Page 1

MAGICARD PRINTER

INSTRUCTIONS FOR REPLACEMENT OF

PRINTHEAD AND PRINTHEAD ASSEMBLIES

WARNING

CAUTION

Devices. All Precautions for handling Electrostatic Sensitive Devices should be

followed at all times, including the use of a grounded wrist strap.

- The Magicard colour printer contains hazardous voltages.

- The following procedures involve contact with Electrostatic Sensitive

HOW TO USE THESE

INSTRUCTIONS

The following procedures are intended to be used for replacement of Magicard

Thermal Printheads and

If replacing a Thermal Printhead Assembly

document written in italics

previous Magicard product training or experience, and must not be undertaken by end

users. Therefore end users are supplied with replacement Printhead Assemblies, which

have already been adjusted for correct head angle.

Magicard Thermal Printhead Assemblies.

do NOT carry out those parts of this

. These procedures, for head angle adjustment, require so me

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

I

Page 2

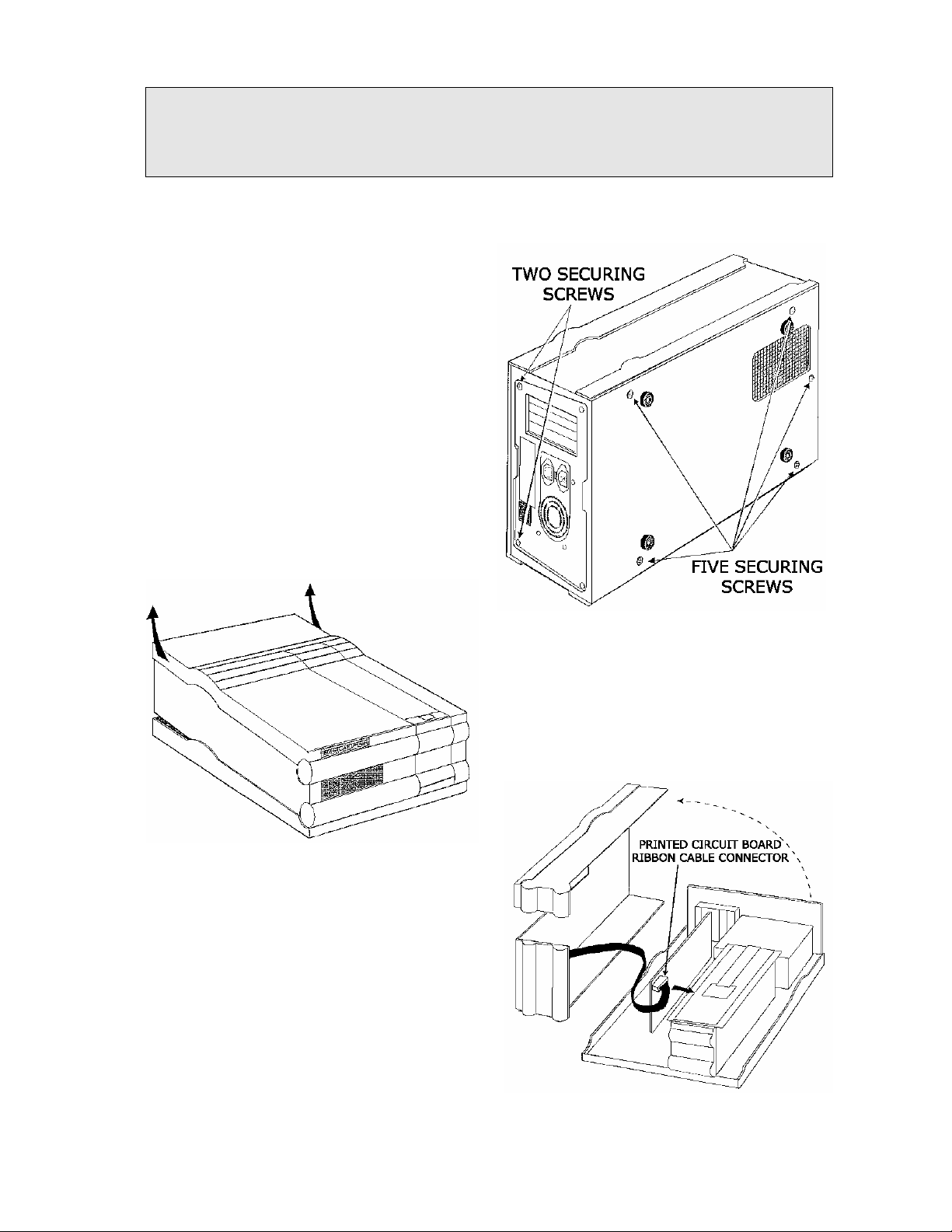

1. (a) Removing the cover

Magicard 300 and Sprinter models.

(1) Set the printer On/Off switch to off(0) and isolate from the mains supply. Remove the

card cassette and Dye-Film from the

printer.

(2) Position the printer on its side with the

rear of the printer facing towards you

and remove the five securing screws

from the base of the printer plus the

two at the rear of the printer.

(3) Place the printer on its base with the front

of the printer facing towards you.

(4) Lift the printer cover from the rear and

carefully remove it from the printer

taking care not to strain the ribbon cable

connection from printer circuit board

PL8, and place the cover aside.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

II

Page 3

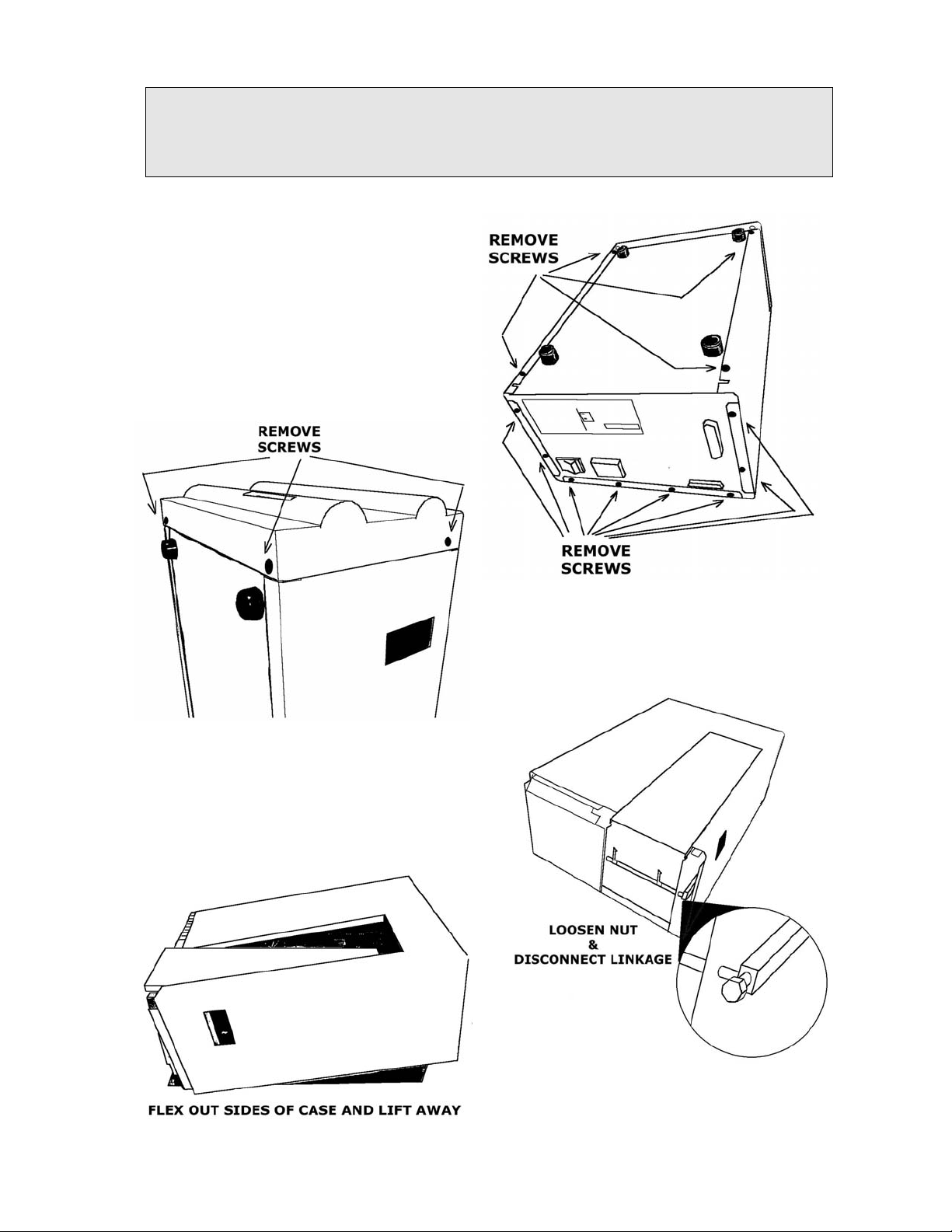

1. (b) Removing the cover

Magicard Turbo models.

(1) Set the printer On/Off switch to Off(O) and isolate from the mains supply. Remove the

card cassette and the Dye-Film from

the printer.

(2) Position the printer upside down

with the rear of the printer facing

towards you and remove the four

securing screws from the base of the

printer plus the eight at the rear of

the printer.

(3) Position the printer with the front panel

facing upwards. Remove the two screws from

the underside of the front panel and remove the

two screws from the top left and top right of the

front panel.

(4) Turn the printer back onto its base and

lift off the front cover. Using an M4

spanner loosen the bolt at the right hand

end of the Door Locking Shaft and

disconnect the operating lever from the

shaft.

(5) Flex out the sides of the cover and lift it

carefully away.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

III

Page 4

2. Removing old printhead/assembly

(1) Remove the dye-film and

dye-film carrier from the

printer.

(2) If a tye-wrap is fitted to the

grey ribbon cable plug on the

back of the printhead, cut this

tye-wrap taking great care not

to cut the ribbon cable itself.

(3) Disconnect both cables from

the printhead.

(4) If a head bar is fitted, remove the securing

screw at each end and lift away the head bar.

This should leave the earthing strap loose at the

right hand side of the chassis cover.

If no head bar is fitted, disconnect the earthing

strap from the reatining screw at the left hand

side ot the printhead assembly

(5) Disengage the two lugs at the ends of the

two nylon side brackets by spreading apart the

legs of the nylon brackets until the lugs just

clear the chassis cover, swing them forwards

and allow them to rest against the leading edge

of the chassis cover.

N.B.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

Before removing the printhead

assembly completely from the printer,

take careful note of how the two

springs are attached at the rear and

each side of the assembly.

(6) Using both hands, hold the

printhead assembly at each side by

the nylon brackets, and move it

upwards. Note : as the assembly

disengages from the chassis cover,

the two springs will push it forwards

and care must be taken not to lose

the springs as the printhead is lifted

clear.

(7) Place the printhead assembly on a bench with the printhead and its labels at the bottom.

Undo and remove the printhead pivot screw (see diagram) and its two washers .

(8) Slide the printhead backwards (plugs first) out of the heatsink.

IV

Page 5

3. Fitting the new printhead to the heatsink

assembly (Magicard Dealers Only)

CAUTION - The following procedures involve contact with the new printhead, all

precautions for handling Electrostatic Sensitive Devices should be followed at all times,

including the use of a grounded wrist strap. Furthermore great care must be taken not to

touch or damage the printing elements of the printhead.

(1) Ensure that the brass backing plate attached to new printhead has a very thin, evenly

spread film of graphite grease over its surface.

(2) Apply a very small amount of Loctite 242 Threadlocker to the hole in the brass backing

plate into which the printhead pivot screw will shortly be inserted .

(3) With the heatsink still in position on the bench, slide in the new printhead until the two

pivot screw holes are aligned and insert the pivot screw with its washers (thin crinkly

washer closest to the head of the screw).

(4) Great care must now be taken to ensure

that this pivot screw is not over tightened

- it must be set loosely enough such that

the printhead can swivel freely about the

axis of the screw (see diagram right) but

not so loose that, with a little pressure,

any

gap can be made between heatsink,

and the printhead with its backing plate

(see diagram below).

4. Fitting the new printhead assembly into

the printer

(1) Offer up the printhead assembly to its position in the chassis cover ensuring that the

earthing strap is routed to outside of the chassis cover and, whilst holding in position,

ensure that the ends of each spring are correctly located on the lugs on the chassis

cover. Compress the springs by pushing the printhead assembly backwards and

downwards against the chassis cover, and the printhead assembly should slot into

place.

(2) Now engage the two lug s at the bottom of the printhead assembly nylon side brackets

by bending them outwards slightly and swinging them backwards until the lugs locate

in the holes in the chassis cover.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

V

Page 6

(3) Check that the springs at the ba ck of the printhead assembly are neatly compressed and

are not bulging outwards or inwards. If they are bulging the assembly will have to be

removed and refitted again until they remain neatly compressed.

(4) If a he ad bar was fitted

screw is also fitted through the terminal of the printhead earthing strap (Loctite 222

threadlocker should be used on these screws). Align the terminal downwards and in

parallel with the leading edge of the chassis cover.

If no head bar was fitted

original securing point

(5) Reconnect the two cables at the rear of the printhead ensuring that the locking arms of

the grey ribbon cable connector are fully engaged.

(6) Ref erring to the rear of the Test Card which was supplied with your new printhead, set

the ‘density hex value’ as

indicated on the rear of the

card.

N.B.

There are two different

diagrams on the rear of the

card (see right), compare the

cicuit board in your printer

against the two diagrams and

decide which diagram is

relevent to your printer.

Then change the settings on

your printer to match those

marked on the diagram on

your card (in the high-lighted area). Do not change any of the unmarked switch

positions.

, refit it with its two securing screws ensuring that the left hand

, ensure that the printhead earthing strap is connected to its’

5. Refitting the cover

Refitting of the case is the reverse of removal.

Ensure the printer interior is free of debris or particles.

Take care not to trap the display cable as the top cover is lowered into position.

6. Setting up your new thermal printhead

(1) Load the card cassette with cards and refit into the printer.

On Flip models ensure that UR8 Dye-Film is fitted.

On all other models fit UR1 Dye-Film.

(2) Reconnect the mains supply and switch on the printer.

(3) After the printer has finished its initialisation sequence (all lights have stopped

flashing and the printer is silent), pr ess the intern al test button at the rear of the printer

(approx 1cm above the Centronics port). After a short delay the printer will start to

print a test image.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

VI

Page 7

(4) The printhead angle has been factory set. In order to ensure that it is still correct,

compare the test card with the images on the back page of this document.

N.B. If your test card shows a completely different test image from those on the back

page, you will need to download the correct test image from the Ultra website at

www.ultra.co.uk/support

PC.

(5) If the printhead angle requires adjustment take note of the current position of the

printhead angle adjustment screws (at the upper rear corner on each nylon side

bracket).

NOTE : There are now two different types

holes and one with 9 adjustment holes (see diagrams below).

(6) With reference to the relevant diagram (below) and the diagram on the rear page,

decide which of the adjustment holes that the screws need to be moved to.

(7) Remove both printhead angle adjustment screws and raise or lower the rear of the

printhead in order to align the required hole in the nylon bracket with the inner hole of

the brass heatsink, and fit and tighten the two printhead adjustment screws.

NOTE : If a printhead angle adjustment screw is moved to a different hole then the other

screw must

assembly.

be moved to the corresponding hole on the other side of the printhead

. This image can then be printed from any paint package on your

of nylon side brackets – one with 7 adjustment

(8) Steps (3) to (7) should be repeated until the optimum printhead angle is obtained.

TWO TYPES OF NYLON SIDE BRACKETS

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

VII

Page 8

7. And finally.....

If your new thermal printhead fails to produce a good test image after following the above

steps then please contact your supplier.

Too Negative

Front or most of the grey

square is pale and washed

out. Density can suddenly

increase in the last third of

the square.

SOLUTION: Increase head

angle by 1 or 2 degrees.

Too Positive

Dark patches stressing

out from the rear edge

of the green square

(watermarking). These

patches have many

jagged edges. Plus

possibly a dark patch at

the front of the grey

square,.

SOLUTION: Decrease

head angle by 1 or 2

degrees.

Correct Head Angle

Uniform density across the whole of the grey

square, with no marks or defects in the green

square.

3461/07/01 ISSUE 2 PRINTHEAD INSTALLATION & COMMISSIONING SPEC. DCR No. 26106

VIII

Loading...

Loading...