Page 1

Para Español, vea páginas 3-4.

Pour le français, consulter les pages 5-6.

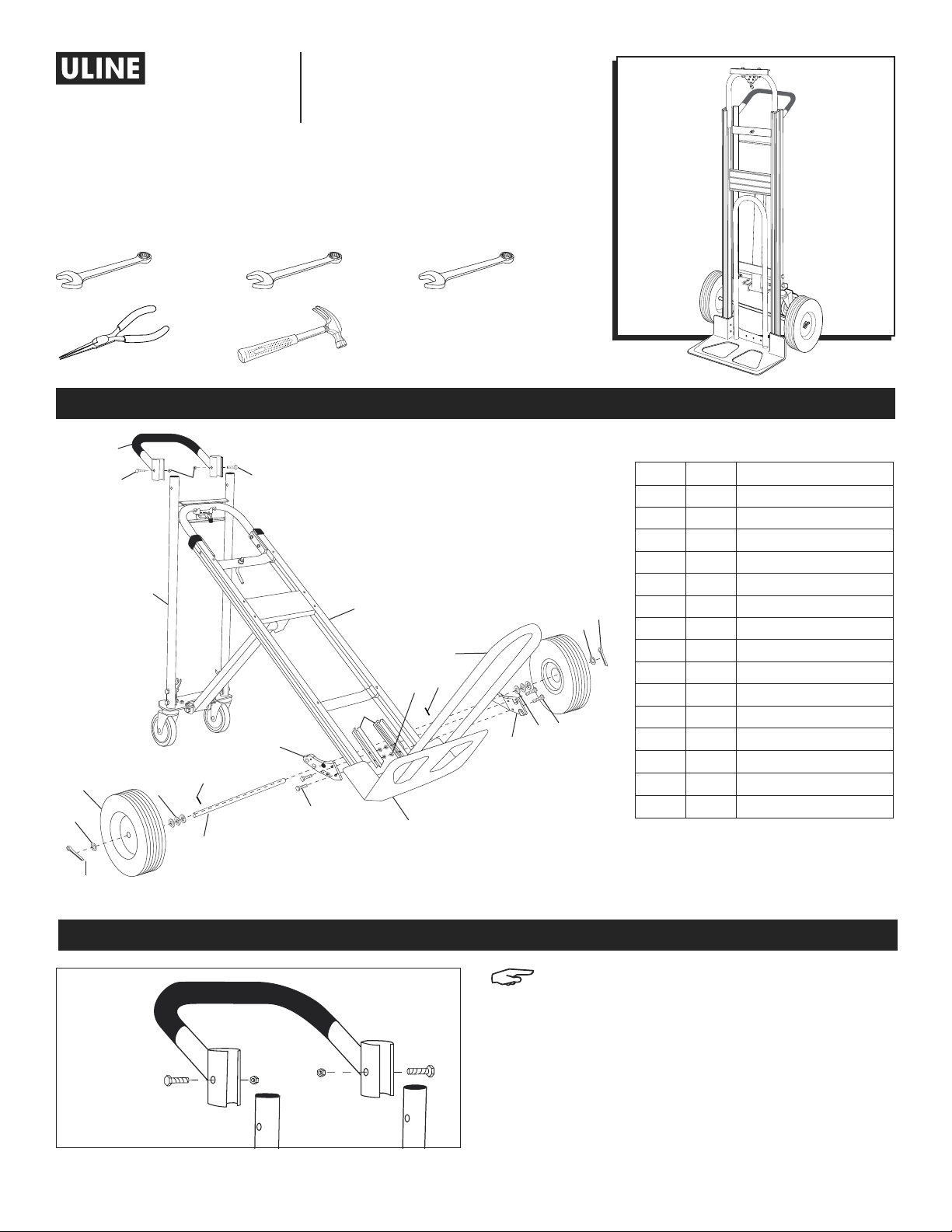

H-4124

3-IN-1 ALUMINUM

HAND TRUCK

WITH SOLID RUBBER WHEELS

TOOLS NEEDED

10mm Wrench 13mm Wrench 14mm Wrench

Pliers

1

2

7

6

3

4

9

6

8

2

11

1-80 0-295 -5510

uline.com

Hammer

4

13

12

10

14

PARTS

15

9

11

REF. QTY. DESCRIPTION

1 1 Handle

2 2 6mm Bolt

3 2 6mm Locknut

4 1 Frame

5 2 Cotter Pin

5

6

6

10

6 8 Washer

7 2 Wheel

8 1 Axle

9 2 Round Pin

10 4 8mm Bolt

11 2 Axle Support

12 2 Frame Reinforcement

13 4 8mm Locknut

14 1 Nose Plate

15 1 Folding Nose Extension

5

ASSEMBLY

Figure 1

ATTACH HANDLE

1. Slide handle onto the top rails of the frame. Align

PAGE 1 OF 6 0421 IH-4124

NOTE: Do not use air or power tools.

holes in handle and frame. Insert two 6mm bolts

through handle and frame and secure with locknuts.

(See Figure 1)

Page 2

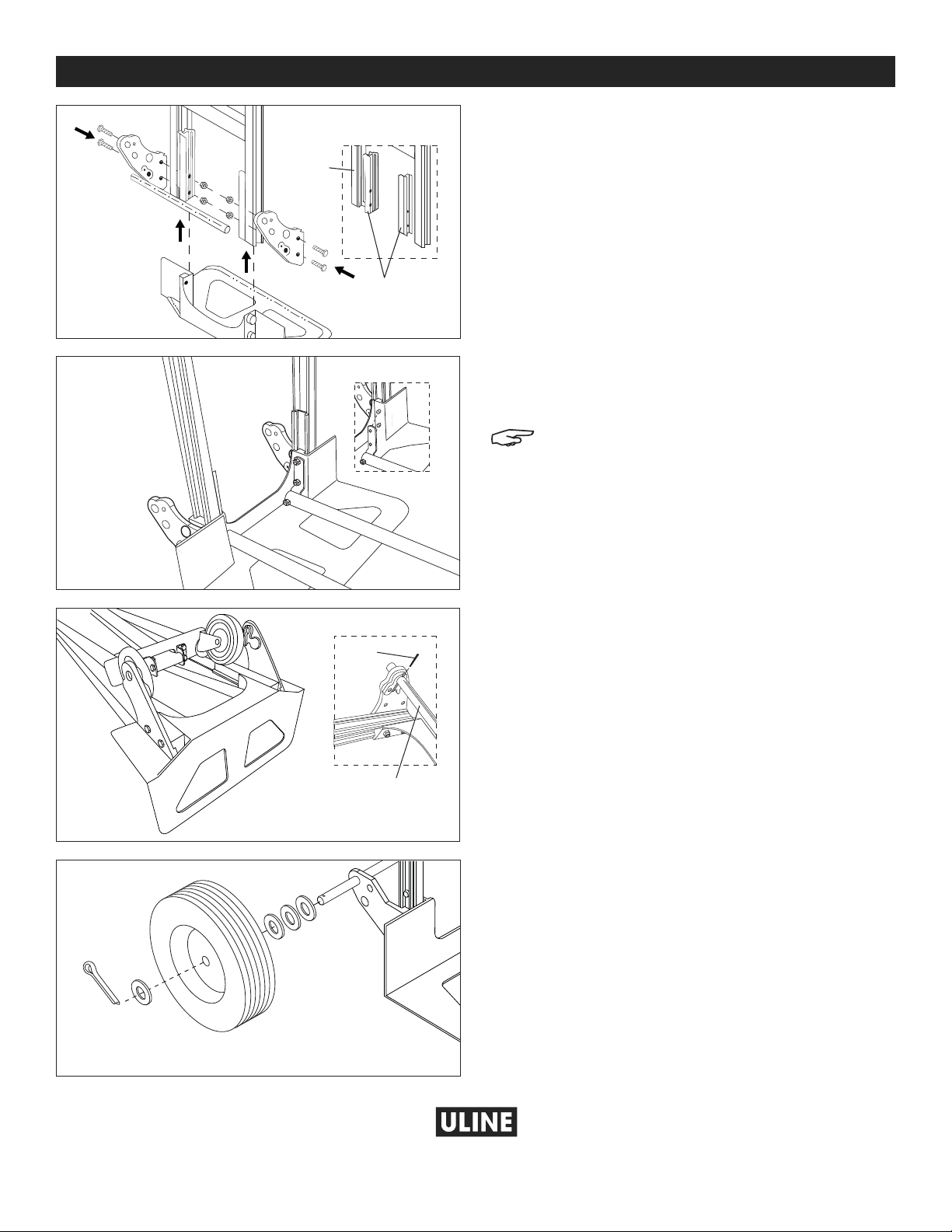

ASSEMBLY CONTINUED

1

0

uline.com

ATTACH NOSE PLATE, FOLDING NOSE EXTENSION

Figure 2a

AND AXLE SUPPORTS

Figure 2

Figure 3

Frame

Frame

Reinforcements

Figure 3a

1. Position frame reinforcements against bottom frame

rail. (See Figure 2a) Slide nose plate into channel on

frame reinforcements, keeping bolt holes aligned.

(See Figure 2)

2. Align axle support with outside rail of frame.

(See Figure 2)

3. Insert four 8mm bolts through the axle supports,

frame, frame reinforcements and nose plate.

(See Figure 2)

4. Slide the folding nose extension bracket over the

8mm bolts protruding from the bolt holes on the

inside of the nose plate. (See Figure 3a)

NOTE: The bolt holes on the bracket are NOT

centered. Make sure the bolt holes are closest

to the back of truck before tightening.

(See Figure 3)

5. Secure with locknuts but DO NOT tighten. (See Figure 3)

Figure 4

Figure 5

Figure 4a

Round

Pin

ATTACH AXLE AND WHEELS

1. Lay hand truck down on front so axle supports face

upwards. (See Figure 4)

2. Insert axle through holes in axle supports. Align holes

in axle with grooves on inside of the axle supports. Use

a hammer to tap in the round pins. (See Figure 4a)

Axle

3. Slide 3 washers onto each end of the axle. Slide

a wheel onto each end of the axle. Slide another

washer onto each end of the axle. (See Figure 5)

4. Insert a cotter pin through the holes in each end

of the axle. Bend cotter pins using pliers to secure

wheel. Wheels should spin freely. (See Figure 5)

5. Tighten all locknuts.

-800-295-551

PAGE 2 OF 6 0421 IH-4124

Page 3

H-4124

DIABLITO DE ALUMINIO

3-EN-1

CON LLANTAS DE

CAUCHO SÓLIDO

HERRAMIENTAS NECESARIAS

Llave de 10mm Llave de 13m m Llave de 14m m

80 0-295 -5510

uline.mx

Pinzas

Martillo

PARTES

1

2

7

6

3

4

9

6

8

2

11

10

12

4

15

9

13

6

11

14

10

5

6

REF. CANT. DESCRIPCIÓN

1 1 Asa

2 2 Perno de 6 mm

3 2 Contratuerca de 6mm

4 1 Armazón

5 2 Pasador

6 8 Rondana

7 2 Llanta

8 1 Eje

9 2 Perno Redondo

10 4 Perno de 8 mm

11 2 Soporte del Eje

12 2 Refuerzo del Armazón

13 4 Contratuerca de 8 mm

14 1 Base

15 1

Extensión Plegable

para la Base

5

ENSAMBLE

Diagrama 1

INSTALE EL ASA

1. Deslice el asa hacia los rieles superiores del

PAGE 3 OF 6 0421 IH-4124

NOTA: No utilice herramientas de aire o

eléctricas.

armazón. Alinee los orificios en el asa y el armazón.

Inserte dos pernos de 6 mm a través del armazón y

el asa y asegúrelos con contratuercas.

(Vea Diagrama 1)

Page 4

CONTINUACIÓN DE ENSAMBLE

8

0

uline.mx

INSTALE LA BASE, EXTENSIÓN PLEGABLE PARA LA

Diagrama 2a

BASE Y SOPORTES DEL EJE

Diagrama 2

Diagrama 3

Armazón

Refuerzos

del Armazón

Diagrama 3a

Diagrama 4a

Perno

Redondo

1. Posicione los refuerzos del armazón contra el fondo

del riel del armazón. (Vea Diagrama 2a) Deslice la

base dentro del canal en los refuerzos del armazón,

manteniendo los orificios de pernos alineados.

(Vea Diagrama 2)

2. Alinee el soporte del eje con el riel exterior del

armazón. (Vea Diagrama 2)

3. Inserte cuatro pernos de 8 mm a través de los

soportes del eje, el armazón, los refuerzos del

armazón y la base. (Vea Diagrama 2)

4. Deslice el soporte de la extensión plegable de la

base sobre los pernos de 8 mm que sobresalen de los

orificios en el interior de la base. (Vea Diagrama 3a)

NOTA: Los orificios de los pernos en el soporte

NO están centrados. Asegúrese de que los

orificios de los pernos estén en la posición más

cercana a la parte posterior del diablito antes

de asegurarlos. (Vea Diagrama 3)

5. Asegure con contratuercas pero NO apriete.

(Vea Diagrama 3)

INSTALE EL EJE Y LAS LLANTAS

1. Acueste el diablito hacia adelante a manera que

los soportes del eje estén hacia arriba.

(Vea Diagrama 4)

2. Inserte el eje a través de los orificios en los soportes

del eje. Alinee los orificios en el eje con muescas

en la parte interior de los soportes del eje. Use un

martillo para introducir los pernos redondos.

Eje

Diagrama 4

(Vea Diagrama 4a)

3. Deslice (3) rondanas sobre el extremo del eje.

Deslice una llanta en cada extremo del eje. Deslice

otra rondana en cada extremo del eje.

(Vea Diagrama 5)

4. Inserte un pasador a través de los orificios en cada

extremo del eje. Doble los pasadores usando pinzas

para asegurar la llanta. Las llantas deben girar

libremente. (Vea Diagrama 5)

5. Apriete todas las contratuercas.

Diagrama 5

00-295-551

PAGE 4 OF 6 0421 IH-4124

Page 5

H-4124

DIABLE 3-EN-1

AVEC ROUES EN

CAOUTCHOUC SOLIDES

OUTILS NÉCESSAIRES

Clé 10 mm Cl é 13 m m Clé 14m m

1-80 0-295 -5510

uline.ca

Pinces

Marteau

PIÈCES

1

2

7

6

3

4

9

6

8

2

11

10

12

4

15

9

13

6

11

14

10

5

6

RÉF. QTÉ. DESCRIPTION

1 1 Poignée

2 2 Boulon 6 mm

3 2 Écrou freiné 6 mm

4 1 Cadre

5 2 Goupille fendue

6 8 Rondelle

7 2 Roue

8 1 Essieu

9 2 Goupille ronde

10 4 Boulon 8 mm

11 2 Support d’essieu

12 2 Renfort de cadre

13 4 Écrou freiné 8 mm

14 1 Bavette

15 1

Rallonge de bavette

repliable

5

MONTAGE

Figure 1

FIXATION DE LA POIGNÉE

1. Glissez la poignée sur les rails supérieurs du cadre.

PAGE 5 OF 6 0421 IH-4124

REMARQUE : Ne pas utiliser d’outils à air ou

électrique.

Alignez les trous dans la poignée et le cadre. Insérez

deux (2) boulons de 6 mm à travers le cadre et la

poignée et fixez-les à l’aide d’écrous freinés.

(Voir Figure 1)

Page 6

Figure 2a

1

0

uline.ca

MONTAGE SUITE

FIXATION DE LA BAVETTE, DE LA RALLONGE DE

BAVETTE REPLIABLE ET DES SUPPORTS D’ESSIEU

Figure 2

Figure 3

Cadre

Renforts

de cadre

Figure 3a

1. Positionnez les renforts de cadre sur le bas des rails

de cadre. (Voir Figure 2a) Glissez la bavette dans le

canal des renforts de cadre, en gardant les trous de

boulons alignés. (Voir Figure 2)

2. Alignez les supports d’essieu avec le rail extérieur du

cadre. (Voir Figure 2)

3. Insérez quatre (4) boulons de 8 mm à travers des

supports d’essieu, du cadre, des renforts de cadre

et de la bavette. (Voir Figure 2)

4. Glissez le support de la rallonge repliable sur les

boulons de 8 mm saillants des trous de boulons à

l’intérieur de la rallonge de bavette. (Voir Figure 3a)

REMARQUE : Les trous de boulon du support ne

sont PAS centrés. Assurez-vous que les trous de

boulon sont positionnés plus près de l’arrière

du diable avant de serrer le tout. (Voir Figure 3)

5. Fixez avec les écrous freinés, mais NE serrez PAS.

(Voir Figure 3)

Figure 4

Figure 5

Figure 4a

Goupille

ronde

FIXATION DE L’ESSIEU ET DES ROUES

1. Posez le diable sur son devant de sorte que les

supports d’essieu sont orientés vers le haut.

(Voir Figure 4)

2. Enfilez l’essieu dans le trou des supports d’essieu.

Alignez les trous de l’essieu avec les rainures à

l’intérieur des supports d’essieu. Utilisez un marteau

pour planter les goupilles. (Voir Figure 4a)

Essieu

3. Enfilez trois (3) rondelles sur chaque extrémité de

l’essieu. Enfilez une (1) roue sur chaque extrémité

de l’essieu. Enfilez une autre rondelle sur chaque

extrémité de l’essieu. (Voir Figure 5)

4. Insérez une goupille fendue dans le trou à chaque

extrémité de l’essieu. Pliez les goupilles fendues à

l’aide de pinces pour sécuriser la roue. Les roues

doivent tourner librement. (Voir Figure 5)

5. Serrez tous les écrous freinés.

-800-295-551

PAGE 6 OF 6 0421 IH-4124

Loading...

Loading...