Page 1

Para Español, vea páginas 10-20.

Pour le français, consulter les pages 21-29.

H-3071

NAIL GUN

SAFETY INSTRUCTIONS

WARNING! EYE PROTECTION which conforms to

ANSI specifications and provides protection

against flying particles both from the FRONT

and SIDE should ALWAYS be worn by the

operator and others in the work area when

connecting to air supply, loading, operating

or servicing this tool. Eye protection is required

to guard against flying fasteners and debris

which could cause severe eye injury.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements

of the American National Standards Institute,

ANSI Z87.1, and provide both frontal and side

protection.

NOTE: Non-side shielded spectacles and

face shields alone do not provide adequate

protection.

CAUTION: Additional safety protection will be

required in some environments. For example,

the working area may include exposure to

noise level which can lead to hearing damage.

The employer and user must ensure that any

necessary hearing protection is provided and

used by the operator and others in the work

area. Some environments will require the use

of head protection equipment. When required,

the employer and user must ensure that head

protection conforming to ANSI Z89.1 is used.

1-800 -295- 5510

uline.com

BOSTITCH

INSTRUCTIONS

AIR SUPPLY AND CONNECTIONS

WARNING! Do not use oxygen, combustible

gases or bottled gases as a power source for

this tool, as tool may explode, possibly causing

injury.

WARNING! Do not use supply sources which

can potentially exceed 200 psig as tool may

burst, possibly causing injury.

WARNING! The connector on the tool must not

hold pressure when air supply is disconnected.

If a wrong fitting is used, the tool can remain

charged with air after disconnecting and thus

will be able to drive a fastener even after the

air line is disconnected, possibly causing injury.

WARNING! Do not pull trigger or depress

contact arm while connected to the air supply

as the tool may cycle, possibly causing injury.

WARNING! Always disconnect air supply:

1) Before making adjustments; 2) When

servicing the tool; 3) When clearing a jam;

4) When tool is not in use; 5) When moving to

a different work area, as accidental actuation

may occur, possibly causing injury.

LOADING TOOL

WARNING! When loading tool: 1) Never place a

hand or any part of body in fastener discharge

area of tool; 2) Never point tool at anyone;

3) Do not pull the trigger or depress the trip

as accidental actuation may occur, possibly

causing injury.

PAGE 1 OF 29 0421 IH-3071

Page 2

INSTRUCTIONS CONTINUED

OPERATION

WARNING! Always handle the tool with care:

1) Never engage in horseplay; 2) Never pull

the trigger unless nose is directed toward the

work; 3) Keep others a safe distance from the

tool while tool is in operation as accidental

actuation may occur, possibly causing injury.

WARNING! The operator must not hold the

trigger pulled on contact arm tools except

during fastening operation as serious injury could

result if the trip accidentally contacted someone

or something, causing the tool to cycle.

WARNING! Keep hands and body away from

the discharge area of the tool. A contact arm

tool may bounce from the recoil of driving a

fastener and an unwanted second fastener

may be driven, possibly causing injury.

WARNING! Check operation of the contact arm

mechanism frequently. Do not use the tool if

the arm is not working correctly as accidental

driving of a fastener may result. Do not interfere

with the proper operation of the contact arm

mechanism.

WARNING! Do not drive fasteners on top of

other fasteners or with the tool at an overly

steep angle as this may cause deflection of

fasteners which could cause injury.

WARNING! Do not drive fasteners close to the

edge of the work piece as the wood may split,

allowing the fastener to be deflected, possibly

causing injury.

WARNING! This nailer produces SPARKS

during operation. NEVER use the nailer near

flammable substances, gases or vapors

including lacquer, paint, benzene, thinner,

gasoline, adhesives, mastics, glues or any

other material that is -- or the vapors, fumes

or by products of which are -- flammable,

combustible or explosive. Using the nailer

in any such environment could cause an

EXPLOSION resulting in personal injury or death

to user and bystanders.

WARNING! Never use rafter hook to hang tool

from body, clothing or belt.

MAINTAINING THE TOOL

WARNING! When working on air tools note the

warnings in this manual and use extra care

when evaluating problem tools.

TOOL SPECIFICATIONS

ALL SCREWS AND NUTS ARE METRIC.

MODEL TOOL ACTUATION LENGTH. HEIGHT WIDTH WEIGHT

N89C-1 Contact Trip

(with sequential trip option)

FASTENER SPECIFICATIONS

The N89C tools uses wire collated coil nails in lengths

of 2" to 3½" (50 - 90mm) with shank diameters of .099" -

.131" (2.5 - 3.3mm)

TOOL AIR FITTING

This tool uses a free-flow connector plug, 1/4" N.P.T. The

minimum inside diameter should be .275" (7mm). The

fitting must be capable of discharging tool air pressure

when disconnected from the air supply.

12¼" (311 mm) 14" (355 mm) 5¼" (133.4mm) 8.2 lb (3.7 kg)

OPERATING PRESSURE

70 to 120 psig (4.8 to 8.3 kg/cm2). Select the operating

pressure within this range for best fastener performance.

WARNING! Do not exceed the recommended

operating pressure.

AIR CONSUMPTION

The N89C requires 8.23 cubic feet per minute (233 liters

per minute) of free air to operate at the rate of 100 nails

per minute, at 80 p.s.i. (5.6 kg/cm2). Take the actual rate at

which the tool will be run to determine the amount of air

required. For instance, if your fastener usage averages 50

nails per minute, you need 50% of the 8.23 c.f.m. (233 liters

per

minute) which is required to operate the tool at 100

nails per minute.

PAGE 2 OF 29 0421 IH-3071

Page 3

INSTRUCTIONS CONTINUED

MODES OF OPERATION

BOSTITCH OFFERS TWO MODES OF OPERATION FOR

THIS SERIES TOOL.

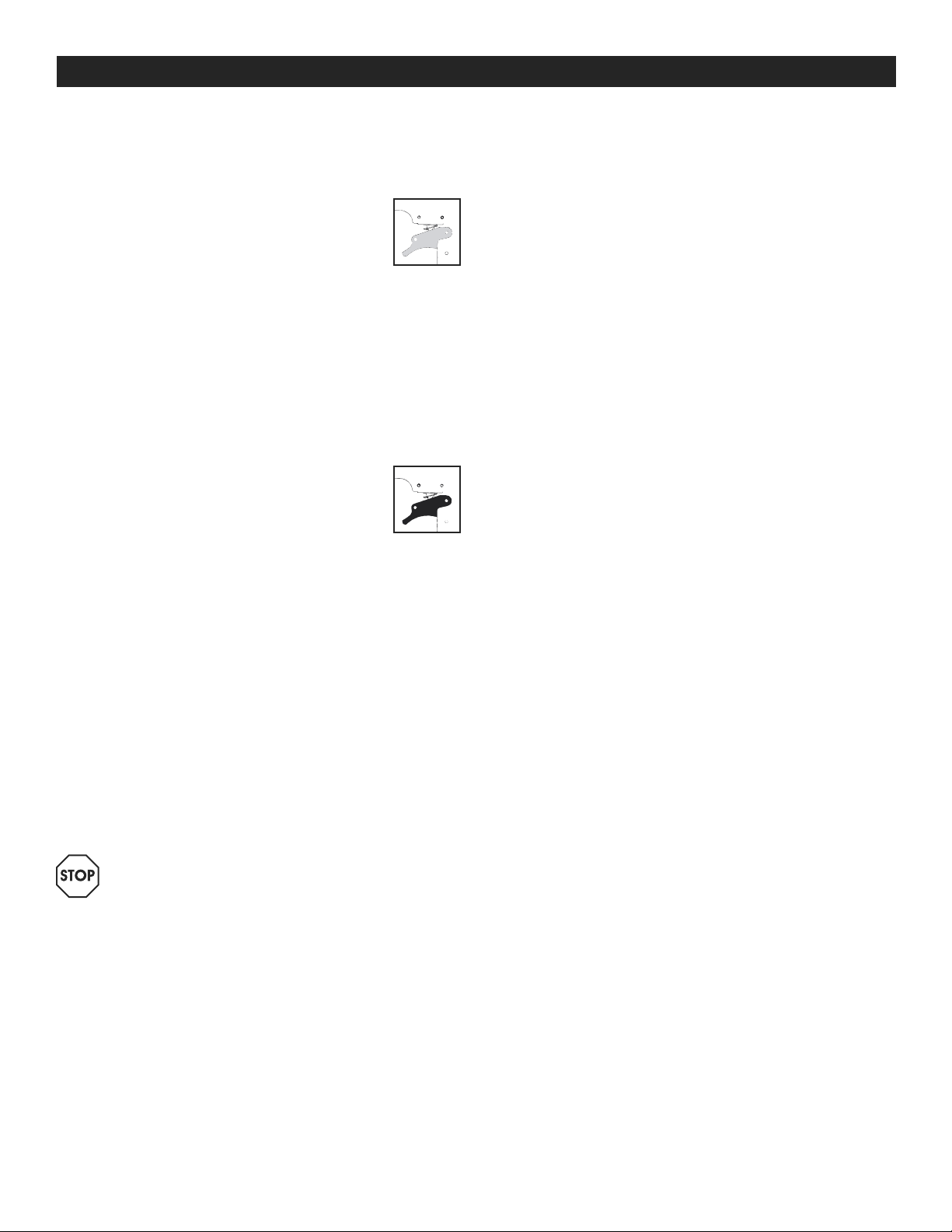

SEQUENTIAL TRIP (GRAY TRIGGER)

The Sequential Trip requires the operator

to hold the tool against the work surface

before pulling the trigger. This makes

accurate fastener placement easier on framing, toe

nailing and crating applications. The Sequential

Trip allows exact fastener placement without the

possibility of driving a second fastener on recoil, as

described under "Contact Trip". The Sequential Trip

Tool has a positive safety advantage because it will

not accidentally drive a second fastener if the tool is

contacted against the work – or anything else – while

the operator is holding the trigger pulled.

CONTACT TRIP (BLACK TRIGGER)

The common operating procedure on

Contact Trip tools is for the operator to

contact the work surface to actuate the trip

mechanism while keeping the trigger pulled, thus

driving a fastener each time the work is contacted.

This will allow rapid fastener placement on many jobs

such as sheathing, decking and pallet assembly. All

pneumatic tools are subject to recoil when driving

fasteners. The tool may bounce releasing the trip and,

if unintentionally allowed to, re-contact the work surface

with the trigger still actuated (finger still holding trigger

pulled). An unwanted second fastener will be driven.

MODEL IDENTIFICATION

Refer to Operation Instructions on page 5 before

proceeding to use this tool.

AIR SUPPLY AND CONNECTIONS

WARNING! Do not use oxygen,

gases or bottled gases as a power source for this

tool as tool may explode, possibly causing injury.

FITTINGS

Install a male plug on the tool which is free flowing

and which will release air pressure from the tool when

disconnected from the supply source.

HOSES

Air hoses should have a minimum of 150 psi (10.6 kg/

cm2) working pressure rating or 150 percent of the maximum pressure that could be produced in the air system.

The supply hose should contain a fitting that will provide

"quick disconnecting" from the male plug on the tool.

combustible

SUPPLY SOURCE

Use only clean regulated compressed air as a power

source for this tool. NEVER USE OXYGEN, COMBUSTIBLE

GASES OR BOTTLED GASES AS A POWER SOURCE FOR THIS

TOOL AS TOOL MAY EXPLODE.

REGULATOR

A pressure regulator with an operating pressure of

0 - 125 psi (0 - 8.79 kg/cm2) is required to control the

operating pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially

exceed 200 psi (14 kg/cm2) as tool may fracture or burst,

possibly causing injury.

OPERATING PRESSURE

Do not exceed recommended maximum operating

pressure as tool wear will be greatly increased. The air

supply must be capable of maintaining the operating

pressure at the tool. Pressure drops in the air supply

can reduce the tool's driving power. Refer to "TOOL

SPECIFICATIONS" for setting the correct operating

pressure for the tool.

FILTER

Dirt and water in the air supply are major causes of

wear in pneumatic tools. A filter will help to get the

best performance and minimum wear from the tool.

The filter must have adequate flow capacity for the

specific installation. The filter has to be kept clean to

be effective in providing clean compressed air to the

tool. Consult the manufacturer's instructions on proper

maintenance of your filter. A dirty and clogged filter

will cause a pressure drop which will reduce the tool's

performance.

LUBRICATION

Frequent, but not excessive, lubrication is required

for best performance. Oil added through the air line

connection will lubricate the internal parts. Use BOSTITCH

air tool lubricant (included), Mobil Velocite #10 or

equivalent. Do not use detergent oil or additives as

these lubricants will cause accelerated wear to the

seals and bumpers in the tool, resulting in poor tool

performance and frequent tool maintenance.

If no air line lubricator is used, add oil during use into

the air fitting on the tool once or twice a day. Only a

few drops of oil at a time is necessary. Too much oil will

only collect inside the tool and will be noticeable in the

exhaust cycle.

PAGE 3 OF 29 0421 IH-3071

Page 4

INSTRUCTIONS CONTINUED

LUBRICATION CONTINUED

COLD WEATHER OPERATION

For cold weather operation near and below freezing,

the moisture in the air line may freeze and prevent tool

operation. We recommend the use of BOSTITCH winter

formula air tool lubricant (included) or permanent

antifreeze (ethylene glycol) as a cold weather lubricant.

CAUTION: Do not store tools in a cold weather

environment in order to prevent frost or ice

formation on the tool's operating valves and

mechanisms that could cause tool failure.

NOTE: Some commercial air line drying liquids

are harmful to O-rings and seals – do not

use these low temperature air dryers without

checking compatibility.

LOADING

CAUTION: EYE PROTECTION which conforms to

ANSI specifications and provides protection

against flying particles both from the FRONT

and SIDE should ALWAYS be worn by the

operator and others in the work area when

connecting to air supply, loading, operating

or servicing this tool. Eye protection is required

to guard against flying fasteners and debris

which could cause severe eye injury.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements

of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side

protection.

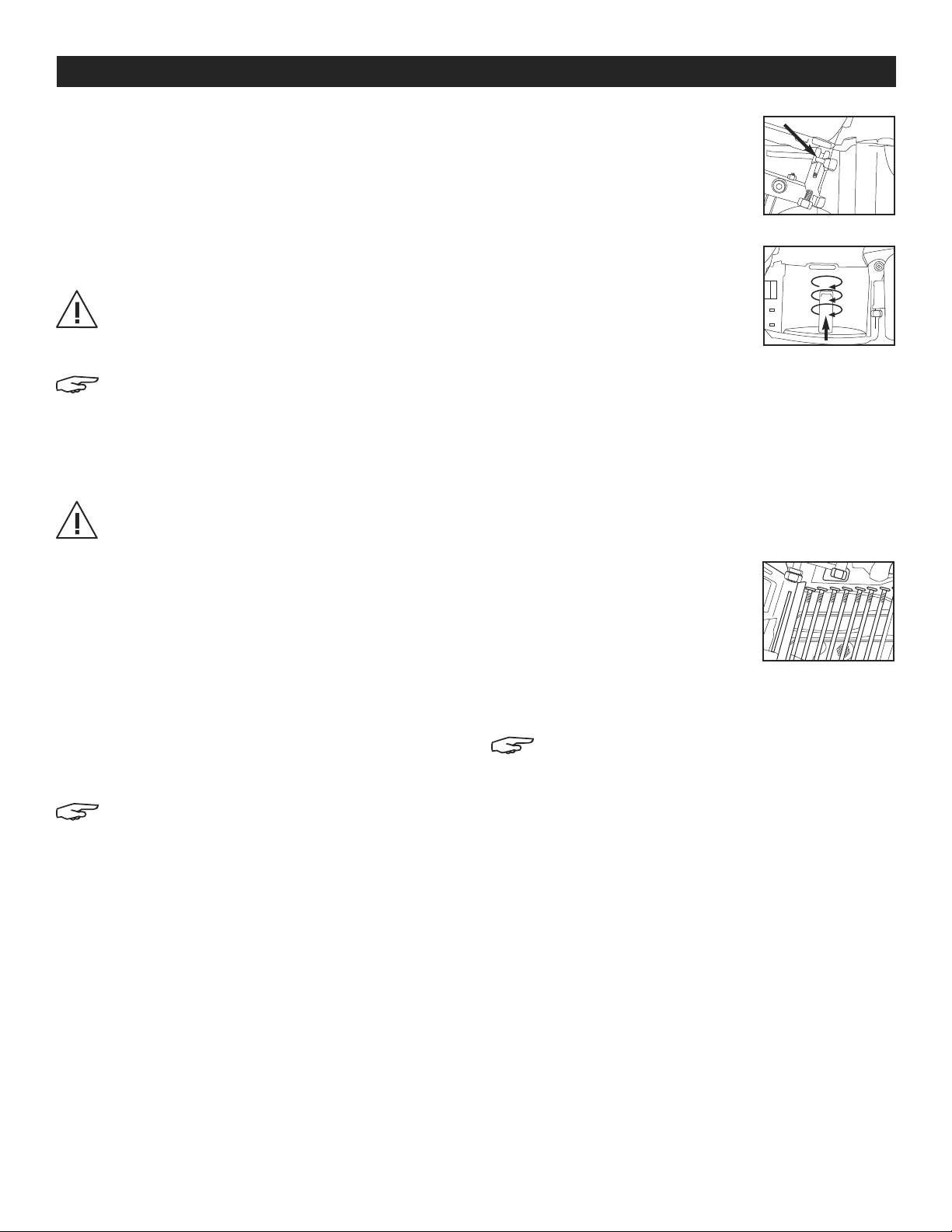

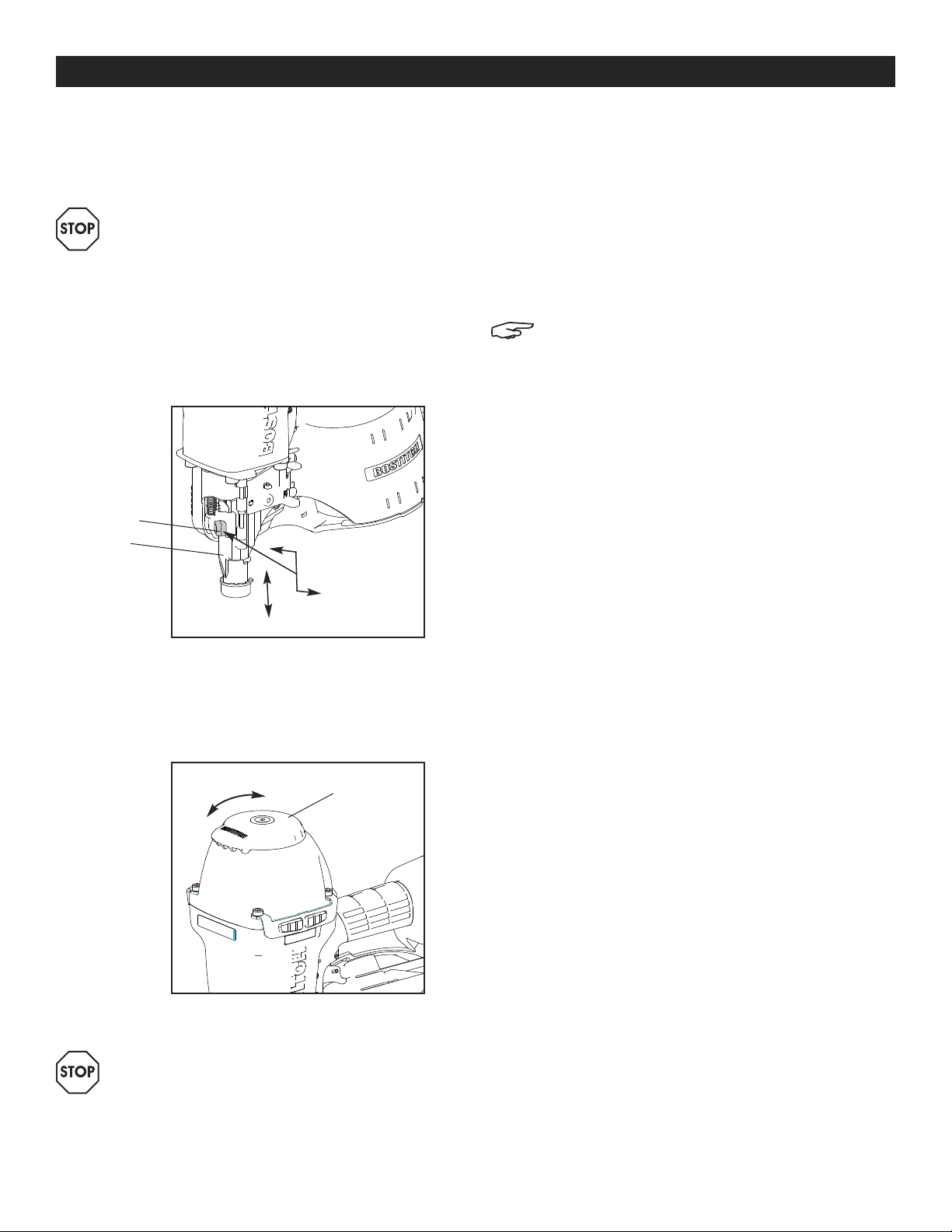

1. Open the canister: Pull down

door latch and swing door/

canister cover outward.

(See Figure 1)

2. Check Adjustment: The nailer

must be set for the length of

nail to be used. Nails will not

feed smoothly if the canister

is not correctly adjusted. The

canister contains an adjustable

nail platform on which the nail

coil rests. The nail platform can

be moved up and down to four

nail settings. To change setting

pull up on the post and twist to

the correct step. (See Figure 2)

PLATFORM SETTINGS

• 1st Step: 2" – 2½" (50 - 65mm) nails

• 2nd Step: 2¾" – 3" (70 - 75mm) nails

• 3rd Step: 3¼" – 3½" (80 - 90mm) nails

3. Load the coil of nails: Place

the coil of nails over the post

in the canister. Uncoil enough

nails to reach the feed pawl.

Place the first nail in front of the

front tooth on the feed pawl

in the driver channel. The nail

heads must be in the slot in the

nose. (See Figure 3)

NOTE: Use only nails recommended by

BOSTITCH for N89C series nailers or nails which

meet BOSTITCH specifications.

Figure 1

Figure 2

Figure 3

NOTE: Non-side shielded spectacles and

face shields alone do not provide adequate

protection.

TO PREVENT ACCIDENTAL INJURIES

• Never place a hand or any other part of the

body in nail discharge area of tool while the

air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed

at the work.

• Always handle the tool with care.

• Do not pull the trigger or depress the trip

mechanism while loading the tool.

PAGE 4 OF 29 0421 IH-3071

4. Swing cover closed.

5. Close the door: Check that latch engages.

(If it does not engage, check that the nail heads

are in the slot on the nose.)

FASTENER DEPTH CONTROL ADJUSTMENT

The Fastener Depth Control Adjustment feature on this

tool provides control of the nail drive depth from flush

with or just above the work surface to shallow or deep

countersink.

Page 5

INSTRUCTIONS CONTINUED

FASTENER DEPTH CONTROL ADJUSTMENT

CONTINUED

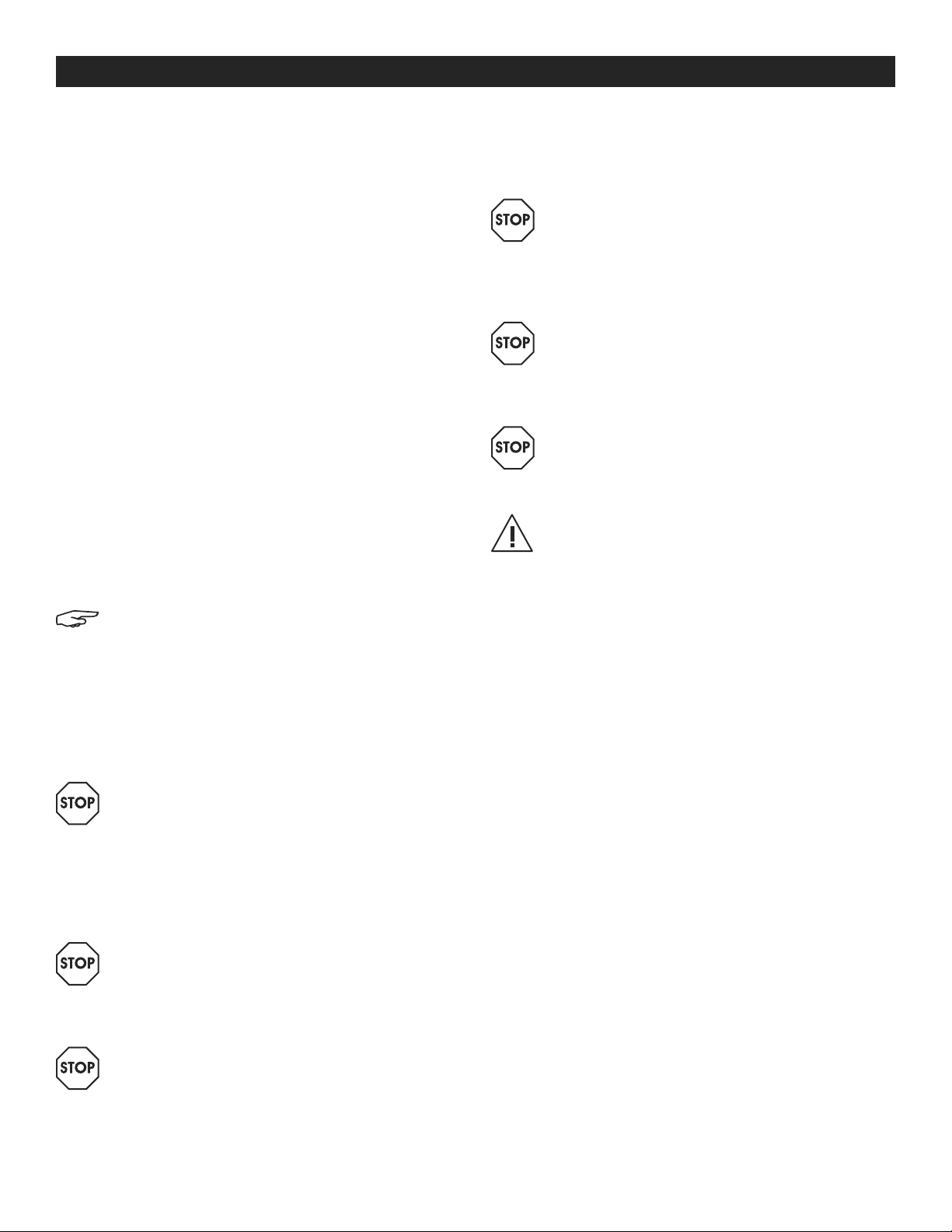

TO ADJUST THE FASTENER DEPTH CONTROL

WARNING! Disconnect tool from air supply

before attempting any parts disassembly and

before changing the work contacting element

adjustment.

1. Push in on locking button.

2. Adjust contact arm up to increase depth

of drive or down to decrease it.

3. Release locking button. (See Figure 1)

LOCKING BUTTON

CONTACT ARM

1. PUSH IN

connecting to air supply, loading, operating

or servicing this tool. Eye protection is required

to guard against flying fasteners and debris,

which could cause severe eye injury.

The employer and/or user must ensure that

proper eye protection is worn. Eye protection

equipment must conform to the requirements

of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side

protection.

NOTE: Non-side shielded spectacles and

face shields alone do not provide adequate

protection.

BEFORE HANDLING OR OPERATING THIS TOOL

I. READ AND UNDERSTAND THE WARNINGS

CONTAINED IN THIS MANUAL.

II. REFER TO "TOOL SPECIFICATIONS" IN THIS

MANUAL TO IDENTIFY THE OPERATING SYSTEM

ON YOUR TOOL.

There are two available operation modes on these

BOSTITCH pneumatic tools. They are:

3. RELEASE

Figure 1

2. ADJUST

DIRECTIONAL EXHAUST DEFLECTOR

The adjustable exhaust deflector can be rotated into

any desired position by hand without the use of any

tools. (See Figure 2)

Figure 2

EXHAUST DEFLECTOR

TOOL OPERATION

WARNING! EYE PROTECTION which conforms to

ANSI specifications and provides protection

against flying particles both from the FRONT

and SIDE should ALWAYS be worn by the

operator and others in the work area when

1. SEQUENTIAL TRIP OPERATION

2. CONTACT TRIP OPERATION

OPERATION

BOSTITCH offers two types of triggers for pneumatic tools:

Sequential Trip (gray trigger) and Contact Trip (black

trigger). Each trigger has specific advantages. You

should evaluate your particular construction project to

determine which trigger is best.

Tool only comes with the black 'Contact Trip' trigger.

The gray 'Sequential Trip' trigger needs to be ordered

separately.

1. SEQUENTIAL TRIP OPERATION (GRAY TRIGGER)

The Sequential Trip (gray trigger) gets its name from

the "sequence" required to drive a fastener. To drive a

fastener, the operator must first depress the "trip" FULLY

against the work surface and then pull the trigger. To

drive a second nail, the operator must lift the tool from

the work surface, release the trigger and then repeat

the above sequence.

a. The Sequential Trip (gray trigger) offers a positive

safety advantage since it will not accidentally

drive a fastener if the tool is bumped against any

surface or anybody while the operator is holding

the tool with the trigger pulled. Sequential Trip

needs to be ordered separately.

PAGE 5 OF 29 0421 IH-3071

Page 6

INSTRUCTIONS CONTINUED

TOOL OPERATION CONTINUED

b. The Sequential Trip (gray trigger) allows "place

nailing" without the possibility of driving a

second, unwanted fastener on recoil as

described below under "Contact Trip". Sequential

Trip needs to be ordered separately

2. CONTACT TRIP (CONVENTIONAL) OPERATION

(BLACK TRIGGER)

Your new BOSTITCH tool can be configured for use in

Contact Trip mode. To drive a nail, the "trip" and the

trigger must both be depressed. In Contact Trip tools,

the trigger may be depressed and held, and each

"contact" between the trip and the work surface will drive

a nail.

a. SINGLE FASTENER PLACEMENT (Place Nailing) –

First position the "trip" FULLY on the work surface

WITHOUT PULLING THE TRIGGER. Depress the "trip"

FULLY until the nose of the tool touches the work

surface and then pull the trigger to drive a nail.

Do not press the tool against the work surface

with extra force. Instead, allow the tool to recoil

off the work surface to avoid a second unwanted

fastener.

NOTE: Remove your finger from the trigger after

each operation.

b. RAPID FIRE OPERATION ("Bump" Nailing) –

hold the tool with the "trip" pointing towards but

not

touching the work surface. Pull the trigger

and then tap or "bump" the trip against the work

surface using a bouncing motion. Each depression

of the "trip" will cause a nail to be driven.

WARNING! The Contact Trip (black) will not

prevent a nail from being accidently driven

if the trigger is depressed and the "trip" is

bumped against any object or person. Never

hold or carry the tool with your finger on the

trigger. Only depress and hold trigger when

you intend to rapidly drive multiple nails and

the tool is pointed at the work surface.

WARNING! Never use contact trigger (black

trigger) with metal connector attachment.

Only use sequential trigger (grey trigger) with

metal connector attachment. Refer to trigger

conversion instruction included in the kit.

WARNING! When using conventional Contact

Trip for Place Nailing, the tool may bounce due

to recoil and if the tool is allowed to re-contact

the work surface while you are holding the

trigger pulled, a second unwanted nail will be

First,

driven. You should allow the tool to recoil far

enough to release the trip and avoid a second

cycle. Don't push the tool down extra hard; let

the tool do the work.

WARNING! The operator must not hold the

trigger pulled on contact trip tools, except

during fastening operation, as serious injury

could result if the trip accidentally contacted

someone or something, causing the tool to

cycle.

WARNING! Keep hands and body away from

the discharge area of the tool. A contact trip

tool may bounce from the recoil of driving a

fastener and an unwanted second fastener

may be driven, possibly causing injury.

WARNING! Never use rafter hook to hang tool

from body, clothing or belt.

TOOL OPERATION CHECK

CAUTION: Remove all fasteners from tool before

performing tool operation check.

1. SEQUENTIAL TRIP OPERATION

a. Press the contact trip against the work surface

without touching the trigger.

THE TOOL MUST NOT CYCLE.

b. Hold the tool off the work surface and pull the

trigger. THE TOOL MUST NOT CYCLE. Release the

trigger. The trigger must return to the trigger stop

on the frame.

c. Pull the trigger and press the contact trip against

the work surface.

THE TOOL MUST NOT CYCLE.

d. With finger off the trigger, press the contact trip

against the work surface. Pull the trigger.

THE TOOL MUST CYCLE.

2. CONTACT TRIP OPERATION

a. With finger off the trigger, press the contact trip

against the work surface.

THE TOOL MUST NOT CYCLE.

b. Hold the tool off the work surface and pull the

trigger. THE TOOL MUST NOT CYCLE.

c. With the tool off the work surface, pull the trigger.

Press the contact trip against the work surface.

THE TOOL MUST CYCLE.

d. Without touching the trigger, press the contact

trip against the work surface, then pull the trigger.

THE TOOL MUST CYCLE.

PAGE 6 OF 29 0421 IH-3071

Page 7

INSTRUCTIONS CONTINUED

TOOL OPERATION CHECK CONTINUED

IN ADDITION TO THE OTHER WARNINGS

CONTAINED IN THIS MANUAL OBSERVE THE

FOLLOWING FOR SAFE OPERATION

• Use the BOSTITCH pneumatic tool only for the

purpose for which it was designed.

• Never use this tool in a manner that could cause a

fastener to be directed toward the user or others in

the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle. Never carry the

tool by the air hose.

• Do not alter or modify this tool from the original

design or function without approval from BOSTITCH.

• Always be aware that misuse and improper handling

of this tool can cause injury to yourself and others.

• Never clamp or tape the trigger or contact trip in an

actuated position.

• Never leave a tool unattended with the air hose

attached.

• Do not operate this tool if it does not contain a

legible WARNING LABEL.

• Do not continue to use a tool that leaks air or does

not function properly. Contact ULINE Customer

Service at 1-800-295-5510 if your tool continues to

experience functional problems.

MAINTAINING THE PNEUMATIC TOOL

WARNING! When working on air tools, note the

warnings in this manual and use extra care

evaluating problem tools.

REPLACEMENT PARTS

BOSTITCH replacement parts are recommended. Do

not use modified parts or parts which will not give

equivalent performance to the original equipment.

ASSEMBLY PROCEDURE FOR SEALS

When repairing a tool, make sure the internal parts are

clean and lubricated. Use Parker O-LUBE or equivalent

on all O-rings. Coat each O-ring with O-LUBE before

assembling. Use a small amount of oil on all moving

surfaces and pivots. After reassembly add a few drops

of BOSTITCH Air Tool Lubricant through the air line fitting

before testing.

AIR SUPPLY PRESSURE AND VOLUME

Air volume is as important as air pressure. The air volume

supplied to the tool may be inadequate because of

undersize fittings and hoses or from the effects of dirt

and water in the system. Restricted air flow will prevent

the tool from receiving an adequate volume of air even

though the pressure reading is high. The results will be

slow operation, misfeeds or reduced driving power.

Before evaluating tool problems for these symptoms,

trace the air supply from the tool to the supply source

for restrictive connectors, swivel fittings, low points

containing water and anything else that would prevent

full volume flow of air to the tool.

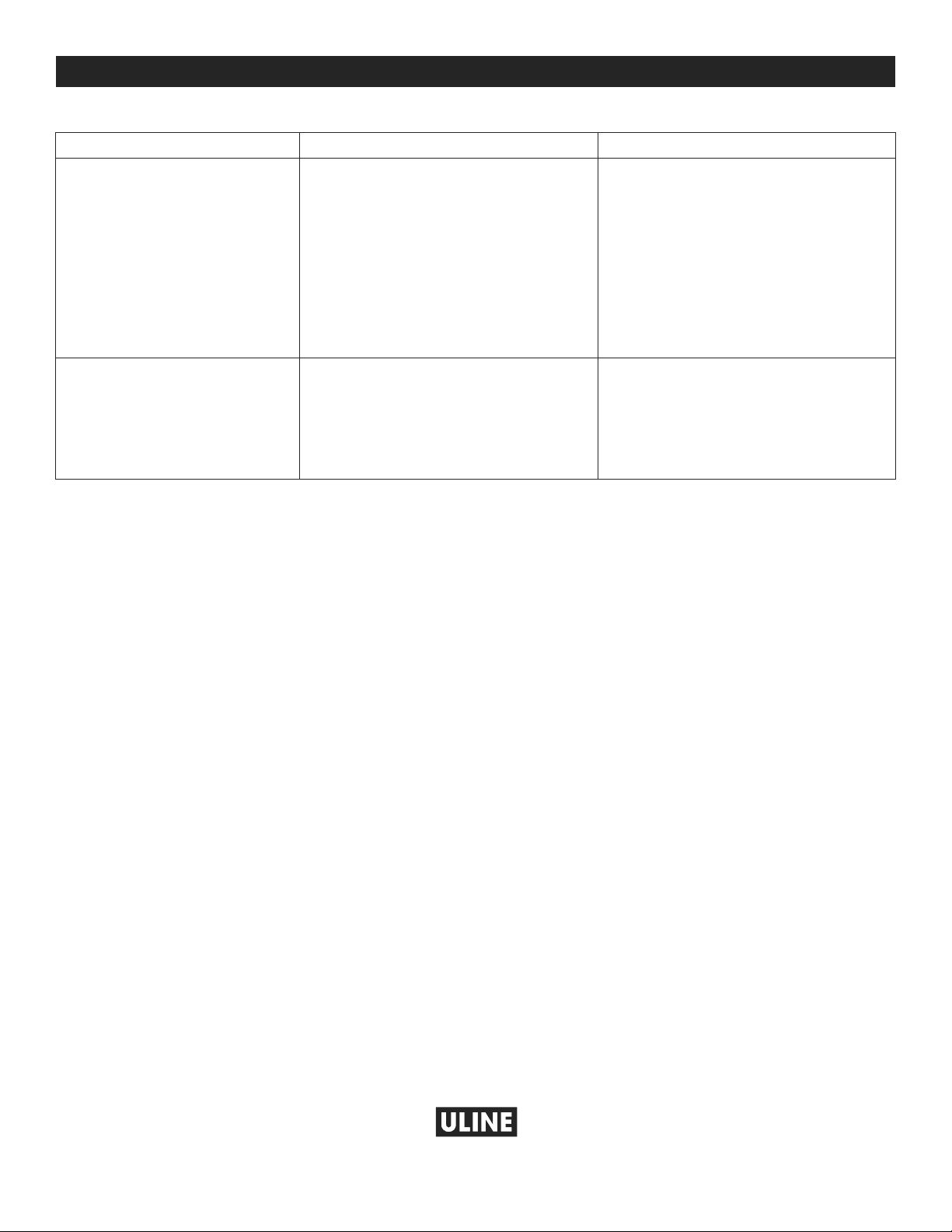

TROUBLESHOOTING

OPERATING ISSUE CAUSE CORRECTION

Trigger valve stem leaks air

Frame/nose leaks air

Frame/cap leaks air

PAGE 7 OF 29 0421 IH-3071

O-ring cut or cracked

O-ring/seals cut or cracked

Loose nose screws

O-ring or gasket is cut or cracked

Bumper cracked/worn

Damaged gasket or seal

Cracked/worn head valve bumper

Loose cap screws

Replace O-ring

Replace trigger valve assembly

Tighten and recheck

Replace O-ring or gasket

Replace bumper

Replace gasket or seal

Replace bumper

Tighten and recheck

Page 8

TROUBLESHOOTING CONTINUED

OPERATING ISSUE CAUSE CORRECTION

Failure to cycle

Lack of power; slow to cycle

Skipping fasteners;

intermittent feed

Air supply restriction

Tool dry, lack of lubrication

Worn head valve O-rings

Broken cylinder cap spring

Tool dry, lacks lubrication

Broken cylinder cap spring

O-rings/seals cut or cracked

Exhaust blocked

Trigger assembly worn/leaks

Dirt/tar buildup on driver

Cylinder sleeve not seated correctly

on bottom bumper

Head valve dry

Air pressure too low

Worn bumper

Tar/dirt in driver channel

Air restriction/inadequate air flow through

quick disconnect socket and plug

Worn piston O-ring

Tool dry, lacks lubrication

Damaged feed piston spring

Low air pressure

Loose canister nose screws

Fasteners too short for tool

Bent fasteners

Wrong size fasteners

Leaking head cap gasket

Trigger valve O-ring cut/worn

Broken/chipped driver

Dry/dirty magazine

Check air supply equipment

Use BOSTITCH Air Tool Lubricant

Replace O-rings

Replace cylinder cap spring

Use BOSTITCH Air Tool Lubricant

Replace cap spring

Replace O-rings/seals

Check bumper, head valve spring, muffler

Replace trigger assembly

Disassemble nose/driver to clean

Disassemble to correct

Disassemble/lubricate

Check air supply equipment

Replace bumper

Disassemble and clean nose and driver

Replace quick disconnect fittings

Replace O-ring, check driver

Use BOSTITCH Air Tool Lubricant

Replace spring

Check air supply system to tool

Tighten all screws

Use only recommended fasteners

Discontinue using these fasteners

Use only recommended fasteners

Tighten screws/replace gasket

Replace O-ring

Replace driver (check piston O-ring)

Clean/lubricate use BOSTITCH Air Tool Lubricant

Driver channel worn

Wrong size fasteners

Fasteners jam in tool

PAGE 8 OF 29 0421 IH-3071

Bent fasteners

Loose canister/nose screws

Broken/chipped driver

Replace nose/check door

Use only recommended fasteners

Discontinue using these fasteners

Tighten all screws

Replace driver

Page 9

COIL NAILERS

1

0

uline.com

OPERATING ISSUE CAUSE CORRECTION

TROUBLESHOOTING CONTINUED

Skipping fasteners;

intermittent feed

Fasteners jam in tool/canister

Feed piston dry

Feed piston O-rings cracked/worn

Check pawl binding

Canister bottom not set correctly

Broken weld wires in nail coil

Wrong size fasteners for tool

Broken welded wires in nail coil

Wrong slide plate adjustment for

wire collated nail coil

Add BOSTITCH Air Tool Lubricant in hole in

feed piston cover

Replace O-rings/check bumper and spring.

Lubricate assembly

Inspect pawl and spring on door

Must work freely

Set canister bottom for length of nails

being used

Remove coil of nails and use another coil

Use only recommended fasteners/check

canister bottom adjustment

Remove coil of nails and use another coil

Adjust switch pins for wire collated nail coil

-800-295-551

PAGE 9 OF 29 0421 IH-3071

Page 10

H-3071

CLAVADORA

800-295-5510

uline.mx

BOSTITCH

INSTRUCCIONES

INSTRUCCIONES DE SEGURIDAD

¡ADVERTENCIA! El operador y las demás

personas en el área de trabajo SIEMPRE deben

utilizar PROTECCIÓN OCULAR que se ajuste a las

especificaciones ANSI y proporcione protección

contra las partículas despedidas desde la parte

FRONTAL y LATERAL al conectar el suministro de

aire, cargar, operar o reparar esta herramienta.

Se requiere protección ocular para proteger

contra residuos y fijadores que salten, los

cuales podrían causar graves lesiones oculares.

El empleador y/o usuario deben asegurarse de

que se use la protección ocular adecuada. El

equipo de protección ocular debe ajustarse

a los requisitos del Instituto Americano de

Normas Nacionales (American National

Standards Institute), ANSI Z87.1 y proveer

protección frontal y lateral.

NOTA: Los lentes o caretas sin protección

lateral no proporcionan una protección

adecuada por sí solos.

PRECAUCIÓN: Se requerirá protección de

seguridad adicional en algunos entornos. Por

ejemplo, el área de trabajo podría incluir la

exposición a niveles de ruido que pueden

dañar la audición.

El empleador y el usuario deben asegurarse

de que se cuente con la protección auditiva

necesaria y sea utilizada por el operador y

las demás personas en el área de trabajo.

Algunos entornos requieren el uso de equipo

de protección para la cabeza. Cuando sea

necesario, el empleador y el usuario deben

asegurarse de que se utilice la protección para

la cabeza conforme a la norma ANSI Z89.1.

SUMINISTRO DE AIRE Y CONEXIONES

¡ADVERTENCIA! No use oxígeno, gases

combustibles ni gases envasados en cilindros

como fuente de energía para operar esta

herramienta ya que puede explotar, lo cual

podría causar lesiones.

¡ADVERTENCIA! No utilice fuentes de suministro

que potencialmente excedan los 200 psig ya

que la herramienta puede estallar y podría

causar lesiones.

¡ADVERTENCIA! El conector de la herramienta

no debe retener presión al desconectar el

suministro de aire. Si se utiliza el conector

incorrecto, la herramienta puede permanecer

cargada con aire después de haberla

desconectado y, por tanto, puede impulsar un

fijador aún después de que se desconecte la

línea de aire, lo cual podría causar lesiones.

¡ADVERTENCIA! No jale el gatillo ni oprima el

brazo de contacto mientras está conectada

al suministro de aire, ya que la herramienta

puede activarse y esto podría causar lesiones.

¡ADVERTENCIA! Siempre desconecte el

suministro de aire: 1) Antes de hacer ajustes;

2) Al dar mantenimiento a la herramienta;

3) Al eliminar un atasco; 4) Cuando la

herramienta no esté en uso; 5) Al trasladarse

a un área de trabajo distinta ya que se puede

accionar accidentalmente y esto podría

causar lesiones.

PAGE 10 OF 29 0421 IH-3071

Page 11

CONTINUACIÓN DE INSTRUCCIONES

CARGUE LA HERRAMIENTA

¡ADVERTENCIA! Al cargar la herramienta:

1) Nunca coloque la mano o cualquier

parte del cuerpo en el área de descarga de

fijadores de la herramienta; 2) Nunca apunte

la herramienta a nadie; 3) No jale el gatillo ni

oprima el disparador ya que se puede activar

accidentalmente y podría causar lesiones.

OPERACIÓN

¡ADVERTENCIA! Siempre manipule la

herramienta con cuidado: 1) Nunca participe

en juegos violentos; 2) Nunca jale el gatillo

a menos que la punta esté apuntada hacia

la superficie de trabajo; 3) Mantenga a las

demás personas a una distancia segura de la

herramienta mientras esta esté en operación,

ya que se puede activar accidentalmente y

esto podría causar lesiones.

¡ADVERTENCIA! El operador no debe mantener

el gatillo accionado sobre las herramientas

con brazo de contacto, salvo

operación de clavado, ya que podría causar

lesiones graves si el disparador accidentalmente

entra en contacto con alguien

causando que la herramienta se active.

¡ADVERTENCIA! Mantenga las manos y el

cuerpo alejados del área de descarga de

la herramienta. El brazo de contacto puede

rebotar debido al retroimpacto de impulsar

un fijador y por tanto se podría impulsar un

segundo fijador no deseado, lo cual podría

causar lesiones.

durante la

o algo,

¡ADVERTENCIA! No coloque fijadores sobre

otros fijadores ni con la herramienta

demasiado inclinada, ya que esto puede

causar que se desvíen y provocar lesiones.

¡ADVERTENCIA! No coloque fijadores cerca

del borde de la pieza de trabajo porque

la madera puede partirse y hacer que el

sujetador se desvíe, lo cual podría causar

lesiones.

¡ADVERTENCIA! Esta clavadora produce

CHISPAS durante la operación. NUNCA utilice

la clavadora cerca de sustancias, gases o

vapores inflamables, incluyendo laca, pintura,

bencina, diluyente, gasolina, adhesivos,

masillas, colas o cualquier otro material que

sea – o vapores, humos o subproductos que

sean – inflamables, combustibles o explosivos.

Usar la clavadora en un entorno como este

podría provocar una EXPLOSIÓN causando

lesiones personales o la muerte del usuario y

espectadores.

¡ADVERTENCIA! Nunca use un mosquetón para

colgarse la herramienta del cuerpo, la ropa o

el cinturón.

MANTENIMIENTO DE LA HERRAMIENTA

¡ADVERTENCIA! Tome nota de las advertencias

en este manual al trabajar con herramientas

neumáticas y tenga mayor cuidado al evaluar

herramientas problemáticas.

¡ADVERTENCIA! Revise la operación del

mecanismo del brazo de contacto

frecuentemente. No utilice la herramienta si

el brazo no está funcionando correctamente

ya que se podría impulsar un fijador

accidentalmente. No interfiriera con el

funcionamiento adecuado del mecanismo del

brazo de contacto.

PAGE 11 OF 29 0421 IH-3071

Page 12

CONTINUACIÓN DE INSTRUCCIONES

ESPECIFICACIONES DE LA HERRAMIENTA

TODOS LOS TORNILLOS Y TUERCAS SON EN SISTEMA MÉTRICO.

MODELO ACCIONAMIENTO DE LA

HERRAMIENTA

N89C-1 Disparo de contacto

(con opción de disparo

secuencial)

LONGIT. ALTUR A ANCHO PESO

311 mm (12¼") 355 mm (14") 133.4 mm (5¼") 3.7 kg (8.2 lbs.)

ESPECIFICACIONES DE LOS FIJADORES

La herramienta N89C usa una barra de alambre

secuencial de clavos, en longitudes de 50 a 90 mm

(2" a 3½") y diámetros de espiga de 2.5 mm a 3.3 mm

(0.099" a 0.131")

CONECTOR DE AIRE DE LA HERRAMIENTA

Esta herramienta usa un enchufe macho N.P.T. de 6.4

mm (1/4"). El diámetro interior mínimo debe ser de 7 mm

(0.275"). El conector debe ser capaz de descargar la

presión de aire de la herramienta al desconectarse del

suministro de aire.

PRESIÓN OPERATIVA

4.8 a 8.3 kg/cm2 (70 a 120 psig). Seleccione la presión

operativa dentro de esta gama para lograr el

rendimiento óptimo.

¡ADVERTENCIA! No supere esta presión

operativa recomendada.

CONSUMO DE AIRE

La N89C necesita 233 litros por minuto (8.23 pies3 por

minuto) de aire libre para funcionar a razón de 100 clavos

por minuto, a 5.6 kg/cm2 (80 psi). Tome la velocidad real

con la cual operará la herramienta para determinar

la cantidad de aire necesaria. Por ejemplo, si el uso

promedia 50 clavos por minuto, necesita el 50% de

los 233 litros por minuto (8.23 pies3 por

necesitan para usar la herramienta a razón de 100

clavos por minuto.

minuto) que se

PAGE 12 OF 29 0421 IH-3071

Page 13

CONTINUACIÓN DE INSTRUCCIONES

MODOS DE OPERACIÓN

BOSTITCH OFRECE DOS MODOS DE OPERACIÓN PARA

LAS HERRAMIENTAS DE ESTA SERIE.

DISPARO SECUENCIAL (GATILLO GRIS)

El Disparo Secuencial exige que el operador

sostenga la herramienta contra la superficie de

trabajo antes de accionar el gatillo. Esto facilita

la colocación precisa de los fijadores en aplicaciones

de enmarcado, clavado de bordes y embalajes. El

Disparo Secuencial permite la ubicación exacta de

la fijador sin la posibilidad de impulsar un segundo al

rebotar, como se describe en "Disparo de contacto". La

herramienta de Disparo Secuencial tiene una ventaja

positiva de seguridad porque no aplica accidentalmente

un segundo fijador si la herramienta entra en contacto

con la superficie de trabajo, o con otra cosa, mientras el

operador mantiene el gatillo apretado.

DISPARO DE CONTACTO (GATILLO

NEGRO)

El procedimiento operativo común en las

herramientas con Disparo de Contacto es

que el operador haga contacto con la superficie

de trabajo para activar el mecanismo de disparo

manteniendo el gatillo accionado, aplicando así cada

fijador cuando entra en contacto con la superficie.

Esto permitirá colocar fijadores más rápidamente en

muchos trabajos, como en el caso de enfundados,

entablados y ensamble de tarimas. Todas las

herramientas neumáticas pueden rebotar al aplicar

fijadores. La herramienta puede rebotar, liberando

el disparo, y si se le permite involuntariamente hacer

contacto con la superficie nuevamente con el gatillo

todavía apretado (el dedo continúa sujetando el

gatillo). Saldrá un segundo fijador indeseado.

IDENTIFICACIÓN DEL MODELO

de la herramienta al desconectarse de la fuente de

alimentación.

MANGUERAS

Las mangueras de aire deben tener un mínimo de 10.6

kg/cm2 (150 psi) de capacidad nominal de presión de

trabajo o un 150 por ciento de la presión máxima que

podría producirse en el sistema de aire. La manguera

de suministro debe contar con un conector de "desco-

nexión rápida" en el enchufe macho en la herramienta.

FUENTE DE SUMINISTRO

Use solamente aire comprimido regulado limpio como

fuente de energía para esta herramienta. NUNCA USE

OXÍGENO, GASES COMBUSTIBLES NI GASES ENVASADOS

EN CILINDROS COMO FUENTE DE ENERGÍA PARA OPERAR

ESTA HERRAMIENTA YA QUE PUEDE EXPLOTAR.

REGULADOR

Se necesita un regulador de presión con una

presión operativa de 0 a 8.79 kg/cm2 (0 a 125 psi)

para controlar la presión operativa con el fin de

que la herramienta funcione en forma segura. No

conecte esta herramienta a la presión de aire que

potencialmente pueda superar 14 kg/cm2 (200 psi)

pues la herramienta puede fracturarse o explotar, lo

cual podría causar lesiones.

PRESIÓN OPERATIVA

No supere la presión operativa máxima recomendada

porque aumentará considerablemente el desgaste de

la herramienta. El suministro de aire debe ser capaz

de mantener la presión operativa de la herramienta.

Las caídas de presión en el suministro de aire pueden

reducir la energía impulsora de la herramienta.

Consulte "ESPECIFICACIONES DE LA HERRAMIENTA"

para configurar la presión operativa correcta de la

herramienta.

Consulte la sección de Funcionamiento en la página

15 antes de proceder a usar esta herramienta.

SUMINISTRO DE AIRE Y CONEXIONES

¡ADVERTENCIA! No use oxígeno,

combustibles ni gases envasados en cilindros

como fuente de energía para operar esta

herramienta ya que puede explotar, lo cual

podría causar lesiones.

CONECTORES

Instale un enchufe macho en la herramienta que está

fluyendo libremente y que liberará presión de aire

PAGE 13 OF 29 0421 IH-3071

gases

FILTRO

La suciedad y el agua en el suministro de aire son las

causas principales de desgaste en las herramientas

neumáticas. Un filtro le ayudará a obtener el mejor

rendimiento y minimizar el desgaste de la herramienta.

El filtro debe tener una capacidad de flujo adecuada

para la instalación específica. El filtro debe mantenerse

limpio para ser eficaz en el suministro de aire

comprimido limpio a la herramienta. Consulte las

instrucciones del fabricante para ver el mantenimiento

adecuado del filtro. Si el filtro está sucio y obstruido

ocasionará una caída de presión que a su vez reduce

el rendimiento de la herramienta.

Page 14

CONTINUACIÓN DE INSTRUCCIONES

LUBRICACIÓN

Se necesita una lubricación frecuente, pero no

excesiva, para obtener el óptimo rendimiento. Agregar

aceite a través de la conexión de la línea de aire

lubricará las partes internas. Use el Lubricante para

herramientas neumáticas BOSTITCH (incluido), Mobil

Velocite No. 10 u otro equivalente. No use aceite ni

aditivos detergentes porque estos lubricantes causarán

un desgaste acelerado a los sellos y topes de la

herramienta, ocasionando un rendimiento deficiente y

mantenimiento frecuente de la herramienta.

Si no se usa un lubricante de línea de aire, ponga

aceite en el conector de aire de la herramienta

durante su uso, una o dos veces al día. Solamente

se necesitan unas pocas gotas de aceite a la vez.

El exceso de aceite se acumulará dentro de la

herramienta y se notará en el ciclo de escape.

FUNCIONAMIENTO EN CLIMA FRÍO

Para el funcionamiento en clima frío, cerca o bajo

cero grados centígrados, la humedad de la línea de

aire puede congelarse e impedir el funcionamiento de

la herramienta. Recomendamos el uso del lubricante

invernal para herramientas neumáticas BOSTITCH

(incluido) o anticongelante permanente (etilenglicol)

como lubricante en clima frío.

PRECAUCIÓN: No guarde herramientas en

un ambiente de clima frío para evitar la

formación de escarcha o hielo en las válvulas

y mecanismos de funcionamiento de las

herramientas que pudieran ocasionarles fallas.

NOTA: Algunos líquidos comerciales secantes

de línea de aire son dañinos para los

anillos-o y sellos – no use estos secadores

de aire de baja temperatura sin verificar la

compatibilidad.

CÓMO CARGAR

PRECAUCIÓN: El operador y las demás

personas en el área de trabajo SIEMPRE deben

utilizar PROTECCIÓN OCULAR que se ajuste

a las especificaciones ANSI y proporcione

protección contra las partículas despedidas

desde la parte FRONTAL y LATERAL al conectar

el suministro de aire, cargar, operar o reparar

esta herramienta. Se requiere protección

ocular para proteger contra residuos y

fijadores que salten, los cuales podrían causar

graves lesiones oculares.

El empleador y/o usuario deben asegurarse de

que se use la protección ocular adecuada. El

equipo de protección ocular debe ajustarse

a los requisitos del Instituto Americano de

Normas Nacionales (American National

Standards Institute), ANSI Z87.1 y proveer

protección frontal y lateral.

NOTA: Los lentes o caretas sin protección

lateral no proporcionan una protección

adecuada por sí solos.

PARA EVITAR LESIONES ACCIDENTALES

• Nunca coloque la mano ni ninguna parte del

cuerpo en el área de descarga de clavos de

la herramienta mientras el suministro de aire

esté conectado.

• Nunca apunte la herramienta hacia nadie.

• Nunca juegue con la herramienta.

• Nunca jale el gatillo a menos que la punta

esté apuntada hacia la pieza de trabajo.

• Siempre manipule la herramienta con

cuidado.

• No jale el gatillo ni oprima el mecanismo de

disparo al cargar la herramienta.

1. Abra el depósito: Mueva el

pestillo hacia atrás y jale la

puerta/cubierta del depósito

hacia afuera. (Vea Diagrama 1)

2. Comprobar el ajuste: La

clavadora se debe configurar

para la longitud de los clavos

que se utilizarán. Los clavos no

entrarán parejos si el depósito

no es ajustado correctamente.

El depósito tiene una

plataforma ajustable para

clavos que sirve de soporte

para el rollo de clavos. La plataforma para clavos

se puede mover hacia arriba y abajo para obtener

cuatro configuraciones de clavado. Para cambiar

la configuración, jale el poste hacia arriba y gire

hasta el paso correcto. (Vea Diagrama 2)

AJUSTES DE LA PLATAFORMA

• Paso 1: Clavos de 50 a 65 mm (2" a 2½")

• Paso 2: Clavos de 70 a 75 mm (2¾" a 3")

• Paso 3: Clavos de 80 a 90 mm (3¼" a 3½")

Diagrama 1

Diagrama 2

PAGE 14 OF 29 0421 IH-3071

Page 15

CONTINUACIÓN DE INSTRUCCIONES

3. Cómo cargar el rollo de

clavos: Coloque el rollo

de clavos sobre el poste

del depósito. Desenrolle

suficientes clavos hasta

que llegue al trinquete de

alimentación. Coloque el

Diagrama 3

primer clavo frente al diente

frontal en el trinquete de alimentación del canal

del impulsor. Las cabezas de los clavos deben

quedar en la ranura de la punta. (Vea Diagrama 3)

NOTA: Use solamente clavos recomendados

por BOSTITCH para usarse con las clavadoras

serie N89C o clavos que reúnan las

especificaciones de BOSTITCH.

4. Cierre la cubierta.

5. Cómo cerrar la puerta: Compruebe que el pestillo

enganche. (Si no engancha, compruebe que las

cabezas de los clavos estén en la ranura de la

punta.)

AJUSTE DEL CONTROL DE PROFUNDIDAD

3. Libere el botón de seguro. (Vea Diagrama 1)

BOTÓN DE SEGURO

BRAZO DE

CONTACTO

Diagrama 1

1. EMPUJE

3. LIBERE

2. AJUSTE

DEFLECTOR DE ESCAPE DIRECCIONAL

El deflector de escape puede girarse a cualquier

posición deseada manualmente sin usar herramientas.

(Vea Diagrama 2)

Diagrama 2

DEFLECTOR DE ESCAPE

DEL FIJADOR

La función de ajuste del control de profundidad del

clavo permite regular el impulso del clavo desde un

nivel al ras o justo sobre la superficie de trabajo hasta

avellanado leve o profundo.

PARA AJUSTAR EL CONTROL DE PROFUNDIDAD

DEL FIJADOR

¡ADVERTENCIA! Desconecte la herramienta del

suministro de aire antes de intentar desarmar

partes y antes de cambiar el ajuste del

elemento de contacto con la superficie de

trabajo.

1. Empuje el botón de seguro hacia adentro.

2. Ajuste el brazo de contacto hacia arriba para

aumentar la profundidad de la aplicación o hacia

abajo para disminuirla.

OPERACIÓN DE LA HERRAMIENTA

¡ADVERTENCIA! El operador y las demás

personas en el área de trabajo SIEMPRE deben

utilizar PROTECCIÓN OCULAR que se ajuste

a las especificaciones ANSI y proporcione

protección contra las partículas despedidas

desde la parte FRONTAL y LATERAL al conectar

el suministro de aire, cargar, operar o reparar

esta herramienta. Se requiere protección

ocular para proteger contra residuos y

fijadores que salten, los cuales podrían causar

graves lesiones oculares.

PAGE 15 OF 29 0421 IH-3071

Page 16

CONTINUACIÓN DE INSTRUCCIONES

CONTINUACIÓN DE OPERACIÓN

DE LA HERRAMIENTA

El empleador y/o usuario deben asegurarse de

que se use la protección ocular adecuada. El

equipo de protección ocular debe ajustarse

a los requisitos del Instituto Americano de

Normas Nacionales (American National

Standards Institute), ANSI Z87.1 y proveer

protección frontal y lateral.

NOTA: Los lentes o caretas sin protección

lateral no proporcionan una protección

adecuada por sí solos.

a. El Disparo Secuencial (gatillo gris) ofrece

una ventaja de seguridad positiva dado que

no impulsa accidentalmente un fijador si se

golpea la herramienta contra alguna superficie

o persona mientras el operador la esté

sosteniendo con el gatillo apretado. El Disparo

Secuencial se debe ordenar por separado.

b. El Disparo Secuencial (gatillo gris) permite el

"clavado de colocación" sin la posibilidad de

poner un segundo fijador no deseado por el

retroimpacto como se describe en "Disparo

de contacto". El Disparo Secuencial se debe

ordenar por separado.

2. OPERACIÓN DEL DISPARO DE CONTACTO

ANTES DE MANIPULAR U OPERAR ESTA

HERRAMIENTA

I. LEA DETALLADAMENTE LAS ADVERTENCIAS

CONTENIDAS EN ESTE MANUAL.

II. CONSULTE LAS "ESPECIFICACIONES DE

LA HERRAMIENTA" EN ESTE MANUAL PARA

IDENTIFICAR EL SISTEMA OPERATIVO DE LA

HERRAMIENTA.

Hay dos modos de operación disponibles en estas

herramientas neumáticas BOSTITCH. Estos son:

1. OPERACIÓN CON DISPARO SECUENCIAL

2. OPERACIÓN CON DISPARO DE CONTACTO

OPERACIÓN

BOSTITCH le ofrece dos tipos de disparos para

herramientas neumáticas: Disparo Secuencial (gatillo

gris) y Disparo de Contacto (gatillo negro). Cada gatillo

tiene ventajas específicas. Debe evaluar su proyecto

de construcción en particular para determinar qué

gatillo es el mejor.

La herramienta solo incluye el gatillo negro de 'Disparo de

Contacto'. El gatillo gris de 'Disparo Secuencial' se debe

ordenar por separado.

1. OPERACIÓN CON DISPARO SECUENCIAL

(GATILLO GRIS)

El disparo secuencial (gatillo gris) se llama así por

la "secuencia" que se necesita impulsar un fijador.

Para impulsar un fijador, el operador debe presionar

primero el disparo COMPLETAMENTE contra la superficie

de trabajo y luego accionar el gatillo. Para impulsar

un segundo clavo, el operador debe levantar la

herramienta de la superficie, soltar el gatillo y luego

repetir la secuencia anterior.

PAGE 16 OF 29 0421 IH-3071

(CONVENCIONAL) (GATILLO NEGRO)

Su nueva herramienta Bostitch se puede configurar

fácilmente para usar en el modo Disparo de Contacto.

Para impulsar un clavo, deben presionarse tanto el

"disparo" como el gatillo. En las herramientas de disparo

de contacto, el gatillo debe presionarse y mantenerse

presionado y cada "contacto" entre el disparo y la

superficie de trabajo impulsará un clavo.

a. COLOCACIÓN DE UN SOLO FIJADOR (Clavado

de colocación) – Primero ubique el "disparo"

COMPLETAMENTE sobre la superficie de trabajo,

SIN ACCIONAR EL GATILLO. Oprima el "disparo"

COMPLETAMENTE hasta que la punta de la

herramienta toque la superficie de trabajo y

luego accione el gatillo para aplicar el fijador.

No presione la herramienta contra la superficie

de trabajo con más fuerza. En cambio, deje que

la herramienta se separe de la superficie de

trabajo para evitar que salga otro fijador

NOTA: quite el dedo del gatillo después de

cada operación.

b. OPERACIÓN DE DISPARO RÁPIDO ("Clavado por

impacto"): – Primero, sostenga la herramienta

con el "disparo

de trabajo pero sin tocarla. Accione el gatillo

luego golpee o "impacte" el disparo de contacto

contra la superficie de trabajo

movimiento de rebote. Cada vez que se presione

el "disparo" saldrá un clavo.

¡ADVERTENCIA! El disparo de contacto (negro)

no evitará que se impulse accidentalmente

un clavo si se mantiene presionado el gatillo

y se toca el disparador contra algún objeto o

alguna persona. Nunca sostenga ni transporte

la herramienta con el dedo en el gatillo.

Solamente oprima y mantenga oprimido el

gatillo cuando tenga la intención de impulsar

varios clavos y la herramienta esté apuntando

a la superficie de trabajo.

" apuntando hacia la superficie

y

usando un

Page 17

CONTINUACIÓN DE INSTRUCCIONES

CONTINUACIÓN DE OPERACIÓN

DE LA HERRAMIENTA

¡ADVERTENCIA! Nunca use el gatillo de

contacto (gatillo negro) con el aditamento

para conector de metal. Solamente use

el disparo secuencial (gatillo gris) con el

aditamento para el conector de metal.

Consulte las instrucciones de conversión de

gatillo que se incluyen en el kit.

¡ADVERTENCIA! Al usar el disparador de contacto

convencional para el clavado de colocación,

la herramienta puede rebotar debido al

retroimpacto, y si se permite que la herramienta

vuelva a tomar contacto con la superficie de

trabajo mientras sostiene accionado el gatillo,

se instalará otro clavo no deseado. Debe

permitir que la herramienta rebote una distancia

suficiente para liberar el disparador y evitar

un segundo ciclo. No empuje la herramienta

hacia abajo con mucha fuerza; deje que la

herramienta haga el trabajo.

¡ADVERTENCIA! El operador no debe mantener

el gatillo accionado en las herramientas con

disparo de contacto, salvo durante la operación

de clavado, ya que podría causar lesiones

graves si el disparador accidentalmente entra

en contacto con alguien o algo, causando que

la herramienta se active.

¡ADVERTENCIA! Mantenga las manos y el

cuerpo alejados del área de descarga

de la herramienta. Una herramienta con

disparo de contacto puede rebotar debido

al retroimpacto de impulsar un fijador y por

tanto se podría impulsar un segundo fijador no

deseado, lo cual podría causar lesiones.

b. Sostenga la herramienta sin tocar la superficie

de trabajo y tire del gatillo. LA HERRAMIENTA NO

DEBE HACER UN CICLO. Libere el gatillo. El gatillo

debe regresar al tope en el marco.

c. Accione el gatillo y presione el disparo de

contacto contra la superficie de trabajo.

LA HERRAMIENTA NO DEBE HACER UN CICLO.

d. Con el dedo fuera del gatillo, presione el

disparo de contacto contra la superficie de

trabajo. Accione el gatillo. LA HERRAMIENTA

DEBE HACER UN CICLO.

2. OPERACIÓN CON DISPARO DE CONTACTO

a. Con el dedo fuera del gatillo, presione el

disparo de contacto contra la superficie de

trabajo. LA HERRAMIENTA NO DEBE HACER UN

CICLO.

b. Sostenga la herramienta sin tocar la superficie

de trabajo y tire del gatillo. LA HERRAMIENTA NO

DEBE HACER UN CICLO.

c. Con la herramienta sin tocar la superficie de

trabajo, accione el gatillo. Presione el disparo

de contacto contra la superficie de trabajo. LA

HERRAMIENTA DEBE HACER UN CICLO.

d. Sin tocar el gatillo, presione el disparo de

contacto contra la superficie de trabajo, luego

accione el gatillo. LA HERRAMIENTA DEBE HACER

UN CICLO.

ADEMÁS DE LAS OTRAS ADVERTENCIAS

CONTENIDAS EN ESTE MANUAL, CUMPLA CON LO

SIGUIENTE PARA UNA OPERACIÓN SEGURA

• Use la herramienta neumática BOSTITCH solamente

para el fin que fue diseñada.

¡ADVERTENCIA! Nunca use un mosquetón para

colgarse la herramienta del cuerpo, la ropa o

el cinturón.

VERIFICACIÓN DE LA OPERACIÓN

DE LA HERRAMIENTA

PRECAUCIÓN: Retire todos los clavos de la

herramienta antes de realizar una verificación

de la operación de la herramienta.

1. OPERACIÓN CON DISPARO SECUENCIAL

a. Presione el disparo de contacto contra la

superficie de trabajo, sin tocar el gatillo.

LA HERRAMIENTA NO DEBE HACER UN CICLO.

PAGE 17 OF 29 0421 IH-3071

• Nunca use esta herramienta de tal modo que

pueda causar la salida de un fijador hacia el

usuario u otros presentes en el área de trabajo.

• No use la herramienta como martillo.

• Siempre lleve la herramienta tomándola por

la empuñadura. Nunca lleve la herramienta

tomándola por la manguera de aire.

• No altere ni modifique el diseño o función original

de esta herramienta sin la aprobación de BOSTITCH.

• Siempre tenga presente que el uso indebido o

la manipulación incorrecta de esta herramienta

puede causarle lesiones a usted y a los demás.

Page 18

CONTINUACIÓN DE INSTRUCCIONES

CONTINUACIÓN DE OPERACIÓN

DE LA HERRAMIENTA

• Nunca use abrazaderas ni cinta para bloquear

el gatillo o el disparo de contacto en la posición

activada.

• Nunca deje una herramienta sin supervisión con la

manguera de aire conectada.

• No opere esta herramienta si no cuenta con una

ETIQUETA DE ADVERTENCIA legible.

• No use la herramienta si tiene fugas de aire o

no funciona bien. Póngase en contacto con

Servicio a Clientes de Uline si la herramienta sigue

presentando problemas funcionales.

MANTENIMIENTO DE LA HERRAMIENTA

NEUMÁTICA

¡ADVERTENCIA! Recuerde las advertencias en

este manual al trabajar con herramientas

neumáticas y tenga mayor cuidado al evaluar

herramientas problemáticas.

REPUESTOS

Se recomienda usar repuestos Bostitch. No use partes

modificadas ni componentes que no tengan un

rendimiento equivalente al equipo original.

PROCEDIMIENTO DE ENSAMBLE PARA LOS SELLOS

Al reparar la herramienta, fíjese en que las partes

internas estén limpias y lubricadas. Use lubricante

Parker O-LUBE u otro equivalente en todos los anillos-o.

Cubra cada anillo-o con lubricante O-LUBE antes de

ensamblar. Use una pequeña cantidad de aceite en

todas las superficies y pivotes móviles. Después del

reensamble, añada unas pocas gotas de lubricante

para herramientas neumáticas BOSTITCH (Air Tool

Lubricant) a través de la grasera de la línea de aire

antes de hacer pruebas.

PRESIÓN Y VOLUMEN DEL SUMINISTRO DE AIRE

El volumen de aire es tan importante como la

presión de aire. El volumen de aire suministrado a

la herramienta puede ser inadecuado debido a

conectores y mangueras de tamaño inferior o por

los efectos de suciedad y agua en el sistema. El

flujo de aire restringido impedirá que la herramienta

reciba un volumen de aire adecuado, aún cuando

la lectura de presión sea alta. Los resultados serán

funcionamiento lento, fijaciones mal dirigidas o menor

potencia de impulso. Antes de evaluar los problemas

de la herramienta según estos síntomas, inspeccione

el suministro de aire desde la herramienta a la fuente

de suministro en busca de conectores restrictivos,

accesorios giratorios, puntos bajos que tengan agua

y cualquier otra cosa que impida el flujo del volumen

completo de aire a la herramienta.

SOLUCIÓN DE PROBLEMAS

PROBLEMA DE OPERACIÓN CAUSA CORRECCIÓN

El vástago de la válvula del gatillo

fuga aire

Armazón/punta fuga aire

Armazón/tapa fuga aire

Anillo-o cortado o agrietado

Anillo-o/sellos cortados o agrietados

Tornillos sueltos en la punta

Anillo-o o junta cortados o agrietados

Tope agrietado o desgastado

Junta o sello dañados

Tope de la válvula cabezal agrietado o

desgastado

Tornillos de casquete sueltos

Reemplace el anillo-o

Reemplace el ensamble de la válvula de

disparo

Apriete y revise

Reemplace el anillo-o o la junta

Reemplace el tope

Reemplace la junta o el sello

Reemplace el tope

Apriete y revise

PAGE 18 OF 29 0421 IH-3071

Page 19

CONTINUACIÓN DE SOLUCIÓN DE PROBLEMAS

PROBLEMA DE OPERACIÓN CAUSA CORRECCIÓN

No hace ciclos

Falta de potencia; ciclo lento

Se saltan fijaciones;

la alimentación es intermitente

Suministro de aire restringido

Herramienta seca, le falta lubricación

Anillos-o desgastados en la válvula cabezal

Resorte en la tapa del cilindro roto

Herramienta seca, le falta lubricación

Resorte en la tapa del cilindro roto

Anillos-o/sellos cortados o agrietados

Escape bloqueado

El ensamble del gatillo está gastado o tiene

fugas

Suciedad/alquitrán acumulados en el impulsor

La funda del cilindro no está asentada

correctamente en el tope inferior

Válvula de cabezal seca

Presión de aire demasiado baja

Tope desgastado

Alquitrán/suciedad en el canal del impulsor

Restricción de aire/flujo indebido de aire por

el enchufe y la toma de desconexión rápida

Anillo-o del pistón desgastado

Herramienta seca, le falta lubricación

El resorte de empuje de alimentación está

dañado

Presión de aire baja

Los tornillos en la punta del depósito están

sueltos

Loas fijadores son demasiado cortos para la

herramienta

Fijadores doblados

Fijadores de tamaño incorrecto

La junta de la tapa cabezal tiene fugas

Anillo-o de la válvula de disparo cortada/

desgastada

Impulsor roto/picado

Cargador seco/sucio

Revise el equipo de suministro de aire

Use lubricante BOSTITCH para herramientas

neumáticas

Reemplace los anillos-o

Reemplace el resorte en la tapa del cilindro

Use lubricante BOSTITCH para herramientas

neumáticas

Reemplace el resorte de la tapa

Reemplace los anillos-o/sellos

Revise el tope, el resorte de la válvula cabezal,

el silenciador

Reemplace el ensamble del gatillo

Desarme la punta/impulsor para limpiarlos

Desármelo para corregirlo

Desármela/lubríquela

Revise el equipo de suministro de aire

Reemplace el tope

Desarme y limpie la punta y el impulsor

Reemplace los accesorios de desconexión

rápida

Reemplace el anillo-o, revise el impulsor

Use lubricante BOSTITCH para herramientas

neumáticas

Reemplace el resorte

Revise el sistema de suministro de aire a la

herramienta

Apriete todos los tornillos

Use sólo fijadores recomendados

Deje de usar estos fijadores

Use sólo fijadores recomendados

Apriete los tornillos/cambie la junta

Reemplace el anillo-o

Reemplace el impulsor (revise el anillo-o del

pistón)

Límpielo/aplique lubricante BOSTITCH para

herramientas neumáticas

PAGE 19 OF 29 0421 IH-3071

Page 20

CONTINUACIÓN DE SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

PROBLEMA DE OPERACIÓN CAUSA CORRECCIÓN

Fijadores atascados en la

herramienta

Canal del impulsor desgastado

Fijadores de tamaño incorrecto

Fijadores doblados

Los tornillos en la punta/depósito están sueltos

Impulsor roto/picado

Cambie la punta/revise la puerta

Use sólo fijadores recomendados

Deje de usar estos fijadores

Apriete todos los tornillos

Reemplace el impulsor

CLAVADORAS DE ROLLO

PROBLEMA DE OPERACIÓN CAUSA CORRECCIÓN

Se saltan fijaciones;

la alimentación es intermitente

El pistón de alimentación está seco

Los anillos-o del pistón de alimentación están

agrietadas/desgastadas

Revise si el trinquete está atascado

La parte inferior del depósito no está bien

colocada

Cables de soldadura rotos en el rollo de clavos

Ponga lubricante BOSTITCH para herramientas

neumáticas en el orificio de la cobertura del

pistón de alimentación

Reemplace los anillos-o/verifique el tope y el

resorte. Lubrique el ensamble

Inspeccione el trinquete y el resorte de la

puerta Deben funcionar libremente

Ajuste la parte inferior del depósito según la

longitud de los clavos que se utilizan

Retire el rollo de clavos y use otro rollo

Fijadores atascados en la

herramienta/depósito

Fijadores de tamaño incorrecto para la

herramienta

Cables de soldadura rotos en el rollo de clavos

Ajuste incorrecto de la placa de deslizamiento

para la barra de alambre secuencial de

clavos

Use sólo fijadores recomendadas/verifique el

ajuste de la parte inferior del depósito

Retire el rollo de clavos y use otro rollo

Ajuste las clavijas es de cambio para la barra

de alambre secuencial de clavos

00-295-551

PAGE 20 OF 29 0421 IH-3071

Page 21

H-3071

CLOUEUSE

1-800 -295- 5510

uline.ca

BOSTITCH

INSTRUCTIONS

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT! Une PROTECTION OCULAIRE qui

ARRÊT ARRÊT

PAGE 21 OF 29 0421 IH-3071

satisfait la spécification ANSI et qui protège les

yeux contre les particules projetées à la fois de

FACE et de CÔTÉ doit être portée EN TOUT TEMPS

par l'utilisateur et les autres personnes présentes

dans la zone de travail durant la connexion de

l'alimentation d'air, le chargement, l'utilisation ou

l'entretien de cet outil. Une protection oculaire est

nécessaire pour protéger contre les clous et les

débris projetés qui pourraient provoquer de graves

blessures aux yeux.

L'employeur et/ou l'utilisateur doit s'assurer qu'un

dispositif de protection oculaire approprié est

porté par tous. L'équipement de protection

oculaire doit être conforme aux exigences de

la norme ANSI (American National Standards

Institute) Z87.1 et offrir une protection à la fois

frontale et latérale.

REMARQUE: Les lunettes et les masques

protecteurs sans écrans latéraux n'offrent pas à

eux-seuls une protection adéquate.

MISE EN GARDE: Certains environnements

exigeront des dispositifs de protection

supplémentaires. Par exemple, la zone de travail

peut présenter un niveau de bruit assez élevé pour

provoquer des dommages auditifs.

L'utilisateur et l'employeur doivent s'assurer de la

disponibilité de dispositifs de protection de l'ouïe

nécessaires, et veiller à ce que l'utilisateur et les

personnes présentes dans la zone de travail les

portent. Certains environnements nécessiteront

l'emploi d'équipement de protection pour la tête.

Lorsque requis, l'employeur et l'utilisateur doivent

s'assurer qu'un équipement de protection pour la

tête conforme aux exigences de la norme ANSI

Z89.1 est utilisé.

ALIMENTATION D'AIR ET RACCORDS

A

VERTISSEMENT! N'alimentez pas cet outil avec

de l'oxygène, du gaz combustible ou du gaz

comprimé en bouteille, car l'outil pourrait

exploser, engendrant le risque de blessures.

A

VERTISSEMENT! N'utilisez aucune source

ARRÊT

ARRÊT

ARRÊT

ARRÊT

d'alimentation qui pourrait dépasser 200lb/po²

(13,8bars), car l'outil pourrait éclater, engendrant

le risque de blessures.

A

VERTISSEMENT! Le raccord installé sur l'outil

ne doit retenir aucune pression suivant la

déconnexion de l'alimentation d'air. Si un

raccord inapproprié a été utilisé, l'outil pourrait

demeurer sous pression suivant la déconnexion

et ainsi pouvoir encore décharger un clou après

la déconnexion de la conduite d'air, engendrant

le risque de blessures.

A

VERTISSEMENT! N'appuyez pas sur la détente

ou n'actionnez pas le bras de contact avec la

conduite d'air connectée, car l'outil pourrait

cycler, engendrant le risque de blessures.

A

VERTISSEMENT! Déconnectez toujours

l'alimentation d'air: 1) avant d'effectuer des

réglages; 2) lors de l'entretien de l'outil; 3) lors du

dégagement d'une obstruction; 4) lorsque l'outil

ne sert pas; 5) lorsque vous vous déplacez vers

une autre zone de travail, car un actionnement

accidentel pourrait se produire, engendrant le

risque de blessures.

CHARGEMENT DE L'OUTIL

A

VERTISSEMENT! Lorsque vous chargez l'outil: 1)

ARRÊT

ne placez jamais une main ou toute autre partie

de votre corps dans la zone de propulsion des

clous de l'outil; 2) ne pointez jamais l'outil en

direction de quelqu'un; 3) n'appuyez pas sur la

détente et n'enfoncez pas le déclencheur, car

un actionnement accidentel pourrait se produire,

engendrant le risque de blessures.

Page 22

UTILISATION

A

VERTISSEMENT! Utilisez toujours l'outil avec

ARRÊT

ARRÊT

ARRÊT

ARRÊT

précaution: 1) Ne vous chamaillez jamais;

2) n'appuyez jamais sur la détente si l'outil

n'est pas orienté vers l'ouvrage; 3) veillez à ce

que les autres se tiennent à l'écart de l'outil

lorsque celui-ci est en cours d'utilisation, car un

actionnement accidentel pourrait se produire,

engendrant le risque de blessures.

A

VERTISSEMENT! L'utilisateur d'outils à bras

de contact ne doit pas maintenir la détente

enfoncée autrement

tâches de fixation, car le contact accidentel

de quelqu'un ou

le déclencheur pourrait actionner l'outil et

possiblement causer des blessures.

A

VERTISSEMENT! Gardez les mains et le corps

à l'écart de la zone de propulsion de l'outil.

Cette cloueuse peut sauter sous l'effet de

recul provoqué par la propulsion d'un clou et

un second clou pourrait alors être propulsé,

engendrant le risque de blessures.

A

VERTISSEMENT! Vérifiez souvent le

fonctionnement du mécanisme de bras de

contact. N'utilisez pas cet outil si le bras ne

fonctionne pas correctement, cela pourrait

provoquer la propulsion accidentelle d'un clou.

Ne pas interferer au fonctionnement correct du

méchanisme de bras de contact.

INSTRUCTIONS SUITE

que durant l'exécution de

de quelque chose avec

A

VERTISSEMENT! Ne propulsez pas de clous

ARRÊT

ARRÊT

ARRÊT

ARRÊT

par-dessus d'autres clous ou en tenant l'outil à un

angle trop aigu, car cela pourrait faire dévier un

clou et possiblement causer une blessure.

A

VERTISSEMENT! N'enfoncez pas des clous trop

près du bord de l'ouvrage, car le bois pourrait se

fendre, engendrant une possible déviation de

l'attache et provoquant un risque de blessures.

A

VERTISSEMENT! Cette cloueuse produit des

ÉTINCELLES durant son fonctionnement. N'utilisez

JAMAIS cette cloueuse à proximité de substances,

de gaz ou de vapeurs inflammables, notamment

laque, peinture, benzène, diluant, essence,

adhésifs, mastic, colles ou toute autre matière

inflammable, combustible ou explosive, ou dont

les vapeurs ou les sous-produits sont inflammables,

combustibles ou explosifs. L'utilisation de la

cloueuse dans un tel milieu peut provoquer une

EXPLOSION entraînant des blessures ou la mort de

l'utilisateur ou de tout observateur.

A

VERTISSEMENT! Ne suspendez jamais l'outil à

votre corps, vos vêtements ou votre ceinture à

l'aide du crochet de rangement.

ENTRETIEN DE L'OUTIL

A

VERTISSEMENT! Lorsque vous travaillez sur des

ARRÊT

outils pneumatiques, prenez connaissance des

avertissements contenus dans ce manuel et

soyez particulièrement vigilant lors de l'évaluation

d'outils en panne.

SPÉCIFICATIONS DE L'OUTIL

LES VIS ET ÉCROUS SONT TOUS MÉTRIQUES.

MODÈLE ACTIONNEMENT DE L'OUTIL LONG. HAUT. LARG. POIDS

N89C-1 Déclenchement à pression

(avec option de déclenchement

séquentiel)

SPÉCIFICATIONS DES CLOUS

La cloueuse N89C emploie des rouleaux de clous

assemblés par fil de soudage en longueurs de 50 à

90mm (2po à 3½po) avec des diamètres de lame de

2,5 à 3,3mm (0,099po à 0,131po)

RACCORD PNEUMATIQUE DE L'OUTIL

Cet outil utilise une fiche de connexion à débit continu,

à filets 1/4po N.P.T. Le diamètre minimum intérieur doit

être 7mm (0,275po). Le raccord doit pouvoir évacuer

la pression d'air de l'outil lorsque déconnecté de

l'alimentation d'air.

311mm (12¼po) 355mm (14po) 133,4mm (5¼po) 3,7kg (8,2lb)

PRESSION DE SERVICE

4,8 à 8,3kg/cm2 (70 à 120lb/po²). Pour la meilleure

performance des clous, sélectionnez une pression de

service comprise dans cette plage.

A

VERTISSEMENT! Ne dépassez pas la pression

ARRÊT

de service recommandée.

DÉBIT D'AIR

La N89C exige un débit d'air de 233litres par minute

(8,23pieds cubes par minute) pour opérer à la vitesse de

100 clous par minute à 5,6kg/cm2 (80lb/po²). Utilisez la

vitesse réelle à laquelle l'outil sera utilisé pour déterminer le

débit d'air requis. Par exemple, si vous utilisez en moyenne

50 clous par minute, vous n'avez besoin que de 50%

des 233litres par

propulsion de 100 clous par minute.

minute (

8,23pcm

) nécessaires pour la

PAGE 22 OF 29 0421 IH-3071

Page 23

INSTRUCTIONS SUITE

MODES D'UTILISATION

BOSTITCH OFFRE DEUX MODES D'UTILISATION POUR CET

OUTIL.

DÉCLENCHEMENT SÉQUENTIEL (DÉTENTE GRISE)

Le déclenchement séquentiel exige que

l'utilisateur appuie l'outil sur la surface de travail

avant d'appuyer sur la détente. Ceci facilite

le positionnement précis des clous pour les

travaux de cadrage, de clouage en biais et de

mise en caisse. Le déclenchement séquentiel

permet le positionnement précis des clous sans la

possibilité de propulser un second clou en raison de l'effet

de recul, tel que décrit sous «Déclenchement à pression».

L'outil à déclenchement séquentiel offre un avantage de

sécurité positif, car il ne propulsera pas accidentellement

un second clou si l'outil entre accidentellement en contact

avec l'ouvrage, ou avec tout autre élément, pendant que

l'utilisateur maintient une pression sur la détente.

DÉCLENCHEMENT À PRESSION (DÉTENTE NOIRE)

La procédure d'utilisation commune des outils à

déclenchement à pression indique que l'utilisateur

devra toucher à la surface de travail pour

actionner le mécanisme de déclenchement tout

en maintenant la détente enfoncée, propulsant

ainsi un clou à chaque contact avec l'ouvrage.

Ceci permettra une mise en place rapide des clous dans

le cadre de nombreuses tâches comme l'installation de

revêtement ou de platelage et l'assemblage de palettes.

Les outils pneumatiques sont tous sujets à un recul lors de

la propulsion des clous. L'outil peut sauter au moment du

déclenchement s'il entre de nouveau accidentellement

en contact avec la surface de travail alors que la détente

demeure actionnée (doigt appuyant toujours sur la détente).

Un second clou non désiré sera propulsé.

IDENTIFICATION DU MODÈLE

Reportez-vous aux instructions d'utilisation à la page 5

avant d'utiliser cet outil.

ALIMENTATION D'AIR ET RACCORDS

A

VERTISSEMENT! N'alimentez pas cet outil avec

ARRÊT

RACCORDS

Installez une fiche de connexion à débit continu qui

évacuera la pression d'air de l'outil suivant la déconnexion

de la source d'alimentation d'air.

CONDUITES

Les conduites d'air doivent offrir une pression de service

nominale de 10,6kg/cm² (150lb/po²) ou 150 pour cent de

la pression maximale que pourrait produire le circuit d'air

comprimé. La conduite d'alimentation doit comporter un

raccord qui permettra le «dégagement rapide» de la

fiche de connexion sur l'outil.

de l'oxygène,

comprimé en bouteille, car l'outil pourrait exploser,

engendrant le risque de blessures.

du gaz combustible ou du gaz

SOURCE D'ALIMENTATION

Utilisez uniquement de l'air comprimé propre et régulé

comme source d'alimentation pour cet outil. N'ALIMENTEZ

JAMAIS CET OUTIL AVEC DE L'OXYGÈNE, DU GAZ

COMBUSTIBLE OU DU GAZ COMPRIMÉ EN BOUTEILLE, CAR

L'OUTIL POURRAIT EXPLOSER.

RÉGULATEUR

Un régulateur de pression avec une pression de service

de 0 à 8,79kg/cm2 (0 à 125lb/po²) doit être utilisé pour

assurer la pression d'air nécessaire au fonctionnement

sécuritaire de cet outil. Ne connectez cet outil à aucune