U-Line Wine Captain 2115WC, Wine Captain 2175WC, 2175WCOL, Wine Captain 2115WCOL, Wine Captain 2175WCOL Use And Care Manual

Page 1

Use and Care Guide

Wine Captain® Models:

2115WC and 2115WCOL

2175WC and 2175WCOL

2115WC 2175WC

Page 2

1 Introduction

Congratulations on your purchase of a U-Line refrigeration product. A pioneer in the field for more than 40 years, U-Line

Corporation is the world’s number one manufacturer of built-in, under-counter, specialty refrigeration and ice making

products. U-Line dedicates 100% of its research and development to these products. The result: U-Line technology

consistently leads the market with innovation, design, depth of product line and performance.

U-Line products are making life more convenient in homes, businesses, and hotels around the world. U-Line supports its

products with a strong dealer network, and its commitment to quality even extends to environmentally safe packaging.

IMPORTANT

READ all of the instructions in this guide completely before operating the unit for the first time.

For future reference, keep this guide in a safe, accessible location. If you need additional information or assistance,

please contact U-Line Corporation directly. Contact information appears on the rear cover of this guide.

If you have a problem with the operation of this product, the SERVICE section of this guide will assist you in quickly

identifying common problems and provide information on possible causes and remedies. If your product needs service,

contact U-Line directly.

Warranty Registration

Your U-Line Corporation Limited Warranty is located on the inside rear cover of this guide. To validate your warranty, the

product and its original purchase date must be registered. A Warranty Registration Card has been included for this

purpose in the package containing this manual. Complete and mail the Warranty Registration Card, or register your

product online at www.U-LineService.com as soon as possible after purchase.

If your product registration is not on file and a request for warranty coverage is received, the date of sale to the U-Line

Selling Dealer or Distributor will be established as the first date of warranty coverage for your product.

Please Record Your Model Information

When you request additional information or service, you will be asked for your products model and serial numbers. You

can find this information on the serial plate located on the upper right or rear wall in the interior of your unit. This

information also appears on the warranty registration card.

1

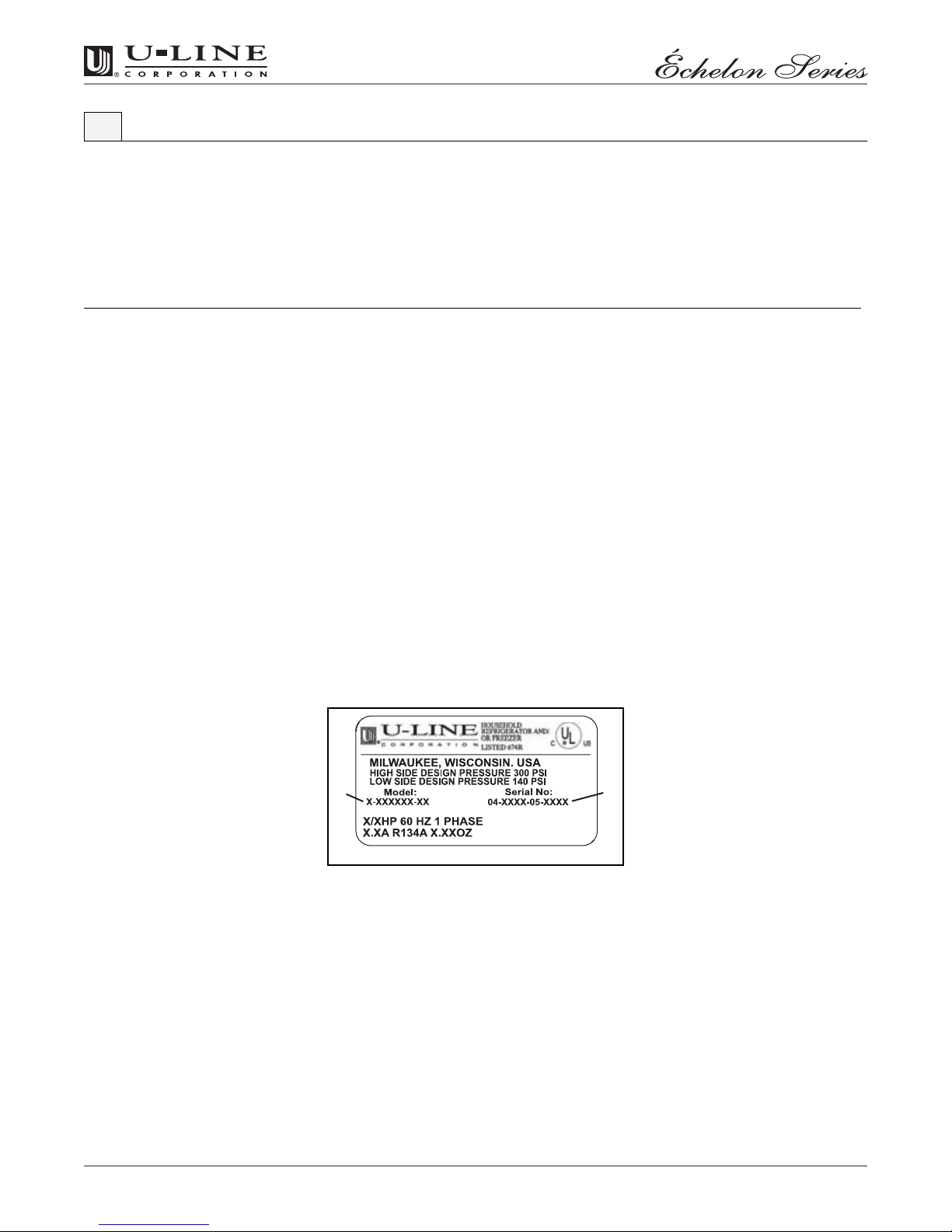

ULIN_0023_A

Figure 1

Please record the model number (Figure 1, 1), serial number (Figure 1, 2), date of purchase, and dealer contact

information for your U-Line product below:

Model Number:

_____________________________________________________

Serial Number:

_____________________________________________________

Purchase Date:

_____________________________________________________

Dealer Name:

_____________________________________________________

Dealer Address:

_____________________________________________________

Dealer Telephone:

_____________________________________________________

2

2 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 3

2 Table of Contents

Introduction ...............................................................................................................................2

Warranty Registration .......................................................................................................2

Please Record Your Model Information ...........................................................................2

Table of Contents .......................................................................................................................3

Safety Precautions ......................................................................................................................5

Safety Alert Definitions .....................................................................................................5

General Precautions ...........................................................................................................5

Product Features ........................................................................................................................6

Échelon Wine Captain .......................................................................................................6

Operation ...................................................................................................................................7

Initial Startup .....................................................................................................................7

Interior Lighting .................................................................................................................7

Electronic Control Panel ....................................................................................................7

Normal Operating Sounds .................................................................................................9

Wine Stocking Recommendations ....................................................................................9

Storage, Vacation, Moving ..............................................................................................10

Product Disposal ...............................................................................................................10

Wine Guide ...............................................................................................................................10

Wine Recommendations ..................................................................................................10

Cleaning and Maintenance .....................................................................................................13

General Cleaning .............................................................................................................13

Maintenance ....................................................................................................................13

Service .......................................................................................................................................19

Before Calling for Service ................................................................................................19

If Service is Required ........................................................................................................19

Replacement Parts ...........................................................................................................19

Troubleshooting Guide ....................................................................................................20

Electronic Control Quick Guide .......................................................................................21

U-Line Corporation Limited Warranty ....................................................................................23

2115WC and 2115WCOL, 2175WC and 2175WCOL 3

Page 4

This page intentionally left blank

4 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 5

3 Safety Precautions

IMPORTANTIMPORTANT

PLEASE READ all instructions completely before

attempting to install, operate, or service your unit.

• Proper installation procedures must be followed

if this unit is being initially installed, or is moved

to a new location after being in service. An

INSTALLATION GUIDE for your unit, providing

complete installation information is available

from U-Line Corporation directly, and must be

consulted before any installation is begun. U-Line

contact information appears on the rear cover of

this guide.

• This unit requires connection to a grounded

(three-prong), polarized receptacle that has been

placed by a qualified electrician in accordance

with applicable electrical codes.

Safety Alert Definitions

Safety items throughout this guide are labeled with a

Danger, Warning or Caution based on the risk type:

WARNING

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance

on the unit until the electricity has been

disconnected.

• Never remove the round grounding prong from

the plug and never use a two-prong grounding

adapter.

• Altering, cutting of power cord, removal of power

cord, removal of power plug, or direct wiring can

cause serious injury, fire and/or loss of property

and/or life and will void the warranty.

• Never use an extension cord to connect power to

the unit.

• Always keep your working area dry.

WARNING

The Anti-Tip Kit must be installed on this unit

before it is used. Serious personal injury could

occur.

CAUTION

DANGER

Danger means that failure to follow this safety

statement will result in severe personal injury or

death.

WARNING

Warning means that failure to follow this safety

statement could result in serious personal injury

or death.

CAUTION

Caution means that failure to follow this safety

statement may result in minor or moderate

personal injury, property or equipment damage.

General Precautions

Use this appliance for its intended purpose only and

follow these general precautions along with those listed

throughout this guide:

DANGER

RISK OF CHILD ENTRAPMENT. Before you throw away

your old refrigerator or freezer, take off the doors

and leave shelves in place so that children may not

easily climb inside.

• Use care when moving and handling the unit. Use

gloves to prevent personal injury from sharp

edges.

• If your model requires defrosting, DO NOT use any

type of heater to defrost. Using a heater to speed

up defrosting can cause personal injury and

damage to the inner lining.

IMPORTANTIMPORTANT

• Do not lift unit by door handle.

• Never install or operate the unit behind closed

doors. Be sure front grille is free of obstruction.

Obstructing free air flow can cause the unit to

malfunction and may void the warranty.

• Failure to clean the condenser every three months

can cause the unit to malfunction. This could void

the warranty.

• Allow unit temperature to stabilize for 24 hours

before use.

• If your model requires defrosting, never use an

ice pick or other sharp instrument to help speed

up defrosting. These instruments can puncture

the inner lining or damage cooling unit.

• Use only genuine U-Line replacement parts.

Imitation parts can damage the unit, affect its

operation or performance and may void the

warranty.

2115WC and 2115WCOL, 2175WC and 2175WCOL 5

Page 6

4 Product Features

Échelon Wine Captain

All Wine Captain Models feature specially designed wine

racks that allow for the proper horizontal storage of

wine. The corks remain moist, which keeps air from

entering the bottles.

Models 2115WC and 2115WCOL will accommodate up to

24 bottles (750 mL size), and Models 2175WC and

2175WCOL will accommodate up to 48 bottles (750 mL

size).

The Right Temperature for Wine

Your Wine Captain has been designed to provide three

temperature zones within the cabinet so the specific

storage requirements of your finest wines can be satisfied.

Superior Features of Échelon

• An electronic control panel with digital display allows

you to display the interior temperature in each zone.

The unit is shipped from the factory with a default

temperature of 50°F. The controller only controls the

middle zone. This zone can be set from 45-54°F. The

upper zone will be approximately 5-6°F warmer and

the lower zone will be approximately 5-6°F cooler than

the middle zone. The electronic control and digital

display provide an attractive appearance, and its

method of control provides precise temperatures for

storage of multiple types of wine.

• An interior light will illuminate automatically as the

door is opened, providing easy visual identification of

the wine. However, you can easily select two other

modes of operation:

a. The interior light can be illuminated while the door

is closed, providing an attractive display of your

wine collection for a period of four hours.

b. A blackout/Sabbath mode (not Star K certified)

allows you to darken both interior lights and the

LED display, while maintaining complete

temperature control in the unit.

• The door features tinted thermal glass that protects

your wines from potentially harmful light rays while

providing a fashionable appearance.

• Wine racks have a contoured maple front trim that

adds a fashionable appearance to the Wine Captain.

The wood facing may be stained, with a WATER-based

stain, or replaced in its entirety with other woods or

manufactured products (such as Corian

• Five fully extendable sliding wine racks provide easy

access to all wine bottles.

• Black vinyl wine racks blend with the wine bottles,

placing greater emphasis on the wines themselves. The

vinyl holds the wine bottles more effectively than a

chromed or painted finish.

®

or Sandstone).

• A Wine Display Rack, located at the lowest level in the

cabinet is another U-Line exclusive. Bottles are

displayed at an approximate 40° angle.

• Wine Captain Models feature either a stainless steel,

black or full overlay ready door frames.

a. Stainless steel units feature a wrapped 2 in. (5.1 cm)

wide door frame, handle. Stainless steel doors are

not field reversible.

b. Black units feature a seamless 1-1/2 in. (3.8 cm) wide

door frame with a slightly contoured top mount

integrated door handle that is field reversible and

easy to maintain.

c. Door full overlay wood frames are customer

provided, and not supplied by U-Line.

• Self-closing door hinges that engage when the door is

open approximately 8-10 in. (20.3-25.4 cm), ensure a

positive door seal and prevents door bounce back.

• Stainless steel models feature a full wrap stainless steel

cabinet.

• Black models feature a vinyl clad steel cabinet that

provides a rich textured look, and resists scratching,

peeling and flaking.

• Wine Captain Models are not recommended for

outdoor use.

• Wine Captain Models installed in either a free-standing

or built-in configuration must be anchored to prevent

tipping, using the originally provided anti-tip kit.

Features and specifications are subject to change without

notice.

6 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 7

5 Operation

ULIN_0080_A

Figure 2

IMPORTANTIMPORTANT

Proper air flow (Figure 2) is required for your unit to

operate at its highest efficiently. A grille, located in

the base of the unit, must not be blocked at any

time, or your unit will not perform as expected.

Initial Startup

All U-Line units are shipped with controls that are preset.

No initial adjustments are required.

IMPORTANTIMPORTANT

U-Line recommends the unit be allowed to run

overnight prior to loading with product.

123 54

Interior Lighting

The interior of the cabinet can be illuminated whenever

the door is opened (default mode), illuminated for a fourhour period, or remained darkened (blackout/Sabbath

mode [not Star K certified]).

The LIGHT icon (Figure 3, 5) on the control panel is used

to change the lighting functions.

To turn the lights and display OFF (blackout/Sabbath

mode [not Star K certified]):

1. Touch and hold the LIGHT icon (Figure 3, 5) for ten

seconds and release (the °F symbol will flash briefly at

the end of the five second period).

2. The interior light and control display

go dark for the next 36 hours.

NOTE: Although the display will not be visible, the

temperature controls in the unit remain active, and the

interior temperature will be maintained.

3. To exit the

certified)

To illuminate the interior of the cabinet for a four-hour

period:

1. Touch and release the LIGHT icon (Figure 3, 5) to

switch from door-operated lighting control to

continuous lighting (the °F symbol will flash briefly

after the LIGHT icon is pressed).

2. To return to door-operated lighting control before the

four-hour period is up, repeat Step 1.

blackout/Sabbath mode (not Star K

before the 36-hour period, repeat Step 1.

(Figure 3, 3)

will

ULIN_0184_A

Figure 3

To turn the unit on or off, touch and hold the POWER icon

(Figure 3, 1) on the display panel for approximately five

seconds until the °F symbol flashes and release.

• A small LED above the icon will illuminate to confirm

the touch of any controller icon.

• The display (Figure 3, 3) will show the unit set-point

temperature when the unit is on and will show OFF

when the unit is off.

• Turning the unit off will override any other control

function.

Electronic Control Panel

Your Wine Captain has been designed to provide three

temperature zones within the cabinet so the specific

storage requirements of your finest wines can be satisfied.

NOTE: These are product temperatures, not air

temperatures.

123 54

ULIN_0184_A

Figure 4

2115WC and 2115WCOL, 2175WC and 2175WCOL 7

Page 8

The electronic control with digital display (Figure 4) is

configured to show a single temperature continuously.

This set-point temperature is a base number used by the

controller to maintain the temperature zones in your unit.

The factory default set-point temperature is 50°F. This setpoint temperature is used as a gauge if further

temperature adjustments are required.

A DISPLAY OFF mode is available through the control

panel. This mode allows you to control whether the

display (Figure 4, 3) will be ON or OFF whenever the

door is closed. The icon touch sequence that follows will

switch between both modes:

1. Touch and hold the WARMER icon (Figure 4, 2), and

within five seconds press the POWER icon (Figure

4, 1) three times.

2. The display will be either visible or dark when the door

is closed.

3. To return to the previous mode, repeat Step 1.

Temperature Display Selection

U-Line products supplied for 110 VAC operation have

temperatures displayed in a default Fahrenheit (°F)

configuration (Figure 4, 3). Models supplied for 220 VAC

operation have temperatures displayed in a default

Celsius (°C) configuration.

The display can easily be adjusted for either type of

temperature display. Press and hold the LIGHT icon

(Figure 4, 5) and within five seconds press the COOLER

icon (Figure 4, 4) three times to change the display as

desired.

Temperature Display

To display all zone temperatures:

1. Press and hold the WARMER icon (Figure 4, 2) for

approximately five seconds and release when the °F

symbol in the display (Figure 4, 3) begins to flash.

2. The display

individual readings at two second intervals per

temperature.

3. The °F symbol in the display will indicate the individual

zone temperature being displayed as they are scrolling.

• The top horizontal bar in the symbol indicates the

upper cabinet zone.

• The middle horizontal bar in the symbol indicates

the middle cabinet zone.

• The bottom horizontal bar in the symbol indicates

the lower cabinet zone.

4. After the third scroll cycle is completed, the display will

return to the set-point temperature.

(Figure 4, 3)

will scroll through three

Checking Product Temperature

ULIN_0093_A

Figure 5

To check the actual product temperature in your unit,

insert an accurate thermometer into a plastic (nonbreakable) bottle that is partially filled with water.

Tighten the bottle cap securely (Figure 5).

Place the bottle in the desired area for 24 hours. Refrain

from opening the unit during the testing period. After 24

hours, check the temperature of the water. If required,

adjust the temperature control in a small increment (See

ADJUSTING TEMPERATURE).

Factors which affect the internal temperatures of the

cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Number of times and length of time the door is

opened and closed.

• Installation in direct sunlight or near a heat source.

Adjusting Temperature

IMPORTANTIMPORTANT

Adjust the set-point temperature in single

increments, and wait 24 hours for the temperature

to stabilize before rechecking.

123 54

ULIN_0184_A

Figure 6

8 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 9

To adjust the set-point temperature:

1. Press and release either the WARMER icon (Figure

6, 2) or COOLER icon (Figure 6, 4) to put the

controller in the SET TEMPERATURE mode. The °F

symbol (Figure 6, 3) will begin to flash.

NOTE: If no further action is taken, this mode will self

cancel in five seconds, and the original set-point

temperature will be displayed.

2. While the °F symbol is flashing, press the WARMER or

COOLER icon as required to adjust the set-point

temperature.

3. The change will be set five seconds after adjusting the

temperature and the new set-point temperature will be

displayed.

Normal Operating Sounds

All models incorporate rigid foam insulated cabinets to

provide high thermal efficiency and maximum sound

reduction for its internal working components. In spite of

this technology, your model may make sounds that are

unfamiliar.

Normal operating sounds may be more noticeable

because of the unit’s environment. Hard surfaces such as

cabinets, wood/vinyl/tiled floors and paneled walls have a

tendency to reflect normal appliance operating noises.

Common refrigeration components, and a brief

description of the normal operating sounds they make,

are listed below. NOTE: Your product may not contain all

of the components listed.

Wine Stocking Recommendations

Specially designed wine racks allow for the proper

horizontal storage of wine. The bottles are properly

positioned so the wine remains in contact with the cork to

assure that the cork does not become dry.

Stock your unit as follows:

ULIN_0205_A

Figure 7

1. The wine racks should be stocked beginning with the

lowest rack, at the back, and working forward.

Stagger the bottles as shown (Figure 7).

• Compressor: The compressor makes a hum or pulsing

sound that may be heard when it operates.

• Evaporator: Refrigerant flowing through an evaporator

may sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may be

heard.

• Automatic Defrost/Drain Pan: Water may be heard

dripping or running into the drain pan when the unit is in

the defrost cycle.

ULIN_0204_A

Figure 8

NOTE: If your unit is equipped with a bottom display

rack (Figure 8), stock that rack first.

ULIN_0019_A

Figure 9

2115WC and 2115WCOL, 2175WC and 2175WCOL 9

Page 10

NOTE: After stocking, allow unit to run for 24 hours

to stabilize product temperatures.

2. Repeat Step 1 to stock the next higher rack, and

continue until all racks are filled

(Figure 9)

.

Storage, Vacation, Moving

If the unit will not be used for an extended period, or

otherwise stored, follow these steps completely:

WARNING

Electrical Shock Hazard. Disconnect power before

servicing. Before operating, replace all panels.

Failure to do so may result in death or electrical

shock.

1. Remove all consumable contents from the unit.

2. Disconnect the power cord from its outlet, and leave it

disconnected until the unit is returned to service.

3. Clean and dry the interior of the cabinet (See CLEANING

AND MAINTENANCE: GENERAL CLEANING).

4. During periods of non-use, the cabinet must remain

open to prevent the formation of mold and mildew.

Open door a minimum of 2 in. (5 cm) to provide the

necessary ventilation.

Product Disposal

If the unit is being removed from service for disposal,

check and obey all Federal, State and/or Local regulations

regarding the disposal and recycling of refrigeration

appliances, and follow these steps completely:

1. Remove all consumable contents from the unit.

2. Disconnect power to the unit and unplug the power

cord from its outlet.

DANGER

RISK OF CHILD ENTRAPEMENT. Before you throw

away your old refrigerator or freezer, take off the

doors and leave shelves in place so that children

may not easily climb inside.

6 Wine Guide

Wine Recommendations

To most, wine is a delicious mystery. We purchase it,

uncork it, and savor its taste and beauty. But there is so

much more to true wine appreciation. Many secrets are

simply too good to keep bottled up. The U-Line

Corporation is proud to present Spilling Wine Secrets

online at www.U-Line.com/resources/wine_secrets. Take a

moment to explore this section of our website to uncover

wine myths, learn ideal storage conditions or ask our wine

expert, Mr. Dave Barna, a specific question relating to

wine. Mr. Barna will respond to your inquiry, and it may

also be selected to appear on our Questions and Answers

page.

Wine Selections Suggestions

Selecting the right wine for the right occasion can

sometimes be a seemingly awkward or difficult task for

the beginning wine enthusiast. We would therefore like

to present you with a few suggestions which may provide

a little more confidence and enjoyment when choosing

and serving your wines.

When selecting wines, keep an open mind and do not be

afraid to be adventurous. Do not view the subject of wine

so seriously it discourages you from learning and

discovering for fear of embarrassment if something is

incorrect. Wine is best viewed as a hobby and enjoyed.

When assembling your collection, try not to become

obsessed with “Vintages.” Although a chart can be a

useful tool, generalizations about a specific year have led

more than one collector to disappointment. In many

instances an “Off Year” will provide a better value and

more drinking enjoyment.

The primary guideline to the subject of wine is your own

palate. Do not be afraid to make mistakes. Experiment,

discover, but most of all, enjoy yourself and your new

U-Line product.

3. Remove the cabinet door.

10 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 11

Suggestions for Matching Food and Wine

Although there are no hard fast rules for matching wine

to food, observe some guidelines. Delicate dishes should

be accompanied by lighter more delicate wines. Fullflavored foods should be matched with fuller-bodied

wines.

As a general rule, one should aim to ascend in flavor and

quality of wines served.

Tabl e 1

Serve a: Before a:

DRY wine SWEET wine

WHITE wine RED wine

YOUNG wine OLD wine

LIGHT-BODIED wine FULL-BODIED wine

Any step back in quality will be noticed. If a fine wine is

tasted prior to a lesser wine, many of the fine wine’s

subtle qualities may be missed.

Common Food and Wine Matches

Tabl e 2

Foods Wines

Fish, Shell Fish, Crab, Oysters Dry White Wines, Light

Beef, Venison Full-Bodied Red Wines

Pork, Veal, Lamb and Poultry Light-Bodied Red Wines

Fruit Sweet White and Sparkling

Sparkling or Extra Dry

Champagne

Wines

2115WC and 2115WCOL, 2175WC and 2175WCOL 11

Page 12

Guide to Common Styles of Wine

Red Wines

Full-Bodied Dry California

French

Italian

Medium-Bodied Dry California

French

Light-Bodied Dry French

Italian

White Wines

Full-Bodied Dry California

French

Medium-Bodied Dry California

French

Light-Bodied Dry French Chablis, Muscadet, Pouilly-Fume

Full-Bodied, Very Sweet Germany

Frency

Hungary

Medium-Bodied, Semi-Sweet California

Germany

Light-Bodied Off Dry Germany Rhine, Mosel, Riesling

Zinfandel, Cabernet

Rhone, Chateauneuf-du-Pape

Barbaresco, Barolo

Pinot Noir

Bordeaux, Burgundy

Beaujolais

Chianti, Bardolino

Chardonnay

Montrachet, Meursault

Puligny-Montrachet

Sauvignon-Blanc

Pouilly-Fuisse, Sancerre,

Vouvray, Graves

Beerenauslese

Sauternes

Tokay

Gewurtztraminer

Liebfraumilch

Common Tasting Terms

Terminology Description

Acidity A critical element of wine that is responsible for preserving the wines freshness. Excess acidity results in an

Balance A desired trait where tannin, fruit and acidity are in total harmony. Wines with good balance tend to age

Body The weight and presence of wine in the mouth provided by the alcohol and tannin level. Full-bodied wines

Bouquet The blending of a wine's aroma within the bottle over a period of time, caused by volatile acidity.

Complex A subjective term often used in tasting. A wine is said to be complex if it offers a variety of flavors and scents

Flabby A wine that lacks structure, or is heavy to the taste, lacks acidity.

Full-Bodied Wine high in alcohol and extract, generally speaking, fills the mouth, powerful.

Lean Generally describes wines that are slim, lacking of generosity or thin.

Oaky A desirable flavor imparted to wine if done in moderation. Most wines are aged in oak barrels one to three

Tannin Tannins are extracted from the grape skins and stems and are necessary for a well-balanced red wine. Tannins

overly tart and sour wine.

gracefully.

tend to have this strong concentration.

that continue to evolve as it develops.

years, thereby receiving this toasty oak characteristic. However, if a weak wine is left in contact too long with

an oak barrel it will tend to be overpowered with an oaky taste.

are easily identified in wine tasting as the drying sensation over the gums. Tannins generally fade as a wine

ages.

12 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 13

7 Cleaning and Maintenance

General Cleaning

Exterior Cleaning (As Required)

Black Models:

• Surfaces may be cleaned with a mild detergent and

warm water solution. Do not use solvent-based or

abrasive cleaners. Use a soft sponge and rinse with

clean water. Wipe with a soft, clean towel to prevent

water spotting.

Stainless Steel Models:

• Stainless steel surfaces and components can discolor

when exposed to chlorine gas, pool chemicals, salt

water or cleaners with bleach.

• Keep your stainless steel unit looking new by cleaning

with a good quality all-in-one stainless steel cleaner/

polish on a monthly basis. For best results use Claire

Stainless Steel Polish and Cleaner, which can be

purchased from U-Line Corporation (P/N 173348).

Comparable products are acceptable. Frequent

cleaning will remove surface contamination that could

lead to rust. Some installations may require cleaning

on a weekly basis.

• Do not clean with steel wool pads.

• Do not use cleaners that are not specifically

intended for stainless steel on stainless steel

surfaces (this includes glass, tile and counter

cleaners).

• If any surface discoloring or rusting appears, clean it

quickly with Bon-Ami

and a non-abrasive cloth. Always clean in the direction

of the grain. Always finish this process with Claire

Stainless Steel Polish and Cleaner or comparable

product to prevent further problems.

• Using abrasive pads such as Scotchbrite™ will

cause the graining in the stainless steel to

become blurred.

• Rust that is not cleaned up promptly can penetrate into

the surface of the stainless steel and complete removal

of the rust may not be possible.

®

or Barkeepers Friend Cleanser®

®

Maintenance

Proper maintenance of your U-Line product will ensure

efficiency, top performance and long life. The

maintenance intervals listed are based on normal

conditions. You may want to shorten the intervals if you

have pets or other special considerations.

Defrosting

Automatic (Cycle) Defrost Models

Automatic defrost models do not produce frost in normal

operating conditions. However, a frost pattern may be

noticed on the interior walls if the unit is repeatedly

opened in a high heat or high humidity location. If this

frost pattern does not clear within 24 hours, your unit will

require manual defrosting.

WARNING

DO NOT use any type of electrical heating device,

ice pick, knife or other sharp instrument to

defrost; this could damage the inner lining or

refrigeration system and void the warranty.

IMPORTANTIMPORTANT

The drain pan was not designed to capture the

water created when manually defrosting. To

prevent water from overflowing the drain pan,

place towels or other absorbent materials over the

interior drain trough, under the evaporator (Figure

10, 1), before defrosting.

Interior Cleaning (As Required)

• Disconnect power to the unit. Clean the interior and all

removed components using a mild non-abrasive

detergent and warm water solution applied with a soft

sponge or non-abrasive cloth. Rinse the interior using a

soft sponge and clean water.

• Do not use any solvent-based or abrasive

cleaners. These types of cleaners may transmit

taste to the interior products and damage or

discolor the interior.

2115WC and 2115WCOL, 2175WC and 2175WCOL 13

1

ULIN_0187_A

Figure 10

Page 14

To defrost:

1. Turn unit off.

2. Remove all products from the interior and prop the

door in an open position (2 in. (5 cm) minimum).

3. Allow the frost to completely melt naturally. Clean the

interior and all removed components using a mild nonabrasive detergent and warm water solution applied

NOTE:

with a soft sponge or non-abrasive cloth.

DO

NOT use any solvent-based or abrasive cleaners. They

will discolor or damage the interior.

4. Dampen a soft sponge or non-abrasive cloth in clean

water and wipe down the cabinet interior and removed

components to remove any detergent residue. Rinse the

sponge or cloth in clean water and repeat as necessary

until the cabinet and components are clean.

5. When the interior is dry, turn unit back on.

Condenser Cleaning

Interval - Every Three Months

To maintain operational efficiency, keep the front grille

free of dust and lint and clean the condenser every three

months. Depending on environmental conditions, more

or less frequent cleaning may be necessary.

CAUTION

DO NOT use any type of cleaner on the condenser

unit.

4. Clean the condenser coil

(Figure 11, 2)

using a soft

brush with a “combing” action or vacuum cleaner. Do

not touch the condenser coil.

5. Position the grille to align the mounting screws with

the holes in the cabinet.

6. Secure, but do not over-tighten both grille screws.

7. Reconnect power to the unit.

Leveling

WARNING

Disconnect electric power to the unit before

cleaning the condenser.

To remove and replace the grille for access to the

condenser fins, follow this procedure:

1

2

Figure 11

1. Disconnect electrical power to the unit.

2. Loosen two screws

NOTE: Screws are held in the grille by o-ring retainers,

and will not come free of the grille.

3. Remove the grille.

(Figure 11, 1)

ULIN_0203_A

completely.

WARNING

ULIN_0206_A

Figure 12

1.

Use a level to check the levelness of the unit from front

to back and from side to side. Level should be placed

along top edge and side edge as shown

1

(Figure 12)

ULIN_0044_A

.

Figure 13

2. If the unit is not level, adjust the feet on the corners of

the unit as necessary

(Figure 13)

.

3. Check the levelness after each adjustment and repeat

the previous steps until the unit is level.

DO NOT touch the condenser fins. The condenser

fins are SHARP and can be easily damaged.

14 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 15

Door Alignment Check and Adjustment

IMPORTANTIMPORTANT

When properly aligned:

• The door will not be flush with the top of the

cabinet. The top edge of the door will be 1/8 in.

(3.175 mm) below the cabinet top.

• The door gasket will be firmly in contact with the

perimeter of the cabinet and not pinched on the

hinge side of the door.

The following procedure will correct for up to 1/4 in.

misalignment:

1

23

Figure 16

3. Turn the door upside down and inspect the hinge plate

mounting holes.

ULIN_0007_A

1/8"

(3.175 mm)

ULIN_0016_A

Figure 14

1. Compare the top edge of the door (opposite the

hinges) to the top edge of the cabinet (Figure 14) and

note the type (up or down) of adjustment needed.

• Your plate has slotted mounting holes (Figure

16, 1). Loosen but do not remove the two hinge

plate screws.

4. If door edge opposite the hinges needs to move up,

move plate toward outside of door

(Figure 16, 2)

door edge needs to move down, move plate toward

inside of door

(Figure 16, 3)

. Repeat until top edge of

door is parallel with top of cabinet and tighten screws

securely

(Figure 16, 1)

.

. If

ULIN_0133_A

Figure 15

2. Remove the top hinge pivot pin with a Phillips

screwdriver

(Figure 15)

and lift door off bottom hinge

pin. Be careful not to lose the door closer insert sets.

2115WC and 2115WCOL, 2175WC and 2175WCOL 15

1

ULIN_0004_A

Figure 17

5. After adjustment is complete, remove the door closers

from the bottom hinge, clean thoroughly and apply

petroleum jelly to the mating surfaces of the closers. Be

sure that bosses on closers

(Figure 17, 1)

align with

holes in the door and bottom cabinet hinge plates.

Mount door and install top hinge pivot pin.

Page 16

Door Reversal

1

ULIN_0002_A

Figure 20

2. Remove plastic screw plugs (three each, top and

bottom)

not discard.

(Figure 20, 1)

from new hinge location. Do

ULIN_0015_A

Figure 18

All U-Line black units may be left- or right-hand opening.

Stainless steel unit doors cannot be reversed. The doors

are easily reversed by moving the hinge hardware to the

opposite side. The top hinge hardware will be used on the

bottom of the other side and the bottom hinge hardware

will be used on the top of the other side (Figure 18).

To reverse the door:

1

3. Remove top hinge (three screws)

reinstall hinge screw pin

(Figure 19, 1)

(Figure 19, 2)

.

and

1

ULIN_0005_A

Figure 21

4. Install the removed top hinge mount on opposite side

BOTTOM

(Figure 21)

.

2

Figure 19

1. Remove top hinge screw pin (Figure 19, 1) from door

using a Phillips screwdriver. Remove door by tilting

forward and lifting off bottom hinge pin.

16 2115WC and 2115WCOL, 2175WC and 2175WCOL

ULIN_0003_A

1

Figure 22

ULIN_0004_A

Page 17

5. Remove the two door closer inserts

(Figure 22, 1)

from

the existing bottom hinge and install as shown on the

new bottom hinge

(Figure 21, 1)

.

6. Remove existing bottom hinge (three screws) and

remount on opposite side TOP. Remove hinge screw pin.

7. Remove the plastic hole plug from the top of the door

to allow the pivot pin to be inserted in the new

location. Install the plug into the vacated hole on the

opposite side.

ULIN_0274_A

Figure 23

8. With bottom of door facing up, remove pivot plate

(two screws), flip over, and remount on opposite side of

(Figure 23). Be sure slanted side of plate

door

faces center.

9. Holding door upright with top of door tilted forward,

place hole of door pivot plate on bottom hinge screw

pin/closer inserts

(Figure 21, 1)

.

10. Tilt top of door into position in top hinge and install top

hinge screw pin.

11. Install plastic screw plugs removed in Step 2 in old hinge

holes (three each, top and bottom).

Light Bulb Replacement

To replace the light bulb in your U-Line unit:

1

Figure 24

1. Grasp the edges of the light housing lens

(Figure 24, 1) opposite the exposed tab and gently

push the lens toward the tab (Figure 24, 2).

2. Pull the edge of the lens down

swing it out of the light housing.

IMPORTANTIMPORTANT

ALWAYS use a genuine U-Line replacement bulb (P/N

31317) in the light housing. Use of any other bulb

within the housing will generate excessive heat,

causing damage to the light housing and cabinet

interior, and will compromise the precise

temperature control of your unit.

3. Replace the bulb only with a genuine U-Line P/N 31317

replacement.

4. Replace the lens by first inserting the tab side back into

the housing at a slight angle. While gently pushing the

lens towards the tab end, push the free end up into the

housing, and release when you will hear a snap/click.

2

ULIN_0001_A

(Figure 24, 1)

and

2115WC and 2115WCOL, 2175WC and 2175WCOL 17

Page 18

Wine Rack Removal/Installation

To remove a rack from the cabinet:

1. Grasp the end of the rack, and gently slide it out until

it stops.

2. Remove any bottles stored on the rack.

ULIN_0207_A

Figure 25

3. Press the left rack release lever

at the same time, lift the corresponding right rack

release lever up, and pull the rack out until it is free of

the tracks and the cabinet.

(Figure 25)

down, and

IMPORTANTIMPORTANT

Do not remove the track side rails from the cabinet.

To insert a rack in the cabinet:

1. Align the left and right rack channels with the tracks

in the cabinet, and ensuring an even track

engagement on both sides, gently push the rack into

the cabinet until it stops.

2. Before reloading the rack, ensure proper operation of

the travel stops in the left and right track rails by

pulling the rack out gently until it completely stops.

Wood Trim Finishing

The U-Line Wine Captain® is equipped with woodtrimmed wine racks that are coated at the factory with a

clear vinyl sealer, which will adequately protect the wood

in normal usage. A final finish coat was not applied so

that the wood trim could be stained to match décor. The

trim on the racks may be coated with a final finish or

stained.

WARNING

To prevent permanent damage to the inner liner

of your unit, the wood trim MUST be removed

from the unit for staining and/or finishing. Allow

stain/finish to dry thoroughly (at least 24 hours

per coat) in accordance with the product

manufacturer’s instructions prior to

reinstallation. Failure to do so may cause the

inner liner of the unit to have a permanent odor,

which is not covered by the warranty.

If staining the trim is desired, it must be done before the

application of any type of final finish. Review the

following staining/final finish and final finish-only

guidelines when staining/ and or sealing the wood to

ensure proper adhesion and durability of the finish.

NOTE: Glass in door is tinted. Stain may look darker

when door is closed.

Staining and final finish application:

1. Remove all screws securing wood trim to interior

components, and remove the trim from the cabinet

interior.

NOTE: Your model will contain an electronic display panel

in the lowest level trim piece. After removing the trim

screws, and gently pulling the trim from its location, a

wiring harness connector will become visible. Unplug the

connector, and remove the trim from the interior.

IMPORTANTIMPORTANT

DO NOT use oil-based stains on wood trim. Vapors

from oil-based stains will permanently penetrate

the liner and will not dissipate over time.

2. Apply Minwax® Water-Based Wood Stain to wood with

a synthetic bristle brush or a foam applicator. Allow

stain to penetrate approximately three minutes. Before

the stain is dry, take a stain dampened rag and remove

any excess stain remaining. Wipe in the direction of the

grain with medium pressure to achieve the desired stain

color.

3. After two hours, repeat step 2. This will even out the

color of the wood.

4. Allow stain to dry for a minimum of three hours before

applying the final finish.

5. If desired, sand the wood with very fine sandpaper to

smooth the surface after the staining process.

18 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 19

6. Remove all dust from the wood, and apply one coat of

Minwax

bristle brush to the wood. This finish should be applied

in a thin coat following the direction of the grain.

Apply the finish to the back and sides of the wood first,

and allow it to dry for two hours. Apply the finish to the

front side of the wood next, and allow it to dry for two

hours. Sand with very fine 220 grit sandpaper. Apply

two addition coats of the finish in the same manner, but

do not sand the trim after the final third coat is applied.

7. Allow the final coat to dry for 24 hours before

reinstalling the trim to the cabinet interior components.

Final finish-only application:

1. Remove all screws securing wood trim to interior

components, and remove the trim.

2. Lightly scruff sand the wood trim with 280 or finer grit

sandpaper.

3. Remove sanding dust with a clean, dry cloth.

4. The factory-applied seal is compatible with virtually all

finishes. A low odor, water clean up, quick-drying finish

such as Minwax® Polycrylic® Protective Finish is

recommended (Minwax

drying water-based finish). Apply a thin coat of a clear,

protective finish, following the container label

directions.

®

Polycrylic® Protective Finish using a synthetic

®

Polycrylic® is an ultra fast-

8 Service

Before Calling for Service

If your U-Line product appears to be malfunctioning, read

through the OPERATION section of this guide to ensure

that the function of all controls are clearly understood. If

the malfunction persists, the TROUBLESHOOTING GUIDE

in this guide will assist you in quickly identifying common

problems, and provide information on possible causes and

remedies. Most often, this will resolve the problem

without the need to call for service.

If Service is Required

If you do not understand a troubleshooting remedy, or

your product needs service, contact U-Line Corporation

directly. Contact information appears on the rear cover of

this guide.

You will be asked for your product Model and Serial

Numbers. This information should be recorded inside the

front cover of this guide, following the products original

purchase. It also appears on the Model and Serial number

plate located on the upper right or rear wall of the

interior of your product.

Replacement Parts

5. Lightly sand and reapply if desired.

6. Allow the final coat to dry for 24 hours before

reinstalling the trim to the cabinet interior components.

When you need replacement parts, always request that

genuine U-Line replacements be used. U-Line products

have been designed and engineered using components

that work efficiently, and provide superior service life and

performance. The use of aftermarket parts or components

may affect the safety, operation, performance or

durability of your product, and may also void its warranty.

2115WC and 2115WCOL, 2175WC and 2175WCOL 19

Page 20

Troubleshooting Guide

DANGER

ELECTROCUTION HAZARD

Never attempt to repair or perform maintenance on

the unit until the main electrical power has been

disconnected.

Troubleshooting - What to check when problems occur:

PROBLEM POSSIBLE CAUSE REMEDY

Unit does not operate and

electronic display is blank.

No interior light Loose or burned out bulb Tighten or replace bulb (See MAINTENANCE; LIGHT

Electronic display is blank and

interior light is OFF with door OPEN.

Electronic display is blank and

interior light is ON with door OPEN.

Electronic display shows repeating,

randomly flashing symbols and

partial characters.

Electronic display shows:

0, 1 to 26, or 99.

Electronic display shows E3. Door has been left open longer than

Electronic display shows one or

more of the following:

E1, E2, E4, E5, E6, E7, E8, E9, E10, P1.

Unit not cold enough. Check

temperatures (See OPERATION for

approximate temperatures).

Unit is too cold. Check temperatures

(See OPERATION for approximate

temperatures)

The unit frosts up. High ambient temperatures or

No electrical supply Plug unit in or check circuit breaker.

BULB REPLACEMENT).

Unit is in blackout/Sabbath mode

(not Star K certified) lighting mode.

A display function has changed. Touch and hold the warmer temperature button and

A factory control mode has been

inadvertently entered.

A factory control mode has been

inadvertently entered.

20 minutes.

The unit is displaying an error code. Record the error code(s) displayed and call for service.

Control set too warm Set control to a cooler setting (See OPERATION). Allow

Airflow to front grille blocked Airflow must not be obstructed to front grille (See

Dirty condenser coils Clean condenser (See MAINTENANCE; CONDENSER

Door gasket not sealing properly Door adjustment required (See MAINTENANCE; DOOR

Inaccurate temperature reading Properly check temperature (See OPERATION).

Control set too cold Set control to a warmer setting (See OPERATION). Allow

humidity

Door gasket not sealing Adjust door (See MAINTENANCE; DOOR ALIGNMENT

Exit blackout/Sabbath mode (not Star K certified)

(See OPERATION; INTERIOR LIGHT CONTROL).

touch and release the POWER button three times, then

release the temperature button. The display should

become visible.

Touch and hold the warmer temperature button and

touch and release the LIGHT button three times, then

release the temperature button to exit the factory

control mode. The set-point temperature should now

be displayed.

Repeatedly touch the warmer temperature button to

advance any number shown to 99 and touch and

release the LIGHT button. The set-point temperature

should now be displayed.

Close door completely. The set-point temperature

should now be displayed.

24 hours for temperature to stabilize.

OPERATION).

CLEANING).

ALIGNMENT CHECK AND ADJUSTMENT).

24 hours for temperature to stabilize.

Defrost unit manually (See MAINTENANCE;

DEFROSTING).

AND ADJUSTMENT and DOOR REVERSAL).

20 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 21

Electronic Control Quick Guide

All Models

Task Touch Touch Display Comment

Turn ON/OFF Hold 10 seconds Release when °F flashes. or

Adjust

Temperature

View Actual

Temperature

Change °F-°C Hold or Repeat to switch back.

Blackout

Mode

* Drawer Wine Cooler: Initially, top bar will flash to set to zone. After five seconds of inactivity (or touching light button), the bottom

zone (bottom bar on F flashing) can be adjusted. After five seconds of inactivity, set-point will be stored in unit.

Glass Door Models

Task Touch Touch Display Comment

Cabinet Light

Display Off

Mode

or

Touch and release

Hold 5 seconds Release when °F flashes.

Hold 10 seconds

Hold

Touch to change temperature

or

Display (and cabinet light) not

operable in Blackout Mode.

°F flashes after first touch,

set-point saved after 5

seconds of inactivity and °F

stops flashing.*

For Wine Coolers, see Use

and Care Manual.

Hold light for 10 seconds to

exit.

Light normally goes on/off

with door opening. Pressing

light button will turn

interior light on for 4 hours,

then it will turn off.

Display off when door is

closed (unless cabinet light is

switched on). Repeat to

switch back.

All Ice Makers

Task Touch Touch Display Comment

Ice Maker Off

Mode

Clear Ice & Clear Combo Only

Task Touch Touch Display Comment

Clean Cycle Hold

Ice Thickness

Adjustment

Temporary

Shutdown

(Office Mode)

Hold

Hold Use warmer/colder to scroll.

Hold

Repeat to switch back

Will automatically return to

ice production when clean

cycle is complete.

Ice maker will automatically

turn back on in three hours.

NOTE: 38°F is an example; the display will vary with actual set-point.

IMPORTANT

Factory recommended set-point is 38°F for refrigerators and beverage centers, and 50°F for wine coolers.

2115WC and 2115WCOL, 2175WC and 2175WCOL 21

Page 22

This page intentionally left blank

22 2115WC and 2115WCOL, 2175WC and 2175WCOL

Page 23

U-Line Corporation Limited Warranty

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship for a period of

one year from the date of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the

evaporator, the hot gas bypass valve, the dryer and the connecting tubing) in each U-Line product to be free from

defects in materials and workmanship for a period of five years from the date of purchase. During the initial one-year

warranty period for all U-Line products U-Line shall: (1) at U-Lines option, repair any product or replace any part of a

product that breaches this warranty; and (2) for all Marine, RV and Domestic U-Line products sold and serviced in the

United States (including Alaska and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with

the replacement of any defective part. During years two through five of the warranty period for the sealed system, ULine shall: (1) repair or replace any part of the sealed system that breaches this warranty; and (2) for all Marine, RV and

Domestic U-Line products sold and serviced in the United States (including Alaska and Hawaii) and Canada, U-Line shall

cover the labor costs incurred in connection with the replacement of any defective part of the sealed system. All other

charges, including transportation charges for replacements under this warranty and labor costs not specifically covered

by this warranty, shall be borne by you. This warranty is extended only to the original purchaser of the U-Line product.

The Registration Card included with the product should be promptly completed by you and mailed back to U-Line or you

can register on-line at www.U-LineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or acts of God,

such as fire, floods, wind and lightening; damages incurred or resulting from shipping, improper installation,

unauthorized modification, or misuse/abuse of the product; customer education calls; food loss/spoilage; door and water

level adjustments (except during the first 90 days from the date of purchase); defrosting the product; adjusting the

controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the dealer from

whom you purchased the product or U-Line at P.O. Box 245040, Milwaukee, Wisconsin 53224 or at 414-354-0300. In no

event shall such notification be received later than 30 days after the expiration of the applicable warranty period. U-Line

may require that defective parts be returned, at your expense, to U-Lines factory in Milwaukee, Wisconsin, for

inspection. Any action by you for breach of warranty must be commenced within one year after the expiration of the

applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not limited to any

implied warranty of merchantability or fitness for a particular purpose; provided however, that to the

extent required by law, implied warranties are included but do not extend beyond the duration of the

express warranty first set forth above. U-Lines sole liability and your exclusive remedy under this warranty

is set forth in the initial paragraph above. U-Line shall have no liability whatsoever for any incidental,

consequential or special damages arising from the sale, use or installation of the product or from any other

cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract, tort or

any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

2115WC and 2115WCOL, 2175WC and 2175WCOL 23

Page 24

For General Inquiries:

P.O. Box 245040

Milwaukee, Wisconsin

53224-9540 U.S.A.

Phone (800) 779-2547

FAX (414) 354-5696

www.U-Line.com

For Service and Parts

Assistance:

Phone (800) 779-2547

(414) 354-0300

FAX (414) 354-5696

Email:

OnLineService@U-Line.com

www.U-LineService.com

E-mail:

OnlineParts@u-line.com

For more than four decades, U-Line has distinguished itself as the

leader in built-in under-counter ice making, refrigeration and

wine storage appliances.

An INSTALLATION MANUAL for your unit, providing complete

installation information, is available for download at

www.U-Line.com. Information for custom panel inserts per model,

including panel size, and instructions are available by visiting

www.U-Line.com.

When you need replacement parts, always request genuine U-Line

replacements be used. Visit www.U-Line.com to locate a parts

distributor in your area.

U-Line Corporation, located in Milwaukee, WI, is a family operated manufacturer of built-in

undercounter ice makers, Combo

refrigerators, refrigerated drawers and refrigerator/freezers.

®

ice maker/refrigerators, Wine Captain® wine storage units,

©2007 U-Line Corporation

Publication No. 30091

02/2007 Rev. C

Loading...

Loading...