Page 1

Models:

Q

Q

ualifies

Cal iforn ia

reba tes

ener gy

for

Ultrafryer Systems, Inc.

B-E15-18

Electric Fryer

B-E15-18-2 B-E15-18-3 B-E15-18-4 B-E15-18-5 B-E15-18-6

Project __________________

Item ____________________

Quantity _________________

Approval _________________

Date ____________________

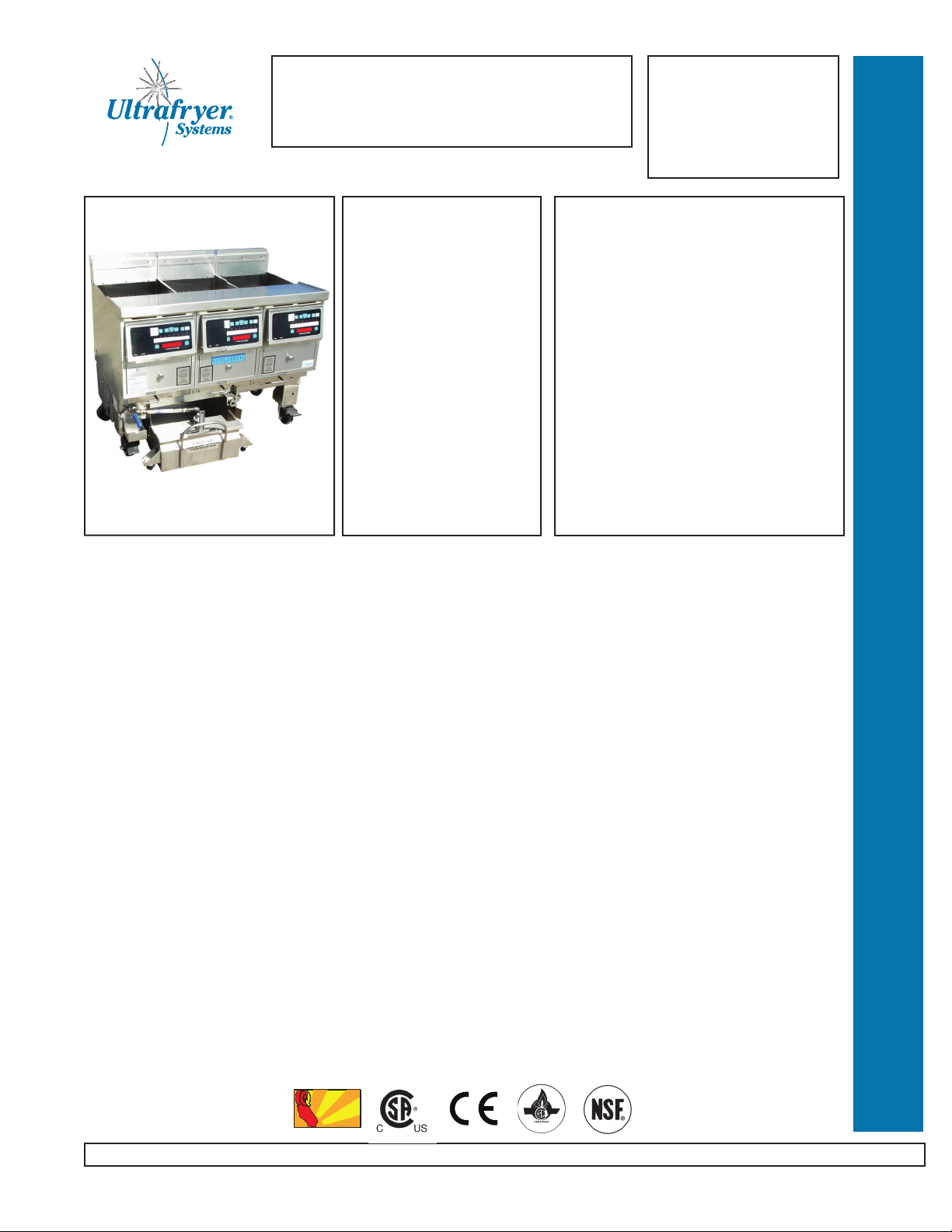

B-E15-18 75 lb. Low Wattage Electric Fryer

Standard Features:

● High effi ciency fl at bar

heating element

● Ultraclear fi ltration system

● Dial thermostat behind door

● Automatic melt cycle

● Stainless steel vats, cabinet

and frame

● Heavy duty 4-inch casters

with front locking brakes

● 2 baskets per vat

● Fast Flow fi lter envelope

Specifi cations

Designed to meet high production frying needs

Options and Accessories:

□ 2 product Ultrastat® cooking computer

□ 8 product Ultrastat® cooking computer

□ Marine edge drain board

□ Vat covers

□ Splash guards

□ Basket lifts

□ Triple baskets

□ Dump station

□ Heat tape

□ Fast Flow fi lter pads

□ Stainless steel fi lter screen

□ Triple fi ltration

□ Drain valve for fi lter tub

□ Boil out hose

□ Shortening disposal valve

□ Shortening disposal line

The Ultrafryer Systems B-E15-18 is a battery of two

to six fryers designed to meet high volume frying

needs. The fryer exceeds Energy Star standards and

qualifi es for California energy rebates. The Ultrafryer®

B-E15-18 fast recovery, shortens cooking time, allows

for large loads during batch cooking, and reduces

shortening absorption. Thermostat controls and melt

cycle are standard features on every fryer, ensuring

accurate temperature control and limiting temperature

excursions, producing a uniformly cooked product

while maintaining shortening quality. Heating elements

are made of low watt density fl at bar construction and

have large surface areas to keep heat fl ux to less than

35 watts/sq.in at full input power. The low watt density

fl at bar offers even heat distribution and zero

recovery time.

The B-E15-18 vats, cabinet and carriage frame are

fabricated from high quality stainless steel to ensure a

long service life.

The B-E15-18 is equipped with the UltraClear fi lter

system to increase shortening life while retaining

quality. The fi lter system, which fi ts under the

fryer, features an oversized drain and drain trough

to allow quick drainage and eliminate clogging.

The large drain handles make drain and pump

operation simple and convenient. The Fast Flow

fi lter envelope removes sediment and impurities

created in the frying process.

The B-E15-18 has a maximum shortening capacity of

75 - 110 lbs. (36 - 56 liters). The cooking zone is

18” x 18” (457mm x 457mm).

The B-E15-18 is rated 15KW and electrical

requirements are 208V/60 Hz/3 phase or 240V/60

Hz/3 phase.

Ultrafryer Systems, Inc. • 302 Spencer Lane • San Antonio, TX 78201 • (800) 545-9189 • (210) 731-5000 • FAX (210) 731-5099 • www.ultrafryer.com

Page 2

41”

7.88”

1

1

ULTRAFRYER SYSTEMS DOES NOT PROVIDE CORDSET.

STANDARD 120V CONNECTION

ONE PER BATTERY

20.5”

12”

1

208/240V

ELECTRICAL HOOKUP

LOCATION

ONE PER VAT

208/240V

ELECTRICAL HOOKUP

LOCATION

STANDARD 120V CONNECTION

39”

58.5”

78”

97.5”

117”

41”

FLAT BAR

HEATING

ELEMENT

Dimensions - inches (mm)

Model Shortening Overall Size Net Shipping Info

No. Capacity Weight

B-E15-18-2

B-E15-18-3

B-E15-18-4

B-E15-18-5

B-E15-18-6

75 lbs. per vat (36 liters)

75 lbs. per vat (36 liters)

75 lbs. per vat (36 liters)

75 lbs. per vat (36 liters)

75 lbs. per vat (36 liters)

Height Depth

41.25” (1054mm)

41.25” (1054mm)

41.25” (1054mm)

41.25” (1054mm)

41.25” (1054mm)

41”(1041mm)

41”(1041mm)

41”(1041mm)

41”(1041mm)

41”(1041mm)

Width

39” (991mm)

58.5” (1486mm)

78” (1981mm)

97.5” (2477mm)

117” (2972mm)

568 lbs. (257.6 kgs)

780 lbs. (353.8 kgs)

975 lbs. (442.3 kgs)

1,035 lbs. (469.5 kgs)

1,229 lbs. (557.5 kgs)

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

F.O.B. Factory

San Antonio, Texas

Power Requirements:

ELECTRICAL RATINGS PER VAT

Model Voltage 60hz Phases/wires Amps

18” 208 3/3w 42 per vat

(457 mm) 240 3/3w 36 per vat

ELECTRICAL REQUIREMENTS FOR CONTROLS

120 V, 60 HZ, 1 phase, 8.5 amps.

Electrical cord is 8’ long and located on

RH side in rear. (control circuit)

Due to continuing engineering development and improvements, specifi cations are subject to change without notice.

Ultrafryer Systems, Inc. • 302 Spencer Lane • San Antonio, TX 78201 • (800) 545-9189 • (210) 731-5000 • FAX (210) 731-5099 • www.ultrafryer.com

Notes:

PERFORMANCE SPECIFICATIONS

Determined in accordance with ASTM F1361-91

Standard Test Method for the performance of open

deep fat fryers:

Nominal Energy Shortening

Vat Size Input Rate Capacity

18” 15 (min. KW) min. 70 - 110 lbs.

(36 - 56 liters)

© May 12, 2009 Ultrafryer Systems, Inc.

Loading...

Loading...