Ultimaker PVA Removal Station

Product data sheet

Find a reseller

Simple post-processing. Faster parts

Experience quicker and easier post-processing when using

PVA support material for complex parts or stunning visual

prototypes, with the Ultimaker PVA Removal Station. Part of our

start-to-nish 3D printing platform, it ensures quicker design

iterations with minimal operator time and no mess.

Remove PVA up to 4x faster

The Ultimaker PVA Removal Station features a high-speed

dissolving process driven by a magnetic rotor. Compared with

motionless water in an improvised container, it removes PVA

up to four times faster – even from hard-to-reach cavities in

complex designs. So you have parts ready as soon as possible.

The Ultimaker platform

Rotor-powered circulation: A magnetic rotor circulates

water to reach all parts of your 3D print

Adjustable rotor speed: Adjust for faster dissolving or to

protect fragile parts

Keeps prints secured: A rinsing basket keeps prints in

place and submerged

Easy to follow progress: A transparent, illuminated

container makes it easy to know exactly when your part

is ready

Low maintenance: Ergonomically designed for

easy cleaning

No chemicals needed: Just ll with regular tap water,

which can be safely disposed of when nished

Clean and no-mess: Ergonomic design features help keep

your workspace clean and tidy

3D printers that

simply work

Our award-winning 3D printers

are robust, reliable, and easy to

use. They deliver quality parts

time and again. Designed and

tested to run 24/7, they allow you

to achieve the results you need

more quickly and easily.

Learn more at ultimaker.com/pva-removal-station

Software ready for

Industry 4.0

Trusted by millions of users across

14 languages, Ultimaker Cura

integrates with any workow

through Ultimaker Marketplace

plugins. Then scale production

and digital distribution with

Ultimaker Digital Factory.

Material choice like

never before

Ultimaker oers the widest

material choice on the market.

Through our Material Alliance,

choose the perfect lament for

your application – from advanced

polymers to carbon ber

composites.

Support dedicated to

your success

Wherever you are in the world,

Ultimaker support is close by.

Our global network of service

partners oer professional

installation, training, and

maintenance in your language

and time zone.

FM 686003EMS 692523

Ultimaker PVA Removal Station specications

Properties Container volume 13.7 L (3.6 US Gal)

Maximum part size (XYZ) 200 x 230 x 165 mm (7.8 x 9 x 6.4 in)

Supported materials Optimized for: PLA and PVA

Supported solvents Water

Rotational speed 225 RPM (normal)

Operating sound < 50 dBA

Physical dimensions Dimensions 303 x 325 x 374 mm (11.9 x 12.8 x 14.7 in)

Dimensions with handle extended 303 x 325 x 528 mm (11.9 x 12.8 x 20.8 in)

Net weight 6.35 kg (14 lbs)

Container weight (empty) 4.2 kg (9.3 lbs)

Shipping box dimensions 400 x 400 x 500 mm (15.7 x 15.7 x 19.7 in)

Shipping weight 8.5 kg (18.7 lbs)

Ambient conditions Operating ambient temperature 15 – 32 °C (59 – 90 °F lbs)

Non-operating temperature 0 – 32 °C (32 – 90 °F lbs)

Relative humidity 10 – 90% RH non-condensing

Electrical requirements Voltage 100 – 240 V AC

Frequency 50 – 60 Hz

Power 38 W

Warranty Warranty period 12 months

Also suitable for PETG, Tough PLA, Nylon, CPE in combination with PVA

(Also supports equivalent third-party materials)

100 RPM (low)

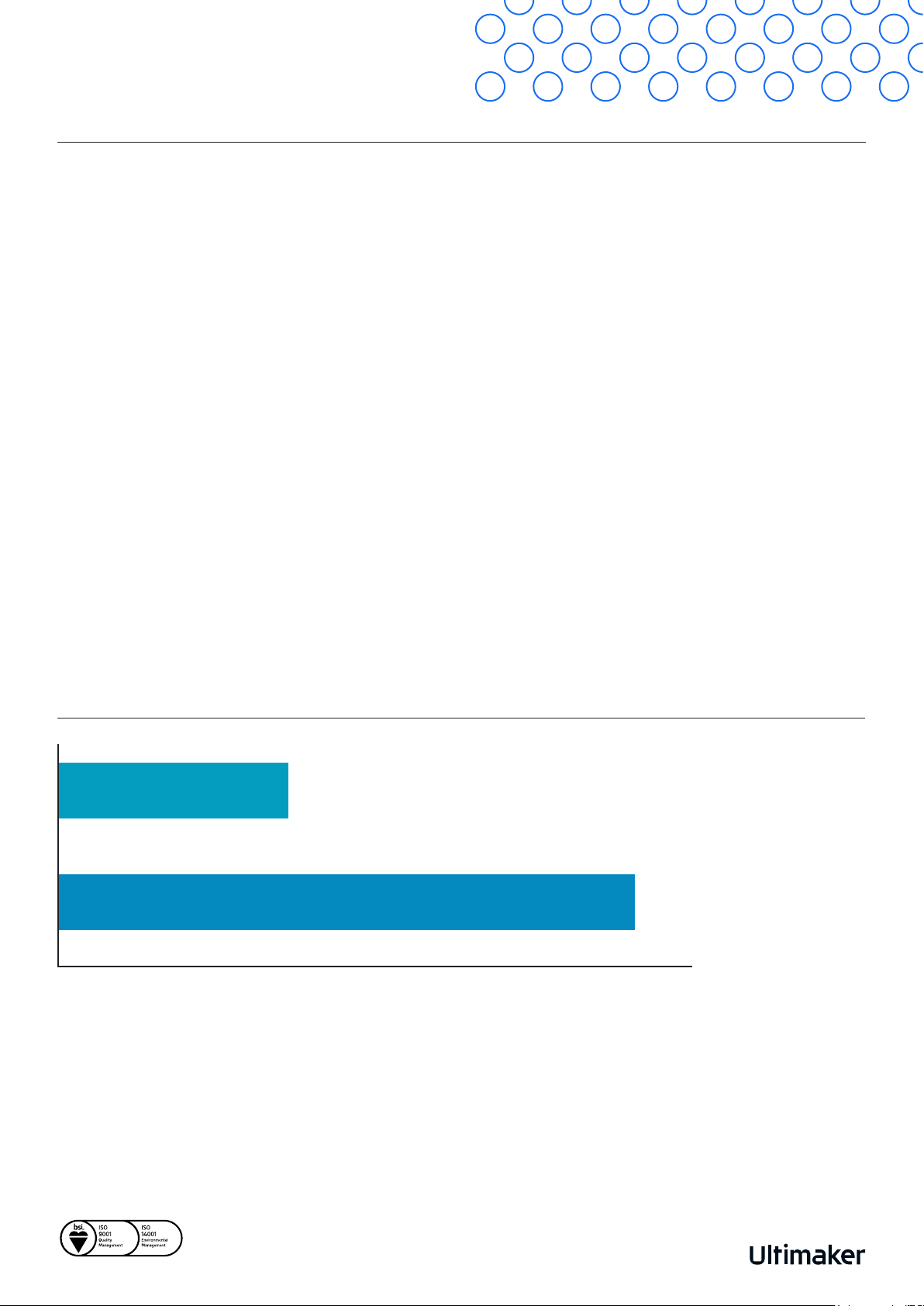

Dissolving time comparison

Ultimaker PVA Removal Station 1–8 hours

Improvised container, motionless water 4–32 hours

*Times may dier and increase this range depending on the size and density of the support structure

*

*

Specications subject to change. EN 2/2022 v1.00

Loading...

Loading...