Ultimate Products UP-206 User Manual

2/08

UP (6-0043) 4/05

2319 Laurelbrook Street, Raleigh, NC 27604 Phone (800)542-7221 Fax (919)834-4526

Air-Powered Door Operator

Installation Guide

This is an installation guide for the Air-Powered Door Operator. It is a general guideline for a normal installation. If

problems arise call (800)542-7221 for specific advice.

Necessary tools:

Drill and 1/4” bit (to drill mounting holes in operator bracket and door track)

2 vise-grips

Set of Allen wrenches

Set of open-end wrenches — 1/4” to 9/16”

Set of screwdrivers — flat head and Phillips

Set of sockets — 1/4” to 9/16”

Impact wrench

3/8” drill — cordless or electric

2-foot level

Masonry drill — 1/2” or 3/8” bit

Saw saw

Supplies needed but not included with this kit:

Track bolts to mount operator to track

Air compressor

Fasteners to mount controls to walls

1

1

Note: Inspect door for smooth rolling and proper balancing before installing Air Powered Operator.

Part 1:BELT INSTALLATION

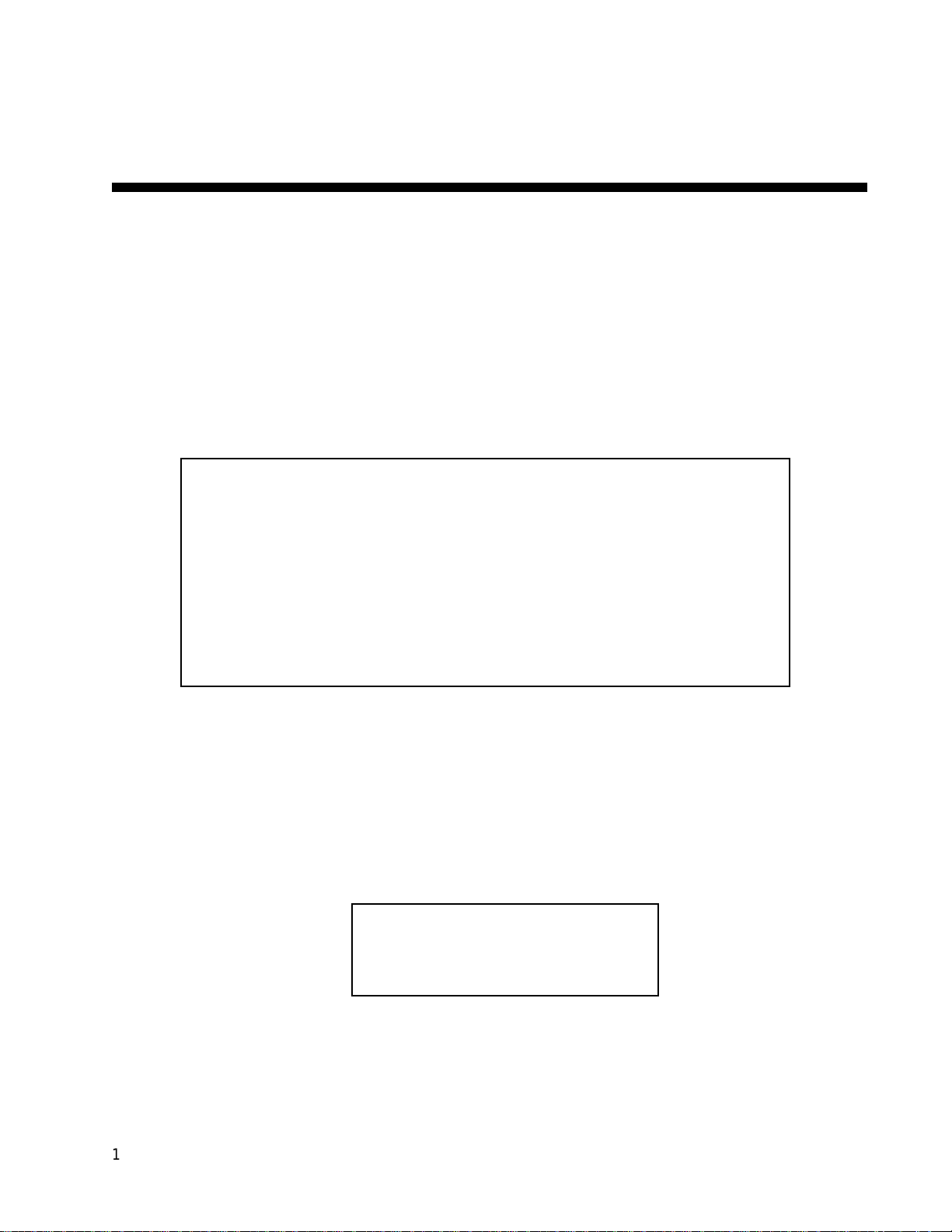

Step 1

Determine which side of door to install the air

powered operator. 6” of shaft is required

beyond track bracket.

Clearance Requirements

8” of side clearance is required to mount

operator.

2

Washers (4)

Tension

Rod

Tensioner Roller

Cotter

Pins

Step 2 Installing Sprocket Kit

Position the 1½” spacer (Part No. SP101)

onto the shaft against the bearing as

shown.

Next slide the sprocket (Part No. BSP01)

against the spacer.

Insert key (Part No. K101) of sprocket kit

into the keyway of sprocket and tighten the

set screws.

Installing Tensioner Kit

Before installing the air cylinder, the

tensioner kit must be installed.(Part No.

OT101).

Set Screws

3

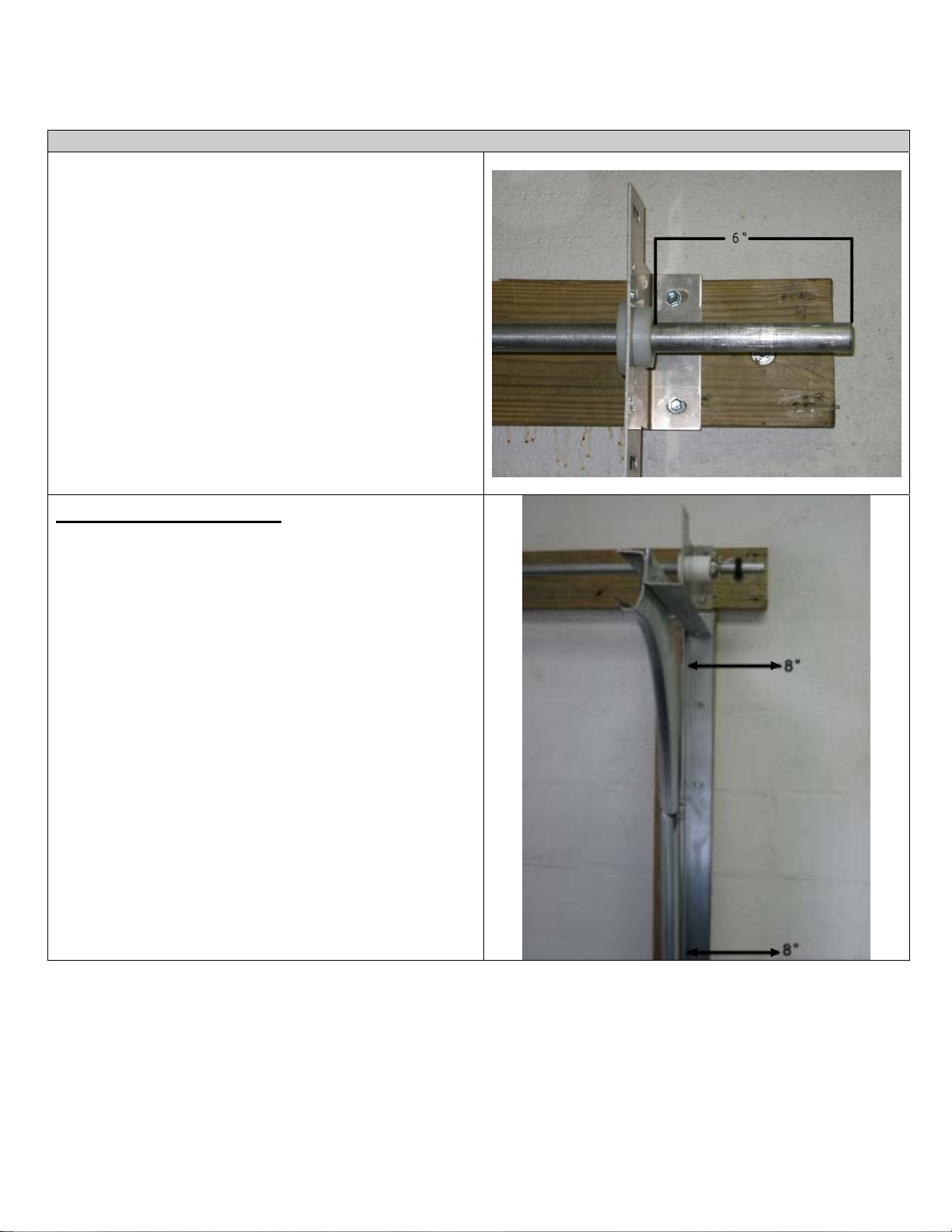

Installing Tensioner Kit

Insert one end of the tensioner rod with

holes into round hole of the track bracket.

Place 1 washer on each side of bracket and

add cotter pins (Part No. DF330).

Place tensioner roller on rod (as shown).

End support bracket will be installed after

hanging the operator. Proceed to Step 3.

4

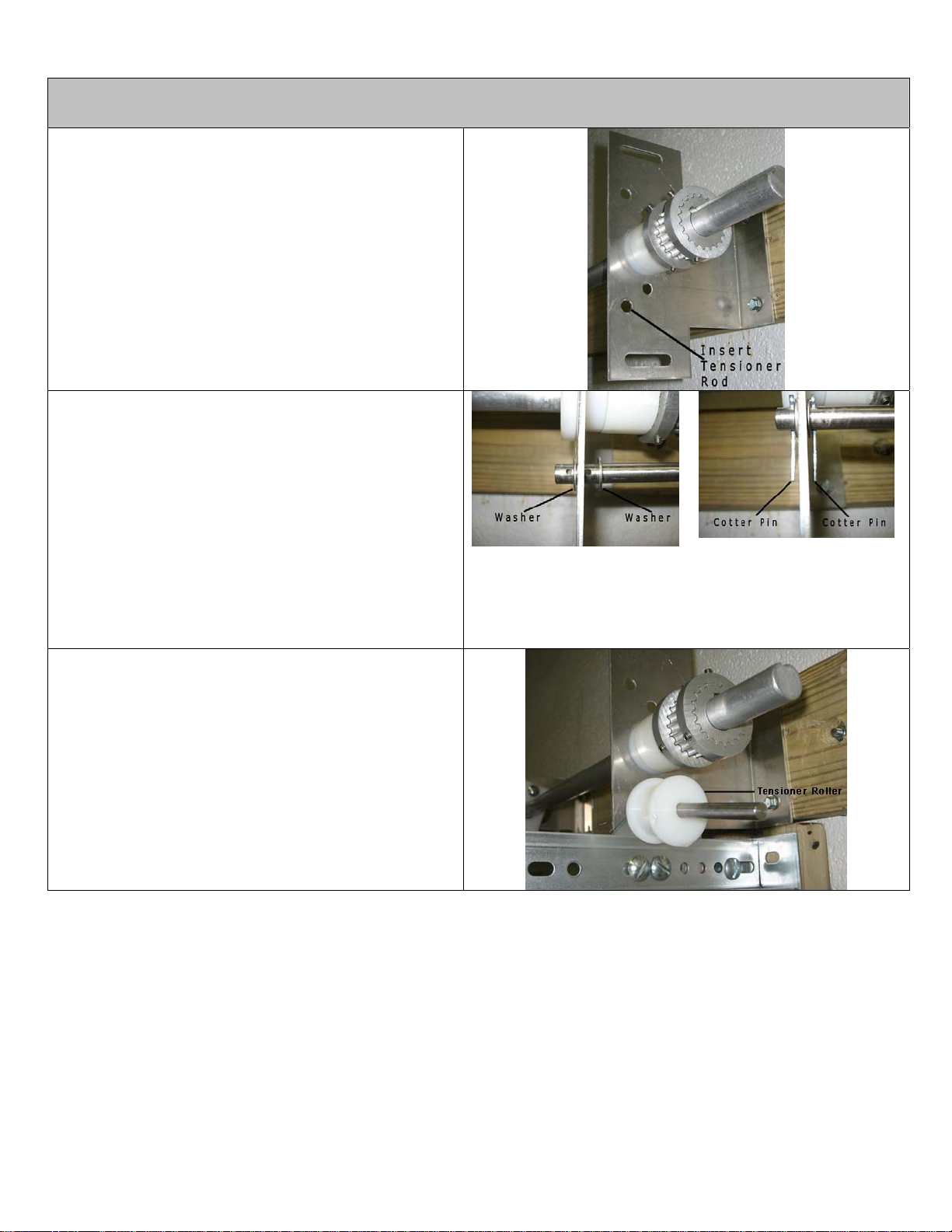

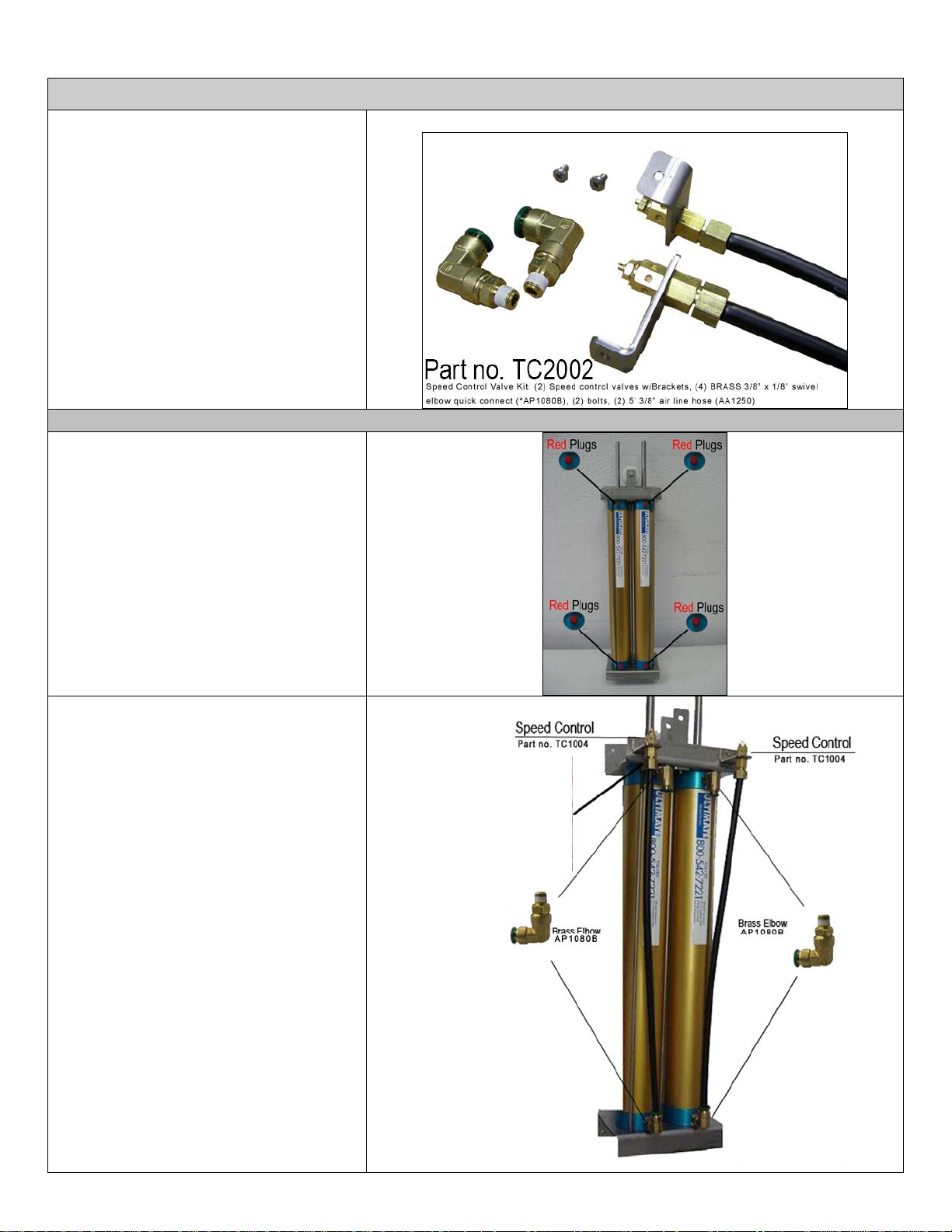

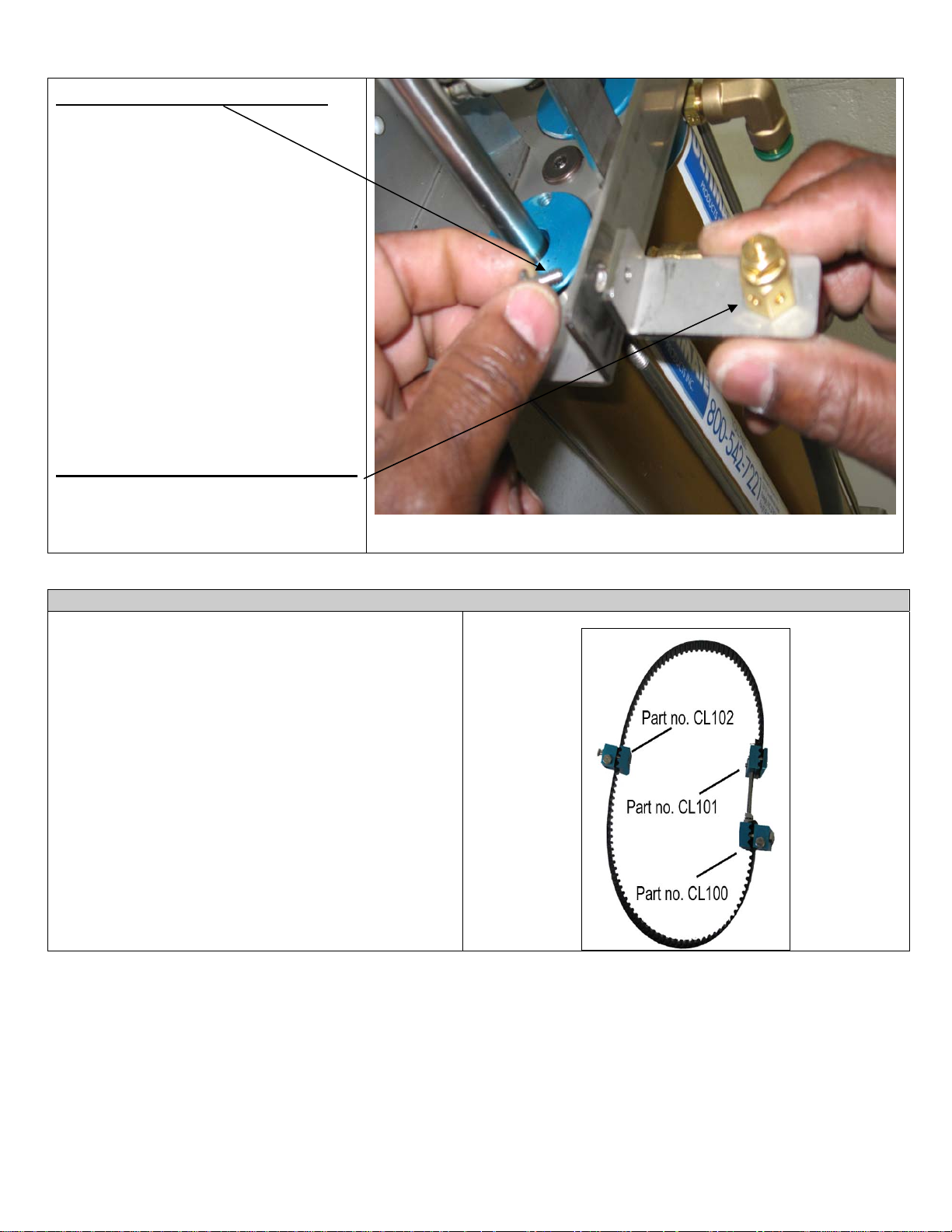

Step 3

Install speed control kit to the

operator. (Part No. TC2002).

Installing Speed Control Kit

Before installing the speed control

kit to the operator, place the

operator flat on floor with the red

plugs facing up. Remove red

plugs from the air powered

Speed Control Kit (Part No. TC2002)

operator.Insert brass elbows

(Part No. AP1080B) into

ports of both cylinders where red

plugs were removed.

Tighten elbows slightly with 9/16

open-end wrench. Attach speed

control valve at top of operator

bracket with (2) two each

10x24x3/8 machine screws.

As shown on Page 5

After installing valves stretch air

lines from top to bottom elbows,

cutting air lines ¾” longer than

bottom elbow. Attach air lines as

See next page for

Larger Image

shown.

5

10 x 24 x 3/8 Machine Screws

Speed Control Valve with bracket

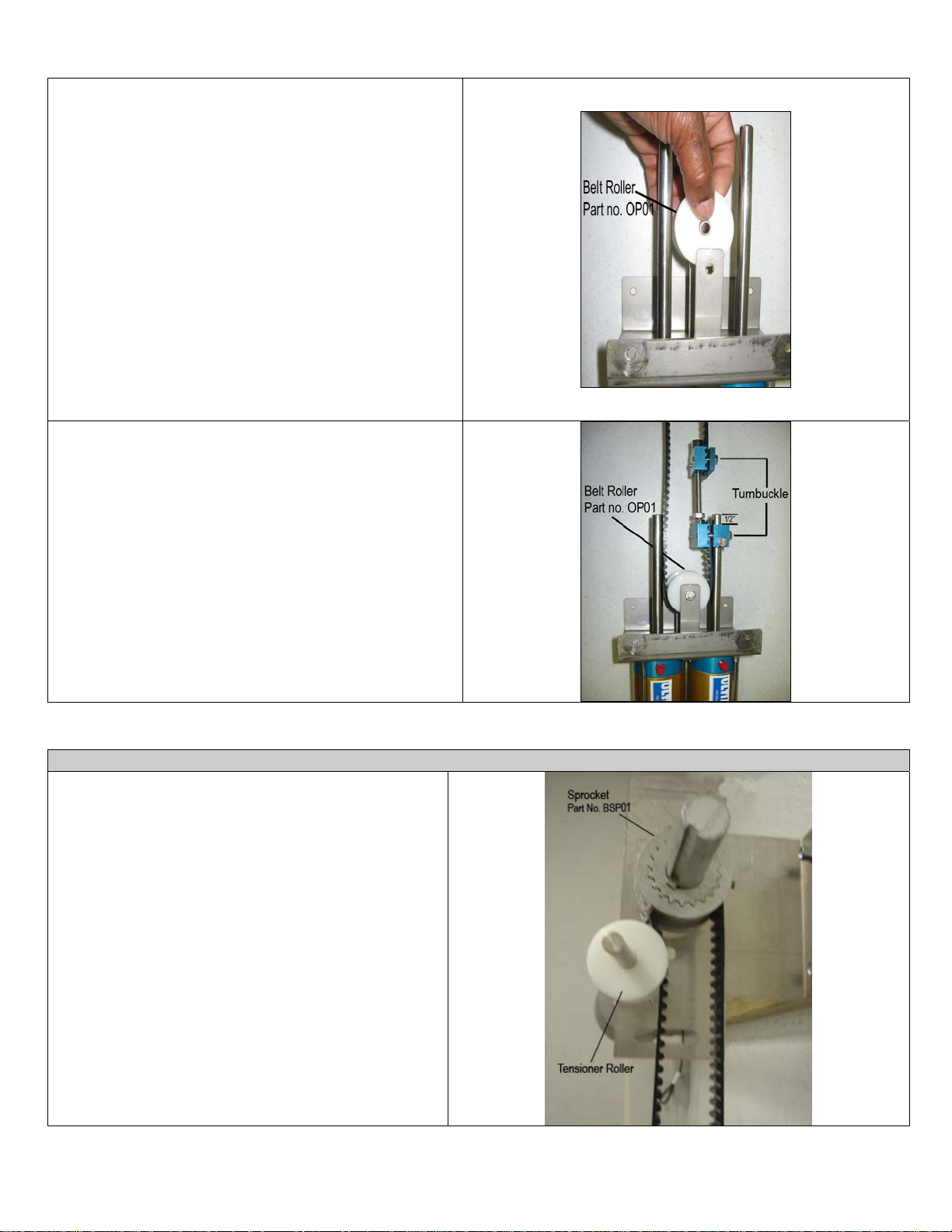

Step 4 Attaching Belt to Operator

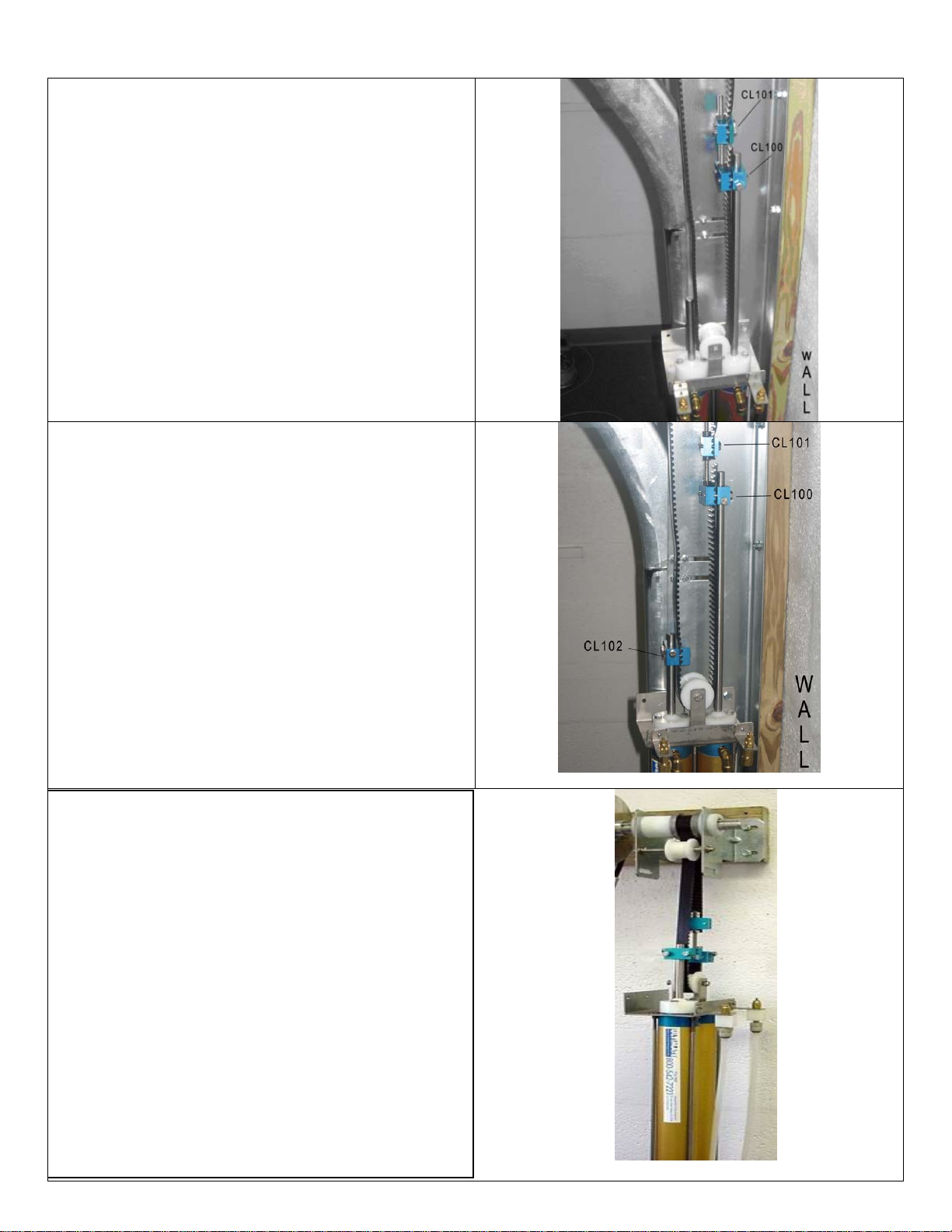

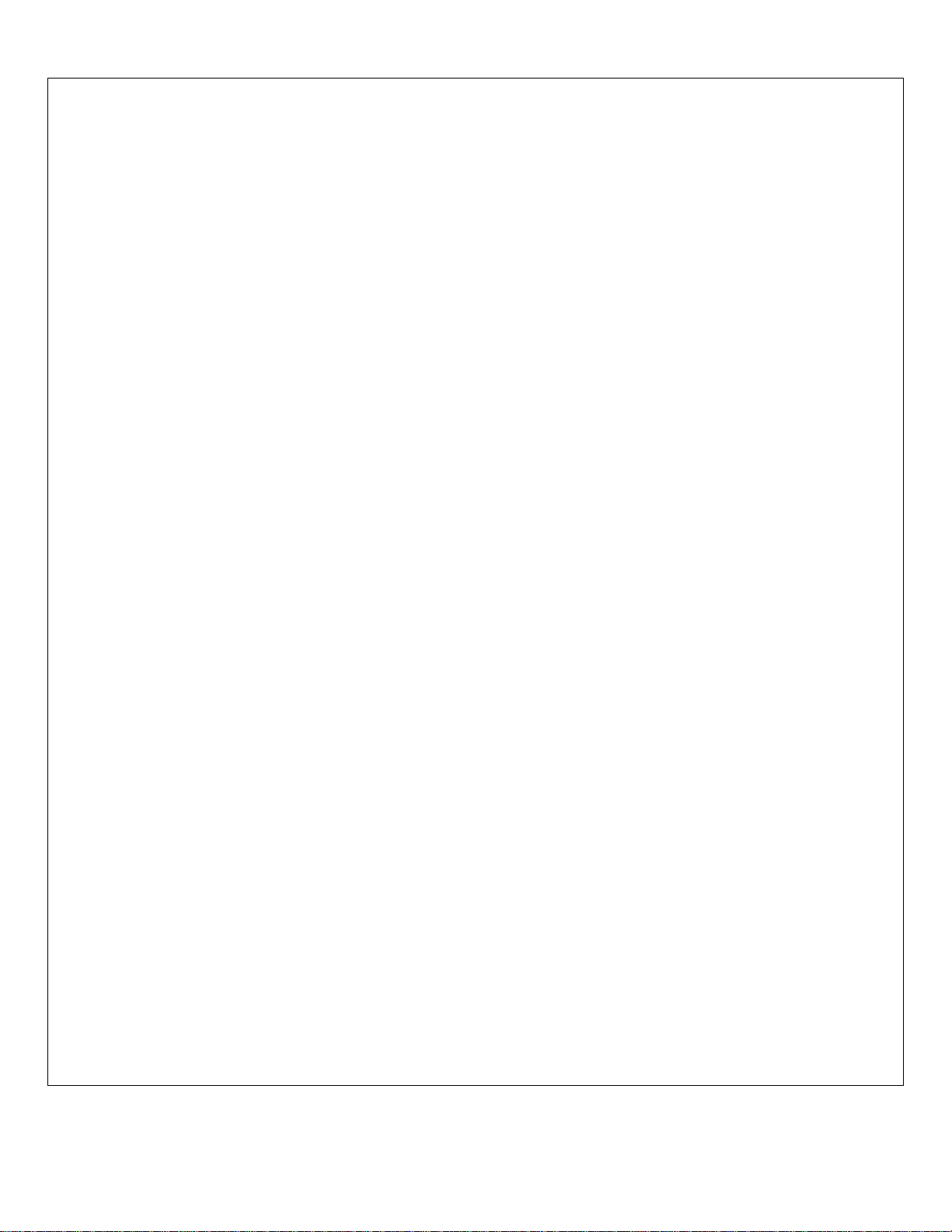

NOTE: Remove clamp assembly CL-102

from belt before installing belt onto

operator.

Operator Belt

6

Remove belt roller (Part No. OP01) from

center of operator. (roller is attached when

operator is shipped from factory)

Slide bottom of turnbuckle onto rod closest

to the wall leaving ½” of rod above

turnbuckle (Part No. CL100). Tighten bolts

of turnbuckle down onto rod and reinstall

Belt Roller on operator.

NOTE: Turnbuckle will always be installed

on rod that is closest to the wall

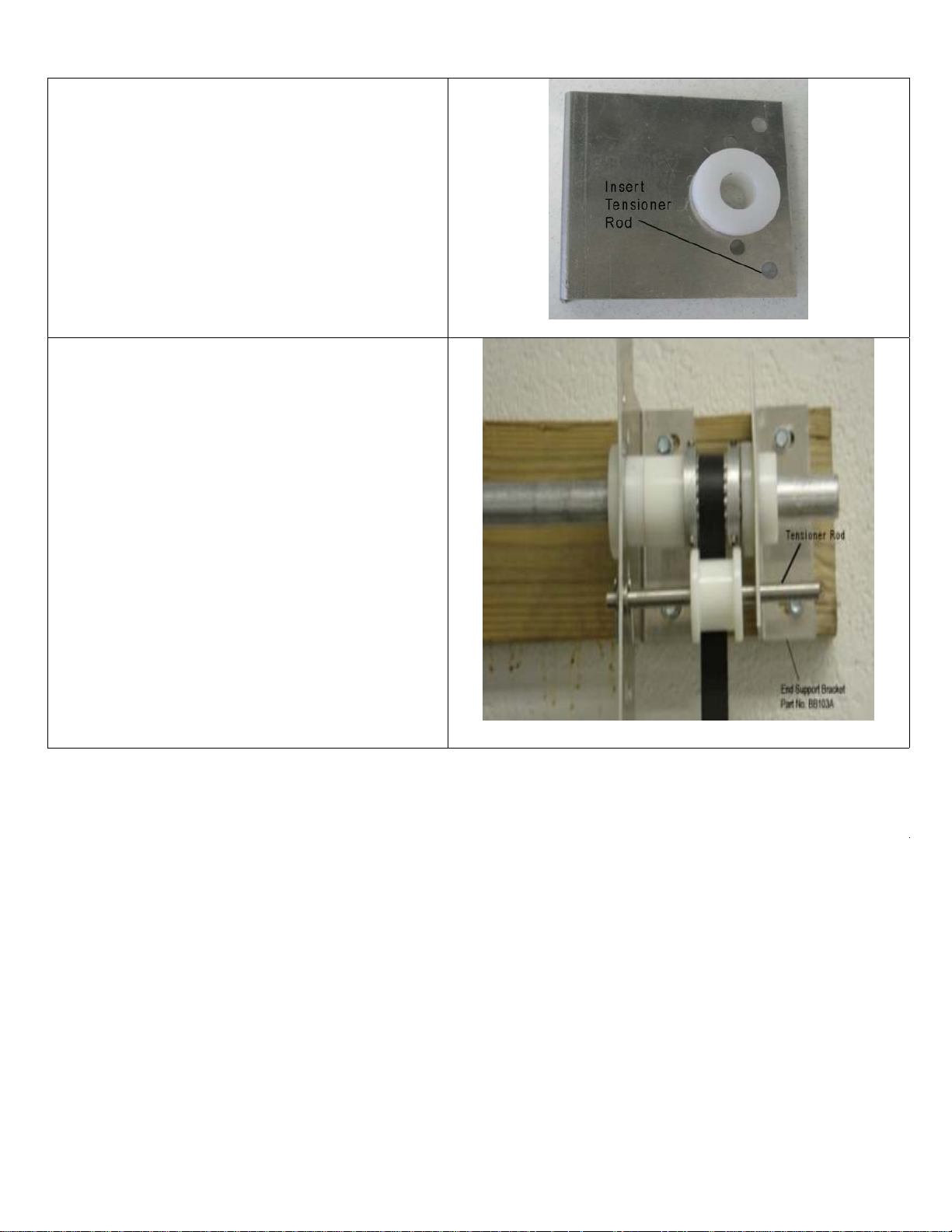

Hanging Operator

Step 5

Note: Insure door is fully closed before

hanging operator.

Hang operator from the belt by placing the

belt around the sprocket and behind

Tensioner Roller, as shown.

7

Install end support bracket (Part No.

BB103A) on door shaft. Making sure

tensioner rod goes through hole of end

support bracket. Attach end support

bracket to wall before attaching operator

to vertical track.

Completed Tensioner Kit will be as

shown.

8

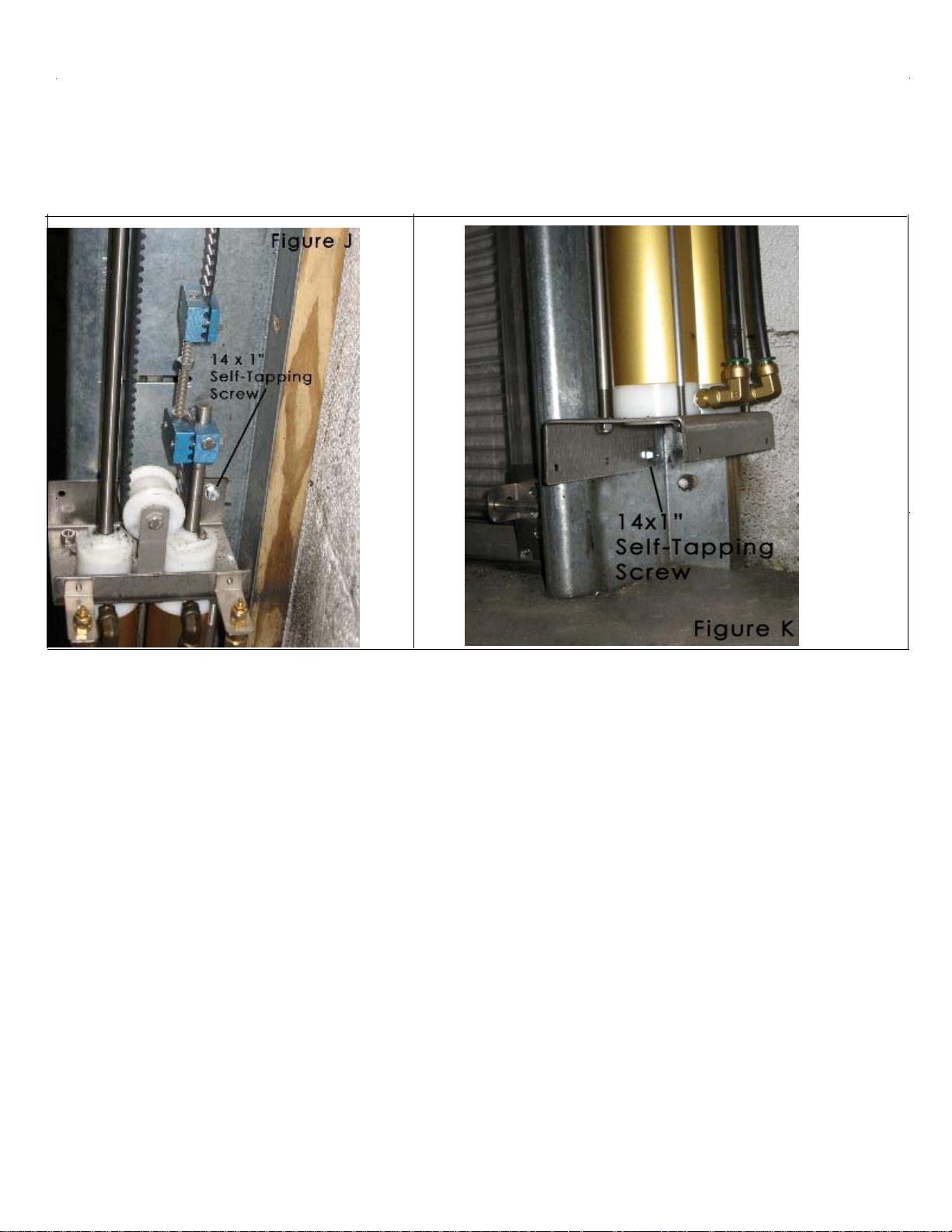

1/4 x 1"

Attach top and bottom of the operator to the vertical track with self-tapping screws. ( As seen in figures J and K on pg. 8 )

Step 6 Setting Open and Close Door Limits

9

Begin by removing ½” nut from top of turnbuckle – (Item ‘A’)

Lower nut (Item 'C') down until desired tightness is achieved.

Using ½” open end wrench tighten nut (Item ‘B’) until belt is snug

After achieving desired tightness, install nut (Item ‘A’) back onto assembly

And tighten both item ‘A’ and Item ‘C’

Item ‘A’

Item B

Step 7

CL101

Item ‘C’

Raise door manually to height of desired

operation -- For example, if you want door to

open 8 feet, raise bottom of door to be 8’ off

finished floor.

10

Rod with turnbuckle (Part No. CL100 and

CL101) will rise when opening the door

Thus after opening door to desired height,

the rod closest to the wall will be extended

out of the cylinder

Now we will attach Part No. ‘CL102’ to the

rod that is not extended out of the cylinder

Your open and close door limits are set. You

are now ready for control box installation.

(See Part 3)

Completed Operator set up view.

11

Installation

Of

Chain

Drive

12

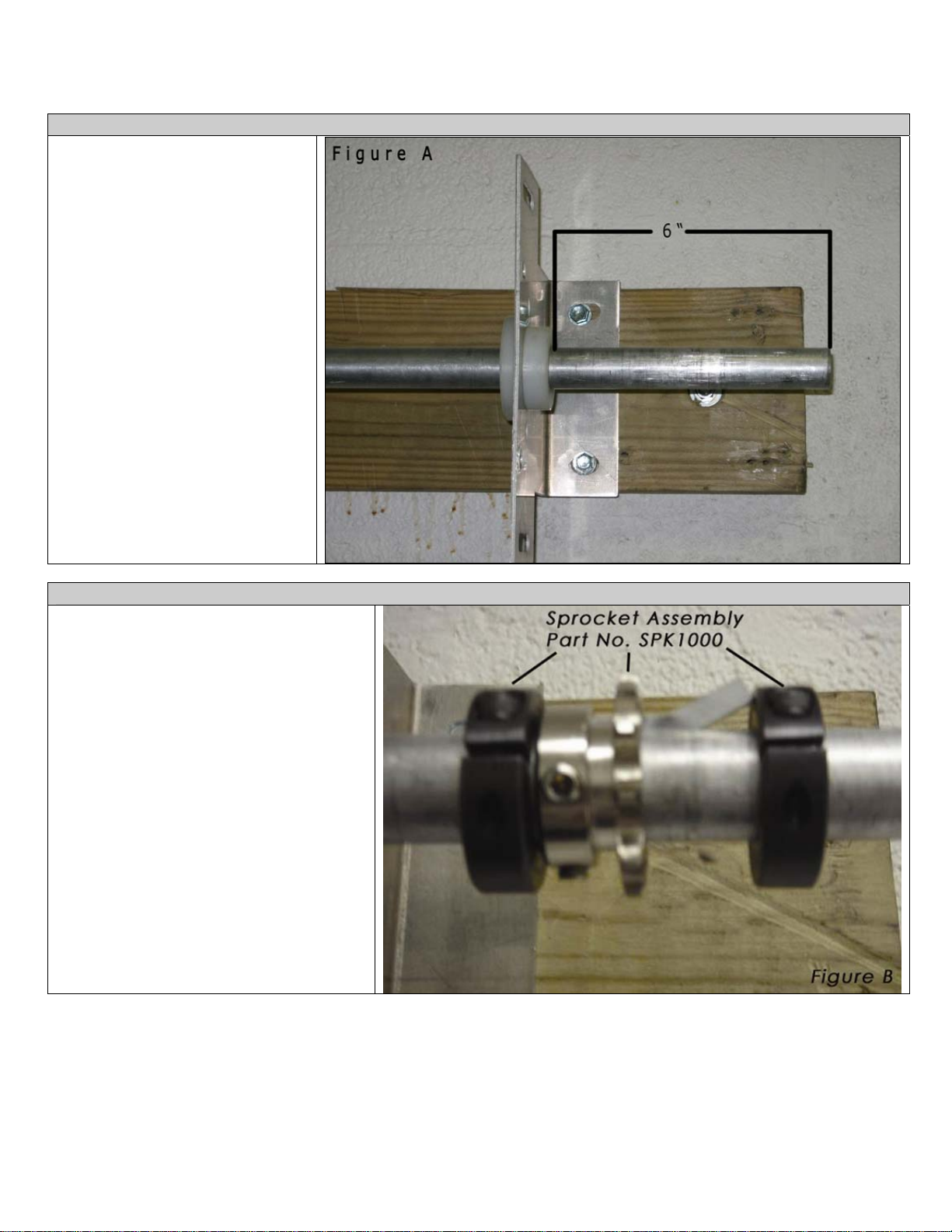

Part 2:

INSTALLING CHAIN DRIVE

STEP 1

NOTE: Before beginning installation

make sure you have chain roller set-up

(Part No. AP1325).

Determine which side of the door you are

installing the air operator on; you will need at

least 6” of shaft beyond track bracket for

installing air-powered operator with chain.

See Figure A.

STEP 2

Position the chain sprocket assembly ( part # spk 1000

) onto shaft against bearing as shown in figure B. Do

not tighten set screws until you have hung operator

around sprocket.

Loading...

Loading...