Assembly manual

The fast, easy to use, Open-source 3D printer

English Version 1.02

Table of Contents

A. Assembly of the Frame

B. Assembly of XY-axle

B1. Sliderblocks

B2. XY-axes

B3. XY-motors

C. Assembly of Z-stage

C1. Z-stage

C2. Placing Z-stage in the frame

C3. Stabilize Z-stage

D. Assembly of the Material feeder

E. Assembly of the Display

F. Assembly of the Hot-end

F1. Hot end

F2. Connecting the fans

F3. Eliminate cables

F4. Placing printhead in frame

G. Assembly of the Electronics

G1. Install the electronics

G2. install the housing parts

A. Assembly of the Frame

Partnr. Part Amount

1024 Limit Switch, Black Short Wire 1x

1161 LED Strip Cold White 1x

1162 Limit Switch Blue Wire 1x

1163 Limit Switch Red Wire 1x

1203 ISO 7380 M3x12 6x

1204 ISO 7380 M3x16 35x

1213 DIN 962 Square Nut M3 A2 35x

1220 Ball Bearing F688-2RA 8x

1230 Front Panel 1x

1231 Back Panel 1x

1232 Left Panel 1x

1233 Right Panel 1x

1234 Bottom Panel 1x

1235 Top Panel 1x

4

Note: The amount of parts

is always times 1, except if

the amount indicates some-

thing dierent. Make sure

you have al the parts before

you start with the next step.

1. Remove the protection foil from the dibond and plexiglas

3. Put the Ball Bearings in the countersunk holes on the front,

left, right and backplate. Make sure you do not damage the

dibont and plexiglass plates. This is a total of 8 Bearings

4. Use a rubber hammer or

use wooden plate between the

hammer and bearing to get the

bearing in place, make sure the

anges ush with the plate.

2. Remove all material left over by the machine.

5

5. Take 35x M3 square nuts and place

them in the T-slots of the front-back, top

and bottom plate. use pliers or tweezers

to make sure the nuts are tted correctly

in the frame

7. Red Endstop on the left

plate (that’s plate with

the extra motor holes).

make sure the lip is facing

upwards (check photo)

6. Attaching the 3 end-

stops with 6x M3X12MM

(rm but not excessive

torque!

6

8. The blue end stop on the top plate.

The lip pointing inwards.

9. The black Endstop

on the back plate on

the bottom of the plate. With the lip pointing

to the right.

7

10. Turn the Front pannel around

so the T-slots are visible. Now

clean the back of the front pannel

with acetone or alcohol, so the

LED strip will stick better.

11. Install the LED strip in

the machine. Remove the

stickytape from the rst LED

strip and start at the bottom

right of the plate. Then move

up wards until you reacht the

top right corner.

12. The second part of the LED strip

goes on the top of the front plate,

start at the right and go to the top

left corner.

13. Make extra sure to

stick the LED strip very

rmly on the housing.

Otherwise, it can deattach at a later stage!

push between each LED

8

14. Attatch the Top and Bottom plate to the

back plate. Make sure all the T-slots are facing

inwards. Next ad the front plate and screw

everything together with M3x16mm screws.

9

15. Place the Two sides on

the machine. Use 35 M3x16mm screws to secure

them into place.

16. Make sure all the cables are

guided through the holes in the

correct way. (use photo’s for

reference)

10

B. Assembly of XY-axle

11

Note: The amount of parts

is always times 1, except if

the amount indicates some-

thing dierent. Make sure

you have al the parts before

you start with the next step.

partnr. Part Amount

1011 Y-linear Shaft 2x

1012 X-linear Shaft 2x

1056 Sintered Bushing 4x

1165 Timing Pulley 5mm Shaft GT2 2x

1166 Timing Pulley 8mm Shaft GT2 8x

1167 Timing Pulley Double 8mm Shaft GT2

1168 Sliding Block Spring 4x

1176 Spacer 8.2x10x5 2x

1177 Spacer 8.2x10x10 5x

1178 Spacer 8.2x10x25

1182 X,Y-motor 2x

1188 Timing Belt GT2 200 2x

1189 Timing Belt GT2 610 4x

1201 Washer Lage M3 8x

1207 ISO 7380 M3x25 8x

1211 Set Screw M4x4 12x

1241 Motor Spacer 2x

1255 Sliding Block 8x

1.This photo shows all the parts needed for the sliderblocks

3. Put the two parts of the sliding

block next to each other and put

a brass bushing in one of the two

(identical parts).

4. Put some tension on the

spring lace the timing belt

with the spring in the slider

block. The timing belt comes

out the slots on both sides of

the slider block

5. Click the two parts of the slider

block together. this is a one-way

mechanisme. Check if everything

is secure.

6. Repeat this pro-

cedure four times,

this will result in 4

assembled sliding

mechanisms

2. Place the timing belt around the spring, so the teeth are to the outside.

12

B1. Sliderblocks

7. Screw a setscrews in all the 8 axes pulleys (with the

8mm holes) and in the double 8mm pulley setscrews:

8x M4x4mm. Doing this now is much easier than later

on in the build.

9. Then slide a 10 mm spacer around it and

then a pulley. The wide side of the pulley

has to face towards the frame.

10. Next is the assembled slider block.

This is followed by a further pulley, and

nally again a 10 mm spacer. Check if its

correct using the photo

8. Slide one of the short axes through the

hole at the front left of the machine.

13

B2. XY-Assen

11. Take two of the assembled slider mechanisms and

place one around each of the pulleys. Make sure the

hole for axes to pass through is underneath the timing

12. Slide the further axle through

the plate until it is exactly ush

with the outside of the housing.

14

13. Take the other short axes and slide it

through the hole back of the left pannel. Then

take the dubble pulley and place it on the axle.

14. Place the sort timing belt on the dubble

pulley. Make sure it’s on the side closest to

the frame. this short belt will attatch to the

motor later on in the process. Now take the

long belt from the left sliderblock and place

it around the pulley.

15. The dubble pulley is followed by

an assembled sliderblock and then

another pulley.

16. Put the right timing belt around the

pulley on the back axle. Then slide the

10mm spacer around the axle. Now slide

the axes through the frame until it is ush

with the side.

15

17. The next shaft that we are going to

assemble, is the axle of the back left.

18. Slide a 25 mm bushing around the axle, it

is followed by a pulley.

19. Place the timing belt attachted to the

front left axle around the pulley. Insert the

axle through the hanging slider block.

20. This is followed by a pulley and ano-

ther 10mm slider block.

21. Attach the timing belt on the right axle

of the pulley and insert the shaft through the

housing, so that it is ush with the frame

16

22. Insert the last axle on the right

back through the housing.

23. You start with a pulley with the

narrow facing the frame. This is dierent from all the other pulleys. Put a

small timing belt around the pulley

24. Then slide a 10mm spa-

cer on to the shaft.

25. Followed by a pulley. With the

broad side facing the frame. and

the slideblock

26. Slide the last 5 mm spacer to the shaft and

attach the timing belt on the right side of the front

axle. Also slide the shaft through the housing until

it is ush with this. When the gantrey is put together all the screws can be tightend down rmly

17

27. These are the nessacery parts to

secure the motors. Make sure that you

take the two with the shorter axels

28. Secure the two pulleys

with the 5mm hole on the

motors with the M4x4 slugs.

the end of the pulley has to

be ush with the axle. make

sure you screw them tight

30. Attatch the small timingbelt

around the pulley. Next make sure

the motor wires are guided around

the little hook at the bottom of the

motorspacer. do this before you

attach the spacer to the frame of

the machine.

29. The wide side of the pulley

has to face away from the motor

18

B3. XY-motoren

31. Attatch the motors with 8 M3x-

25mm screws.Use 8 M3 Washers

between the screwhead and the

frame. Start with the top two screws

to make it easier to position the

motor.

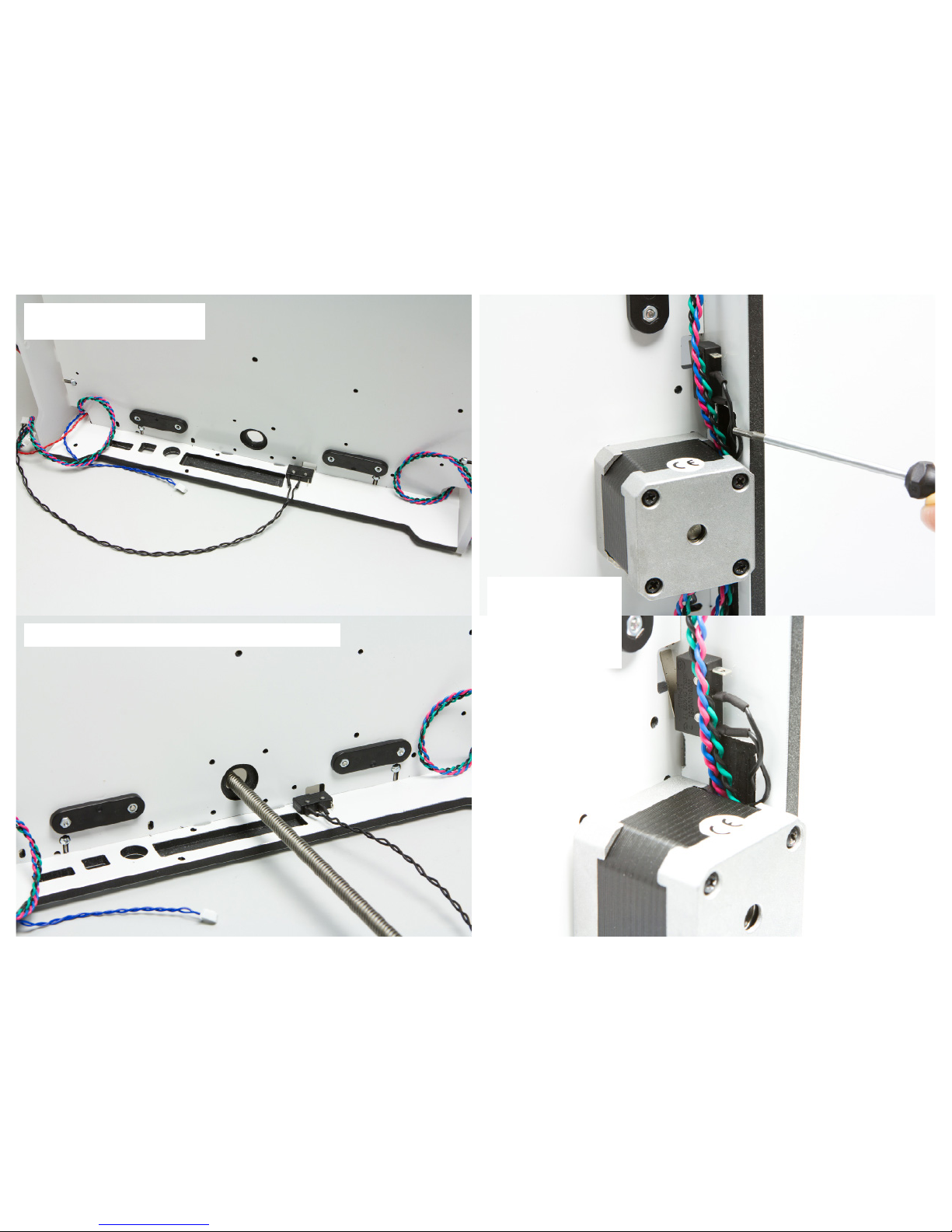

32. guide all the cables, both those of

the motors aswell as the endstop ones

down throught the hole in the bottom

o f the frame.

33. Repeat this entire procedure for the other motor.

19

C. Assembly of the Z-stage

20

Note: The amount of parts is always times 1, except if the

amount indicates something dierent. Make sure you have

al the parts before you start with the next step.

partnr. Part Amount

1152 Table Spring D2150 3x

1153 Print Table Base Plate

1154 Print Table Glass

1155 Print Table Heated Bed

1156 Z-shaft Cap Bottom 2x

1157 Print Table Back Cover

1159 Z-motor With Trapezoidal Lead Screw

1169 Z-linear Shaft 2x

1170 Square Flanged Linear Bearing LMK12LUU 2x

1183 Heated Bed Cable

1187 Trapezoidal Lead Nut

1200 ISO 7380 M3x8 4x

1202 ISO 7380 M3x10 14x

1204 ISO 7380 M3x16 2x

1206 ISO 7380 M3x20 4x

1213 DIN 962 Square Nut M3 A2 2x

1214 ISO 7040 nut M3 Prev. Torque A2 8x

1215 ISO 10642 M3x8 A2 4x

1216 ISO 10642 M3x20 A2 3x

1217 ISO 10642 M4x10 A2 8x

1243 Heated Bed Cable Clip

1254 Print Table Mounting Aid 3x

1256 Build Platform Glass Retainer Back 4x

1257 Knurled Nut Platform 3x

1288 Washer M6 3x

1402 Key Wrench T2.5

1. Make sure all plastic has been re-

moved from the small dibond plate.

2. Remove all jagged particles that have been left by milling.

3. To make sure the tting of the bearings

is correct. Testt the bearings in the holes

and make sure the tting is correct by

turning them fron left to right .

4. Place two nuts in the 2 T-slots of this Dibont plate.

21

C1. Z-stage

5. To build the heated bed. You need these

parts.

6. The top of the stainless steel ring comes in contact with

the aluminum and therefore should be greased with copper

7. Place the greased ring on the

adjustment screw.

8. Now remove all the foil from the aluminum plate.

22

9. position the aluminium plate in such a way

that the notch is on the right side of the middle

hole

10. Insert the adjustment screws with washers

from the bottom through the base plate.

11. Place them in the 3 appro-

priate holes.

12. Place the spring on part of the adjust-

mentscrew sticking out of the aluminium plate

23

14. Place the heated bed on the

base plate and place a glass retainer on both corners between

the heater and the spring

13. The glass retainers are screwd into

place by 4x M3x8mm screws and 4x

lock nuts.

15. Screw it down with 3x M3x20 countersunk screws.

24

12.1. Don’t forget to screw

the cable into the heated bed

orientated as in this image.

25

16. Slide the glass in the rear two

glass retainers. Click the two

front glasretainers onto the glass,

so the glass is secure.

26

17. Attach the cable guide on

the heated bed with 2xM3x10

mm screws.

27

18. Attach the trapezoidal nut

screws on the base plate and

insert the 4x M3x10 screws

from the bottom

19. Attach the ange be-

arings loosely to the base

plate with 8xM4x10mm. the

bearings need to be able to

move a little bit and will be

tightened at a later stage.

28

20. Screw a M3x20 screw in this hole

from the top. This will act as Endstop.

21. Put 4xM3 locknut into

the two cover plates.

29

23. Insert the shafts in the bottom

of the frame. Don’t slide the axles

all the way to the top

22. Remove any jagged bits left in

the milled hole in the top plate.

C2. Install Z-stage in the frame

30

24. Put the build platform in the

fram and insert the 12mm axle

through the build platform . Put

something (a piece of paper)

between the screw and the

frame to prevent scratches.

25. Fold the small Dibond

plate at an angle of 90 degrees, please note this can

be done only once.

26. Slide the Dibond plate

over the axes as follows.

31

27. Remove any dirt into the milled hole in

the top plate and slide the axle all the way

to the top.

28. Make sure the shaft is ush with the

frame, if this does not work then check

whether there is debris in the opposite hole.

if not, use a wooden plate and a hammer to

gently tap it into place.

30. Install the covers for the axes from the inside

of the housing. The notches fall into the milled

holes in the bottom plate. Fix it into place with

4xM3x10mm screws. There can’t be any gap between the black cover plate and the housing.

29. Make sure the end is ush with the frame

32

31. Make sure that both cover

plates are attached as in the picture

32. Place the Z-motor through the bottom plate and the Z table

33. Put the cable from

the motor / ends stops

behind the z-motor

through the milled slot.

Then press the Z motor in

place so it ts securely.

33

34. Now screw the

Z motor from inside

using 4x 10m3 bolts.

35. Put the frame with

Z-table upright and

tape the Dibond plate

on the top edge, this

simplies your work in

the next step.

37. Zet nu het frame

met Z-tafel rechtop

en tape voor even het

dibont plaatje aan de

bovenkant vast, dit

vermakkelijkt je werken

in de volgende stap.

36. Lift the Z-table

and place the black

calibration plugs on

the three places in the

37. Let the Z-table down

again and make sure it

is exactly on top of the

calibration plugs

34

38. Turn 1 of the 8 bolts that

hold the bearing on the Z-table. Then wiggle the Z-table

and up and down so that the

bearing can turn into the best

position.

39. Repeat until you have all

had the 4 bolts.

40. Repeat until you have all had

the 4 bolts for the other bearing

C3. Stabilize z-stage

41. Then push the Dibond cap

on the Z-table so it falls on

the bearings, press it rmly

so that the bearings are in

rmly into place

42. Then lock it in place with

2 x 16 mm bolts m3 inserted

from the bottom.

43. The heated bed cable

is guided by giving it an

extra loop through the

plate in the bottom. this

way, he can not get caught underneath the bed..

35

D. Assembly of the Material feeder

36

Note: The amount of parts is always times 1, except if the

amount indicates something dierent. Make sure you have

al the parts before you start with the next step.

partnr. Part Amount

1021 Ball Bearing 688-2RS 1x

1069 Tube Coupling Collet 1x

1143 Feeder Spring D2110 1x

1158 Reel Holder 1x

1179 Feeder Motor 1x

1201 Washer Large M3 4x

1206 ISO 7380 M3x20 1x

1207 ISO 7380 M3x25 4x

1209 Nut M3 1x

1212 Set screw M3x3

1258 Feeder Part A 1x

1259 Feeder Part B 1x

1260 Feeder Lever A 1x

1261 Feeder Lever B 1x

1263 Feeder Knurled wheel 1x

1264 Feeder Nut Holder 1x

1400 Key Wrench T1.5 1x

1. Screw the M3 socket screw

in the sleeve.

37

2. put the sleeve on the end

of the motor, with the screw

towards the end then screw

this very rmly. Make sure

that the top of the sleve and

the axle are ush.

3. Press the two parts of the

lever to each other, with the 8

mm the bearing in between

38

4. Put the lever in the

housing. Add a little green

grease between the two

parts of the lever and axle.

As a result, he turns slightly

smoother.

5. Place a hex nut in the

t-part and screw in M3x20

screw

39

6. Place the T-piece in the

housing in such a way, that

the screw pointing towards

the outside.

8. Place the tube coupler

7. Attach the spring bet-

ween the t-piece and the

lever. Sometimes it is more

convenient to combine the

spring and the t-piece and

then place the combined

parts in the extruder.

40

9. Close it by placing the other half on the extruder

10. Place The feeder

motor is on the inside of the housing

and the direct drive

to the outside of the

back plate.

11. The slide in direct

drive should point

to the side of the

machine

E. Assembly of the display

41

Note: The amount of parts is always times 1, except if the

amount indicates something dierent. Make sure you have

al the parts before you start with the next step.

partnr. Part Amount

1171 Double Flat Cable 10 Wire 2x

1202 ISO 7380 M3x10 3x

1204 ISO 7380 M3x16 4x

1214 ISO 7040 Nut M3 Prev. torque A2 3x

1244 Knob Front 1x

1245 Knob Housing 1x

1247 Display 1x

1249 Ulticontroller Board 1x

1251 Ulticontroller Electronics Cover 1x

1287 Washer M7 1x

1354 DIN 13-4 Ring M7 1x

42

1. Connect the display to the electronics as follows.

2. Slide the black latch open (towards the edge of the Ulticontroller).

3. Place the end of the at

yellow cable inside (connectors down). Make sure that

the cable is the ush into the

connector.

43

4. Push the lever back. Check whether

the at yellow cable is still sits straight in

the lock. Next remove the protective lm

from the display.

5. You can now carefully mount the

display in the opening by sliding it

in. Make sure that you do not put

(mechanical) tension on the at

yellow cable! The Ulticontroller can

be screwed from the inside of the

housing with 4x M3x16mm screws

44

6. Mount of the 4 bolts , from the inside of the machine. 7. Slide the buttoncasing in the frame-

hole in the front of the frame. the oval

hole should be orientated upward .

8. Slide the housing over knob and install the nut

and tighten up.

45

9. Connect the large at cables. (Mark the two

ends that are still hanging loose with Exp 1 and

Exp 2. (Corresponding to the appropriate output

of the electronics)

10. Put the at cable diago-

nally across the electronics,

so it is better orientated to

move out of the housing.

Make sure you don’t fold

the cables!

46

11. The cover of the display electronics

has two aps. These hold the display

pressed against the front plate. Slide

the tabs along the display inside. Then

insert the front pins in rst and then the

bottom pins.

12. Then mount the cover with 2x M12

bolts and matching lock nuts. Flat cable should come out on one side.

47

13. Finally push the button itself in

the housing on the shaft.

F. Assembly of the hot end

48

Note: The amount of parts is always times 1, except if the

amount indicates something dierent. Make sure you have

al the parts before you start with the next step.

partnr. Part Amount

1065 Linear Bearing LM6LUU 2x

1069 Tube Coupling Collet

1071 Clamp Clip 2x

1074 Print Head Thumb screw 4x

1172 Print Head Shaft X

1173 Print Head Shaft Y 1185 PT100B sensor

1186 Print Head Cable

1200 ISO 7380 M3x8 4x

1266 Bowden Tube

1268 Heater Cartridge 24V 25 W

1280 Braided Sleeve

1281 Clip 5x

1301 Integrated nozzle heater block 3mm lament

1306 Hot end holder bottom

1307 Hot end holder top

1308 Cooling Rib Hot End

1309 PTFE Isolator Coupler 3.2 mm

1310 Hot end Isolator

1311 Spring D2000

1313 Model Cooling Fan 12VDC 0.1A 2x

1320 Print Head Top

1321 Print Head Middle

1322 Print Head Bottom

1329 Dual Fan bracket

1330 Hot-End Cooling Fan 5VDC 0.08A

1348 ISO 7380 M3x4 4x

1351 ISO 4762 M2,5x10

1352 Set Screw M3x14

49

1. Make sure you have the signal

cable, Pt100 and the heater cartridge

with the tops taped together. now

slide the braided sleeve around it.

and you can remove the tape again.

2. These are the components requi-

red for the hot-end

3. Take the metal part without the

notches .This is the lower part of the

hot-end. Screw the adapter on it with

2x M3x8 screws

F1. Hot end

50

4. Lubricate the left hole (the

orientation) with copper grease. This is to prevent corrosion between aluminum and

stainless steel

5. Attach the Teon insulator

coupler, the hot-end insulator and

spring together. Place it on the

hole which you just lubricated the

copper grease.

51

6. Then place the Top Plate of

the Hot-end (with the notches

around the holes) on top. squeeze it together so you get to the

upper two screwholes and screw

it together with 2x M3x8 screws.

8. Screw the hot-end

cooling fan 5vDC onto the

back of the hot-end with

2xm2,5x10mm screws. position the fan in such a way

that the sticker is facing

the aluminium.

7. Parts hot end fan.

52

9. Place the 2 Linear Bearings

in the plastic casing in the

following fashion.

10. Snap the parts together. these

are supposed to go together

without any eord.

53

11. Guide the printhead cable

with the braided sleeve and

the Cartridgeheater and

PT100 through the plasic

casing. making sure the signal cable still sits above the

housing.

12. Now insert the

M3x14mm slug into the

messing heater block

12. Slide the cartridge

heater and the PT100

into the nozzle

54

13. Parts for the Printhead fan.

14. Attatch the fans to the

fanduct with the philipsheads

screws.

F2. bevestigen van de fans

55

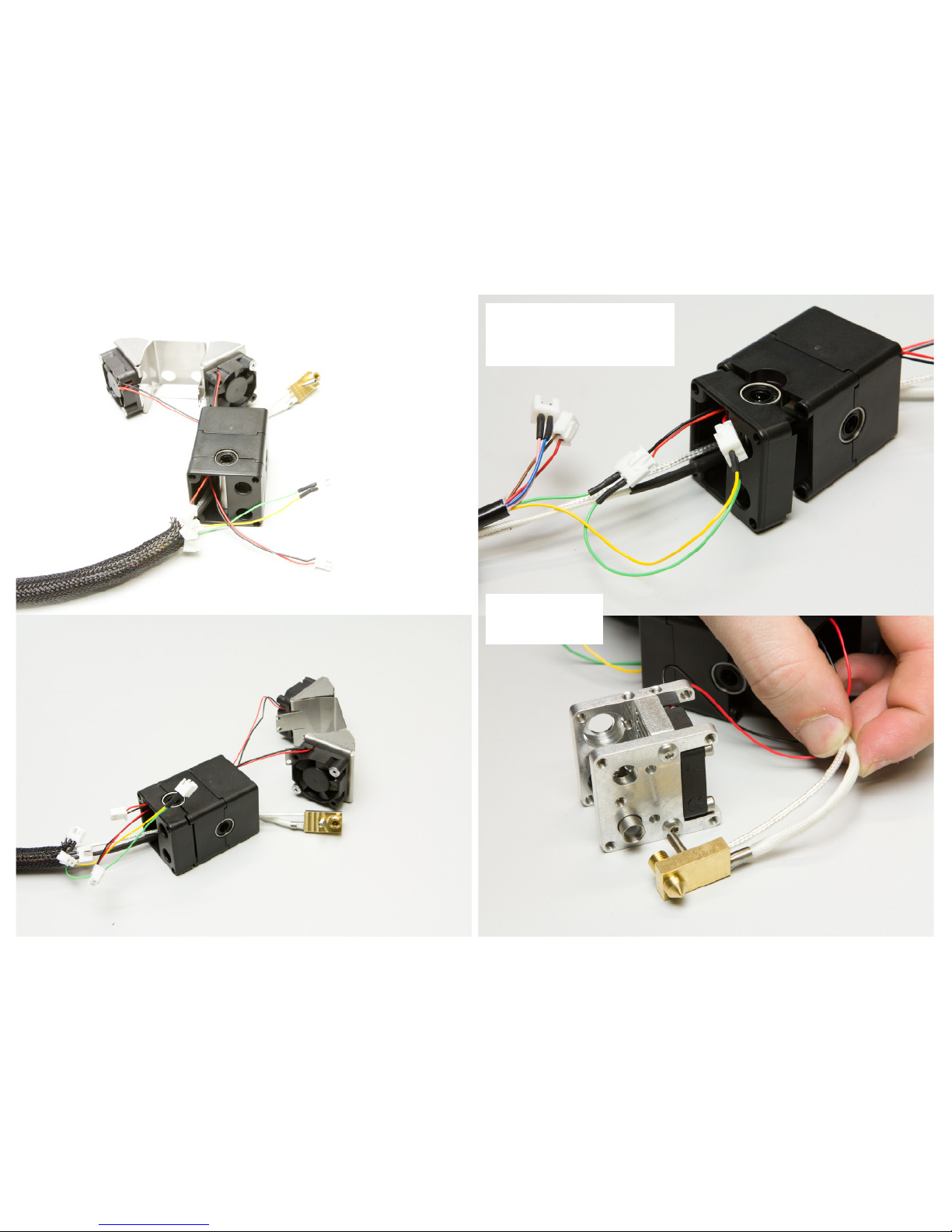

15. Guide the 2 fancables up through

the housing and attach them to the

printhead cable.

16. Attach the 2 fancables from the

fanduct to the green and yellow wires. and the fanduct from the hotend

to the pink blue cable

17. Attatch the nozzle

to the aluminium

frame.

56

18. Now turn the

hot-end isolater until

the teon isolator

part creates a gap of

at least 1 mm and the

bottom of the hotend isolater is just not

touching the messing

part.

1 mm

57

19. Attatch the fan-

duct to the alluminium frame with 4x

M3x4 screws

20. Place the 4

thumbscrews in the

plastic frame. and

tighten them down.

58

21. Make sure that the cables are not

touching the fans and are not stuck

between the housing. Now completely screw down the thumbscres

22. Make sure all the connectors are connected.

F3. kabels wegwerken

59

23. Guide the Braided sleeve around the

connectors and into the top of the frame.

so u don’t see anything sticking out.

60

24. Take the X and Y axes and

Put the X axis through bearing

in the plastic Printhead housing.

25. To prevent the axes

from bending, move

the sliderblocks all the

way to the side of the

machine. Make sure you

apply pressure to the sliderblock instead of the

supporting axes. Then

carefully click them in

place. do the same thing

for the Y axis. move it

to the side, support it

and carefully click it into

place.

F4. Printhead bevestingen in frame

61

26. Take the other side of the

bowdentube (the side with the

tape) and attach it to the direct

drive. secure everything with the

red clamp.

62

26. Attach the 5 clips between the

bowdentube and the braided sleeve.

so they run parralel together. The

braided sleve is supposed to be

underneath the bowden tube.

27. Guide the cables through the

frame and underneath the feeder

downwards until they reach the

electronics.

G. Assembly of the electronics

63

Note: The amount of parts is always times 1, except if the

amount indicates something dierent. Make sure you have

al the parts before you start with the next step.

partnr. Part Amount

xxxx Mainboard v2.1 1x

xxxx Mainboard electronics cover 1x

xxxx Spacers 3.2x6x10mm 8x

xxxx jumper 2x

xxxx cable cover 2x

xxxx ISO 7380 m3x8 2x

xxxx ISO 7380 m3x12 2x

xxxx ISO 7380 m3x30 4x

xxxx ISO 7040 Nut m3 pin torq 6x

64

1. Attach the heated-bed cable to

the electronics on the therminal

marked Heated Bed.

2. Attatch the White heater cables to therminal heater 1.

65

3. Attach the Hot-end Fan to the connector

in the middle of the electronics.

5. Now from the inside put the

4xM3x30mm screws through the

bottom plate. these will be used to

secure the electronics.

4. Check if the jumpers are attached

at the SAFETY1 en SAFETY2. if not,

attach them.

66

6. Het electronica Mainboard attaches to

the bottom. attach the electonics with

4xM3x25mm screws.

8. Attach the endstop cables to the main

board. The red cable connects at Y-stop ,

the blue one at X-stop and the black one

connects at Z-stop.

7. Attach the X,Y and Z motor cables to

the corresponding connectors on the

Electronics board. The extruder motor

cable connects at the E1 connector.

67

9. The brown and white connector

ot the heatedbed cable is the PT100,

Connect it to Temp 3. The silver sleeved

cable is the printhead PT100, connect

this to Temp 1.

10. Bevestig de Ledstrip connector in LED PWM

10. The atcables from the display

can now be connected to the electronics. Follow the numbers you put

on the cable a couple of steps back.

11. The Yellow/green

connector attaches to

the port marked Fan

PWM.

- The brown/white connector is not used at the

moment.

68

12. Now slide the

electronics coverplate into place. start

witht the pins that

t in the back plate

and then the pins

that t in the bottom

plate. Secure it with

2xM3x12 mm screws

and 2x M3 locknuts.

G1. Plaatsen van kappen

69

14. Attach both the

motor covers by

placing them in the

corners and placing

the pins in the correct

holes.

15. secure them with

2xM3x8mm screws on

the side and the back

of the machine.

13. Push the bed all the way

down by pressing just in front

of the Ultimaker 2 logo.

16. Make sure the

Heated-bed cable is

twisted when placing

the motor covers.

this is to prevent the

cable from getting

caught underneath

the bed

Loading...

Loading...