Page 1

H -2917

ADJUSTABLE

PALLET TRUCK

1- 800 -295-5 510

uline.com

TECHNICAL DATA

MODEL H -2917

Capacity 5,500 lbs.

Max. Fork Height 7.7 "

Min. Fork Height 3.0"

Fork Length 45½"

Overall Fork Width 21-27"

Fork Wheel Diameter 3" Polyurethane

Steering Wheel Diameter 7" Polyurethane

Net Weight 204 lbs.

OPERATION

WARNING! Operator must read and understand

instructions here and on truck prior to use.

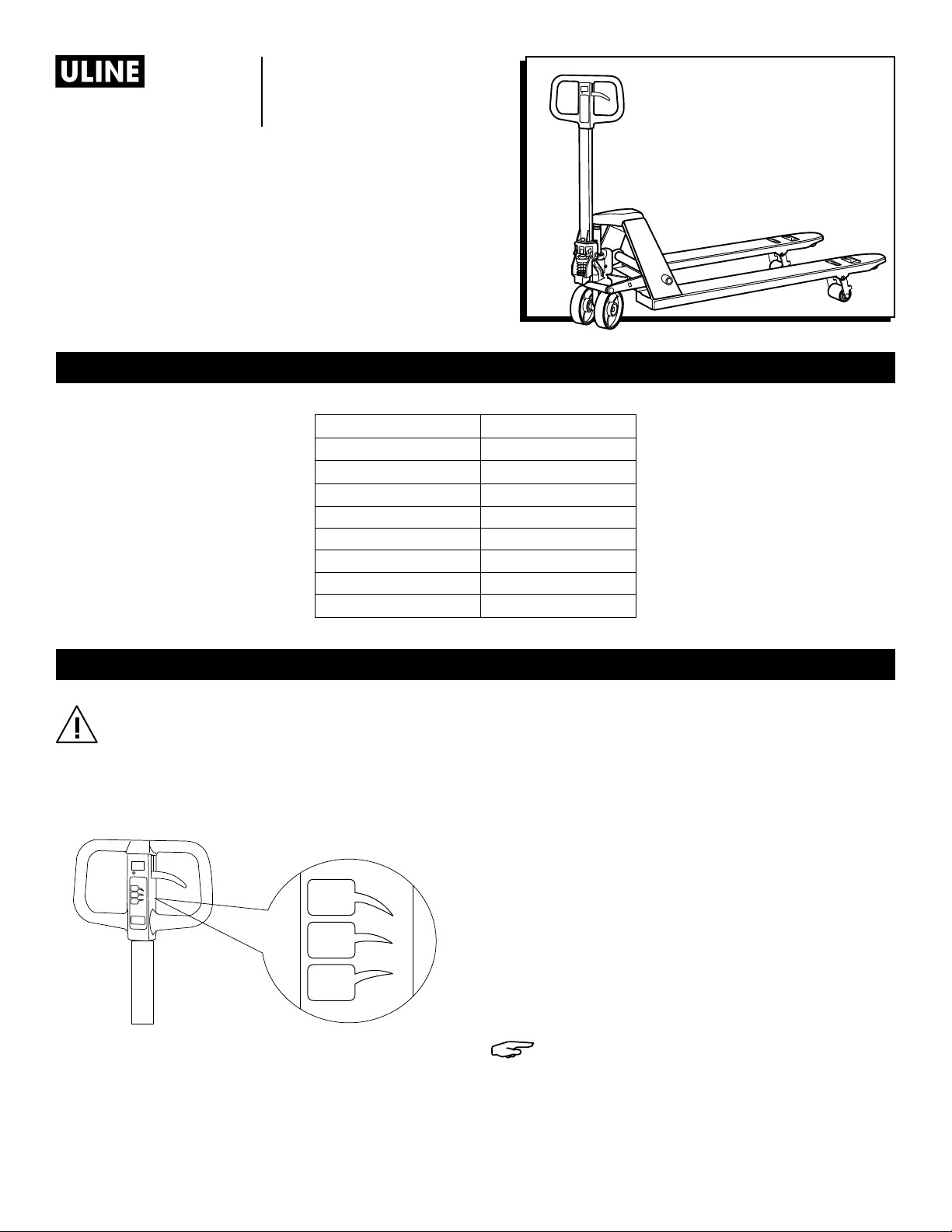

On the handle of the pallet truck, you will find the control

lever, which can be set in three positions.

(See Figure 1)

Figure 1

- UP = to raise the forks

- NEUTRAL = to move the load

- DOWN = to lower the forks

UP

N

DOWN

1. If the forks elevate while pumping in the NEUTRAL

position, turn the setting screw clockwise until

pumping the handle does not raise the forks and the

NEUTRAL position functions correctly.

2. If the forks descend while pumping in the NEUTRAL

position, turn the setting screw counterclockwise until

the forks do not lower.

3. If the forks do not descend when the control lever is

in the DOWN position, turn the setting screw clockwise

until raising the control lever lowers the forks. Then

check the NEUTRAL position as per steps 1 and 2.

4. If the forks do not lift while pumping in the UP position,

turn the setting screw counterclockwise until the forks

elevate while pumping in the UP position. Then check

the NEUTRAL and DOWN position as per steps 1, 2

and 3.

NOTE: When viewing the truck from the handle

side, the setting screw is located on the right

side of the pump above the right wheel. The

truck will lower faster or slower depending on

how far in or out the screw is adjusted.

0114 I H -2917PAGE 1 OF 6

Page 2

MAINTENANCE

OIL

Please check the oil level every six months.

Use the hydraulic oil SAE #10.

HOW TO EXPEL AIR FROM THE PUMP UNIT

Air may enter the unit over time or when the seals are

replaced. To expel the air, lift the control lever to the

DOWN position and move the handle up and down

several times.

SAFETY

For safe operation of the Hand Pallet Truck, please read

all warning signs and instructions here and on the pallet

truck prior to use.

1. Do not operate the pallet truck unless you are familiar

with it and have been trained and authorized to do so.

2. Do not use the truck on sloping ground.

3. Never place any part of your body in the lifting

mechanism or under the forks or load. Do not carry

passengers.

4. We advise that operators should wear gloves and

safety shoes.

DAILY CHECK AND MAINTENANCE

Daily checks of the pallet truck can limit wear and tear

on the unit. Pay special attention to the wheels, the axles,

the handle, the forks and lift and lower control.

LUBRICATION

Use motor oil or grease to lubricate all movable parts.

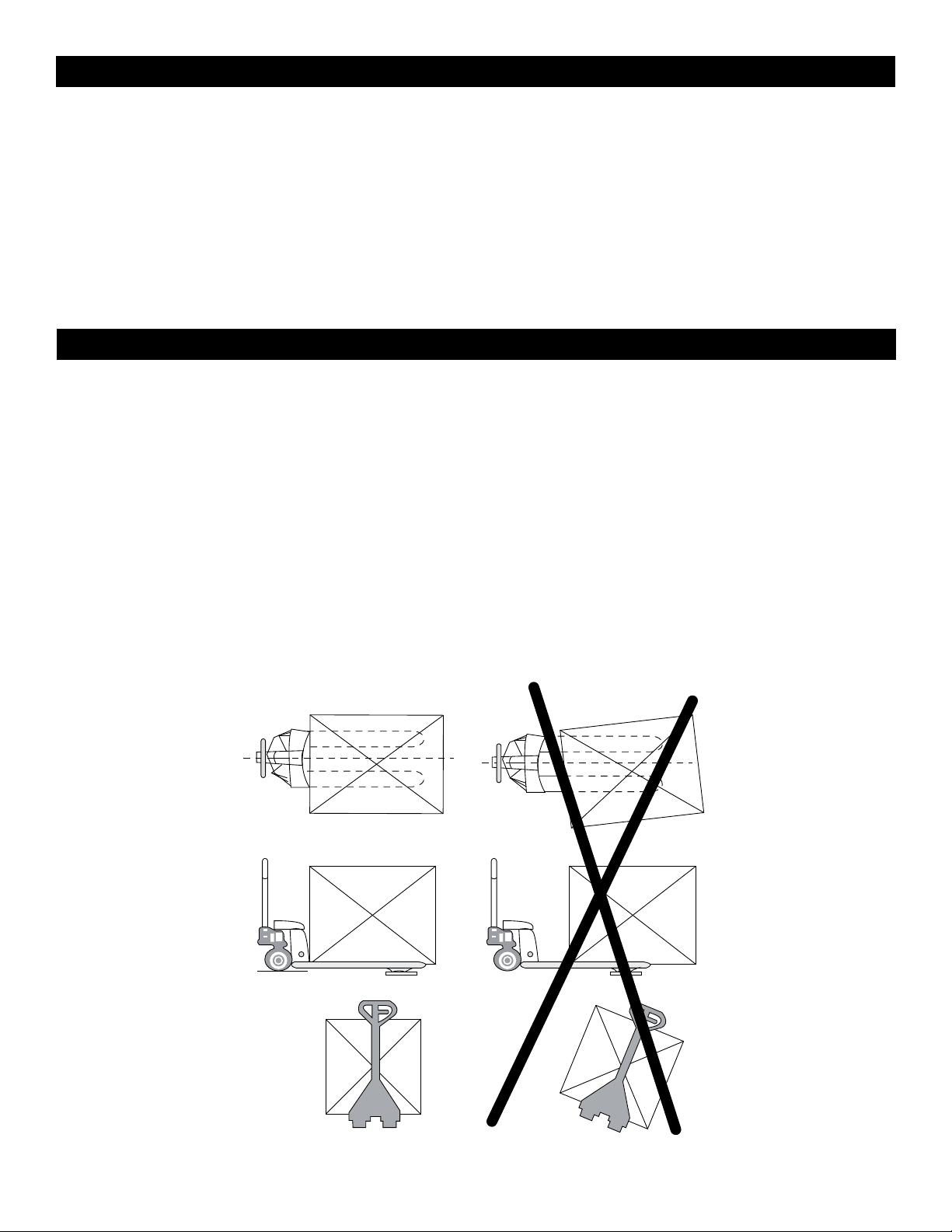

5. Do not handle unstable or loosely stacked loads.

6. Do not overload the truck.

7. Always center loads on the forks, not at the end of the

forks. (See Figure 2)

8. The capacity of the truck assumes an evenly

distributed load with the center of the load being at

the halfway point of the length of the forks.

9. Make sure that length of the forks matches the length

of the pallet load.

10. Lower the forks to lowest height when the truck is not

being used.

Figure 2

A B

0114 I H -2917PAGE 2 OF 6

Page 3

ADJUSTING FORK WIDTH

Figure 3

Figure 4 Figure 6

Figure 5 Figure 7

1. Locate and remove the Allen wrench from its clip on

the truck body. (See Figure 3)

2. Loosen the screws on the front and back of each

fork of the truck. (See Figure 4)

3. Slide each fork to the desired position. (See Figure 5)

TROUBLESHOOTING

OPERATING ISSUE CAUSES RECOMMENDATIONS

The forks do not lift to

maximum height

Air in the hydraulic system

Insufficient hydraulic oil

4. Tighten the screws on each fork of the truck.

(See Figure 6)

5. Return the Allen wrench to its clip on the truck body.

(See Figure 7)

Expel the air (as noted in Maintenance)

Remove the oil plug (No. 25) and add oil

The forks do not lift

when the handle is

in lifting position

The forks drop after

every pump stroke

The forks do not lower

The forks drop when the handle

is in the neutral position

Forks lift when the handle is in

the neutral position

Insufficient hydraulic oil

Valve chain or setting screw are

out of alignment

Leak from valve cone (No. 16) assembly

Air in the hydraulic system

Leak from valve cone

Valve chain or setting screw are

out of alignment

Valve chain or setting screw are

out of alignment

Leak from the valve cone

Leak from the seal rings

Valve chain or setting screw are

out of alignment

Remove the oil plug (No. 25) and add oil

Adjust the valve chain with adjusting nut

(No. 71) or adjust the setting screw (as noted

in Operation)

Replace steel ball (No. 19)

Expel the air (as noted in Maintenance)

Replace valve cone (No. 16) valve housing

(No. 17), O-ring (No. 18) and O-ring (No. 13)

Adjust the valve chain with adjusting nut

(No. 71) or adjust the setting screw (as noted

in Operation)

Adjust the valve chain with adjusting nut

(No. 71) or adjust the setting screw (as noted

in Operation)

Replace valve cone (No. 16), valve housing

(No. 17), O-ring (No. 18) and O-ring (No. 13)

Replace cup packing (No. 43)

Adjust the valve chain with adjusting nut

(No. 71) or adjust the setting screw (as noted

in Operation)

Oil leaks from the pump

Seal ring damaged

or worn out

Replace O-ring (No. 32) and (No. 38)

0114 I H -2917PAGE 3 OF 6

Page 4

H -2917

ADJUSTABLE

PALLET TRUCK

1- 800 -295-5 510

uline.com

67

68

66

71

51

52

53

55

69

79

70

73

75

78

77

76

14

13

77

78

74

56

2

3

5

7

8

4

6

15

16

17

18

19

1

29

30

59

28

22

41

12

11

24

10

9

21

25

27

26

33

38

31

46

36

54

54

58

81

80

72

22

41

44

23

45

37

40

43

35

32

34

39

20

48

50

65

62

63

62

65

57

47

48

49

42

64

60

61

0114 I H -2917PAGE 4 OF 6

Page 5

H -2917

ADJUSTABLE

PALLET TRUCK

# DESCRIPTION QT Y. ULINE PART NO. MFG. PART NO.

1 Hydraulic Pump with Bypass 1 H-2917 P U MP 27015 0

2 Plunger Piston 1 ------------ 270101

3 Cap Washer 1 ------------ 270578

4 Spring 1 ------------ 270102

5 Dust Seal 1 ------------ 270103

6 Handle Base Bolt 1 ------------ 270313

7 Cup Packing 1 ------------ 270104

8 Nut 1 ------------ 270236

9 Roller 1 ------------ 270105

10 Bushing 1 ------------ 270105

11 Axle 1 ------------ 270105

12 Ball 1 ------------ 270105

13 O-Ring 1 ------------ 270106

14 Screw 1 ------------ 270107

15 Spring 1 ------------ 270108

16 Valve Cone 1 ------------ 270109

17 Valve Housing 1 ------------ 270110

18 O-Ring 1 ------------ 2 70111

19 Steel Ball 1 ------------ 27 0 112

20 Spring Pin 2 ------------ 270113

21 Axle 1 ------------ 270114

22 Screw 3 ------------ 270105

23 Handle Base 1 ------------ 270105

24 Spring Pin 1 ------------ 2 7 0116

25 Oil Plug 1 ------------ 270117

26 Axle Pin 1 ------------ 270118

27 Pin 1 ------------ 270119

28 Locking Ring 1 ------------ 270120

29 Spring Pin 1 ------------ 270121

30 Thrust Bearing 1 ------------ 270122

31 Spring 1 ------------ 270123

32 O-Ring 1 ------------ 270124

33 Relief Cylinder 1 ------------ 270576

34 Release Piston 1 ------------ 270125

35 Lowering Arm 1 ------------ 270126

36 Table Bolt 2 ------------ 270127

37 Dust Seal 1 ------------ 270128

38 O-Ring 1 ------------ 270268

39 Rubber Boot 1 ------------ 270267

40 O-Ring 1 ------------ 270129

41 Washer 2 ------------ 270115

1- 800 -295-5 510

uline.com

0114 I H -2917PAGE 5 OF 6

Page 6

H -2917

ADJUSTABLE

PALLET TRUCK

# DESCRIPTION QT Y. ULINE PART NO. MFG. PART NO.

42 Load Wheel Pin 2 ------------ 270265

43 Cup Packing 1 ------------ 270131

44 Ball 1 ------------ 270132

45 Ram Piston 1 ------------ 270133

46 Wheel Shaft 1 ------------ 270134

47 Steering Wheel 2 H-2917 S T WH L 270785

48 Ball Bearing 4 H-2917BBRNG 270273

49 Locking Ring 2 H-2917-LKRNG 270137

50 Cap 2 H -2 917-C A P 270314

51 Nut 1 ------------ 270581

52 Screw 1 ------------ 270 581

53 Pivot Rod 1 ------------ 270 575

54 Fork 2 ------------ 270772

55 Spring Pin 1 ------------ 270272

56 Adjustable Tie Rod 2 H - 2 917- T RO D 270773

57 Load Wheel Yoke 2 ------------ 270263

58 Pin 2 H-2917RODPIN 270264

59 Yoke 2 ------------ 270284

60 Axle 1 ------------ 270144

61 Spring Pin 1 ------------ 270266

62 Ball Bearing 4 ------------ 270273

63 Load Wheel 1 ------------ 270288

64 Axle 2 ------------ 270145

65 Nylon Cover 4 ------------ 270289

66 Coated Handle (Part Of A Kit) 1 ------------ 270141

67 Handle (Part Of A Kit) 1 ------------ 27 0141

68 Spring Pin (Part Of A Kit) 1 ------------ 270141

69 Pull Pole (Part Of A Kit) 1 ------------ 270141

70 Adjustment Rod (Part Of A Kit) 1 ------------ 270141

71 Adjustment Nut (Part Of A Kit) 1 ------------ 270141

72 Exit Roller 2 ------------ 270821

73 Frame 1 ------------ 270774

74 Fixity 2 ------------ 270775

75 Fixity 2 H-2917-75 270790

76 Screw 2 H - 2 917-76 270777

77 Spring Washer 6 H-2917-77 270778

78 Washer 6 H -2917-78 270779

79 Screw 4 ------------ 270780

80 Adjust Screw 2 ------------ 270782

81 Adjust Screw Nut 2 ------------ 270783

1- 800 -295-5 510

uline.com

π

CHICAGO • ATL ANTA • DALL AS • LOS ANGELES • MINNE APOLIS • NYC/PHIL A • SEATTLE • MEXICO • CANADA

0114 I H -2917PAGE 6 OF 6

Loading...

Loading...