Page 1

Page 2

Sales and

Customer Support

1-800-545-9189

www.ultrafryer.com

CHECK US OUT ONLINE

www.ultrafryer.com For the most current information,

spec sheets and manuals.

Page 3

Contents

What Makes Ultrafryer® Superior? ........ 2

Patented Heat Exchanger Systems ........ 6

Which Heat Exchanger is best for you? ........ 8

Do you prefer Electric? ....... 10

Electric Heating Element ........ 11

High Production Fryers ........ 12

Chicken Fryers ........ 14

Floor / Stand Alone Fryers ........ 16

Controllers ....... 18

Ultra Filtration - Features ....... 20

Portable Filter Machine ....... 21

Rethermalizers ....... 22

Batter Tables....... 23

UltraWarmer ........ 24

Customize your Ultrafryer ....... 25

Fryer Accessories ........ 26

Industry Affi liations ........ 29

1

Page 4

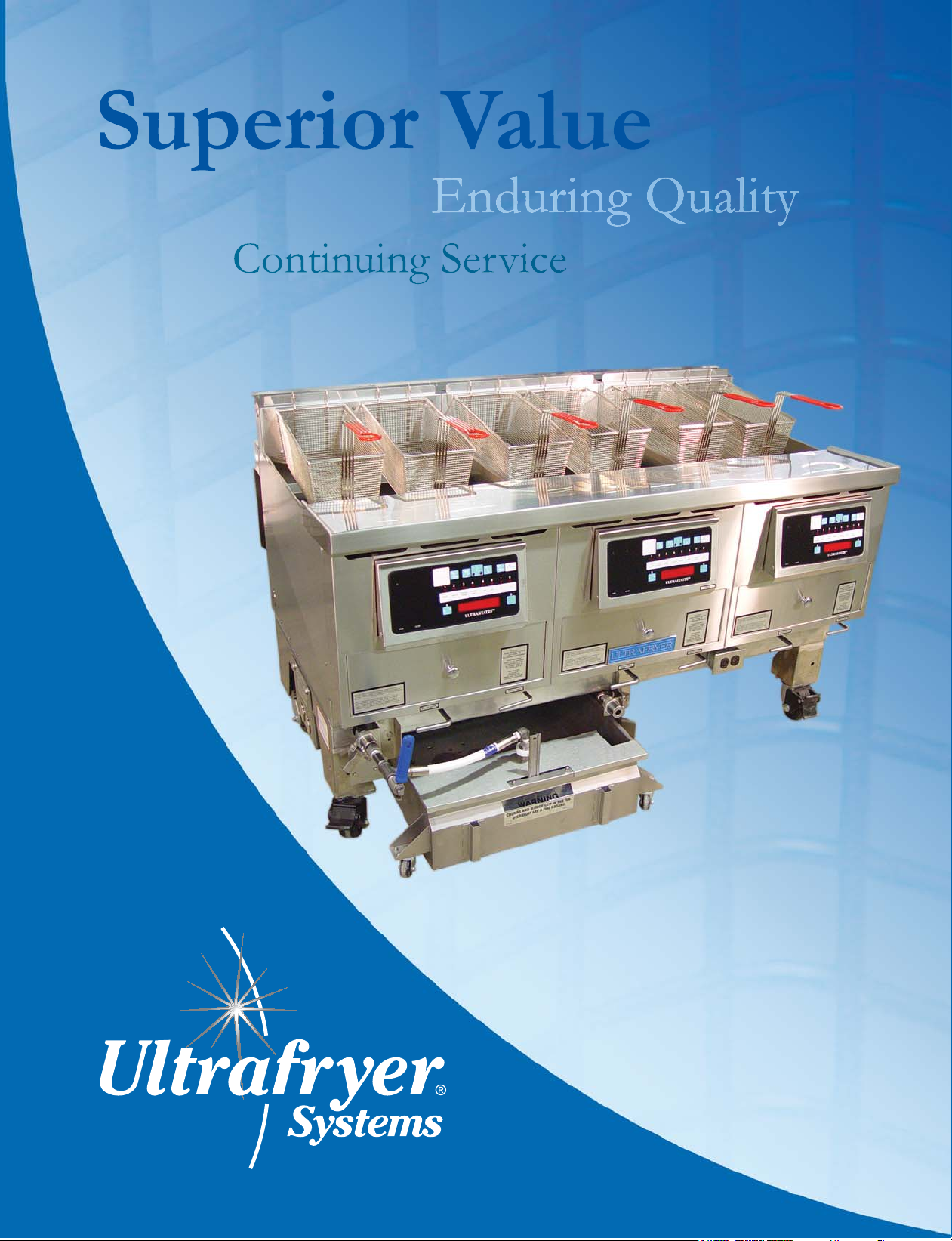

What Makes

Ultrafryer

® Superior?

Highest Production

Due to the recovery capacity and faster cook times the Ultrafryer

provides, it becomes possible for more food to be cooked per

hour. This is particularly benefi cial for the busiest times of the

day. For some operations, fewer Ultrafryers are needed to keep

up with the same volume ordinary fryers can produce.

Imagine the benefi ts of having one less fryer! A smaller

hood is required, less exhaust and make-up air

needed, lower energy cost to operate the fryers,

and more fl oor space available, just to name a few.

Energy Effi ciency

that saves real

DOLLARS

With PAR-3 technology, science fi ction has become science

fact. Energy effi ciency has not been sacrifi ced for cook-

ing power in the Ultrafryer. For the fi rst time, power and

effi ciency has been maximized in the same unit. Ultrafryer’s

PAR 3 technology is the clear leader in both power and

cooking effi ciency. With the Ultrafryer, your accountant will

love the energy savings, operators will love the fryer’s

performance, and your customers will love your food.

Better Tasting Food

This is a bold statement, but many users have discovered it to be true.

The Ultrafryer has the fastest recovery time preventing the food

from absorbing excessive shortening. During the

cook cycle, the temperature reaches the set point

faster, allowing the food to be cooked at a

higher average temperature. This results in less

shortening absorption producing

a better tasting product.

2

Page 5

Safe and Easy Filtration

to

g

n

To improve food quality and save shortening costs add the benefi ts

and convenience of built in fi ltration. This is only

the beginning of our commitment to

shortening management. Our entire

line of fryers include a shortening

melt cycle. Our control options

include features to ensure

proper shortening handling.

We also offer multiple fi ltration

systems tailored to individual

needs.

entire

in

Faster Cook

Times

The food cooks quicker in the Ultrafryer because

our patented heat exchangers put more energy

into the shortening and quickly recovers from the temperature

drop caused by the food placed inside the vat. It is

common for french fries, onion rings, chicken wings and

many other items to cook faster in the Ultrafryer vs. Traditional fryers

$

$

$

$

$

$

$

$

$

Lowest

Lifecycle Cost

It is a costly mistake to consider the purchase price

as the main expense. Energy costs today are large

and the Ultrafryer saves signifi cant operating energy.

Ultrafryer uses half the energy of ordinary tube

fryers and substantially less energy than infrared

fryers. When total owning and operating costs are

considered, Ultrafryer is a clear winner.

$0

Initial

Year 1

Year 2

Year 3

Ultrafryer

Competition

Yea r 4

Year 5

3

Page 6

Ultrafryer

Features

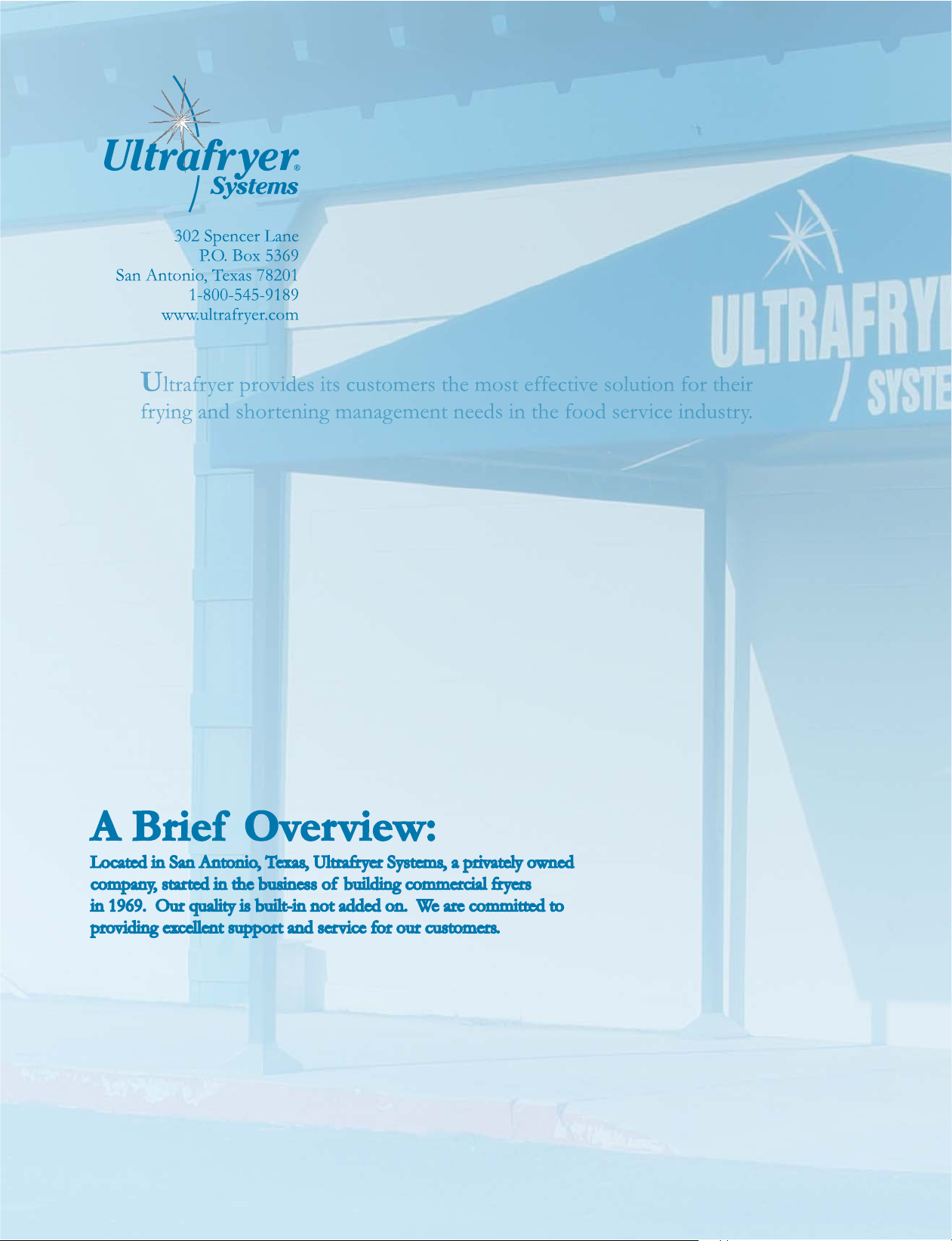

Standard Split Baskets

High Quality

Stainless Steel

Drain Apron

Standard Dial ermostat or

Optional Computer Controls

UltraClear Oil

Management

System

High Quality Stainless

Steel Filter Tub

4

Page 7

Optional Basket Li s for

split or triple baskets

Flue Exhaust

less than 500°F

Optional Triple Baskets

High Quality Stainless

High Quality Stainless

Steel Body

Access Door for Quick and

Easy Maintenance

Heavy Duty Stainless

Steel Frame

Steel Vats

Wash Wand Hose Connection

for ltering of Oil

Heavy-Duty 4 inch Casters

w/ locking brakes

5

Page 8

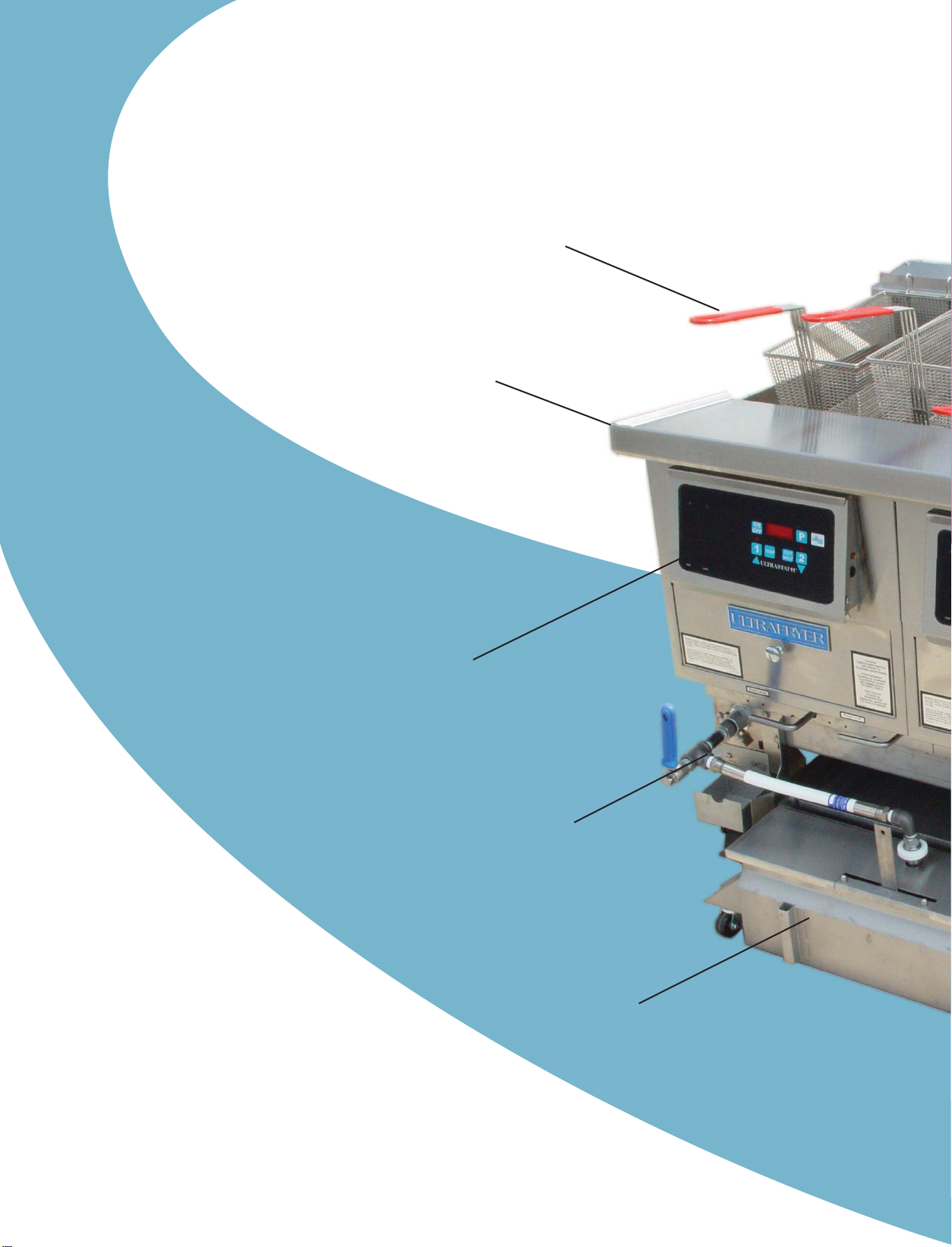

Patented Heat

2

Exchangers

How Do They Work?

The combustable gases travel through the tubes and boxes of

the patented PAR-2 and PAR-3 heat exchangers transferring heat

energy to the oil. Combustable gases enter the heat exchanger at

approximately 3000° F. Exiting the fryer, temperature is 500° F

or less. The heat exchanger has transferred the available energy

to the oil.

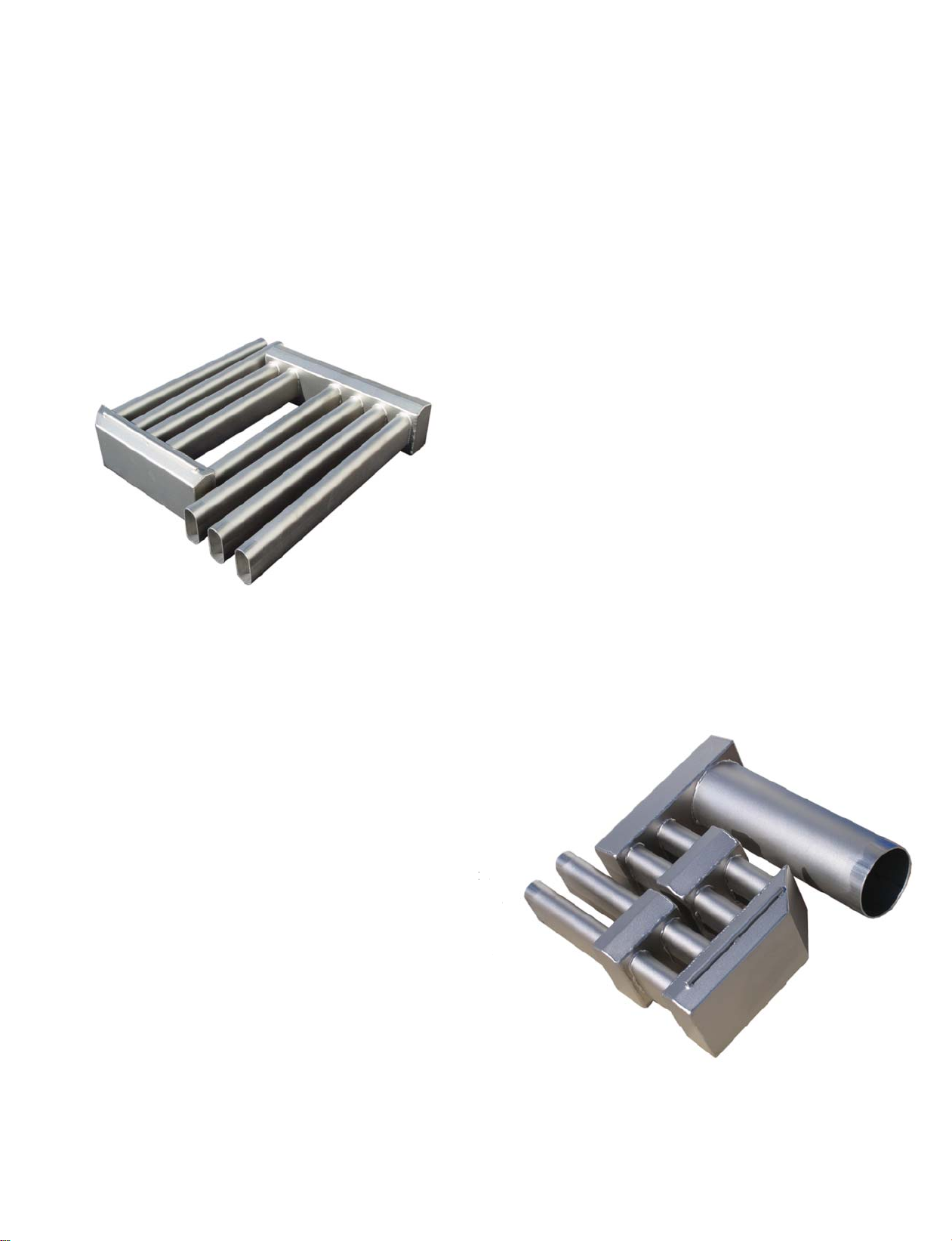

PAR-2

PAR-

Patented

Baffl es

An important design feature

of the PAR-3 heat exchanger is the strategic

use of baffl es in several locations. The agitator

baffl es are different from standard baffl es as these have

multiple ports and defl ectors to swirl the hot air in all directions,

which increases the effi ciency of the heat exchanger.

6

Page 9

PAR-3

T

a

PA

3

R-

Extended Oil Life

The air temperature inside the PAR-3 heat exchanger

he air temperature inside the PAR-3 heat exch

changes dramatically from the fl ame in the beginning to the

exiting air. The outer walls of the heat exchanger are much more

uniform in temperature. The heat exchanger in turn heats the shortening.

Because the temperature is very uniform throughout the vat, the result is perfectly

cooked food. Most users discover that food cooks faster in the PAR-3 vat. Exposed

to oil a shorter period of time, food absorbs less shortening, resulting in better tasting

food. It is common for users to save on shortening usage since less is absorbed in the

food, less must be added back to the vat.

[ Path of the Combustable Gases ] [ Uniform heat distribution ]

7

Page 10

Which Heat Exchanger

s

is Best for You?

PAR-2

High Effi ciency

Good for long duration cook times,

such as bone-in chicken. The PAR-2

technology cooks the chicken perfectly

throughout in the least amount of time

possible.

(Available in 18” and 20”)

PAR-3

High Production/

High Effi ciency

For the highest production possible the PAR-3

is the best choice. Great for fast food restaurants.

If you have a fast pace restaurant and you need lots

of french fries really fast, this is the way to go.

The Ultrafryer PAR-3 technology has proven time

and again to have the fastest recovery time in the

industry. All of our heat exchangers are also

the most energy effi cient. You could save 40-60%

in energy costs each year with an Ultrafryer.

s.

ot

e

(Available in 14” and 18”)

8

Page 11

What Size & Confi guration

B

0

is Best for You.

F-P30-14

B-P30-18

B-P20-20

-P2

9

Page 12

Do You

Prefer Electric?

Electric Fryers

Available in 45 lb., 75 lb., and 125 lb.•

High Effi ciency - 17 to 20 KW of power•

Longer heating elements provide high power with lower heating •

element temperature to protect shortening

Element has streamlined vertical cross section (fl at bar) for •

more effective heat transfer

Element is given extra bends to increase overall length meaning •

lower power per inch of run

All power needed for productivity with less than 35 watts/sq. in.•

Insulated vats control heat loss during idle to save expensive •

electric energy

Shortening fl ows around the fl at bars easier than round•

Helps preserve shortening•

10

Page 13

Electric

Heating Element

Battery of 4 - 75 lb. Vats

11

Page 14

High

Production Fryers

PAR-3

High Production/High Effi ciency Fryers

The PAR-3 is the best choice for the highest production requirements. The perfect choice for

high volume restaurants.

The Ultrafryer PAR-3 technology has proven time and again to have the fastest recovery time in

the industry, producing the most energy savings.

You could save 40-60% in energy costs each year with an Ultrafryer while increasing your

production.

12

Page 15

Chicken Fingers, Wings

& Fries

High Production/

High Effi ciency

1300 Wings/Hour

Large Cooking Area•

Gas fryer saves up to 50% in energy costs•

Large Cold Zone – Captures sediments from frying •

to prevent shortening from burning

Melt Cycle standard – Protects shortening from scorching during start up•

Automatic Vat Protection standard – Prevents accidental dry fi ring of the fryer •

to ensure long life

Computer Control options – Allows product to be cooked to perfect profi le •

every time at every location

Safe and Easy Filtration options – Control product quality and food costs with •

fi ltration designed specifi cally for fi ltering breaded products

Total Stainless Steel Construction standard – High quality stainless steel •

construction ensures a long life

Heavy Duty Casters standard•

Large Drain Apron standard – Speeds loading and recovery of product•

Available in gas or electric versions•

ching during start up

PAR-3

Heat Exchanger

Energy Input Rate

Gas (PAR3)

45 lb. - 90,000 BTU’s/hr

75 lb. - 110,000 BTU’s/hr

Electric

45 lb. - 17 KW

75 lb. - 20 KW

125 lb. - 20 KW

13

Page 16

P

2

H

ha

Chicken

ggg

p

y

Fryers

High Effi ciency

Chicken Fryers

Cooks large loads•

Gas fryer saves up to 50% in energy costs•

Large Cold Zone – Captures sediments from frying to prevent shortening from •

burning

Melt Cycle standard – Protects shortening from scorching during start up•

Automatic Vat Protection standard – Prevents accidental dry fi ring of the fryer •

to ensure long life

Computer Control options – Allows chicken to be cooked to perfect profi le •

every time at every location

Safe and Easy Filtration options – Control product quality and food costs with •

fi ltration designed specially for fi ltering breaded products

Total Stainless Steel Construction standard – High quality stainless steel •

construction ensures a long life

Large Drain Apron standard – Speeds loading and recovery of product•

Heavy Duty Casters standard•

Available in gas or electric versions•

Optional Batter Cart – Specifi cally designed to bread chicken and sift fl our•

(Shown on page 23)

PAR-2

AR-

Heat Exchanger

eat Exc

Energy Input Rate

Gas (PAR2)

75 lb. - 65,000 BTU’s/hr

125 lb. - 75,000 BTU’s/hr

Electric

75 lb. - 20 KW

125 lb. - 20 KW

14

Page 17

The PAR2 - 125 lb. Chicken Frying

ggg

p

y

System addresses all of the needs of the high

volume chicken operator

High Production – 95 pounds of chicken per vat, per hour•

Large cooking area – 20” by 20” surface cooking area with a 6 inch deep •

cooking zone, gives large loads plenty of swim room

Battery of 5 - 125 lb. Vats

The PAR2 - 75 lb. Chicken Frying System

addresses all of the needs of the operator

who needs to do bone-in chicken and other

products as part of a varied menu

Designed to be a swing fryer / Free fl oat or basket fry as required•

High Production – 78 pounds of chicken per vat, per hour•

Large cooking area – 18” by 18” surface cooking area with a 6 inch deep•

cooking zone gives large loads plenty of swim room

Battery of 3 - 75 lb. Vats

15

Page 18

Floor

Fryers

45 lb. Fryer (14”)

PAR-3

Zero Recovery Time, high effi ciency, high •

production 35-45 lb. fryer

High effi ciency 90,000 BTU/h burner/•

heat exchanger provides the equivalent of

140,000 BTU/h or more on conventional

atmospheric fryers

Flue temperatures do not exceed 500° F•

Cooks up to 91 lbs. of frozen French •

fries per hour using ASTM standards

“Perfect for Fries, Wings or Fingers”

16

Page 19

75 lb. Fryer (18”)

PAR-3

Zero Recovery Time, high effi ciency, high production 75 lb. fryer•

High Effi ciency PAR-2 65,000 BTU/h burner/heat exchanger and the •

High Effeciency PAR-3 110,000 BTU/h provides the equivalent of

110,000 - 160,000 BTU/h or more than conventional atmospheric fryers.

Integrated compact concealed central fi ltration system•

Flue temperatures do not exceed 500° F•

Cooks up to 120 lbs. of frozen French fries per hour using ASTM •

standards

75 lb. Fryer (18”)

PAR-2

17

Page 20

Fryer

Controllers

Full Featured

Computer

Control

• Multiple Programmable Product Keys

- Each button can be programmed with up

to 10 times and temperatures

• Multiple Temperature Settings

- Can be varied from product key to product

key for versitility of fryer

- Can be varied during cook cycle for each

product key to match optimum cooking

“curve” with different loads

• Boil Out Mode

- Easy timed control of boil out

• Item Menu Strip

- Each button can be labeled

• Flex Time

- Compensates for variation from expected

temperature due to odd load size, wrong

product storage temperature, ice crystals on

product, restaurant voltage variations on

electric fryers and similar anomalies

• Shortening Management System

- Programmable feature provides message

when to fi lter and when to dispose of shortening

• Overshoot Protection

- Highly accurate in controlling temperature

- Proportional power control when close to set point

• Stir Alarms

- Provides reminder to shake or stir during

cook cycle

• Hold Times

- Tracks cooked products hold time to ensure

quality

• Operates Basket Lifts

Will operate two basket lifts independently

18

Page 21

2 Button Computer

Control

• Electronic Temperature Control

Allows for precise temperature control

• Temperature/Cooktime Display

Visual temperature display at actual set point

• Front Panel Temperature Adjustment

Easy to change cook temperature

• Timing Multiple Cook Times

Can program two different cooking events

• Alarm

Can program alarm to sound as cook time elapses

Dial

Control

Thermostat

• Automatic Vat Protection

Prevents the vat from dry fi ring

• Melt Cycle

Prevents scorching of shortening

• Easy to Use Dial Thermostat

+/- 5 degree accuracy

19

Page 22

B

0

Ultra

Filtration

UltraClear Plus Filtration

Easy to use and operate, simple filtration system •

with automatic shortening return.

Simple shortening return with inside vat fitting•

Simple as turning a single handle to drain•

Simple as turning a single handle to pump•

Oversized Drain Trough simply drains better•

Simple to use filter envelope makes clean up easy•

Simple to use wash wand makes vat cleaning and •

filling a snap

UltraClear Filtration

Easy to use and operate, simple filtration system •

with manual shortening return

Easy to access pump pack•

Simple as turning a single drain handle and •

flipping a single switch

Oversized Drain Trough simply drains better•

Simple to use filter envelope makes clean up easy•

Simple to use wash wand makes vat cleaning and •

filling a snap

Available on fryers of 3 vats or more•

20

Page 23

Portable

Filter Machine

Ultrafi lter®

Disposable fast fl ow fi lter envelope•

All stainless steel construction•

1/3 HP / 7.6 GPM pump / motor•

Light weight, easy to clean•

Wash Wand hose and nozzle standard•

Stainless steel fi lter scraper•

Optional triple fi ltration (shown in picture)•

Optional disposable fast fl ow fi lter pad•

Optional stainless steel fi lter screen (shown below)•

Optional

Items

Triple Filtration

• Breading Strainer

• Sludge Pan Screen

• Sludge Pan

Stainless Steel

Filter Screen

Drain valve with Boil out

Auto Shortening

Removal Hose

Filtration system can

be confi gured to pump

shortening directly out of

the building to a holding

tank.

hose

21

Page 24

T

a

PA

3

Rethermalizers

Gas Rethermalizer

Thaws, heats and holds frozen food packets (chubs)•

12 Button Timer and power-on indicator light•

Digitally displayed timer (Optional) •

All stainless steel construction•

Twin chrome plated wire baskets with dividers included•

Enclosed base construction and hinged access door•

Available power 65,000 BTU/hr•

Automatic water fi ll•

Automatic low-water heat shut down•

Patented, energy effi cient, phased array heat exchanger.•

Low fl ue temperature•

22

Electric Rethermalizer

Thaws, heats and holds frozen food packets (chubs)•

Can accomodate 12 product bags simultaneously•

Optional 12 product timer•

Lever-action handle for drain•

Twin chrome plated wire baskets with dividers included•

Open based construction and hinged access door•

All stainless steel construction•

Automatic water fi ll•

Automatic low-water heat shut off•

Page 25

Batter

Tables

HiSpeed Batter Table

Motorized sifter with toggle switch and dough • ball separator

4” (101mm) swivel casters for mobility•

Removable, stainless steel breading pan•

Heavy-duty 18 gauge stainless steel construction•

Sifter shuts off automatically when bin door is opened•

User friendly parts disassemble without tools for easy cleaning•

Compact size — 24”W x 29” D •

(610mm W x 737mm D)

Includes “dip & fl ip” basket with cold batter pan•

Super Batter Table

Includes “dip & fl ip” basket with cold batter pan•

5” (127mm) Heavy-duty casters for easy mobility•

Compact size: 37 1/2” W x 32” D •

(953mm W x 813mm D)

Easy to clean: all parts are removable for in-sink cleaning•

Durable, all stainless steel construction•

Side shelf (right-left interchangeable)•

Speedy sifter for fast, effi cient performance•

23

Page 26

Ultra

Warmer

Standard Features:

● Heated air holding

● Large dividable holding area

● Stainless steel construction

● Open top construction

● Removable holding bin

● Components located in

back panel

The Ultrawarmer® Food Holding Station has been designed to hold a variety of fried products. The

Ultrawarmer® directs heated air over and under and through fried foods keeping food at the perfect serving

temperature while preserving the products surface crispness and moisture content ensuring freshness and

quality for your customer.

The Ultrawarmer’s large holding area can be divided to fi t your specifi c product mix. Open top construction

makes transfer of products from the fryer effi cient and serving of products fast and easy.

The Ultrawarmer® features stainless steel construction and is designed with longevity and ease of cleaning in

mind. All components are located in the back panel to prevent grease contamination. The holding bin is easily

removable for cleaning and the unit features a slide out debris collector to ease cleaning throughout the day.

24

Page 27

Customize Your

Ultrafryer®

Quality Built-In Quality Built-In

Not Added OnNot Added On

We can design a fryer that

fi ts your particular restaurant.

You can choose a variety of

components to come up with a

design that best suits your needs.

Some oSome of your options your options

to choose from:to choose from:

• Vat sizes

• Controls

• Filtration

• Work Station/Dump Station

• Basket lifts

25

Page 28

to

g

n

Ultrafryer

Accessories

Vat Covers

Available for • all vat sizes

Griddle

Can be used to convert any•

Ultrafryer into a griddle

Available for all vat sizes •

Marine Edge

Available on batteries only•

26

Automatically lifts • baskets out of the vat

when food is fi nished

Field adaptable (2006 or later)•

Available on batteries only•

Basket Lifts

Page 29

Pictograms

FLOOR MODEL AND COUNTERTOP - GAS FRYERS

FLOOR MODEL AND COUNTERTOP ELECTRIC FRYERS

PICTOGRAM

F-P30-14 F-P30-18 F-P20-18

W 15 3/4”

D 32”

H 40 1/2”

BTU’S 90,000

Ship Wt. 250

Gas line 3/4”

Gas req. 7” w.c.

19 3/4”

37”

40”

110,000

275

3/4”

7”

19 3/4”

40”

40”

65,000

275

3/4”

7” w.c.

W 15 3/4”

D 32”

H 40 1/2”

KW 17

Ship Wt. 250

208v 47 Amps

240v 41 Amps

MULTIPLE VATS-HIGH PRODUCTION/HIGH EFFICIENCY - GAS FRYERS

PICTOGRAM

F-E17-14 F-E20-18

19 3/4”

37”

40”

20

275

56

48.1

B-P30-14-2 B-P30-14-3 B-P30-14-4 B-P30-14-5 B-P30-14-6

W 31”

D 35”

H 41 1/4”

BTU’S 180,000

Ship Wt. 498

Gas line 3/4”

Gas req. 7” w.c.

B-P30-18-2 B-P30-18-3 B-P30-18-4 B-P30-18-5 B-P30-18-6

W 39”

D 41”

H 41 1/4”

BTU’S 220,000

Ship Wt. 568

Gas line 3/4”

Gas req. 7” w.c.

46 1/2”

35”

41 1/4”

270,000

720

1”

7”

58 1/2”

41”

41 1/4”

330,000

780

1”

7”

PICTOGRAM

62”

35”

41 1/4”

360,000

920

1”

7”

78”

41”

41 1/4”

440,000

975

1 1/4”

7”

77 1/2”

35”

41 1/4”

450,000

990

1 1/4”

7”

97 1/2”

41”

41 1/4”

550,000

1,035

1 1/4”

7”

93”

35”

41 1/4

540,000

1,220

1 1/4”

7”

117”

41”

41 1/4”

660,000

1,229

1 1/4”

7”

27

Page 30

MULTIPLE VATS-HIGH EFFICIENCY - GAS FRYERS

B-P20-18-2 B-P20-18-3 B-P20-18-4 B-P20-18-5 B-P20-18-6

W 39”

D 41”

H 41 1/4”

BTU’S 130,000

Ship Wt. 568

Gas line 3/4”

Gas req. 7” w.c.

B-P20-20-2 B-P20-20-3 B-P20-20-4 B-P20-20-5 B-P20-20-6

W 43”

D 41”

H 41 1/4”

BTU’S 150,000

Ship Wt. 590

Gas line 3/4”

Gas req. 7” w.c.

58 1/2”

41”

41 1/4”

195,000

780

3/4”

7”

64 1/2”

41”

41 1/4”

225,000

810

3/4”

7”

78”

41”

41 1/4”

260,000

975

1”

7”

86”

41”

41 1/4”

300,000

987

1”

7”

97 1/2”

41”

41 1/4”

325,000

1,035

1”

7”

107 1/2”

41”

41 1/4”

375,000

1,267

1”

7”

117”

41”

41 1/4”

390,000

1,229

1”

7”

129”

41”

41 1/4”

450,000

1,400

1 1/4”

7”

MULTIPLE VATS - ELECTRIC FRYERS

PICTOGRAM

B-E17-14-2 B-E17-14-3 B-E17-14-4 B-E17-14-5 B-E17-14-6

W 31”

D 35”

H 41

KW 34

Ship Wt. 498

208v 47 Amps ea. vat

240v 41 Amps ea. vat

B-E20-18-2 B-E20-18-3 B-E20-18-4 B-E20-18-5 B-E20-18-6

W 39”

D 38 3/4”

H 41”

KW 40

Ship Wt. 568

208v 56 Amps ea. vat

240v 48 Amps ea. vat

B-E20-20-2 B-E20-20-3 B-E20-20-4 B-E20-20-5 B-E20-20-6

46 1/2”

35”

41”

51

720

41 Amps ea. vat

58 1/2”

38 3/4”

41”

60

780

48 Amps ea. vat

47 Amps ea. vat

56 Amps ea. vat

62”

35”

41”

68

920

41 Amps ea. vat

78”

38 3/4”

41”

80

975

48 Amps ea. vat

47 Amps ea. vat

56 Amps ea. vat

PICTOGRAM

77 1/2”

35”

41”

85

990

41 Amps ea. vat

97 1/2”

38 3/4”

41”

100

1,035

48 Amps ea. vat

47 Amps ea. vat

56 Amps ea. vat

93”

35”

41”

102

1,220

41 Amps ea. vat

117”

38 3/4”

41”

120

1,229

48 Amps ea. vat

47 Amps ea. vat

56 Amps ea. vat

W 43”

D 38 3/4”

H 41”

KW 40

Ship Wt. 590

208v 56 Amps ea. vat

240v 48 Amps ea. vat

28

64 1/2”

38 3/4”

41”

60

810

48 Amps ea. vat

56 Amps ea. vat

86”

38 3/4”

41”

80

987

48 Amps ea. vat

56 Amps ea. vat

107 1/2”

38 3/4”

41”

100

1,267

48 Amps ea. vat

56 Amps ea. vat

129”

38 3/4”

41”

120

1,400

48 Amps ea. vat

56 Amps ea. vat

Page 31

.!4)/.!,

2%34!52!.4

!33/#)!4)/.

Industry

Affiliations

ESC

Energy Solutions Center

Winner

of Numerous

Fryer Challenge Awards

29

Page 32

Revised October

2010

Loading...

Loading...