Ultrasound Technologies PD1, Fetatrack 120 Doppler Service manual

Ultrasound Technologies Ltd

PD1 & Fetatrack 120 series Dopplers

Service manual

©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom.

T +44 (0) 1291 425425 F: +44 (0) 1291 427093

E: ultratec@doppler.co.uk W: www.doppler.co.uk

PD1 & FT120 service manual Issue 3 Jan 2007

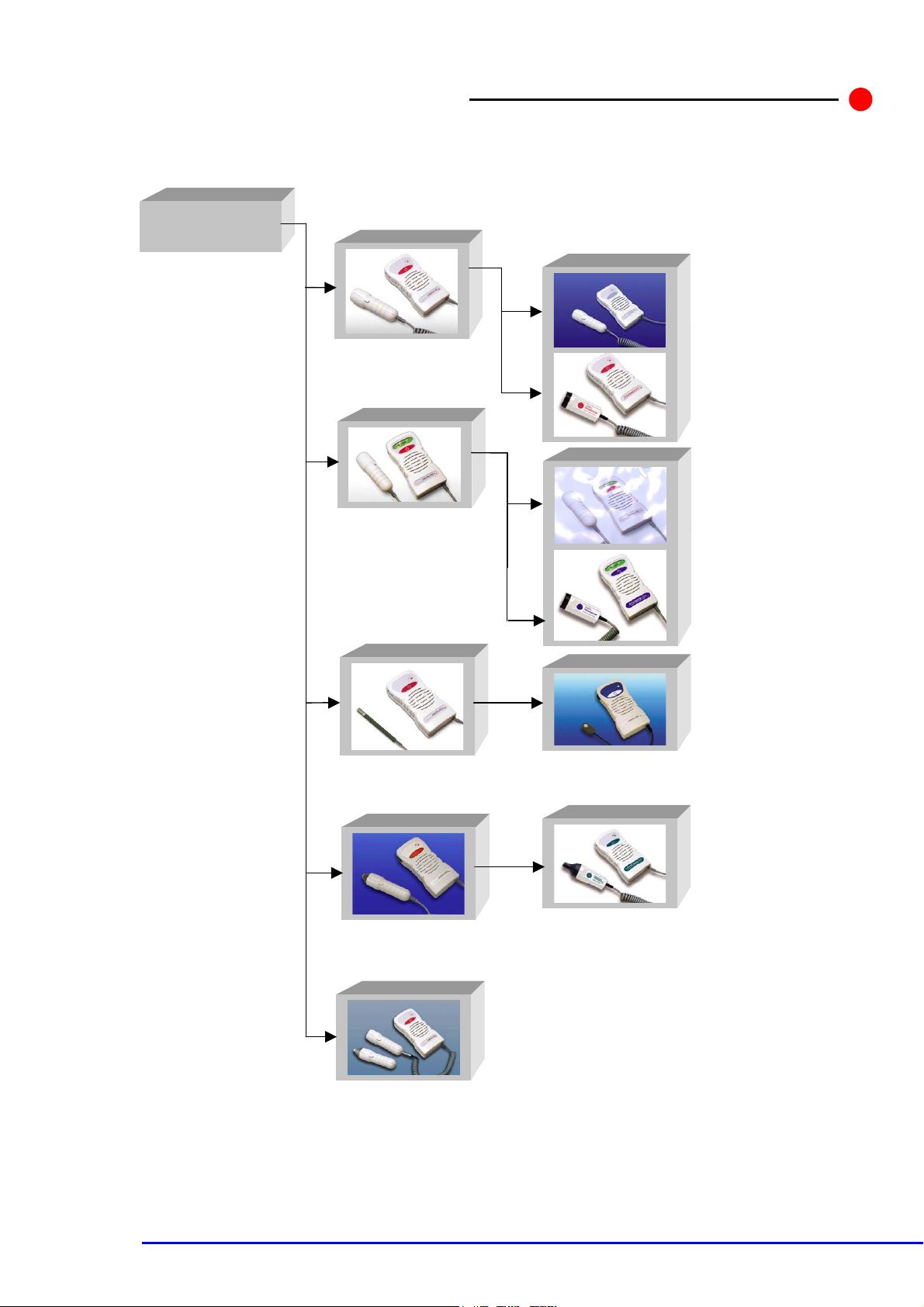

V

Product Group

Ultrasound Technologies Ltd

Products covered by this service manual

PD1 series

pocket dopplers

Product version

PD1 audio pocket

doppler

PD1+ fetal doppler

with FHR display

Product variation

Babypulse home use

doppler

Fetatrack 120 audio

doppler

PD1dwr waterbirth

doppler

Fetatrack 120+ fetal

doppler with FHR

PD1v vascular

doppler

PD1cv low cost

vascular doppler

PD1v flat probe

vascular doppler

ascutrack 120

vascular doppler

PD1combi fetal /

vascular doppler

PD1 service manual Issue 2 January 2005

©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom.

T +44 (0) 1291 425425 F: +44 (0) 1291 427093

E: ultratec@doppler.co.uk W: www.doppler.co.uk

1. 0General Introduction

1.1.

Introduction

14

Re Order Information

1.2.

15

Symbols

1.3.

16

CE Marking

1.4.

17

Guidelines for identifying and resolving adverse EMC conditions

1.5.

18

Specification

1.6.

19

2.

Description of the Instrument

1

2.1.

Audio Unit.

20

Audio Unit

2.2.

21

Audio Unit

2.3.

22

Dismantling Instructions

2.4.

23

Audio Unit

2.5.

24

Transducers

2.6.

25

3.

Circuit Description

2

3.1.

Introduction

26

Audio Unit Power Supply

3.2.

27

Battery Low Indicator

3.3.

28

Ultrasound Transducer

3.4.

29

Oscillator and Detector

3.5.

30

Receiver and Detector

3.6.

31

Audio Amplifier

3.7.

32

Velocity Processor

3.8.

33

4.

Test and Calibration

3

4.1.

Introduction

34

Performance Checks

4.2.

35

Test Procedure

4.3.

36

Audio Unit

4.4.

37

Transducer

4.5.

38

Velocity Processor

4.6.

39

Transducer Calibration

4.7.

40

5.

Fault Finding

4

5.1.

Fault Finding Guidelines

41

6.

Parts Lists

5

6.1.

Audio Unit PCB Assembly

42

Audio Unit with heart rate PCB Assembly

6.2.

43

2MHz Transducer assembly

6.3.

44

General Assembly

6.4.

45

+ units General Assembly

6.5.

46

7.

Drawings and Circuit Diagrams

6

Ultrasound Technologies Ltd

CONTENTS

PD1 service manual Issue 2 January 2005

©Ultrasound Technologies Ltd, Lodge Way, Portskewett, Caldicot, South Wales NP26 5PS, United Kingdom.

T +44 (0) 1291 425425 F: +44 (0) 1291 427093

E: ultratec@doppler.co.uk W: www.doppler.co.uk

Ultrasound Technologies Ltd

1. 7General Introduction

1.1. 47Introduction

This service manual is written to support the maintenance and repair of the PD1 Series Doppler detectors.

Servicing of this equipment should be performed by a qualified technician, after carefully studying this manual.

The drawings and circuit descriptions in this manual are correct as of the date it was prepared, however, however the Company

reserves the right to make changes to improve the operation of the instrument. If your instrument does not exactly match the

information in this manual, contact the manufacturer or distributor for revision information.

Inspect the instrument upon receipt, in the unlikely event that the unit has been damaged, notify your distributor or Ultrasound

Technologies directly at the following address: -

Ultrasound Technologies Ltd.,

Lodge Way, Portskewett

Caldicot, NP26 5PS

48

South Wales , UK

Telephone: +44 (0) 1291 425425

FAX: +44 (0) 1291 427093

E-mail: service@doppler.co.uk

49

Retain the packing material for possible future use.

Important Note:

In the unlikely event that the instrument must be returned to Ultrasound Technologies for service or for any other reason, use

the same packing material in which the instrument was delivered.

If this is not available, the instrument should be packed in such a way that will provide adequate packing. The Company will not

accept any responsibility for loss or damage due to improper use of packing material.

©Ultrasound Technologies Ltd Page 1 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

1.1 50Re - Order Information

Listed below are the consumables used with the PD1 Series Pocket Dopplers: -

Description

Ultrasound Coupling Gel 0.25ltr.

MN1604 series Alkaline Battery

51

1.2

Symbols

52

The following symbols have been used on the PD1 and are here defined according to IEC60601

IEC Symbol 878-02-02

Type B Equipment.

IEC Symbol 348

Attention Consult accompanying documents

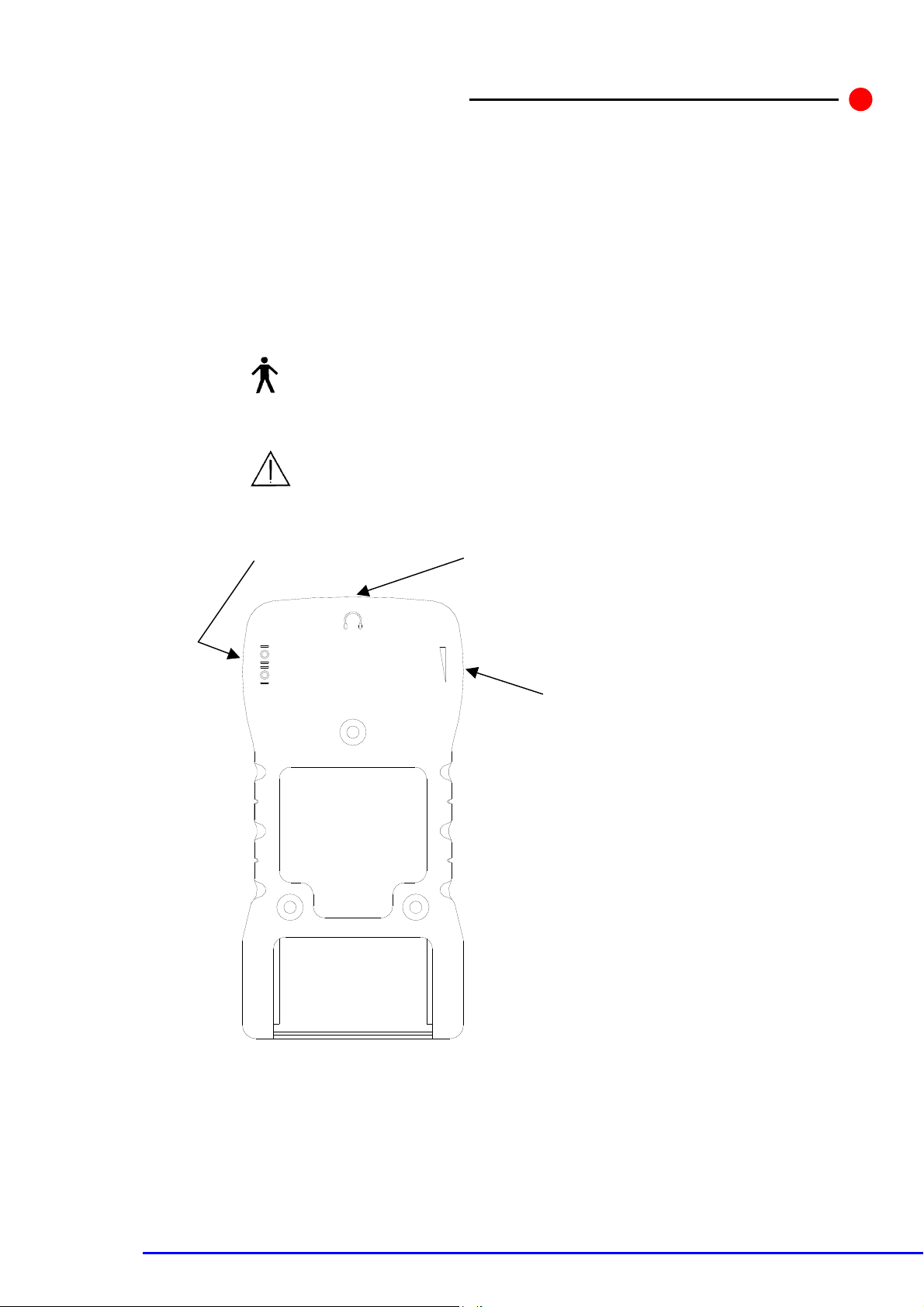

86

Serial DATA Out

Headset Output

Volume Control

Rear View of doppler

Showing additional symbols

©Ultrasound Technologies Ltd Page 2 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

1.3 53CE Mark

This product complies with the essential requirements of the European Council Directive 93/42/EEC relating to Medical

Devices.

0120

1.4

Guidelines for identifying and resolving adverse EMC conditions

54

This product is classified as a Class A Group 1 type of product according to EN55011.

Emissions

Care has been taken through the design and manufacturing process to minimise the EM emissions, which may be

produced by this equipment. However, in the unlikely event that the unit causes an EM disturbance to adjacent

equipment, we suggest that the procedure is carried out ‘out of range’ of the affected equipment.

Immunity

If the user has any doubt regarding the units EM immunity during routine operation, we suggest that the source of EM

disturbance is identified and it’s emissions reduced. If there is any doubt regarding the identification and resolution of

adverse EM conditions, contact Ultrasound Technologies Ltd directly who will advise on the situation. The address

can be found in the front of this manual.

©Ultrasound Technologies Ltd Page 3 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

1.5 Series specifications

Ultrasound

Frequency (PD1+ / PD1dwr / fetatrack 120+) 2 MHz continuous wave fixed probe

(PD1v / PD1cv / Vascutrack 120) 5 or 8 MHz continuous wave fixed probe

(PD1 combi /PD1+ combi / Combitrack) 2, 3, 5 or 8MHz interchangeable probe

Transducer 2 crystal narrow beam.

Output power <5mW/cm² SATA (2, 3 MHz fetal probe)

<15mW/cm² SATA (5 and 8MHz vascular probe)

Audio response 300Hz – 1KHz (fetal)

300Hz – 4KHz (vascular)

Audio output 500mW

Fetal heart rate (PD1+ / PD1+ combi / PD1dwr / fetatrack 120+) Multipoint real time autocorrelator

Fetal Heart Range 50 to 210 bpm

Unit Controls

Keys 1 Key (for unit on/off on audio unit – all models)

1 Key (for unit on/off on probe – fetatrack 120 and vascutrack 120 models)

Controls Rotary volume

Indicators (PD1 / PD1/ combi / PD1v / fetatrack 120 / vascutrack 120) Yellow battery low LED

Indicators (PD1+ / PD1+ combi / PD1dwr / fetatrack 120+)

icon / Battery Low icon

Power Supply

Battery MN1604 (PP3) 9V Alkaline Manganese

Expected battery life (PD1 / PD1v / fetatrack 120 / vascutrack 120) >9 hours

Expected battery life (PD1+ / PD1dwr / fetatrack 120+) >8 hours

Outputs

Headset Audio output to optional headset

Serial (PD1+ / PD1dwr / fetatrack 120+) RS232 interface to optional UltraTrace software

Recorder (PD1v [not PD1v CAT] / vascutrack 120) Voltage output proportional to velocity of

flow

Enclosure

Material ABS

Size 150mm by 75mm

Weight 295g typically including transducer

Safety

Classification Class 1 Type B - IEC 60601-1

3 digit FHR LCD display / FHR pulse

©Ultrasound Technologies Ltd Page 4 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

2. 8Description of the Instrument

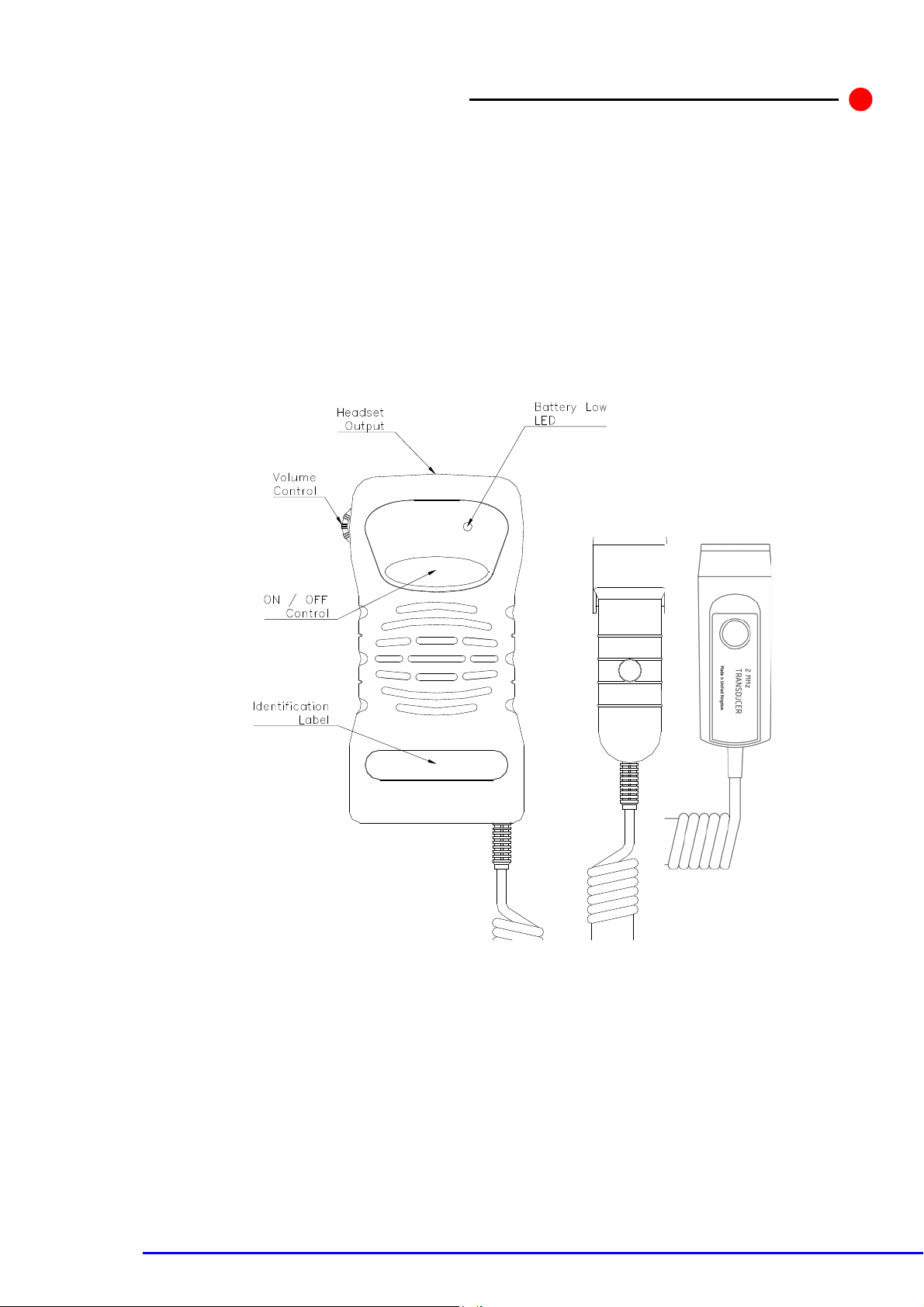

2.1. 55Audio Unit PD1 (Fetatrack 120, Babypulse)

The following functions are found in the relevant page of the operating instructions.

UNIT ON/OFF On / Off control.

BATTERY LOW LED indicator to show when the battery has reached a point when it requires changing.

VOLUME CONTROL Rotary edge potentiometer, which increases or decreases the setting of the volume.

HEADSET Audio output for connection to a stereo headset for private listening.

PD1 / Babypulse

fetal transducer

Fetatrack 120

fetal transducer

©Ultrasound Technologies Ltd Page 5 of 32

PD1 service manual Issue 2 January 2005

ansduce

Ultrasound Technologies Ltd

2.2. 56Audio Unit PD1+ (PD1dwr / fetatrack 120+ / babypulse +)

The following functions are found in the relevant page of the operating instructions.

UNIT ON/OFF On / Off control.

VOLUME CONTROL Rotary edge potentiometer, which increases or decreases the setting of the volume.

HEADSET Audio output for connection to a stereo headset for private listening.

RS 232 Interface Serial data output, for connection to the optional ULTRATRACE 2 PC software. Connections are

made via the 3.5mm Stereo jack socket.

FHR DISPLAY Custom LCD module displays FHR rate, FH pulse and Battery condition.

PD1+ / Babypulse+ /

PD1dwr fetal

tr

r

Fetatrack 120 + fetal

transducer

©Ultrasound Technologies Ltd Page 6 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

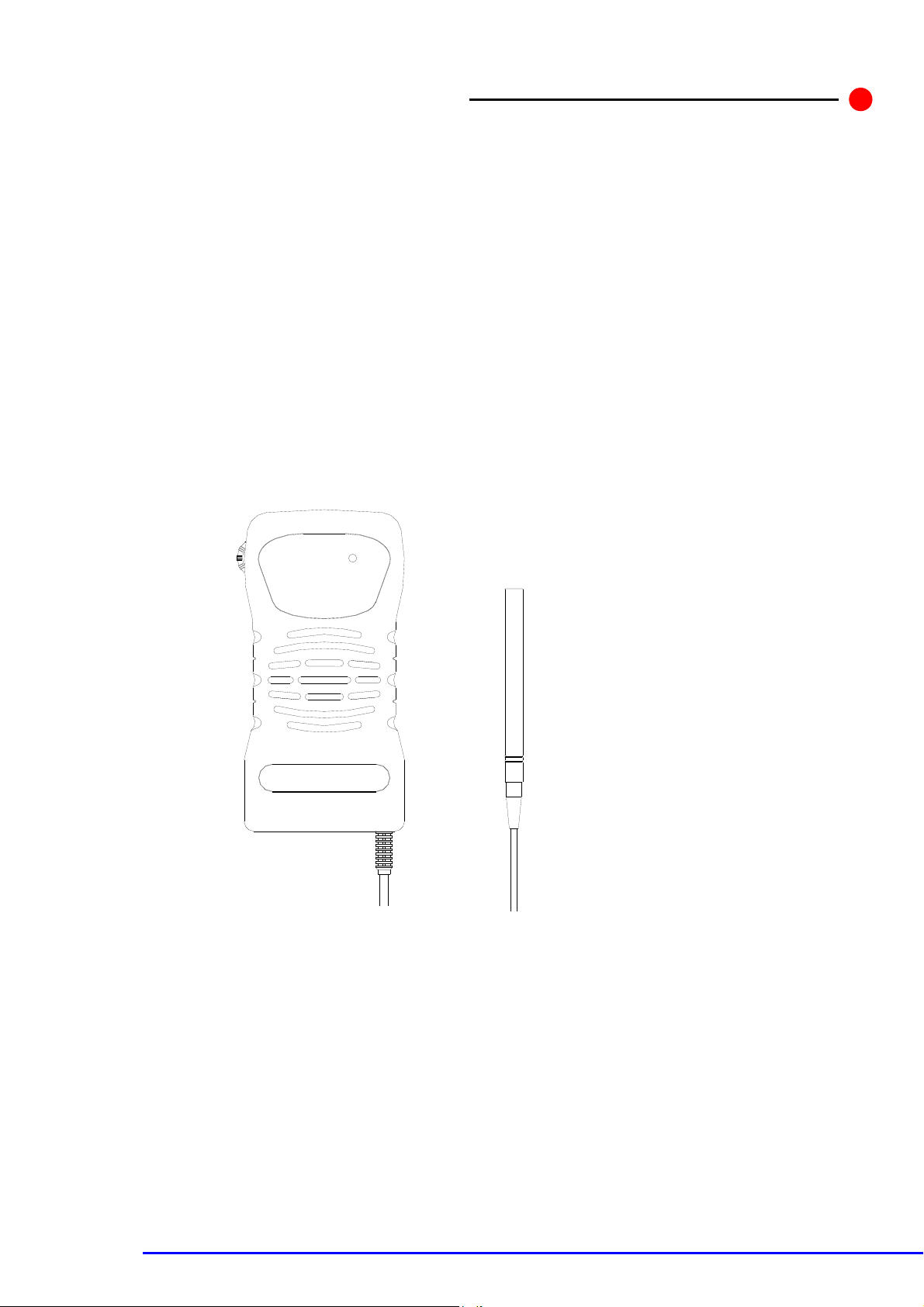

2.3.

The following functions are found in the relevant page of the operating instructions.

UNIT ON/OFF On / Off control.

BATTERY LOW LED indicator to show when the battery has reached a point when it requires changing.

VOLUME CONTROL Rotary edge potentiometer, which increases or decreases the setting of the volume.

HEADSET Audio output for connection to a stereo headset for private listening.

Audio Unit PD1v

57

©Ultrasound Technologies Ltd Page 7 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

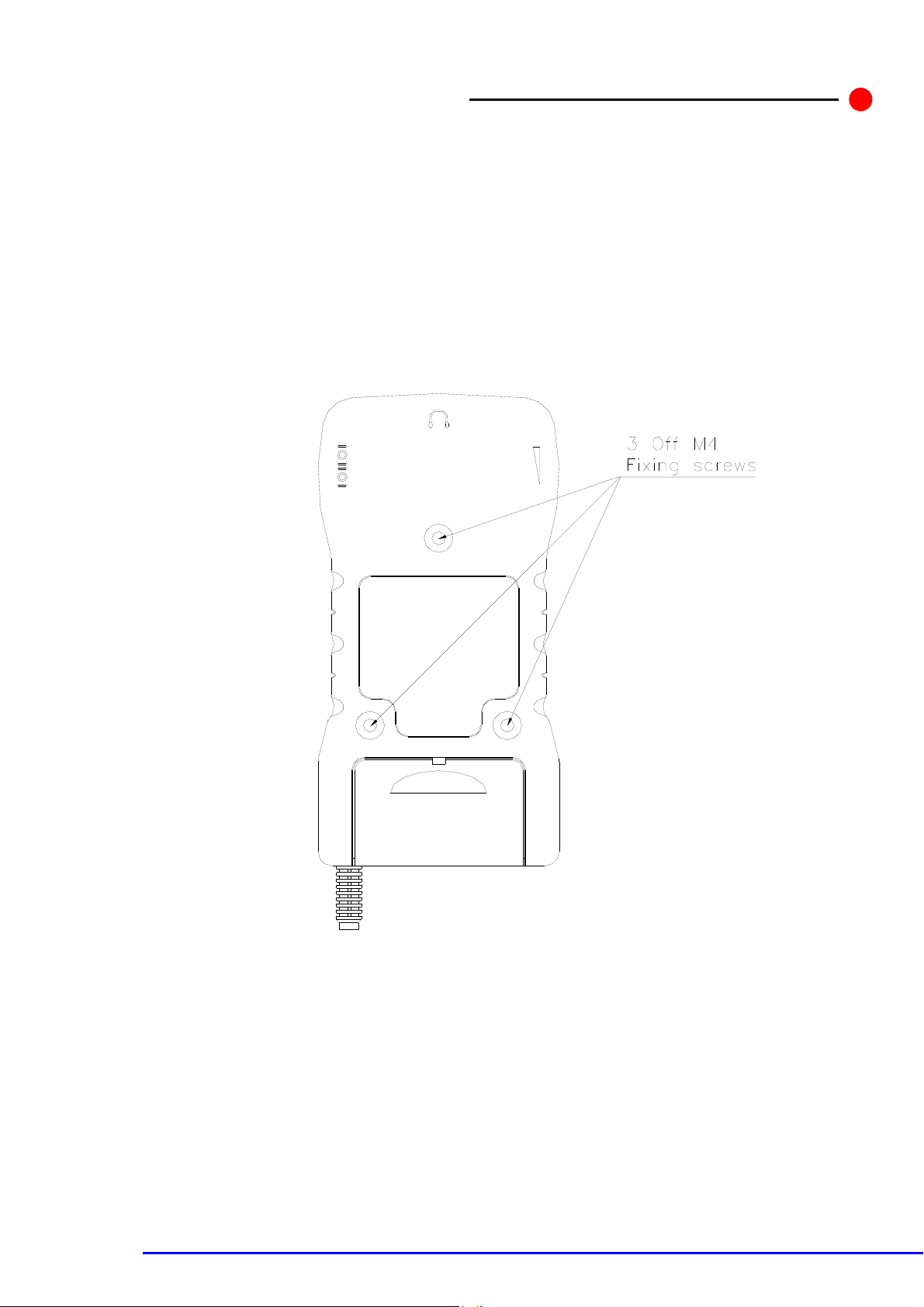

2.4. 58Dismantling Instructions

Special Note: -The instrument must not be dismantled when in use on a patient, ensure all accessories

are disconnected.

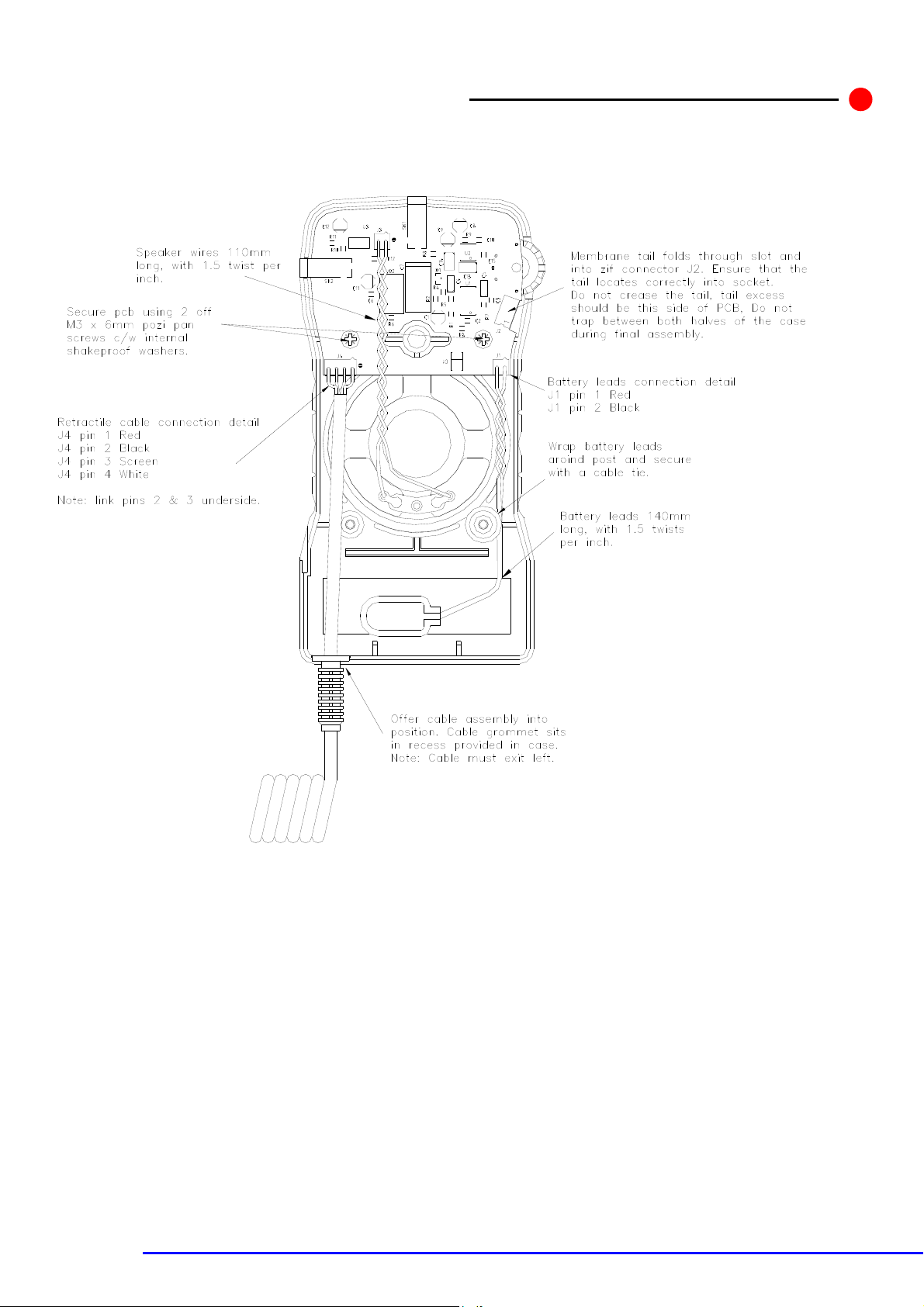

2.5. 59Audio Unit

The Audio unit houses the main circuit board. To remove the circuit board, turn the unit onto it's front and

remove the three M4 countersunk screws. The rear panel will now come away revealing the PCB.

Remove the two M3 screws securing the PCB.

©Ultrasound Technologies Ltd Page 8 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

The transducers, loudspeaker and battery connections are ‘hard wired’ to the PCB. De-solder the

connections at J4 (retractile cable) and J3 (loudspeaker), the PCB can then be pulled clear of the case.

©Ultrasound Technologies Ltd Page 9 of 32

PD1 service manual Issue 2 January 2005

Ultrasound Technologies Ltd

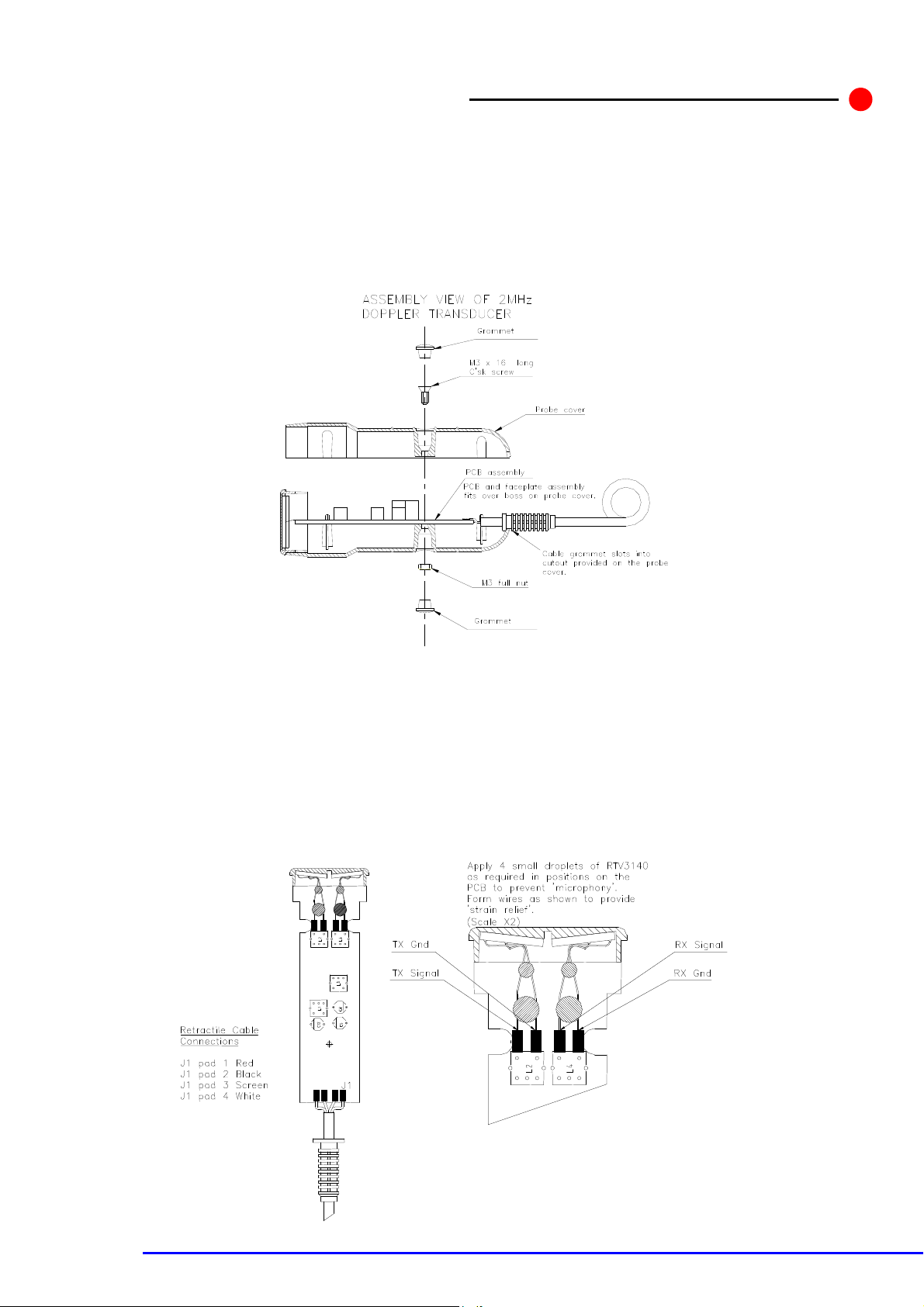

2.6 Transducers

60

The transducers are a ‘sealed unit’. However, it is possible to gain access to the 2 MHz assembly by

removing the two blanking grommets and M3 countersink screws. Removing the screws will allow the

assembly to be split along its length. Gently prise the assembly apart.

The circuit board is bonded and keyed to the faceplate assembly using a high strength cyno-acrylic

adhesive.

Circuit board removal is carried out by carefully breaking the bond and de-soldering the crystal wires and

retractile cable connections (see diagram below).

©Ultrasound Technologies Ltd Page 10 of 32

PD1 service manual Issue 2 January 2005

Loading...

Loading...