USER INSTRUCTION MANUAL

DESCRIPTION: PARACHUTE BUCKLE HARNESS

MODEL:

F-96305, UPF-96305, 96305NALK

P

MEETS OSHA & ANSI Z359.11-2014

96305, 96307, 96305N, 96305FB, 96305F, 96305WS, PF-96305N,

1-800-850-5914

PHOENI X, AZ US A

MODEL:

_________________________

SIZE: ____________________

DATE: __________________

WATCH VIDEOS 6, 12 & 25 ON ULTRASAFEUSA.COM

Anchorage: The anchorage to which this product is attached must be

capable of sustaining a static load in the direction applied by the

personal fall arrest system of at least 3600 lbs. with certification of a

_

_

Warning: Manufacturer's instructions supplied with this product at time of shipment must be

followed and provided to the end user. Failure to do so could result in serious injury or death.

Contact manufacturer if instructions are needed.

• Warnings and instructions must be read and understood before using equipment.

• Equipment must be used by trained personnel only.

• Users must understand all OSHA regulations, ANSI standards, and other relevant

regulations and standards pertaining to fall protection equipment.

qualified person or 5000 lbs. without certification. When more than one

personal fall arrest system is attached to the same structure, the

strength requirements stated above must be multiplied by the number

of personal arrest systems attached to the structure.

Plan your personal fall protection system.

Before installing and using this equipment, consider all factors

affecting your safety during use of this equipment.

WARNING!

This product is part of a personal fall

arrest system. The user must read and

follow the manufacturer’s instructions for

each component of the system. These

instructions must be provided to the user

of this product. The user must read and

understand these instructions before

using this product. Manufacturer’s

instructions must be followed for proper

use and maintenance of this product.

Alteration or misuse of this product, or

failure to follow instructions may result

in serious injury or death

.

This product is part of a personal fall arrest system; a fall arrest system is required if there is any

risk that a worker may fall from an elevated position. It is a requirement that the fall arrest system

be used any time a working height of six feet or more is reached. Working height is defined as the

distance from the walking/working surface to a grade or lower level.

This product shall require the user to have a rescue plan and the means at hand to implement it

when using the FBH for fall arrest. The following is recommended as part of fall arrest system.

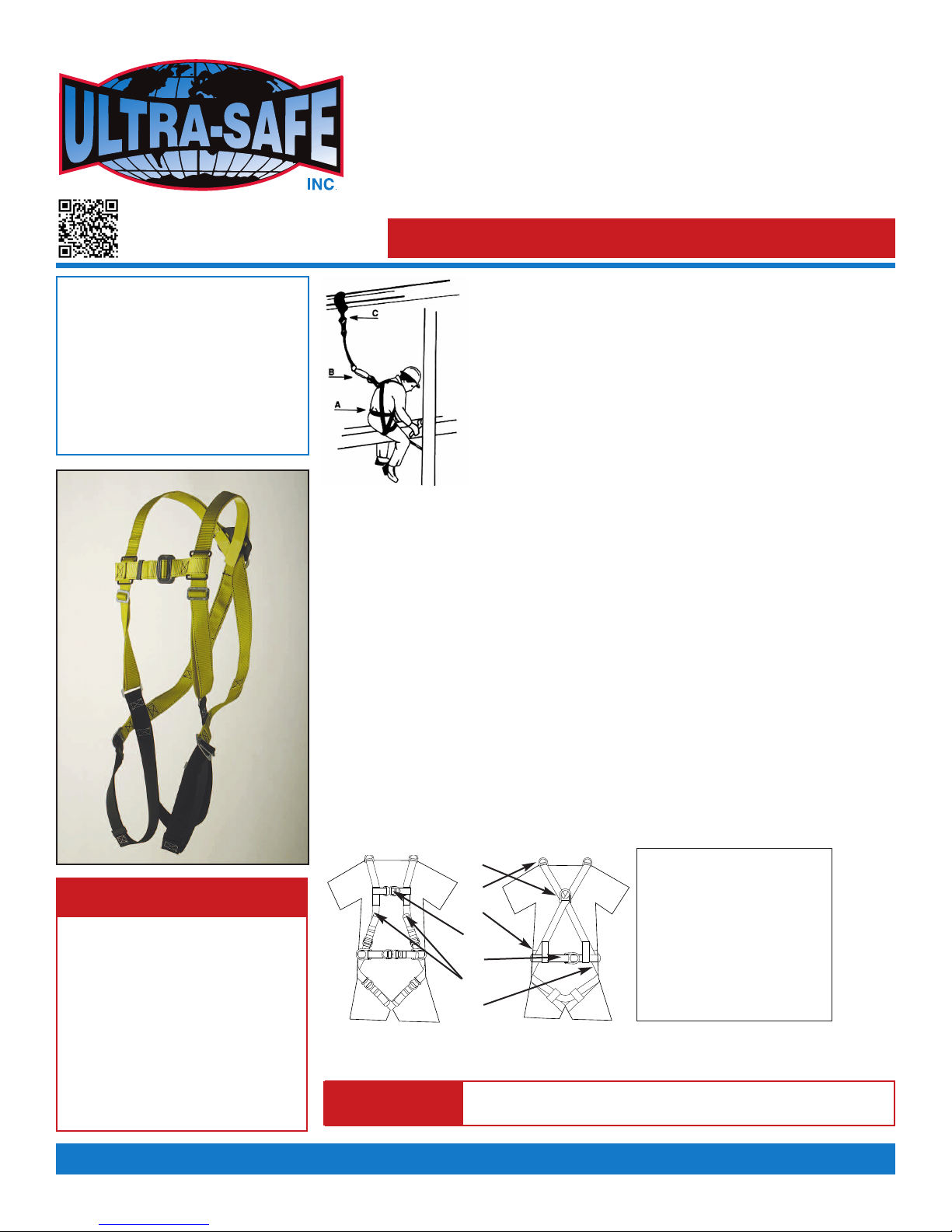

A. Full Body Harness Material: Nylon

1.

2.

3.

4.

5.

6.

7.

1. Back 'D' ring is for fall arrest

2. Shoulder 'O' rings. (if present) are for

retrieval use only use locking snaps.

3. Side 'D' rings (if present) are for

positioning only.

4. Front 'D' ring (if present) are for falls

` greater than 24" with a maximum impact

of 900 lbs. Inspection card

5. Hip attachment elements are for work

positioning or travel restraint

6. Park lanyard here

7. Load indicator

Note: See additional instructions on buckle adjustment for proper fit. Maximum free-fall

distance six feet or maximum fall arrest force of 1800 lbs. Avoid lower level contact.

These instructions are good for all 98 Series Alumi-Safe

NOTE

& Custom designs with parachute buckles.

1

313H1

B. Shock Absorbing Lanyard Material: Nylon

Warning tags located in front and back of shock

C. Anchorage Connector Material: Nylon

Warning tags are located towards hook, D-ring or eye end.

absorber or located towards hook, D-ring or eye end.

•

Use energy absorbers or retractable lanyards

• Energy absorber resting force 900 lbs.

Plus 42 inch maximum extension.

• Rig lanyard to allow a maximum free fall distance

of not more than six feet.

• Connectors and anchorage points must be

compatible and able to support 5,000 lbs.

• Do not allow lanyard or harness to contact sharp

or abrasive surfaces, sparks or temperature

above 180º.

• Snap hooks with gate openings larger than

one inch (1") must not be connected to D-rings

on harnesses and belts.

when hazard of free fall can occur.

• Connectors and anchorage points must be compatible and able to

support 5,000 lbs. Always work directly under anchorage to avoid a

swing fall injury.

• Anchorage and tie off points must be at a height

that will not allow a lower level to be struck should

a fall occur. Do not allow product to contact sharp

or abrasive surfaces, sparks or temperatures

above 180º.

• Snap hooks with gate openings larger than

one inch (1”) must not be connected.

•

Remove from service if any damage is detected.

• Remove from service if any damage is detected

and destroy.

Quick release buckle harnesses come in different styles, pads on back, no tool belt, etc.,

but proper adjustment and fit is critical. Refer to these instructions for key adjustment points.

1. Hold harness by back

D-ring. Shake harness

to allow all straps to

fall into place.

5. Pull leg straps around

to the outside of leg

and fasten.

2. Slip straps over

shoulders so D-ring

is located at

middle of back.

6. Properly worn harness.

3. Adjust strap for the

correct torso length.

2

4. Pull chest strap around

shoulder strap and fasten

at mid chest. Tighten to

keep shoulder straps taut.

7. To remove harness,

reverse procedure.

Note: For more on proper fit, refer to our website. Click on Videos and refer to video #12.

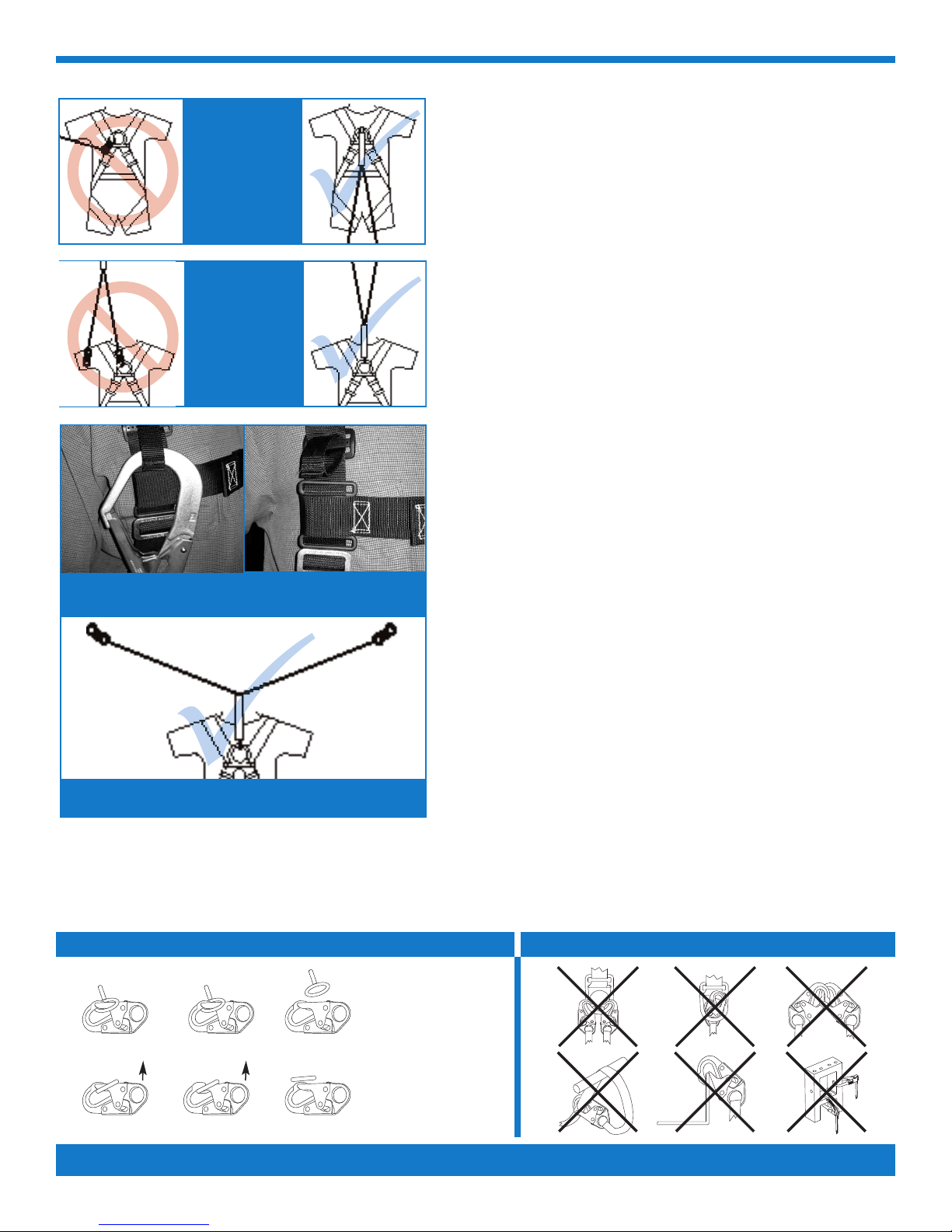

When using lanyards commonly referred to as "100% tie-off”, "Y" type,

ATTACH

NERGY

E

ABSORBER

ONLY TO

DORSAL

D-RING

DO NOT

TTACH

A

ENERGY

ABSORBER

TO ANCHOR

"double" or "twin leg" shock absorbing lanyards. This supplement provides

additional information on the use of these types of lanyards that are used

with a personal fall arrest systems.

ractices that must be followed in order to use a 100% tie-off lanyard

P

safely.

1. The shock absorber pack portion of the lanyard assembly MUST be

connected to the back dorsal D-ring ONLY, by way of a double locking

lanyard snap hook (other connectors provided, consult ULTRA-SAFE,

INC.) connect shock absorber directly to the dorsal D-ring.

2. Do not connect shock absorber to the anchorage point at any time.

3. Do not connect the unused leg of the lanyard assembly to any portion

of the full body harness, unless a specifically designed lanyard snap

hook loop retainer is provided for this purpose.

4. When connecting from one anchorage point to the next (traversing a

vertical or horizontal structure) do not connect to an anchorage point

further apart than, the length of the lanyard.

5. When using a 100% tie-off lanyard assembly, do not allow any part of

the lanyard to pass under arms or legs.

WITH HOOK WITHOUT HOOK

ACCEPTABLE DESIGNED RETAINER

6. Connection of both lanyard legs to separate anchorage points is

acceptable, as long as anchorage points are within the length of the

lanyard.

7. The hip attachment elements shall be used as a pair, and shall be used

solely for work positioning. the hip attachment elements shall not be

used for fall arrest. Hip attachments are often used for work

positioning by arborists, utility workers climbing poles and

construction workers tying rebar and climbing on form walls. Users

are cautioned against using the hip attachment elements (or any other

rigid point on the Full Body Harness) to store the unused end of a fall

MAXIMUM ATTACHMENT DISTANCE

arrest lanyard, as this may cause a tripping hazard.

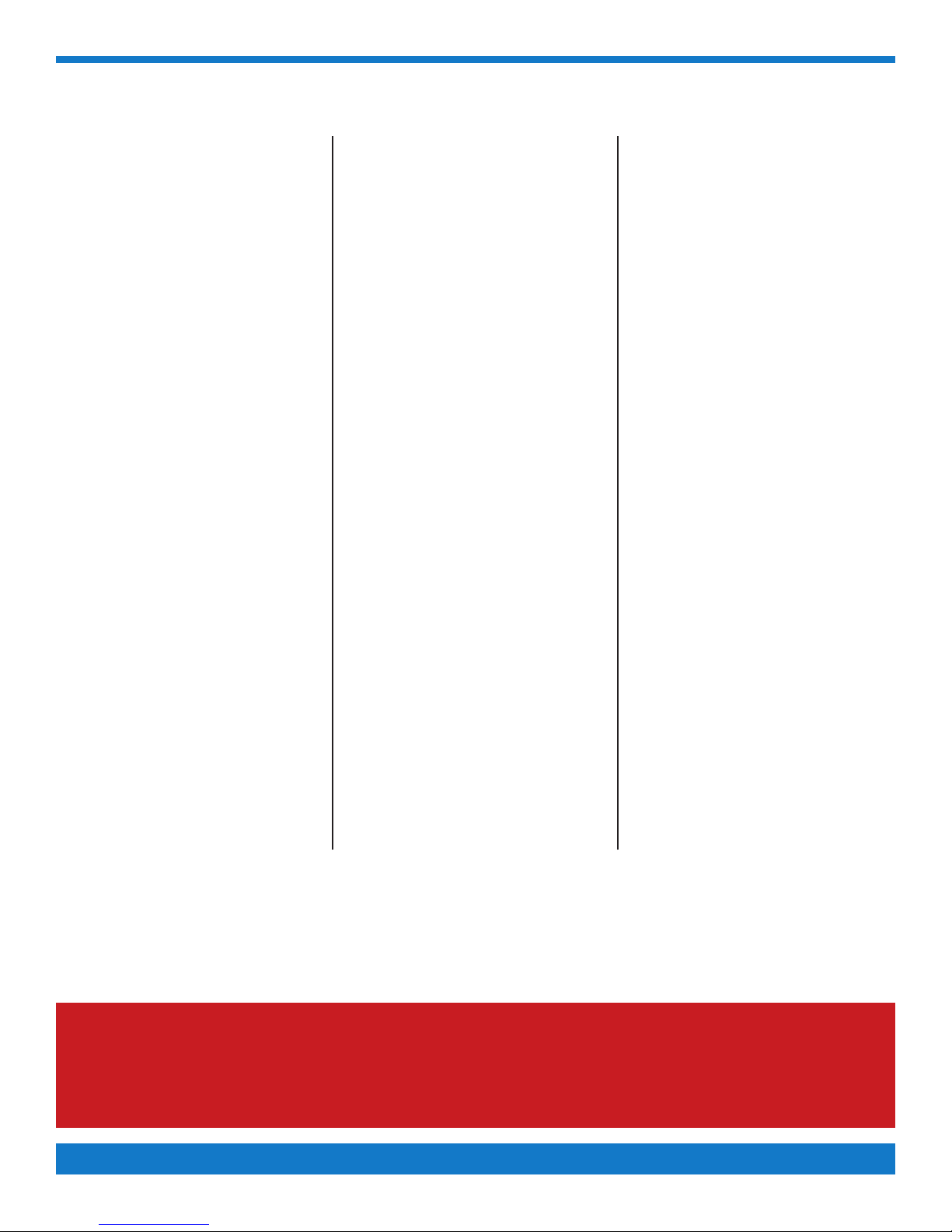

UNINTENTIONAL DISENGAGEMENT

If the connecting element to which a snap hook (shown) or carabiner attaches is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of the snap hook or carabiner. This force may cause the gate (of either a

self-locking or a non-locking snap hook) to open, allowing the snap hook or carabiner to disengage from the connecting point.

Inappropriate ConnectionsUnintentional Disengagement

A.

B. C. D.

A. Small ring or other

non-compatability

shaped element.

B. Force is applied to the

snap hook.

C. The gate presses

against the

connecting ring.

D. The gate opens allowing

the snap hook to slip off.

3

Harness System Inspection Procedures

General -

1. Check for wear and deterioration.

Before each use, the user must carefully inspect

the harness for signs of wear, deterioration, or

evidence of impact loading. Visually inspect for

loose threads, pulled rivets, burns, cuts,

distortions, abrasions, or any other evidence

of chemical or physical deterioration that

may have weakened the material or assembly.

2. Inspect hardware for malfunctions and cracks.

Check all snap hooks, buckles and D-Rings.

3. Remove from service and replace all worn

or damaged equipment.

If any part does not pass inspection, immediately

remove the harness from service and destroy.

4. Working environment influences

Be aware of your surroundings and potential

danger to you and your equipment.

• Exposure of the equipment to chemicals, heat,

flames or other environmental conditions,

which may produce a harmful effect.

Be sure to consult the manufacturer

in case of doubt.

• Use of harness around moving machinery

or electricity.

• Use of harness near sharp edges

or abrasive surfaces.

• Exposure to light (UV degradation).

5. Annual Inspection

Harness must undergo a written inspection by

competent person once a year.

6. Repairs

Repairs may only be made by Ultra-Safe or

by authortized distributors, who have written

permission from Ultra-Safe to make repairs.

Specific -

1. Stitching and webbing.

Check stitching for broken, burned, cut or pulled

stitches. Broken strands appear as tufts on the

surface. To inspect, hold the webbing with your

hands six to eight inches apart. Bend the webbing

in an inverted U to cause surface tension,

exposing problem areas. Inspect all web areas.

Damage from cuts, abrasion, corrosives, heat or

chemicals should be apparent.

2. Buckle and belt ends.

Inspect the ends of all straps. They are subject to

wear as a result of repeated opening and closing.

Enlargement or distortion of holes may indicate

excessive wear or possible damage through

impact loading. Harnesses with unusually

enlarged or distorted holes should fail inspection.

3. D-Rings.

All D-Rings should be checked for distortion.

D-ring attachment points should be checked for

unusual wear or damaged Fibers. Badly pitted

D-rings indicate chemical corrosion, and the

equipment should fail inspection.

4. Stitching or rivets at hardware attachment

points.

For stitched attachment points, check that

stitching is not broken, burned, cut or pulled.

Check all riveted attachment points for tightness.

Badly pitted rivets indicate chemical corrosion,

and the equipment should fail inspection.

5. Tongue buckles.

All tongue buckles should be checked for

distortion, sharp edges and cracks. The tongue

should move freely and overlap the frame. Rollers

should not be distorted and should roll freely.

6. Friction slide adjusters.

Friction slide adjusters should be checked for

sharp edges, distortion. Make sure that the outer

bars and center bars are straight. Also check

corners and attachment points for wear and

cracks.

7. Easy-connect buckle.

Easy-connect buckle (square rings) should be

checked for distortion, sharp edges and cracks.

For stitched attachment points, check that

stitching is not broken, burned, cut or pulled.

8. Friction style buckle.

Friction style buckles should be checked for sharp

edges, cracks and distortion. Make sure outer

bars and center bar are straight. Also check

corners and attachment points for wear.

9. Leather.

Leather should be soft and supple. Visually check

leather for cracks tears, burns, brittleness or

other signs of damage age or abuse. While the

leather components of the system are not load

bearing, damage to the leather is a sign that the

entire harness MAY NOT be in acceptable

condition. Re-inspect entire system. Leather

should both look and feel good.

1O. Destroy or replace worn or damaged

Harnesses.

If evidence of excessive wear, deterioration or

mechanical malefaction is observed; the harness

should be destroyed. Never work with worn or

damaged equipment. Using damaged or worn

equipment can cause serious injury or death.

11. The inspector is the most important part

of any inspection procedure.

Check all equipment thoroughly and follow all

safety procedures and guidelines. Don't take

any shortcuts.

12. Cleaning Harness

Harnesses are machine washable, light detergent

and in small mesh bag w/draw string. Let air dry,

do not machine dry.

IMPORTANT NOTE: OSHA specifies that all employers covered by the Occupational Safety and Health Act are

responsible for inspection and maintenance of all tools and equipment used by employees, whether owned by the

employees or by the company. All Ultra-Safe equipment should be inspected before each use, and immediately

removed from service if equipment does not pass inspection

.

4

LIMITATIONS:

Always consider the following application limitations before using this equipment:

1. CAPACITY: The Full Body Harness is designed for use by persons with a

combined weight (clothing, tools, etc.) ranging from 130 lbs (59 kg) to 310 lbs (140

kg). Make sure all of the components in your system are rated to a capacity

appropriate to your application.

NOTE: 310 lbs (140 kg) is the maximum capacity allowed by ANSI/ASSE

Z359.11. Ultra-Safe safety harnesses are factory tested to a maximum

capacity of 400 lbs (182 kg).

2. FREE FALL: Personal fall arrest systems used with this equipment must be rigged

to limit the free fall to 6 feet (1.8m). Restraint systems must be rigged so that no

vertical free fall is possible. Work positioning systems must be rigged so that free

fall is limited to 2 feet (.6 m) or less. Personnel riding systems must be rigged so

that no vertical free fall is possible. Climbing systems must be rigged so that free

fall is limited to 18 in. (.46 cm) or less. Rescue systems must be rigged so that no

vertical free fall is possible.

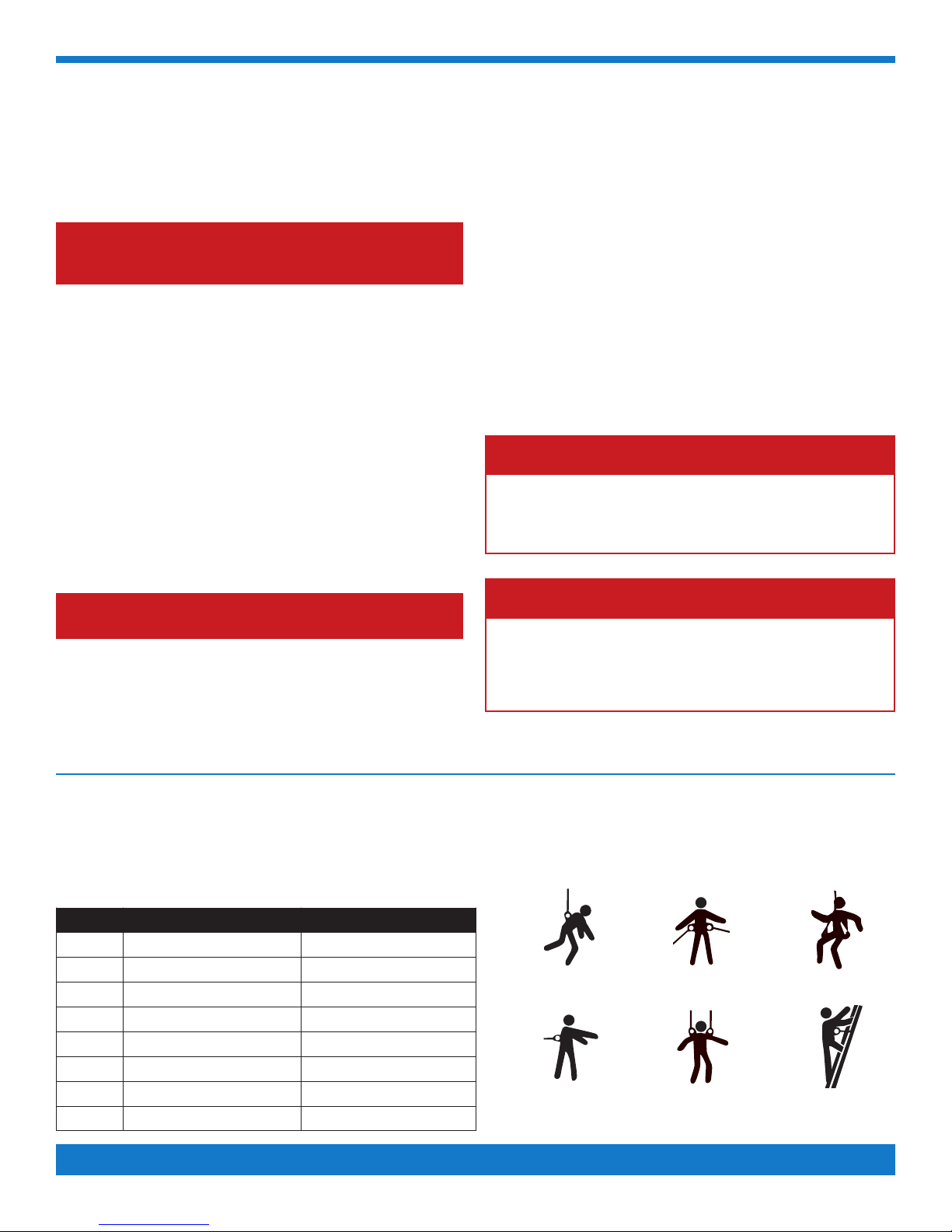

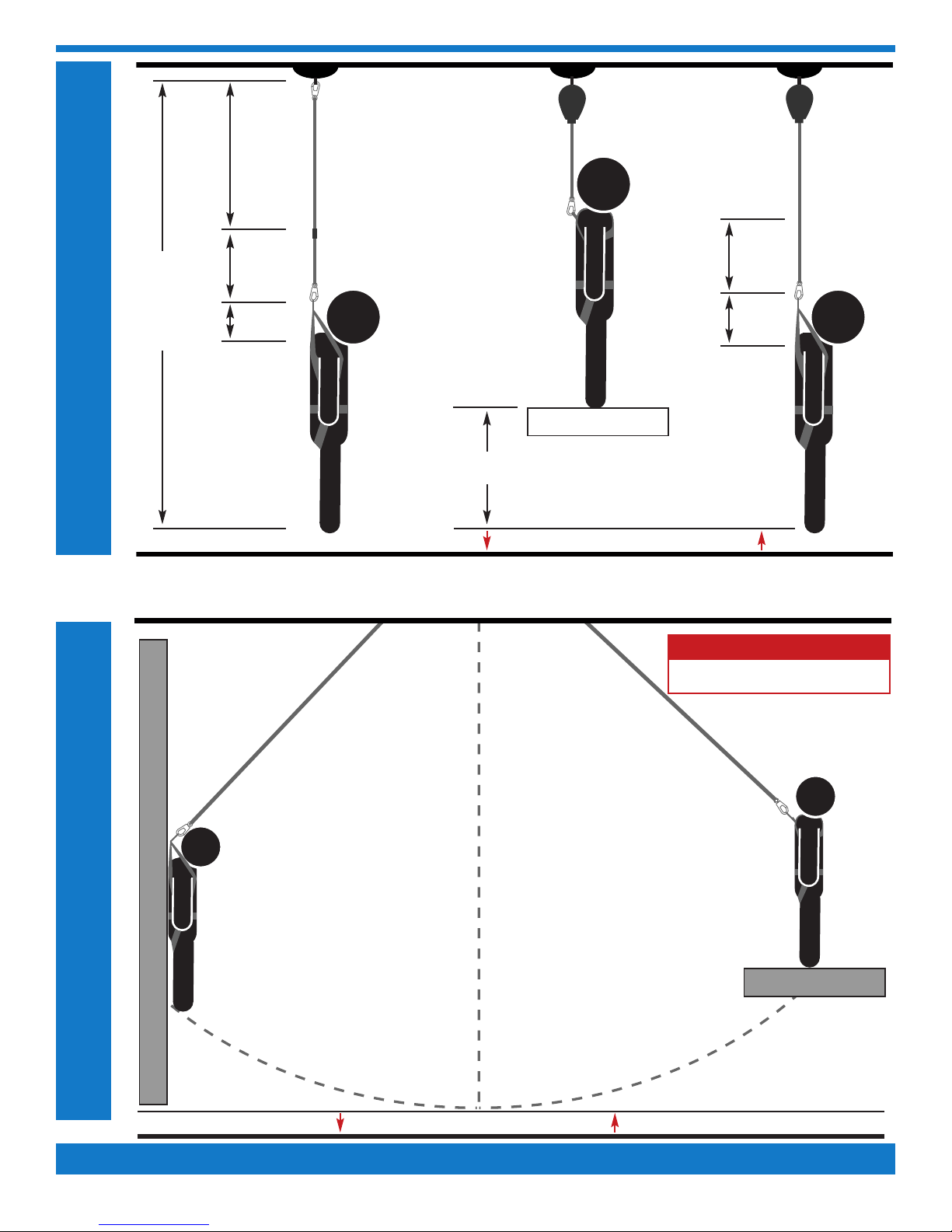

3. FALL CLEARANCE: Figure 3 illustrates the components of a Fall Arrest. There

must be sufficient clearance below the user to arrest a fall before the user strikes

the ground or other obstruction. Clearance is affected by a number of

factors including the following parameters:

• Elevation of Anchorage

• Free Fall Distance

• Worker Height

• Connecting Subsystem Length

• Deceleration Distance

• Attachment Element Movement and Harness Stretch

NOTE: Refer to the instructions included with your Fall Arrest subsystem for

specifics regarding Fall Clearance calculation.

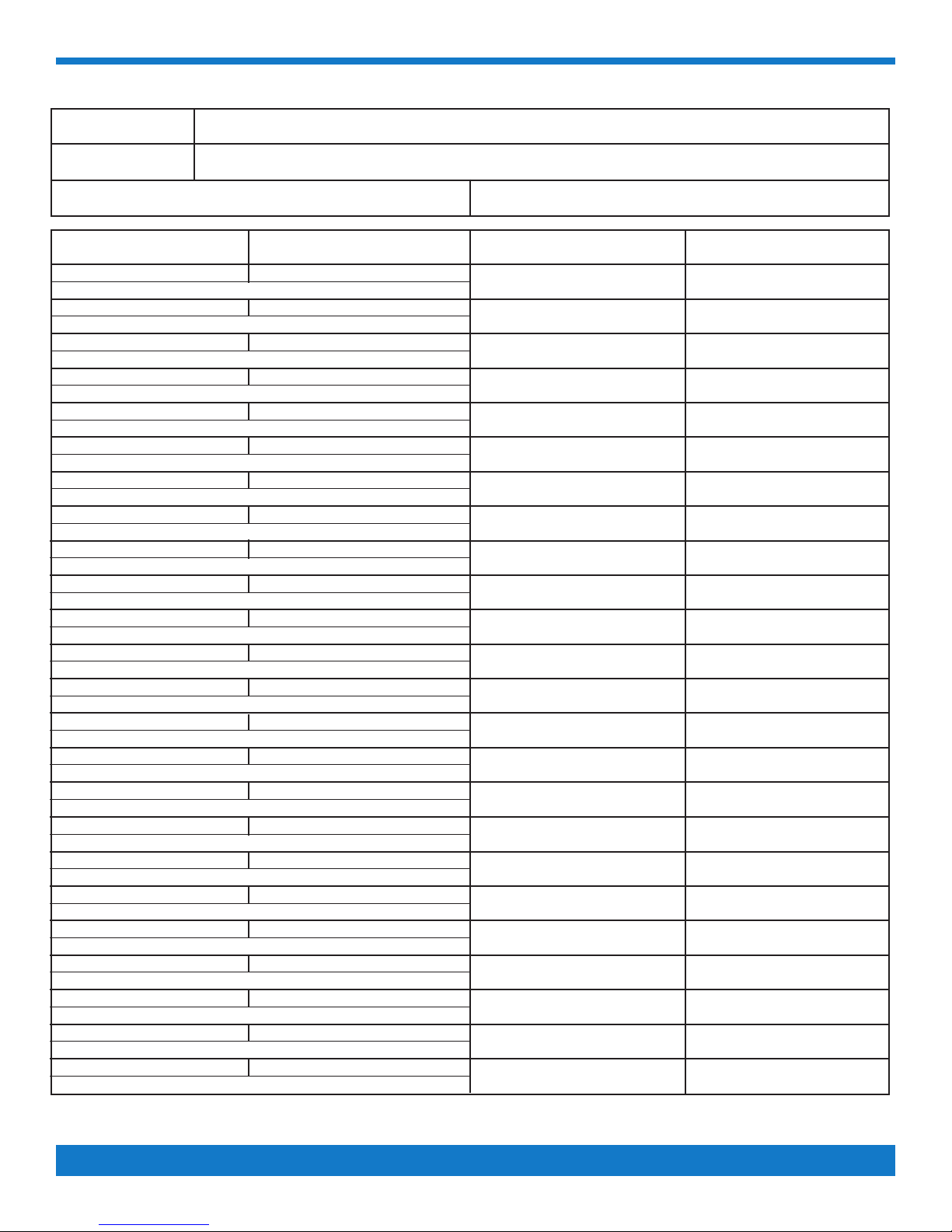

4. SWING FALLS: Swing Falls occur when the anchorage point is not directly

above the point where a fall occurs (see Figure 4). The force of striking an object

in a swing fall may cause serious injury or death. Minimize swing falls by

working as directly below the anchorage point as possible. Do not permit a swing

fall if injury could occur. Swing falls will signifi cantly increase the clearance

required when a Self-Retracting Device or other variable length connecting

subsystem is used.

5. EXTENDED SUSPENSION: A Full Body Harness is not intended for use in

extended suspension applications. If the user is going to be suspended for

an extended length of time it is recommended that some form of seat support

be used. Capital Safety recommends a seat board, suspension work seat, seat

sling, or a boatswain chair. Contact Ultra-Safe for more information on these

items.

6. ENVIRONMENTAL HAZARDS: Use of this equipment in areas with environmental

hazards may require additional precautions to prevent injury to the user or

damage to the equipment. Hazards may include, but are not limited to; heat,

chemicals, corrosive environments, high voltage power lines, gases, moving

machinery, and sharp edges.

7. HARNESSES FOR HIGH TEMPERATURE ENVIRONMENTS: Harnesses with

Kevlar webbing are designed for use in high temperature environments, with

limitations: Kevlar webbing begins to char at 800° to 900° Fahrenheit. Kevlar

webbing can withstand limited contact exposure to temperatures up to 1,000° F.

Standard webbing is limited to 180° F.

WARNING!

When working with tools, materials, or in high temperature

environments, ensure that associated fallprotection equipment

can withstand high temperatures, or provide protection for those

items.

WARNING!

Although PVC coated and zinc plated hardware exhibit excellent

corrosion resistance in chemical, acidic, alkaline, and atmospheric

conditions, frequent inspections may be required. Consult with

Ultra-Safe if you question the use of this equipment in hazardous

environments.

HOW TO MEASURE FOR A FULL BODY HARNESS:

Proper fit is critical for personal safety & working comfort. The chart

below specifies how to measure your body for the correct

fit of fall protection equipment.

Size Waist (Inches) Lbs

XS 24-30 100-130

S 28-34 130-160

M-L 32-40 160-220

XL 38-48 220-250

2XL 46-54 250-280

3XL 54-58 280-310

4XL 58-62 310-350

5XL 62-66 350-400

(Measurements are over clothing)

USA INDUSTRY SYMBOLS

Fall Arrest Positioning Suspension

Fall Prevention Retrieval Ladder Climbing

5

A

B

C

FALL CLEARANCE

FALL ARREST COMPONENTS

FALL

CLEARANCE

SAFETY FACTOR TO LOWER LEVEL

A = Lanyard Length B = Lanyard Deceleration Distance or SRL Maximum Arrest Distance

C = Safety Factor - Harness Stretch (Hs) + D-Ring/Connector Length + Settling = 1.5 ft (0.5 m) (add 6” w/ Pillow Flex.

NOTE: When using 965018 D-Ring extender add an additional 18”

THIS IS AN EXTREME EXAMPLE

B

C

C A U T I O N

OF A PEDULUM SWING FALL.

SWING FALL FOR RETRACTABLES

SAFETY FACTOR TO LOWER LEVEL

6

INSPECTION AND MAINTENANCE LOG

Serial Number:

Model Number:

Date Purchased:

Date of First Use:

Inspection Date Inspection Items Noted Corrective Action Maintenance Performed

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

7

EXAMPLE

OF TAGS

. BACK 'D' RING IS FOR FALL ARREST

1

2. SHOULDER 'D' RINGS. (IF PRESENT) ARE FOR RETRIEVAL USE

Initials

HO56215

SEE RFID TAG

SERIAL NUMBER:

INSPECTION LOG

Date

ONLY USE LOCKING SNAPS.

. SIDE 'D' RINGS (!F PRESENT) ARE FOR POSITIONING ONLY.

3

. FRONT 'D' RING (IF PRESENT) ARE FOR FALLS GREATER THAN

4

24" WITH A MAXIMUM IMPACT OF 900 LBS. INSPECTION CARD

5. HIP ATTACHMENT ELEMENTS ARE FOR WORK POSITIONING

R TRAVEL RESTRAINT

O

. PARK LANYARD HERE

6

. LOAD INDICATOR

7

WARNING

Manufacturer's instructions must be read and understood prior to use. Instructions

upplied with this product at time of shipment must be followed. Failure to do so

s

could result in serious injury or death. Contact Ultra-Safe if instruction sheet is

needed. Inspect before each use. Do not use if wear or damage is present. This

ody harness is intended to be used to arrest the most severe free falls. Items

b

subjected to fall arrest or impact forces must be immediately removed from service

nd destroyed. Connecting snap and d-ring must be compatible in size, shape, and

a

strength. This item is not flame or heat resistant. Repairs only to be performed by

ltra-Safe. Equipment modification or misuse voids warranty.

U

User Inspection, Maintenance, and Storage of Equipment

Users of personal fall arrest systems shall, at a minimum, comply with all

manufacturer instructions regarding the inspection, maintenance and storage of

the equipment. the user's organization shall retain the manufacturer's instructions

and make them readily available to all users. See ANSI/ASSE Z359.2, Minimum

Requirements for a Comprehensive Managed Fall Protection Program, regarding

user inspection, maintenance and storage of equipment.

1. In addition to the inspection requirements set forth in the manufacturer's

instructions, the equipment shall be inspected by the user before each use and,

additionally, by a competent person, other than the user, at interval of no more

than one year for:

• Absence or illegibility of markings.

• Absence of any elements affecting the equipment form, fit or function.

• Evidence of defects in, or damage to, hardware elements including cracks,

sharp edges, deformation, corrosion, chemical attack, excessive heating,

alteration and excessive wear.

• Evidence of defects in or damage to strap or ropes including fraying,

unsplicing, unlaying, kinking, knotting, roping, broken or pulled stitches,

excessive elongation, chemical attack, excessive soiling, abrasion,

alteration, needed or excessive lubrication, excessive aging

and excessive wear.

1.

2.

3.

4.

5.

6.

7.

2. Inspection criteria for the equipment shall be set by the user's organization.

Such criteria for the equipment shall equal or exceed the criteria established by

this standard or the manufacturer's instructions, whichever is greater.

3. When inspection reveals defects in, damage to, or inadequate maintenance of

equipment, the equipment shall be permanently removed from service or undergo

adequate corrective maintenance, by the original equipment manufacturer or their

designate, before return to service.

4. Maintenance and storage of equipment shall be conducted by the user's

organization in accordance with the manufacturer's instructions. Unique issues,

which may arise due to conditions of use, shall be addressed with the

manufacturer.

5. Equipment which is in need of, or scheduled for, maintenance shall be tagged as

unusable and removed from service.

6. Equipment shall be stored in a manner as to preclude damage from

environmental factors such as temperature, light, UV, excessive moisture, oil,

chemicals and their vapors or other degrading elements.

ALSO AVAILABLE IN

5000lbs. M.B.L. Soft Loop Made for Non-Conductive Applications and/or Impalement Reasons

8

Loading...

Loading...