Page 1

H-2957

AUTOMATIC STRETCH

WRAP DISPENSER

SYSTEM SPECIFICATIONS

MACHINE DIMENSIONS

Length 116"

Width 65"

Height 92"

Turntable Diameter 65"

Turntable Height from Floor 3 1/4"

Wrapping Height 80"

Operation Space 125 x 70 x 100"

Maximum Load Size 56 x 56 x 80"

Approximate Shipping Weight 1220 lbs

ELECTRICAL SPECIFICATIONS

• 120 VAC, 60 Hz, Single-phase, 15 AMP

• NEMA-12 rated electrical panel

• Operating temperature: +32˚F to +110˚F

• Lockable disconnect switch

• NEC wiring standard

• Programmable Logic Controller (PLC) with input/

output diagnostic lights

TURNTABLE SYSTEM

• Low Profile: ½ HP 3-phase AC motor, ½ HP AC

frequency drive

• 20-30 loads per hour (spiral)

• 12 RPM turntable maximum speed

• 4,000 lbs turntable maximum load capacity

FILM CARRIAGE / ELEVATOR SYSTEM

• ½ HP 3-phase AC motor, ½ HP AC frequency drive

• Adjustable raise and lower speeds

• Automatic height detection photoelectric sensor

FILM DELIVERY SYSTEM

• ¼ HP 3-phase AC motor, ½ HP AC frequency drive

• Adjustable film force

• 200% / 250% average pre-stretch level

• 10" diameter roll capacity

• 20" height roll capacity

CAUTION! Motor control equipment and

electronic controllers are connected to

hazardous line voltages. When servicing

drive and controllers, there may be exposed

components with housings or protrusions at or

above line potential. Extreme care should be

taken to protect against shock.

The user is responsible for conforming to all

applicable code requirements with respect

to grounding all requirements. Do NOT use

extension cords to operate the equipment.

Disconnect AC input power before checking

components, performing maintenance,

cleaning up, and when the machine is not in

use. Do NOT connect or disconnect wires and

connectors while power is applied to circuit.

Wiring work should be carried out only by

qualified personnel. There is a danger of

electric shock or fire.

WARNING! Loose clothing must NOT be worn

while the machine is in operation. Stay clear of

moving parts while the machine is running.

0411 IH-2957PAGE 1 OF 17

Page 2

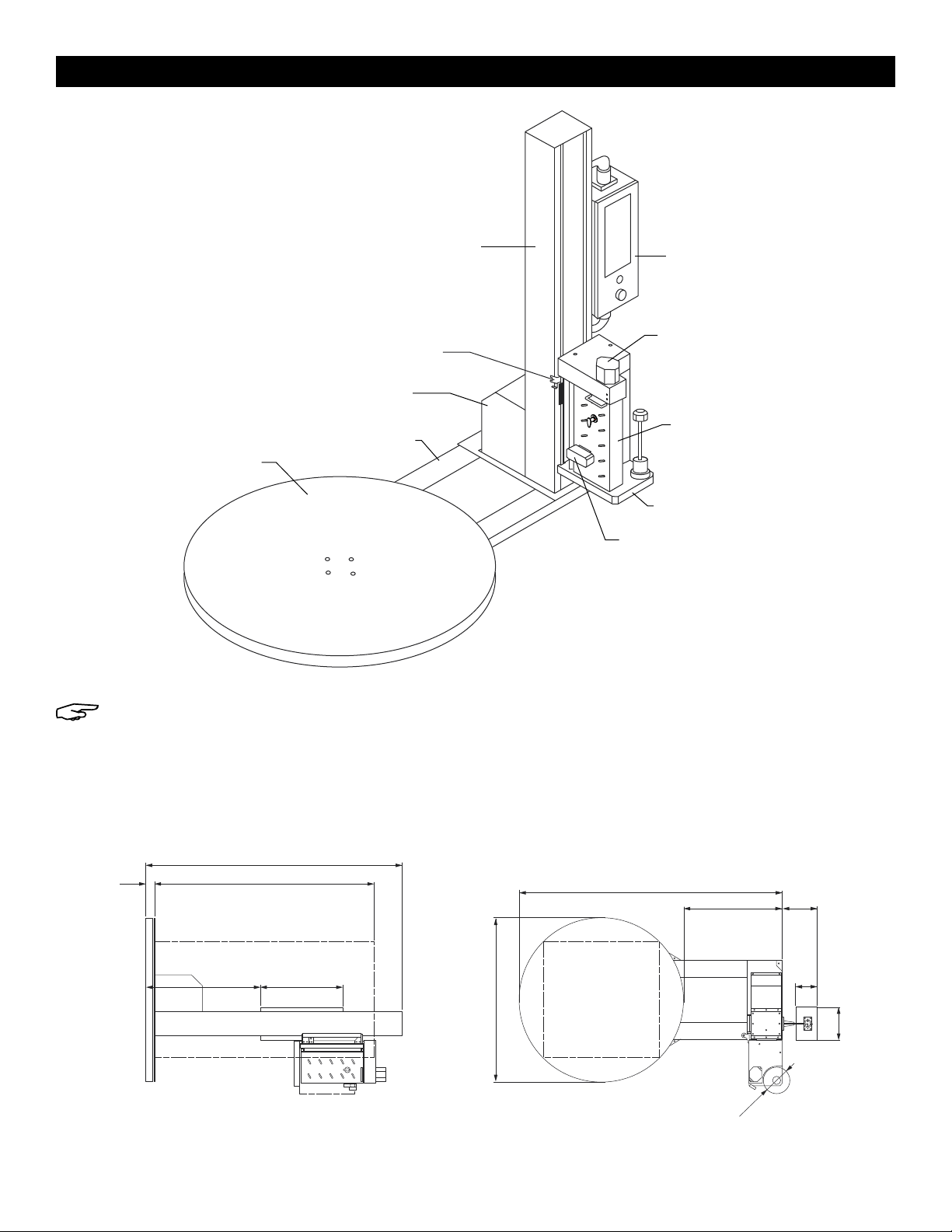

SYSTEM DESCRIPTION

0"

92" Machine Height

Turntable

Photo Sensor

Motor Cover

Frame

Tower

Control Box

Stretch Selector

Cover

Film Carriage

Foot Security Pan

Auto Film Cut

Solenoid

NOTE: Shown below are STANDARD assembly

drawings. It may not reflect your purchased

system, especially when optional items are

added. Refer to assembly drawings shipped

inside the electrical enclosure for more detail

information.

3.25"

80" Wrapping Height

41"

Turntable Size

65"

101.5"

Machine Length

35.5"

12.5"

8"

1

0411 IH-2957PAGE 2 OF 17

Page 3

SYSTEM SET-UP

MACHINE PLACEMENT

Place the Automatic Stretch Wrap Machine close to

an area where you will be wrapping your pallet loads.

Make sure that there is sufficient room to load/unload

the machine and that you do not stretch the wiring

cable. Remember, you will need to provide electrical

service to a 120 VAC, 15-AMP outlet.

FLOOR WEIGHT BEARING TOLERANCE

The floor must be able to bear the weight of the

machine, the weight of the maximum load, plus a safety

factor. The floor must also be able to tolerate the stress

of the machine’s operation. If the fork trucks will operate

on the same weight bearing area, add the weight

of the trucks to the weight bearing stress tolerance

requirements.

WARNING! The Stretch Wrap Machine must be

anchored securely to the floor, using the type

of anchor recommended for your floor.

MACHINE SET-UP

1. Place skidded machine close to the designated

wrap area. Remove all shipping fasteners holding

the machine to the pallet. The machine may be

crated with the tower tilted down with the motor

cover front carriage roller removed for shipping

purpose.

2. Place forks of the forklift through the tubes provided

at the rear base of the module, remove the machine

from these skids, and place it at the designated

wrap area.

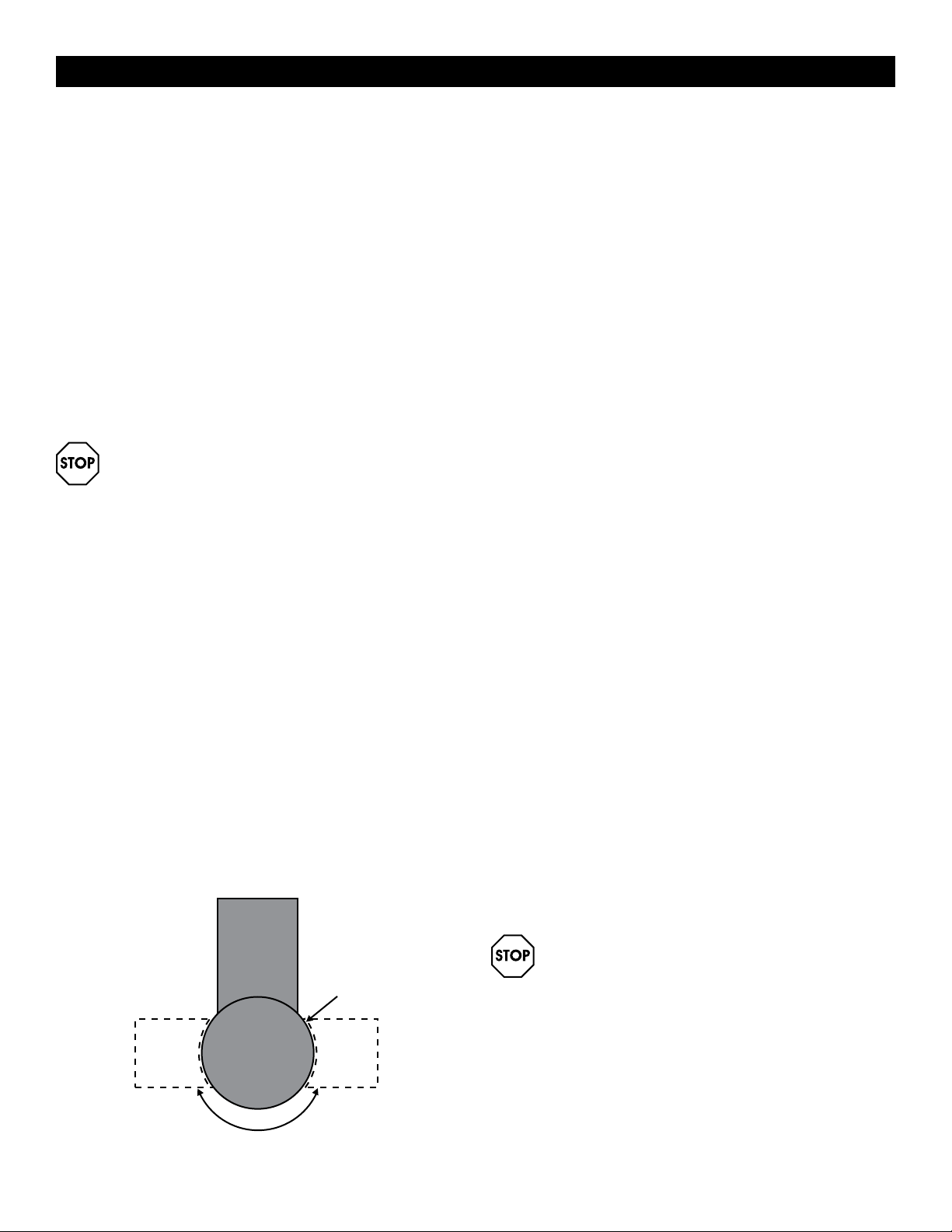

3. If the optional ramp (H-2958) is purchased:

Select a ramp position as illustrated below. The

ramp can be positioned anywhere in a 180° rotation

around the front of the turntable. There should be a

¼" gap between the turntable and the ramp. The

ramp should be fully supported by the floor. Both the

ramp and the machine should be lagged to the floor.

POWER AND SAFETY WIRING CHECKS

1. Using a voltage meter, check the AC voltage

coming to the system to insure proper voltage is

present.

2. Make sure the "E-STOP" button is pressed in. Turn the

disconnect switch to ON position.

3. Pull the "E-STOP" button on the operator panel out.

Power should be applied to the frequency drives,

operating touch-panel, photoelectric sensors,

switches, and LED’s.

4. Press the "E-STOP" button. Make sure all machine

power is completely removed when the "E-STOP" is

depressed. Pull the "E-STOP" button out to resume.

5. Open the film carriage door. Make sure all machine

power is completely removed when the carriage

door is open. Close the film carriage door to resume.

6. Open the electrical control box. Make sure all

machine power is completely removed when the

electrical control box is open. Close the electrical

control box to resume.

7. Trip the carriage foot security bar. Make sure all

machine power is completely removed when the

carriage foot security bar is tripped. Clear the bar to

resume.

PLC'S INPUT MODULE CHECKS

1. Open the electrical control box, and insert the key

latch onto the safety door switch.

2. Depress push buttons and activate selector

switches on the operator panel, check for each

corresponding input lights on the front face of PLC.

3. Block the "Product Height Detection" photoelectric

sensor (located on the film carriage), check for

corresponding input light on the front face of PLC.

4. Trigger magnetic proximity and limit switch sensors,

check each corresponding input lights on the front

face of the PLC.

180˚

¼" Gap

WARNING! Do NOT remove or modify the fixed

upper and lower limit switch stops.

5. Remove the key latch, and close the electrical

control box to resume.

0411 IH-2957PAGE 3 OF 17

Page 4

PRE-STRETCH ADJUSTMENT

Low-Ratio

High-Ratio

Safety Line

Safety Lock

PRE-STRETCH PERCENTAGE CHANGE

To change the pre-stretch percentage, follow the

procedure below:

1. Turn the main disconnect switch off.

2. Remove the knob cover on the film carriage.

3. Push the safety lock and slide the knob to change

the pre-stretch percentage. Lift the knob for the high

percentage, or lower the knob for low percentage.

Standard percentages are 200% (low) and 250%

(high).

4. To ensure safety and correct operation of the stretch

gears, check the following items:

a) The safety line is back to its home position

following the profile of the knob.

b) The light indicates the selected pre-stretch

percentage.

High Ratio

Low Ratio

Safety Lock

0411 IH-2957PAGE 4 OF 17

Page 5

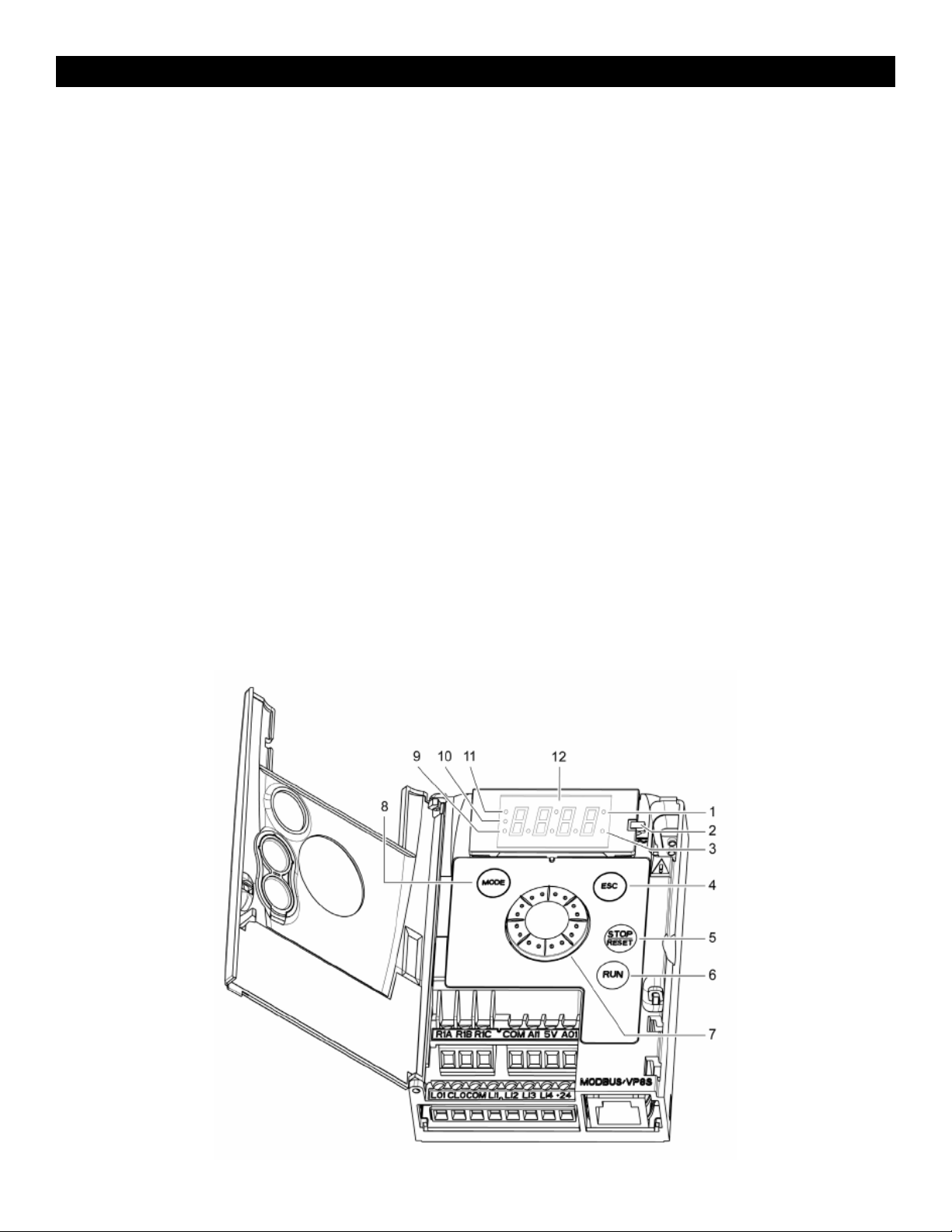

FREQUENCY DRIVE

An electronic frequency motor drive is a device that

controls the 3-phase AC induction motor’s speed by

varying the frequency of the power sent to the motor.

The Predator Turntable Stretch Wrapper uses Schneider

Electrical Altivar 12 Adjustable Frequency Drives.

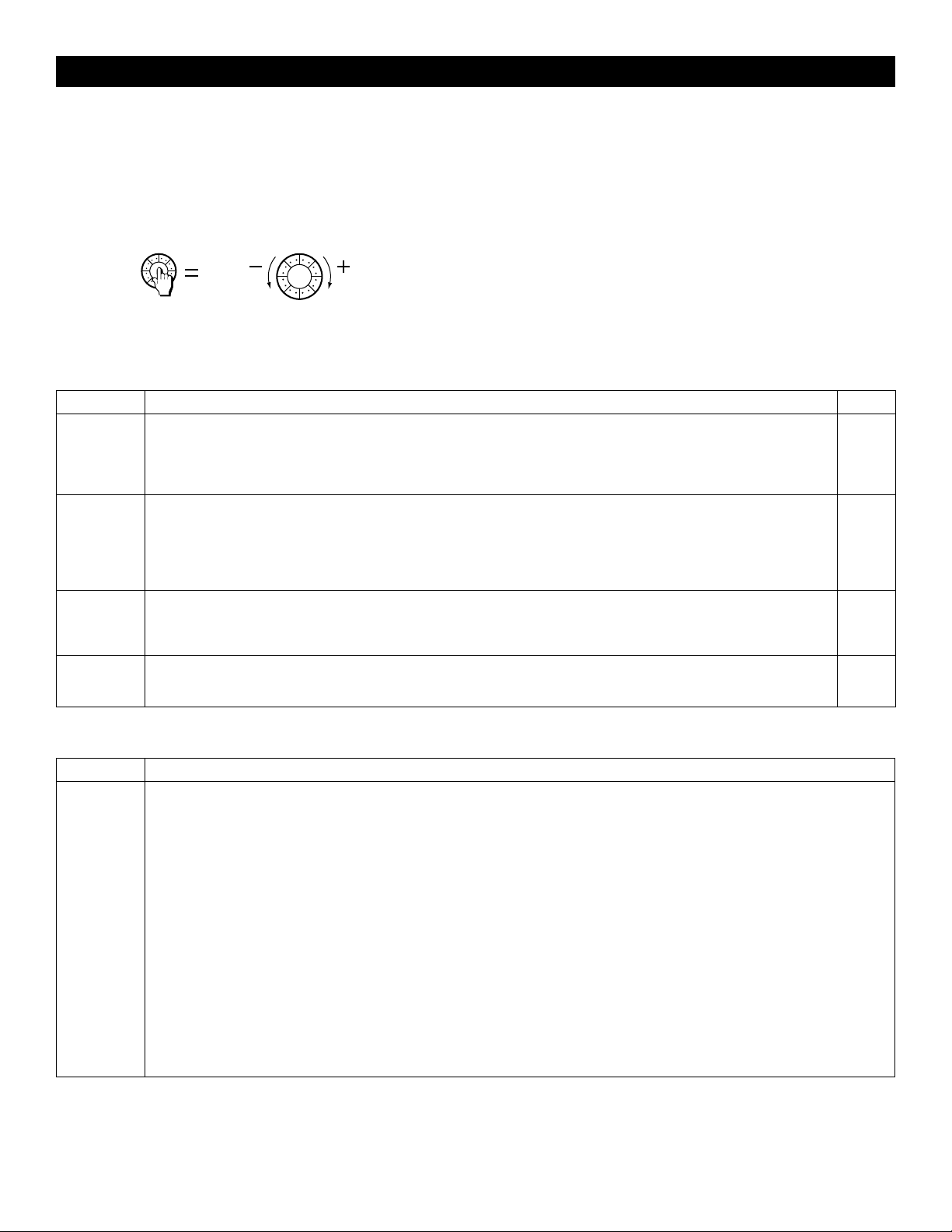

ALTIVAR 12 DIGITAL KEYPAD DESCRIPTION

The digital keypad includes the displays panel and

the keypad. The display panel provides the parameter

display and shows the operation status of the AC

drive. The keypad provides programming and control

interface.

DESCRIPTION:

1. Value LED (a) (b)

2. Charge LED

3. Unit LED (c)

4. ESC button: Exits a menu or parameter, or aborts

the displayed value to return to the previous value

in the memory.

5. STOP button: Stops the motor (could be hidden

by door if function disabled). Important: See

instructions for "RUN/STOP" cover removal.

7. Jog dial

- For navigation when turned clockwise or

counterclockwise

- and selection / validation when pushed

8. MODE button

Switches between the control/programming modes.

The MODE button is only accessible with the HMI

door open.

9. CONFIGURATION mode LED (b)

10. MONITORING mode LED

11. REFERENCE mode LED

12. Four "7-segment" displays

(a) If illuminated, indicates that a value is displayed,

for example, 0.5 is displayed for "0.5".

(b) When changing a value the configuration mode

LED and the value LED are on steady.

(c) If illuminated, indicates that a unit is displayed,

for example, AMP is displayed for "Amps".

6. RUN button: Starts running if the function is

configured (could be hidden by door if function

disabled).

0411 IH-2957PAGE 5 OF 17

Page 6

FREQUENCY DRIVE CONTINUED

MENU STRUCTURE

To access the complete set of drive parameters first

press the wheel to access different modes. Using the

To access the monitoring parameters, press the wheel

on the face of the frequency drive. Using the wheel,

scroll through the list until the display shows Non (Mon)

for monitoring mode. This gives the user access to all the

wheel, scroll to "COnF" and press the wheel again; this

will access different sets of parameters. Using the wheel,

scroll to "FULL" and press the wheel; this will give the user

access to the complete parameter set.

monitoring parameters.

ENT

MONITORING PARAMETERS

CODE NAME/DESCRIPTION UNIT

LFr

rFr

External Reference Value:

External keypad or local force mode configured. Forced local reference FLOC set to LCC and forced local

assignment FLO different to nO. Displays the speed reference coming from the remote keypad. This value is not

visible in factory setting.

Output Frequency:

This function provides the estimated motor speed. It corresponds to the estimated motor frequency (on the motor

shaft). In standard law the output frequency rFr is equal to stator frequency. In performance law the output

frequency rFr motor speed is equal to the estimated motor speed.

Range: -400 to 400 Hz

Hz

Hz

LCr

ULn

CODE NAME/DESCRIPTION

StAt

rdY

rUn

ACC

dEc

dCb

CLl

nSt

Obr

CtL

tUn

FSt

nLP

Motor Current:

Estimation of the effective motor current from phase current measurements with an accuracy of 5%. During DC

injection, the current displayed is the maximum value of current injected in the motor.

Main Voltage:

Line voltage from the point of view of the DC bus, motor running or stopped.

ß Product Status

This parameter shows the state of the drive and motor.

ß Drive ready.

ß Drive running, the last six segments to the right of the code also indicate direction and speed.

ß Acceleration, the last six segments to the right of the code also indicate direction and speed.

ß Deceleration, the last six segments to the right of the code also indicate direction and speed.

ß DC injection braking in progress.

ß Current limit, the four segments located on right down of display are blinking.

ß Freewheel stop control.

ß Auto-adapted deceleration.

ß Controlled stop on mains phase loss.

ß Auto-tuning in progress.

ß Fast stop.

ß No line power. When the control part is energized via the RJ45 connector and there is no power on the main input and

no run order is present.

A

A

0411 IH-2957PAGE 6 OF 17

Page 7

FREQUENCY DRIVE CONTINUED

PROGRAMMABLE FUNCTIONS

All functions have been Highlight factory set and

tested. The factory settings listed in this manual are the

drive manufacturer's factory setting, not the Highlight

Industries factory settings. Refer to the Electrical

Schematic Drive Parameters page for the Highlight

I_O MENU

CODE SUB-

CODE

tCC Type of Control:

Al1- Al1t Analog Input 1 Type:

r1 Relay Output 1 Assignment:

AO1- AO1 Analog Output 1 Assignment:

AO1t Analog Output 1 Type:

NAME/DESCRIPTION

2C – 2-wire control

3C – 3-wire control

5U – 0-5VDC input voltage

10U – 0-10VDC input voltage

0A – 0-20mA current input

nO – Not assigned

FLt – No error detected

rUn – Drive run

nO – Not Assigned

OCr – Motor current

OFr – Output Frequency

10U – 0-10VDC

0A – 0-20mA

4A – 4-20mA

factory settings. Some of the most commonly adjusted

programmable functions (parameters) are listed below:

NOTE: Refer to the manufacturer's operation

manual or website for complete lists and

explanations.

FACTORY

SETTING

2C

5U

FLt

nO

0A

drC MENU

CODE

SUBCODE

bFr Standard Motor Frequency 50/60 50Hz

nPr Rated Motor Power (% of drive rated HP) 0.5-1.2 1

UnS Rated Motor Voltage 100-480V 230V

nCr Rated Motor Current plate Varies

FrS Rated Motor Frequency 10-400Hz 50 Hz

nSP Rated Motor Speed 0-24000rpM Varies

tFr Maximum Frequency 10-400Hz 72 Hz

Ctt Motor Control Type:

UFr IR Compensation:

SLP Slip Compensation 0-150% 100%

StA Frequency Loop Stability: Adjusts overshoots and oscillations at the end of

FLG Frequency Loop Gain: Adjusts the slope of the speed increase. A lower number

tUn Motor Auto Tuning: Automatically tunes the drive to the motor profile nO/YES/dOnE nO

NAME/DESCRIPTION ADJUSTMENT

RANGE

PErF – Performance, Sensorless Vector

Std – Standard, Volts/Hertz

PUNP – Pump, low torque

25-200% 100%

Optimizes torque at very low speeds

0-100% 20%

acceleration or deceleration. A higher number decreases oscillations

0-100% 20%

decreases oscillations.

FACTORY

SETTING

0411 IH-2957PAGE 7 OF 17

Std

Page 8

CtL MENU

FREQUENCY DRIVE CONTINUED

CODE

SUB-

NAME/DESCRIPTION FACTORY

CODE

Fr1 Speed Reference Channel 1:

CHCF Channel Configuration:

Cd1 Command Channel 1 (run fwd/rev, stop):

Al1 – Terminal analog input

LCC – Remote Display

Ndb – Modbus

AIU1 – Jog dial (wheel) on drive

SIN – Not separate mode. Speed and run commands from the same source.

SEP – Separate mode. Speed and run commands from different sources.

Only appears if CHCF is set to SEP.

tEr – terminals

LOC – Local

LCC – Remote display

Ndb – Modbut

FUn MENU

CODE

SUBCODE

rPt- ACC Acceleration Time (seconds) 0.0-999.9 s 3.0 s

dEC Deceleration Time (seconds) 0.0-999.9 s 3.0 s

brA Decel Ramp Adaptation Assignment:

NAME/DESCRIPTION ADJUSTMENT

RANGE

nO – Function inactive. (Used with dynamic braking)

YES – Automatically increases the deceleration time to prevent a DC bus overvoltage

dYnA – Most rapid deceleration possible without a dynamic braking resistor.

SETTING

Al1

SIM

tEr

FACTORY

SETTING

YES

Stt- Stt Type of Stop:

rNP – Ramp Stop

FSt – Fast Stop

nSt – Freewheel

rrS Reverse Direction Assignment:

nO – Function inactive

L1H – Input L1 active high

L2H – Input L2 active high

L3H – Input L3 active high

L4H – Input L4 active high

AdC- AdC Automatic DC Injection:

nO – function inactive

YES – Time limited DC injection

Ct – Continuous DC injection

SdC1 Automatic DC Injection Current 0-120% if nCr 70%

tdC1 Automatic DC Injection Time (seconds) 0.1-30 s 0.5 s

PSS- PS2 Second Preset Speed Assignment:

nO – Function inactive

L1H – Input L1 active high

L2H – Input L2 active high

L3H – Input L3 active high

L4H – Input L4 active high

SP2 Second Preset Speed Reference 0-400 Hz 10 Hz

CLI- CL1 Current Limitation 0.25-1.5 plate varies

rNP

nO

YES

nO

SPL- LSP Low Speed Setting (Hz) 0-HSP 0 Hz

HSP High Speed Setting (Hz) LSP-tFr 60 Hz

0411 IH-2957PAGE 8 OF 17

Page 9

FLt MENU

FREQUENCY DRIVE CONTINUED

CODE

SUBCODE

rSF Fault Reset Assignment:

Atr- Atr Automatic Restart:

tAr Max automatic restart time 5 min

FLr Flying Restart (Catch on the fly):

tHt- ltH Motor Thermal Current varies

NAME/DESCRIPTION

nO – Function inactive

L1H – Input L1 active high

L2H – Input L2 active high

L3H – Input L3 active high

L4H – Input L4 active high

nO – Function inactive

YES – Automatic drive restart after fault condition

Restarts the motor at the estimated speed the motor is already going.

nO – Function inactive

YES – Function active

FACTORY

SETTING

FAULT DETECTION

The AC drive has a comprehensive fault diagnostic system

that includes several different alarms and fault messages.

Once a fault is detected, the corresponding protective

functions will be activated. The following faults are

displayed as shown on the AC drive digital keypad display.

NOTE: Not all faults can be cleared by resetting

at the keypad.

nO

nO

nO

CODE NAME POSSIBLE CAUSES REMEDY

OCF

SCF 1

SCF 3

SCF 4

SOF

Overcurrent

Motor short circuit • Short circuit or grounding at the drive output

Ground short circuit

IGBT short circuit • Internal power component short circuit detected

Overspeed • Instability

• Parameters in the Motor Control Menu

not correct

• Inertia or load too high

• Mechanical locking

• Ground fault during running status

• Commutation of motors during running status

• Significant current leakage to ground if several

motors are connected in parallel

at power on

• Overspeed associated with the inertia of the

application

drC - are

• Check the parameters

• Check the size of the motor/drive/load

• Check the state of the mechanism

• Connect line motor chokes

• Reduce the Switching Frequency

• Check the ground connection of drive, motor

cable and motor insulation

• Check the cables connecting the drive to the

motor, and the motor insulation

• Connect motor chokes

• Contact your local Schneider Electric

representative

• Check the motor

• Overspeed is 10% more than Maximum

Frequency tFr so adjust this parameter if

necessary

• Add a braking resistor

• Check the size of the motor/drive/load

• Check parameters of the speed loop (gain

and stability)

5Fr

0411 IH-2957PAGE 9 OF 17

Page 10

FREQUENCY DRIVE CONTINUED

CODE NAME POSSIBLE CAUSES REMEDY

tnF

Auto-tuning • Motor not connected to the drive

• One motor phase loss

• Special motor

• Motor is rotating (being driven by the load, for

example)

• Check that the motor/drive are compatible

• Check that the motor is present during autotuning

• If an output contactor is being used, close it

during auto-tuning

• Check that the motor is completely stopped

LFF 1

ObF

OHF

OLC

OLF

OPF 1

Al current lost fault Detection if:

• Analog input Al1 is configured as current

• Al1 current scaling parameter of 0% CrL 1 is

greater than 3 mA

• Analog input current is lower than 2 mA

Overbraking • Braking too sudden or driving load too high • Increase the deceleration time

Drive overheat • Drive temperature too high • Check the motor load, the drive ventilation

Process overload • Process overload • Check the process and the parameters of the

Motor overload • Triggered by excessive motor current • Check the setting of the motor thermal

1 output phase loss • Loss of one phase at drive output • Check the connections from the drive to the

• Check the terminal connection

• Install a module unit with a braking resistor if

necessary

• Check the line supply voltage, to be sure that

it is under the maximum acceptable (20% over

maximum line supply during run status

and the ambient temperature. Wait for the

drive to cool down before restarting. See

mounting and temperature conditions

drive to be in phase

protection, check the motor load

motor

• In case of using downstream contactor, check

the right connection, cable and contactor

OPF 2

OSF

3 output phase loss • Motor not connected

• Motor power too low, below 6% of the drive

nominal current

• Output contactor open

• Instantaneous instability in the motor current

Main overvoltage • Line voltage too high:

- At drive power on only, the supply is 10% over the

maximum acceptable voltage level

- Power with no run order, 20% over the maximum

line supply

• Disturbed line supply

• Check the connections from the drive to the

motor

• Test on a low power motor or without a motor:

In factory settings mode, motor phase loss

detection is active Output Phase loss detection

OPL = yES. To check the drive in a test or

maintenance environment, without having to

use a motor with the same rating as the drive,

deactivate motor phase loss detection Output

Phase loss detection OPL = nO

• Check and optimize the following parameter:

IR compensation (law U/F) UFr. Rated motor

voltage UnS and Rated motor current nCr

and perform an Auto-tuning tUn.

• Check the line voltage

0411 IH-2957PAGE 10 OF 17

Page 11

FREQUENCY DRIVE CONTINUED

CODE NAME POSSIBLE CAUSES REMEDY

PHF

Input phase loss • Drive incorrectly supplied or a fuse blown

• Failure of one phase

• 3-phase ATV12 used on a single-phase line supply

• Unbalanced load

• This protection only operates with the drive on load

• Check the power connection and the fuses

• Use a 3-phase line supply

• Disable the fault by setting Input Phase loss

detection IPL = nO

SCF 5

SLF 1

SLF 2

SLF 3

ULF

tJF

Load short circuit • Short circuit at drive output

• Short circuit detection at the run order or DC

injection order if parameter IGBT test Strt is set

to YES

Modbus

communication

SoMove

communication

HMI communication • Fault communicating with the external display

Process underload

fault

IGBT overheat • Drive overheated

• Interruption in communication on the Modbus

network

• Fault communicating with SoMove • Check the SoMove connection cable

terminal

• Process underload

• Motor current below the application underload

threshold LUL parameter during a perid set

by application underload time delay ULt

parameter to protect the application

• IGBT internal temperature is too high according

to ambient temperature and load

• Check the cables connecting the drive to the

motor, and the motor’s insulation

• Check the connections of communication bus

• Check the time-out (Modbus time out ttO

parameter)

• Refer to the Modbus user manual

• Check the time-out

• Check the terminal connection

• Check the process and the parameters of the

drive to be in phase

• Check the size of the load/motor/drive

• Reduce the Switching frequency

• Wait for the drive to cool before restarting

SFr

0411 IH-2957PAGE 11 OF 17

Page 12

OPERATOR CONTROLS

The operator panel for Predator XS is shown and

described as follows:

START

The "Start" button

initiates all operations,

in automatic or manual

modes. When the system

is in automatic mode,

the button LED stays on

until the wrapping cycle

is complete. In manual

mode, the button LED

flashes until the operation

is stopped.

WRAP/RESET

Switch to "Reset" and press

the "Start" button to clear

any operation. The film

carriage will lower to the

bottom limit switch and the

turntable will return to its

home position.

Switch to "Up Only" to

select automatic single

wrap mode. Press the

"Start" button to begin

cycle. The film carriage will

begin applying the bottom

wraps, travel upwards to

top of the product, apply top wraps, and then stops.

Press the "Start" button again to lower the film carriage

to the bottom limit switch.

Switch to "Up/Down" to select automatic double wrap

mode. Press the "Start" button to begin cycle. The film

carriage will begin applying the bottom wraps, travel

upwards to top of the package, apply top wraps, and

travel downwards to finish cycle.

TURNTABLE

To run an automatic mode, switch to "Auto" and press

the "Start" button. To jog the turntable manually, switch

to "Manual" and press the "Start" button. To stop the

turntable, switch to "Auto", or press the "Stop" button.

FILM CARRIAGE

To run an automatic mode, switch to "Auto" and press

the "Start" button. To raise or lower the film carriage

manually, switch to "Manual Up" or "Manual Down", and

press the "Start" button. To stop, switch to "Auto", or press

the "Stop" button.

TURNTABLE SPEED

The "Turntable Speed" potentiometer dial determines the

speed of the turntable in both automatic and manual

modes. Turn clockwise to increase, counter-clockwise to

decrease. Adjusting this will affect the film overlap. The

maximum turntable speed is 12 rotation-per-minute (RPM).

CARRIAGE SPEED

The "Carriage Speed" potentiometer dial determines the

speed of the turntable in both automatic and manual

modes. Turn clockwise to increase, counter-clockwise to

decrease. Adjusting this will affect the film overlap.

FILM FORCE

The "Film Force" potentiometer dial determines the

amount of film tension applied to the load in a

wrapping cycle. Turn clockwise to increase, counterclockwise to decrease. The best product wrapping

and proper dancer bar response is achieved when the

dancer bar is set to between half and two thirds of its

full extension. This gives the proper force to load setting

and allows a good proportion of the spring return travel

on the dancer bar to be used when the turntable slows

down at the end of cycle.

STOP

TOP WRAPS

Switch to the desired number of rotations for applying

wraps to the top of the product.

BOTTOM WRAPS

Switch to the desired number of rotations for applying

wraps to the bottom of the product.

The "STOP" button cuts machine operation and removes

power to frequency drives. In the event this button is

pressed during the course of operation, it is necessary to

pull this button fully out to reset the machine.

WARNING! If the "STOP" button is depressed

while the turntable is rotating, the turntable will

NOT stop immediately, but rather it will coast

and decelerate to a stop.

POWER INDICATOR LIGHT

The LED indicates that power is supplied to the machine.

0411 IH-2957PAGE 12 OF 17

Page 13

MACHINE OPERATION

FILM LOADING

Follow procedure below to thread film onto the

carriage:

1. Rotate the handle and open the film carriage.

2. Pull six (6) feet of film off the film roll.

3. Follow the diagram below and "thread" the 6-foot

film tail all the way through the rollers.

4. Close the film carriage and rotate the handle in the

opposite direction to lock.

5. Attach the film securely to the pallet. Tying the end

of the film in a knot often helps to secure the film to

the pallet.

Film

C

B

A

STOP CONDITION

Follow procedure below in the event of emergency.

1. Press the "STOP" button. This cancels the current

wrapping cycle and immediately stops the system.

2. Correct the problem.

3. Pull the "STOP" button out, and then perform normal

system start-up procedure.

NOTE: After pressing the "E-STOP" button,

wait for at least 60 (sixty) seconds before

pulling the button back out. This will allow the

frequency drives to completely go off.

APPLYING REINFORCEMENT WRAPS

Automatic operation can be paused in order to apply

reinforcement wraps to an additional top sheet or

corner boards on the product. Follow the procedure

below.

1. Press the "Start" button as normal to initiate cycle.

2. As the carriage travels up, switch the "Turntable"

selector from Auto to Manual. Both the turntable

and the film carriage will pause.

3. Apply the top sheet or corner boards to the

product.

Security Door

NORMAL SYSTEM START-UP

After the machine has been positioned and supplied

with proper voltage, you are ready to begin operation.

Read thoroughly and follow these steps to operate your

system:

1. Place product on the turntable.

2. Make sure the turntable is at home position.

3. Make sure the film carriage is situated at the max

down position.

4. Thread the film as instructed, and attach it to the

product.

5. Set the desired numbers for top and bottom wrap

counts.

6. Select the "Up Only" or "Up/Down" wrapping mode.

7. Turn the "Turntable" and "Film Carriage" selector

switches to Auto position.

8. Press the "Start" button to initiate cycle.

4. Press the "Start" button to resume cycle. Leave the

"Turntable" selector switch in Manual position. The

turntable will now rotate in Manual mode.

5. Once the reinforcement wraps have been applied,

switch the "Turntable" selector switch from Manual to

Auto. The turntable will pause.

6. Press the "Start" button again to complete the

automatic operation.

If the "Turntable" selector is switched from Auto to

Manual while the carriage is traveling down, the

carriage will travel back up and apply the top wraps

before completing the wrap cycle. This to ensure the

top sheet applied during the manual operation is

properly wrapped into the product.

AUTOMATIC FILM CUT

The automatic film cut feature is always enabled in

the automatic mode. On the last wrap revolution,

the puncture solenoid, located on the film carriage,

engages, tearing a small hole in the film. The powered

film feed motor stops to allow the film force-to-load to

increase the turntable rotates to its home position. The

punctured film is stretched, until eventually cut.

0411 IH-2957PAGE 13 OF 17

Page 14

MAINTENANCE

As with all machinery, proper attention and

maintenance is the key to long component life,

maximum performance, and safe operation. By

spending a few minutes reading and following these

preventive measures, you should reduce the downtime

and prolong the life of your system.

It is important to understand that these maintenance

schedules are minimum recommendations. Anyone

who maintains or services a stretch wrap machine

must first satisfy himself/herself as to the schedules of

preventive maintenance based on cycling operation

and environmental locations.

WARNING! All maintenance operations require

the equipment to be powered down and

locked out for personnel safety.

LOCK-OUT/ TAG-OUT PROCEDURES

Be sure that anyone performing any type of

maintenance on this equipment is familiar with and is

adhering to the lock-out/tag-out procedures set forth by

the General OSHA or the State OSHA guidelines.

VISUAL CHECKS

Visual checks should be conducted at least once per

month:

TURNTABLE BELT ADJUSTMENT

Refer to figure below to adjust the turntable belt. First,

loosen the four motor flange (M10) screws. Turn the

(M10) bolt on the adjuster tab until the belt is tensioned.

Retighten the four motor flange screws.

M10 Screw

M10 Bolt

FILM CARRIAGE LIFT CHAIN ADJUSTMENT

Refer to figure below to adjust the film carriage lift

chain. First, loosen nut (M12) on the adjustment bracket.

Turn the bottom bolt until desired tension is achieved.

Retighten nut (M12). Note that the driving chain

and adjustment bracket should be parallel with the

moveable pulley base.

1. Keep the machine and surrounding area as clean

as possible, especially near moving components.

2. Check for loose hardware, especially set screws

located in: sprocket hubs, bearing hubs, and

flanges.

3. Check for oil leaks around the speed reducers.

4. Check for dry seals at the bearings.

5. Check for chain wear and proper tension on the

power roller stretch sprockets. The correct amount of

chain tension can be checked by pulling the chain

taut and having 3/8" slack.

6. Check for loose electrical connections and for

frayed cords and cables. Replace immediately any

damaged cords and cables.

SPROCKET AND CHAINS

All sprockets should be inspected for wear, and chains

should be checked for proper tension and lubrication

on a periodic basis. Failure to do so will lead to

premature sprocket failure. Any general-purpose chain

lube should be sufficient for lubrication. Replace chain

guards when preventative maintenance is complete.

0411 IH-2957PAGE 14 OF 17

Page 15

MAINTENANCE SCHEDULE TABLE

PART SCHEDULE SERVICE WITH

Turntable Reducer

Sealed, lubricated with premium lubricant. No maintenance required. N/A

Film Carriage Reducer

Film Delivery Reducer

All Pivot Bearings

Sealed, lubricated with premium lubricant. No maintenance required. N/A

Sealed, lubricated with premium lubricant. No maintenance required. N/A

N/A N/A

NOTE: Refer to electrical and mechanical

component's operations manuals shipped

inside the enclosure for additional

maintenance information.

WARNING! Make sure that only qualified

personnel will perform inspection,

troubleshooting, and part replacement.

HIGH VOLTAGE! Disconnect all power including

external control power that may be present

before servicing the frequency drive controllers.

WAIT for 3 (three) minutes for the DC bus

capacitors to discharge. The frequency drive

controller’ display and/or LED’s are not accurate

indicators of the absence of DC bus voltage.

TROUBLESHOOTING

This section will guide you in identifying typical problems

while operating the Predator Turntable Stretch Wrapper,

and provide you with corresponding solution(s). If further

assistance is required, call the number listed on the

last page of this manual. To receive quick and proper

technical support, please be prepared to provide the

following information:

1. Machine serial number

2. Date of purchase

3. Symptoms of any problem

OPERATING ISSUE CAUSES RECOMMENDATIONS

Machine not powering on.

Turntable is malfunctioning.

The electrical control box is not closed.

The film carriage loading door is not closed.

The film carriage foot safety switch is not clear.

The system is not plugged into a 120VAC outlet.

Use a voltmeter to test supply voltage from the plant's

outlet. Is it reading 120VAC.

Use a voltmeter to test supply voltage from the plant's

outlet. Does it have continuity.

Turntable speed potentiometer dial not set high enough.

Resistance of potentiometer not equal to 5KΩ across.

Is the LED display on the turntable frequency drive.

The frequency drive is not functioning. Push the "STOP"

button. Wait 60 seconds, and then pull the button out. Is

the fault cleared?

The frequency drive is not connected properly to motor.

The parameters of the frequency drive are not set

correctly.

The turntable motor is not running.

None of the recommendations work.

Close the control box properly.

Close the carriage door properly.

Remove obstruction from the switch.

Plug machine into a 120VAC outlet.

Plug machine into a 120VAC outlet.

Replace the power cord to the machine.

Adjust potentiometer towards 100% to set speed.

Tighten wiring, replace dial if necessary.

Check and switch on main circuit breaker.

Refer to frequency drive manual for specific fault.

Tighten or replace wiring as necessary.

Restore drive parameters setting.

Check turntable motor for mechanical

restrictions.

Replace turntable frequency drive.

0411 IH-2957PAGE 15 OF 17

Page 16

TROUBLESHOOTING CONTINUED

OPERATING ISSUE CAUSES RECOMMENDATIONS

Turntable does not stop at

home.

Are the parameters of the frequency drive set properly.

Does the indicator light of the turntable home proximity

switch turn on when the table is at home position. If not,

clear obstructions and adjust sensor to pick up target.

Now does the indicator light turn on.

Restore drive parameter setting.

Tighten power wiring the sensor, replace if

necessary.

Film carriage does not move.

The carriage does not raise

in a wrapping cycle.

Film carriage speed is not set high enough.

Resistance of potentiometer not equal to 5KΩ across.

The carriage limit switch lever arm does not move freely.

The limit switch is not wired properly.

The LED display is not on the film carriage frequency drive.

The frequency drive is not functioning. Push the "STOP"

button. Wait 60 seconds, and then pull the button out. Is

the fault cleared?

The frequency drive is not connected properly to motor.

The parameters of the frequency drive are not set

correctly.

The film carriage motor is not running.

None of the recommendations work.

The product height detection photoelectric sensor does

not see the product.

The indicator light does not turn on as the turntable passes

the home position. If not, clear obstructions and adjust

sensor to pick up target. Now does the indicator light turn on.

Adjust potentiometer towards 100% to set

speed.

Tighten wiring, replace dial if necessary.

Remove obstruction, and/or clean limit switch

head.

Tighten or replace limit switch as necessary.

Switch the film carriage circuit breaker on.

Refer to frequency drive manual for specific

fault.

Tighten or replace wiring as necessary.

Restore drive parameters setting.

Check film carriage motor for mechanical

restrictions.

Replace film carriage frequency drive.

Adjust the sensitivity of the sensor.

Tighten power wiring to the sensor, replace if

necessary.

The carriage does not stop

at the top of product in a

wrapping cycle.

The carriage does not lower

after the completion of top

wraps count.

The film mandrel does not

rotate.

The film carriage product height detection photo sensor

does not have power.

The sensor sees objects other than the product.

The indicator light does not turn on as the turntable passes

the home position.

sensor to pick up target. Now does the indicator light turn on.

The film carriage dancer bar limit switch is not positioned

correctly.

The indicator light does not turn on as the dancer bar is

pulled.

The LED display is not on the film delivery frequency drive.

The frequency drive is not functioning. Push the "STOP"

button. Wait 60 seconds, and then pull the button out. Is

the fault cleared?

The frequency drive is not connected properly to the motor.

The parameters of the frequency drive are not correct.

The film delivery motor is not running.

None of the recommendations work.

If not, clear obstructions and adjust

Tighten power wiring to the sensor, replace if

necessary.

Adjust the sensitivity of the sensor.

Tighten power wiring to the sensor, replace if

necessary.

Adjust the switch so that it activates when the

dancer bar is pulled.

Tighten siring to the sensor, replace if

necessary.

Switch the circuit breaker on.

Refer to frequency drive manufacturers

manual for specific fault.

Tighten or replace wiring as necessary.

Restore drive parameters setting.

Check film carriage motor for mechanical

restrictions. Replace if necessary.

Replace film delivery frequency drive.

0411 IH-2957PAGE 16 OF 17

Page 17

TROUBLESHOOTING CONTINUED

OPERATING ISSUE CAUSES RECOMMENDATIONS

The film does not stay

attached to the product at

start.

The film is not threaded correctly.

The film is not in good condition.

The acceleration parameter on the film delivery frequency

drive is not set properly.

The acceleration parameter on the turntable frequency

drive is not set properly.

Refer to film loading diagram.

Use proper film.

Restore parameters as listed on the electrical

schematics.

Restore parameters as listed on the electrical

schematics.

The film does not stay

attached to the product in a

wrapping cycle.

The film is not threaded correctly.

The film is not in good condition.

The "Film Force" dial on the operator panel is not set

correctly.

Resistance of potentiometer not equal to 5KΩ across.

Refer to film loading diagram.

Use proper film.

Make a small adjustment at a time to set the

film force.

Tighten wiring, replace dial if necessary.

0411 IH-2957PAGE 17 OF 17

Loading...

Loading...