U-Line U-ADA15IMB-00 Installation Manual

®

INSTALLATION GUIDE

ICEMAKER SERIES

U-ADA15IMB-00

U-ADA15IMS-00

U-ADA15IMS-01

BI2115ADA15IM BI98

U-BI2115B-00 U-BI2115SOD-00

U-BI2115B-20 U-BI2115SOD-01

U-BI2115S-00 U-BI2115SOD-20

U-BI2115S-01 U-BI2115SOD-22

U-BI2115S-20 U-BI2115W-00

U-BI2115S-22 U-BI2115W-20

BI95

ULN-BI95B-00

ULN-BI95B-20

ULN-BI95BTP-03

ULN-BI95BTP-20

ULN-BI95WH-00

ULN-BI95WH-20

ULN-BI98B-00

ULN-BI98B-20

ULN-BI98WH-00

ULN-BI98WH-20

ULN-SP18B-03

ULN-SP18B-20

ULN-SS1095FC-03

ULN-SS1095FC-20

ULN-SS1095FD-03

ULN-SS1095FD-20

ULN-SS1095NF-03

ULN-SS1095NF-20

SS98SS1095SP18

ULN-SS98-03

ULN-SS98-20

WH95

ULN-WH95TP-03

ULN-WH95TP-20

The American Built-In Undercounter Leader Since 1962

U-LINE.COM

Ta b l e o f C o n t e n t s

1 - Safety Precautions

Safety Alert Definitions.........................................................................................................................................1

General Precautions..............................................................................................................................................1

2 - Inspect & Plan

Product Registration .............................................................................................................................................2

Models Covered.....................................................................................................................................................2

Tools / Material Required ....................................................................................................................................2

Exterior Cleaning ...................................................................................................................................................2

3 - Prepare Site

Cut-Out Dimensions.............................................................................................................................................3

4 - Product Dimensions

Door Swing Dimensions.......................................................................................................................................7

5 - Other Site Requirements

Power Supply ..........................................................................................................................................................7

Water Supply ..........................................................................................................................................................7

Environmental Requirements..............................................................................................................................7

6 - Door Reversal

BI95 & BI98..............................................................................................................................................................8

WH95TP, BI95BTP, BCM95 & SP18 .................................................................................................................9

SS1095 ....................................................................................................................................................................10

7 - Door Panel Installation

Door Panel Preparation......................................................................................................................................12

Panel Dimensions.................................................................................................................................................12

Door Panel Installation (98, SP18, & ADA15)...............................................................................................12

8 - Adjust Door

Checking Door Alignment.................................................................................................................................13

Adjusting Door Alignment.................................................................................................................................13

9 - Power Supply

Electrical Specifications.......................................................................................................................................13

10 - Plumbing

Water Supply Connection .................................................................................................................................14

11 - Install

Leveling Information............................................................................................................................................15

Installation..............................................................................................................................................................15

Grille Installation ..................................................................................................................................................15

Installation Troubleshooting..............................................................................................................................16

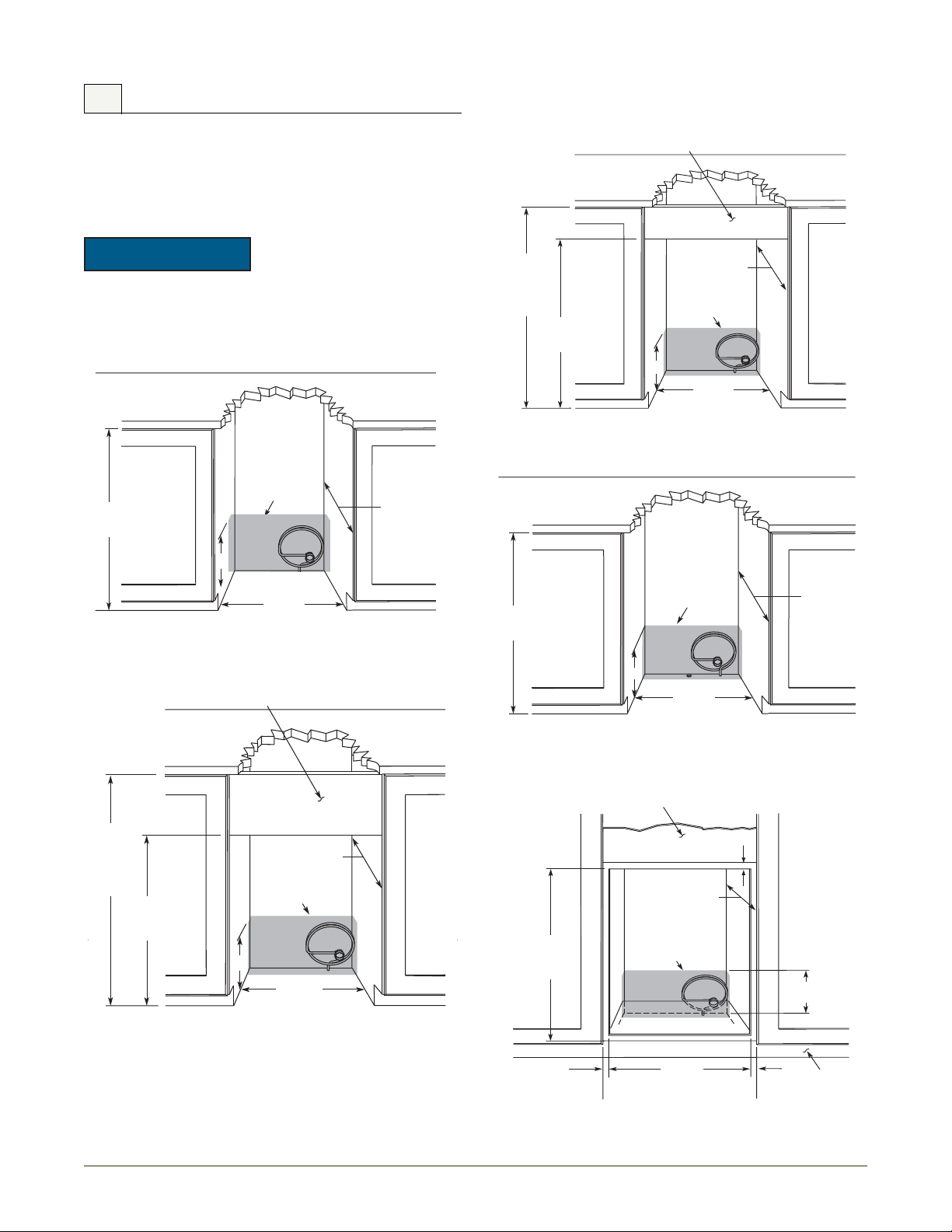

ADA15IM Models ....................................................................................................................................... 3

BI-95(B)(WH) Models................................................................................................................................ 3

BI-98 / SS-98 Models .................................................................................................................................. 3

BI-2115 Models............................................................................................................................................ 3

SP-18 Models................................................................................................................................................ 3

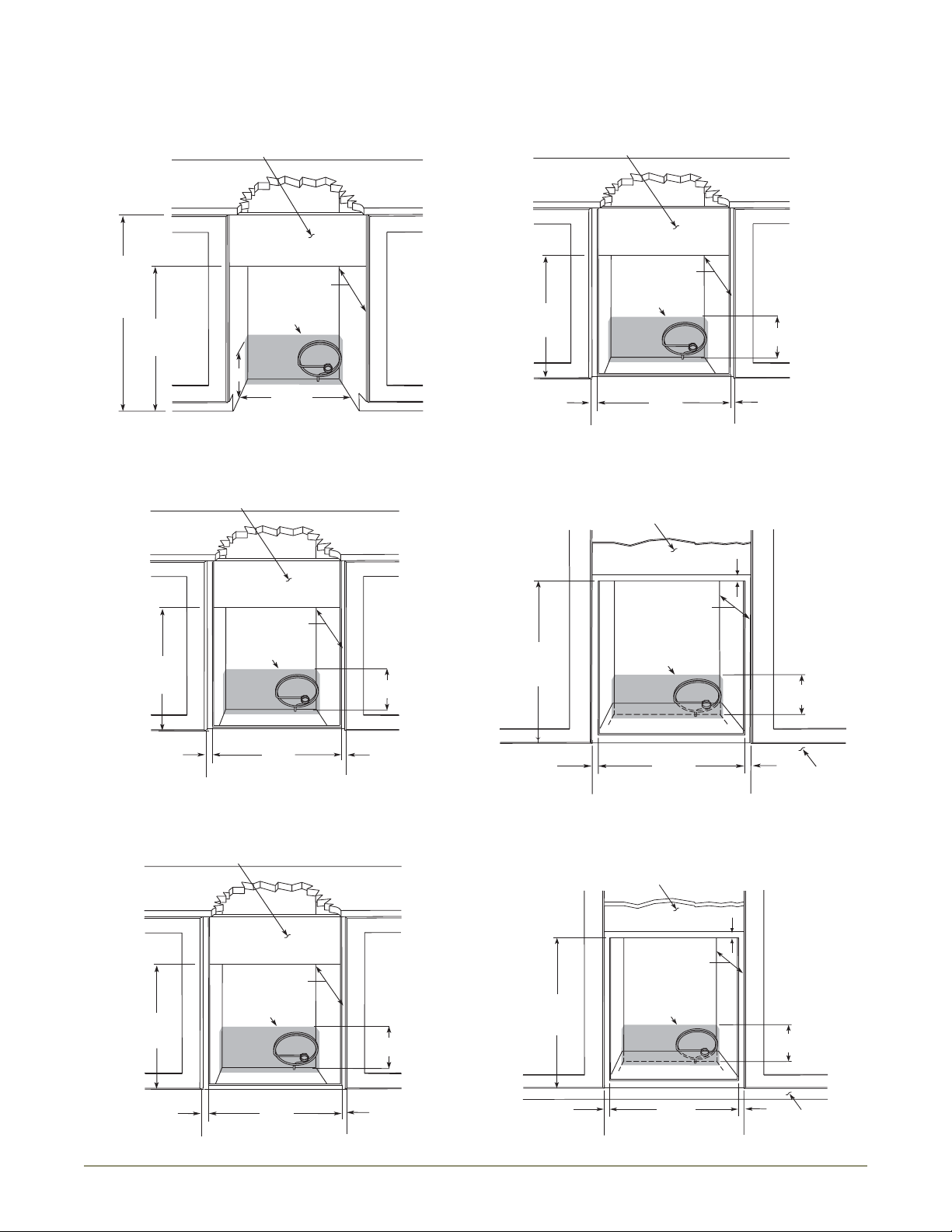

SS-1095NF Models...................................................................................................................................... 4

SS-1095FC Models...................................................................................................................................... 4

SS1095FD...................................................................................................................................................... 4

BCM95 Models ............................................................................................................................................ 4

WH95TP Models ........................................................................................................................................ 4

BI95BTP......................................................................................................................................................... 4

ADA15IM BI95 BI95BTP BI98 BI2115.................................................................................................... 5

SS1095 SP18 BCM95 WH95.................................................................................................................... 6

NOTICE

DANGER

!

WARNING

!

CAUTION

!

1 Safety Precautions

General Precautions

Use this appliance for its intended purpose only. Follow these

general precautions with those listed throughout this guide:

• PLEASE READ all instructions before installing,

operating, or servicing the appliance.

• Proper installation procedures must be followed when

completing an installation or relocation of a unit. An

INSTALLATION GUIDE for the unit, providing

complete installation information, is available from

U-Line Corporation direct. Consult the installation

guide before any installation begins. U-Line contact

information appears on the rear cover of this guide.

• This unit requires connection to a dedicated 15 Amp

grounded (three-prong), polarized receptacle, installed

by a qualified electrician, compliant with applicable

electrical codes.

Safety Alert Definitions

Throughout this guide are safety items labeled with a Danger,

Warning or Caution based on the risk type:

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

Warning means that failure to follow this safety

statement could result in serious personal injury or

death.

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property

or equipment damage.

DANGER

!

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take off the doors and leave shelves

in place so children may not easily climb inside.

WARNING

!

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance on

the unit until the electricity has been disconnected.

• Never remove the round grounding prong from the

plug and never use a two-prong grounding adapter.

• Altering, cutting of power cord, removal of power

cord, removal of power plug, or direct wiring can

cause serious injury, fire and or loss of property and

or life, and will void the warranty.

• Never use an extension cord to connect power to the

unit.

• Always keep your working area dry.

WARNING

!

Install provided Anti-Tip kit. Serious personal injury

could occur.

CAUTION

!

• Use care when moving and handling the unit. Use gloves

to prevent personal injury from sharp edges.

• If your model requires defrosting, DO NOT use an ice

pick or other sharp instrument to help speed up

defrosting. These instruments can puncture the inner

lining or damage the cooling unit. DO NOT use any type

of heater to defrost. Using a heater to speed up

defrosting can cause personal injury and damage to the

inner lining.

NOTICE

• Do not lift unit by door handle.

• Never install or operate the unit behind closed doors.

Be sure front grille is free of obstruction. Obstructing

free airflow can cause the unit to malfunction and will

void the warranty.

• Failure to clean the condenser every six months can

cause the unit to malfunction. This could void the

warranty.

• Do not Block any internal Fans

Use only genuine U-Line replacement parts. Imitation

parts can damage the unit, affect its operation or

performance and may void the warranty.

u-line.com 1

2 Inspect & Plan

Product Registration

You have received a carton containing your ice maker unit with a

package inside containing a Use and Care Guide, a Product

Registration Card, and a water line kit. Please complete and

mail the Product Registration Card or register online at

www.U-LineService.com. Once your unit is installed, keep the Use

and Care Guide and this Installation Guide in a safe place for future

reference.

Models Covered

This installation guide covers the following models

Tools / Material Required

• Screwdrivers — slotted and Phillips head

• 1/4-inch thick door panel material and cutting tools (If installing

a 1/4" Panel)

• 1/4" Nut Driver

• 5/16" Nut Driver

• Side Cutter

• Copper tubing cutter

• 12" Level

• 9/16" Open end wrench

• 7/16" Open end wrench

• Pliers

• Copper tubing

A complete water hook up kit is also available for purchase from

your dealer. Order U-Line Part No. WATERHOOKUP.

U-ADA15IMB-00 ULN-BI98B-00

U-ADA15IMS-00 ULN-BI95WH-00

U-ADA15IMS-01 ULN-SP18B-03

U-BI2115B-00 ULN-SP18WH-03

U-BI2115S-00 ULN-SS1095FC-03

U-BI2115S-01 ULN-SS1095FD-03

U-BI2115SOD-00 ULN-SS1095NF-03

U-BI2115SOD-01 ULN-SS95-03

U-BI2115W-00 ULN-SS98-03

ULN-BI95B-00 ULN-WH95TP-03

ULN-BI95WH-00

Please carefully follow the directions that apply to your unit and

your intended design.

Exterior Cleaning

Black and White Models:

• Black and White surfaces may be cleaned with a mild detergent

and warm water solution. Do not use solvent-based or abrasive

cleaners. Use a soft sponge and rinse with clean water. Wipe

with a soft, clean towel to prevent water spotting.

Stainless Models:

• Stainless door panels, handles and frames can discolor when

exposed to chlorine gas, pool chemicals, salt water or cleaners

with bleach.

• Keep your Stainless unit looking new by cleaning with a good

quality all-in-one stainless steel cleaner/polish on a monthly

basis. For best results use Claire Stainless Steel Polish and

Cleaner, which can be purchased from U-Line Corporation

(Part numbers 173348). Frequent cleaning will remove surface

contamination that could lead to rust. Some installations may

require cleaning on a weekly basis.

• Do not clean with steel wool or abrasive pads.

• Do not use cleaners that are not specifically intended

for stainless steel on stainless surfaces (this includes

glass, tile and counter cleaners).

• If any surface discolors or rust appears, clean it quickly with

Bon-Ami or Barkeepers Friend Cleanser and a non-abrasive

cloth. Always clean in the direction of the grain. Always finish

this process with Claire Stainless Steel Polish and Cleaner or

comparable product to prevent further problems.

Rust that is allowed to linger can penetrate into the

surface of the stainless steel and complete removal of the

rust may not be possible.

2 u-line.com

CAUTION

!

NOTICE

3 Prepare Site

23-3/4"

Minimum

15-1/4"

32"

to

33"

See Electrical

Specifications

for Power Supply

8"

8"

Typical

Counter

Height

34-1/4"

to

35-1/8"

Cut-Out

Height

25-1/16"

Filler Panel (Not Provided by U-Line) –

May Be Added Above or Below Unit

to Enclose for a Built-In Look

14-3/16"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

8"

Typical

Counter

Height

34-1/4"

to

35-1/8"

Cut-Out

Height

27-3/8"

Filler Panel (Not Provided by U-Line) –

May Be Added Above or Below Unit

to Enclose for a Built-In Look

15-3/16"

21-1/2"

Minimum

See Electrical

Specifications

for Power Supply

See Electrical

Specifications

for Power Supply

34-1/8"

to

35-1/8"

15-1/4"

8"

23-7/8"

Minimum

Cut-Out

Height

18-7/8"

26" Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

k

14-1/4"

Cut-Out Width

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

Your U-Line product has been designed for either free-standing or

built-in installation. When built-in, your unit does not require

additional air space for top, sides or rear. However, the front grille

must NOT be obstructed and clearance is required for an

electrical and water connection in the rear.

Units can NOT be installed behind a closed cabinet door.

Cut-Out Dimensions

ADA15IM Models

BI-98 / SS-98 Models

BI-2115 Models

BI-95(B)(WH) Models

SP-18 Models

Toe Kic

u-line.com 3

SS-1095NF Models

8"

Typical

Counter

Height

34-1/4"

to

35-1/8"

Cut-Out

Height

25-1/16"

Filler Panel (Not Provided by U-Line) –

May Be Added Above or Below Unit

to Enclose for a Built-In Look

14-1/4"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

Cut-Out

Height

25-1/8”

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-1/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

25-1/8”

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2”” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-1/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

26-1/16"

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-3/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

25-1/8"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

Toe Kick

14-1/4"

Cut-Out Width

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

25-1/16"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

Toe Kick

14-1/4"

Cut-Out Width

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

SS-1095FC Models

BCM95 Models

WH95TP Models

SS1095FD

4 u-line.com

BI95BTP

Loading...

Loading...