Page 1

ULTRAFRYER GAS FRYER

MODEL F-P25-14 / 18 / 20 / 24

OPERATION INSTRUCTIONS

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors or

liquids in the vicinity of this or other appliance.

302 Spencer Lane • P.O. Box 5369

WARNING

Improper Installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death. Read the

installation, operating, and maintenance instructions thoroughly

before installing or servicing this equipment.

San Antonio, Texas 78201

(800) 525-8130 • (210) 731-5000 • Fax: (210) 731-5099

www.ultrafryer.com

PN 30A169 rev Jan2008 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 2

PREFACE

This Manual was written and published by the Engineering Department, Ultrafryer Systems for use by personnel

who will operate a Model P25 Gas Fryer in a commercial cooking environment.

This appliance is intended for professional use and is to be operated by qualied personnel.

Throughout this manual, NOTES, CAUTIONS, and WARNINGS are used to alert the operator to items of spe-

cial circumstances. These items are identied as follows:

NOTE: Pull on the lter tub to ASSURE the male docking plug is SEATED in the female bulkhead

socket.

CAUTION: To assure producing a quality product while prolonging the life expectancy of the fryer,

ensure that the ltering, boil-out, and cleaning instructions are strictly followed.

WARNING: Do not allow any cleaning solution or water to splash into a vessel of hot cooking

oil, as it will contaminate the oil and may cause the oil to splatter, causing severe burns.

This manual is intended as a guide for all model PNP fryers, regardless of conguration, ltration options and

controllers. It is to be used in conjunction with the applicable controller manual that is included with the fryer.

Retain this manual for future reference.

PN 30A169 rev Jan2008 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Description / Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dimensions & Operational Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Controls Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automatic Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rating Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Inlet Gas Line Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inlet Gas Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PRE-INSTALLATION

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Air Supply & Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RECEIVING & INSTALLING

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cooking Computers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INITIAL START-UP

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lighting Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sequence Of Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Burner Operation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ABBREVIATED OPERATING INSTRUCTIONS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cooking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Filtering Shortening. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Leveling Shortening. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Boiling Out Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Closing / Shutdown Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PN 30A169 rev Jan2008 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

TABLE OF CONTENTS.....Continued

PREVENTIVE MAINTENANCE & TROUBLESHOOTING

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FILTER TUB ASSEMBLY & INSTALLATION

Filter Tub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Filter Tub Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TECHNICAL ASSISTANCE & ORDERING INFORMATION

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

RECOMMENDED SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PARTS IDENTIFICATION

Parts Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PN 30A169 rev Jan2008 4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

GENERAL INFORMATION

PN 30A169 rev Jan2008 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

A. Warranty

ULTRAFRYER® LIMITED WARRANTY: PAR-2

Ultrafryer Systems warrants to the original purchaser of a gas Ultrafryer® sold within the United States that it will be

free of defects in material and workmanship for the periods listed below:

STAINLESS STEEL FRYER VAT – Stainless Steel fryer vats are warranted for (10) ten years upon the terms hereinafter

described. The (10) ten year warranty coverage applies ONLY to the Stainless Steel fryer vat and does not apply to the other

components such as controls, re boxes, gaskets, mounting hardware, or the heat shield weldment. The (10) ten year limited

warranty coverage for the Stainless Steel fryer vats are as follows: (1) Vats that fail due to faulty workmanship or materials

within the rst twelve (12) months from the date of initial start up will be exchanged at no cost. Standard delivery ground

freight will be prepaid by Ultrafryer Systems for rst year failures only. The cost of labor to install the replacement vat will

be covered by Ultrafryer Systems for vats, which fail within twelve (12) months from the date of initial start up. Labor for vat

replacements after the rst year is the responsibility of the owner.(2) Vats that fail within the second through fth year will be

exchanged at $250.00 FOB San Antonio. (3) Vats that fail within the sixth through eight year will be exchanged at 50% of current selling price of said vat FOB San Antonio. (4) Vats that fail within the ninth through tenth year will be exchanged at 70%

of the current selling price of said vat FOB San Antonio. (Example: If the current selling price for a particular vat is $2,000.00,

then a failure during the sixth through eighth year would be exchanged for $1,000.00; if the failure occurred in the ninth or tenth

year it would be exchanged for $1,400.00.) Proper credit issue for vat failures is contingent upon receipt, by Ultrafryer Systems,

of the serial number identication tag for any failed vat.

ULTRAFRYER PARTS – All parts on the Ultrafryer® are covered for a period of one (1) year from the initial date of start up.

This is to include gas valves, switches, thermostats, etc. Ultrafryer Systems reserves the right to charge for certain parts such as

computers, lter pumps and motors or any item over the amount of $100.00 until Ultrafryer Systems receives the defective part

back. After inspection, credit for the part will be issued to the purchaser provided the part is deemed defective and that

defect is not the result of neglect or abuse by the user. The shortening ltration system, (hoses) are warranted for ninety (90)

days from the initial date of start up.

PROCESSING WARRANTY CLAIMS – The equipment owner must promptly notify Ultrafryer Systems Warranty Department of any alleged defects as soon as they are discovered by calling 1-800-525-8130. After such notice, the Warranty Department will perform its obligation under this warranty within a commercially reasonable period of time. If alleged defects develop

after normal business hours, on weekends or on holidays the owner must call Ultrafryer Systems rst at the above number. This

number is monitored 24 hours a day, 7 days a week. Ultrafryer Systems will notify an authorized service agent to make repairs

during normal hours or after hours. Any parts that need to be shipped back to Ultrafryer Systems will be shipped back prepaid

by the customer marked with the processing number and to the attention of the WARRANTY DEPARTMENT.

NON WARRANTY COVERAGE – This warranty does not include coverage for any consequential cost of damages including,

but not limited to, any loss in store sales, spoiled food products, transportation, duty or custom cost. This warranty does not

cover the Ultrafryer® exported to countries outside the United States and its territories. This warranty does not cover original

installation and adjustments such as leveling, calibrations and electrical and gas connections. This warranty does not cover travel

over 100 miles or 2 hours driving time from the location of the Ultrafryer® or overtime or holiday charges unless the Warranty

Department granted prior approval. This warranty does not cover damage due to misuse, abuse, alteration or accident. This

Warranty does not cover improper or unauthorized repair or installation, damage in shipment, normal maintenance items such as

gaskets, hoses, and exterior nishes. Ultrafryer Systems will begin the fryer warranty one week after shipment but will adjust the

warranty upon receiving approved documentation. We reserve the right to void component part warranty on any Ultrafryer that

is stored more than six (6) months after shipment from Ultrafryer Systems and not put into service.

LABOR COVERAGE – The cost for labor to replace parts are covered for one (1) year after the initial start up. The Warranty

Department must be promptly notied of any defects within the rst year of operation. The labor warranty does not include

the cost to repair or clear dirty lter systems or perform any adjustments that would normally fall under the tasks associated with

a proper start up and/or demonstration. Labor is covered by Ultrafryer Systems for repairs by an AUTHORIZED service

agent. Owner is responsible for all costs associated with fryer installation and start up unless prior arrangements have been

made with Ultrafryer Systems.

DISCLAMIER OF WARRANTIES

Other than as stated herein, ULTRAFRYER SYSTEMS makes no warranty of any kind, express or implied, including

but not limited to any warranty of merchantability of tness for a particular purpose, including trade usage. Ultrafryer

Systems’ sole obligation, and purchaser’s sole remedy, under this warranty is repair or replacement, at the discretion of

Ultrafryer Systems, of any part or component that proves to be defective in materials or workmanship. In no event shall

Ultrafryer Systems be liable for consequential, incidental, or special loss or damages arising from the use of, or inability

to use, the ULTRAFRYER®. This limited warranty is the only and complete statement with respect to warranties of

NEW Ultrafryer® PAR-2,Gas ULTRAFRYERS® sold after June 1st, 2000. There are no other documents or oral statements for which Ultrafryer Systems will be responsible. Effective 2-1-2008.

PN 30A169 rev Jan2008 6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

B. SAFETY

The major safety concern associated with the Ultrafryer Gas Fryer is burns from hot shortening. In order to prevent

serious burns, good housekeeping habits are required. The oor in front of and the area around the fryer should be kept

clean and dry. Whenever anything is placed in to a fryer vat, care should be used not to splash the hot shortening.

Product

an apron

120 volts single

without rst disconnect

water. To do so can result in serious

should always be “PLACED” into the shortening, NOT THROWN. Safety goggles, neoprene insulated gloves and

must be worn while ltering or boiling-out a fryer vat. Electrical controls on all Ultrafryer Fryers operate on

phase electrical power. No adjustments or replacement of electrical controls should ever be attempted

ing

electrical power. The fryer should never be operated with wet hands or while standing in

electrical shock or death.

C. DESCRIPTION / SPECIFICATIONS

The Ultrafryer Gas Fryer is constructed from 16 & 18 gauge, “300” series, polished, satin nish stainless steel. Most Models

are equipped with a Default-To-Manual-Restart (DTMR) Control or an Ultrastat 11 Cooking Computer; however ,

customers may request the fryer be equipped with an Ultrastat 21 or Ultrastat 25 Cooking Computer. In addition, the

Model PAR25 can be equipped with the EZ Dock Filtration System, which uses a stainless steel Filter Screen. The

Customer has the option of ordering a Filter Pad Assembly that uses an impregnated Filter Pad in lieu

of the

S/S lter screen. The dimensions and gas rating of the Model PAR25 Gas Fryer are as follows:

D.

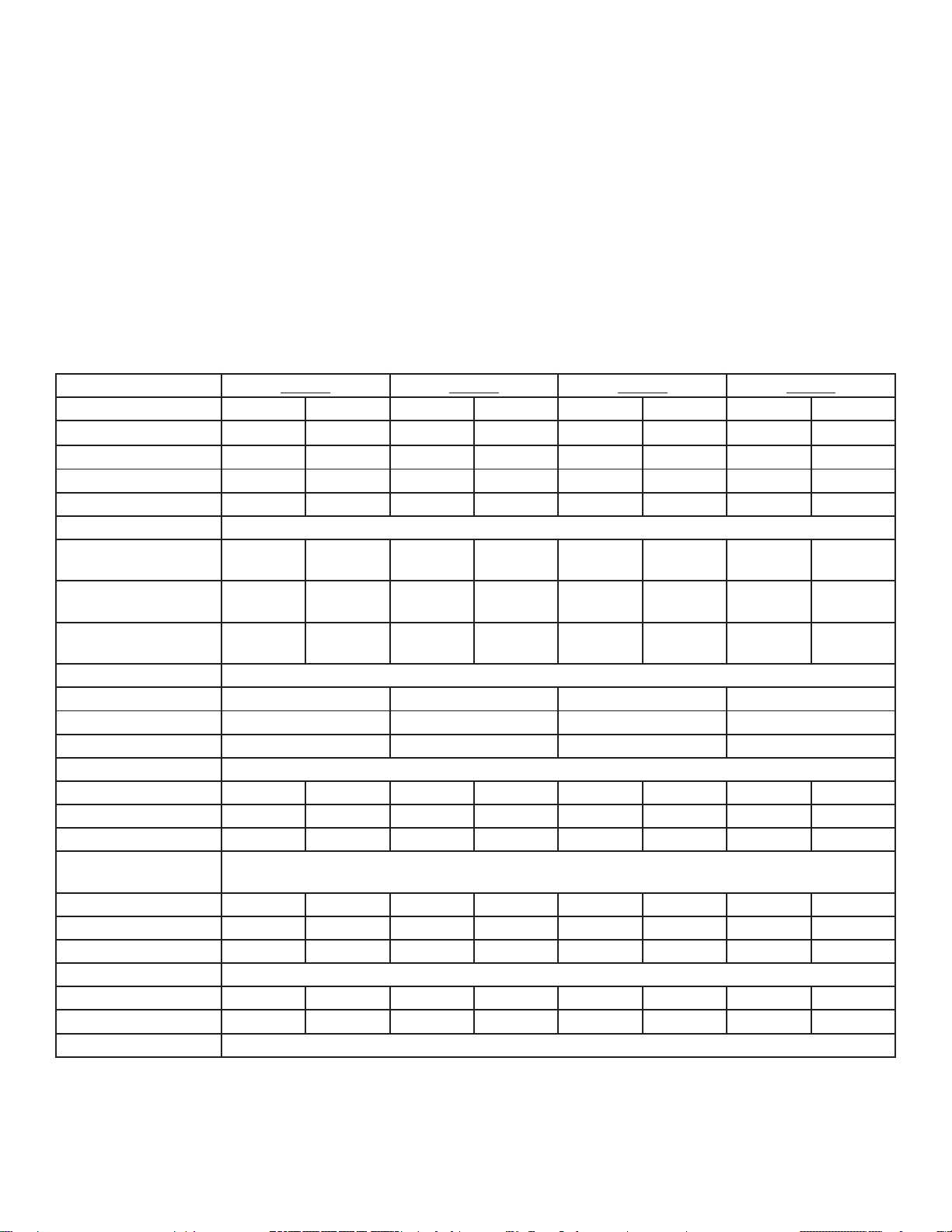

ULTRAFRYER MODEL PAR3/PAR25 GAS FRYER DIMENSIONS & OPERATIONAL REQUIREMENTS

14” VAT

18” VAT

20” VAT

24” VAT

Overall Width 15.625 in 397 mm 19.625 in 498 mm 21.625 in 549 mm 25.625 in 651 mm

Overall Depth 30.75 in 781 mm 30.75 in 781 mm 30.75 in 781 mm 30.75 in 781 mm

Work Height 35.75 in 908 mm 35.75 in 908 mm 35.75 in 908 mm 35.75 in 908 mm

Oil Capacity - High Level 45 Lb 20.4 kg 75 Lb 34 kg 98 Lb 44.4 kg 120 Lb 54.4 kg

Oil Capacity - Low Level 35 Lb 15.9 kg 75 Lb 34 kg 98 Lb 44.4 kg 120 Lb 54.4 kg

Gas Rating

Butane

Natural

Propane

70,000

BTU/hr

80,000

BTU/hr

80,000

BTU/hr

73.9 MJ/hr

84.4 MJ/hr

84.4 MJ/hr

80,000

BTU/hr

85,000

BTU/hr

85,000

BTU/hr

84.4 MJ/hr

89.7 MJ/hr

89.7 MJ/hr

70,000

BTU/hr

80,000

BTU/hr

80,000

BTU/hr

73.9 MJ/hr

84.4 MJ/hr

84.4 MJ/hr

80,000

BTU/hr

85,000

BTU/hr

85,000

BTU/hr

84.4 MJ/hr

89.7 MJ/hr

89.7 MJ/hr

Orice Drill Size

Butane #42 2.7 mm #42 2.7 mm

Natural #20 #18 #20 #18

Propane #38 #33 #38 #33

Gas Valve Pressure

Butane (W.C.) 10”w.c. 254 mm 10”w.c. 254 mm 10”w.c. 254mm 10”w.c. 254mm

Natural (W.C.) 4”w.c. 102 mm 4”w.c. 102 mm 4”w.c. 102mm 4”w.c. 102mm

Propane (W.C.) 10”w.c. 254 mm 10”w.c. 254 mm 10”w.c. 254mm 10”w.c. 254mm

Inlet ow Required at

STP

Butane 22 ft3/hr 0.62 m3/hr 25 ft3/hr 0.71 m3/hr 22 ft3/hr 0.62 m3/hr 25 ft3/hr 0.71 m3/hr

Natural 80 ft3/hr 2.27 m3/hr 85 ft3/hr 2.40 m3/hr 80 ft3/hr 2.27 m3/hr 85 ft3/hr 2.40 m3/hr

Propane 32 ft3/hr 0.91 m3/hr 34 ft3/hr 0.96 m3/hr 32 ft3/hr 0.91 m3/hr 34 ft3/hr 0.96 m3/hr

Shipping Cube 10 ft

3

3.05 m

3

12 ft

3

3.66 m

3

14 ft

3

4.27 m

3

16 ft

3

4.88 m

3

Shipping Weight 165 Lb 74 kg 170 Lb 77 kg 177 Lb 80 kg 250 Lb 113 kg

Power Input All units use 120Volt 6 amp 60 Hz 1 O

NOTE:

CONSULT THE INCLUDED COMPUTER CONTROLLER MANUAL AND FILTRATION MANUAL FOR TEST START-UP,

OPERATIONS, COOKING, FILTERING, AND BOIL OUT PROCEDURES.

PN 30A169 rev Jan2008 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

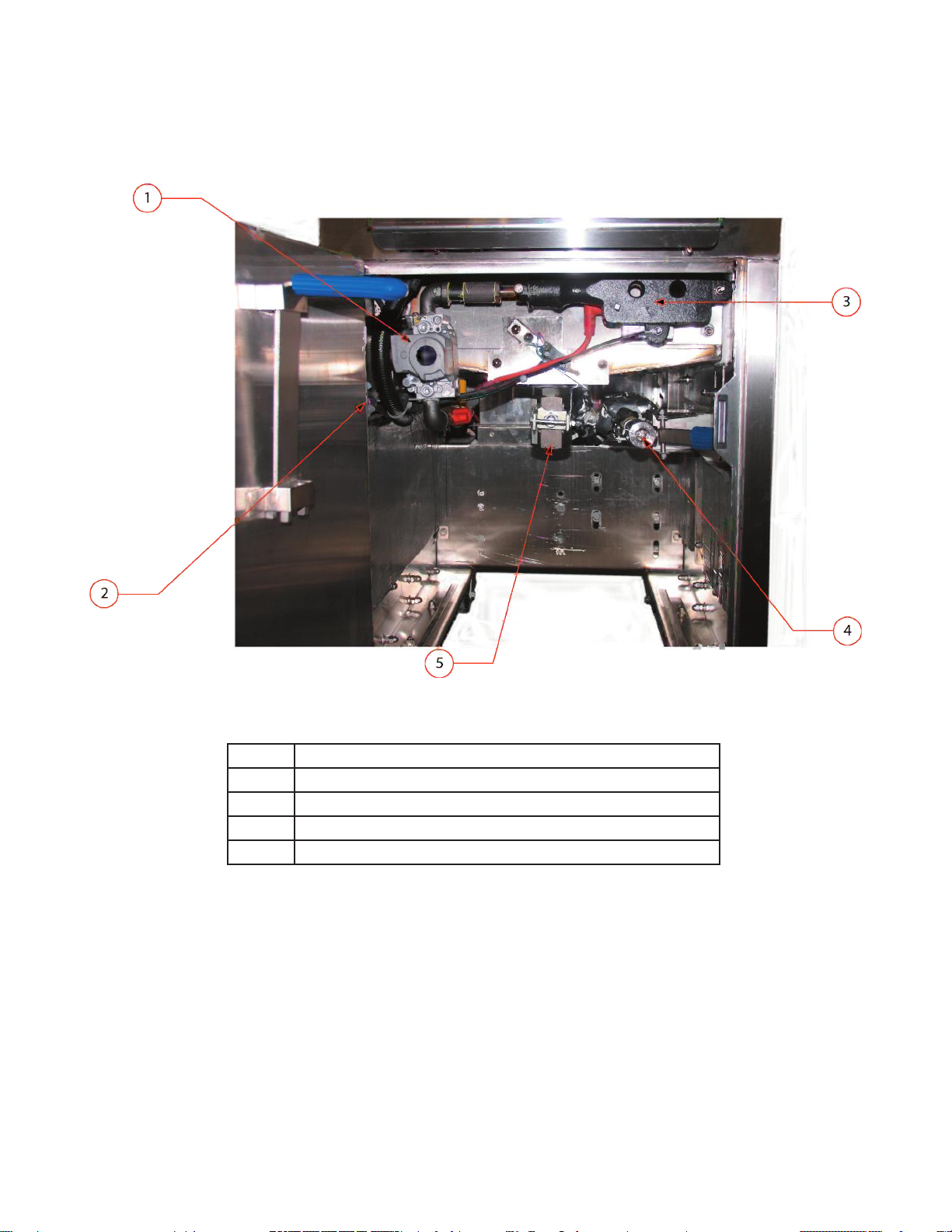

E. OPERATING CONTROLS LOCATION

MODEL PAR25

GAS FRYER

1 Gas Regulator and Shutoff Valve

2 High Limit

3 Burner

4 Docking Connection

5 Main Drain Valve

PN 30A169 rev Jan2008 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

MODEL PAR25 GAS FRYER

F. OPERATING CONTROLS:

The “basic” PAR25 gas fryer is equipped with an Electronic Thermostat and

however, customers may request the fryer be equipped with an “optional” Ultrastat Cooking Computer, such as an Ultrastat 11,21

or 25 Cooking Computer. When applicable, operating instructions for the Ultrastat Cooking Computer will be provided with the

fryer. Operating controls on the Model PAR25 gas fryer include the Toggle HEAT/OFF Switch, AMBER

RED Burner Indicator Lamp, and the applicable Temperature Controller. These controls are mounted on the Temperature

Access Panel; and the Electronic Thermostat and other fryer controls are located behind the access door. The main drain valve and

(if applicable) shortening return levers are located behind the Service Access Panel.

Default-to-Manual-Restart (DTMR) control;

Power Indicator Lamp,

Control

Figure (from left to right): 18” Model Par25 and 24” Model Par25

G. AUTOMATIC SAFETY FEATURES:

1. High limit thermostat to shut off gas to the main burners by opening a solenoid-actuated safety valve in the combination gas

control valve.

2. Combination gas control valve which includes a built-in pressure regulator and manual valve.

3. Sensing circuit within the spark ignitor module to turn gas to the fryer OFF if a burner FLAME OUT occurs.

4. A Drain Valve Safety Switch and a Default-to-Off circuit in the Default-to-Manual-Restart (DTMR) Control that will DIS-

ABLE the fryer each time the drain valve is OPENED.

5. An AIR PRESSURE switch to open the electrical circuit to the spark ignitor and gas valve which will turn the gas to the fryer

OFF in the event the blower motor fails.

H. RATING PLATE:

Information on this plate includes the model and serial number; BTU/HR input rating of the burners; gas manifold pressure in

inches W.C. ; minimum inlet gas

communicating

of the Service Access door.

with ULTRAFRYER SYSTEMS or requesting special parts or information. The rating plate is located on the inside

required, orice size; and type of gas. This data is essential for proper identication when

THE FRYER MUST BE CONNECTED ONLY TO THE TYPE OF GAS IDENTIFIED ON THIS RATING PLATE!

PN 30A169 rev Jan2008 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

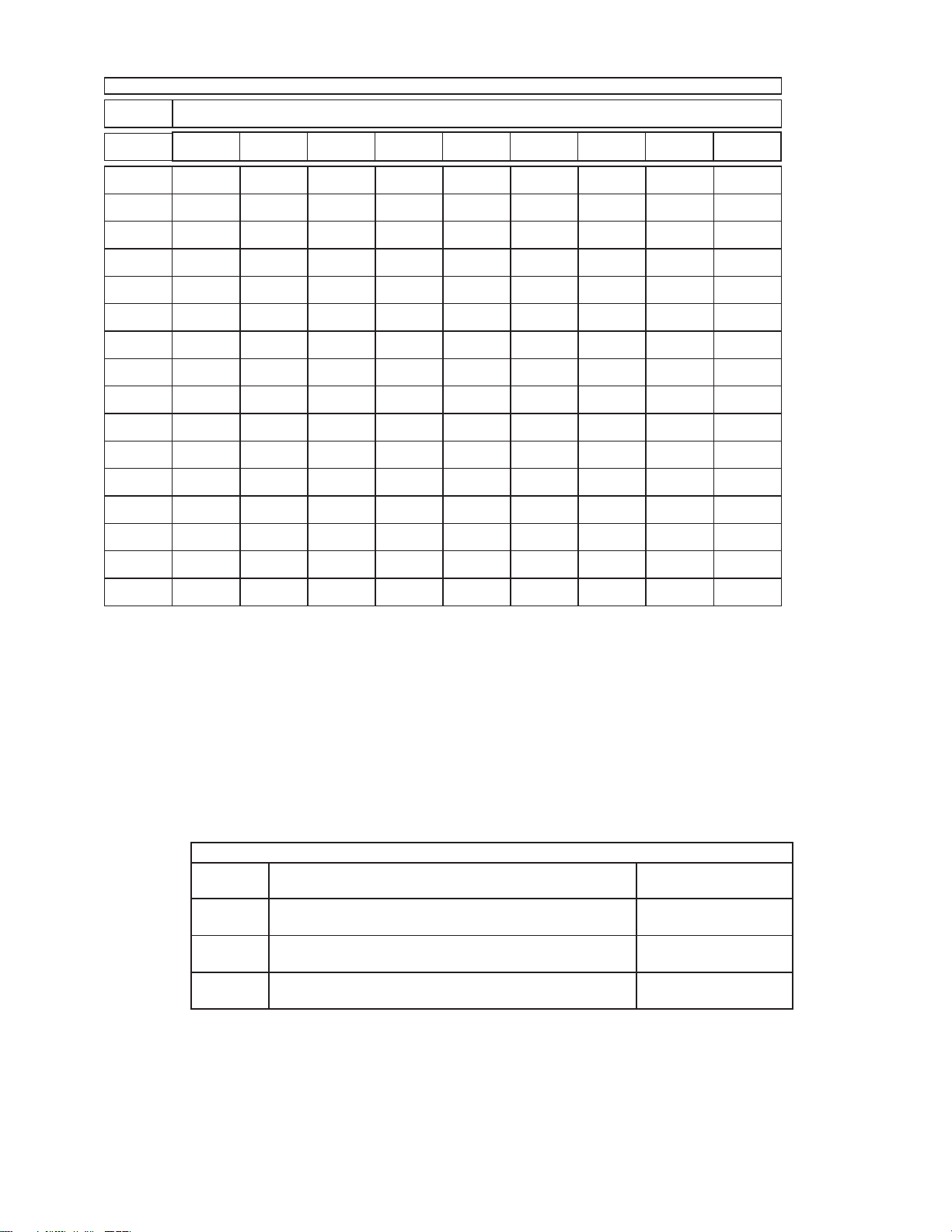

I. INLET GAS LINE SIZING:

The Table below is used to calculate the size (diameter) of the inlet gas line from the building regulator to the fryer manifold.

INLET GAS LINE REQUIREMENTS

PIPE

LENGTH

Feet

(Meters)

15

(4.6)

30

(9.1)

45

(13.7)

60

(18.3)

75

(22.9)

90

(27.4)

105

(32.0)

120

(36.6)

150

(45.7)

180

(54.9)

210

(64.0)

240

(73.2)

270

(82.3)

300

(91.4)

450

(137.2)

600

(182.9)

NOTE: 1) FT3/HR (M3/HR) values may vary due to heating value and specic gravity of gas supplied by local companies.

2) To determine the inlet gas line diameter for the distance between the fryer and main gas regulator, locate the FT3/HR (M3/HR) of gas required for the fryer and

pipe length and read the pipe diameter on the top row. For example: a PAR25 fryer operating on NATURAL GAS requires 90 FT3/HR (2.5 M3/HR)

of gas at the fryer’s inlet gas manifold. If the fryer bank is located 60 feet from the building gas regulator, a 1” (25mm) diameter gas line MUST be installed

between the manifold and regulator.

"

(13 mm)

62

(1.7)

43

(1.2)

35

(1.0)

30

(0.8)

27

(0.8)

25

(0.7)

23

(0.6)

21

(0.6)

19

(0.5)

17

(0.5)

16

(0.4)

15

(0.4)

14

(0.4)

14

(0.4)

11

(0.3)

10

(0.3)

"

(19mm)

170

(4.7)

120

(3.4)

98

(2.7)

84

(2.4)

76

(2.1)

70

(2.0)

64

(1.8)

60

(1.7)

54

(1.5)

49

(1.4)

44

(1.2)

43

(1.2)

40

(1.1)

38

(1.1)

31

(0.9)

27

(0.8)

(25mm)

PIPE DIAMETERS (inches & (mm equivalents))

Maximum Allowable Flow (Shown in ft3/hr (M3/hr))

1

350

(9.8)

245

(6.9)

200

(5.6)

175

(4.9)

155

(4.3)

145

(4.1)

132

(3.7)

125

(3.5)

110

(3.1)

100

(2.8)

94

(2.6)

88

(2.5)

83

(2.3)

79

(2.2)

64

(1.8)

56

(1.6)

"

1

(32mm)

620

(17.4)

430

(12.0)

355

(9.9)

310

(8.7)

275

(7.7)

250

(7.0)

232

(6.5)

215

(6.0)

195

(5.5)

175

(4.9)

165

(4.6)

155

(4.3)

145

(4.1)

138

(3.9)

112

(3.1)

97

(2.7)

"

1

(38mm)

960

(26.9)

680

(19.0)

530

(14.8)

480

(13.4)

430

(12.0)

395

(11.1)

370

(10.4)

340

(9.5)

310

(8.7)

280

(7.8)

260

(7.3)

240

(6.7)

230

(6.4)

215

(6.0)

176

(4.9)

152

(4.3)

"

2

"

(51mm)

2,000

(56.0)

1,400

(39.2)

1,150

(32.2)

1,000

(28.0)

890

(24.9)

810

(22.7)

(750

(21.0)

700

(19.6)

630

(17.6)

570

(16.0)

530

(14.8)

500

(14.0)

470

(13.2)

440

(12.3)

360

(10.1)

315

(8.8)

2

(64mm)

3,500

(98.0)

2,450

(68.6)

2,000

(56.0)

1,760

(49.3)

1,560

(43.7)

1,430

(40.0)

1,300

(36.4)

1,200

(33.6)

1,080

(30.2)

960

(26.9)

890

(24.9)

840

(23.5)

780

(21.8)

750

(21.0)

630

(17.6)

530

(14.8)

"

3

"

(76mm)

5,400

(151.2)

3,800

(106.4)

3,200

(89.6)

2,700

(75.6)

2,450

(68.6)

2,260

(63.3)

2,100

(58.8)

1,950

(54.6)

1,750

(49.0)

1,600

(44.8)

1,450

(40.6)

1,350

(37.8)

1,300

(36.4)

1,250

(35.0)

1,000

(28.0)

860

(24.1)

4

"

(102mm)

11,200

(313.6)

7,900

(221.2)

7,900

(182.0)

5,600

(156.8)

5,000

(140.0)

4,550

(127.4)

4,200

(117.6)

4,000

(112.0)

3,550

(99.4)

3,200

(89.6)

3,000

(84.0)

2,800

(78.4)

2,650

(74.2)

2,500

(70.0)

2,050

(57.4)

1,750

(49.0)

J. GAS LINES

The Flexible Gas Line used to connect the gas manifold to the building gas supply line must be rated for the BTU/Hr (MJ/Hr)

designated for the Fryer. Flexible gas lines and their ratings stocked by Ultrafryer Systems are listed below:

FLEXIBLE GAS LINES STOCKED BY ULTRAFRYER SYSTEMS

NUMBER DESCRIPTION

24322

24323

24456

3/4" (19mm) Diameter Flexible Gas Line (w/quick connect

couplings) 48" (1219mm) long. Connect-It SSGC75-48-UCQ

1” (25mm) Diameter Flexible Gas Line (w/quick connect

couplings) 48" (1219mm) long. Connect-It SSGC100-48-UCQ

1 1/4" (32mm) Diameter Flexible Gas Line (w/quick connect

couplings) 48” (1219mm) long. Connect-It SSGC125-48-UCQ

225,000 (238)

435,000 (459)

875,000 (924)

RATING

BTU/HR (MJ/HR)

PN 30A169 rev Jan2008 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

PRE-INSTALLATION

PN 30A169 rev Jan2008 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

A. GENERAL: Safe and satisfactory operation of a Model PAR25 gas fryer depends on its proper installation. Installation

must conform to local codes or, in the absence of local codes, with the current National Fuel Gas Code ANSI Z223.1 (latest edi tion). In Canada, gas installation shall be in accordance with the current CAN/CGA B 149.1 and .2 installation codes and/or local

codes. Each Model PAR25 fryer should be installed as follows:

1. Placed beneath a properly designed exhaust hood

2. Installed by a licensed plumber.

3. Connected to the type gas for which the unit was fabricated as shown on the rating plate.

4. Connected to the proper size pressure regulator installed in the gas supply line and adjusted to the proper manifold pressure.

5. Connected to the main gas supply line with the proper size supply line.

6. Restrained by use of a restraining device to avoid splashing of hot liquid and to assure tension cannot be placed on the exible

gas line or ttings.

CLEARANCES: The appliance must be kept free and clear of all combustibles. The minimum clearance from combustible and

non-combustible construction is 6" (152 mm) from the sides, and 6" (152 mm) from rear. The fryer may be installed on combustible oors.

NOTE: Adequate clearances must be provided for servicing and proper operation.

B. STANDARDS: Installation must be planned in accordance with all applicable state and local codes, taking into account the following

standards

1. The fryer and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing

2. The fryer must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pres-

3. When installed the fryer must be electrically grounded in accordance with local codes, or in the absence of local codes, in

4. Other applicable nationally recognized installation standards such as:

a. National Fuel Gas Code ANSI Z223.1 (latest edition)

American Gas Association

1515 Wilson Blvd.

Arlington, VA22209

b. NFPA Standards #54, #94 and #221 (latest edition)

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

c. ANSI Z21.69/CAN/CGA-6.16 AND Z21.41/CAN1 6.9

5. Exhaust vent hood, when installed must conform to the current NFPA 54-1 and Canadian CAN/CGA-1.11 (latest edition)

:

of that system at pressures in excess of psig (3.45kPa). In Canada, gas installation shall be in accordance with the current

CAN/CGA B 149.1 and .2 installation codes and/or local codes.

sure testing of the gas supply piping system at pressures equal to or less than psig (3.45kPA).

accordance with the current National Electrical code ANSI/NFPA 70 (latest edition). In Canada electrical installation must be

in accordance with the current CSA C22.1 Canadian Electrical Code and/or local codes.

NOTE: Local building codes will usually not permit a fryer with its open tank of hot oil to be installed immediately next to an

open ame of any type, whether a broiler or an open burner or range. Check local codes before beginning installation.

C. AIR SUPPLY AND VENTILATION: The area around the appliance must be kept clear of any combustible or ammable products

and avoid any obstruction to the ow of ventilation air as well as for ease of maintenance and service. NOTHING is to be stored

in the interior of the fryer’s cabinet except the lter tub assembly.

1. A means must be provided for any commercial, heavy duty-cooking appliance to exhaust combustion wastes outside of the

building. It is essential that a fryer be set under a powered exhaust vent hood or that an exhaust fan be provided in the wall

above the unit, as exhaust temperatures are in the vicinity of 400˚F (204˚C).

NOTE: Strong exhaust fans in a hood or in the overall air conditioning system can produce slight air drafts in the room, which

can interfere with burner performance and be hard to diagnose. Air movement should be checked during installation and

if burner problems persist, make-up air openings or bafes may have to be provided in the room.

2. Exhaust temperature, in addition to the open tank of hot oil, make the storage of anything on shelving over or behind the

fryer unsafe.

3. Filters and drip troughs should be part of any industrial hood, but consult local codes before constructing and installing any

hood.

4. Provisions must be made for an adequate supply of fresh air and adequate clearance must be maintained for air openings into

the combustion chamber.

PN 30A169 rev Jan2008 12

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

RECEIVING & INSTALLING

PN 30A169 rev Jan2008 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

A. UNPACKING: Check that the container is upright. Use an outward prying motion – DO NOT USE A HAMMER - to remove the

carton. Check the fryer for visible damage; if such damage has occurred do not refuse shipment, but contact the carrier and le

the appropriate freight claims.

B. INSTALLING: Roll the assembled fryer into the building, to its operating location.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

C. LEVELING:

1. When the fryer is placed in its operating location check to be sure it is level. If not, loosen the casters and insert the

appropriate number of shim plates between leg and caster plates then retighten the caster bolts.

2. If the oor is smooth and level, adjust to the high corner and measure with a spirit level. If the oor is uneven or has a

decided slope, level the unit with metal shims.

NOTE: A caster may not return exactly to the same position after being moved, which may require re-leveling after each move.

3. Connect the gas manifold to the building gas supply line by means of a CSA International APPROVED exible gas line as

shown in the gure below.

NOTE: CONNECT-IT inc. " (19mm), 1" (25mm) and 1 " (32mm) exible gas hose 4 feet long (1219mm) with a quick

disconnect coupling on one end is available from Ultrafryer Systems under PN 24322 (" (19mm) hose), PN 24323

(1" (25mm) hose) and PN 24456 (1 " (32mm) hose). These hoses are euipped with a fusible link, which melts at

361°F (183ºC) that will SHUT OFF the gas supply when it melts. A 44" (1119mm) long restraining device is also

available under PN 24324.

CAUTION: THE BUILDING GAS SUPPLY LINE MUST BE SIZED TO PROVIDE THE VOLUME OF GAS REQUIRED FOR

PROPER OPERATION

TYPICAL GAS CONNECTION

WARNING: THE RESTRAINT DEVICE (ITEM 9) MUST BE INSTALLED TO PREVENT TIPPING AND / OR SPLASHING OF

HOT LIQUID AND TO ASSURE TENSION CANNOT BE PLACED ON THE FLEXIBLE GAS LINE OR FITTING.

1. BUILDING GAS SERVICE LINE 6. APPLIANCE MANIFOLD/NIPPLE

2. MAIN GAS CUT-OFF VALVE 7. EYELET FASTENERS

3. CONNECT-IT QUICK-DISCONNECT 8. SPRING HOOK

4. FLEX-CON CONNECTOR 9. RESTRAINING CHAIN

5. ELBOW

AS EXPLAINED ON THE PREVIOUS PAGE.

PN 30A169 rev Jan2008 14

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

D. GAS CONNECTION: The gas supply (service) line must be the same size or greater than the inlet line of the appliance. THE GAS

SUPPLY

TO THAT SUPPLY. Refer to the Inlet Gas Line Sizing Table and inlet gas requirements.

NOTE: Sealant used on all pipe joints must be resistive to butane and propane gas.

1. Manual shut off valve: This supplier-installed valve must be installed in the gas service line ahead of the appliance and in a

position where it can be reached quickly in the event of an emergency.

2. Pressure regulator: All commercial cooking equipment must have a pressure regulator on the incoming service line for safe

and efcient operation, because service pressure may uctuate with local demand. External regulators are not required on this

fryer, as that function is performed by a combination gas control valve, however if the incoming pressure is in excess of psig,

a step-down regulator will be required.

3. Natural gas: Natural gas fryers require 7” (178mm) water column (W.C.) “inlet” pressure to the fryer’s combination gas con-

trol valve for

(356mm) water column (W.C.)

units are operating simultaneously. This “inlet” pressure MUST be checked with a manometer PRIOR to placing the fryer in

operation.

LINES MUST BE SIZED TO ACCOMMODATE ALL THE GAS FIRED EQUIPMENT THAT MAY BE CONNECTED

proper operation, when all gas units are operating simultaneously. Butane and Propane gas fryers require 14"

“inlet” pressure to the fryer’s combination gas control valve for proper operation, when all gas

WARNING: IF THE “INLET” GAS PRESSURE AT THE FRYER’S COMBINATION GAS CONTROL VALVE “EXCEEDS” lb/in

(

VENT DAMAGE TO THE COMBINATION GAS VALVE, AND VOIDING OF WARRANTY. FAILURE TO ADDRESS

THIS COULD RESULT IN AN EXPLOSION OR A FIRE.

4. Combination gas control valve: The correct combination gas control valve and orice is installed at the factory for BUTANE,

NATURAL and PROPANE units based on each Purchase Order. This valve should be CHECKED/ADJUSTED by qualied

service personnel using proper test equipment for the following “OUTLET” gas pressure PRIOR to start-up of a fryer. NATU RAL GAS FRYERS 4" (102mm) W.C. BUTANE/PROPANE FRYERS 10" (254mm) W.C.

5. Rigid connections: Check any installer-supplied intake pipe(s) visually and/or blow them out with compressed air to clear dirt

particles, threading chips or any other foreign matter before connecting to the service line as these particles may clog the

orice when gas pressure is applied. All connections must be tested with a soapy solution before lighting the fryer.

USE AN OPEN FLAME TO

will often miss small leaks that a soapy solution would nd.

6. Flexible Couplings, Connectors: The installation is to be made with a connector that (1) complies with the Standard for Con-

nectors for Movable Gas Appliances, ANSI Z21.69 (CAN/CGA-6.16), and a quick-disconnect device that complies with the

Standard for Quick-Dis-connect Devices for Use With Gas Fuel, ANSI Z21.41 (CAN1-6.9) (2) adequate means must be pro-

vided to limit the movement of the appliance without depending on the connector and the quick dis-connect device or its asso ciated piping to limit the appliance movement and (3) the location(s) where the restraining means may be attached to the

appliance shall be specied. DOMESTIC CONNECTORS ARE NOT SUITABLE!!!

7. Fryer Service: The fryer is equipped with swivel casters. To service the fryer:

a) Turn “OFF” gas supply at the supply source.

b) Disconnect the exible gas line quick-disconnect

c) Disconnect restraint means and roll fryer out for rear service access.

d) When the fryer is re-positioned, be sure to reconnect the restraint and level the fryer.

E. ELECTRICAL CONNECTION: The MAXIMUM current draw per vat at Initial Start-up or during a Warm-up Cycle will be 3

Amperes at 120 Volts. When running the Filter System simultaneously allow for an additional 3 Amperes. Refer to the wiring

diagram attached to the inside of the Service Access door for internal electrical connections.

.035 kg/cm2) OR APPROXIMATELY 14” (356 mm) W.C., AN EXTERNAL REGULATOR MAY BE NEEDED TO PRE-

CHECK FOR LEAKS! Putting an open ame beside a new connection is not only dangerous, but

2

DO NOT

PN 30A169 rev Jan2008 15

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

F. Cooking Computers

All fryers from Ultrafryer are shipped with the applicable manual for the cooking computer or computers that are specic to that

fryer. The following list shows the cooking computer types and their related manuals.

NOTE: The appearance of a given cooking computer’s control panel may vary slightly depending upon the style of fryer on which

the computer is installed. This does not affect the actual operation of the computer. Please refer to the pertinent cooking computer

manual for more information.

U03 / DTMR Cooking Computer (refer to Manual P/N 30A192; French Version 30A192 FR)

Ultrastat 25 Cooking Computer (refer to Manual P/N 30A190; French Version 30A190 FR)

PN 30A169 rev Jan2008 16

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

Ultrastat 21 Cooking Computer (refer to Manual P/N 30A189; French Version 30A189 FR)

Ultrastat 11 Cooking Computer (refer to Manual P/N 30A191; French Version 30A191 FR)

PN 30A169 rev Jan2008 17

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

INITIAL START-UP

PN 30A169 rev Jan2008 18

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

WARNING - ELECTRIC GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard and should be plugged

directly into a proplerly grounded three-prong receptacle. Do not cut or remove the grounding prong from this plug.

A. CLEANING: New units are wiped clean at the factory to remove any visible signs of dirt, oil, grease, etcetera, remaining from the

manufacturing process. Each fryer vessel should be thoroughly washed with hot soapy water to remove lm residues, installation

dust or debris; rinsed and then wiped dry before being used for food preparation.

B. START-UP: The fryers are tested, adjusted and calibrated prior to being shipped: however adjustments may be necessary on instal lation to meet local conditions, high or low gas pressure, differences in altitudes, variations in gas characteristics and to correct

possible problems caused by rough handling or vibration during shipment. Initial calibration or adjustment is the responsibility

of the customer and will not be covered by the Ultrafryer Systems warranty.

NOTE: Calibration and adjustments must be performed by qualied personnel.

C. LIGHTING INSTRUCTIONS: Each fryer is equipped with a spark ignition system and to test this system, perform the following

steps, in sequence:

1. Turn the Toggle ON/OFF SWITCH to the OFF position.

2. Fill the fryer vessel with hot or cold water to the SHORTENING LEVEL mark on the rear wall of the fryer vat.

CAUTION : IF THE MAIN BURNERS ARE OPERATED WITH THE VESSEL EMPTY, THE HEAT WILL CAUSE THE JOINTS

OF THE FRYER VESSEL TO BE PLACED UNDER UNDO STRESS AND MAY CAUSE THE HEAT EXCHANGER

VESSEL TO WARP OR BUCKLE, VOIDING WARRANTY.

3. Turn the manual gas valve located behind the fryer Service Access door to the OFF position and wait FIVE (5) minutes

for any accumulated gas to disperse.

4. ENSURE the MAIN gas shut-off is in the ON position, MANUAL VALVE on the combination GAS CONTROL VALVE

(located behind the fryer Service Access door) is in the ON position and the Vent Hood EXHAUST FAN is ON.

5. Turn the manual gas valve to the ON position.

6. Turn the ON/OFF switch ON; then place the DTMR or ULTRASTAT Cooking Computer into the MELT MODE.

WARNING!!! DO NOT USE A MATCH OR CANDLE TO LIGHT A FRYER… EVER!

D. SEQUENCE OF IGNITION:

occur:

1. Blower will come ON activating the air pressure switch.

2. The air pressure switch will CLOSE completing the electrical circuit to the IGNITOR MODULE and GAS CONTROL VALVE,

and the ignitor will SPARK, lighting the gas in the burner.

WARNING!!! WHEN CHECKING FOR BURNER PERFORMANCE, DO NOT STAND WITH YOUR FACE CLOSE

TO THE BURNER…. IT MAY LIGHT WITH A “POP” AND COULD FLASH BACK AND CAUSE FACIAL

BURNS.

NOTES: 1) If the burner ame fails, it will be sensed by the SPARK IGNITOR, the Spark Ignitor Module will open the electrical

circuit to the GAS CONTROL VALVE shutting off gas to the burner.

2) If the blower fails, the air pressure switch will open the electrical circuit to the SPARK IGNITOR MODULE and GAS

CONTROL VALVE, shutting off gas to the burner.

E. BURNER OPERATION TEST: Perform above LIGHTING INSTRUCTIONS and observe operation of the burners. When

satised that the burner is operating properly, drain the fryer vessel of water and dry the vessel thoroughly; then ll the fryer

vessel with shortening. Refer to the accompanying Computer Controller manual for more information.

When the lighting instruction steps are performed in the sequence listed above, the following will

F. TEST START-UP: Refer to the accompanying Computer Controller manual for procedures on test operating the fryer.

PN 30A169 rev Jan2008 19

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

ABBREVIATED OPERATING INSTRUCTIONS

PN 30A169 rev Jan2008 20

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

WARNING - To Avoid Injury:

1. Do not move a fryer lled with hot liquid.

2. Always wear oil-proof, insulated gloves when working with a fryer lled with hot oil.

3. Always drain hot oil into a metal container. Hot oil will melt plastic buckets or shatter glass.

A. GENERAL: This gas fryer is equipped with a shortening lter system which is to be operated and cleaned according to the

FRYER OPERATION section of this manual.

1. SHORTENING: Use a high quality shortening to achieve a consistent quality product as well as a long term savings.

2. SHORTENING TEMPERATURE: Most products should be cooked with a shortening temperature about 350˚F (177˚C);

however, each product should be cooked at the LOWEST temperature that produces a high quality product while obtaining

maximum usage of the shortening.

3. SALTING: Products should not be salted over the fryer vessel as salt quickly deteriorates the shortening and avors other

products cooked in the same shortening.

4. POWER FAILURES: The fryer cannot be operated during power failures. DO NOT attempt to manually operate the fryer.

5. PUMP MOTOR: The lter pump motor is protected by a motor thermal overload switch.

CAUTION: ENSURE THE WASH WAND HOSE IS NOT CONNECTED TO A FRYER PRIOR TO RESETTING A THERMAL

B. COOKING: Refer to the included Cooking Computer Manual for specic procedures on operating the fryer using the cooking

computer.

OVERLOAD SWITCH.

Computer Manual Number

U03 / DTMR 30A192 (French: 30A192 FR)

U11 30A191 (French: 30A191 FR)

U21 30A189 (French: 30A189 FR)

U25 30A190 (French: 30A190 FR)

C. FILTERING SHORTENING :

1. If the customer decides to use a shortening ltration system (whether provided by Ultrafryer or from another source), then

the fryer must be ltered at least twice a day (once after the lunch rush and again after the dinner rush).

2. Place the recommended amount of lter agent in the shortening as prescribed by the chemical supplier.

3. Follow the procedures outlined in the appropriate included ltration manual:

Filtration Topic Manual Number

General Filtration Procedures

“R” Filtration Procedures 30A182 (French: 30A182 FR)

“S” Filtration Procedures 30A183 (French: 30A183 FR)

“T” Filtration Procedures 30A184 (French: 30A184 FR)

Portable Filtration Machine Procedures 30A211 (French: 30A211 FR)

WARNING: CRUMBS AND SLUDGE LEFT IN THE FILTER TUB OVERNIGHT ARE A FIRE HAZARD.

D. LEVELING SHORTENING: After ltering, the shortening level must be checked and fresh shortening added when necessary.

1. The shortening in the vat should reach to the middle line of the “E” in the word LEVEL of the shortening level mark

wall of the fryer.

2. If shortening is needed, use the lter scraper to cut off a small block of solid shortening.

3. Place the small block of shortening into a fry basket, lower the basket into the shortening; then turn the basket to allow the

block to oat freely.

4. Repeat the above steps until the shortening in the vat is at the proper level.

30A181 (French: 30A181 FR)

on the rear

E. BOILING OUT FRYER: The fryer should be BOILED OUT every 7 DAYS to remove carbon buildup and other encrusted materi als. Add the amount of boil out compound to the fryer as prescribed in the cleaning manual provided by the chemical supplier

and follow instructions for boiling out a fryer in the “General Filtration Procedures” manual (UFS # 30A181).

PN 30A169 rev Jan2008 21

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 22

F. CLOSING / SHUTDOWN INSTRUCTIONS:

1. CLOSING: When closing at night; lter the shortening in the fryer, THOROUGHLY drain all lter lines and cover the fryer

vessel. Turn the ON/OFF Switch on the fryer OFF and turn the Manual Gas Valve OFF.

2. SHUTDOWN OR PROLONGED POWER FAILURE:

a. Shutdown: Perform the following whenever a fryer is being shutdown for an extended period of time:

1) Drain and discard the shortening.

2) THOROUGHLY clean the fryer vat.

3) Turn the ON/OFF Switch to the OFF position, disconnect the 120-volt power cord and turn applicable Circuit

Breakers OFF.

4) Turn the Manual Gas Valve OFF.

b. Prolonged power failure: The gas fryer cannot be operated during power failures. DO NOT attempt to bypass safety

controls and manually start the fryer.

PN 30A169 rev Jan2008 22

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

PREVENTIVE MAINTENANCE & TROUBLESHOOTING

PN 30A169 rev Jan2008 23

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 24

A. PREVENTIVE MAINTENANCE: Minimal maintenance is required on a gas fryer because of its design and the materials

used in the manufacturing process. However, some preventive maintenance and inspection must be performed periodically to

prevent break downs which could curtail food sales.

Any preventive maintenance or inspection should be accomplished with CAUTION while the fryer is in operation since HOT liquid

shortening could cause severe burns. If service or repair is required, all gas and electric power MUST BE TURNED OFF PRIOR TO

performing that service or repair.

PREVENTIVE MAINTENANCE SCHEDULE

INSPECTION ITEM

Grease Filters DAILY

Filter Tub (if applicable) DAILY

Drain Valve & Shortening

Return Levers

Temperature Sensing Probes WEEKLY

Blower Motor SEMIANNUALLY

Agitator Bafe SEMIANNUALLY

INSPECTION

PRIORITY

WEEKLY

Clean grease lters in the exhaust vent hood each evening

and allow them to dry overnight.

Thoroughly clean the lter tub

assembly prior to leaving the store at closing

Determine that all levers are securely attached and that they

can be easily opened and closed.

During Boil-Out of the fryer, inspect the temperature and

high limit sensing probes for any visual damage.

A qualied technician or authorized service agent should

inspect and thoroughly clean the motor of dirt and debris

every SIX (6) MONTHS.

A qualied technician or authorized service agent is to remove and inspect the agitator bafe in each fryer for metal

fatigue or weld deterioration every SIX (6) MONTHS. If

no defect is found, reinstall the original bafe.

INSPECTION

DESCRIPTION

NOTE: Slight warp or a few broken ns is normal wear. DO NOT REPLACE during semiannual inspection.

A qualied technician or authorized service agent is to in-

Agitator Bafe ANNUALLY

stall a NEW agitator weldment in each fryer AUTOMATICALLY every TWELVE (12) MONTHS.

B TROUBLESHOOTING

The problems and possible solutions listed in the troubleshooting chart below are typical problems that are frequently

encountered. ONLY qualied repairmen are to use the troubleshooting chart to repair this fryer. In the event a main burner mal function occurs, perform the following checks PRIOR to contacting a repairman:

a. Ensure Gas Valves are in their proper position.

b. Check that the fryer electrical plug is connected to an electrical receptacle.

c. Ensure the applicable Circuit Breaker is in the ON position and that the fryer ON/OFF switch is in the ON position.

d. Ensure the applicable fryer control has been placed in the FULL ON mode.

e. Ensure the gas supply line quick-disconnect coupling is SEATED on the gas manifold tting.

f. Determine that the blower is operating.

C TROUBLESHOOTING CHART: Should a problem occur that cannot be corrected after performing the above CHECKS, contact

an AUTHORIZED repairman and/or Ultrafryer Systems Customer Service 1-800-525-8130 and provide the information

acquired while performing these checks.

CAUTION: ENSURE REPAIRMEN ARE ADVISED THAT FRYER RESTRAINTS MUST BE DISCONNECTED/CONNECTED.

IF A FRYER IS TO BE MOVED DURING MAINTENANCE OR REPAIR, AND THAT ELECTRICAL POWER AND

GAS MUST BE TURNED OFF PRIOR TO PERFORMING ANY MAINTENANCE OR REPAIR.

PN 30A169 rev Jan2008 24

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 25

TROUBLESHOOTING CHART

ITEM PROBLEMS POSSIBLE SOLUTIONS

A. Check the Blower air pressure Switch by temporarily

Main burner will not ignite. Blower is operating; but

1

gas is not present at the burner.

Electrical power is present at the fryer, but the

2

Blower is not operating.

Excessive time is required to raise the shortening to

cooking temperature. Temperature recovery is slow

3

and main burner ames are small and appear to be

lethargic.

Shortening temperature is too high and breaks down

4

quickly.

The lter pump motor fails to operate when the Vat

5

Shortening Return / Topside Shortening Lever is

placed in the OPEN position.

6 Decreased shortening ow rate while ltering.

Pump/Motor operates but does not pump shoreten-

7

ing.

8 Pump / Motor hums but will not pump shortening

discon

connecting them together. If the IGNITOR sparks when these

wires are connected, the air pressure switch is defective and it will

have to be replaced.

B. Check the following components and replace if found to be

defective: Gas Control Valve

Hi-Limit Switch

Transformer

A. Blower may have over-heated and shut off on thermal overload.

If this situation did occur, it will correct itself when the motor

cools (10-20 minutes). If this overheating problem persists, re place the blower motor.

A. Ensure that the MANUAL GAS VALVE is completely open.

B. Check for an obstruction in the gas line.

C. Check for an obstruction in the ue pipe.

D. Check that the ORFICE PLUG has the correct drill size opening as

indicated on the operational requirements chart.

E. Check for damaged BLOWER ns.

F. Use a standard water-type U-gauge Manometer to check the pres sure at the gas control valve pressure tap. Proper gas pressure is

indicated on the operational requirements chart.

NOTE: If necessary remove the Pressure Regulator Adjustment Cover

and

CLOCKCLOCKWISE

A. Check the gas pressure as described above.

B. Check calibration of the Electronic Thermostat with an

ACCURATE digital thermometer.

A. Insure the lter pump micro-switch is good, then check the manual

reset button on the lter pump motor.

B. If the lter pump motor fails to operate after the reset button has

been depressed, repair or replace the motor.

A. Check for excessive sediment on the lter screen, standpipe suction

A. Check for congealed shortening in the shortening system.

B. Check for loose Standpipe / Suction Line Coupler connection.

A. Check for congealed shortening in the pump or in shortening

plumbing.

necting the two (2) air switch wires and

adjust this control to the proper pressure. (Turn adjusting screw

WISE to increase gas pressure to the burner and COUNTER

to decrease gas pressure. Replace adjustment cover.)

tting or in lter tub.

PN 30A169 rev Jan2008 25

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 26

CLEANING

PN 30A169 rev Jan2008 26

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 27

CLEANING - Any item of equipment operates better and lasts longer when it is kept clean and properly maintained. The Gas Fryer is

no

exception. In order for this fryer to provide years of trouble-free service, it must be CLEANED and MAINTAINED according to instruc-

tions

herein and at the intervals listed below:

WARNING!!! TO ASSURE PRODUCING A QUALITY PRODUCT WHILE PROLONGING THE LIFE EXPECTANCY OF

THE FRYER, ENSURE FILTERING, BOIL-OUT AND CLEANING INSTRUCTIONS ARE STRICTLY

FOLLOWED.

1. Clean the fryer surface periodically during operating hours with a solution of sanitizer and hot water, and at closing with stainless

steel cleaner. If necessary, use a dampened 3M type 7447 RED or 7440 BROWN (heavy duty) Scotch Brite pad to remove

encrusted material. DO NOT use steel wool, abrasive cloths, cleaners, powders or metal devices to scrape stainless steel! Scratches

on stainless steel are almost impossible to remove!

CAUTION: DO NOT ALLOW ANY CLEANING SOLUTION OR WATER TO SPLASH INTO A VESSEL OF HOT COOKING

OIL, AS IT WILL CONTAMINATE THE OIL AND MAY CAUSE THE OIL TO SPLATTER CAUSING SEVERE BURNS.

Docking

Release

Handle

2. If a Filter Tub Assembly is used with this fryer, then the Filter Tub Assembly and

Filter Screen should be cleaned EACH DAY AFTER FILTERING and AT

CLOSING, and THOROUGHLY cleaned once each week. To remove the Filter

Tub Assembly from the fryer:

a. OPEN the Fryer’s Temperature Control Access Door.

b. PRESS the DOCKING RELEASE HANDLE, shown above.

c. PULL the Filter Tub Assembly from the fryer using the Standpipe Docking

Handle Assy.

d. Clean the Filter Tub Assembly according to the ltration manuals provided

with the fryer:

Filtration Topic Manual Number

General Filtration Procedures

30A181 (French: 30A181 FR)

“R” Filtration Procedures 30A182 (French: 30A182 FR)

“S” Filtration Procedures 30A183 (French: 30A183 FR)

“T” Filtration Procedures 30A184 (French: 30A184 FR)

Portable Filtration Machine Procedures 30A211 (French: 30A211 FR)

1 Crumb Catcher Screen

2 Filter Tub Cover

3 Standpipe Docking

Handle Assembly

4 Filter Tub Latch

WARNING: CRUMBS AND SLUDGE LEFT IN THE FILTER TUB OVERNIGHT ARE

A FIRE HAZARD!

PN 30A169 rev Jan2008 27

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 28

FILTER TUB ASSEMBLY & INSTALLATION

PN 30A169 rev Jan2008 28

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 29

NOTE: The following applies only to those fryers that are equipped with a hard dock ltration assembly from Ultrafryer Systems.

A. FILTER TUB ASSEMBLY - ENSURE all components of the lter tub have been thoroughly cleaned and that the Filter Screen has

been assembled; then assemble the lter tub as follows:

1. Connect the KNURLED KNOB to the STANDPIPE DOCKING

HANDLE ASSEMBLY; then attach this assembly to the SUCTION

FITTING on the Filter Screen.

DO NOT OVERTIGHTEN THIS CONNECTION!!!

2. Place the Filter Screen in the bottom of the Filter Tub with the screen

butted against the rear wall of the tub.

3. Insert the Crumb Catcher Screen in the Filter Tub with the Drain Valve

DOCKING FLANGE and MALE DOCKING PLUG over the leading

edge of the pan.

4. Position the FILTER TUB COVER on the open

end of the Filter Tub

with the SLOT on the cover seated around the Standpipe Docking Handle

Assembly. Then, SECURE

the cover to the standpipe assembly by locking the

latch on the cover.

B. FILTER TUB INSTALLATION - Position the ASSEMBLED Filter Tub in front of the FILTER TUB GUIDES beneath the fryer;

then CAREFULLY insert the Filter Tub into the fryer using the standpipe handle assy until the MALE In-Line Plug on the Dock-

ing Handle Assembly seats in the FEMALE Bulkhead Socket adjacent to the Drain Valve Assembly.

PN 30A169 rev Jan2008 29

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 30

TECHNICAL ASSISTANCE, ORDERING INFORMATION

PN 30A169 rev Jan2008 30

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 31

A. TECHNICAL ASSISTANCE - Contact an authorized service agent or the Customer Service Department, Ultrafryer

Systems

B. ORDERING INFORMATION:

1. REPLACEMENT PARTS - Provide the following information when ordering replacement parts by phone, fax or

mail:

Your company name and phone number

Your company purchase order number

Bill-to address

Ship-to address

Quantity desired

Part number and description of the desired-item

Your name or signature of authorized-buyer

Phone in order to: 1-800-545-9189 Ext 5029

FAX order to: 1-210-731-5099

Mail order to: Ultrafryer Systems

Order Entry Ofce

P.O. Box 5369

San Antonio, TX 78201

E-Mail your order to: Ultrafryerservice@ultrafryer.com

at 1-800-525-8130 for technical assistance.

2. TERMS - Net 30 days for customers on approved accounts. Past due balances will be charged 1% per month

(12% per annum) until full balance is paid.

3. DAMAGES - Ultrafryer Systems is not responsible for damage occurring in transit. All deliveries must be

inspected for damage to shipping containers prior to departure of the delivering carrier. Any damage must be

documented on the receiving document to facilitate ling of freight claims. Carriers must be notied

immediately and freight inspections must be requested from the carrier. Ultrafryer Systems can and will gladly

assist you in preparing and processing of the necessary claims only if proper notication has been accomplished

on the carrier delivery document. Damaged equipment and or containers must be available for the claims

inspector to inspect.

4. RETURNS - Ultrafryer Systems cannot guarantee credit for items returned without proper authorization. All

returns must have prior Ultrafryer Systems Customer Service or Warranty department approval. An assigned

number will be issued by the approval authority. Please print the assigned number on all returned packages and

corresponding paperwork. Returned goods are subject to a l5% restocking charge. Ultrafryer Systems is not

responsible for freight charges on returned goods unless authorized by Customer Service and or Warranty per sonnel. Ultrafryer Systems does not receive freight collect or C.O.D. shipments.

PN 30A169 rev Jan2008 31

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 32

RECOMMENDED SPARE PARTS

PN 30A169 rev Jan2008 32

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 33

RECOMMENDED SPARE PARTS: To minimize downtime on the Model PAR25 gas fryer upon failure of a component part, at least

one (1) of the following items should be kept as a spare part in the local area:

MODEL PAR25 GAS FRYER

RECOMMENDED SPARE PARTS LISTING

Description

Ignitor Spark Module Honeywell S87B1008 18179

24 Volt Stepdown Transformer Honeywell AT40A1121 18180

24 Volt Combination Gas Control Valve Honeywell VR8203A-1005 18227

DPST Toggle ON / OFF Switch --- 18A081

Air Pressure Switch SMD 1204 18A291

Hi-Limit Switch Model 103KM1 Stemco 103K 19A144

" (13mm) Apollo Pump Control Valve Brass Craft TBV8 24036

" (5mm) Compression Fitting --- 24247

" (13mm) Manual Gas Valve Glacomini R602 24326

Manufacturer’s Part Number

PN

PN 30A169 rev Jan2008 33

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 34

PARTS IDENTIFICATION

PN 30A169 rev Jan2008 34

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 35

C. PARTS IDENTIFICATION: Locate the part on the following sketches and note the index number i.e, 3, 6, etc; then

obtain the part number and description for that index number on the page facing the sketches. Use that part number

when ordering a replacement part.

ULTRAFRYER MODEL PAR25 GAS FRYER

FRONT VIEW

Note: Fryer shown is 18” Par25 without Filtration. For information on other

fryer models, contact Ultrafryer Customer Service.

ITEM DESCRIPTION PN

Hi-Limit Switch 19B782 (14” fryer)

1

2

Main Cable

3

Gas Regulator / Shutoff Valve

4 Orice see chart, page 7

5 Ignitor Wire 18A095

6 Burner 22A341

7 Burner Bracket 19B505

8

Docking Release Handle (for fryers with lter tub)

9 Docking Connection 24A238

10 Micro Switch (optional) 18185

Main Drain Valve 19A564 (14” or 18” fryer)

11

19B783 (18”, 20”, or 24” fryer)

12B711

18227 / 24326

19C177

12B886 (18” or 20” fryer)

PN 30A169 rev Jan2008 35

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 36

ULTRAFRYER MODEL PAR25 GAS FRYER

REAR VIEW

Note: Fryer shown is 14” Par25 with Filtration. For

information on other fryer models, contact Ultrafryer

Customer Service.

Note: Parts listed below are for 14” Par25 with Filtration. For information on other fryer models, contact Ultrafryer Customer Service.

ITEM DESCRIPTION PN

1 Model SMD 1204 Air Pressure Switch 18A291

* 2

* 4

* 7

Rear Exit Weldment Bafe

3

Exhaust Blower Motor Drip Pan

14" Model PAR25 Exhaust Blower Motor Gasket

5

14" Model PAR25 115 Volt 60 HZ Exhaust Blower Motor Kit w/Mounting Bracket

6

14" Model PAR25 5

” x 8" High (146 x 208mm) Rectangular Flue Tube with deector 19A910

125 Volt 75 Watt Silicon Heater 5’ (1524mm) Long

* 8 Gemini " (13mm) Pump Ball Valve 24-036

9

3/16" (5mm) ID, 5/16" (8mm) OD Air Pressure Switch Plastic Tube rated for 500˚ F (260˚C)

Model GPV-0514 5.5 GPM (19.25 LPM) Viking Pump/Motor Kit. NOTE: For replacement, Pump Only order

10

24339.

11 Medium Duty 3" (76mm) Rear Caster w/out Brake 28A011

12 Type SJO 16/3 Electrical Cord with 90˚ Molded Plug 33048

*

NOT SHOWN

19A463

19A527

19A545

19A547

23341

24A068

24A206

PN 30A169 rev Jan2008 36

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 37

ELECTRONIC THERMOSTAT

PN 12B077

ITEM DESCRIPTION PN

1 Electronic Thermostat Face Plate 18A070

2 Temperature Probe 18A276

3 Electronic P14 Thermostat Bracket 19B174

4 Electronic Thermostat Knob 22A169

PN 30A169 rev Jan2008 37

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 38

PAR25 EZ DOCK FILTER TUB ASSEMBLY

14" With Micromesh Filter PN 12B112

14" With Magnepad Filter PN 12B177

ITEM DESCRIPTION PN

*1 Filter Tub Scraper 12567

Micromesh S/S Filter Screen Assembly with

2

StandPipe & Docking Assembly

*3 Magnepad Magnesol Impregnated Filter

Pad with Standpipe and Docking Assembly

*4 Wash Down Hose Assembly 12B115

5 Filter Tub cover with hinge latch and

Proximity sensor actuator for 14" Filter Tub

*6 Proximity Actuator Sensor 18A059

7 14" Model PAR25 Filter Tub 19B227

8 14" Model PAR25 Crumb Catcher Screen 19B233

9 RH S/S Hinge Latch 22479

10 Medium Duty Caster 28A005

12B113

12B178

19B227

* NOT SHOWN

WASH WAND HOSE ASSEMBLY

PN 12B115

ITEM DESCRIPTION PN

1 6’ (1829mm) Wash Wand Hose w/Fittings 12541

2 Wash Wand Hose & Nozzle Assembly 12675

3 Proximity Sensor Actuator 18A059

4 Cool II Handle 22734

5 "(13mm) S/S Locking Seal Inline Plug 24A208

ITEM DESCRIPTION PN

1 Micro-Mesh S/S Filter Screen 21A278

2 Handle Assy, Weld "(13mm) Street Elbow 19A598

3 Top Compression Cap (Knurl Knob) 24369

4 "(13mm) x 7" (178mm) Black Iron Nipple 24471

5 "(13mm) S/S Locking Seal Inline Plug 24A208

MICRO-MESH FILTER ASSEMBLY

WITH STANDPIPE & DOCKING ASSEMBLY

PN 12B113

PN 30A169 rev Jan2008 38

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 39

FILTER SCREEN ASSEMBLY

ITEM

DESCRIPTION

1 Replacement Frame Set 21A284

2 Replacement “Upper” Screen 21A285

3 Replacement Bafe Assembly 21A286

4 Replacement “Lower” Screen 21A287

PN

STANDPIPE CLIP, BAFFLE AND MAGNEPAD ASSEMBLY

PN 12B178

ITEM DESCRIPTION PN

5 1/2" (13mm) Black Iron Close Nipple 24003

6 3/8"(10mm) x 7" (177.8mm) Black Iron Nipple 24470

7 1/2" (13mm) S/S Locking Seal Inline Plug 24A208

8 1/2" (13mm) Handle Assy With 90˚ Black Iron Elbow 19A598

11" x 18 1/4" (279mm x 464mm) Bafe Kit consists of items 9,10&11

29A058

9 Top Compression Cap (Knurl Knob) 24A153

10 11" (279mm) Standpipe Clip 29A052

11 9 3/8" x 16 7/8" (238mm x 429mm) Bafe 29A060

12 11" x 18 1/4" (279mm x 464mm) Filter Pad 29A059

Case of (PN 29A059) Filter Pads 29A057

* NOT SHOWN

PN 30A169 rev Jan2008 39

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 40

ULTRAFRYER MODEL PAR25 GAS FRYER

AUTOMATIC VAT CLEANER

14” PN 12B157

ITEM DESCRIPTION PN

1 Proximity Actuator Sensor 18A059

2 Cool II Handle 22734

3 ” (13mm) HH-2236 SQ Spray Nozzle 22A111

4 " (13mm) x 90˚ Black Iron Elbow 24007

5 " (13mm) 5 Way Black Iron Crossover Manifold 24A082

6 14" PAR25 "(13mm) x 5" (133mm) Black Iron Nipple 24A101

7 " (13mm) S/S Locking Seal Inline Plug 24A208

8 " (13mm) x 6” (152mm) Black Iron Nipple 24A178

ULTRAFRYER MODEL PAR25 GAS FRYER

AUTOMATIC VAT CLEANER

14” PN 12B434

ITEM DESCRIPTION PN

1 Proximity Actuator Sensor 18A059

2 Cool II Handle 22734

4 " (13mm) x 90˚ Black Iron Street Elbow 24256

7 Handle Assy, P3H Weld Coupling Male 19B242

8 " (13mm) S/S Locking Seal In-Line Plug 24A208

9 ” (13mm) x 21” (533mm) AVC Flexible Shortening Line 24A220

PN 30A169 rev Jan2008 40

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 41

WIRING DIAGRAMS

PN 30A169 rev Jan2008 41

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 42

WIRING DIAGRAM - Since minor wiring changes may occur in the future, USE the diagram pasted to the fryer for circuit

tracing and/or troubleshooting a gas fryer.

PN 30A169 rev Jan2008 42

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...