Ultrasource Magnum 6000 Specifications

M A G N U M S E R I E S 6 0 0 0

M A S S A G E R / T U M B L E R

Why vacuum tumble?

Vacuum tumbling is a method of marinating meat,

poultry, and seafood and is designed to provide

ready-to-cook, value-added products. Without

vacuum tumbling, marinating requires 24-48

hours of soaking before the product is ready

for loading into the smokehouse. Vacuum

tumbling opens the cell structure of the

product allowing the marinade to penetrate

evenly throughout the product, which

eliminates flavor “hot spots” and “dead zones.”

The vacuum tumbling process significantly reduces

the production time.

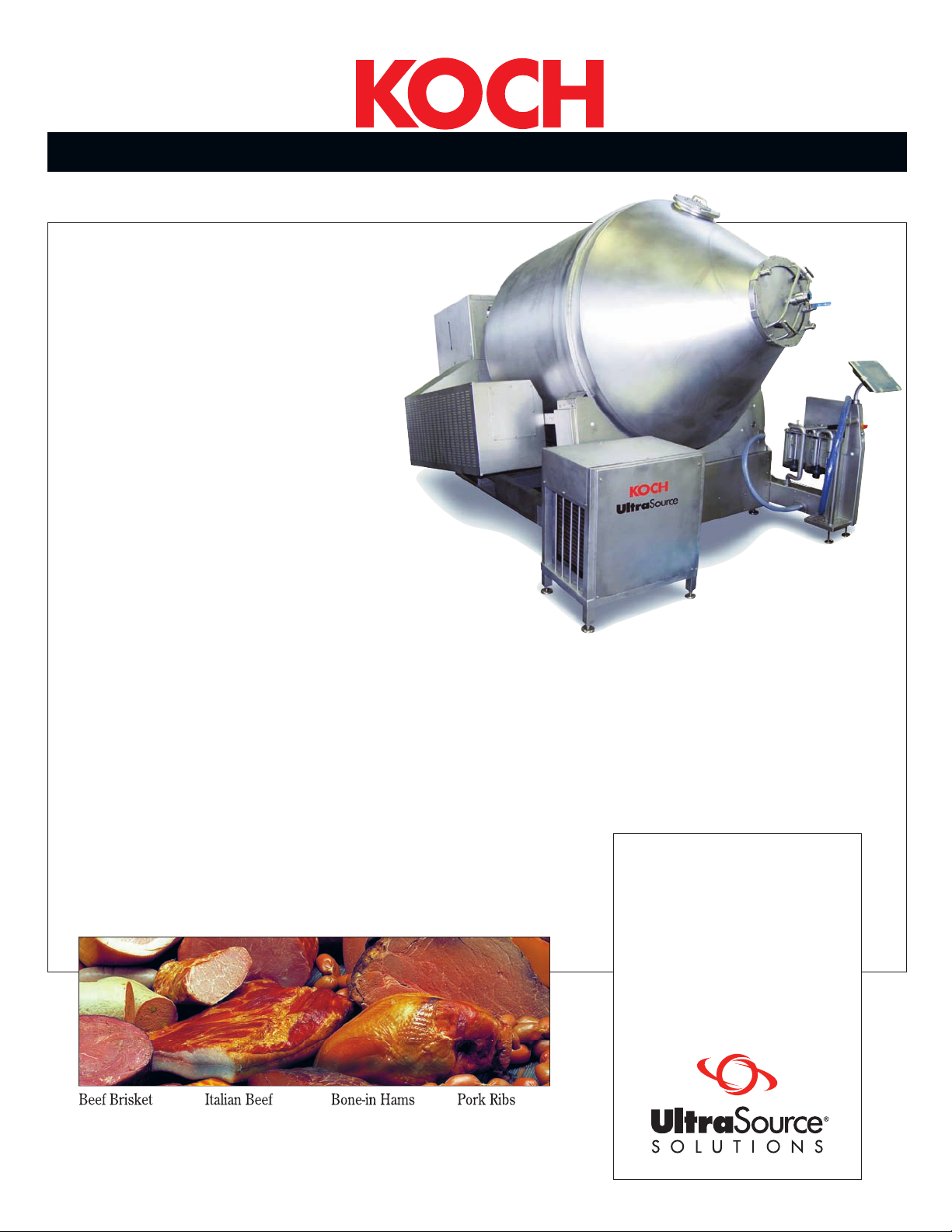

Designed to meet the needs of large and industrial-sized meat

and poultr y processors, our stainless steel Magnum Series 6000

massager is equipped with a uniquely designed baffle that rotates

and slides the product throughout the drum during processing. This results in the product remaining against

the walls and baffles of the drum versus the actual “tumbling” delivered by competitor models. The advantage is

a more gentle massaging action while extracting protein in a highly efficient manner under constant vacuum.

Double-jacketed cooling is also available on our Magnum 6000 to compensate for the temperature rise that

occurs during the massaging process.

Benefits of Vacuum Tumbling

• Improved product quality (juicier, more tender, and flavorful)

• Increased profit margins through the delivery of ready-to-cook,

value-added products

• Increased productivity through reduced handling/processing time

• Even distribution of brine throughout product, which eliminates

“hot spots” and “dead zones”

Vacuum Tumbled Products

Beef Brisket

Beef Fajitas

Beef Jerky

Beef Ribs

Corned Beef

Italian Beef

Marinated Steaks

Roast Beef

Babyback Ribs

Bacon

Bone-in Hams

Boneless Hams

Picnic Hams

Pork Fajitas

Pork Loins

Pork Ribs

Pork Steaks

Chicken Breasts

Chicken Fajitas

BBQ Chicken

Buffalo Wings

Contact us at:

Koch Equipment LLC

1414 West 29th Street

Kansas City, MO 64108-3604 USA

800-777-5624

Telephone: (816) 753-2150

Fax: (816) 753-4976

E-mail: info@kochequipment.com

Internet: kochequipment.com

© Copyright 2010 Koch Equipment LLC

M A G N U M S E R I E S 6 0 0 0 M A S S A G E R / T U M B L E R

Features:

• 6,000-liter drum capacity (recommended load:

60% of capacity)

• Available with or without cooling

• Driven via gear motor and chain

• Automatic integrated lift (holds 400-lb.

capacity buggy)

• IP-65 rated ISC-B20 touch-screen computer control

with Ethernet interface stores up to 99 product

programs. Remote connection enables collection

of production data, including:

• Massaging speed and duration

• Rotation direction and position of drum

• Processing time / Rest time

• Vacuum / Ventilation

• Temperature

• Thawing time (optional)

• Personnel identification

Options:

• Double-jacketed or insulated cooling

• Defrosting system

• Tiltable model (recommended load: 70% of capacity)

• Conveyor belt for loading

• Jumbo lid opening

• Hydraulic lid

• Vacuum-suction filling/loading system

• Built-in weight cells to record production quantities

• Mobile lift (holds 400-lb. capacity buggy)

• Connection with existing cooling system via

heat exchanger

• Additional baffles

Technical Specifications:

• Drum speed: 0.4-6 rpm

• Electrical: 220 volt, 60 Hz, 3-phase

• Electrical (connected load): 11.0kW

• Dimensions (without cooling):

15.2-ft. L x 9.9-ft. W x 6.9-ft. H

(4,624mm x 3,022mm x 2,114mm)

• Net weight (without cooling): 5,490-lbs. (2,490kg)

• Dimensions (with cooling):

16-ft. L x 10.2-ft. W x 6.9-ft. H

(4,900mm x 3,100mm x 2,100mm)

• Net weight (with cooling): 9,259-lbs. (4,200kg)

Optional defrosting system

Loading...

Loading...