Page 1

H-2708, H-2900

H-3045

INDUSTRIAL

PALLET TRUCKS

TECHNICAL DATA

MODEL H-2708/H-2900/H-3045

Capacity (Lbs) 5,500

Max. Fork Height (In) 7.5

Min. Fork Height (In) 3.0

Fork Length (In) 48

Width Overall Forks (In) 27

Fork Wheel Diameter (In) 3" Polyurethane

Steering Wheel Diameter (In) 7" Polyurethane

Net Weight (Lbs) 186

OPERATION

WARNING! Operator must read and understand

instructions here and on truck prior to use.

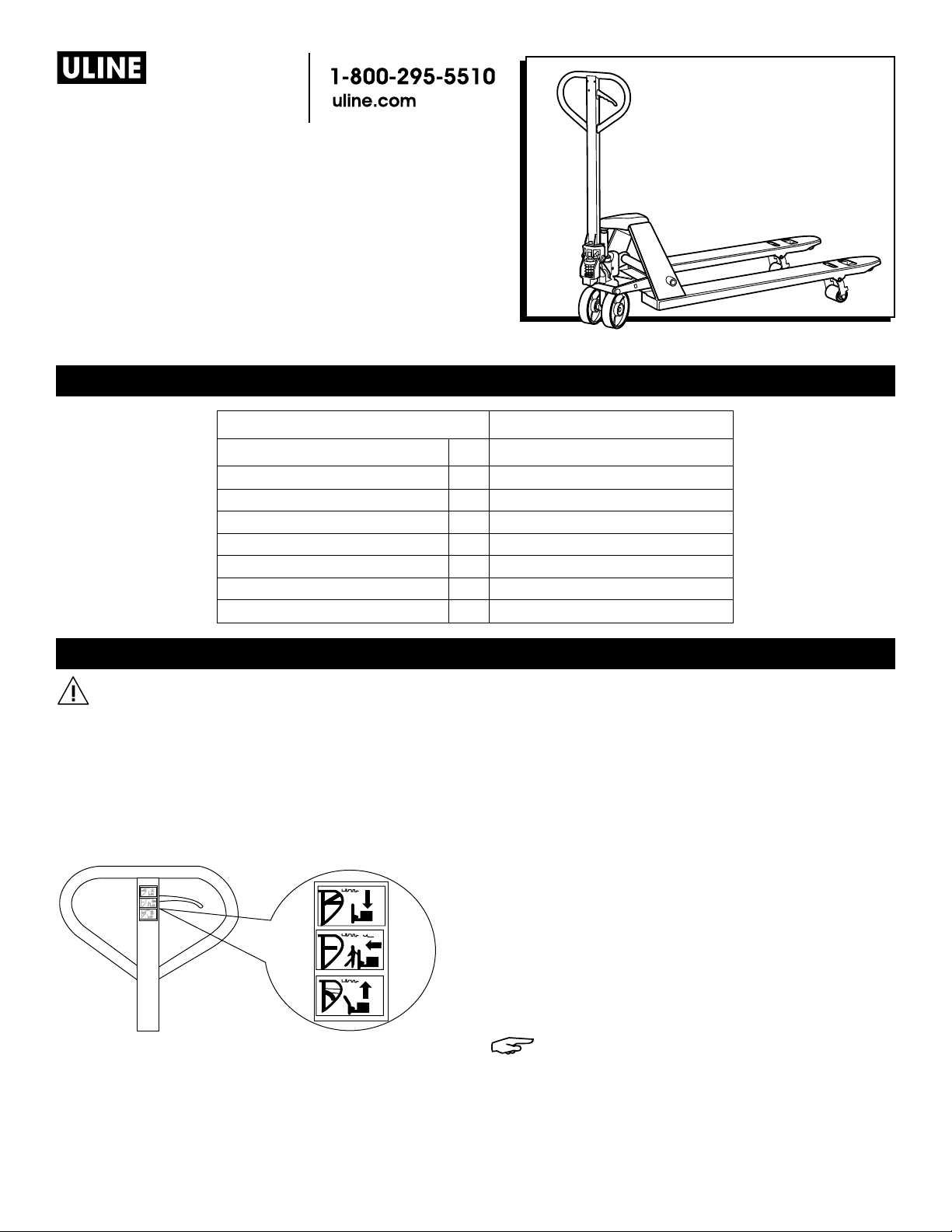

On the handle of the pallet truck, you will find the control

lever, which can be set in three positions.

(See Figure 1)

Figure 1

- LOWER = to lower the forks

- NEUTRAL = to move the load

- RAISE = to raise the forks

1. If the forks elevate while pumping in the NEUTRAL

position, turn the setting screw clockwise until

pumping the handle does not raise the forks and the

NEUTRAL position functions correctly.

2. If the forks descend while pumping in the NEUTRAL

position, turn the setting screw counter-clockwise until

the forks do not lower.

3. If the forks do not descend when the control lever is in

the LOWER position, turn the setting screw clockwise

until raising the control lever lowers the forks. Then

check the NEUTRAL position as per step 1 and 2.

4. If the forks do not lift while pumping in the RAISE

position, turn the setting screw counter-clockwise

until the forks elevate while pumping in the RAISED

position. Then check the NEUTRAL and LOWER position

as per steps 1, 2 and 3.

NOTE: When viewing the truck from the handle

side, the setting screw is located on the right

side of the pump above the right wheel. The

truck will lower faster or slower depending on

how far in or out the screw is adjusted.

PAGE 1 OF 3 1211 IH-2708

Page 2

MAINTENANCE

OIL

Please check the oil level every six months. The oil ca-

pacity is about 0.3L. Restore the fluid level in the rubber

reservoir to 5mm below the top; this must be

done with the forks in the lowered position.

Use the hydraulic oil ISO-VG32 or equivalent.

Oil viscosity should be 30cSt at 104°.

HOW TO EXPEL AIR FROM THE PUMP UNIT

Air may enter the unit over time or when the seals are

replaced. To expel the air, lift the control lever to the

SAFETY

For safe operation of the Hand Pallet Truck, please read

all warning signs and instructions here and on the pallet

truck prior to use.

1. Do not operate the pallet truck unless you are familiar

with it and have been trained and authorized to do so.

2. Do not use the truck on sloping ground.

3. Never place any part of your body in the lifting

mechanism or under the forks or load. Do not carry

passengers.

4. We advise that operators should wear gloves and

safety shoes.

LOWER position and move the handle up and down

several times.

DAILY CHECK AND MAINTENANCE

Daily checks of the pallet truck can limit wear and tear

on the unit. Pay special attention to the wheels, the axles,

the handle, the forks and lift and lower control.

LUBRICATION

Use motor oil or grease to lubricate all moveable parts.

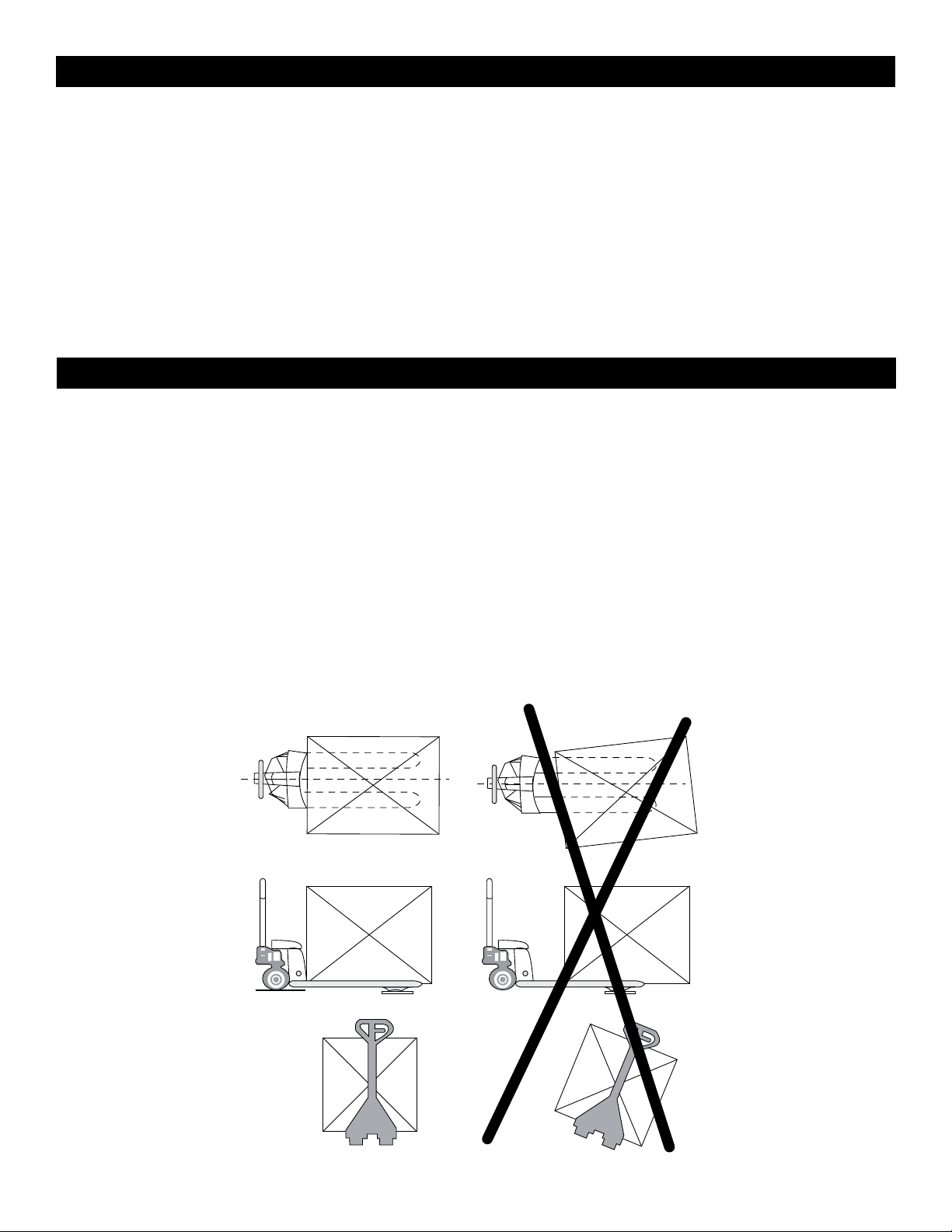

5. Do not handle unstable or loosely stacked loads.

6. Do not overload the truck.

7. Always center loads on the forks, not at the end of the

forks. (See Figure 2)

8. The capacity of the truck assumes an evenly

distributed load with the center of the load being at

the halfway point of the length of the forks.

9. Make sure that length of the forks matches the length

of the pallet load.

10. Lower the forks to lowest height when the truck is not

being used.

A B

Figure 2

PAGE 2 OF 3 1211 IH-2708

Page 3

TROUBLESHOOTING

OPERATING ISSUE CAUSES RECOMMENDATIONS

The forks do not lift to maximum height. Not enough hydraulic oil. Add more oil.

The forks do not raise. Not enough hydraulic oil.

The oil has impurities.

Discharge valve is out of adjustment.

Air in the hydraulic oil.

The forks do not descend. The rod and the cylinder are deformed resulting

Leaks Seals worn out or damaged.

The forks descend without being

lowered.

from a seriously unbalanced load.

A part has been broken or been deformed resulting

from an unbalanced load.

The setting screw is not in the correct position.

Some parts may be cracked or worn out.

Impurities in the oil cause the discharge valve to fail

to close.

Air in the oil.

Seals worn or damaged.

Discharge valve is out of adjustment.

Add more oil.

Change the oil.

Adjust the setting screw. (As noted in

Operation)

Expel the air. (As noted in Maintenance)

Replace the rod or cylinder.

Repair or replace component.

Adjust the setting screw. (As noted in

Operation)

Replace seals with new ones.

Check and replace with new ones.

Change the oil.

Expel the air. (As noted in Maintenance)

Replace with new ones.

Adjust the setting screw. (As noted in

Operation)

NOTE: Do not attempt to repair the pallet truck unless you are trained and authorized to do so.

PAGE 3 OF 3 1211 IH-2708

Loading...

Loading...