Para Español, vea páginas 6-10.

Pour le français, consulter les pages 11-15.

π H-35, H-669

BETTER PACK MANUAL

333 PLUS KRAFT TAPE

DISPENSER

1-800-295-5510

uline.com

IMPORTANT! Read this manual thoroughly

and familiarize yourself with ALL controls

and operating features. Keep this manual

for future reference and maintenance.

Unpacking: Check the machine for

damage. If damage is found, return to

Uline.

TECHNICAL DATA

Dimensions of Machine: 19⁄ x 9½ x 12⁄"

Water Bottle Capacity: 44 oz.

Tape Width: 1⁄ to 3"

Maximum Roll Size: Up to 600' of tape

Up to 7½" diameter roll

Tape Lengths Dispensed: Up to 30" in one stroke

(repeat pulls provide

unlimited lengths)

Shipping Weight: 22 lbs.

Brushes: 2

Power Requirements:

For H-35: None (Manual Dispenser)

For H-669: 75 Watts, 115 V

NOTE: All specifications subject to

change without notice.

PAGE 1 OF 15 0614 IH-35

GENERAL INFORMATION

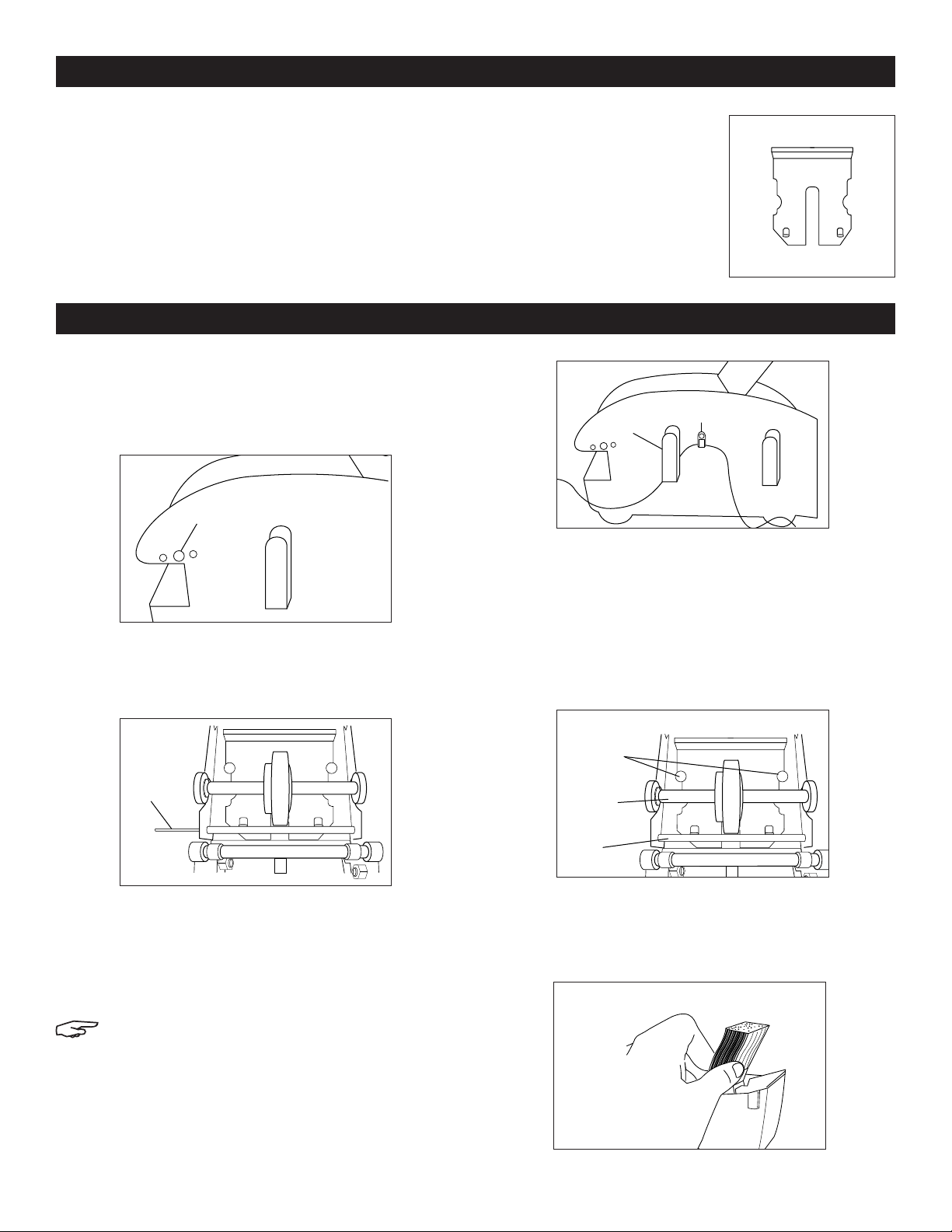

BEFORE USING THE MACHINE

After removing the machine from the carton, check the

following items before storing the shipping cartons:

• Brush Tank and two Moistening Brushes: These are

packed inside the rear of the machine.

• Plastic Water Bottle: This is packed on the side of the

dispenser.

HEATER SETUP (FOR H-669 ONLY)

1. Locate the heater kit box.

2. Remove retaining ring. (See Figure 2)

Figure 2

Retaining

Ring

• Upper Tape Plate: This is

Figure 1

held in position by packing

material, but may have

become dislodged in

shipping. Remove tape, etc.

before using the machine.

(See Figure 1)

SETUP

Figure 4

Bottle

Bracket

SETUP

1. If the upper tape plate has been dislodged in

shipping, replace as follows:

Cord

Clamp

3. Remove shaft and gold rollers and set aside.

4. Install heater shaft with silver rollers from spare parts

bag. (See Figure 3)

Figure 3

Shaft

5. Use replacement retaining ring provided to hold the

shaft in place.

6. Direct the heater cord under the bottle bracket. Place

cord clamp on heater cord and, using screw and nut

provided, fasten to existing hole. (See Figure 4)

NOTE: Make sure there is enough slack in the

cord near the heater so the heater assembly

can pivot freely up and down.

With the slot towards the front of the machine, slide feed

wheel shaft under from rear until the cut-out portions

are over the retaining buttons. Allow the plate to slide in

place so that the front end of the plate is under the rod,

and the rear portion is under the buttons. (See Figure 5)

Figure 5

Retaining

Buttons

Feed

Wheel

Shaft

Rod

2. Wash out the moistening brushes in soap or mild

detergent and place both brushes into the tank so

the angle on the brushes slopes toward the rear of

the tank. (See Figure 6)

Figure 6

PAGE 2 OF 15 0614 IH-35

SETUP CONTINUED

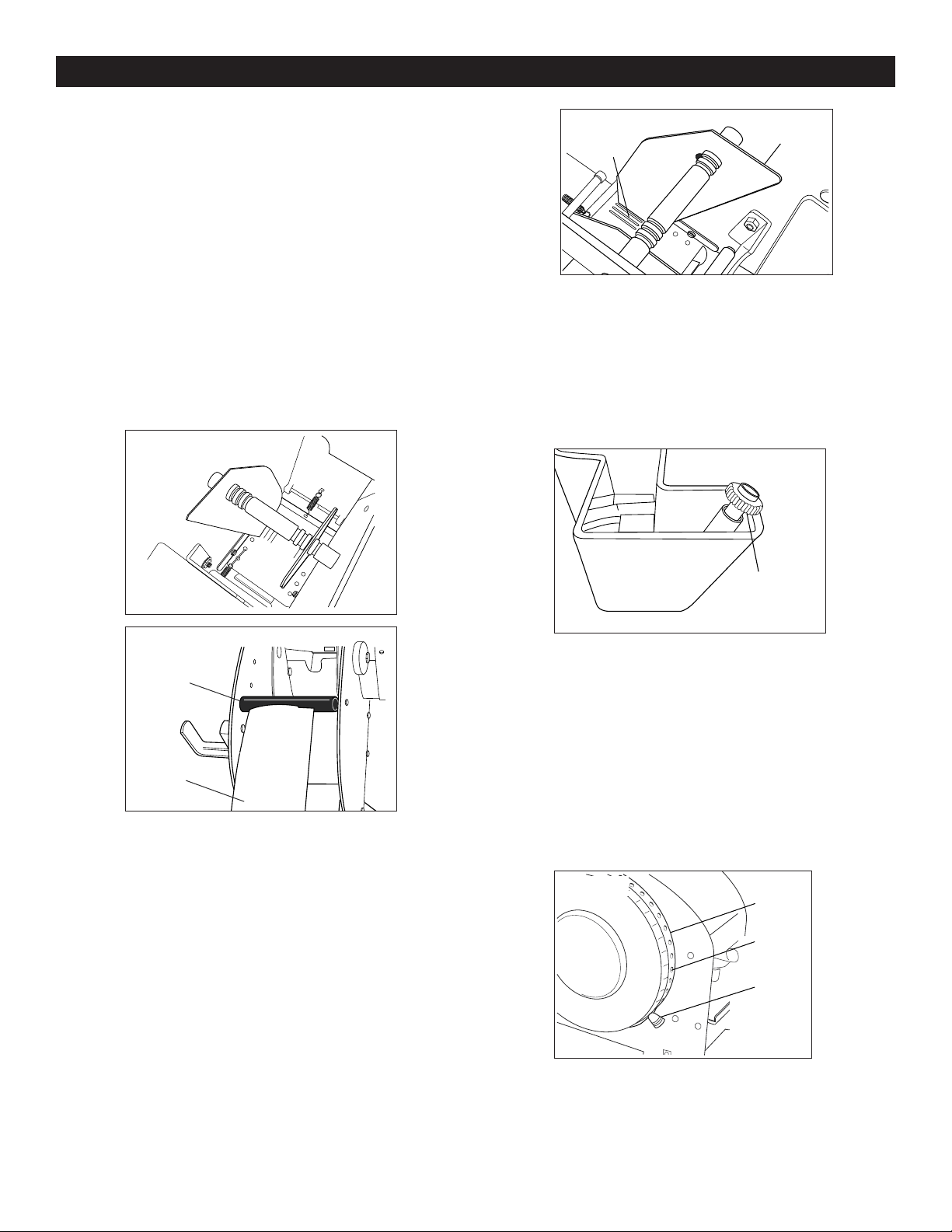

3. Insert the tank into the opening on the front of the

machine, making sure the tank is behind the upward

lip on the tank shelf.

4. Fill the bottle with water and place in the bottle

holder so that the spout of the bottle is in the tank.

5. Adjust the roll guides for proper width of tape.

6. To load tape, take the roll of tape and peel off about

18 inches. Place the roll of tape in the basket so that

the strip of tape unwinds off the rear of the roll as

the leading end is brought towards the front of the

machine with the gummed side down. Thread the

tape over the black roller at the upper rear and slide

leading edge forward under the upper tape plate

and feed wheel. Close front and rear covers.

(See Figures 7a and 7b)

Figure 7a

Figure 8

Roll Guide

Slots

WATER LEVEL ADJUSTMENT

The amount of water required for proper moistening

of different grades of tape will differ. Heavier glues

or reinforced tapes will normally require higher levels

of water. Water level is controlled by the water level

adjustment screw located in the projecting portion of the

water tank. (See Figure 9)

Figure 9

Figure 7b

Black Roller

Tape

ADJUSTMENTS

TAPE WIDTH

The adjustable roll guides in the tape basket should be

properly set for the width of tape being dispensed. The

roll of tape should be centered between the frames

by threading the tape loosely between the roll guides,

which engage in slots in the basket and roll guide

separator.

To set the roll guides in position, lift them out of the slots in

the basket and tie rod. Slide to the desired position and

drop guides into slots in the bottom of the basket.

(See Figure 8)

Water Level

Adjustment

Screw

To raise the water level, turn the screw counterclockwise.

To decrease the water level, turn the screw clockwise.

REPEAT LENGTH STOP

The Better Pack 333 Plus is equipped with a feed stop. To

set for desired length, pull outwardly on the feed stop

until the pin disengages the hole in the drum skirt. Then

slide the feed stop assembly until the length desired

is set on the scale just above the feed stop assembly.

Release the knob, being sure the pin on the feed stop

engages with the proper hole in the skirt. (See Figure 10)

Figure 10

10

12

14

16

17

18

19

20

21

22

23

Drum

Skirt

Hole

Feed

Stop

PAGE 3 OF 15 0614 IH-35

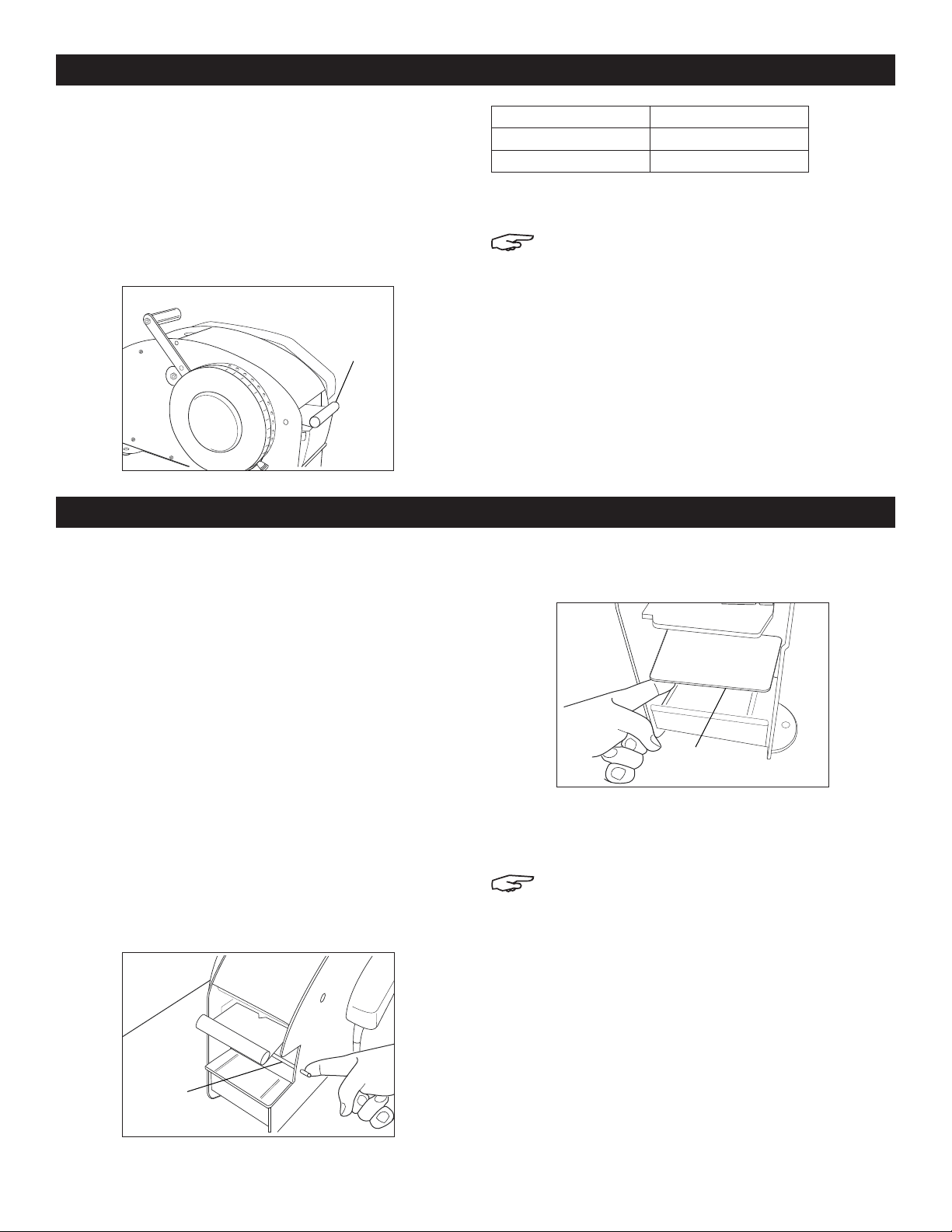

SETUP CONTINUED

CRANK HANDLE

If desired, the crank handle can be reversed.

PRESSURE PLATE WEIGHTS

The pressure plate, which rests on top of the brushes,

has removable weights. (See Figure 11) The number of

weights can be varied to suit the tape being dispensed.

Heavyweight tapes require more weight inserts than lighter

tapes. The suggested number of weights is as follows:

Fig ur e 11

Weights

10

12

14

16

17

18

19

20

21

22

23

MAINTENANCE AND CARE

MAINTENANCE

The best way to ensure long and carefree service

from your Better Pack 333 Plus is to KEEP IT CLEAN.

Tape dust, adhesive accumulation and other foreign

matters are harmful as they get into the working parts

of the machine. Likewise, be sure to wash the brushes

thoroughly at least once a week to ensure perfect

moistening, being careful to replace them with the

lower bevel to the back of the machine.

35 lb. Kraft Tape 0 to 1 Slug

60 lb. Kraft Tape 1 to 2 Slugs

Reinforced Tape 2 to 3 Slugs

The weights can be added or removed by pushing

them in or out from each side.

NOTE: If the machine consistently jams, there

is too much weight on the pressure plate and

some should be removed.

c. Reach inside the machine where tank was

removed, pull blade assembly down and swing

out to cleaning position. (See Figure 13)

TO CLEAN BLADE

Where reinforced tapes are used, it may be necessary

to periodically clean accumulation of laminate from the

cutting blade.

To clean the blade, follow these simple steps:

a. Remove water bottle and water tank assemblies.

b. Depress rocker stop rod protruding from the right

side of the machine with right hand and keep

it in this position until the blade assembly has

been released. (See Figure 12)

Figure 12

d. To clean blade: wipe off with suitable solvent.

When adhesive is removed, wipe with lightly

oiled cloth.

NOTE: DO NOT SCRAPE WITH HARD OBJECTS

as resulting scratches will quickly

accumulate adhesive.

e. Reinsert the blade to the cutting position by

depressing the rocker stop rod. Tip the blade

up into cutting position and push upward so the

blade will come between the stationary blade

rollers. Release rocker stop rod.

f. Try feeding and cutting tape to check if parts

are in proper position.

Rocker

Stop

PAGE 4 OF 15 0614 IH-35

g. Install tank and water bottle.

Blade

Assembly

Figure 13

SAFETY PRECAUTIONS

MUST READ BEFORE SERVICING EQUIPMENT

NOTE: This machine is designed for sealing

cartons with water-activated tape. Any

other use will void all warranties and any

responsibility or liability of Uline.

CAUTION! Read all Safety Precautions and

Operating Instructions before using this

machine.

CAUTION! Any operator of this machine must

be fully trained in its operation and safety.

WARNING! Keep the machine away from

children and from personnel who are not

authorized or adequately instructed in the

use of it.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

PAGE 5 OF 15 0614 IH-35

uline.com

Loading...

Loading...