Ultrasource 6600 MG Specifications

T H O M P S O N 6 6 0 0

M I X E R / G R I N D E R

T H O M P S O N 6 6 0 0

M I X E R / G R I N D E R

Contact us at:

Koch Equipment LLC

1414 West 29th Street

Kansas City, MO 64108-3604 USA

800-777-5624

Telephone: (816) 753-2150

Fax: (816) 753-4976

E-mail: info@kochequipment.com

Internet: kochequipment.com

© Copyright 2010 Koch Equipment LLC

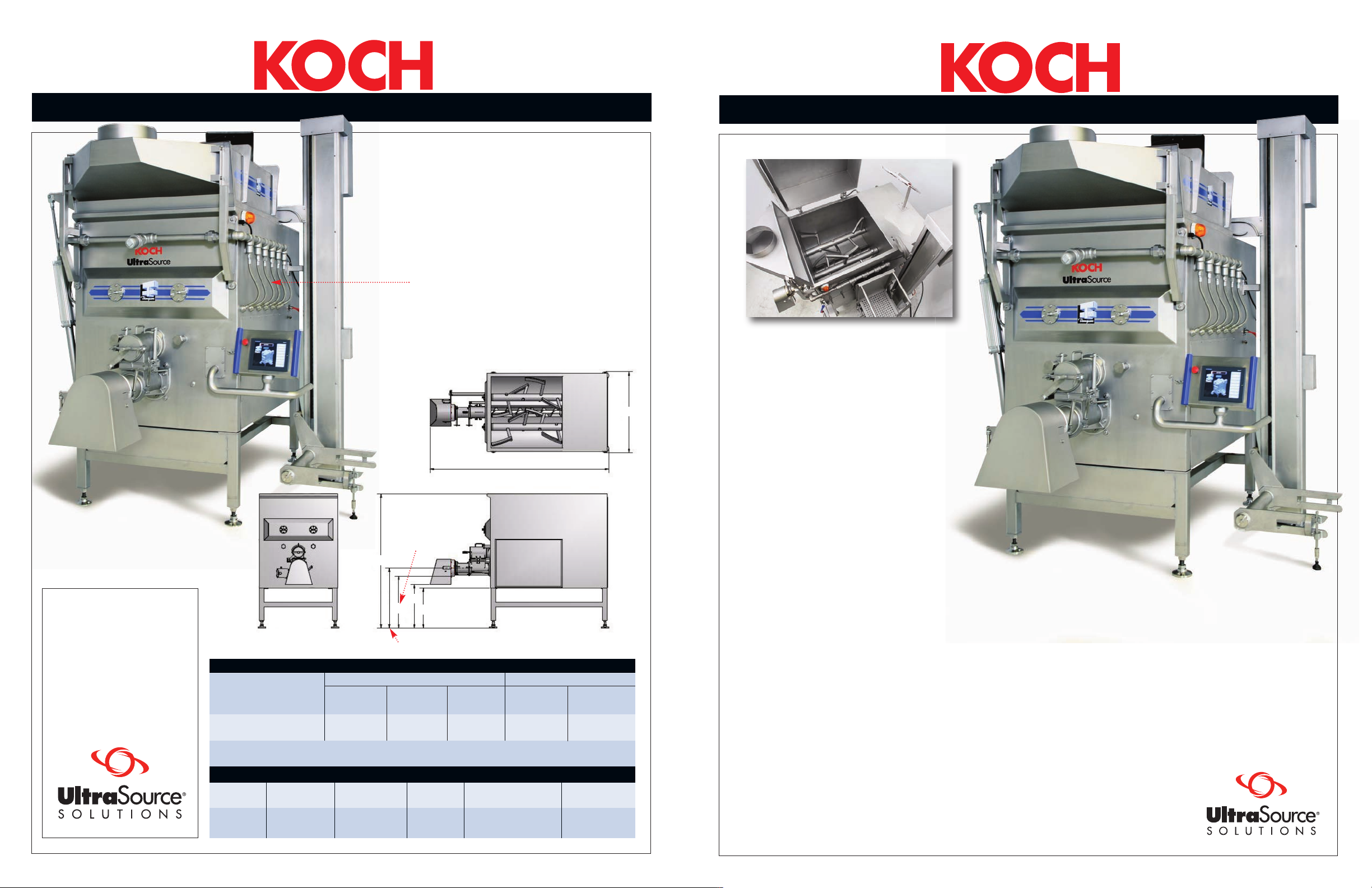

Shown with CO

2

bottom injection

2,995

TOP VIEW

(Under Lock Ring)

2,257

730

875

675

LEFT SIDE VIEW

1,010

Production Capacities (per hour)*

Muscle and Trim Sausage Emulsion

Model

6600-66F - #66 6,000kg 5,200kg 3,600kg 5,000kg 3,600kg

(220mm) grinding head (13,228-lbs.) (11,464-lbs.) (7,937-lbs.) (11,023-lbs.) (7,937-lbs.)

*Production rates based on -1° C to +4° C meat temperatures

Technical Specifications

Model

6600-66F 900 liters (1,320-lbs.) 5.5-hp 7.5-hp 30-hp

Hopper Mixing Mixer Feedscrew Grinding

Volume Capacity Motor Motor Motor

12mm 6mm 3mm 6mm 3mm

hole plate hole plate hole plate hole plate hole plate

(variable speed drive) (two-speed)

FRONT VIEW

Featuring a twin-paddle hopper

design and counter-rotating,

multi-directional mixing

paddle design

1,355

Designed for large volume production

environments, our Thompson 6600 industrial

mixer/grinder is capable of grinding fresh

or frozen meat (1 ½” pieces – or flaked

material – at -10°C) while producing up to

6,400 kilograms (14,110 pounds) per hour

(depending on plate size, product temperature

and product). With a hopper volume of 900

liters, the production range is endless.

The Thompson 6600 is manufactured of heavy-duty stainless steel and feature

seam-welded corners inside and out. The smooth easy-to-clean surfaces, heavy-duty stainless steel

feed screws, grinding head, lock ring and mixing arm reflect the quality construction of this machine.

The Thompson 6600 is equipped with twin solid stainless steel feedscrews – one which is variable speed and

rotates slower than the other feedscrew to convey the product from the hopper into a uniquely designed channel

where the two-speed grinding feedscrew is located. The variable-speed transfer feedscrew enables the operator

to adjust the machine’s product feed rate according to the application. This results in a constant supply of

material to the grinding feedscrew for continuous output based on the product and product temperature

(i.e., whole muscles, frozen flaked meat, sausage emulsion, or coarse ground product).

While mixing, the transfer feedscrew operates in reverse, shifting the product away from

the transfer feedscrew channel, resulting in thoroughly blended batches. This action,

combined with the multi-directional product movement of the ribbon-style paddle,

maximizes particle definition throughout the meat mixture resulting in a very

homogenous blend.

T H O M P S O N 6 6 0 0

M I X E R / G R I N D E R

Counter-Rotating, Multi-Directional Mixing

Results in Thoroughly Blended Batches

To increase the mixing efficiency required when blending

such large batches of product, our 6600 model features

counter rotating multi-directional overlapping twin

mixing paddles combined with the reverse action

transfer feedscrew. In addition, the transfer feedscrew

operates in reverse, shifting the product away

from the transfer feedscrew channel, resulting

in thoroughly blended batches.

The result: Minimal pressure.

Clean cut. Minimal temperature rise.

Maximum particle definition.

The #56 size (152.4mm) grinding head delivers

high production rates for a variety of products,

including fresh and tempered or flaked frozen

meat. Equipped with reliable independent gear

drives, you never have to worr y about down time

due to belt or chain failure.

Features:

• #56 size (152.4mm) grinding head

• 900-liter hopper volume

• 600kg (1,322-lbs.) mixing capacity

• Seamless, fully-welded, heavy-duty

stainless steel construction inside

and out

• Automatic forward/reverse

mixing action

• Solid twin stainless steel feedscrews,

stainless steel mixing paddle, and

stainless steel grinding head

• Independent helical gear drives for

mixing and grinding

• Heavy-duty locking casters

• Inspection mirror

From quality design to tough construction,

outstanding performance, and amazing reliability,

that’s Thompson!

Options:

• #66 (220mm)

• Variable speed drives

• PLC programmable controls

• Digital thermometer

• Measurable discharge shut-off

• Pneumatic lid

• Vacuum

• CO2cooling

• Bone removal system

• Feedscrew knife and plate cart

• Automatic lift holds 400-lb. capacity buggy (buggy not included)

• Safety interlocking inspection step (magnet coded)

• Heavy-duty interlocking dome-shaped lid with viewing slots so spices or

other ingredients can be added while mixing. Mixing action stops when

safety lock on lid is released.

Loading...

Loading...