Page 1

Ultra Electronics Card Systems Quick Start Guide

MAGICARD Sicura Laminator

Quick Start Guide

Laminator Setup

Iss. 09 January 03

Stock No. M9004-593

MAGICARD Sicura Laminator Page 1

3504-22-01

DCR 27634 refers

Page 2

Quick Start Guide Ultra Electronics Card Systems

Setting up your Sicura Laminator

takes just two easy steps:

1. Unpack and install the laminator

A Preparing a Location for the Laminator

B Removing the Laminator from the Box

C Check the Package Contents

D Install the Lamination Film

E Connect the Laminator to a Power Supply

F Set the Optimum operating temperature and test the

Laminator Operation

G Interfacing to a Rio/Tango printer

with the Sicura Laminator

H Interfacing to a Turbo series printer

Important Note for Setting Up your Rio/Tango Printer Driver to work

2. Stand-alone Mode

I Operation of the Hopper

J Adjusting the Hopper

K Error Indicators

3. Verify correct operation

L Important Cleaning Procedures

M In Case of Difficulty

Note: The Ultra WEB site at http://www.ultramagicard.com contains comprehensive technical support

information including the latest downloadable software, WINDOWS Drivers, Technical Bulletins etc

Conventions

Throughout this guide, the following conventions are used to identify important

information.

WARNING - Warning messages indicate where personal injury could result from not

following the correct procedures.

CAUTION - Caution messages indicate where damage to equipment could result

from not following the correct procedures.

NOTE - Notes convey important information that is identified within the text.

Page 2 MAGICARD Sicura Laminator

Page 3

Ultra Electronics Card Systems Quick Start Guide

•

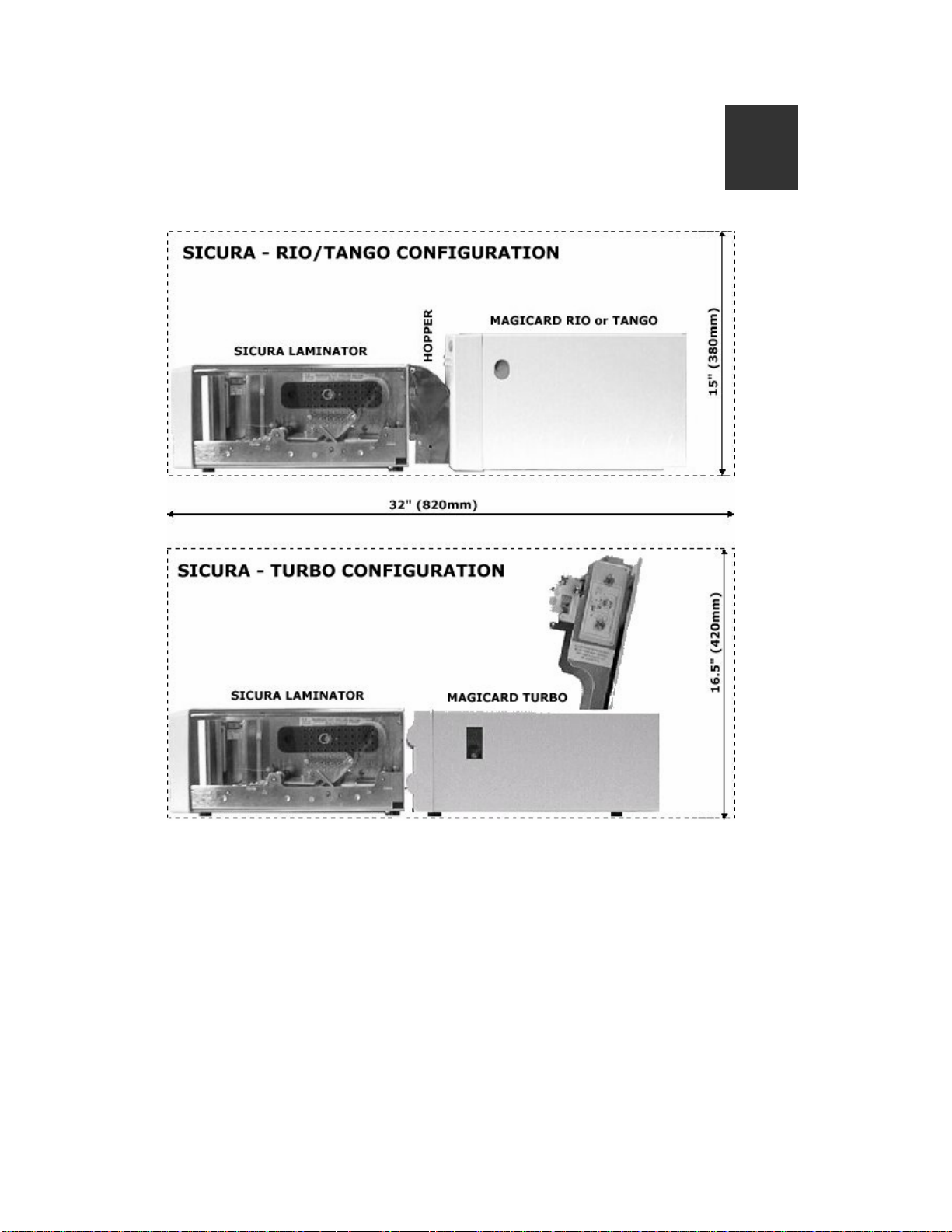

Preparing a Location for the

Sicura Laminator and Printer

A

Location Requirements for your laminator/printer:

• A clean, level surface.

• Adequate space for:

- opening the printer cover

– opening the laminator cover

– cable access at the rear and RH side

– allowance for air circulation.

An adequately ventilated room.

•

MAGICARD Sicura Laminator Page 3

An adequate power supply.

Ambient temperature +10 to +30 deg C.

•

• Relative Humidity 20/70% RH.

• Protection from direct sunlight and

chemicals.

• Protection from abrupt temperature

changes.

Page 4

Quick Start Guide Ultra Electronics Card Systems

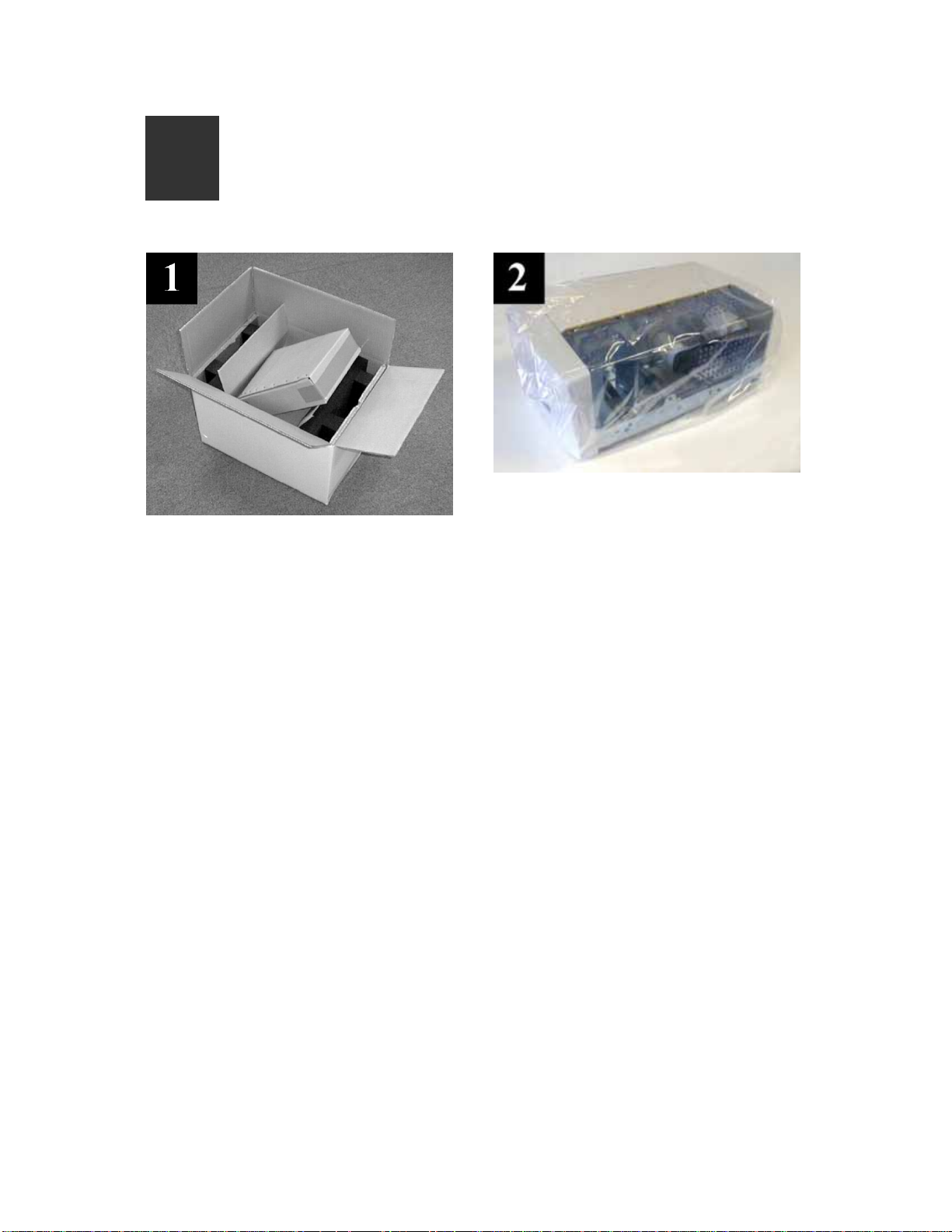

Removing the Laminator

B

Carefully open the box and remove any

accessories.

from the Box

Place on a smooth, level surface and

remove the polyethylene container.

Page 4 MAGICARD Sicura Laminator

Page 5

Ultra Electronics Card Systems Quick Start Guide

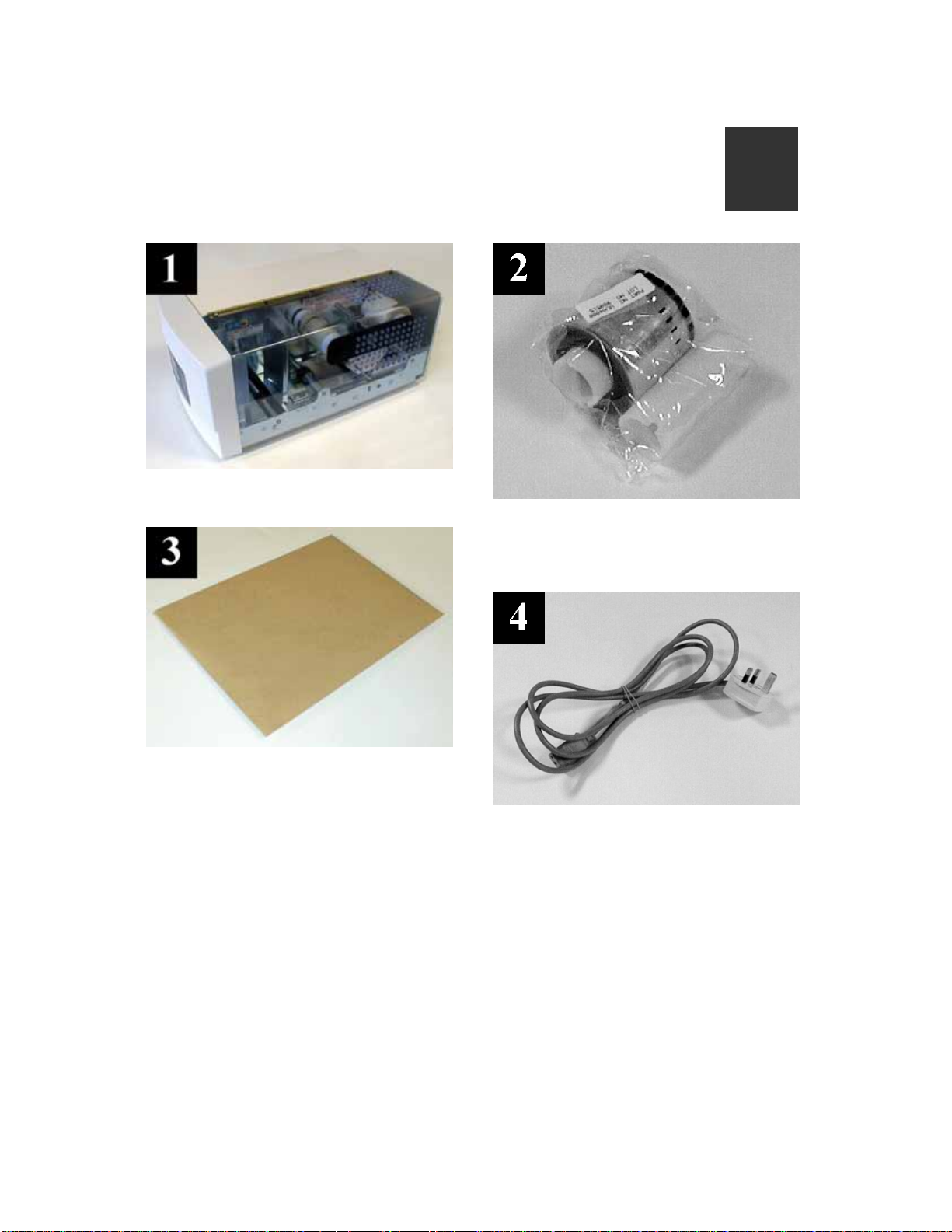

Checking the

The MagiCard Sicura Card Laminator

Envelope containing this Quick-Start

guide

Package Contents

A Roll of Lamination Film and a Take-up

Core (only supplied when ordered with

the Laminator)

A Power Cord with Molded Plug for

your country’s voltage standard

C

MAGICARD Sicura Laminator Page 5

Page 6

Quick Start Guide Ultra Electronics Card Systems

Check that the Mains Supply Voltage is

correct for your country.

(Different models are manufactured for

each supply voltage.)

Page 6 MAGICARD Sicura Laminator

Page 7

Ultra Electronics Card Systems Quick Start Guide

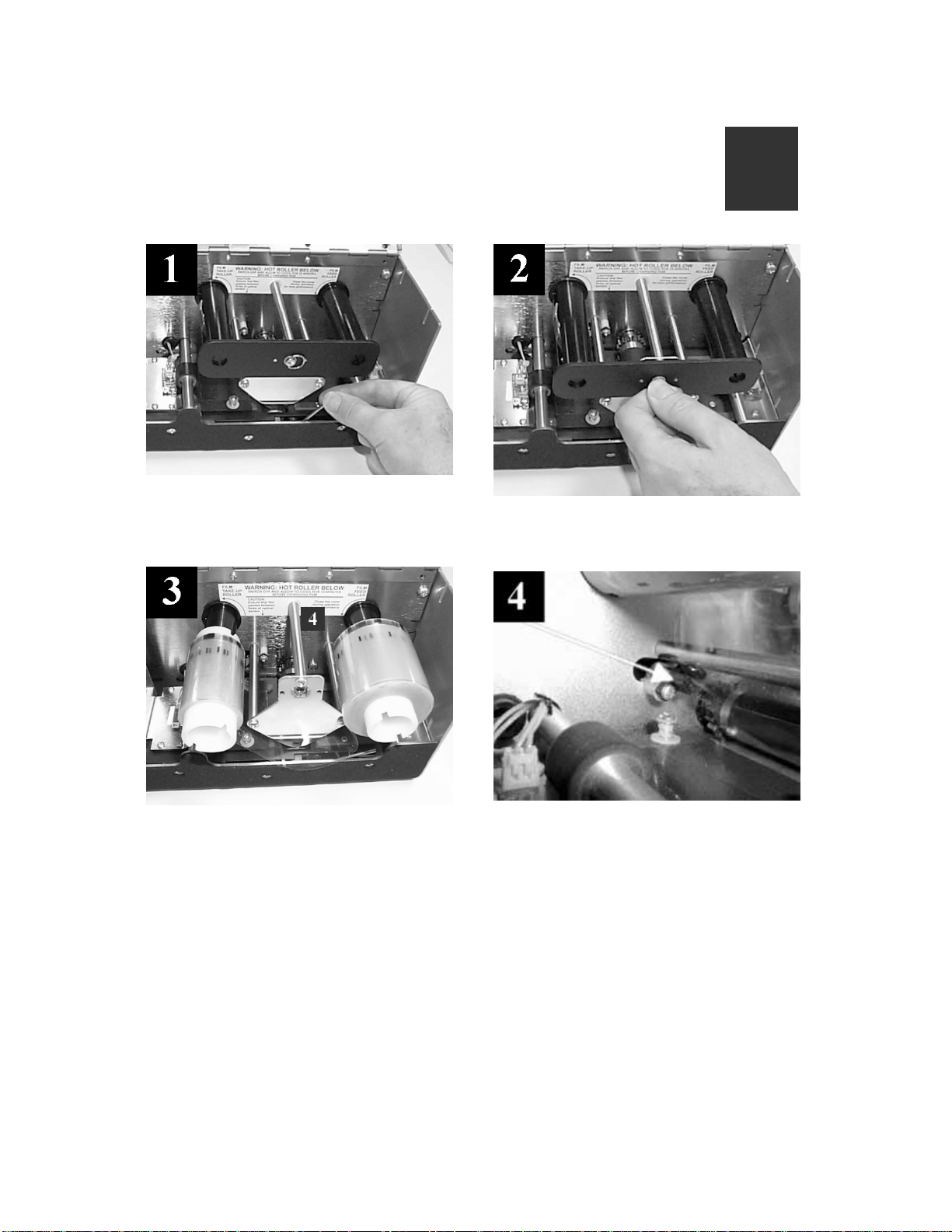

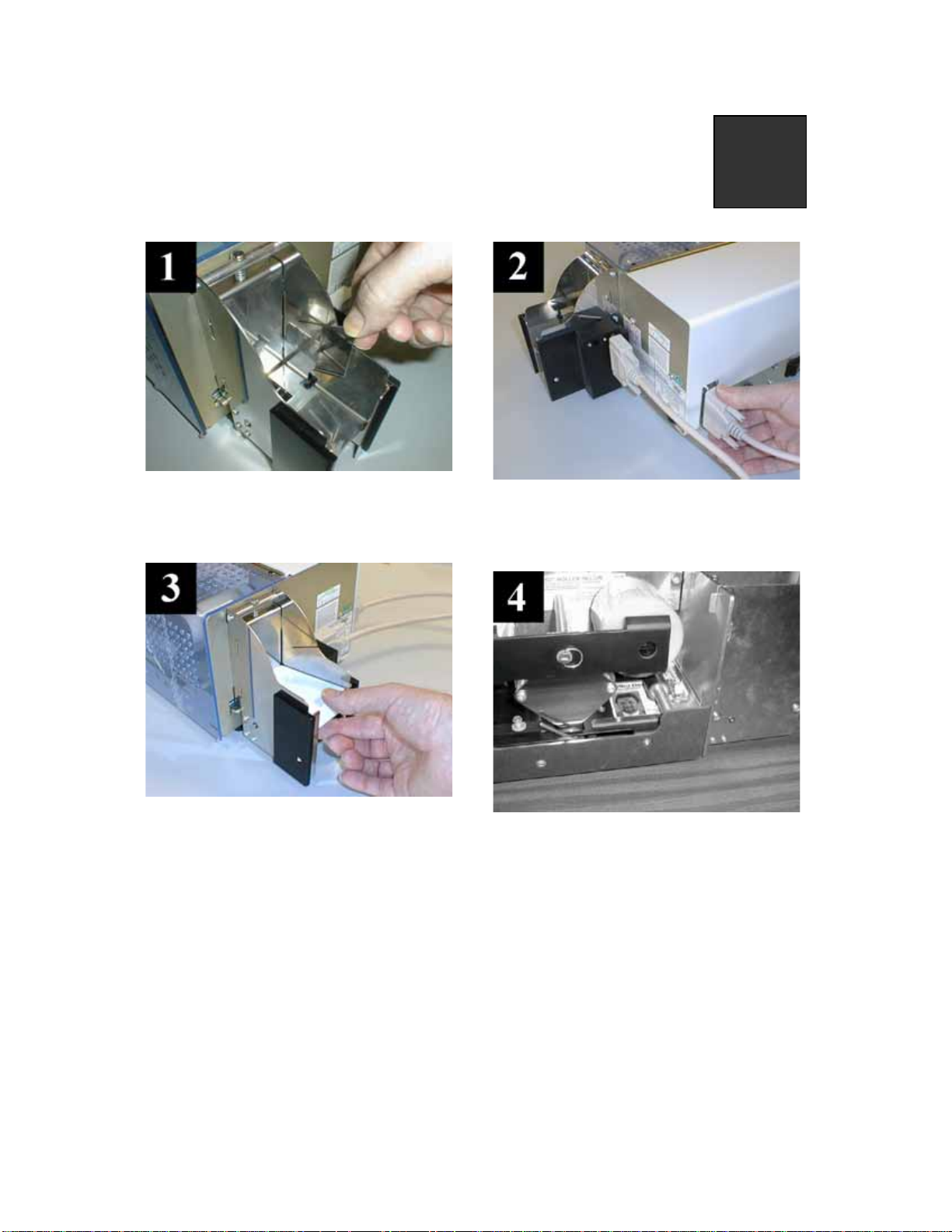

Install the

Lift the transparent cover and move the

roller lever to the OPEN position.

Gently install the roll of film between

the rollers. The black alignment marks

on the film should be innermost.

Lamination Film

Turn the fastener ¼ turn counterclockwise and remove the plate.

Ensure that the film passes between the

forks of the optical sensor.

D

MAGICARD Sicura Laminator Page 7

Page 8

Quick Start Guide Ultra Electronics Card Systems

Replace and fasten the film retaining

plate, and close the lever.

Gently turn both rolls, to ensure that

there is no slack film.

Close the transparent cover.

Page 8 MAGICARD Sicura Laminator

Page 9

Ultra Electronics Card Systems Quick Start Guide

Connect the Laminator

to a Power Supply

Check that the Laminator operating

voltage is correct for your supply

voltage.

(Units cannot be changed from one

voltage to another.)

Check that the temperature Controller’s

LED’s flash.

E

Connect to the AC supply and switch

ON.

After a few seconds, the display will

indicate the temperature of the

laminating roller in °C, which will begin

to increase in value.

MAGICARD Sicura Laminator Page 9

Page 10

Quick Start Guide Ultra Electronics Card Systems

The temperature will achieve the set

point level after a delay of 4 minutes,

and the READY indicator will illuminate.

Notes:

1. When switched on, the laminating

roller and take-up roll turn for

30 seconds or until a black

alignment panel is found by the

optical sensor.

2. The Ready LED will flash for

4 minutes until the roller has heated

up, cards cannot be fed in until

then.

3. Opening the roller lever will stop all

card/film movement. Closing the

lever performs a Reset function but

without the 4 minutes delay.

Page 10 MAGICARD Sicura Laminator

Page 11

Ultra Electronics Card Systems Quick Start Guide

Select the Operating Temperature

and Test the Laminator Operation

NOTE: The optimum roller temperature is best determined by trial and error, using

your own cards and laminating film. The following notes are for your guidance only.

• Cards with large, unprinted white areas require a higher temperature for

lamination.

• We recommend that lamination is performed with the cover down.

• PET/PVC composite cards are more resistant to heat deformation than plain PVC

cards.

F

• Holographic film requires a higher temperature for lamination than clear film.

• For laminating PVC cards with clear film, a roller temperature of 180°C should be

adequate.

• For laminating PET/PVC cards with holographic film, a roller temperature of 190°C

is suggested.

There will be slight variations from laminator to laminator, as well as between different

card types. However, if film bonding is poor, increase the roller temperature. If the

cards are too deformed, or the surface is marked, reduce the temperature.

MAGICARD Sicura Laminator Page 11

Page 12

Quick Start Guide Ultra Electronics Card Systems

Insert a card into the slot, side to be

laminated uppermost.

Cards should be clean, dust-free and

not already overcoated.

Adjust the IN/OUT position of the

laminate on the card by screwing the

core in or out, if necessary.

The card will be laminated in 3540 seconds.

The READY indicator should be off

during lamination.

ROTARY SWITCH AND DIP SWITCH

ADJUSTMENTS

The LEFT/RIGHT position of the

laminate on the card can be adjusted

by means of the rotary switch scaled 0

to F.

The second rotary switch (Spare) is not

used (future option).

DIP SWITCH SETTINGS

All switches are to be left in the UP

position except when operating the

Sicura in conjunction with a TURBO

printer, in which case Switch 1 (brown)

should be DOWN.

Page 12 MAGICARD Sicura Laminator

Page 13

Ultra Electronics Card Systems Quick Start Guide

Adjust the roller temperature for good

laminate adhesion as required (up to

200°C max).

The display normally shows the roller

core temperature in °C.

Press the LH Scroll Key once to select

display of setpoint value. The SP

indicator will illuminate.

Adjust the setpoint temperature with

the ↑ and ↓ keys as desired. Press the

Scroll Key once to return to normal

operation. The SP indicator will go out.

Keep the cover down for best results.

White cards need higher temperatures

than printed cards, for best adhesion,

as does Holographic film.

MAGICARD Sicura Laminator Page 13

Page 14

Quick Start Guide Ultra Electronics Card Systems

Interfacing to a RIO/TANGO Printer

G

IMPORTANT NOTE FOR SETTING UP YOUR RIO/TANGO PRINTER DRIVER TO WORK

WITH THE SICURA LAMINATOR –

Please select the appropriate option in your printer driver for best results.

It is necessary to make the correct settings to the overcoat page in your printer driver

when using a laminator.

If your printer is installed with a custom Holokote key, or you are using the standard

UltraSecure logo you can select the UltraShield box under the Security Options. This

selection uses selective overcoat application to give a 3D security logo effect.

If you are overlaminating with no additional security option, ensure the overcoat

enabled box is not checked.

Page 14 MAGICARD Sicura Laminator

Page 15

Ultra Electronics Card Systems Quick Start Guide

Clip the card Feed Hopper to the end of

the Sicura card laminator. Make sure

the Card Deflection Plate is fitted.

Connect the interface cable from the

laminator. Check that the DIL Switch

selections are ‘UP’ (see Section F4).

Position the Sicura against the Printer

so that cards frpm the printer drop into

the hopper.

Note:

The Rio/Tango printer can print cards faster than the Sicura can laminate them. There

is a hopper capacity of about 12 cards, but to reduce the speed discrepancy, it is

recommended that the printer is operated in ColorSure mode (refer to the Rio/Tango

Quick-Start Guide).

An interface cable ensures that the printer does not feed cards into the Sicura

laminator until the laminator is ready.

Switch on and allow the laminator to

warm up. Print and laminate a test card

by operating the Test pushbutton at the

rear of the printer.

MAGICARD Sicura Laminator Page 15

Page 16

Quick Start Guide Ultra Electronics Card Systems

r

Interfacing to a TURBO Series

H

Switch off the printer, remove the

UltraSecure dongle, and attach the

cable from the laminator to the printer.

Switch both units ON, and allow to

warm up. Print and laminate a test card

by pressing the Test Card button at the

rear of the printer.

Notes:

1. If the Magicard card printer prints a card before the lam in ator is ready (ie not fully armed up, or

2. All new Turbo printers are configured to detect the presence of a Sicura laminator. If UltraSecure

3. If UltraSecure is turned on however, the printer will copy the standard or key-based security logo

4. When cards are subsequently overlami nated, the result is a clearly visible ‘3D’ logo effect which

5. When view ed under UV light, the logo fluore sc es brightly , produ cin g a security check agai nst

Printe

still laminating the previous card), the card is held within the body of the printer until the

laminator is ready, and further printing is queued.

is de-selected in the Windows driver, the Turbo produces cards with no overcoat.

onto the card, laying down solid overcoat only in the area of the logo itself.

is clearly visible in normal daylight.

counterfeit IDs.

Position the laminator so that the

location tab at the card entry slot is

located in the card exit slot of the

Magicard printer.

Check that the DIP Switch Section 1

(brown) is in the DOWN position (see

Section F4).

Page 16 MAGICARD Sicura Laminator

Page 17

Ultra Electronics Card Systems Quick Start Guide

Clip the Card Feed Hopper to the end of

the Sicura card laminator and remove

the Card Deflection Plate.

Load the hopper with cards to be

laminated (100 cards maximum).

Operating the Hopper/Sicura in

Stand Alone Mode

Connect the interface cable from the

lamintor. Check that the DIL Switch

selections are UP (see Section F4).

Switch on the laminator and the hopper.

The hopper will start to feed cards into

the laminator when it is READY.

I

MAGICARD Sicura Laminator Page 17

Page 18

Quick Start Guide Ultra Electronics Card Systems

J

Adjusting the Hopper

The Card Feed Hopper has been factory set for use with 30 thou cards. Should it

require adjustment, carry out the following procedure:

Remove the hopper from the laminator,

remove the interface cable.

View the cards edge-on at the card exit

aperture and adjust the shutter screw

so that 1½ cards thicknesses are

exposed.

Insert a stack of your normal cards to

be laminated. Cards should be flat for

correct feeding.

Re-fit the Card Feed Hopper and the

cable.

Check for correction operation.

Page 18 MAGICARD Sicura Laminator

Page 19

Ultra Electronics Card Systems Quick Start Guide

Error Indicators

K

The Sicura card laminator has three indicators to tell you what is happening:

READY (Green) - When lit, indicates that it is ready to laminate a card.

When flashing, indicates that it is still warming up.

When off, either busy laminating a card, or the power is off.

MEDIA (Red) - When lit, indicates that the sensor did not detect the black

patches on the film, so either out of film or incorrectly loaded.

ERROR (Red) - Checks the progress of a card through the laminator.

Indicates that card transport has failed and requires

investigation.

Reset by opening and closing the roller lever.

MAGICARD Sicura Laminator Page 19

Page 20

Quick Start Guide Ultra Electronics Card Systems

Important Cleaning Procedures Important Cleaning Procedures

L

Correction operation depends on clean rollers to transport cards, an undamaged

laminating roller, and a dust-free environment.

It is recommended that the laminator be cleaned after every roll of lamination film

(250 cards).

PREPARATION

Set the temperature controller to 20°C, then switch off.

Allow to cool down for 15 minutes.

Remove cards and both film cores.

CLEAN DUST FROM FILM BOSSES

Using a slightly damp cloth, wipe any plastic dust from the two film core bosses, the

retaining plate, and any visible dusty surfaces.

CLEAN THE ROLLERS

Switch the laminator on.

Using a slightly damp cloth, wipe the exposed surfaces of the two pinch rollers and

the laminating roller. Operate the open/close lever to turn the rollers.

Switch off and allow to dry.

RE-LOAD

Re-load the laminator with a fresh roll of film and take-up core. It is not recommended

that take-up cores be re-used.

New cores are supplied with each roll of film.

Switch on and set the temperature controller to the desired laminating temperature.

When warmed up, laminate two or three plain cards to get rid of any residual dust and

to check the film alignment on the card.

Page 20 MAGICARD Sicura Laminator

Page 21

Ultra Electronics Card Systems Quick Start Guide

In Case of Difficulty

M

Check the Installation

• Repeat the installation steps in this guide.

• Check that the laminator mains voltage is correct.

• Check that the laminating film is the right way round and passes through the

optical sensor.

• Check that the unit has warmed up (3 minutes).

• Check that the rollers are clean.

• Check the status of the Error LEDs (section K).

For further assistance

• There are a number of useful Technical Bulletins on the MAGICARD WEB page at

http://www.ultramagicard.com

requested from Customer Service.

:

:

. If you do not have WEB access, copies can be

• Call your local Dealer, giving the Model Number and Serial Number, a description

of the nature of the problem, and the flashing error codes if pressent.

• Call the Ultra Magicard Customer Service Hotline number - +44(0)1305 762115 or

+44(0)11305 762121.

• Email us at: customer_service@ultramagicard.com

.

MAGICARD Sicura Laminator Page 21

Page 22

Quick Start Guide Ultra Electronics Card Systems

Notice

The information contained in this document is subject to change without notice.

Ultra Electronics Limited shall not be liable for errors contained herein or for incidental consequential

damages in connection with the furnishing, performance or use of this material.

This document contains proprietary information belonging to Ultra Electronics Limited and may not

wholly or partially be copied, stores in a data retrieval system, disclosed to third parties or used for any

purpose other than that for which it was supplied, without the express written authority of Ultra

Electronics Limited. All rights are re served.

©Ultra Electronics Limited, 2002

Federal Communications Commission (FCC) Statement

Warning: This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A computing

device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operating in a commercial environment.

Operation of this equipment in a residential area is likely to cause interference in which case the user

at his own expense will be required to take whatever measures may be required to correct the

interference.

Note: Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this equipment.

Canadian Department of Communications Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites applicable

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélect rique

édicté par le ministère des Communications du Canada.

WINDOWS is a trademark of Microsoft Corporation.

MAGICARD , Sicura and UltraSecure are trademarks of Ultra Electronics Limited.

PrintMagic is a trademark of Software 2000 Limited.

IBM, AT and PC are trademarks of International Business Machines Inc.

Page 22 MAGICARD Sicura Laminator

Page 23

Ultra Electronics Card Systems Quick Start Guide

Limited Warranty Information

1) Coverage: Ultra Electronics Ltd Warrants that the MAGICARD Sicura card laminator shipped with this Warranty statement

will conform to the manufacturers specifications and be free from defects in materials or workmanship for a period of 12

months from the date of original purchase by the user.

2) Warranty Claims: If the MAGICARD laminator proves defective during this period, please contact the Ultra Service

Center, at the address and telephone/fax number given below. The Ultra Service Center personnel may first ask

you to carry out certain simple checks to confirm the nature of the problem, and if a return is appropriate they will

give you a Return Authorisa tion Number and consi gnment ins tructi ons to the appro priate re pair cente r. Ultra w ill,

at its option, repair or replace the defective parts at no charge to the customer.

3) Warranty Limitations: The Warranty does not apply to MAGICARD laminators that have been:

• Damaged through physical or electrical mishandling.

• Damaged through operation in environments which are outside normal office conditions in terms of corrosive

atmosphere, temperature, humidity, shock or vibration.

• Improperly installed or interfaced to other products which may exhibit software problems or expose the

MAGICARD to improper voltages or control signals.

• Fitted with lamination film rolls from any source other than Ultra Electronics, or have been used to laminate on

anything other than card surfaces which are approved by Ultra and which will generally be made of PVC, be

completely flat, and be free of harmful particles or substances.

• Serviced or interfered with by anyone other than an Ultra Authorised Service provider.

4) Shipping: Insurance and shipping costs incurred in sending the MAGICARD laminator for Warranty service are

the responsibility of the customer. Whenever possible Ultra Service Centers will use the same class of shipping

service selected and paid for by the customer to return the laminator. Return shipping costs from Ultra to the

customer will be at Ultra's expense. After obtaining the Return Authorisation Number as described above, the

laminator should be securely packed in its original packaging with proof of date of purchase and a note

describing the proble m and quoting the Return Authori sation Number. The printer must be sent to the service

center address supplied with the Return Authorisation Number by the main service center. This address may be

different to the address listed below, but will generally be closer to you. Please also mark the Return

Authorisation Number on the outside of the shipping carton. All customs duties and taxes, if applicable, are the

responsibility of the customer.

5) Applicability: The Warranty and remed y provide d above are excl usive and in l ieu of a ll othe r warra nts, eit her expr ess or

implied, including but not limited to, implied warranties of merchantability and fitness for a particular purpose. Any

statements or representations made by any other person or firm are void.

Neither Ultra Electronics Ltd nor its affiliates shall be liable for any loss, inconvenience, or damage, including direct,

special, incidental, or consequential damages, resulting from the use or inability to use the Ultra product, whether resulting

from breach of Warranty or other legal theory even if Ultra has been advised of the possibility of such damage or loss.

This Warranty is governed by the laws of England. Any dispute arising out of or relating to this Warranty shall be submitted

for arbitration of this dispute or disputes pursuant to the rules and regulations of the UK Arbitration Act.

This Warranty gives you specific legal rights, and you may also have other legal rights which vary from country to country

so the above limitations and exclusions may not apply to all customers.

For Warranty enquiries please call or fax our Warranty Service Manager:-

Ultra Electronics Limited

MAGICARD Service Center

Waverley House

Hampshire Road

Granby Estate

Weymouth

Dorset, DT4 9XD, U.K.

Tel: +44 (0)1305 762121 or 762115

Fax: +44 (0)1305 777904

MAGICARD Sicura Laminator Page 23

Page 24

Quick Start Guide Ultra Electronics Card Systems

EC Declaration of Conformity

Manufacturer's Name: Ultra Electronics Limited.

Manufacturer's Address: Waverley House,

Hampshire Road,

Granby Estate,

Weymouth,

Dorset DT4 9XD

England.

declares that the products

Product Name: MAGICARD Sicura™ Card Laminator.

Model Numbers: 3504-0240 (240V Model)

3504-0115c (115V Model)

conform to the following Product Specifications:

Safety: BS7002 : 1992 EN 60950 : 1992

Safety of information technology equipment

including business equipment.

EMC: EN50-081-1 1992 Generic Emission Standard

Part1: Domestic, Commercial and Light Industry.

EN50-082-1 1992 Generic Immunity Standard

Part 1: Domestic, Commercial and Light Industry.

Supplementary Information:

Date: November 2002

Page 24 MAGICARD Sicura Laminator

Loading...

Loading...