Page 1

BOSTITCH

Screw

Para Español, vea páginas 7-13.

Pour le français, consulter les pages 14-19.

H-3532, H-3534

BOSTITCH®

PNEUMATIC STAPLER

LOADING THE MAGAZINE

1. Disconnect from air supply.

WARNING! When loading stapler, never place

a hand or any part of the body in fastener

discharge area of the stapler. Never point

stapler at anyone. Do not pull the trigger or

depress the trip as accidental actuation may

occur, possibly causing injury.

1-800-295 -5510

uline.com

OPERATION

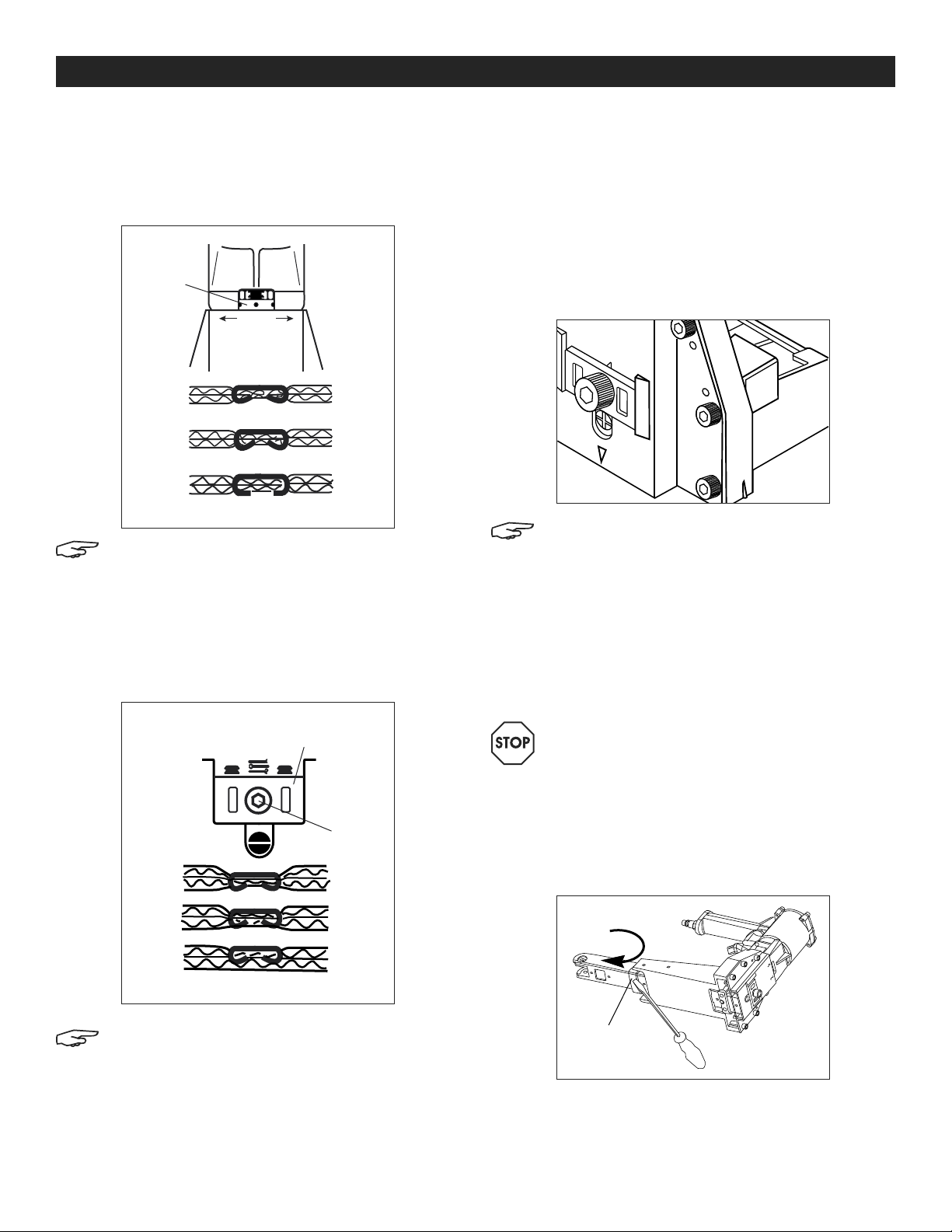

b. To change shallow clinchers (see part charts for

part numbers) remove screws and front bracket

to provide access to clinchers. Change one at a

time to prevent reversing part. Also part #45

(See Figure 3) will need to be changed to

specified spacer in the table.

Figure 3

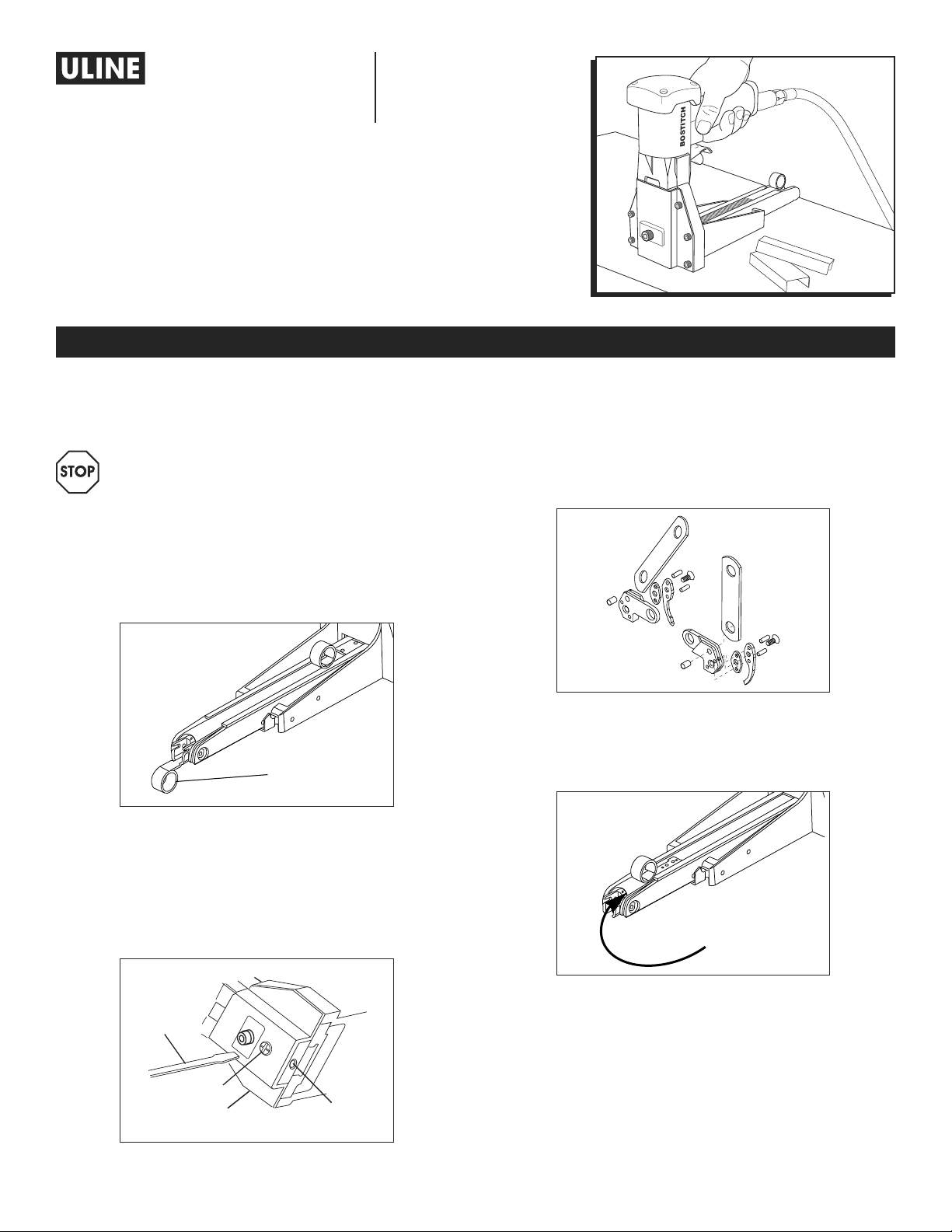

2. Pull back the pusher until it is tucked under the rear

of the magazine in position 1. (See Figure 1)

Figure 1

Position1

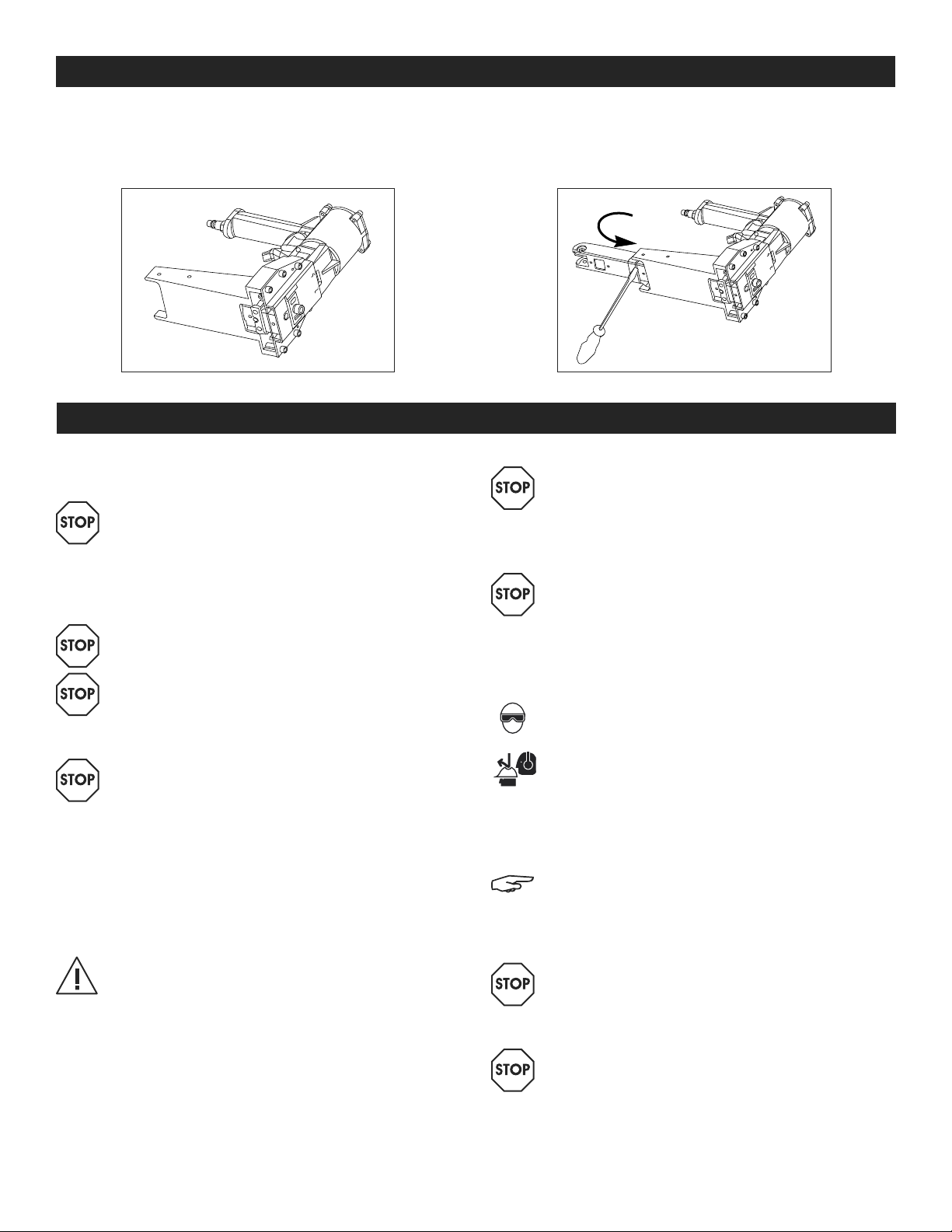

3. Check staple leg length – Adjustment is provided in

the H-3532/H-3534 for different staple leg lengths.

a. To adjust machine for leg length, loosen set

screw (See Figure 2) and turn pivot pin 180º with

a screwdriver to the desired adjustment as noted.

Tighten set screw.

Figure 2

Screw

Driver

4. Load the staple stick from the rear of the tool.

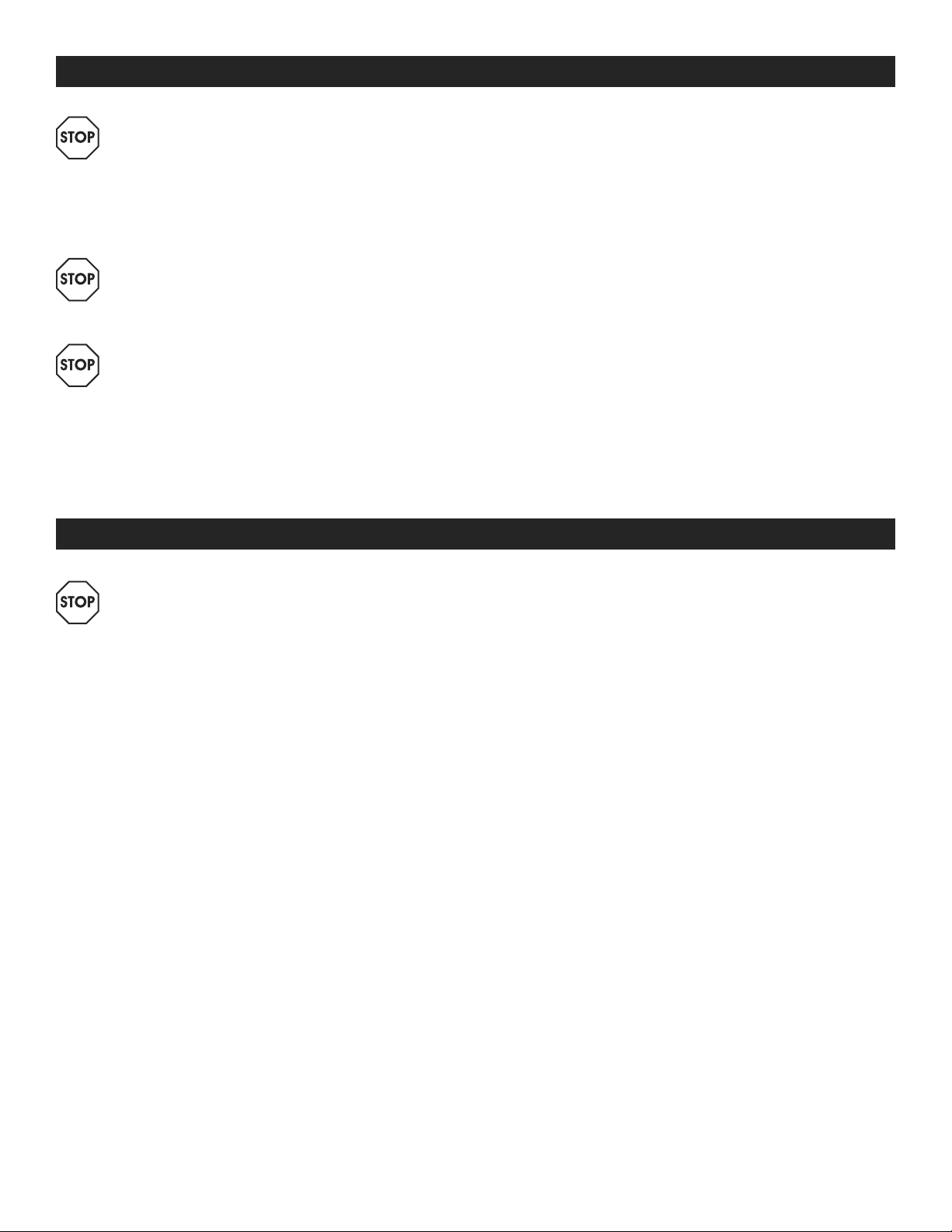

5. Slide the pusher from position 1 to the rear of the

staple stick (See Figure 4)

Figure 4

PAGE 1 OF 19 0421 IH-3532

Pivot Pin

Front Bracket

Set

Page 2

OPERATION CONTINUED

LOADING THE MAGAZINE CONTINUED

6. Clinch Adjustment – Turn special nut clockwise

to tighten clinch and counterclockwise to loosen

clinch. Use a tool to fit 1/8" (3mm) hole (See Figure 5).

Special

Nut

Clinch

Tight Loose

Tight

Medium

Loose

NOTE: Remove adjusting tool after adjustment.

7. Depth Adjustment – Loosen front screw and adjust

to desired length (See Figure 6). When the top edge

of adjustment plate is at highest setting (#4), the

clinchers are at their shallowest penetration. If set at

lowest setting (#1), the clinchers are at their deepest

penetration.

Figure 5

USING THE STAPLER

Stapling – Grasp handle with one hand. Position on

box in line with the desired staple location. There is a

small projection on either side of the frame as an aid in

locating the position of the staple (See Figure 7). Press

trigger. Strongest closure requires end staples close to

end of box. Check packaging requirements. Test staple

clinching in a sample of the board being used. Adjust

clinch for depth of penetration and tightness.

Figure 7

NOTE: Always disconnect air supply:

1. Before making adjustments;

2. When servicing the stapler;

3. When clearing a jam;

4. When stapler is not in use;

5. When moving to a different work area,

as accidental actuation may occur,

possibly causing injury.

Figure 6

Adjustment

Plate

Front

Screw

NO. 1

NO. 2 & 3

NO. 4

NOTE: Tighten screw after adjusting stapler.

REMOVING STUCK STAPLES

WARNING! Always disconnect air supply:

1. When servicing the stapler;

2. When clearing the jam;

3. When stapler is not in use;

4. When moving to a different work area, as

accidental actuation may occur.

1. Remove the remaining stick from the magazine. Pry

jam release forward with a screwdriver (See Figure 8).

Jam Release

Figure 8

PAGE 2 OF 19 0421 IH-3532

Page 3

OPERATION CONTINUED

REMOVING STUCK STAPLES CONTINUED

2. Remove magazine. (See Figure 9)

Figure 9 Figure 10

SAFETY WARNINGS

OPERATION

WARNING! Always handle the stapler with care:

1. Never engage in horseplay. 2. Never pull

the trigger unless nose is directed toward the

work. 3. Keep others at a safe distance from

the stapler while in operation as accidental

actuation may occur, possibly causing injury.

WARNING! Keep hands and body away from

the discharge area of the stapler.

WARNING! Do not drive fasteners on top of

other fasteners or with the stapler at an overly

steep angle as this may cause deflection of

fasteners which could cause injury.

WARNING! This stapler produces SPARKS

during operation. NEVER use the stapler near

flammable substances, gases or vapors

including lacquer, paint, benzene, thinner,

gasoline, adhesives, mastics, glues or any

other material that is – or vapors which are –

flammable, combustible or explosive. Using the

stapler in any such environment could cause

an EXPLOSION resulting in personal injury or

death to user and bystanders.

CAUTION: Remove all fasteners from the stapler

before performing stapler operation check.

TRIGGER-OPERATED STAPLER

a. With finger off the trigger, hold the stapler with a

firm grip on the handle.

b. Place the nose of the stapler against the work.

3. Clear the jam and reinsert the magazine. Pry jam

release shut. (See Figure 10)

WARNING! This is a full-cycle stapler. The stapler

will cycle each time the trigger is pulled!

Clinchers will discharge and retract.

EYE PROTECTION

WARNING! Eye protection which conforms to

ANSI specifications and provides protection

against flying particles from both the FRONT

and the SIDES should always be worn by the

operator and others in the work area when

connecting to air supply, loading, operating or

servicing this stapler. Eye protection is required

to guard against flying fasteners debris which

could cause severe eye injury.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements

of the American National Standards Institute

ANSI Z87.1 and provide both frontal and side

protection.

NOTE: Non-side shielded spectacles and face

shields do not provide adequate protection.

AIR SUPPLY AND CONNECTIONS

WARNING! Do not use oxygen, combustible

gases or bottled gases as a power source

for this stapler, as the stapler may explode,

possibly causing injury.

WARNING! Do not use supply sources which

can potentially exceed 200 psig as stapler

may burst, possibly causing injury.

c. Pull the trigger to drive.

PAGE 3 OF 19 0421 IH-3532

Page 4

SAFETY WARNINGS CONTINUED

WARNING! The connector on the stapler

must not hold pressure when air supply is

disconnected. If a wrong fitting is used, the

stapler can remain charged with air after

disconnecting and thus will be able to drive a

fastener even after the air line is disconnected,

possibly causing injury.

WARNING! Do not pull trigger or depress

contact arm while connected to the air supply

as the stapler may cycle, possibly causing

injury.

WARNING! Always disconnect air supply.

In addition to the other warnings contained in this

manual, observe the following for safe operation:

• Use the Bostitch® pneumatic stapler only for the

purpose for which it was designed.

MAINTENANCE

• Never use this stapler in a manner that could cause

a fastener to be directed toward the user or others in

the work area.

• Do not use the stapler as a hammer.

• Always carry the stapler by the handle. Never carry

the stapler by the air hose.

• Do not alter or modify this stapler from the original

design or function without approval from Bostitch Inc.

• Always be aware that misuse and improper handling

of this stapler can cause injury to yourself and others.

• Never leave unattended with the air hose attached.

• Do not operate this stapler if it does not have a

legible WARNING LABEL.

• Do not continue to use a stapler that leaks air or

does not function properly. Notify Uline if your stapler

continues to experience functional problems.

WARNING! When working on air tools, note the

warnings in this manual and use extra care

evaluating problem tools.

REPLACEMENT PARTS

• Bostitch® replacement parts are recommended. Do

not use modified parts or parts which will not give

equivalent performance to the original equipment.

ASSEMBLY PROCEDURE FOR SEALS

• When repairing a stapler, make sure the internal

parts are clean and lubricated. Use Parker O-LUBE

or equivalent on all O-Rings. Coat each O-Ring

with O-Lube before assembling. Use a small amount

of oil on all moving surfaces and pivots. After

reassemble add a few drops of Bostitch Air Tool

Lubricant through the air line fitting before sealing.

AIR SUPPLY - PRESSURE AND VOLUME

• Air volume is as important as air pressure. The air

volume supplied to the stapler may be inadequate

due to undersized fittings and hoses or from the

effects of dirt and water in the system. Restricted

air flow will prevent the stapler from receiving an

adequate volume of air even though the pressure

reading is high. The result will be slow operation,

misfeeds or reduced driving power.

Before evaluating stapler problems for these

symptoms, trace the air supply from the stapler to

the supply source for restrictive connectors, swivel

fittings, low points containing water or anything else

that would prevent full volume flow of air to

the stapler.

PAGE 4 OF 19 0421 IH-3532

Page 5

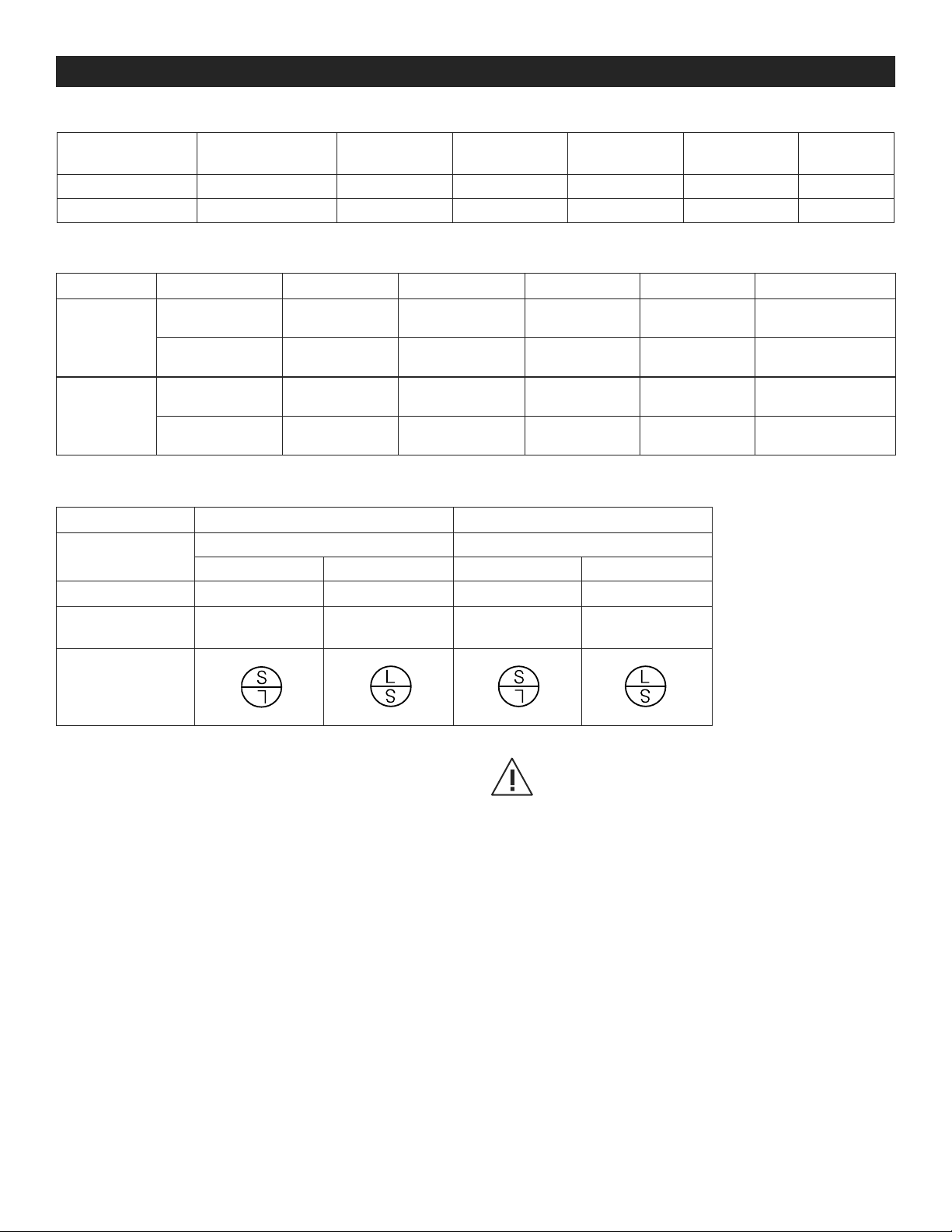

STAPLER SPECIFICATIONS

SPECIFICATIONS

ULINE PART NO. MFG. PART NO. LENGTH HEIGHT WIDTH WEIGHT

H-3532 DS -3219 12.6" (320 mm) 8.86" (225mm) 4. 5 " (115 m m)

H-3534 DS-3522 12.6" (320 mm) 8.86" (225mm) 4. 5 " (115 m m)

5.45 lbs. (2.45 kg)

5.45 lbs. (2.45 kg)

CAPACITY

FASTENER SPECIFICATIONS

STAPLER ULINE PART NO. LEG LENGTH STAPLE SERIES WIRE SIZE CROWN WIDTH FASTENER RANGE

H-3532

H-3534

S-18710 5/8" (24mm) B58C

S -18711 3/4" (29mm) B34C

S-18715 5/8" (24mm) S W 7437

S-18716 3/4" (29mm) SW7437

.074 x 0.37"

(1.88 x .94mm)

.074 x 0.37"

(1.88 x .94mm)

.074 x 0.37"

(1.88 x .94mm)

.074 x 0.37”

(1.88 x .94mm)

1⁄"

(32mm)

1⁄"

(32mm)

1⁄"

(35mm)

1⁄"

(35mm)

5/8 - 3/4"

(15 -19mm)

5/8 - 3/4"

(15 -19mm)

5/8 - 3/4"

(15 -19mm)

5/8 - 3/4”

(15 -19mm)

PARTS/STAPLE CHART

MODEL

CLINCHERS

SPACERS

STAPLE

LENGTHS

A01900601(L.H.) A01900501(R.H.) A01200601(R.H.) A01200601(L.H.)

A02300801 A02300801 — —

5/8" (16mm) 3/4" (19mm) 3/4" (19mm) 7/8" (22mm)

H-3532/H-3534 H-3534

STANDARD/FLAT DEEP

STAPLE

120

120

DIAL

POSITION

STAPLER AIR FITTING

This stapler must use a male free-flow connector plug,

1/4" (11mm) N.P.T. The minimum inside diameter should

be .300" (5mm). Fitting must be capable of discharging

stapler air pressure when disconnected from the air

supply.

OPERATING PRESSURE

The operating pressure of the stapler is 70 to 100 psi

(5 to 7 kg/cm2). Select the operating pressure within this

range for best fastener performance.

CAUTION: Do not exceed the recommended

operating pressure.

AIR CONSUMPTION

Model H-3532/H-3534 requires 4.0 cubic feet per minute

(.113 cubic meters) of free air to operate at the rate

of 100 fasteners per minute, at 80 psi (5.66kg/cm2).

Take the actual rate at which the stapler will be run to

determine the amount of air required. For instance, if

your fastener usage averages 50 fasteners per minute,

you need 50% of the stapler's cfm of free air which is

required for running at 100 fasteners per minute.

PAGE 5 OF 19 0421 IH-3532

Page 6

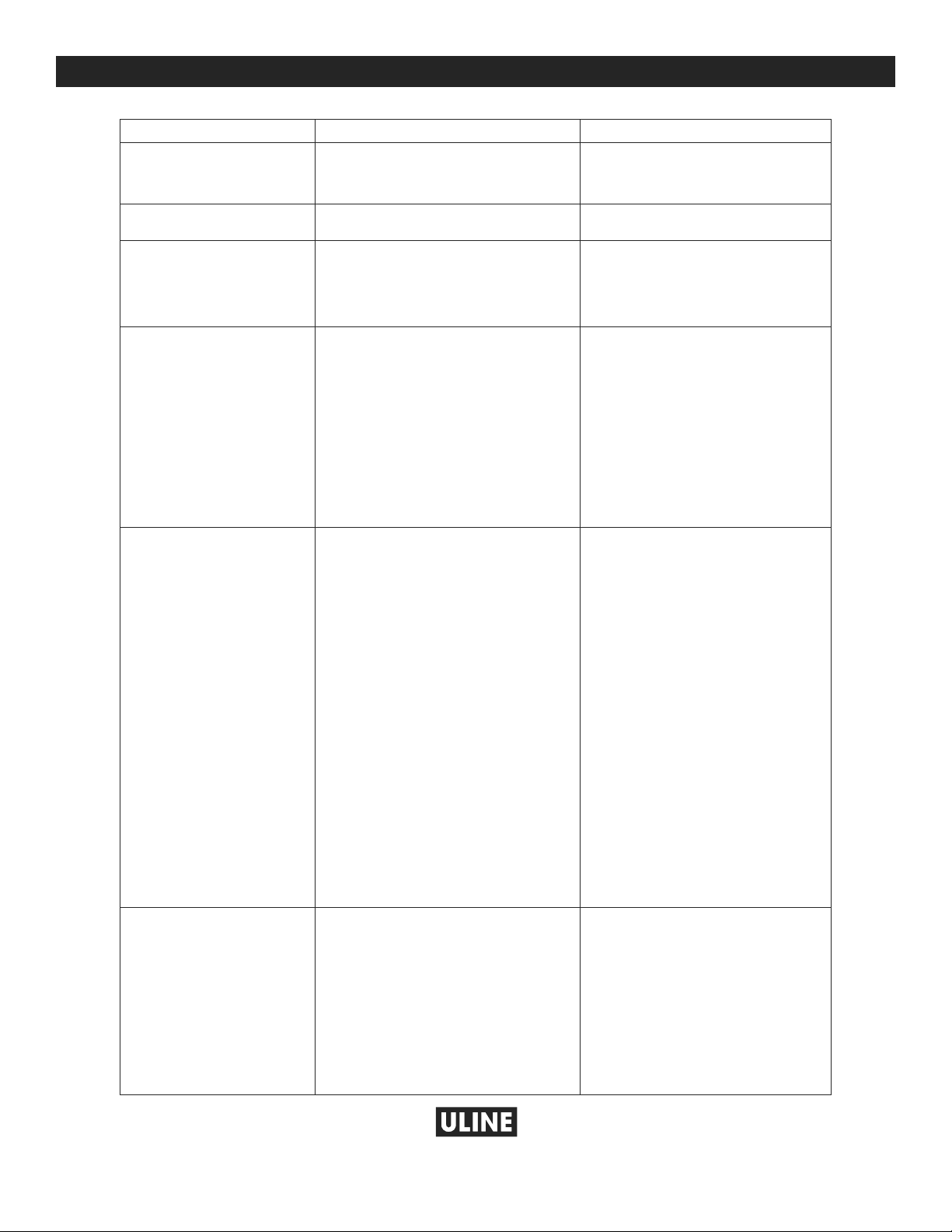

TROUBLESHOOTING

1

0

uline.com

OPERATING ISSUE CAUSES RECOMMENDATIONS

Trigger valve housing leaks air

Trigger valve stem leaks air

O-Ring cut or cracked

O-Ring/seals cut or cracked

Replace O-Ring

Replace trigger valve assembly

Frame/piston rod leaks air

Frame/cap leaks air

Lack of power; slow to cycle

Skipping fasteners,

Intermittent feed

O-Ring Replace O-Ring

Damaged O-Ring

Loose cap screws

Broken piston

Tool dry, lacks lubrication

O-Rings/seals cut or cracked

Exhaust blocked

Trigger assembly work, leaks

Dirt/tar buildup on driver

Air pressure too low

Worn or misadjusted cycle lever

Tar/dirt in driver channel

Air restriction/inadequate air flow through

quick disconnect socket and plug

Worn piston O-Ring/piston

Tool dry, lacks lubrication

Low air pressure

Loose magazine nose screws

Leaking head cap gasket

Trigger valve O-Ring cut/worn

Broken/chipped driver

Worn anvil/pusher

Broken pusher spring

Worn former

Dry/dirty magazine

Replace O-Ring

Tighten and recheck

Replace piston

Use Bostitch Air Tool Lubricant

Replace O-Rings/seals

Check bumper, head valve spring

Replace trigger assembly

Disassemble nose/driver to clean

Check air supply equipment

Adjust adjustment nut or replace

adjustment lever

Disassemble and clean nose and

driver

Replace quick disconnect fittings

Replace O-Ring/piston

Use Bostitch Air Tool Lubricant

Check air supply system to tool

Tighten all screws

Tighten screws/replace gasket

Replace O-Ring

Replace driver (check piston O-Ring)

Replace anvil/pusher

Replace pusher spring

Replace former

Clean/lubricate use Bostitch Air Tool

Lubricant

Fasteners jam in stapler

Driver channel worn

Wrong size fasteners

Bent fasteners

Loose magazine nose screws

Broken/chipped driver

Worn former

Worn anvil/pusher

Replace nose/check door

Use only recommended fasteners

Discontinue using these fasteners

Tighten all screws

Replace driver

Replace former

Replace pusher

-800-295-551

PAGE 6 OF 19 0421 IH-3532

Page 7

H-3532, H-3534

BOSTITCH

BOSTITCH®

ENGRAPADORA

NEUMÁTICA

800-295 -5510

uline.mx

FUNCIONAMIENTO

CARGUE EL CARTUCHO

1. Desconecte del suministro de aire.

¡ADVERTENCIA! Nunca coloque la mano o

cualquier otra parte del cuerpo en el área

de descarga de grapas de la engrapadora

al cargarla. Nunca apunte la engrapadora

hacia otra persona. No jale el gatillo ni

oprima el disparador ya que se puede activar

accidentalmente y es posible que cause

lesiones.

2. Cierre el impulsor hasta que se trabe por debajo de

la parte posterior del cartucho en la posición 1.

(Vea Diagrama 1)

Diagrama 1

Posición1

b. Para cambiar los remachadores superficiales

(consulte el gráfico de partes para ver los

números de las mismas) retire los pernos

y el soporte frontal para de acceder a los

remachadores. Cámbielos uno a la vez para

no mezclar las partes. Además, la pieza No. 45

(Vea Diagrama 3) debe cambiarse según el

separador especificado en la tabla.

Diagrama 3

4. Cargue la tira de grapas por la parte de atrás de la

máquina.

5. Deslice el empujador desde la posición 1 hasta la

parte de atrás de la tira de grapas. (Ver Diagrama 4)

3. Revise el largo de las patas de las grapas - La

H-3532/H-3534 cuentan con ajustes para grapas con

patas de diferentes largos.

a. Para ajustar la máquina según el largo de las

patas, afloje el tornillo de ajuste (Vea Diagrama 2)

y gire el selector en 180º con un desarmador

hasta el punto deseado, tal como se indica.

Apriete el Tornillo de Ajuste.

Diagrama 2

Desarmador

PAGE 7 OF 19 0421 IH-3532

Perno del Pivote

Soporte Frontal

Tornillo

de Ajuste

Diagrama 4

Page 8

CONTINUACIÓN FUNCIONAMIENTO

CONTINUACIÓN DE CARGUE

EL CARTUCHO

6. Ajuste del remache: Gire la tuerca especial en

el sentido de las agujas del reloj para apretar el

remache y gírela en el sentido contrario de las

agujas del reloj para aflojarlo. Use una herramienta

que calce en el orificio de 3 mm (1/8")

(Vea Diagrama 5).

Tuerca

Especial

Remache

Apretado Suelto

Apretado

Medio apretado

Suelto

NOTA: Retire la herramienta de ajuste después

de hacer el ajuste.

7. Ajuste de la profundidad: Afloje el perno

delantero y ajústelo en la profundidad deseada

(Vea Diagrama 6). Cuando el borde superior

de la placa de ajuste esté en la configuración

más alta (No. 4), los remachadores están en la

penetración más superficial. Si está en el ajuste

más bajo (No. 1), los remachadores están en su

penetración más profunda.

Diagrama 6

Placa de Ajuste

Diagrama 5

USE LA ENGRAPADORA

Engrapado: Tome el asa con una mano. Colóquela

en la caja alineando con la ubicación deseada de la

grapa. Hay una proyección pequeña en cada lado

del armazón que permite ubicar la posición de la

grapa (Vea Diagrama 7). Apriete el gatillo. Los cierres

más fuertes requieren que las grapas de los extremos

queden cerca del extremo de la caja.

requisitos de empaque. Revise el engrapado en

Revise

los

muestras

del cartón que está usando. Ajuste el remachador para

profundidad de penetración y opresión.

Diagrama 7

NOTA: Siempre desconecte el suministro

de aire:

1. Antes de hacer ajustes;

2. Al hacer mantenimiento a la engrapadora;

3. Al eliminar un atasco;

4. Cuando la engrapadora no esté en uso;

5. Al trasladarse a un área de trabajo distinta,

ya que se puede accionar accidentalmente

y es posible que cause lesiones.

RETIRE GRAPAS ATASCADAS

¡ADVERTENCIA! Siempre desconecte

el suministro de aire:

1. Al hacer mantenimiento a la engrapadora;

2. Al eliminar el atasco;

3. Cuando la engrapadora no esté en uso;

4. Al trasladarse a un área de trabajo distinta,

ya que se puede accionar accidentalmente.

Tornillo

Frontal

NO. 1

NO. 2 y 3

NO. 4

NOTA: Apriete el tornillo después de ajustar

la engrapadora.

PAGE 8 OF 19 0421 IH-3532

con un desarmador (Vea Diagrama 8).

Liberador

de Atascos

Diagrama 8

1. Quite la tira restante del cargador. Abra el liberador

Page 9

CONTINUACIÓN FUNCIONAMIENTO

CONTINUACIÓN DE RETIRAR

3. Liberar el atasco y volver a insertar el cargador.

Vuelva a cerrar el liberador. (Vea Diagrama 10)

GRAPAS ATASCADAS

2. Quitar el cargador (Vea Diagrama 9)

Diagrama 9 Diagrama 10

ADVERTENCIAS DE SEGURIDAD

OPERACIÓN

¡ADVERTENCIA! Siempre manipule la

engrapadora con cuidado: 1. Nunca juegue

con la engrapadora. 2. Nunca jale el gatillo

a menos que la punta esté apuntando

hacia la pieza de trabajo. 3. Mantenga

a las demás personas a una distancia segura

de la engrapadora mientras esté en operación,

ya que puede activarse accidentalmente

y es posible que cause lesiones.

¡ADVERTENCIA! Mantenga las manos

y el cuerpo alejados del área de descarga

de la engrapadora.

¡ADVERTENCIA! No coloque grapas sobre otras

grapas ni con la engrapadora demasiado

inclinada, ya que esto puede causar que las

grapas se desvíen y provocar lesiones.

¡ADVERTENCIA! Esta engrapadora produce

CHISPAS durante la operación. NUNCA utilice

la engrapadora cerca de sustancias, gases o

vapores inflamables, incluyendo laca, pintura,

bencina, diluyente, gasolina, adhesivos,

masillas, colas o cualquier otro material

que sea - o vapores que sean - inflamables,

combustibles o explosivos. Usar la engrapadora

en un entorno como este podría provocar

una EXPLOSIÓN causando lesiones personales

o la muerte del usuario y espectadores.

PRECAUCIÓN: Retire todas las grapas

de la engrapadora antes de realizar

la comprobación del funcionamiento.

PAGE 9 OF 19 0421 IH-3532

ENGRAPADORAS CON GATILLO

a. Con el dedo fuera del gatillo, sostenga la

engrapadora firmemente por el mango.

b. Ponga la punta de la engrapadora contra

la superficie de trabajo.

c. Jale el gatillo para engrapar.

¡ADVERTENCIA! Esta es una engrapadora de

ciclo completo. ¡La engrapadora efectuará

un ciclo cada vez que tire del gatillo! Los

remachadores se descargarán y retraerán.

PROTECCIÓN OCULAR

¡ADVERTENCIA! El operador y las demás

personas en el área de trabajo siempre

deben utilizar protección ocular que se ajuste

a las especificaciones ANSI y proporcione

protección contra las partículas despedidas

desde la parte FRONTAL y LATERAL al conectar

al suministro de aire, cargar, operar o reparar

esta engrapadora. Se requiere protección

ocular para proteger contra residuos y

fijadores que salten, los cuales podrían causar

graves lesiones oculares.

El empleador y / o usuario deben asegurarse

de que se use la protección ocular adecuada.

El equipo de protección ocular debe ajustarse

a los requisitos del Instituto Americano de

Normas Nacionales (American National

Standards Institute), ANSI Z87.1 y proveer

protección frontal y lateral.

NOTA: Los lentes o caretas sin protección

lateral no proporcionan una protección

adecuada.

Page 10

CONTINUACIÓN DE ADVERTENCIAS DE SEGURIDAD

SUMINISTRO DE AIRE Y CONEXIONES

¡ADVERTENCIA! No use oxígeno, gases

combustibles ni gases envasados como fuente

de energía para operar esta engrapadora, ya

que puede explotar y es posible que cause

lesiones.

¡ADVERTENCIA! No utilice fuentes de suministro

que puedan exceder los 200 psig ya que la

engrapadora puede estallar y es posible que

cause lesiones.

¡ADVERTENCIA! El conector de la engrapadora

no debe retener presión al desconectar el

suministro de aire. Si se utiliza un conector

incorrecto, la engrapadora puede

permanecer cargada con aire después de

haberla desconectado y, por tanto, podrá

impulsar una grapa aún después de que se

desconecte la línea de aire y es posible que

cause lesiones.

¡ADVERTENCIA! No tire del gatillo ni oprima el

brazo de contacto mientras está conectada al

suministro de aire, ya que la engrapadora se

puede activar y es posible que cause lesiones.

¡ADVERTENCIA! Siempre desconecte

el suministro de aire.

Además de las otras advertencias que aparecen

en este manual, cumpla con lo siguiente para una

operación segura:

• Use la engrapadora neumática Bostitch® solamente

para el fin para el que fue diseñada.

• Nunca use esta engrapadora de tal modo que

pueda causar la salida de una grapa hacia el

usuario u otras personas presentes en el área de

trabajo.

• No use la engrapadora como martillo.

• Siempre lleve la herramienta tomándola

por el asa. Nunca lleve la herramienta

tomándola por la manguera de aire.

• No altere ni modifique el diseño o función

original de esta engrapadora sin la aprobación

de Bostitch, Inc.

• Siempre tenga presente que el uso indebido

o la manipulación incorrecta de esta engrapadora

puede causarle lesiones a usted y a los demás.

• Nunca la deje sin supervisión con la manguera

de aire conectada.

• No opere esta engrapadora si no cuenta con

una ETIQUETA DE ADVERTENCIA legible.

• No use la engrapadora si tiene fugas de aire o no

funciona bien. Notifique a Uline si la engrapadora

sigue presentando problemas de funcionamiento.

MANTENIMIENTO

¡ADVERTENCIA! Recuerde las advertencias

en este manual al trabajar con herramientas

neumáticas y tenga mayor cuidado al evaluar

herramientas problemáticas.

PAGE 10 OF 19 0421 IH-3532

PARTES DE REPUESTO

• Se recomienda usar partes de repuesto Bostitch®

No use partes modificadas ni componentes que

no tengan un rendimiento equivalente al equipo

original.

Page 11

CONTINUACIÓN DE MANTENIMIENTO

PROCEDIMIENTO PARA ENSAMBLE

DE SELLOS

• Al reparar la engrapadora, asegúrese que las

partes internas estén limpias y lubricadas. Use

lubricante Parker O-LUBE u otro equivalente en todas

los anillos-o. Cubra cada anillo-o con lubricante

O-LUBE antes del ensamble. Use una pequeña

cantidad de aceite en todas las superficies y

pivotes móviles. Después de reensamblar, añada

unas gotas de lubricante para herramientas

neumáticas Bostitch (Air Tool Lubricant) a través del

conector de la línea de aire antes de sellar.

ESPECIFICACIONES

SUMINISTRO DE AIRE - PRESIÓN

Y VOLUMEN

• El volumen de aire es tan importante como la

presión. El volumen de aire suministrado a la

engrapadora puede ser inadecuado debido

a conectores y mangueras de tamaño inferior

o por los efectos de suciedad y agua en el

sistema. El flujo de aire restringido impedirá que la

engrapadora reciba un volumen de aire adecuado,

aún cuando la lectura de presión sea alta. Los

resultados serán un funcionamiento lento, fijadores

mal dirigidos o menor potencia de impulso. Antes

de evaluar los problemas de la engrapadora según

estos síntomas, inspeccione el suministro de aire

desde la engrapadora a la fuente de suministro

en busca de conectores restrictivos, accesorios

giratorios, puntos bajos que tengan agua

y cualquier otra cosa que impida el flujo del

volumen completo de aire a la engrapadora.

ESPECIFICACIONES DE LA ENGRAPADORA

NO. DE PARTE

ULINE

H-3532 DS -3219 320 mm (12.6") 225 mm (8.86") 115 mm (4.5")

H-3534 DS-3522 320 mm (12.6") 225 mm (8.86") 115 mm (4.5")

ESPECIFICACIONES DE LAS GRAPAS

ENGRAPADORA

H-3532

H-3534

NO. DE PARTE DEL

FABRICANTE

NO. DE PARTE

ULINE

S-18710 24 mm (5/8") B58C

S -18711 29 mm (3/4") B34C

S-18715 24 mm (5/8") S W7437

S-18716 29 mm (3/4") SW7437

LARGO

DE PATA

LARGO ALTO ANCHO PESO

2.45 kg (5.45 lbs.)

2.45 kg (5.45 lbs.)

SERIE

DE GRAPA

TAMAÑO

DE ALAMBRE

1.88 x 0.94 mm

(0.074 x 0.37")

1.88 x 0.94 mm

(0.074 x 0.37")

1.88 x 0.94 mm

(0.074 x 0.37")

1.88 x 0.94 mm

(0.074 x 0.37")

ANCHO

DE CORONA

32 mm

(1⁄" )

32 mm

(1⁄" )

35 mm

(1⁄")

35 mm

(1⁄")

CAPACIDAD

DE

ENGRAPAR

120

120

RANGO DE LA GRAPA

15 a 19 mm

(5/8 a 3/4")

15 a 19 mm

(5/8 a 3/4")

15 a 19 mm

(5/8 a 3/4")

15 a 19 mm

(5/8 a 3/4")

PAGE 11 OF 19 0421 IH-3532

Page 12

GRÁFICO DE PARTES/GRAPAS

MODELO

REMACHADORES

SEPARADORES

LARGO

DE GRAPAS

POSICIÓN

DEL SELECTOR

A01900601(M.I.) A01900501(M.D.) A01200601(M.D.) A01200601(M.I.)

A02300801 A02300801 — —

16 mm (5/8") 19 mm (3/4") 19 mm (3/4") 22 mm (7/8")

CONTINUACIÓN DE ESPECIFICACIONES

H-3532/H-3534 H-3534

ESTÁNDAR/PLANO DE PROFUNDIDAD

CONECTOR DE AIRE DE LA ENGRAPADORA

Esta engrapadora usa un enchufe conector de flujo

libre de 11 mm (1/4") N.P.T. El diámetro interior mínimo

debe ser de 0.30" (5 mm). El conector debe ser capaz

de descargar la presión de aire de la engrapadora al

desconectarse del suministro de aire.

PRESIÓN OPERATIVA

La presión operativa de la engrapadora es de 5

a 7 kg/cm2 (70 a 100 psi). Seleccione la presión

operativa dentro de esta gama para lograr un óptimo

rendimiento.

SOLUCIÓN DE PROBLEMAS

PROBLEMA DE OPERACIÓN CAUSAS RECOMENDACIONES

La carcasa de la válvula del

gatillo fuga aire

El vástago de la válvula del

gatillo fuga aire

Anillo-o roto o agrietado

Anillo-o/sellos rotos o agrietados

PRECAUCIÓN: No supere la presión operativa

recomendada.

CONSUMO DE AIRE

El modelo H-3532/H 35340 necesita 0.113 metros

cúbicos (4.0 pies3) por minuto de aire libre para

funcionar a razón de 100 fijadores por minuto,

a 5.66kg/cm2 (80 psi.). Tome la velocidad real

con la cual operará la engrapadora para determinar

la cantidad de aire necesaria. Por ejemplo, si su uso

de fijadores promedia 50 por minuto, necesita el 50%

de los 0.049 m³ (1.75 pies3) por minuto requeridos para

funcionar a razón de 100 fijadores por minuto.

Remplace el anillo-o

Remplace el ensamblado

de la válvula de disparo

El armazón/vástago del

pistón fuga aire

El armazón/tapa fuga aire

PAGE 12 OF 19 0421 IH-3532

Anillo-o Remplace el anillo-o

Anillo-o dañado

Tornillos de casquete sueltos

Pistón roto

Remplace el anillo-o

Apriételos y revíselos

Remplace el pistón

Page 13

CONTINUACIÓN DE SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

PROBLEMA DE OPERACIÓN CAUSAS RECOMENDACIONES

Falta de potencia; ciclo lento

Herramienta seca, le falta lubricación

Anillos-o/sellos rotos o agrietados

Escape bloqueado

Ensamble del gatillo desgastado/con

fugas

Suciedad/alquitrán acumulados en el

impulsor

Presión de aire demasiado baja

Palanca de ciclo desgastada o

desajustada

Use lubricante Bostitch para

herramientas neumáticas

Remplace los anillos-o/sellos

Revise el tope, el resorte de la válvula

cabezal

Remplace el ensamble de disparo

Desarme la punta/impulsor para

limpiarlos

Revise el equipo de suministro de aire

Regule la tuerca de ajuste o cambie la

palanca ajustadora

Se saltan fijadores;

la alimentación es

intermitente

Fijadores atascados en la

engrapadora

Alquitrán/suciedad en el canal del

impulsor

Restricción de aire/flujo indebido de aire

por el enchufe y la toma de desconexión

rápida

Pistón/Anillo-o del pistón desgastados

Herramienta seca, le falta lubricación

Presión de aire baja

Tornillos sueltos en la punta del cartucho

La junta de la tapa cabezal tiene fugas

Anillo-o de la válvula de disparo

cortada/desgastada

Impulsor roto/picado

Yunque/impulsor desgastados

Resorte del impulsor roto

Formador desgastado

Cartucho seco/sucio

Canal del impulsor desgastado

Grapas de tamaño incorrecto

Grapas dobladas

Tornillos sueltos en la punta del cargador

Impulsor roto/picado

Formador desgastado

Yunque/impulsor desgastados

Desarme y limpie la punta y el impulsor

Remplace los accesorios de

desconexión rápida

Remplace el anillo-o/pistón

Use lubricante Bostitch para

herramientas neumáticas

Revise el sistema de suministro de aire

a la herramienta

Apriete todos los tornillos

Apriete los tornillos/cambie la junta

Remplace el anillo-o

Remplace el impulsor (revise el

anillo-o del pistón)

Remplace el yunque/impulsor

Remplace el resorte del impulsor

Remplace el formador

Límpielo/aplique lubricante Bostitch

para herramientas neumáticas

Cambie la punta/revise la ventanilla

Use sólo grapas recomendadas

Deje de usar esas grapas

Apriete todos los tornillos

Remplace el impulsor

Remplace el formador

Remplace el impulsor

00-295-551

PAGE 13 OF 19 0421 IH-3532

Page 14

H-3532, H-3534

BOSTITCH

BOSTICHMD - AGRAFEUSE

PNEUMATIQUE

1-800-295 -5510

uline.ca

UTILISATION

CHARGEMENT DU MAGASIN

1. Déconnectez l'alimentation d'air.

AVERTISSEMENT! Lors du chargement de

ARRÊT

2. Tirez le pousseur vers l'arrière jusqu'à ce qu'il se loge

l'agrafeuse, ne placez jamais une main ou

toute autre partie de votre corps dans la zone

de propulsion des agrafes. Ne pointez jamais

l'agrafeuse sur quelqu'un. N'appuyez pas sur

la détente ou n'actionnez pas le déclencheur,

car une mise en marche accidentelle peut se

produire, engendrant ainsi le risque de blessures.

sous l'arrière du magasin, en position 1.

(Voir Figure1)

Figure 1

Position1

a. Pour régler l'appareil selon la longueur des

pattes d'agrafe, desserrez la vis de réglage (Voir

Figure 2) et tournez l'axe d'articulation sur 180º

au réglage voulu tel que noté, à l'aide d'un

tournevis. Serrez la vis de réglage.

b. Pour changer les rivets de faible profondeur (voir

les tableaux des pièces pour les numéros de

pièce), retirez les vis avant et le support avant

pour accéder aux rivets. Remplacez-les un à la

fois afin d'éviter d'inverser les pièces. La pièce n°

45 (Voir Figure 3) devra aussi être remplacée par

l'entretoise spécifiée dans le tableau.

Figure 3

4. Chargez la bande d'agrafes depuis l'arrière de

l'agrafeuse.

3. Vérifiez la longueur des pattes d'agrafe: Le réglage

pour différentes longueurs de pattes d'agrafe figure

dans le document H-3532/H-3534.

Figure 2

Tournevis

PAGE 14 OF 19 0421 IH-3532

Cheville Pivot

Support Avant

Vis de

Réglage

5. Glissez le pousseur de la position 1 à l'arrière de la

bande d'agrafes (Voir Figure 4)

Figure 4

Page 15

UTILISATION, SUITE

CHARGEMENT DU MAGASIN, SUITE

6. Réglage de la fermeture: Tournez l'écrou spécial

dans le sens horaire pour serrer la fermeture, et

dans le sens antihoraire pour desserrer la fermeture.

Employez un outil qui peut entrer dans l'orifice de

3mm (1/8po) (Voir Figure 5).

Écrou

spécial

Fermerure

Serrée Lâche

Serrée

Moyenne

Lâche

REMARQUE: Retirez l'outil au terme du réglage.

7. Réglage de profondeur: Desserrez la vis avant et

réglez à la longueur voulue (Voir Figure 6). Quand le

rebord supérieur de la plaque de réglage est à son

réglage supérieur (n° 4), les rivets sont positionnés

à leur pénétration la moins profonde. Si réglés

au réglage le plus bas (n° 1), les rivets sont à leur

pénétration la plus profonde.

Figure 5

UTILISATION DE L'AGRAFEUSE

Agrafage: Saisissez la poignée à une main. Positionnez

l'agrafeuse à l'emplacement voulu sur la boîte en ligne.

Il y'a une petite saillie de chaque côté du cadre pour

aider à localiser la position de l'agrafe (Voir Figure 7).

Appuyez sur la détente. La fermeture la plus solide exige

que les agrafes en bordure soient installées près des

rebords de la boîte. Vérifiez les exigences d'emballage.

Testez la fermeture des agrafes sur un échantillon du

carton à utiliser. Réglez la pénétration et le niveau de

serrage de la fermeture.

Figure 7

REMARQUE: Déconnectez toujours

l'alimentation d'air:

1. avant d'effectuer des réglages;

2. lors de l'entretien de l'agrafeuse;

3. lorsque vous dégagez une obstruction;

4. lorsque vous n'utilisez pas l'agrafeuse;

5. lorsque vous vous déplacez vers une autre

zone de travail, car un déclenchement

accidentel peut se produire, engendrant le

risque de blessures.

RETRAIT D'AGRAFES COINCÉES

A

Figure 6

Plaque de

Réglage

ARRÊT

VERTISSEMENT! Déconnectez toujours

l'alimentation d'air:

1. lors de l'entretien de l'agrafeuse;

2. lorsque vous dégagez l'obstruction;

3. lorsque vous n'utilisez pas l'agrafeuse;

4. lorsque vous vous déplacez vers une

Vis avant

autre zone de travail, car un actionnement

accidentel peut se produire.

N˚ 1

N˚ 2 et 3

N˚ 4

Dispositif de

REMARQUE: Serrez la vis au terme du réglage

de l'agrafeuse.

déverrouillage en

cas d'obstruction

Figure 8

1. Retirez la bande restante du magasin. Forcez le

dispositif de déverrouillage en cas d'obstruction vers

l'avant avec un tournevis (Voir Figure 8).

PAGE 15 OF 19 0421 IH-3532

Page 16

UTILISATION, SUITE

RETRAIT D'AGRAFES COINCÉES, SUITE

2. Retirez le magasin. (Voir Figure9)

Figure 9 Figure 10

3. Dégagez l'obstruction et réinsérez le magasin.

Forcez la fermeture du dispositif de déverrouillage

en cas d'obstruction. (Voir Figure10)

AVERTISSEMENTS DE SÉCURITÉ

UTILISATION

A

VERTISSEMENT! Utilisez toujours l'agrafeuse

ARRÊT

ARRÊT

ARRÊT

ARRÊT

avec précaution: 1. Ne vous chamaillez jamais.

2. N'appuyez jamais sur la détente si la sortie

des agrafes n'est pas orientée vers l'ouvrage.

3. Gardez les autres personnes à l'écart de

l'agrafeuse lorsque celle-ci est en cours

d'utilisation, car un actionnement accidentel

peut se produire, engendrant le risque de

blessures.

A

VERTISSEMENT! Gardez les mains et le corps à

l'écart de la zone de décharge de l'agrafeuse.

A

VERTISSEMENT! Ne pas poser d'agrafes sur

d'autres agrafes, ou en tenant l'agrafeuse à

un angle trop aigu, une agrafe pourrait être

déviée, engendrant le risque de blessures.

A

VERTISSEMENT! Cette agrafeuse produit

des ÉTINCELLES durant son fonctionnement.

N'utilisez JAMAIS l'agrafeuse à proximité

de substances, de gaz ou de vapeurs

inflammables, dont laque, peinture, benzène,

diluant, essence, adhésifs, mastic, colles ou

toute autre matière inflammable, combustible

ou explosive, ou dont les vapeurs sont

inflammables, combustibles ou explosives.

L'utilisation de l'agrafeuse dans un tel milieu

peut provoquer une EXPLOSION entraînant la

blessure ou la mort de l'utilisateur ou de tout

observateur.

MISE EN GARDE: Retirez toutes les agrafes de

l'agrafeuse avant d'exécuter le contrôle de

fonctionnement de l'outil.

AGRAFEUSE À DÉTENTE

a. Avec le doigt retiré de la détente, saisissez

fermement l'agrafeuse par la poignée.

PAGE 16 OF 19 0421 IH-3532

b. Placez le nez de l'agrafeuse sur la surface de

travail.

c. Appuyez sur la détente pour propulser une agrafe.

A

VERTISSEMENT! Celle-ci est une agrafeuse à

ARRÊT

cycle complet. L'agrafeuse exécutera un cycle

à chaque actionnement de la détente! Les

rivets se déploieront et se rétracteront.

PROTECTION OCULAIRE

AVERTISSEMENT! Une protection oculaire qui

ARRÊT

satisfait à la spécification ANSI et qui protège les

yeux contre les particules projetées à la fois de

FACE et de CÔTÉ doit être portée en tout temps

par l'utilisateur et les autres personnes présentes

dans la zone de travail durant la connexion de

l'alimentation d'air, le chargement, l'utilisation

ou l'entretien de cette agrafeuse. Une protection

oculaire est nécessaire pour se prémunir contre

les agrafes et les débris projetés qui pourraient

provoquer de graves blessures aux yeux.

L'employeur et/ou l'utilisateur doit s'assurer qu'un

dispositif de protection oculaire approprié est

porté par tous. L'équipement de protection

oculaire doit être conforme avec les exigences

ANSI (American National Standards Institute)

Z87.1 et offrir une protection à la fois frontale et

latérale.

REMARQUE: Les lunettes et les masques

protecteurs sans écrans latéraux n'offrent pas à

eux-seuls une protection adéquate.

ALIMENTATION D'AIR ET RACCORDS

A

VERTISSEMENT! N'alimentez pas cette agrafeuse

ARRÊT

avec de l'oxygène, du gaz combustible ou du

gaz comprimé en bouteille, car l'agrafeuse

peut exploser, engendrant le risque de

blessures.

Page 17

AVERTISSEMENTS DE SÉCURITÉ, SUITE

A

VERTISSEMENT! N'utilisez aucune source

ARRÊT

ARRÊT

ARRÊT

ARRÊT

En plus des autres avertissements contenus dans ce

manuel, respectez ce qui suit pour une utilisation

sécuritaire:

• Utilisez l'agrafeuse pneumatique BostitchMD

d'alimentation qui pourrait dépasser 13,8bars

(200lb/po²), car l'agrafeuse peut éclater,

engendrant le risque de blessures.

A

VERTISSEMENT! Le raccord installé sur

l'agrafeuse ne doit retenir aucune pression

après la déconnexion de l'alimentation d'air. Si

un raccord inapproprié a été utilisé, l'agrafeuse

peut demeurer sous pression après être

déconnectée, risquant de propulser une agrafe

après la déconnexion de la conduite d'air,

engendrant le risque de blessures.

A

VERTISSEMENT! N'appuyez pas sur la détente

ou n'actionnez pas le bras de contact lorsque

la conduite d'air est connectée, car l'agrafeuse

pourrait s'actionner, engendrant le risque de

blessures.

A

VERTISSEMENT! Déconnectez toujours

l'alimentation d'air.

uniquement aux fins pour lesquelles elle a été

conçue.

• N'utilisez jamais cette agrafeuse d'une façon qui

pourrait propulser une agrafe en direction de

l'utilisateur ou de toute autre personne présente dans

la zone de travail.

• N'utilisez pas l'agrafeuse comme marteau.

• Transportez toujours l'agrafeuse par la poignée. Ne

transportez jamais l'agrafeuse à l'aide de la conduite

d'air.

• N'altérez ou ne modifiez pas la conception ou

la fonction originale de cette agrafeuse sans

l'approbation préalable de Bostitch Inc.

• Soyez toujours conscient que l'abus ou la

manutention inappropriée de cette agrafeuse peut

provoquer des blessures à vous-même et aux autres.

• Ne la laissez jamais sans surveillance avec la

conduite d'air connectée.

• Si l'agrafeuse n'est pas munie d'une ÉTIQUETTE DE

SÉCURITÉ lisible, ne l'utilisez pas.

• Cessez immédiatement d'utiliser une agrafeuse

qui présente une fuite d'air ou qui ne fonctionne

pas correctement. Notifiez Uline si votre agrafeuse

continue à présenter des problèmes de

fonctionnement.

ENTRETIEN

A

VERTISSEMENT! Lorsque vous travaillez sur des

ARRÊT

PIÈCES DE RECHANGE

• Il est recommandé d’utiliser les pièces de rechange

PROCÉDURE D'INSTALLATION DE JOINTS

D'ÉTANCHÉITÉ

• Lorsque vous réparez une agrafeuse, assurez-vous

outils pneumatiques, prenez connaissance des

avertissements contenus dans ce manuel et

prenez grand soin lors de l'évaluation d'outils

en panne.

BostitchMD. N'employez pas des pièces modifiées

ou des pièces qui n'offriront pas une performance

équivalente à celle du matériel d'origine.

que les pièces internes sont propres et lubrifiées.

Utilisez le produit Parker O-LUBE ou un équivalent sur

tous les joints toriques. Enduisez chaque joint torique

d'un produit de type O-LUBE avant de l'installer. Huilez

légèrement toutes les surfaces mobiles et pivots.

Suivant le remontage, déposez quelques gouttes

d'huile pour outils pneumatiques Bostitch dans le

raccord de conduite d'air avant de la raccorder.

PRESSION ET VOLUME D'ALIMENTATION

D'AIR

• Le volume d'air est aussi important que la pression

d'air. Le volume d'air fourni à l'agrafeuse peut

être inadéquat en raison de raccords et de

conduites sous-dimensionnés, ou de la présence

de saleté et d'eau dans le système. Un débit d'air

restreint empêchera l'agrafeuse de recevoir un

volume d'air adéquat même si la pression d'air

affichée est élevée. Il en résultera une lenteur de

fonctionnement, des défauts d'alimentation ou une

réduction de la puissance de propulsion.

Avant d'évaluer les problèmes d'agrafeuse liés

à ces symptômes, inspectez l'alimentation d'air

de l'agrafeuse à la source pour la présence de

raccords restrictifs, de raccords pivotants, de points

bas contenant de l'eau et tout autre élément qui

pourrait entraver l'acheminement du volume d'air

nécessaire vers l'agrafeuse.

PAGE 17 OF 19 0421 IH -3532

Page 18

SPÉCIFICATIONS DE L'AGRAFEUSE

SPÉCIFICATIONS

RÉF. ULINE RÉF. DE FABRICATION LONGUEUR HAUTEUR LARGEUR POIDS

H-3532 DS -3219 320mm (12,6po) 225mm (8,86po) 115mm (4,5po)

H-3534 DS-3522 320mm (12,6po) 225mm (8,86po) 115mm (4,5po)

2,45kg (5,45lbs.)

2,45kg (5,45lbs.)

SPÉCIFICATIONS DES AGRAFES

AGRAFEUSE RÉF. ULINE

S-18710 24mm (5/8po) B58C

H-3532

S -18711 29mm (3/4po) B34C

S-18715 24mm (5/8po) S W 7437

H-3534

S-18716 29mm (3/4po) SW7437

LONG. DES

PATTES

SÉRIE D'AGRAFES DIM. DU FIL

1,88x0,94mm

(0,074x0,37po)

1,88x0,94mm

(0,074x0,37po)

1,88x0,94mm

(0,074x0,37po)

1,88x0,94mm

(0,074x0,37po)

LARG. DE LA

COURONNE

32mm

(1⁄po)

32mm

(1⁄po)

35mm

(1⁄po)

35mm

(1⁄po)

TABLEAU DES PIÈCES/AGRAFES

MODÈLE

FERMEURS

ENTRETOISES

LONGUEURS

D'AGRAFE

A01900601(GAUCHE) A01900501(DROIT) A01200601(DROIT) A0120 0601(GAUCHE)

A02300801 A02300801 — —

16mm (5/8po) 19mm (3/4po) 19mm (3/4po) 20mm (7/8po)

H-3532/H-3534 H-3534

STANDARD/PLAT PROFOND

CAPACITÉ

AGRAFES

120

120

GAMME D'AGRAFES

15 à 19mm

(5/8 à 3/4po)

15 à 19mm

(5/8 à 3/4po)

15 à 19mm

(5/8 à 3/4po)

15 à 19mm

(5/8 à 3/4po)

POSITION DU

SÉLECTEUR

RACCORD D'AIR DE L'AGRAFEUSE

Cette agrafeuse utilise une fiche de connexion à

débit continu, à filets 11 mm (1/4po) N.P.T. Le diamètre

minimum intérieur doit être 5mm (0,300po). Le raccord

doit pouvoir évacuer la pression d'air de l'agrafeuse

lorsque déconnecté de l'alimentation en air.

PRESSION DE SERVICE

La pression de service de l'agrafeuse est de 5 à 7 kg/

cm2 (70 à 100 lb/po²). Pour la meilleure performance

des agrafes, sélectionnez une pression de service

comprise dans cette plage.

MISE EN GARDE: Ne dépassez pas la pression

de service recommandée.

DÉBIT D'AIR

Le modèle H-3532/H-3534 exige un débit d'air de

0,113mètre cube par minute (4,0pieds cubes par

minute) pour opérer à la vitesse de 100 agrafes par

minute à 5,66kg/cm2 (80lb/po²). Utilisez la vitesse réelle

à laquelle l'agrafeuse sera utilisée pour déterminer

le débit d'air requis. Par exemple, si vous utilisez en

moyenne 50 agrafes par minute, vous n'avez besoin

que de 50% des 0,113mètre cube par minute

(4,0pieds cubes par minute) nécessaires pour la

propulsion de 100 agrafes par minute.

PAGE 18 OF 19 0421 IH-3532

Page 19

DÉPANNAGE

1

0

uline.ca

PROBLÈME DE FONCTIONNEMENT CAUSES RECOMMANDATIONS

Fuite d'air dans le boîtier de la soupape dedétente

Fuite d'air de la tige de soupape de la détente

Fuite d'air du cadre/tige de piston

Fuite d'air du cadre/couvercle

Absence de puissance; lenteur d'activation

Saut d'agrafes,

alimentation intermittente

Joint torique coupé ou fissuré

Joints toriques/bagues d'étanchéité

coupés ou fissurés

Joint torique Remplacez le joint torique

Joint torique endommagé

Vis de couvercle desserrées

Piston brisé

Outil asséché, manque de lubrification

Joints toriques/bagues d'étanchéité

coupés ou fissurés

Échappement obstrué

Usure/fuites de l'ensemble de détente

Accumulation de saleté/goudron sur la

lame de poussée

Pression d'air trop basse

Levier de cyclage usé ou mal réglé

Goudron/saleté dans le guide de lame

de poussée

Restriction d'air/débit d'air inadéquat

dans le raccord et la fiche à

dégagement rapide

Joint torique de piston/piston usé

Outil asséché, manque de lubrification

Basse pression d'air

Vis de magasin desserrées

Fuite du joint d'étanchéité de couvercle

de tête

Joint torique de soupape de détente

coupé/usé

Lame de poussée brisée, ébréchée

Enclume/pousseur usé

Ressort de pousseur brisé

Plieur usé

Magasin desséché/sale

Remplacez le joint torique

Remplacez la soupape de la détente

Remplacez le joint torique

Serrez et revérifiez

Remplacez le piston

Utilisez l'huile pour outils pneumatiques

Bostitch

Remplacez les joints toriques/bagues

d'étanchéité

Vérifiez la buté et le ressort de soupape

de tête

Remplacez l'ensemble de détente

Démontez le nez/la lame de poussée

pour nettoyage

Vérifiez le matériel d'alimentation en air

Réglez l'écrou de réglage ou remplacez

le levier de réglage

Démontez et nettoyez le nez et la lame

de poussée

Remplacez les raccords à dégagement

rapide

Remplacez le joint torique/piston

Utilisez l'huile pour outils pneumatiques

Bostitch

Vérifiez le système d'alimentation en air

vers l'outil

Serrez toutes les vis

Serrez le vis/remplacez le joint

d'étanchéité

Remplacez le joint torique

Remplacez la lame de poussée (vérifiez

le joint torique du piston)

Remplacez l'enclume/pousseur

Remplacez le ressort de pousseur

Remplacez le plieur

Nettoyez/lubrifiez avec de l'huile pour

outils pneumatiques Bostitch

Les agrafes se coincent dans l'agrafeuse

Guide de lame de poussée usé

Agrafes de taille incorrecte

Agrafes courbées

Vis de magasin desserrées

Lame de poussée brisée, ébréchée

Plieur usé

Enclume/pousseur usé

Remplacez le nez/contrôlez la porte

Utilisez uniquement des agrafes

recommandées

Cessez d'utiliser ces agrafes

Serrez toutes les vis

Remplacez la lame de poussée

Remplacez le plieur

Remplacez le pousseur

-800-295-551

PAGE 19 OF 19 0421 IH-3532

Loading...

Loading...