These are the positioning features:

● Initial Alignment – the faceting Mast is set onto the Fantasy Machine and aligned to a “home position” –

an initial retrievable 0 reference.

● X (in-out) directional positioning (“parallel stepping”) of the grinding/polishing tool, relative to the

workpiece is provided - Dial indicator readout.

● Y (side-to-side) directional positioning (“parallel stepping”) of the grinding/polishing tool, relative to the

workpiece is provided - Dial indicator readout.

● θ (theta – angular) 180º of angular positioning, of the grinding/polishing tool relative to the workpiece is

provided. The Pivot axis is the 0-0 position

● Lateral Stop Bracket -- locks out lateral motion of the Quill and tweaks Quill-to-Mandrel alignment

● There are two settable motor positions – Position 1, in line with a cylindrical tool axis - that axis

intersecting the “pivot axis” (the axis of horizontal angular positioning) - and maintaining in-line

reciprocation regardless of θ angular setting. Position 2 is at 90º, for use of grooving type of tool - it

allows for setting the slitting tool so that it intersects the “pivot axis”, and it also maintains in-line

reciprocation regardless of θ angular setting.

• Reciprocation of the mandrel amplitude is adjustable – from very little (including none) to over an inch

and reciprocation rate is adjustable up to 140 CPM – a high reciprocation rate is valuable for polishing.

The Reciprocation Motor is independent of other controls.

Page 6

Revision 7 (Feb 2019)

3.0 SETTING UP

3.1 The Machine – The machine should be placed on a workbench or desk surface. It is fairly heavy, about

about 65 pounds, so be sure the work bench is sturdy and you may need assistance in lifting it to the

surface. The machine will need a plug-in electrical supply and a container for draining, a gallon

container is adequate.

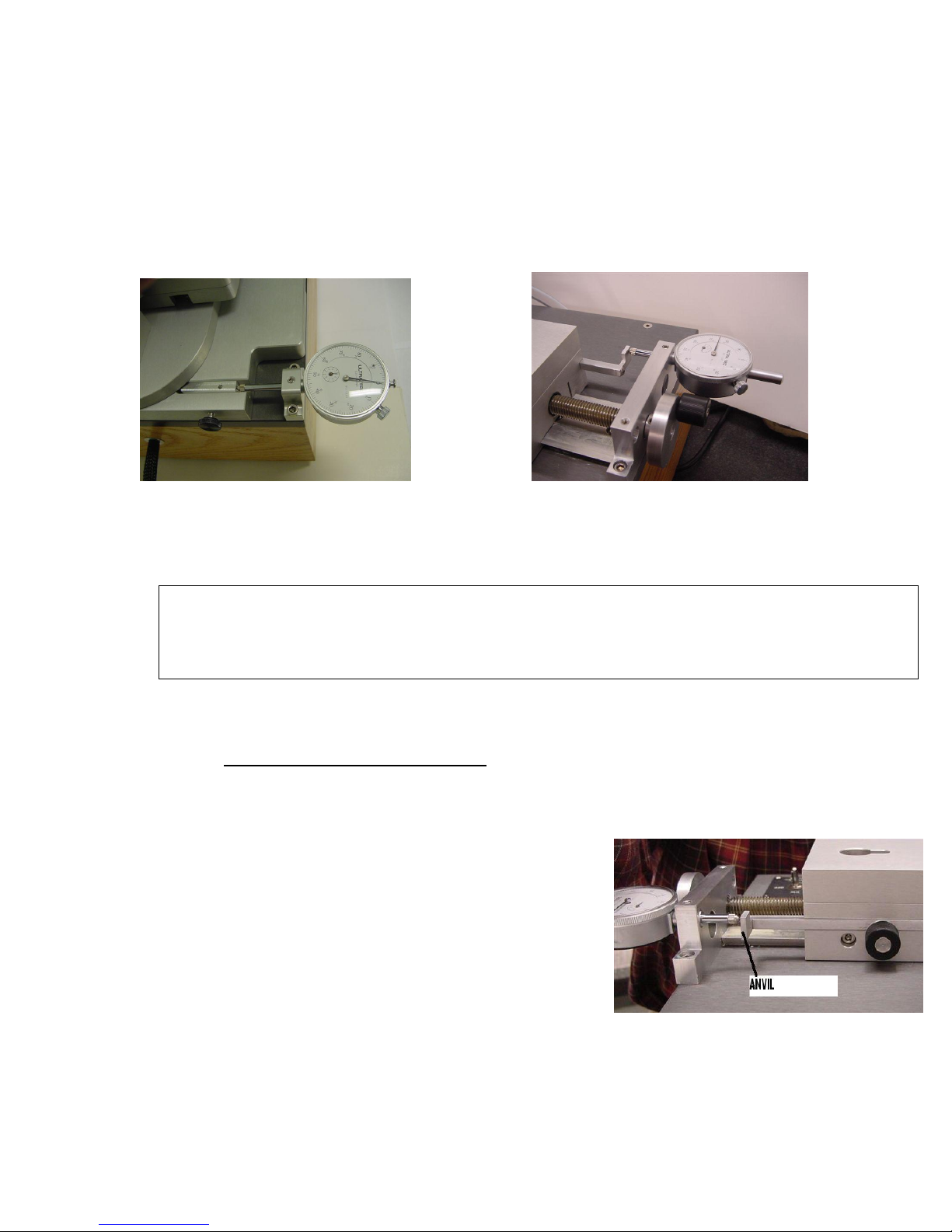

3.2 Install Dial Indicators – There are two Dial Indicators (these are shipped unassembled to avoid

damage). As you face the machine, the position at the close left corner is designated “X”; the position at

the right side, toward the back, is designated “Y”.

The two Indicators are identical. Inserted, each one into its bracket, (as shown in the photos) leaving a

small gap of several millimeters between the round dial case and the bracket.

Each of these indicators has an Indicator Anvil to set the indicator reading.

Note: The Indicator has an outer dial that the long needle tracks around – one full rotation being 1 mm

(capable of very small incremental settings). There is a small inner dial that counts rotations of the outer

dial – it reads 10 turns, and then 10 more –so you can read 20 mm in all (.800”) [you can squeeze another

millimeter at the end of the scale]. When the following paragraph says: set the indicator to 0-0 it means set

the Dial Indicator’s long needle readout to 0 with the inner dial (rotation counter) at 0.

3.2.1 The X Indicator Anvil (left) can be positioned by loosening the Black Knob at the left side of the

plate, sliding the anvil to the desired position and then re-tightening the knob.

In setting up, set the X Indicator to 0-0 – there is some preloading, even at 0-0 (see the boxed note

above). After initial mounting of the X Indicator, slide the Anvil against the indicator shaft to get that

reading (you just have to get the 0 setting close, because you can “fine-tune” the alignment by

turning the outer ring of the indicator until the outer 0 position is exact).

3.2.2 The Y Indicator Anvil (right) can be positioned by

loosening the Black Knob at the rear of the Mast

Mounting Block -- sliding the anvil to the desired

position, and then retightening the knob.

At the time of initial setup, this Anvil is pulled away

from the Dial Indicator – not activated, at least until the

Y linear position of the Mast has been set. Later, when

the Y setting is involved in the process, slide the Anvil

into contact with the Indicator shaft then set it at 0-0.

Page 7

Revision 7 (Feb 2019)

3.3 Install Drip Tank - The Drip Tank post slips into a black Bushing in the left rear of the

Reciprocating Table (see the picture on right). Place the Drip Tank onto the post, position

the Post into the Bushing, tighten the set screw, and it is ready. The flow rate is adjusted by

turning the valve stem, and the water shuts off with an easy pressure. Avoid over tightening

the valve. The tank will fit snugly, but loose enough for you to rotate its position.

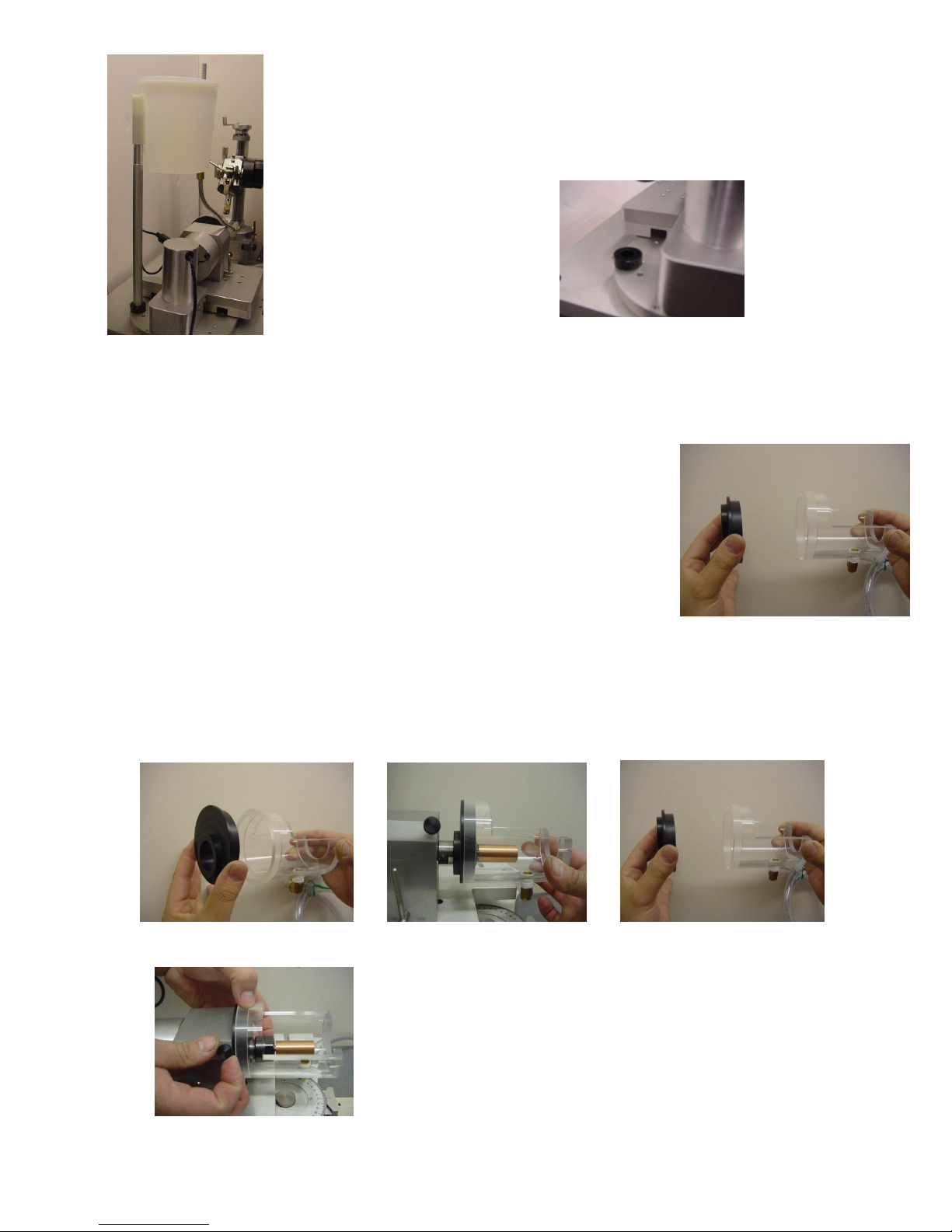

3.4 Adjusting Splashguard Position

The machine is shipped with the Splashguard in place. You may want to later adjust its position (or you may

not) no urgency about this. If you grip the Splashguard and pull, the

entire Splashguard pulls out. Then you will find that the clear plastic piece can be pulled

away from the Black Positioning Disc.

To reassemble and adjust the positioning, slip the black piece over the Spindle and set it into the hole – it’s a

“slip fit” (but fairly snug). Note that the hole through which the motor spindle passes is off center from the

outside diameter of the black piece – it can be set with the hole downward (as in fig.2) or with the hole upward

(as in fig 3), or at positions in-between. Those various positions allow you to set the amount of exposure of the

Mandrel, providing more or less splash protection – it’s a “judgment” setting that you will make (based on

experience, starting out – leave it in its hole-upward starting point).

Figure 1 Figure 2 Figure 3

Set the clear Splashguard in place, and use the Black Knob to secure it. Note

that there is a pre-installed drain and draintube that extends from the bottom of

the clear Splashguard – lead it to an appropriate drain container.

Page 8

Revision 7 (Feb 2019)

3.5 Install Lamp

The Lamp mounts onto the pre-assembled stud located in the right rear corner of the Baseplate. The Lamp

Mounting Lock has a Snap-On design. Pull back the nylon ring, place the Lamp onto the stud, and push down

the ring. You will feel the ring snap into the down position, where it holds the lap securely.

3.6 Install Lateral Stop Arm (If you have purchased this option

HD Lateral Stop Arm is an option. When ordered it is delivered as a sub-assembly that needs mounting onto

the Base that holds the Mast. This is easily done (see the picture) the two screws that are part of the kit thread

into two tapped holes in the Base, as shown. Completing the mounting is easy.

In use, an HD Lateral Stop Arm is positioned to stabilize lateral positioning of the Quill. Is this a duplication of

the function of the Lateral Stop Bracket? Yes – , but the Lateral Stop Bracket is for Ultra Tec masts only – a

HD Lateral Stop Arm it is a necessity in order to use any Mast other than an Ultra Tec Mast, - Also, HD

Lateral Stop Arm is preferred as a more positive stop for older Ultra Tec Masts.

Page 9

Revision 7 (Feb 2019)

4.0 OPERATION

4.1 The Control Panel

The Electronic Control converts AC current to DC, which the motors require. It contains controls for both

motors that are part of the unit, the Tool-drive Motor and the Reciprocation Motor. Note that the motor controls

are independent – modifying the running characteristics of one of the motors does not affect the other one.

4.1.1 Control of Tool-drive Motor-The right-side Switch is a two-way ON-OFF

toggle for the Tool-drive Motor. It has a choice for motor direction – UP for clockwise

(CW) rotation of the tool, and DOWN for counter clockwise (CCW) rotation of the

tool. The central position of the switch is OFF.

The Central Knob is a speed selector for the Tool-drive Motor. Most frequently, the

Tool-drive Motor is operated at full or close-to full speed.

4.1.2 Control of Reciprocation Motor-The left Knob combines both power and rate control for the

Reciprocation Motor. The extreme CCW position of the Knob is power OFF. Rotation starts and

increases rate as the Knob is rotated CW.

4.1.2.1Setting the Amplitude of the Reciprocation Motor-The amplitude (the in-line stroke) of the

Reciprocation Motor is variably adjustable, from the maximum stroke of 30 mm – over an inch

to a minimal stroke approaching 0. Commonly, a full stroke is used (and the unit is shipped that way),

but often, because of the length of the particular tool that is being used less than full stroke is

appropriate.

The setting is performed by engaging a screw that is visible in the side

“window”, as shown. The adjusting screw rotates with the rotation of

the motor – and to perform the adjustment, obviously, the head of the

screw must be visible (and so, reachable) in the window. A slow

jogging of the motor can bring the head into view, or…

…it can be positioned by pushing or pulling the Tool-drive Motor Plate

(it’s OK to grip the Motor housing to do this as shown). This method

will not work if the head is located, by chance, in a straight line with the

reciprocation action (at an extreme of the reciprocation). If that

happens, jog the motor so that the reciprocation stroke moves to

About the half-way point, and try again.

In making the adjustment, CW rotation decreases the amplitude. CCW rotation increases the amplitude. The

Reciprocation Motor is independent from the Tool Drive Motor—and none of these adjustments have an effect

on the Tool Drive, and, the Reciprocation motor can be left in a power OFF condition, that is, with 0

reciprocation.

Page 10

Revision 7 (Feb 2019)

4.2 Tool-drive Motor position.

There are two optional positions for the Tool-drive Motor. Position 1, shown in figure 1, is the position in which

the unit is shipped, and the position in which the initial setup alignment of the Mast to the machine is made.

Position 1 is the “main setup position” – and is the position for using cylindrical

mandrels. When the Drive Motor is set into position 1, the centerline of the

mandrel intersects the pivot axis of the θ motion, and remains in that

relationship even if the θ angle position is changed, or, if the X or Y linear

position is changed.

With the motor in Position 1, reciprocation is always in line with the axis of the

Tool-drive Motor shaft – in line with the axis of the mandrel.

Position 2 is the position for using slitting and grooving tools. In Position 2,

reciprocation is always in line with the cutting plane of the grooving tool, and

remains in that relationship even if the θ angle position is changed, or if the X

or Y linear position is changed. .

In setting up Position 2, there is a procedure for aligning the cutting plane so

that it intersects pivot axis of the θ motion. It is usually a good idea to do this

alignment since it establishes a 0 Home position for that tool. Once that

alignment is made, the cutting plane intersects the pivot axis even if the θ

angle index position is changed, or if the X or Y linear position is changed.

4.2.1 MOVING MOTOR POSITION.

This view of the Motor mount Plate tells the story. Central in the photo is the

Position 1 Mounting provision. At the upper part of the photo is the Position

2 Mounting provision.

Position 1 has the familiar Ultra Tec “keyhole” mount cutout – and the Motor

Housing has the familiar cam gripping mechanism.

In removing the Motor from Position 1, loosen the cam lever, pull the Motor

Housing forward and up (see the photo).

Insertion is the reverse of that action – insert – side back firmly against the

two dowel pins (note that there are two notches in the Motor Housing that the

pins fit into) – and tighten the lever to lock.

For Position 2

Before setting the Drive Motor into position 2, set the

Position 2 Spacer Bar in place, engaging the two

dowel pins.

Page 11

Revision 7 (Feb 2019)

Position 2 continued:

Slide the Motor into position – push the Drive Motor firmly against the rear of

the Spacer Bar - the rear pins on the Bar will engage the notches on the

face of the Motor Housing. Lock the Drive Motor there.

4.3 The Mast-Most often, preparation of the workpiece is done on the standard flat Faceting Machine, and

after the preparation is complete, the Mast, holding the stone, is moved to the Fantasy unit for further

work.(in “concave” faceting – as distinguished from “fantasy” – that’s always the case).

4.3.1 The Mounting Block. The Mounting Block holds and positions the Mast in relation to the Mandrels

and other cutting and polishing tools.

The “keyhole” cutout on the Mounting Block accepts the cam-lock mechanism of the Mast.

4.3.2 Mounting the Mast.

The Mast is mounted onto the Mounting Block, fitting into the “keyhole slot” in the

Block. Perform a visual alignment—just sort of point things in the right direction

(no precision required) and tighten the cam, locking the Mast in place.

There will be an careful alignment of the “Home” position later.

Page 12

Revision 7 (Feb 2019)

4.3.2.1 Affixing the Lateral Stop Bracket to the Mast. For fantasy cutting, it is necessary to eliminate lateral

swinging of the Yoke – to align the Quill, and the dopped stone it holds, on the centerline of the GrindingPolishing tool. To do this, a “Lateral Stop Bracket” is provided – it mounts onto the Mast. Here are the

mounting steps.

Here is the Lateral Stop Bracket that eliminates Yoke lateral swing –

and allows tweaking of the fixed lateral position.

The Lateral Stop Bracket attaches to the Riser Block (the Block that rides up

and down on the Leadscrew), - a forward-extending arm of the Bracket extends

forward, making contact with the Yoke – acting as a brake on the Yoke –

preventing lateral movement. The actual contact with the Yoke is through a

Screw (a Screw that can be used to tweak – fine adjust - the lateral position of

the Yoke, aligning the Quill with the centerline of the position 1 Motor

The Lateral Stop Bracket attaches to the Riser Block, held by two screws.

This picture shows the upper of the two screws being inserted – ready to be CW

tightened. If you have an old Ultra Tec Mast, you will see those two side holes

are missing – in which case you will see that the Bracket Plate also works as a

C-clamp gripper). Finish mounting that plate – snug the screws. (Can the Cclamp screws be used as backup for the two main screws? Yes, if you feel like)

Page 13

Revision 7 (Feb 2019)

Mounted. The forward Screw pointed at the Yoke is treaded in, making

contact with and stabilizing the Yoke. Tightening (or loosening) that forward

screw can be used to tweak the set lateral position.

Now, - final setting of the aligned HOME position

4.3.2 The Position 1 “Home” position. You have already mounted the Lateral Stop Bracket.

Aligning the Mast to the Drive Motor- Lateral alignment of the Mast in relation to the

tools driven by the Drive Motor is important. It establishes a 0 reference that relates

to the stepped positions of the work piece. Alignment, and repeated alignment, if

that becomes necessary, typically takes a few minutes. Here it is, step by step:

a) Ready the Drive Motor. Insert one of the nominal 6 mm Dops into the Collet, and

lock it there.

b) Ready the Mast. Mount the Mast onto its Mounting Plate. Don’t worry about

the exact position – it will be adjusted later.

4.3.3 You have already mounted the Lateral Stop Bracket.

Insert one of the nominal 6 mm Dops into the Quill, and lock it there.

c) Offset the Y position In – away from the front edge – about 6.5 mm (reading on

the indicator). Use the Adjustment Knob.

Page 14

Revision 7 (Feb 2019)

d) Then, set the quill at 90°, pointing forward, with the Mast height position set so

that the dops are in the same horizontal plane. This level setting is not critical, it

just needs to look ok by eye - it will look something like this photo (there has been

nothing “critical” about the positioning, so far).

e) Watching the spacing of the Dops, manipulate the position of the Mast –

making the gap between the Dops narrower and even, finally bringing the Dops in

contact. Do that by adjusting the position of the Mast on its Mounting Plate. The

final “tweaking” – reducing the gap to very little, and getting the sides parallel – can

be assisted, if necessary, by tweaking (in tiny increments), the front adjusting

screw on the already mounted Lateral Stop Bracket.

Visual observation of the gap is really ok, but if you wish, you can confirm the

parallelism by using the “feeler” method, as shown (some slick paper from a magazine

will do).

Draw back the position of the Mast, so the there is no overlap of Dops, return the main

Y-Plate to its original position – alignment accomplished – the Dops will be in a

straight line. The Drive Motor will be ready to accept a grinding or polishing tool and

the Mast ready to accept the work piece.

4.4.2 Position 2 Alignment-The Position 2 “Home” setup is a matter of aligning the cutting plane of the tool so

that it intersects with the pivot axis, providing a retrievable dimension starting point (¶ 4.2.1 showed mounting

the Drive Motor in Position 2).

To do this alignment, before setting the Drive Motor

onto position 2, set the “use the Position 2 Spacer

Bar “in place, engaging the two dowel pins.

Slide the Motor into position – push the Drive Motor firmly against the rear of

the Spacer Bar - the rear pins on the Bar will engage the notches on the face

of the Motor Housing. Lock the Drive Motor there.

What you have done is to position the Drive Motor so that the Slitting Tool is

close to the desired central position – ready for the final tweaking…

Insert the grooving tool with the Collet lightly tightened, so that the tool can

slide in and out slightly, as part of the alignment procedure (that is, setting the

cutting plane of the tool in line with the θ pivot axis - “on center”).

Page 15

Revision 7 (Feb 2019)

Set the right-angle Alignment Plate in place (down onto the plate) the back

edge pushed against the face of the Drive Motor Spacer. Slide it toward the

tool. The V groove in the Brass Rod will engage the tool - the Brass Rod

moves in and out - longer or shorter - to manage engagement with the tool.

The V groove of the Rod is on center - manipulate the tool in-out until it aligns in

the V groove, you can see it and feel it. Lock the tool there - it is now on center

of rotation.

This technique will work with ball-shaped or cylindrical tools as well.

4.5 Horizontal Work Positioning – X, Y, θ

4.5.1 X Positioning.

When you want to adjust the position of the workpiece relative to the tool in

an X direction, you turn the nearby Knob [C] – CW rotation of the Knob

brings the tool closer to the front edge, CCW rotation moves it away from

the front edge. What you are actually doing is adjusting the position of the

X Traveling Plate which carries the Tool Drive Motor. The X position is

reflected on the X Dial Indicator.

At start out, when the Indicator was mounted, it was set to a readout of 0-0.

If for some reason it is no longer 0-0 (you may have been fiddling with the

machine—that’s fine), reset it there. (Notice, by the way, that at this Home-

0 setting, the close edge of the X Traveling Plate is pretty well aligned with

the close edge of the Baseplate – that may become handy information

later on).

The Traveling Plate has a range of +/- 25mm (1”) from the Home-0 position – so, features as far apart

as 50mm (2”) can be put onto the workpiece.

The range of the Dial Indicator is 20mm (.8”) so, from its initial setup position (“Home 0”), an X offset up

to 20mm can be done. That allows for features with up to 40mm (1.6”) of separation on the stone

without resetting the indicator position.

For X offsets larger than 20mm, resetting of the Dial Indicator is needed. To do that—at the end of the

20mm stroke, with the Indicator reading 0 and the inner rotation counter at 20 (0-20), loosen the Knob

that holds the Anvil in position and reset the Anvil so that the Indicator again reads 0-0, lock the Anvil.

It is now ready for the setting of new additional offset positions. You can get back to the Home-0 by

running the process backwards. An example: suppose you have performed the resetting and continued

working on the stone, and you’ve put in your last feature with the Indicator reading, lets say, 4.5mm

(that is, the inner dial now reads 4, and the main dial now reads 5) and, you’d like to reset to the Home0 position. Turning the C Knob, return to the 0–0 Indicator reading, unlock the Anvil and reposition the

Anvil so that the indicator reads 0-20; again turning the C Knob, return to the 0-0. That’s it, you are back

to Home-0.

All of this allows you to return to any particular offset feature position – for modification, polishing,

whatever, if you kept track of the Indicator reading where you placed that particular feature.

4.5.1.1 If you get “lost” and need to reestablish the X Home-0?

Remember? You took note that when you did the original alignment of the Mast to the tool--the close

edge of the X Traveling Plate was aligned with the close edge of the Baseplate. If you get “lost”

(perhaps after going through a number of re-settings of the X position – and just losing track), it is

helpful to know that edge-to-edge relationship exists – a sort of “macro” target.

You can precisely reset the X home 0 position with this procedure: Using C, move away from that

edge-to-edge condition by perhaps a half inch, and, referring to Section 4.4, above, set the Alignment

Page 16

Revision 7 (Feb 2019)

Plate in position, set the Quill of the Mast onto the top edge of the Alignment plate (as in 4.4, figure 4 –

but keeping the Mast firmly locked to the Mounting Block), drag the Quill along the top of the Plate

toward the notch by rotating C. When the Quill “pops” firmly into the notch, that’s it. Reset the X

Home-0.

4.5.2 Y Positioning.

This is similar to the preceding section on X positioning – except, that in making adjustments, instead of

moving the tool’s position, you are moving the Mast’s position. When you turn the Knob – CW rotation

withdraws the Mast from the Tool Drive Motor, CCW rotation moves it closer to the Tool Drive Motor.

What you are actually doing, of course, is adjusting the position of the Mounting Block which carries the

Mast. At the end of the alignment process, the Y Indicator was left disengaged—and there are

common conditions (described below) where engagement of the Y Indicator remains unnecessary –

and so remains disengaged. When it is needed, however, the Y position is set on the Y Dial Indicator.

There is no strict Home-0 position for Y as there is for X. This is because Y positioning is a matter of

user judgment – until a Y feature is added. Once a Y feature is added, that position can be used as a

positioning reference – that is, when that position is selected, the indicator can be set so that

subsequent positions are measured and resettable. (An observation: Usually, the workpiece stone is

significantly narrower in the Y dimension than it is in the X dimension, making re-setting of the indicator

a less likely requirement).

At the start of the process (after completing alignment of the Mast to the Tool Drive Motor), set the first

working angle on the Mast, set the working height of the Mast (the Z direction) and, using the Knob,

position the stone in relation to the tool. Turn on the Reciprocation Motor so that you can observe the

amplitude of the Tool’s movement, and set the stone’s Y position in relation to it – (a non-critical

judgment call).

If you are working with a cylindrical tool, with the Motor in Position 1, there is no reason to engage the Y

Indicator. If, however, you are working with the Motor in Position 2, you would engage the Y Indicator.

The Mounting Block has a range of 3”. Similar to the X situation, the Indicator has a range of 20mm

(8”). Read the part of paragraph 4.5.1 that deals with re-setting of the Indictor, if that becomes

necessary—it works the same way as the X position (except that a specific Home position, as X has, is

replaced in the Y direction by a selected reference position (see the second paragraph of this section,

above, for a description of this setting).

4.5.3 θ Positioning This controls the angular position of the tool, in the horizontal plane, relative to the

workpiece.

Just as X, Y and Z are used to describe linear directions of positioning. θ, the Greek letter “theta” is used for

radial positioning around an axis. We could have called it “indexing”, as it is called on the faceting Mast, but

here, the designation of θ avoids confusion between those two devices.

θ positioning is on the Y traveling Plate, and the entire plate moves to any new θ setting. The axis of θ rotation

is the centerline of the Pivot Knob which intersects the centerlines of the Tool drive Motor in Position 1 and

Position 2 – and so, this axis is directly associated with the Home-0 alignment – as the θ position is moved, the

tool remains on the θ axis – allowing radial features to be centered around a settable point. θ can be set

through a full 180º range - settings in 5º increments are standard (1º increments are available with the HD

Protractor mod).

Page 17

Revision 7 (Feb 2019)

Note that when the Y traveling Plate is rotated to a new θ position, it carries with it the Reciprocation

Mechanism – continuing the reciprocation in line with the cutting action.

At time of alignment, θ is set at 0º (left photo).

To change the θ position, loosen the Pivot Knob, push in the lever, as shown -

that swings out the detent pin, and swivel the Y Traveling Plate to align the new

angular position (to move the Plate, grip the housing of the Reciprocating

Motor) - move to the new angular position.

(NOTE: with the 1º HD Protractor installed, see the pictures below, the detent

pin is locked out and angular position is set visually, using the line on the

indicator block, and locked with the Pivot Knob)

4.5.3.1 Locking the θ Position

When the θ position is set, it can be

locked by tightening the Pivot Knob. The

standard 5º notches will usually have

sufficient locking force without tightening

the Knob, but, if the HD Protractor Mod

is installed, tightening of the Knob is

necessary. In general, finger tightening

is sufficient, but, the Knob does have a

side hole for added tightening or

loosening, if desired.

A CW angle setting is shown on the left,

A CCW angle setting is shown on the

right.

5.0 TOOLS

5.1 Mounting Tools into the Tool-drive Motor

Page 18

Revision 7 (Feb 2019)

5.1.1– Cylindrical tools

Cylindrical tools (commonly referred to as “mandrels”) are used when

the Drive Motor is in Position 1. In that position the reciprocation

action is always in line with the axis of the tool. Regardless of the θ

position, the reciprocation action remains in line with the axis of the tool

and the tool’s rotational axis is aligned to the rotational axis of the θ

settings.

5.1.2 Slitting Tools.

Slitting tools are used when the Drive Motor is in Position 2, in that position the reciprocation action is always

in line with the peripheral edge of the tool. The reciprocation action remains in line with the peripheral edge of

the tool regardless of the θ position,

Ultra Tec supplies two 90° included angle Slitting Tools in the tool kit – Copper and Phenolic. Other slitting

tools are available.

These mount onto a special Adapter Shaft:

The Slitting tools…

A slitting tool is selected…

Ready the Adapter Shaft and screw, and the wrench. Remove the screw and

set it to the side for a moment…

Page 19

Revision 7 (Feb 2019)

Mount the tool to the Adapter Shaft – carefully and patiently – it’s a close fit, to

maintain good concentricity. Engage the screw and tighten it snugly.

The slitting tool is positioned over and in line with the axis of θ rotation (not

always critical, but sometimes desirable).

5.1.2.1 Purchased Slitting Tools

For “off the shelf” slitting tools that come with attached shanks, ¼“, 1/8”, or 3/32”, use the following procedure:

A) After moving the Motor to Position 2, insert the Tool Adapter (the same as used for the cylindrical tools)

with a diameter appropriate for the tool you will be using – lock it.

B) Insert the tool. You will have some leeway in setting the linear position of the cutting tool. Lock it in

position with the set screw.

5.2 CUTTING AND POLISHING TOOLS

We’ve learned that Concave faceting IS strongly related to flat faceting, and is properly called Concave faceting.

A comparatively small number of cylindrical tools (mandrels) accomplish the task. Yes, of course, it can get

pretty “fancy”, and there is room for creativity, but still, within faceting design “discipline”. A look for concave

tools on Internet sites reveals the availability of a number of diameter sizes (sometimes in inches, sometimes

metric) – in several materials.

Fantasy cutting, on the other hand is a craft much more closely related to carving. It is Geometric Carving, in

which the symmetry (or purposeful non-symmetry) is craftsman controlled—craftsman “dreamed up”. In Fantasy

cutting, tools are a major consideration. The number of tools that might be useful becomes very many. A visit

to the workshop of such a craftsman typically reveals a wall of tools with sizes ranging from very small to very

large, of different materials – much of it the result of experimentation.

It is a situation in which the selections are many, and the choice is growing. It is also a situation in which we

understand that many purchasers of a Fantasy Machine have already ventured into this sort of work and have a

collection of favorite tools.

Our plan is that we will supply certain materials – in certain sizes – and include them in a “starter kit”. The

“standard” materials are Copper, Maple, and Phenolic. Right now, the sizes are limited – but if you need a

certain size, contact us (email is best – info@ultratec-facet.com), we will try to accommodate your need. (and if

it is not a completely “oddball” size, we may add it to the list of available sizes).

Technically, we can offer other materials – specifically, we’ve made and experimented with Zinc and Corian

mandrels. Right now, there’s no “plan” to proceed with standard tools in those materials, but if you have a

strong wish to have a particular tool, again, talk to us about it – we have a desire to support your efforts in this

relatively new field.

All in all – faced with the impossibility of offering and having in inventory hundreds of tools – it is better for us

NOT to be a middle man. It is better for you, the user, to purchase directly from the tool suppliers – google

them. Here are a few suggestions—

Page 20

Revision 7 (Feb 2019)

● Special materials—that have been very successful in flat faceting – “Lightning Laps” and “Batt

Laps” have made mandrels available.

From the Lightning Lap page – “ The advantage of the LLMandrel is in the ability to have just one lap to do all your

work, just by cleaning and changing the polishing medium.

Your angle-integrity is preserved, as there are no lap changes” (www.lightninglap.com).

● Many companies offer a large array – shapes and sizes - of carving tools. The finest diamond

mesh that is available is 3000.

Hard Felt Bobs. The emphasis is on the “hard” – the right type to use, there’s a rock-hard [too

hard] and a soft [too soft] – double check when you order. Inexpensive (a little run-out won’t

hurt at this point), the stone has been formed - let it bounce around with a slurry.

5.2.1 THE KIT:

Included are Cylindrical Tools of Copper, Phenolic, and Maple, in diameters of 8mm, 13mm, and 17mm

Included are Slitting Tools of nominal 24mm diameter of Copper and Phenolic with included angles of 90º and

Adaptor Shafts.

6.0 CUTTING INFORMATION

● A very useful book – an interesting and informative read - confirming that “Fantasy” is close to carving – is

Lapidary Carving for Creative Jewelry by Henry Hunt. It’s new at $25 – very worth it.

● This is, we hope, in the “coming soon” category –an instruction book by Dalan Hargrave. Very good news!

Dalan is an extraordinary lapidary artist who is willing to share his expert techniques.

● The various tools would be used with Diamond Powder slurries – coarse diamond for cutting, and, for

polishing, in addition to fine diamond (14K – commonly used by many professionals, 50K – used by

“perfectionists”), Aluminum Oxide slurry or Cerium Oxide slurry can be used. Various oils are used as

carriers – very commonly, olive oil (a carry-over [?] of the use of olive oil in diamond faceting).

Miscellaneous Minor notes:

● There are inexpensive contact holders available in drugstores – plastic, two compartment

devices. These are very handy – one compartment is used for holding dry powder; the other

holds the diamond/oil mix. The hinged lid closes nicely. Use a black marker to identify the

mesh inside.

Page 21

Revision 7 (Feb 2019)

● When using a ball end cutter, straight forward plunging leads to swirl marks (the dead center

isn’t moving much – it’s a dead center all right). Approaching the stone from the side at some

angle or other provides the same cutting profile, but much swiping action.

● Setting a rapid reciprocation is generally advantageous. The side swiping action acts against

the radial grooving that develops in the small contained areas.

● Through much of the process you will probably not be using water or thin slurry, at which times

you may not want to use the Splashguard. The clear plastic part is easy to remove and set to

the side. Leave the black part in place (it functions to protect the motor area).

Appendix

A. HD Protractor Mod. (1901.85) This modifies the theta

positioning increments from the standard 5º to 1º. The Kit

includes the items shown.

It is a self-installable Kit - only a small screwdriver is

needed.

Loading...

Loading...