Page 1

Service Manual

2010

SP 18

ULN-95 Icemaker

ULN-98 Icemaker

ULN-SS1095 Icemaker

U-CO29F

U-CO29A

ULN-29R

U-1075BEV

U-1075WC

U-CO1175

BI-2115

ADA15IM

Entertain with U-Line Elegance

www.u-line.com

Page 2

Section 1 - General Information

IMPORTANT

IMPORTANT

INTRODUCTION

Three generations of pride and quality manufacturing and

design improvements are built into all U-Line products. The

result: U-Line leads the market with innovative technology and

superior craftsmanship.

This manual contains specific instructions for servicing the ULine Products which include these models:

MODELS

SP18

ULN-95 Icemaker

ULN-98 Icemaker

SS-1095 Icemaker

U-CO29F

U-CO29A

ULN-29R

U-1075BEV

U-1075WC

U-CO1175

BI-2115

ADA15IM

POTENTIAL PROBLEMS WITH

HFC-134A

This service manual has been written to cover products

manufactured with HFC-134A. HFC-134A compressors

receive a synthetic based ester oil charge. The hygroscopic

(water attraction) property of ester oil is many times greater

than the mineral oils previously used with CFC-12. High

system moisture causes the formation of acids and alcohol

which can damage the compressor. Systems should not be left

open for more than fifteen (15) minutes at any time as

humidity from the air will enter the system. To ensure system

dehydration, the system should be pulled down to 100

microns and vacuum pump oil (mineral oil) must not be

allowed to enter the system.

Cleanliness of the system is extremely important. The

presence of residues (chlorinated or greasy residues, mineral

oil, or impurities) can lead to capillary tube restrictions, oil

return problems and compressor damage. Do not use flux on

brazed joints.

Check for the latest service related information at ULineService.com. The Technical Knowledge base is

continuously updated and can be accessed anytime. Each ULine product has a unique method of installation, but it is

consistent with U-Line’s methods and requirement. Follow

the installation guidelines for the U-Line product you are

installing.

1-1

Page 3

Section 1 - General Information

TABLE OF CONTENTS

SECTION 1 - GENERAL INFORMATION

Introduction ..................................................................................................................................................................1-1

Potential Problems With HFC-134A.......................................................................................................................1-1

Safety Precautions .......................................................................................................................................................1-3

Safety Alert Definitions ....................................................................................................................................1-3

General Precautions .........................................................................................................................................1-3

U-Line Corporation Limited Warranty...................................................................................................................1-4

Product Liability Policy................................................................................................................................................1-5

Serial Number Format ................................................................................................................................................1-6

Warranty Claims Procedure......................................................................................................................................1-6

Proof of Purchase.........................................................................................................................................................1-6

Parts Listing....................................................................................................................................................................1-7

SECTION 2 - TROUBLESHOOTING

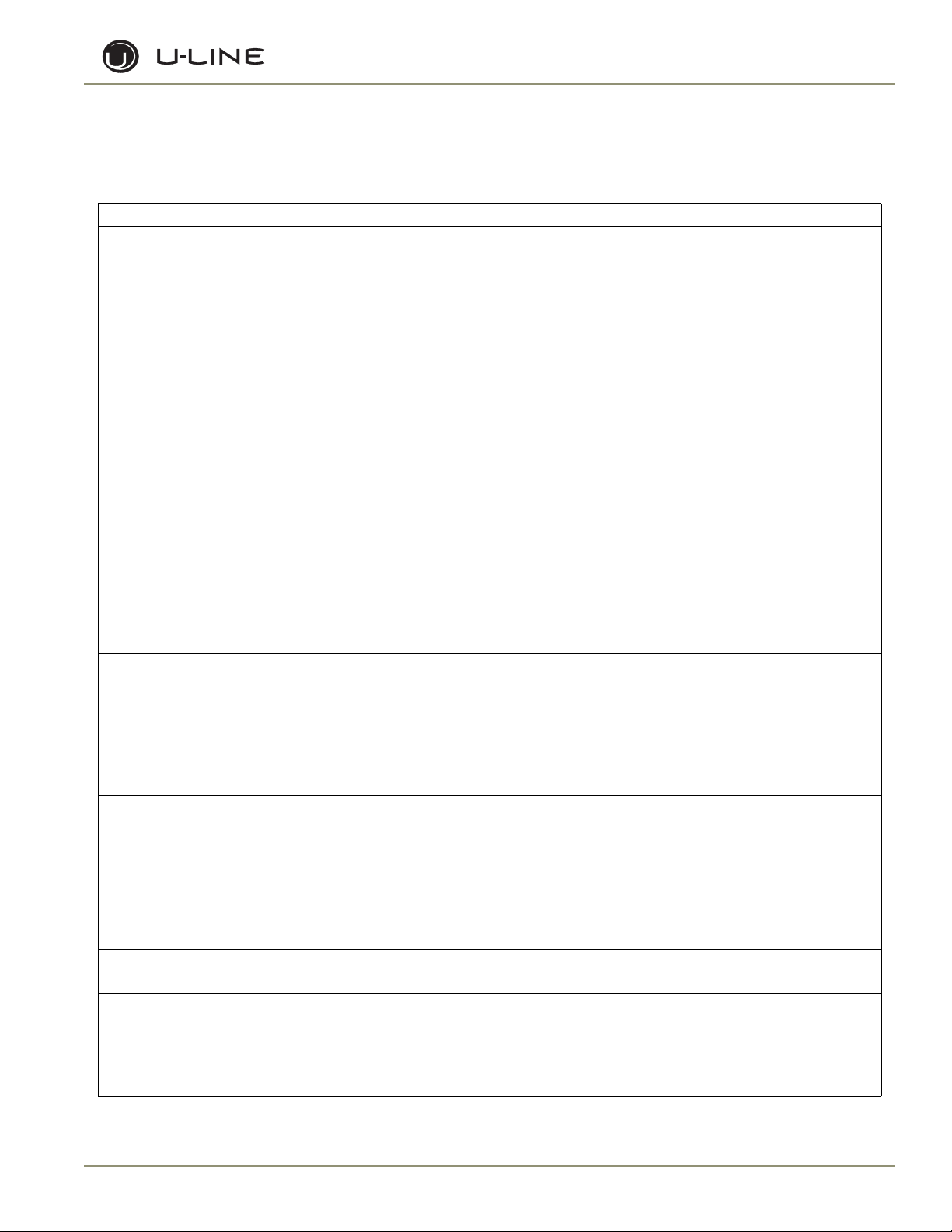

Customer Call Guide ..................................................................................................................................................2-1

Refrigeration System Diagnosis Guide....................................................................................................................2-2

Ice Maker Diagnosis Flow Chart...............................................................................................................................2-3

Troubleshooting ...........................................................................................................................................................2-4

SECTION 3 - SERVICE AND REPAIR

Refrigeration Systems..................................................................................................................................................3-1

Normal Vapor/Compression Cycle Refrigeration......................................................................................3-1

U-Line Frost Free Refrigeration System .......................................................................................................3-2

Compressor/Electrical Specifications.......................................................................................................................3-4

Ice Maker Operating Cycles ......................................................................................................................................3-6

Ice Maker Operating Cycles (Model U-CO29F)...................................................................................................3-8

Temperature Control Specifications .......................................................................................................................3-9

Limit Switch Specifications .......................................................................................................................................3-10

Replacing Ice Maker Assembly (CO29F Only)....................................................................................................3-11

Replacing Ice Maker Assembly (All Models Except CO29F)............................................................................3-11

SECTION 4 - PARTS

220 Volt Conversion List............................................................................................................................................4-1

Ice Maker Assembly Information..............................................................................................................................4-2

Model SP18 ....................................................................................................................................................................4-4

Model ULN-95 - BI95B, BI95WH, BCM95 ............................................................................................................4-6

Model ULN-95 - BI95BTP, WH95TP, SS95 ...........................................................................................................4-8

Model ULN-98 - BI98B, BI98WH, SS98................................................................................................................4-10

Model SS-1095 ............................................................................................................................................................4-12

Model U-CO29F.........................................................................................................................................................4-14

Model U-CO29A........................................................................................................................................................4-18

Model ULN-29R .........................................................................................................................................................4-20

Model U-1075BEV......................................................................................................................................................4-22

Model 1075WC..........................................................................................................................................................4-24

Model U-CO1175 ......................................................................................................................................................4-26

Model BI-2115.............................................................................................................................................................4-30

Model 402-BI2015......................................................................................................................................................4-32

SECTION 5 - WIRING DIAGRAMS

ULN-95, ULN-98, SP18 & SS-1095- 115 Volt........................................................................................................5-1

U-CO29F - 115 Volt....................................................................................................................................................5-1

U-CO29A, CO1175, BI2115, ADA15IM - 115 Volt ............................................................................................5-2

U-29R - 115 Volt ..........................................................................................................................................................5-2

1075BEV, 1075WC - 115 Volt..................................................................................................................................5-3

ULN-95, ULN-98, SP18 & SS-1095- 220 Volt........................................................................................................5-4

U-CO29A, CO1175, BI2115, ADA15IM - 220 Volt ............................................................................................5-4

1-2

Page 4

Section 1 - General Information

IMPORTANT

IMPORTANT

DANGER

DANGER

WARNING

CAUTION

DANGER

DANGER

WARNING

WARNING

CAUTION

IMPORTANT

IMPORTANT

SAFETY PRECAUTIONS

PLEASE READ all instructions completely before

attempting to service the unit.

• Proper installation procedures must be followed if this

unit is being initially installed, or is moved to a new

location after being in service. An INSTALLATION

GUIDE for your unit, providing complete installation

information is available from U-Line Corporation directly,

and must be consulted before any installation is begun. ULine contact information appears on the rear cover of this

guide.

• This unit requires connection to a grounded (threeprong), polarized receptacle that has been placed by a

qualified electrician in accordance with applicable

electrical codes.

Safety Alert Definitions

Safety items throughout this guide are labeled with a Danger,

Warning or Caution based on the risk type:

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

Warning means that failure to follow this safety

statement could result in serious personal injury or death.

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property

or equipment damage.

General Precautions

• Altering, cutting of power cord, removal of power cord,

removal of power plug, or direct wiring can cause

serious injury, fire and/or loss of property and/or life

and will void the warranty.

• Never use an extension cord to connect power to the

unit.

• Always keep your working area dry.

Failure to use the Anti-Tip Kit when it is included with the

product can cause serious personal injury. The Anti-Tip

Kit must be installed before the unit is used.

• Use care when moving and handling the unit. Use gloves

to prevent personal injury from sharp edges.

• If your model requires defrosting, DO NOT use any type

of heater to defrost. Using a heater to speed up defrosting

can cause personal injury and damage to the inner lining.

• Do not lift unit by door handle.

• Never install or operate the unit behind closed doors. Be

sure front grille is free of obstruction. Obstructing free air

flow can cause the unit to malfunction and may void the

warranty.

• Failure to clean the condenser every three months can

cause the unit to malfunction. This could void the

warranty.

• Allow unit temperature to stabilize for 24 hours before

use.

• If your model requires defrosting, never use an ice pick or

other sharp instrument to help speed up defrosting. These

instruments can puncture the inner lining or damage

cooling unit.

• Use only genuine U-Line replacement parts. Imitation

parts can damage the unit, affect its operation or

performance and may void the warranty.

Use this appliance for its intended purpose only and follow

these general precautions along with those listed throughout

this guide:

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take off the doors and leave shelves

in place so that children may not easily climb inside.

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance on

the unit until the electricity has been disconnected.

• Never remove the round grounding prong from the

plug and never use a two-prong grounding adapter.

1-3

Page 5

Section 1 - General Information

U-LINE CORPORATION LIMITED WARRANTY

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship

for a period of one year from the date of purchase; and warrants the sealed system (consisting of the

compressor, the condenser, the evaporator, the hot gas bypass valve, the dryer and the connecting tubing) in

each U-Line product to be free from defects in materials and workmanship for a period of five years from

the date of purchase. During the initial one-year warranty period for all U-Line products U-Line shall: (1) at

U-Lines option, repair any product or replace any part of a product that breaches this warranty; and (2) for

all Marine, RV and Domestic U-Line products sold and serviced in the United States (including Alaska and

Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement of any

defective part. During years two through five of the warranty period for the sealed system, U-Line shall: (1)

repair or replace any part of the sealed system that breaches this warranty; and (2) for all Marine, RV and

Domestic U-Line products sold and serviced in the United States (including Alaska and Hawaii) and Canada,

U-Line shall cover the labor costs incurred in connection with the replacement of any defective part of the

sealed system. All other charges, including transportation charges for replacements under this warranty and

labor costs not specifically covered by this warranty, shall be borne by you. This warranty is extended only

to the original purchaser of the U-Line product. The Registration Card included with the product should be

promptly completed by you and mailed back to U-Line or you can register on-line at www.ULineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or

acts of God, such as fire, floods, wind and lightening; damages incurred or resulting from shipping, improper

installation, unauthorized modification, or misuse/abuse of the product; customer education calls; food loss/

spoilage; door and water level adjustments (except during the first 90 days from the date of purchase);

defrosting the product; adjusting the controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the

dealer from whom you purchased the product or U-Line at P.O. Box 245040, Milwaukee, Wisconsin 53224

or at 414-354-0300. In no event shall such notification be received later than 30 days after the expiration of

the applicable warranty period. U-Line may require that defective parts be returned, at your expense, to ULines factory in Milwaukee, Wisconsin, for inspection. Any action by you for breach of warranty must be

commenced within one year after the expiration of the applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not

limited to any implied warranty of merchantability or fitness for a particular purpose;

provided however, that to the extent required by law, implied warranties are included but do

not extend beyond the duration of the express warranty first set forth above. U-Lines sole

liability and your exclusive remedy under this warranty is set forth in the initial paragraph

above. U-Line shall have no liability whatsoever for any incidental, consequential or special

damages arising from the sale, use or installation of the product or from any other cause

whatsoever, whether based on warranty (express or implied) or otherwise based on contract,

tort or any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of

incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state.

1-4

Page 6

Section 1 - General Information

PRODUCT LIABILITY POLICY

Field service technicians are authorized to make an initial assessment. If in the servicer’s judgment

the damage is the result of a product defect, the product would be removed and returned to U-Line in an

unaltered condition. The dealer would then be authorized to permanently replace the end-user’s product at

no cost to the end-user. Please call U-Line immediately at 800-779-2547 to initiate the RA and product exchange process.

If in the servicer’s judgment the damage is the result of installation issues (water

connection/drain, etc.), the consumer would be so notified and the correction would be made by the servicer

or installer without requiring removal of the product. Any claim for damages should be directed to the

original installer.

Any U-Line unit involved in an alleged property damage claim must remain unaltered and unrepaired,

for evaluation. No service or repairs should be performed on any unit suspected to be involved

in a property damage situation. If a unit has been altered or repaired in the field prior to ULine’s evaluation, any claim for damage may be declined.

If the unit in question is a U-Line CLR or CLRCO with a drain pump, both the unit and the drain pump

(regardless of the manufacturer) must be returned to U-Line Corporation.

To complete the damage claim process for the customer, please obtain the following and forward to

U-Line at onlineservice@U-Line.com, fax to 414-354-5696 or mail to the address below.

Pictures of the unit, installation and any alleged property damage.

Inquire when the problem first appeared, any prior problems with the product and provide a brief

description of the alleged damages.

To expedite the claim process, U-Line will need two damage repair estimates.

Reference the RA number and customer name when providing this information.

If a unit is returned to U-Line, this evaluation will take approximately ten business days. No field service

company is authorized to perform this evaluation. When a Return Authorization Number is issued,

and the unit has been boxed in a U-Line carton, U-Line should be contacted and then will make arrangements

for shipping, or designate a truck line to have the unit shipped freight collect.

If U-Line’s evaluation finds the unit, (or U-Line P60 pump) to be defective, causing the property damage, the

damage claim will be reviewed by the U-Line Customer Assurance Department.

If U-Line’s evaluation finds the unit not to be defective, does not repeat a failure or does not leak any water

from the U-Line unit or U-Line P60 pump, all claims for damage will be declined.

When a product evaluation is needed, it is the customer’s responsibility to assure that the unit is returned

for evaluation. If the customer fails to do so, or has the unit repaired in the field prior to U-Line’s evaluation,

any claim for damage will be declined.

8900 N. 55th St. • P.O. Box 245040

Milwaukee, WI 53224-9540

414/354-0300 • Fax: 414/354-7905

Website: www.u-line.com

Leaders In Quality Undercounter Refrigeration

1-5

Page 7

Section 1 - General Information

09 67167-12-0002

Year MonthShop

Order

Number

Factory

Internal

Control

Number

SERIAL NUMBER FORMAT

The serial number is divided into four segments. A typical

serial number is 089469-01-0002.

The first two digits of the first segment, 08, represents the

year the unit was made.

The next four digits of the first segment, 9469, represent the

shop order number. Order number 9469 is assigned for the

Model CLR2160 B-00 units.

The next two digit segment, 01, represents the month the unit

was made.

The last four digit segment, XXXX, is a factory internal

control number used at U-Line Corporation.

WARRANTY CLAIMS PROCEDURE

Occasionally the customer does not return their warranty cards. In

this case we use the date the unit was shipped to our distributor for

a beginning warranty date. This may cause the claim to be rejected

for a proof of purchase. If you want to check on a purchase date, you

may contact the U-Line Corporation Customer Assurance

Department at 1-800-779-2547. This will allow you to get a proof of

purchase, if needed, before you submit the claim.

At U-Line, parts and labor claims are paid separately. Included

in labor are freon and recovery charges, all other parts are

handled by the parts department. We require that some parts

be returned to us, so we may return them to our vendor. It

will be noted on your packing list if we require you to return

the part. If a part is to be returned please include a copy of the

packing list and a copy of your claim. If the part was purchased

at one of our part distributors, you must handle the part

warranty with that company. For labor payment please send a

readable copy of your claim to U-Line Corporation, P.O. Box

245040, Milwaukee WI, 53224-9540, or fax it to 414-354-

5696. Claims can also be filed on-line at www.ulineservice.com.

PROOF OF PURCHASE

Proof of Purchase and/or Proof of Install is an important part

of the warranty claim process. Sometimes it is difficult to

obtain a proper Proof of Purchase/Proof of Install for a

number of different reasons:

When submitting claims for warranty payment, please

follow these guidelines.

You can use any form you would normally use to bill your

customer (your own computer generated form, Narda, USA,

etc.). Claims can also be filed on-line at

www.u-lineservice.com.

The model and serial number MUST be on the claims. Claims

will not be paid without a model and serial number.

If you used a part in your repair, you MUST put the part

number, the invoice number and where the part came from.

Claims will be returned without this information.

If you work on more than one unit per service call please

submit a separate claim for each unit.

We track all defects through warranty claims, so please be

specific on what the repair was. If it is a system leak, please

specify where the leak was.

Please be sure the claim is legible. If the claim form cannot be

read, it will be returned, unpaid.

Remember: Door and water level adjustments are 90 day

warranties only.

If you are changing out a unit please supply the model and

serial number of both units (the unit being replaced and the

new unit) and the R.A. number.

• The customer does not have a copy (only the original).

• The customer has only their copy of the final Walk Through or

sign-off of new construction.

• Other valid reasons that prevent your technician from leaving the

job site with a suitable Proof of Purchase/ Proof of Install.

We understand the problem and have modified our Proof of

Purchase policy to help you in these situations.

Effective immediately, if a copy of the Proof of Purchase/Proof

of Install is not available at the site, the technician should

record the following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw, i.e. Store Receipt, Closing Papers,

Sign-Off of Building Permit, Final Walk Through, etc.

If we have this information on the Labor Invoice, and we have

the other information that is needed (correct Serial

Number, type of repair, time spent on repairs, etc.),

we will be able to process the invoice for you in a timely

manner.

1-6

Page 8

Section 1 - General Information

PARTS LISTING

How to Order Replacement Parts

1. Refer to Service Parts and locate the illustration(s) for the model

you are servicing.

2. Locate the desired part to be serviced and note the item number

assigned to it.

3. Locate the item number within the parts list. Note the full

description and the corresponding part number. If this is for a

warranty unit, indicate and record the model and serial numbers.

4. When ordering parts, it will be necessary to supply Model

Number, Serial Number, Part Number, Part Description and in

some cases Color or Voltage.

All warranty parts will be shipped at no charge as long as

warranty status has been confirmed. If we require that a part

be returned to U-line, you will be informaed at the time the

order is placed. It will be noted on your packing list if we

require you to return a part or if you may field scrap it. If ULine requires a defective part to be returned, a prepaid

shipping label will be included with your new replacement

part. When returning parts enclose a copy of your packing list

and a copy of your labor claim, showing the model and serial

number, and tag or label the part with the nature of the defect.

Our warranty records may not match the customer's information. In

this case, a proof of purchase will be required. If you do not have the

proof of purchase at the time the order is placed, the part will be

sent net 15 days, charged to a Visa or MasterCard or COD if you

don't have an open account with U-Line Corporation. When the

proof of purchase is provided, we will credit your account (a check

will be sent if the part was sent COD).

5. Parts may be ordered on-line, by FAX or phone:

www.U-LineService.com

onlineparts@u-line.com

FAX Number (414) 354-7905

Phone Number (414) 354-0300 or (800) 779-2547;

REPLACEMENT PARTS: Use only genuine U-Line replacement

parts. The use of non-U-Line parts can reduce ice rate, cause water

to overflow from ice maker mold, damage the unit, and can void the

warranty.

1-7

Page 9

Section 1 - General Information

This page intentionally left blank.

1-8

Page 10

CUSTOMER CALL GUIDE

Section 2 - Troubleshooting

U-Line’s warranty does not cover customer education calls. It

has been reported that as high as 50% of all service calls

performed are customer education calls.

Concern Response

The unit is not cold enough. • Are you familiar with the factory temperature specifications for

• Is the door or drawers sealing properly? If the door or drawer is

• Has the door or drawers been left open?

• Is the condenser clean? U-Line’s warranty does not cover

• Is the unit behind closed doors or the vent restricted? The front

• Is the unit in an application of heavy usage? Heavy usage or

• Did you try adjusting the temperature to a colder level? Adjust

Temperature is too cold. • Check actual temperature versus set-point.

• Did you try adjusting the temperature to a warmer level? Adjust

The unit is frosting up. • Are you familiar with the defrost technology of your unit?

• Is the door or drawers sealing properly? If the door or drawer

• Has the door or drawers been left open?

• Is the unit in an application of heavy usage? Heavy usage or

The ice cubes are sticking together. • Have you tried to shake the ice bucket? If the ice sits without

• Is the door or drawers sealing properly? This could cause the ice

• Does the unit need to be defrosted?

Water is leaking out of the unit.

Have you checked the water connection to the unit? U-Line’s

The following guide has been developed to help answer frequently

asked questions. It can be used by persons scheduling service calls.

Things to consider before scheduling a service call:

your unit? Many factors can cause these temperatures to vary;

ambient temperature, application, amount of use (number of

times and length of time the door or drawers or opened and

closed), etc.

not sealed properly, it allows heat into the unit. U-Line’s

warranty is 90 days for door or drawer adjustments.

cleaning the condenser.

grille must be free of obstruction.

high ambient temperatures will cause a unit to frost up.

to a colder level. Be sure to allow 24 hours between

temperature control adjustments.

to a warmer level. Be sure to allow 24 hours between

temperature control adjustments.

is not sealing properly, it allows heat/humidity into the unit.

U-Line’s warranty is 90 days for door or drawer adjustments.

high ambient temperatures will cause a unit to frost up.

being used, it will tend to stick together. Shaking the bucket

will usually break the ice cubes apart. If the ice has been sitting

for a long time, you should consider discarding it and make a

fresh batch.

cubes to stick together.

warranty does not cover installation adjustments.

No ice or not enough ice. • Are you aware of the factory specifications for ice production?

• Is the ice maker bin arm down? When the arm is up, the ice

maker will not make ice.

• Is the door or drawers sealing properly? U-Line’s warranty is 90

days for door adjustments.

2-1

Page 11

Section 2 - Troubleshooting

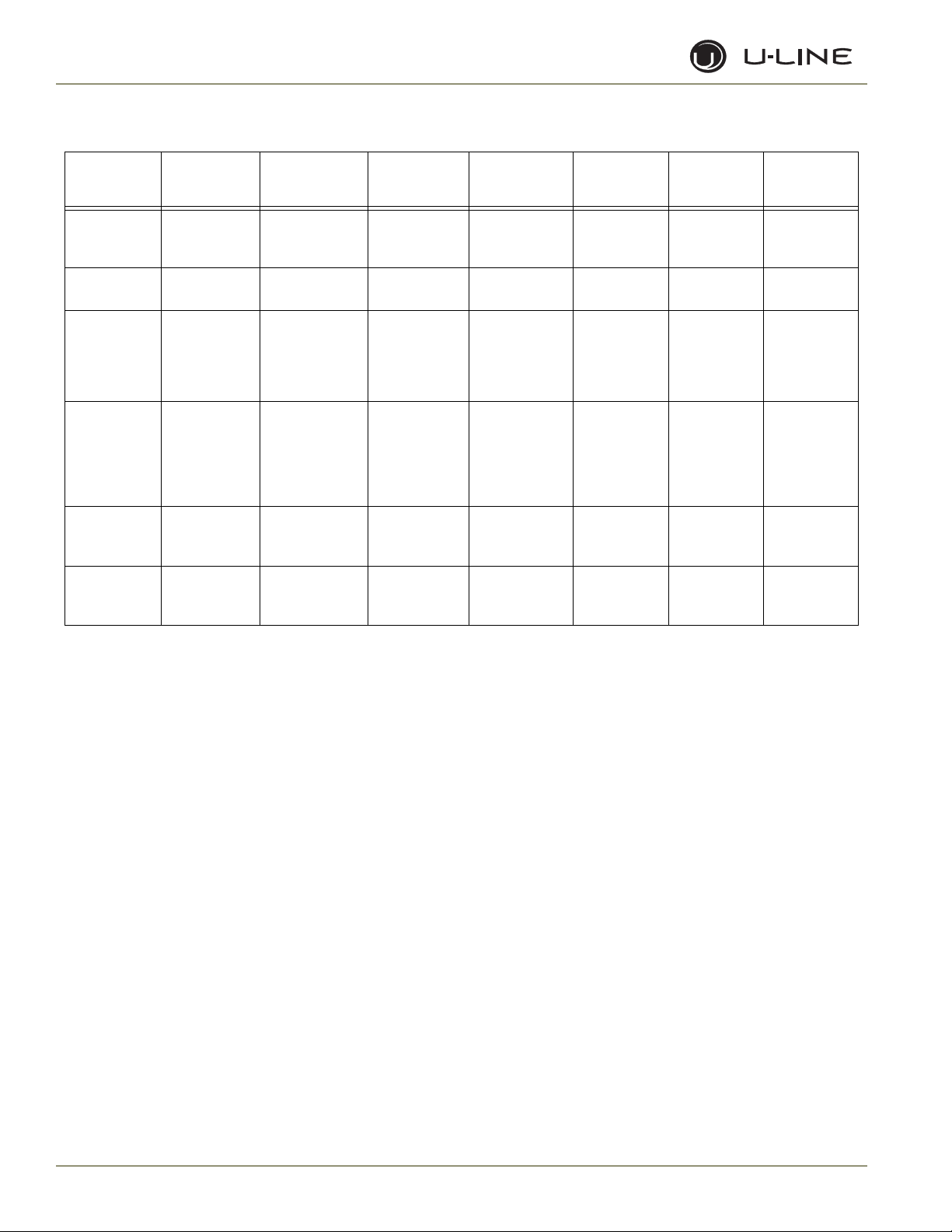

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

System

Condition

Normal Normal Slightly below

Overcharge Higher than

Undercharge Lower than

Partial

Restriction

Complete

Restriction

No Gas 0 PSIG to 25” Room

Suction

Pressure

normal

normal

Somewhat

lower than

normal

vacuum

In deep

vacuum

Suction

Line

room

temperature

Very cold may

frost heavily

Warm-near

room

temperature

Warm - near

room

temperature

Room

temperature

(cool)

temperature

(cool)

Compressor

Discharge

Very hot Very hot Warm Cold Normal

Slightly warm

to hot

Hot Warm Warm Extremely

Very hot Top passes

Room

temperature

(cool)

Cool to hot Room

Condenser Capillary

Evaporator Wattage

Tub e

Hot to warm Cool Cold Higher than

Lower than

cold near

inlet - Outlet

below room

temperature

warm - Lower

passes cool

(near room

temperature)

due to liquid

Room

temperature

(cool)

temperature

(cool)

Room

temperature

(cool) or

colder

Room

temperature

(cool)

Room

temperature

(cool)

Extremely

cold near

inlet - Outlet

below room

temperature

backing up

No

refrigeration

No

refrigeration

Lower than

Lower than

Lower than

normal

normal

normal

normal

normal

2-2

Page 12

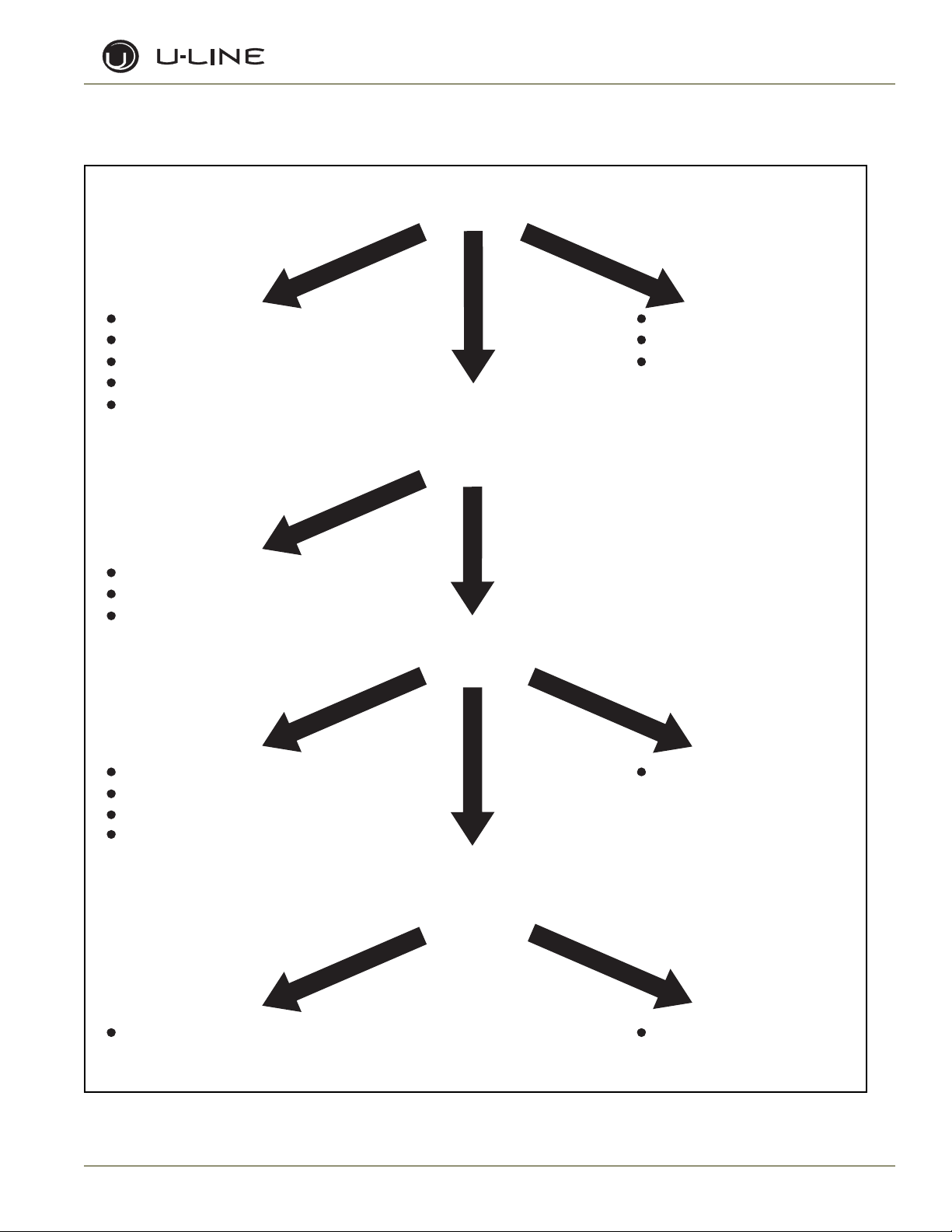

ICE MAKER DIAGNOSIS FLOW CHART

UL183-11

DOES THE UNIT REFRIGERATE?

NO

Section 2 - Troubleshooting

INTERMITTENT

Sealed System Leak

Electrical Failure

Compressor Failure

Fan Motor Failure

Defrost System Failure

YES

Temperature Control Failure

Water Adjustment

Bin Switch Failure

EVERYWHERE

YES

DOES THE UNIT HARVEST ICE

IF THE EJECTOR BLADES ARE

MOVED BY HAND OR WITH A

WRENCH ?

NO

WHERE DO THE

EJECTOR BLADES

STOP?

AT 3:00

Low Voltage

Voltage Drop

Wiring

Ice Motor Failure

Hold Switch Failure

Limit Switch Failure

Binding Cam/Ejector

Water Switch Failure

AT 12:00

IS THERE VOLTAGE AT THE

SOLENOID VALVE TERMINALS

DURING HARVEST?

YES

NO

Mold Heater Failure

Solenoid Valve Failure

2-3

Page 13

Section 2 - Troubleshooting

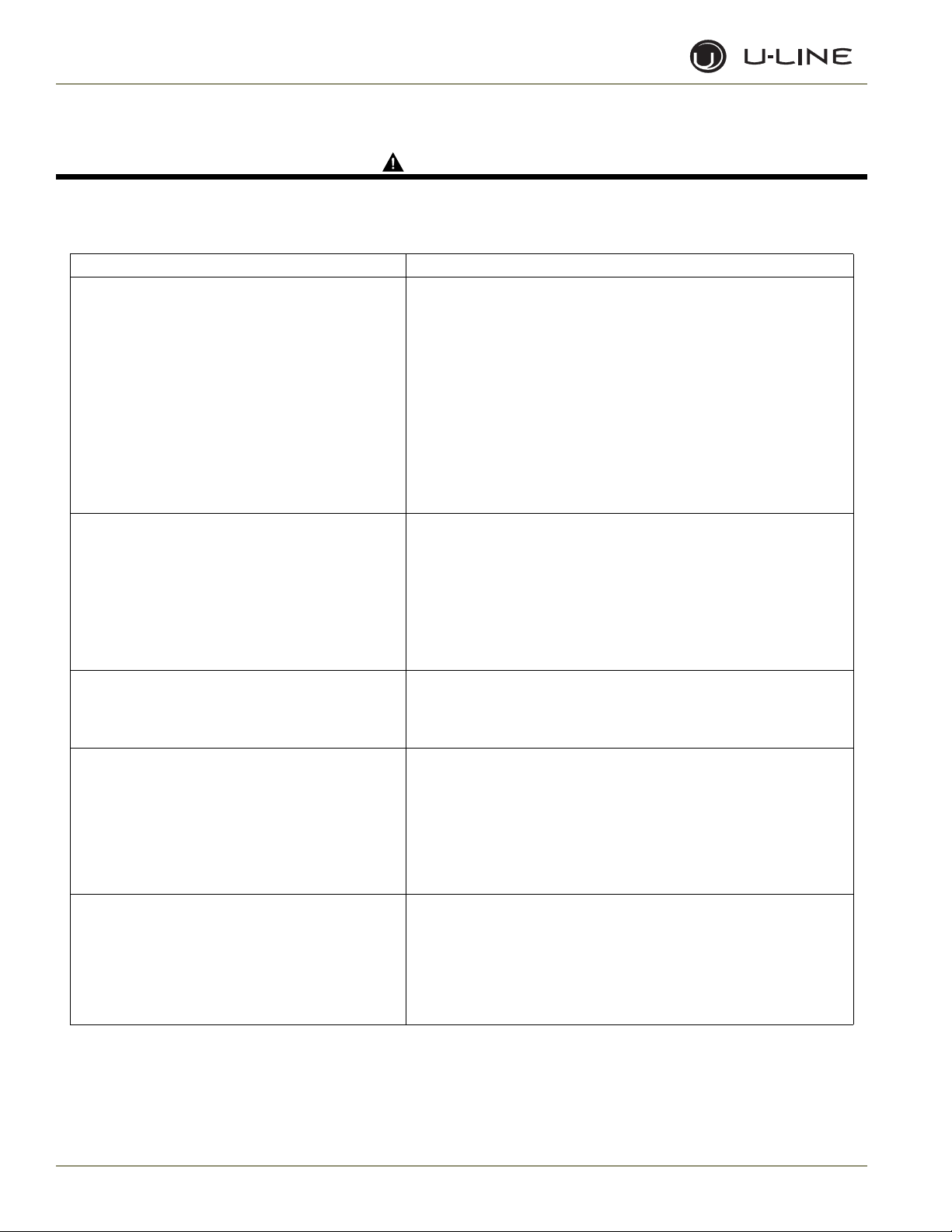

TROUBLESHOOTING

DANGER

Never attempt to repair or perform maintenance on the unit until the main electrical power has been disconnected from the

unit

Additional specific troubleshooting information can be found in Theory of Operation - Section 3, under the applicable model.

Cause Remedy

Will not eject ice (water frozen).

1. Control setting too cold.

2. Control inoperable (1-2 contacts open)

3. Bin switch inoperable.

4. Limit switch defective (open).

5. Ice maker assembly motor stalled.

6. Broken wire in ice maker circuit.

7. Water soaked cabinet insulation.

8. Dirty condenser.

Will not fill with water.

1. Water supply valve closed.

2. Water switch inoperable (open).

3. Solenoid valve inoperable.

4. Fill tube outlet frozen.

5. Broken wire in water fill circuit.

Will not stop making ice.

1. Adjust control warmer (counterclockwise).

2. Replace control.

3. Replace bin switch.

4. Replace limit switch.

5. Replace motor.

6. Repair or replace wiring.

7. Replace foamed cabinet assembly.

8. Clean condenser.

1. Open water supply valve.

2. Replace water switch.

3. Replace solenoid valve.

4. Defrost fill tube.

5. Repair or replace wiring.

1. Bin switch inoperable (closed).

2. Bin arm binding.

Water will not stop filling.

1. Water switch inoperable (closed).

2. Solenoid valve inoperable.

3. Stalled ice maker motor.

4. Temperature control inoperable. Ice maker is in

continuous harvest cycle (contacts 1-2 closed).

Ejector blades will not stop turning.

1. Control inoperable (1-2 contacts will not open).

2. Hold switch inoperable.

3. Broken wiring.

4. Short in mold heater.

1. Replace bin switch.

2. Lubricate bin arm pivot points or loosen bin arm lever screw.

1. Replace water switch.

2. Replace solenoid valve.

3. Replace motor.

4. Replace temperature control.

1. Replace control.

2. Replace hold switch.

3. Repair or replace wiring.

4. Replace heater.

2-4

Page 14

Low ice production.

Section 2 - Troubleshooting

Cause Remedy

1. Control set too cold.

2. Fan motor stalled.

3. Ice cubes too large.

4. Dirty condenser.

5. Bypass valve stuck open (Frost Free units only).

Not freezing (compressor and fan motors

operating).

1. Little or no frost pattern on evaporator.

2. Bypass valve stuck open (Frost Free units only).

Not freezing (compressor not operating - fans

operating).

1. Relay inoperable.

2. Overload inoperable (open).

3. Compressor inoperable.

Not freezing (compressor and fans not

operating).

1. Power cord not plugged in.

2. On/Off switch in off position.

3. On/Off switch inoperable (open).

4. Hold switch inoperable (open).

5. Control inoperable (2-3 contacts open).

6. Broken wire in freeze circuit.

7. Ejector blades not in freeze position (12:00)

Compressor overheating.

1. Adjust control warmer (counterclockwise).

2. Replace fan motor.

3. Lower water fill adjustment.

4. Clean condenser.

5. Replace bypass valve (Frost Free units only).

1. Check for sealed system leak or restriction.

2. Replace bypass valve (Frost Free units only).

1. Replace relay.

2. Replace overload.

3. Replace compressor.

1. Plug in power cord.

2. Turn switch to on position.

3. Replace On/Off switch.

4. Replace hold switch.

5. Replace control.

6. Repair or replace wiring.

7. Manually advance ejector blades to the 12:00 position (test ice maker and

limit switch).

1. Condenser air flow restricted.

2. Condenser fan blade obstructed.

3. Condenser fan motor stalled.

4. Compressor inoperable.

Compressor will not stop operating.

1. Control set too cold.

2. Control inoperable (2-3 contacts will not open).

3. Control sensing bulb not sensing mold temperature.

4. Evaporator fan stalled (Frost Free units only).

1. Remove restriction (clean condenser and grille).

2. Remove blade restriction.

3. Replace fan motor.

4. Replace compressor.

1. Adjust control warmer (counterclockwise).

2. Replace control.

3. Fully insert bulb into ice maker tube. Rout bulb away from compressor

discharge tube.

4. Remove obstruction or replace motor.

2-5

Page 15

Section 2 - Troubleshooting

Cause Remedy

Water leak (under unit).

1. Water supply line leaking at solenoid valve inlet.

2. Water line leaking at solenoid valve outlet.

3. Water line leaking at fill tube.

4. Defrost drain line not in drain pan.

5. Crack in water line.

Water leak (inside unit).

1. Ice maker assembly fill cup obstructed.

2. Fill ice cup and fill tube out of alignment.

3. Water level too high.

4. Defrost drain plugged (Frost Free units only).

Excessive frost buildup.

1. Door gasket not sealing properly.

2. Door out of alignment.

3. Water soaked cabinet insulation.

4. Light stays on when door is closed.

Noisy.

1. Copper refrigeration tube touching cabinet.

2. Fan blade touching shroud.

3. Fan blade obstruction (wiring, foam insulation,

packaging material).

Ice buildup in drain trough or drainage problem.

1. Tighten fitting or replace fitting gasket and/or fitting.

2. Replace water line and fitting.

3. Tighten clamp or replace fill tube assembly.

4. Position drain line in drain pan.

5. Replace water line.

1. Remove obstruction.

2. Align fill tube and fill cup.

3. Adjust water level.

4. Ice in drain trough (Frost Free units only) (see below).

1. Adjust door hinges or replace door gasket.

2. Adjust door hinges.

3. Replace foamed cabinet assembly.

4. Repair or adjust light bracket.

1. Carefully adjust tubing.

2. Adjust fan mounting or shroud.

3. Remove obstruction.

1. Obstructed drain cup or tube.

2. Drain trough heater failed (Frost Free units only).

3. Kinked drain tube.

4. Drain trough spout and drain cup not aligned.

Unit will not defrost (Frost Free units only).

1. Bypass coil inoperable.

2. Defrost timer inoperable.

3. Bypass valve inoperable.

Fresh food temperature too cold.

1. Temperature control set too cold.

2. Bin/Freezer door not closing.

3. Ice bucket not fully inserted.

1. Clear obstruction.

2. Replace drain trough heater (Frost Free units only).

3. Reroute drain tube.

4. Align drain trough and drain cup.

1. Replace bypass valve.

2. Replace defrost timer.

3. Replace bypass valve.

1. Adjust control to warmer setting (counterclockwise).

2. Adjust or replace door.

3. Check for ice behind bucket and push ice bucket in place.

2-6

Page 16

Section 3 - Service and Repair

REFRIGERATION SYSTEMS

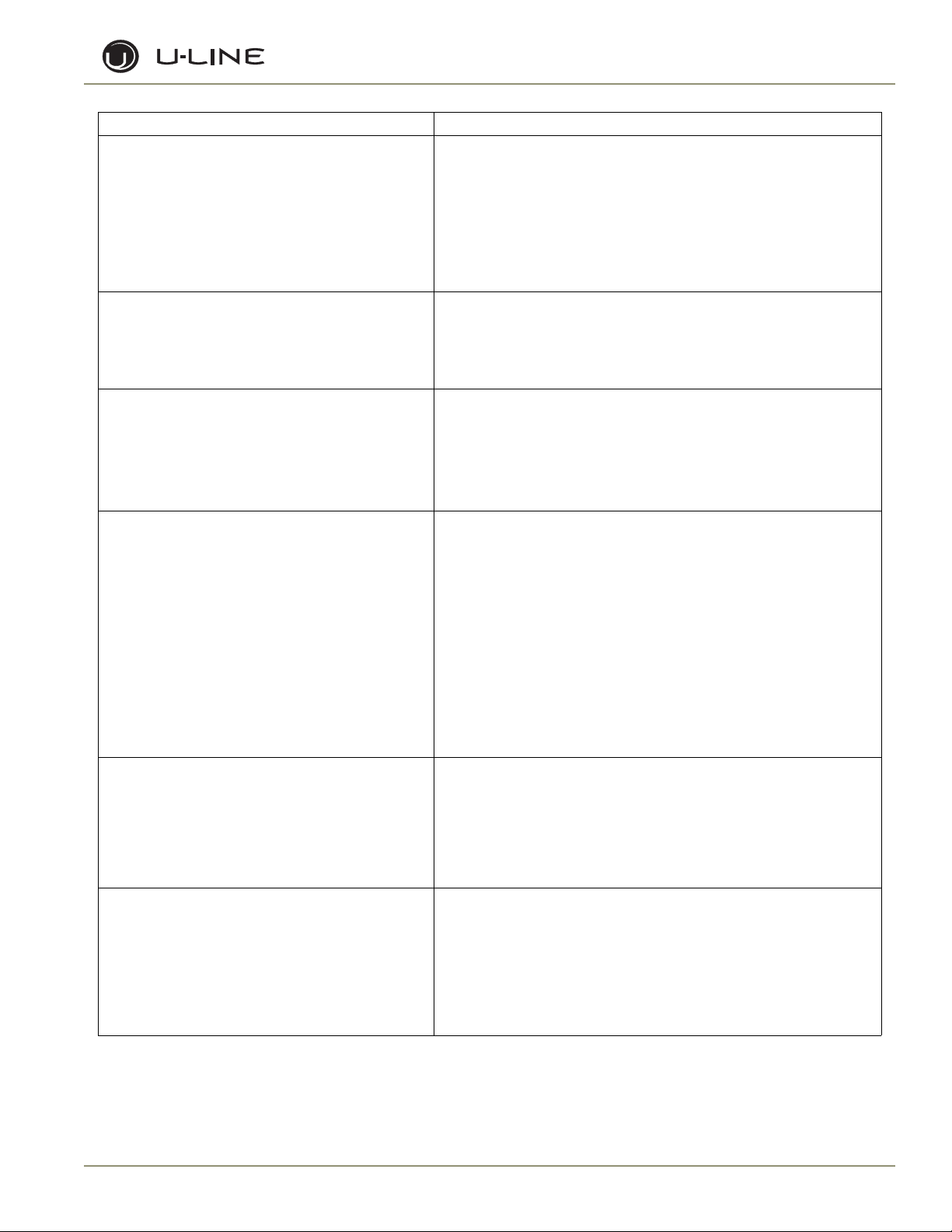

Normal Vapor/Compression Cycle

Refrigeration

• Refrigerant is pumped from the compressor to the

condenser as a high pressure, high temperature vapor.

• As the refrigerant cools in the high pressure condenser,

the vapor condenses to liquid. During this phase change, a

great amount of heat is rejected with the help of the

condenser fan.

• The liquid then flows to the dryer where is strained and

filtered.

• From the dryer, the refrigerant flows through the capillary

tube which meters the liquid refrigerant to the evaporator.

The pressure of the refrigerant is reduced to the

evaporating, or low side, pressure.

• The reduction of pressure on the liquid refrigerant causes

it to boil, or vaporize, until it reaches saturation

temperature. As the low temperature refrigerant passes

through the evaporator coil, it continues to absorb a lot of

heat, causing the boiling action to continue until the

refrigerant is completely vaporized. It is during this phase

change that most heat is absorbed (the cooling takes place)

in the refrigerator.

• The refrigerant vapor leaving the evaporator travels

through the suction line to the compressor inlet. The

compressor takes the low pressure vapor and compresses

it, increasing both pressure and temperature. The hot high

pressure gas is pumped out the discharge line and into the

condenser. The cycle then repeats

.

CONDENSER

COMPRESSOR

DRYER

EVAPORATOR

CAPILLARY TUBE

UL183-1

Figure 1. Normal Vapor/Compression Cycle Refrigeration System

3-1

Page 17

Section 3 - Service and Repair

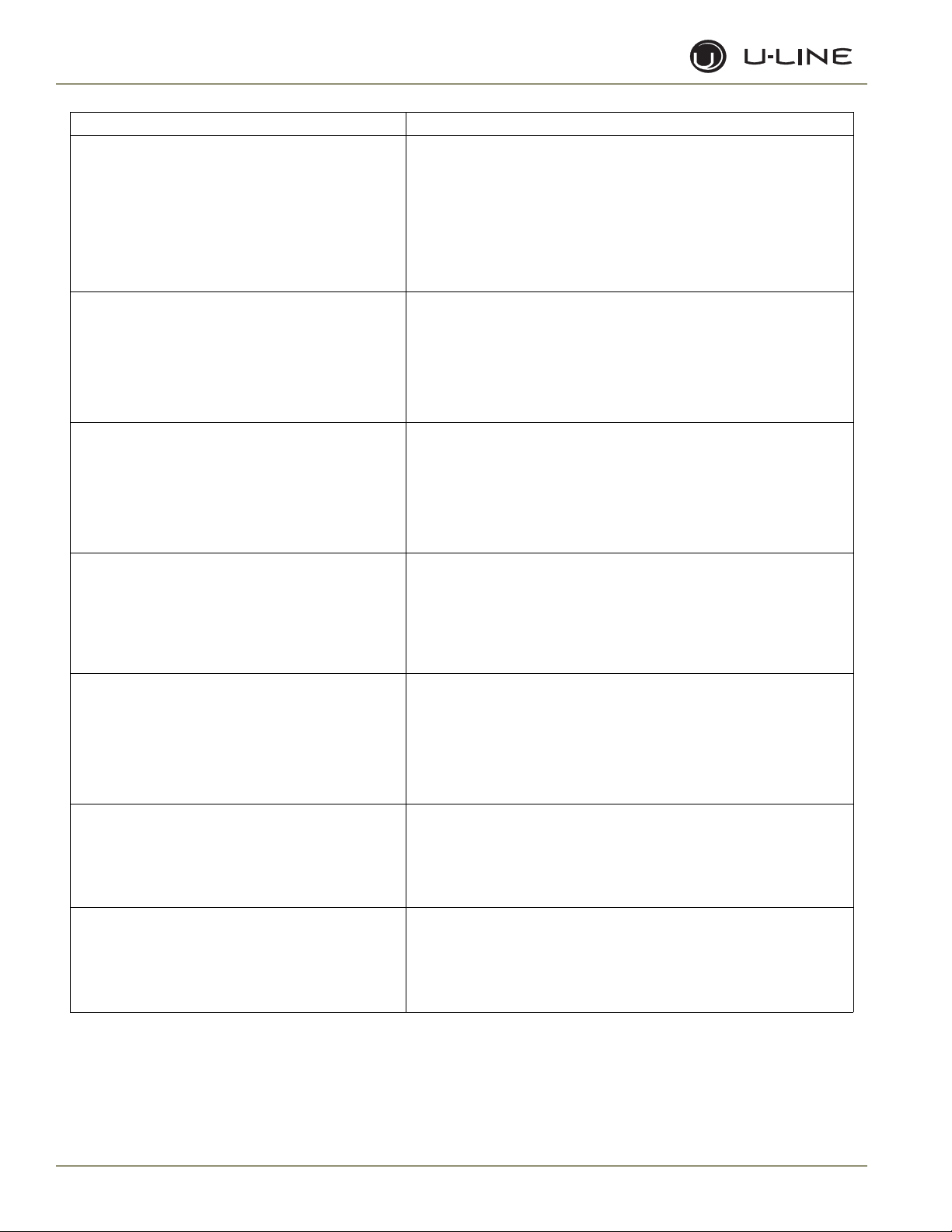

Frost Free Refrigeration

COOLING MODE

• Bypass solenoid closed.

• Evaporator fan operating.

• Refrigerant flows through capillary tubes.

• Normal vapor/compression cycle refrigeration (see page 3-

1).

COMPRESSOR

CONDENSER

DRYER

FLOW WHEN SOLENOID

VALVE IS CLOSED

DEFROST MODE

• Bypass solenoid valve open.

• Refrigerant flows through bypass system.

• Vapor flows from condenser to evaporator without a

phase change.

• Drain heater on (U-CO29F only).

EVAPORATOR

CAPILLARY TUBE

FLOW WHEN SOLENOID

VALVE IS OPEN

SOLENOID VALVE

Figure 2. Frost Free Refrigeration System.

•

ULIN_0369_A

3-2

Page 18

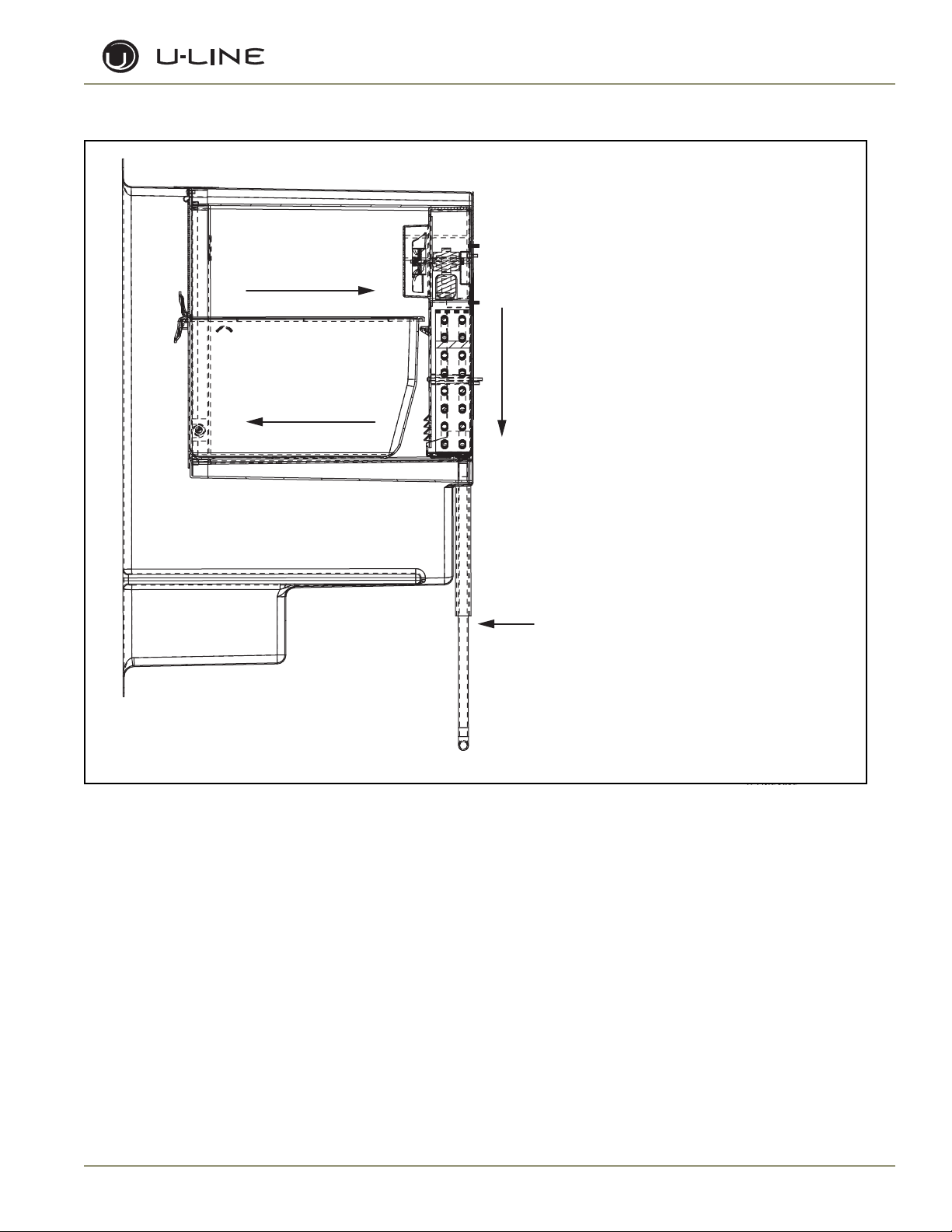

Air flow in at

n

evaporator blade

Air flow out at

evaporator outlet

Section 3 - Service and Repair

Air passes though

fin tube evaporator

Condensate drains down past the

evaporator, into drain pan, and into

condensate pan through drain hose. The

drain trough is warmed during defrost by

contact with evaporator fins. On U-CO29F

model, drain trough is also warmed by drai

heater attached to the drain pan.

Figure 3. Frost Free Air Flow

3-3

Page 19

Section 3 - Service and Repair

UL183-3

EMI ER

UL183-3.1

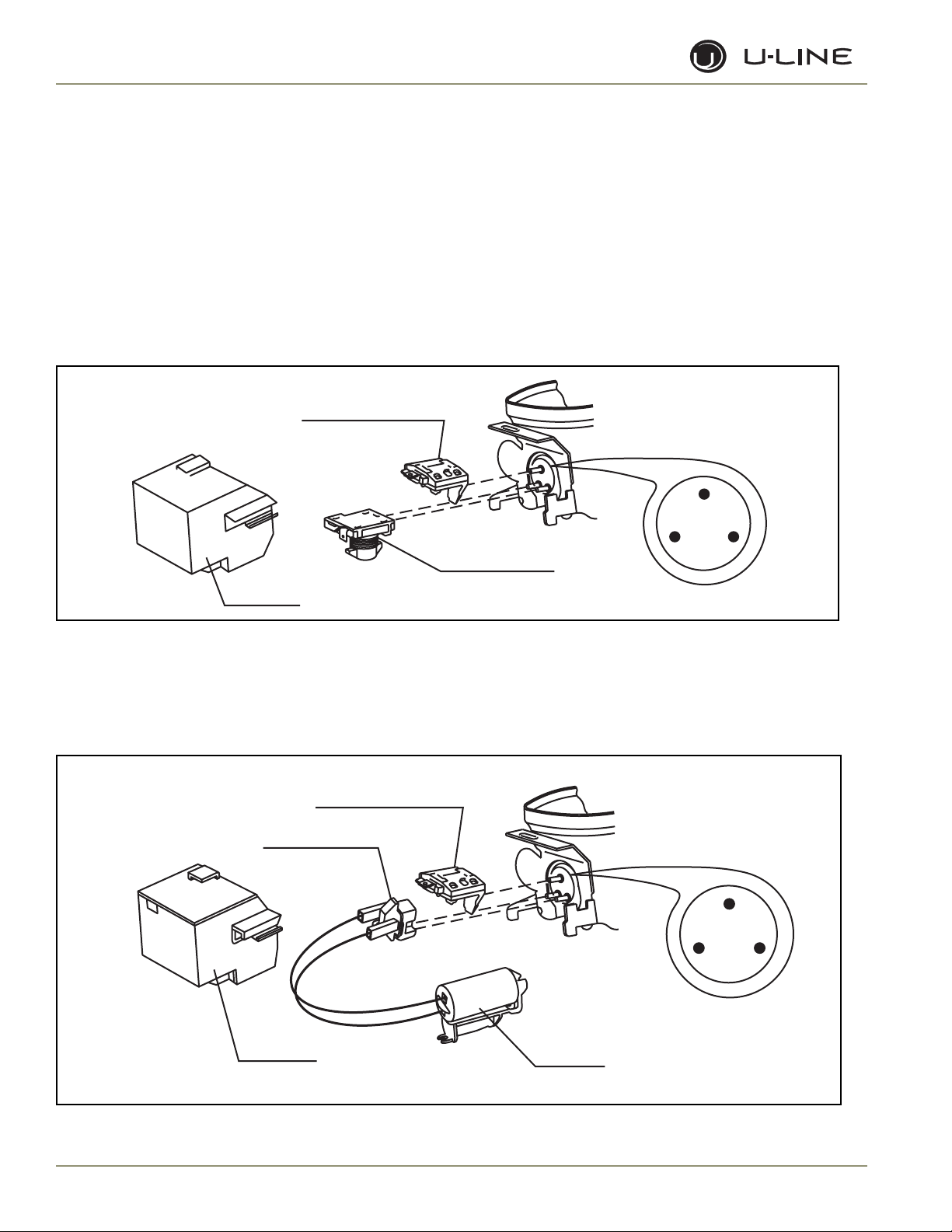

COMPRESSOR/ELECTRICAL

SPECIFICATIONS

Compressor Pins

To measure start winding resistance, measure across the C-S

pins.

To measure run winding resistance, measure across the

C-R pins. These pins should never measure any resistance to

ground. This would indicate a shorted compressor.

OVERLOAD PROTECTOR

Models ULN-95, ULN-98, SP18, U-CO29A, U-CO1175,

BI2115, SS-1095 - Figure 4

EMI30HER Start winding resistance28 OHMS

EMI30HER Run winding resistance8 OHMS

SD39 Start winding resistance11 OHMS

SD39 Run winding resistance5 OHMS

EMI50HER Start winding resistance12 OHMS

EMI50HER Run winding resistance4 OHMS

SD51 Start winding resistance5 OHMS

SD51 Run winding resistance5 OHMS115 Volt Ice maker

heater resistance80 OHMS

115 Volt Water valve coil resistance335 OHMS

C

R

STARTING RELAY

S

MODEL U-CO29F - Figure 5

EMU45HSC Start winding resistance5.60 OHMS

EMU45HSC Run winding resistance6.70 OHMS

RELAY COVER

Figure 4. Electrical Relay and Overload Protector

Models SP18, ULN-95, ULN-98, U-CO29A, U-CO1175, BI2115,ADA15IM, & SS-1095

115 Volt Ice maker heater resistance80 OHMS

115 Volt Water valve coil resistance335 OHMS

115 Volt Drain pan heater630-661 OHMS

OVERLOAD PROTECTOR

STARTING RELAY

C

S

R

3-4

RELAY COVER

Figure 5. Electrical Relay and Overload Protector

Model U-CO29F

CAPACITOR

Page 20

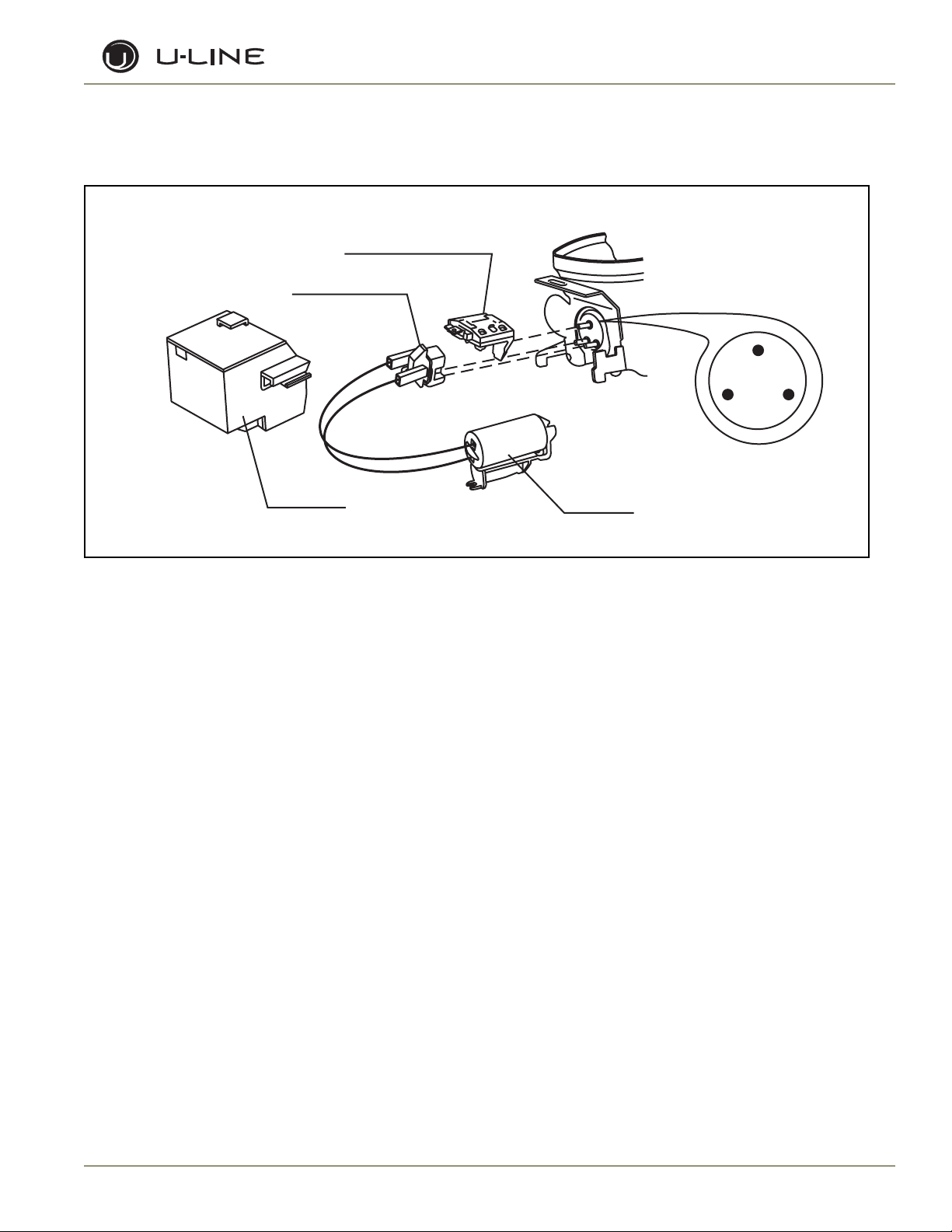

MODELS U-1075BEV, U-1075WC, 29R- Figure 6

UL183-3.1

EMI30HER Start winding resistance21.2 OHMS

EMI30HER Run winding resistance7.9 OHMS

OVERLOAD PROTECTOR

STARTING RELAY

Section 3 - Service and Repair

C

R

S

RELAY COVER

Figure 6. Electrical Relay and Overload Protector

Models U-1075BEV, U-1075WC, 29R

CAPACITOR

3-5

Page 21

Section 3 - Service and Repair

(Hold Switch In Normal Position)

UL183-5

ICE MAKER OPERATING CYCLES

Freeze Cycle (Figure 7)

• Temperature control terminals 2 and 3 are closed.

ON

OFF

SWITCH

LIMIT

SWITCH

black

black

black

COMP.

START

RELAY

black

orange

black

FAN

MOTOR

OVER

LOAD

C

black

WATER

FILL

SWITCH

• Power to the compressor.

• Power to the condenser fan.

black

blue

NC

ICE

MAKER

MOTOR

MOLD HEATER

orange

Figure 7. Freeze Cycle\

black

black

brown

3

yellow

TEMP .

CONTROL

ground

WATER

VALVE

HOLD

SWITCH

NC

2

NO1C

red

BIN

SWITCH

white

C

NO

orange

UL183-4

Harvest-1 Cycle (Figure 8

• Temperature control terminals 2 and 3 are open - 2 and 1 close.

• No power to the compressor or condenser fan.

ON

OFF

SWITCH

LIMIT

SWITCH

black

black

black

black

COMP.

START

RELAY

FAN

MOTOR

OVER

LOAD

WATER

FILL

C

SWITCH

black

orange

black

NC

black

blue

ICE

MAKER

MOTOR

MOLD HEATER

Figure 8. Harvest-1 Cycle (Hold Switch in Normal Position)

• If bin arm is down, power goes through bin arm switch to the ice

maker motor. If bin arm is up, the ice maker will not harvest.

black

ground

orange

black

brown

3

CONTROL

yellow

TEMP .

WATER

VALVE

HOLD

SWITCH

NC

2

NO1C

red

BIN

SWITCH

white

C

NO

orange

3-6

Page 22

Harvest-2 Cycle (Figure 9)

UL183-6

UL183-7

• Ice maker ejector blades reach approximately 2:00 position and

cam depresses the hold switch. Power goes through the hold

switch to the ice maker motor and mold heater.

Section 3 - Service and Repair

• Ejector blades stall on ice and ice maker motor pulsates until

mold heater warms and ice releases.

ON

OFF

SWITCH

LIMIT

SWITCH

black

black

black

COMP.

START

RELAY

black

orange

black

FAN

MOTOR

OVER

LOAD

C

black

SWITCH

WATER

FILL

NC

black

blue

ICE

MAKER

MOTOR

MOLD HEATER

Figure 9. Harvest-2 Cycle (Hold Switch in Switched Position)

Water Fill Cycle (Figure 10)

• Ice maker ejector blades reach approximately 10:00 position and

cam depresses the water fill switch.

black

ground

brown

3

orange

black

yellow

2

TEMP .

CONTROL

WATER

VALVE

HOLD

SWITCH

NC

NO1C

red

BIN

SWITCH

white

C

NO

orange

• Power to the water valve. Ice maker mold fills.

orange

black

black

brown

3

yellow

2

TEMP .

CONTROL

ground

WATER

VALVE

HOLD

SWITCH

NC

NO1C

red

BIN

SWITCH

white

C

NO

orange

ON

OFF

SWITCH

LIMIT

SWITCH

black

black

black

COMP.

START

RELAY

black

orange

black

FAN

MOTOR

OVER

LOAD

C

black

WATER

FILL

SWITCH

NC

black

blue

ICE

MAKER

MOTOR

MOLD HEATER

Figure 10. Water Fill Cycle

Eject Cycle

• Ejector blades push ice into bucket and stop at 12:00 position.

• Temperature control terminals 2 and 3 have closed during

harvest cycle.

• Next freeze cycle begins with power to the compressor and

condenser fan.

3-7

Page 23

Section 3 - Service and Repair

ICE MAKER OPERATING CYCLES

(U-CO29F MODEL)

Note: The refrigeration system operates independently of the ice

maker. This is a new design for U-Line. All other U-Line ice makers

use a double throw control system where the unit is either in a

freeze mode or harvest mode. In the U-CO29FF, the refrigeration

system will cycle on and off depending on the temperature of the

freezer. In most cases, this means the refrigeration system will be

operating during the ice making and harvest modes. If the freezer

control is set too warm, the refrigeration system may cycle off during

ice making mode, slowing the ice production rate. If this happens,

adjust the freezer control colder.

Freeze Cycle

• Ice maker thermostat (located behind grille) open.

• Freezer control closed and refrigeration system is operating.

Harvest Cycle - 1

•Ice maker thermostat closed.

• Refrigeration system operating.

• If bin arm is up, the harvest will not initiate.

• Power goes through the bin switch to the ice maker motor and

mold heater.

Harvest Cycle - 2

• Ice maker ejector blades reach 2:00 position and cam depresses

the hold switch.

• Ejector blades stall on ice and ice maker motor pulsates until

mold heater warms and ice releases.

• Refrigeration system operating.

Water Fill Cycle

• Ice maker blades reach approximately 10:00 position and cam

depresses the water fill switch.

• Power to the water valve. Ice maker mold fills.

• Refrigeration system operating.

Eject Cycle

• Ejector blades push ice into bucket and stop at 12:00 position.

• Ice maker temperature control opens.

• Refrigeration system still operating.

3-8

Page 24

Section 3 - Service and Repair

TEMPERATURE CONTROL

SPECIFICATIONS

Double Throw Ice Maker Thermostat

Numbers 4548, AR-19-12, 2636, 2690, 2691,

2717, 2783, 2782, 2781, 2780

These temperature controls are double throw, single pole

controls. The sensing tube is inserted into the ice maker mold

YELLOW WIRE

CONNECTION

2

ICE MAKER CONTROL

1

22

and senses mold temperature. After ice is sensed in the mold,

the 2-3 contacts open (stopping the compressor) and the 2-1

contacts are closed (starting the ice maker motor). The 2-3

contacts close (2-1 contacts open) before the end of the ice

harvest cycle.The hold switch prevents power going back to

the compressor. This prepares the control for the next cycle

.

RED WIRE

CONNECTION

1

3

BLUE/BLACK WIRE

CONNECTION

183-8

1

3

FREEZE POSITION ICE HARVEST POSITION

CYCLE

CIRCUIT

FREEZE 2 - 1 2 - 3

HARVEST 2 - 3 2 - 1

Figure 11. Temperature Controls - Manual Defrost Ice Makers

OPEN

CLOSED

CIRCUIT

3

183-9

3-9

Page 25

Section 3 - Service and Repair

LIMIT SWITCH SPECIFICATIONS

• Normally closed Bi-metal switch

• Open temperature: 104°F

• Close temperature: 83°F

3.00

28.12

The function of this switch is to open in the event of an

overheating condition. This bi-metal thermostat is normally

closed and does not initiate the ice harvest cycle. The ice

harvest cycle is initiated by a double throw, single pole

temperature located remotely from the ice maker assembly.

183-10

Figure 12. Limit Switch

3-10

Page 26

Section 3 - Service and Repair

REPLACING ICE MAKER ASSEMBLY

(CO29F ONLY)

1. Unplug the unit from the main power source.

2. Disconnect ice maker wire harness at plug (1).

3. Remove control capillary tube from sensing tube on ice maker

assembly (2).

4. Remove water inlet tube.

5. Remove front cover (3).

6. Advance the ejector blade to the 3 o’clock position by turning the

5/16” hex head on the small brass gear counterclockwise (4).

7. Remove three screws from wall of freezer housing (5).

8. Remove ice maker assembly.

9. Place new ice maker assembly into position and secure with three

screws (5).

10. Reconnect wire harness at plug.

11. Insert control capillary tube into ice maker sensing tube.

12. Insert water inlet tube.

®

13. Apply Permagum

14. Install back panel.

15. Plug in unit and test.

to all exit holes.

Figure 13. Ice Maker Assembly

REPLACING ICE MAKER ASSEMBLY

(ALL MODELS EXCEPT CO29F)

1. Remove back panel.

2. Disconnect all wires at bell connectors (5 wires-Models 95, 98 or

SP18; or Plug-Models BI2115, ADA15IM, CO29A or CO1175).

(1)

3. Remove capillary tube from sensing tube on ice maker assembly.

(2)

4. Remove water inlet tube.

5. Remove front cover (3)

6. Advance ejector blades to the 3:00 position by turning the 5/16”

hex head on the small brass gear counterclockwise (4).

7. Remove two screws from the side wall of evaporator(5).

8. Remove three screws from the bottom of the evaporator plate.

9. Remove ice maker assembly from evaporator shelf.

10. Clean alumilastic from evaporator shelf.

11. Apply 1/4” layer of fresh alumilastic to heater side of new ice

maker.

12. Replace parts in reverse order of removal.

13. Reconnect all wires.

14. Insert capillary tube into ice maker sensing tube.

15. Insert water inlet tube.

16. Apply permagum to all exit holes.Mount back panel.

17. Mount the back panel.

18. Plug in unit and test.

3-11

Page 27

Section 3 - Service and Repair

THIS PAGE INTENTIONALLY LEFT BLANK

3-12

Page 28

Section 4 - Parts

220 VOLT CONVERSION LIST

All models listed in this manual are equipped to run on

110/115 volt. This document is a conversion list for the

applicable 220 volt parts for the following models:

•ULN-SP18

•ULN-95

•ULN-98

• SS-1095

• U-CO29A

• U-CO1175

110V P/N 220V P/N Description

5263-S 5195 Fan motor

80-39015-00 628109 I.M motor (ice makers)

402 619 Ice maker assembly

- Models SP18, 95, 98, and

model 1095

402-29/1175 620 Ice maker assembly

- Models C029A, CO1175

2552A 2555A Water valve

5402-S 5404-S Compressor (ice makers)

150 650 Faceplate assembly

5414 5418 Relay

5413 5417 Overload

4-1

Page 29

Section 4 - Parts

U-LINE ICE MAKER ASSEMBLY

4-2

Page 30

Section 4 - Parts

U-LINE ICE MAKER ASSEMBLY

U-Line no longer offers individual ice maker parts for replacement. If there is a defect in the ice maker assembly, you have the choice

of replacing the face plate assembly or the complete ice maker assembly.

IMPORTANT

Ice Maker assemblies vary from model to model. You must use the correct ice maker for the model you are currently

working on.

Please refer to this guide to get the correct Ice Maker or Face Plate assembly

Model Ice Maker Face Plate Assembly

Part Number Part Number

SP18 series 402* 150

95 series 402* 150

98 series 402* 150

1095 series 402* 150

CO29 manual defrost 402-29/1175* 150

CO1175 manual defrost 402-29/1175* 150

CO29F frost free 402-CO29FF 150

BI2115 series 402-BI2015* 150

ADA15IM 402-BI2015* 150

*Alumalastic is included

4-3

Page 31

Section 4 - Parts

MODEL SP18

1

27

30

28

31

29

26

5

2

3

13

6

7

4

8

9

10

14

12

11

6

4-4

25

23

24

18

20

16

19

15

17

21

22

Page 32

MODEL SP18

Item Part No. Black Part No. White Description

1 SP18B-TRAVELPIN SLV-TRAVEL-PIN Travel Pin Assembly

2 31476-BLK 31476-SS Pin only

3 402 402 Ice Maker Assembly

150 150 Face Plate Assembly (See page 2)

4 SP18B-FRAME SP18-FRAME Trim frame (includes rivets)

5 11698-SSB-S 11698-SS-S Hinge Assembly, top (includes screws)

6 41915 41915 Screw

7 41747-SSB 41747-SSS Pivot screw, top

8 31489-1-BLK 11777 Door handle

9 31493-1-GRY 31493-1-WHT Gasket, door

10 95-DOORBLK WH95M-DOOR Door Assembly

11 SP18-GRILLE SP18-GRILLE Grille Assembly (includes screws)

12 31429 31429 Ice bucket

13 2182-S18-BLK 2182-S18-KIT Evaporator Assembly (includes drier and process tube)

14 11696-SSB-S 11696-SS-S Hinge Assembly, bottom (includes screws)

15 41785-SSB 41747-SSS Pivot Screw, bottom

16 2258-S 2258-S Condenser Assembly (includes drier and process tube)

17 41125 41125 Feet, cabinet

18 2053 2053 On/Off switch

19 2552A 2552A Water valve

20 41826 41826 Brass fitting, 90°

21 41254 41254 Plastic Nut & Sleeve Assembly

22 404-SP18 404-SP18 Fill Tube Assembly

23 5263-S 5263-S Fan motor

24 5188 5188 Fan blade

25 2264 2264 Power cord

26 5402-S 5402-S Compressor Assembly (includes compressor grommet,

relay, relay, overload, drier and process tube)

27 5414 5414 Relay

28 5413 5413 Overload

29 2783 2783 Control

30 41893-ZP 41893-ZP Screw, control

31 11811 11811 Back panel

Not 2693 2693 Drier

Shown

Not 2800 2800 Process tube

Shown

Not 31021 31021 Grommet, compressor

Section 4 - Parts

4-5

Page 33

Section 4 - Parts

MODEL ULN-95 (1 OF 2)

BI95B, BI95WH, BCM95

30

24

10

29

8

9

18

1

14

12

31

33

4

32

2

3

11

13

5

4-6

21

27

7

20

19

28

34

26

22, 23

21

16

17

6

24

25

15

Page 34

MODEL ULN-95 (1 OF 2)

BI95B, BI95WH, BCM95

Item Part No. Part No. Part No. Description

BI95B BI95WH BCM95

1 2053 2053 2053 On/Off switch

2 31489-1-BLK 31489-1-KIT 31489-1-BLK Door handle

3 31493-1-GRY 31493-1-WHT 31493-1-GRY Gasket, door

4 11697-ST-BLK 11697-ST-KIT 11697-ST-BLK Hinge, top

5 11695-S-BLK 11695-S-KIT 11695-S-BLK Hinge, bottom

6 11662-BLK 11662-KIT 11662-BLK Grille

7 2628-S 2628-S 2628-S Condenser Assembly

8 402 402 402 Ice Maker Assembly

150 150 150 Face Plate Assembly (See page 2)

9 31429 31429 31429 Ice bucket

10 2182-S-BLK 2182-S-KIT 2182-S-BLK Inner Liner Assembly/

Evaporator

11 95-DOORBLK 95-DOORKIT 80-17112-01 Door Assembly

12 41785-SSB 41785-SSW 41785-SSB Pivot screw, top

13 41747-SSB 41747-SSW 41747-SSB Pivot screw, bottom

14 2783 2783 2783 Control

15 404-95 404-95 404-95 Fill Tube Assembly

16 405 405 405 Brass Fitting Assembly

17 41254 41254 41254 Plastic Nut & Sleeve

Assembly

18 5401-S 5401-S 5401-S Compressor

19 71005 71005 71005 Capacitor

20 41125 41125 41125 Foot, cabinet

21 2964 2964 2964 Dryer

22 5263-S 5263-S 5263-S Fan motor

23 5188 5188 5188 Fan blade

24 11444 11444 11444 Back panel

25 1855-1 1855-1 1855-1 Power cord

26 31154 31154 31154 Insulator Tube Armaflex

27 2552A 2552A 2552A Water valve

28 71004 71004 71004 Relay

29 N/A N/A 11714-BLK Trim Frame

30 N/A N/A BL-TRAVEL-PIN Travel Pin Assembly

31 N/A N/A 31476-BLK Travel pin only

32 41893-BLK 41893-ZP 41893-BLK Screw, hinge

33 41893-ZP 41893-ZP 41893-ZP Screw, control

34 71603 71603 71603 Overload

Not 2819 2819 2819 Process Tube

Shown

Not 31021 31021 31021 Grommet, compressor

Shown

Section 4 - Parts

4-7

Page 35

MODEL ULN-95 (2 OF 2)

BI95BTP, WH95TP, SS95

Section 4 - Parts

30

24

8

9

29

18

10

1

14

12

31

33

4

32

2

3

11

13

5

21

27

7

20

19

28

34

26

22, 23

21

16

17

6

24

25

15

4-8

Page 36

MODEL ULN-95 (2 OF 2)

BI95BTP, WH95TP, SS95

Item Part No. Part No. Part No. Description

BI95BTP WH95TP SS95

1 2053 2053 2053 On/Off switch

2 31489-1-BLK 11777 31489-1-BLKDoor handle

3 31493-1-GRY 31493-1-WHT 31493-1-GRY Gasket, door

4 11698-SSB-S 11698-SS-S 11698-SSB-S Hinge, top

5 11696-SSB-S 11696-S-KIT 11696-SSB-S Hinge, bottom

6 11662-BLK 11662-SPL-KIT 11662-BLK Grille

7 2628-S 2628-S 2628-S Condenser Assembly

8 402 402 402 Ice Maker Assembly

150 150 150 Face Plate Assembly (See page 2)

9 31429 31429 31429 Ice bucket

10 2182-S-BLK 2182-S-KIT 2182-S-BLK Inner Liner Assembly/

Evaporator

11 95-DOORBLK WHT95M-DOOR SS95-DOOR Door Assembly

12 41785-SSB 41785-SSS 41785-SSB Pivot screw, top

13 41747-SSB 41747-SSW 41747-SSB Pivot screw, bottom

14 2783 2783 2783 Control

15 404-95 404-95 404-95 Fill Tube Assembly

16 405 405 405 Brass Fitting Assembly

17 41254 41254 41254 Plastic Nut & Sleeve

Assembly

18 5401-S 5401-S 5401-S Compressor

19 71005 71005 71005 Capacitor

20 41125 41125 41125 Foot, cabinet

21 2964 2964 2964 Dryer

22 5263-S 5263-S 5263-S Fan motor

23 5188 5188 5188 Fan blade

24 11444 11444 11444 Back panel

25 1855-1 1855-1 1855-1 Power cord

26 31154 31154 31154 Insulator Tube Armaflex

27 2552A 2552A 2552A Water valve

28 71004 71004 71004 Relay

29 11708-BLK 11708-KIT N/A Trim Frame

30 BL-TRAVEL-PIN SLV-TRAVEL-PIN BL-TRAVEL-PIN Travel Pin Assembly

31 31476-BLK 31476-SS 31476-BLK Travel pin only

32 41941 41941 41941 Screw, hinge

33 41893-ZP 41893-ZP 41893-ZP Screw, control

34 71603 71603 71603 Overload

Not 2819 2819 2819 Process Tube

Shown

Not 31021 31021 31021 Grommet, compressor

Shown

Section 4 - Parts

4-9

Page 37

MODEL ULN-98

BI98B, BI98WH, SS98

Section 4 - Parts

30

8

24

9

32

10

31

12

4

26

2

3

11

13

29

21

19

33

6

14

7

27

16

17

22, 23

28

20

18

25

5

15

4-10

Page 38

MODEL ULN-98

BI98B, BI98WH, SS98

Item Part No. Part No. Part No. Description

BI98B BI98WH SS98

1 2053 2053 2053 On/Off switch

2 31489-2-BLK 31489-2-KIT 31489-2-BLK Door handle

3 31493-2-GRY 31493-2-WHT 31493-2-GRY Gasket, door

4 11697-ST-BLK 11697-ST-KIT 11698-SSB-S Hinge, top

5 11695-S-BLK 11695-S-KIT 11696-SSB-S Hinge, bottom

6 11661-BLK 11661-KIT 11661-BLK Grille

7 2628-S 2628-S 2628-S Condenser Assembly

8 402 402 402 Ice Maker Assembly

150 150 150 Face Plate Assembly (See page 2)

9 31430 31430 31430 Ice bucket

10 2183-S-BLK 2183-S-KIT 2183-S-SS Inner Liner Assembly/

11 98-DOORBLK 98-DOORKIT SS98-DOOR Door Assembly

12 41785-SSB 41785-SSW 41785-SSB Pivot screw, top

13 41747-SSB 41747-SSW 41747-SSB Pivot screw, bottom

14 2783 2783 2783 Control

15 404-98 404-98 404-98 Fill Tube Assembly

16 405 405 405 Brass Fitting Assembly

17 41254 41254 41254 Plastic Nut & Sleeve

18 5401-S 5401-S 5401-S Compressor

19 71005 71005 71005 Capacitor

20 41125 41125 41125 Foot, cabinet

21 2964 2964 2964 Dryer

22 5263-S 5263-S 5263-S Fan motor

23 5188 5188 5188 Fan blade

24 11443 11443 11443 Back panel

25 1855-1 1855-1 1855-1 Power cord

26 41893-BLK 41893-ZP 41941 Screw, hinge

27 2552A 2552A 2552A Water valve

28 71004 71004 71004 Relay

29 41893-ZP 41893-ZP 41893-ZP Screw, control

30 N/A N/A BL-TRAVEL-PIN Travel Pin Assembly

31 N/A N/A 31476-BLK Travel pin only

32 31021 31021 31021 Grommet

33 71603 71603 71603 Overload

Not 2800 2800 2800 Process tube

Shown

Section 4 - Parts

Evaporator

Assembly

4-11

Page 39

MODEL SS-1095

Section 4 - Parts

19

24

31

34

30

4

31

12

10

9

18

8

3

11

2

35

13

5

32

6

29A

29

32

28

22

23

7

20

1

27

16

17

33

14

15

26

22, 23

21

24

25

4-12

Page 40

MODEL SS-1095

Item Part No. Description

1 2053 On/Off switch

2 14206-S Door handle

3 31493-1-GRY Gasket, door

4 11698-SS-S Hinge, top

5 11696-SS-S Hinge, bottom

6 80-29017-02 Grille, flush with door

80-29017-01 Grille, flush with cabinet & no frame

7 2628-S Condenser Assembly

8 402 Ice Maker Assembly

150 Face Plate Assembly (See page 2)

9 31429 Ice bucket

10 2182 Inner Liner Assembly/

Evaporator

11 80-17106-03 Door Assembly

12 41785-SS Pivot screw, top

13 41747-SS Pivot screw, bottom

14 2783 Control

15 404-95 Fill Tube Assembly

16 405 Brass Fitting Assembly

17 41254 Plastic Nut & Sleeve

Assembly

18 5401-S Compressor

19 71005 Capacitor

20 41125 Foot, cabinet

21 2964 Dryer

22 5263-S Fan motor

23 5188 Fan blade

24 11444 Back panel

25 1855-1 Power cord

26 31154 Insulator Tube Armaflex

27 2552A Water valve

28 71004 Relay

29 95SS-FRAME Frame, flush to cabinet

29A 95SS-FLUSHFRAME Frame, flush to door assembly

30 26109-S Travel Latch Assembly

31 41941 Screw, hinge

32 71603 Overload

33 41893-ZP Screw, control

34 41342 Screw, back panel

35 41787 Nut, bottom hinge

Not 31021 Grommet

Shown

Not 2819 Process Tube

Shown

Section 4 - Parts

4-13

Page 41

Section 4 - Parts

MODEL U-CO29F

17

21

Model U-CO29F (1 of 2)

22

50

43

8

46

20

26, 27

23

16

19

18

1

5

3

4

2

7

6

10

9

11

12

14

4-14

38

30

37

39

42

47

32

49

24

48

25

44

51

31

45

34

33

15

35

28

29

13

36

41

40

Page 42

MODEL U-CO29F (1 OF 2)

Item Part No. Black Part No. White Description

1 80-35003-S 80-35003-S Freezer Housing Assembly

2 26069-S 26069-S Freezer Door Assembly

3 12013-S 12013-S Hinges, freezer door

4 42135 42135 Spring, hinge, freezer door

5 42157 42157 Tape, hinge, freezer door

6 40010-09 40010-09 Glass shelf

7 31443-6 31443-6 Trim, shelf front

8 402-CO29FF 402-CO29FF Ice Maker Assembly

150 150 Face Plate Assembly (see page 2)

9 11697-ST-BLK 11697-ST-KIT Hinge Assembly, top

10 41893-BLK 41893-ZP Screw, hinge

11 41785-SSB 41785-SSW Pivot screw, top

12 31489-3-BLK 31489-3-KIT Door handle

13 31493-3-GRY 31493-3-WHT Gasket, door

14 80-17014-01 80-17014-02 Door Assembly

15 80-29014-01 80-29014-02 Grille Assembly

16 26011 26011 Ice bucket

17 2334-FFS 2334-FFS Evaporator Assembly

18 11955 11955 Cover, evaporator

19 11952 11952 Cover, evaporator fan

20 2349 2349 Drain Pan Assembly

21 5434 5434 Fan motor, evaporator

22 31656 31656 Fan blade, evaporator

23 41967-1 41967-1 Drain tube

24 2692 2692 Dryer

25 2800 2800‘ Process tube

26 66005 66005 Heater, drain pan

27 35014 35014 Tape, drain pan heater

28 11695-S-BLK 11695-S-KIT Hinge Assembly, bottom

29 41747-SSB 41747-SSW Pivot screw, bottom

30 1893-FFS 1893-FFS Condenser Assembly

Section 4 - Parts

4-15

Page 43

Section 4 - Parts

MODEL U-CO29F (2 OF 2)

17

21

22

50

43

8

46

20

26, 27

23

16

19

18

1

5

3

4

2

7

6

10

9

11

12

14

4-16

38

30

37

39

42

47

32

49

24

48

25

44

31

45

51

34

33

15

35

28

29

13

36

41

40

Page 44

MODEL U-CO29F (2 OF 2)

Item Part No. Black Part No. White Description

31 41125 41125 Foot, cabinet

32 2053 2053 On/Off switch

33 2552A 2552A Water valve

34 41826 41826 Fitting, brass, 90°

35 41254 41254 Plastic Nut & Sleeve Assembly

36 404FF 404FF Fill Tube Assembly

37 5300 5300 Fan motor

38 5428 5428 Fan blade

39 2902 2902 Power cord

40 73002-FFS 73002-FFS Bypass Valve Assembly

41 73002-2 73002-2 Coil only, Danfoss

42 68000 68000 Defrost timer

43 5408-FFS 5408-FFS Compressor Assembly

44 71021 71021 Relay

45 71020 71020 Overload

46 71022 71022 Capacitor

47 2885-S 2885-S Control, refrigerator

48 2792 2792 Control, ice maker

49 42003 42003 Screw, control

50 11545-1 11545-1 Back panel

51 31550-1-F 31550-1-F Drain pan

Section 4 - Parts

4-17

Page 45

Section 4 - Parts

CO29A

16

MODEL U-CO29A

37

38

6

1

3

7

4, 5

15

20

19

8

9

10

2

3

1

15

11

12

13

4-18

28

24

25

29

27

26

18

14

17

22

31

21

23

32

33

30

34

36

35

Page 46

MODEL U-CO29A

Item U-CO29B-03 U-CO29WH-03 U-CO29B-00 U-CO29WH-00 Description

1 11957-S 11957-S 11957-S 11957-S Flap Door Assembly

2 31463 31463 31463 31463 Clamp, flap door

3 31434-1 31434-1 31434-1 31434-1 Snap rivets

4 40010-09 40010-09 40010-09 40010-09 Glass shelves

5 31443-6 31443-6 31443-6 31443-6 Trim, shelf front

6 402-29/1175 402-29/1175 402-29/1175 402-29/1175 Ice Maker Assembly

150 150 150 150 Face Plate Assembly

7 11698-SSB-S 11698-SS-S 11697-STBLK 11697-ST-KIT Hinge Assembly, top

8 41941 41941 41893-BLK 41893-ZP Screw, hinge

9 41747-SSB 41747-SSW 41747-SSB 41747-SSS Pivot screw, top

10 31521-2 31521-2 31521-2 31521-2 Retainer, shelf

11 31489-3-BLK 11777-29 31489-3-BLK 31489-3-KIT Handle, door

12 31493-3-GRY 31493-3-WHT 31493-3-GRY 31493-3-WHT Gasket, door

13 80-17014-01 80-17031-02 80-17014-01 80-17014-02 Door Assembly

14 80-29014-01 80-29014-03 80-29014-01 80-29014-02 Grille Assembly

15 31687 31687 31687 31687 Ice Bucket

16 74000-75/29 74000-75/29 74000-75/29 74000-75/29 Evaporator Assembly

17 2693 2693 2693 2693 Dryer

18 2800 2800 2800 2800 Process tube

19 11696-SSB-S 11696-S-KIT 11695-S-BLK 11695-S-KIT Hinge Assembly, bottom

20 41785-SSB 41785-SSW 41785-SSB 41785-SSW Pivot screw, bottom

21 1893-S 1893-S 1893-S 1893-S Condenser Assembly

22 41125 41125 41125 41125 Foot, cabinet

23 2053 2053 2053 2053 On/Off switch

24 2552A 2552A 2552A 2552A Water valve

25 41826 41826 41826 41826 Fitting, brass, 90°

26 41254 41254 41254 41254 Plastic Nut & Sleeve Assembly

27 404FF 404FF 404FF 404FF Fill Tube Assembly

28 5263-S 5263-S 5263-S 5263-S Fan motor

29 5188 5188 5188 5188 Fan blade

30 2905 2905 2905 2905 Power cord

31 5402-S 5402-S 5402-S 5402-S Compressor Assembly

32 5414 5414 5414 5414 Relay

33 5413 5413 5413 5413 Overload

34 2782 2782 2782 2782 Control, refrigerator

35 42067 42067 42067 42067 Knob, control

36 42003 42003 42003 42003 Screw, control

37 11545-1 11545-1 11545-1 11545-1 Back panel

38 TRVL-PIN-CO29BSLV-TRAVEL-PIN N/A N/A Travel Pin Assembly

Section 4 - Parts

(see page 2)

4-19

Page 47

MODEL ULN-29R

11

3, 5

10

Section 4 - Parts

35

9

1

2

6

4

7

8

13

14

12

26

27

22

15

16

21

17

28

24

23

25

18

20

19

31

29

30

32

33

34

4-20

Page 48

MODEL 29R

Item Part No. Black Part No. White Description

1 31391 31391 Drain trough

2 41885 41885 Screws

3 40010-08 40010-08 Glass shelf, no logo

4 25032-4 23052-4 Trim, rear, glass shelf

5 40010-07 40010-07 Glass shelf, with logo

6 11508 11508 Funnel drain cup

7 31578 31578 Washer, drain tube

8 31579 31579 Drain tube

9 11697-ST-BLK 11697-ST-KIT Hinge Assembly, top

10 41893-BLK 41893-ZP Screw, hinge

11 41747-SSB 41747-SSW Pivot screw, top

12 31489-3-BLK 31489-3-KIT Door handle

13 31493-3-GRY 31493-3-WHT Gasket, door

14 29-DOORBLK 29-DOORKIT Door Assembly

15 31521-2 31521-2 Retainer, door shelf, long

16 31521-3 31521-3 Retainer, door shelf, short

17 80-29014-01 80-29014-02 Grille Assembly

18 1960-S 1960-S Evaporator Assembly

19 2693 2693 Dryer

20 2800 2800 Process tube

21 11695-S-BLK 11695-S-KIT Hinge Assembly, bottom

22 41785-SSB 41785-SSW Pivot screw, bottom

23 1893-S 1893-S Condenser Assembly

24 41125 41125 Foot, cabinet

25 31550-1-F 31550-1-F Drain pan

26 5263-S 5263-S Fan motor

27 5188 5188 Fan blade

28 2305 2305 Power cord

29 70077-S 70077-S Compressor Assembly

30 71010 71010 Relay

31 71009 71009 Overload

32 71008 71008 Capacitor

33 2766 2766 Control

34 42003 42003 Screw, control

35 11545-1 11545-1 Back panel

Section 4 - Parts

4-21

Page 49

Section 4 - Parts

3

MODEL 1075BEV

9

8

7

6

10

11

13

12

14

1

42

5

15

16

4

3

17

2

18

19

20

22

23

21

15

24

41

39

40

25

28

26

38

27

29

34

37

33

30

36

31

32

35

4-22

Page 50

MODEL 1075BEV

Item Part No. Description

1 80-17105-03 Door Assembly (Field Reversable )