Page 1

π H-2781

MITUTOYO DIGITAL

THICKNESS GAUGE

1-80 0-295- 5510

uline.com

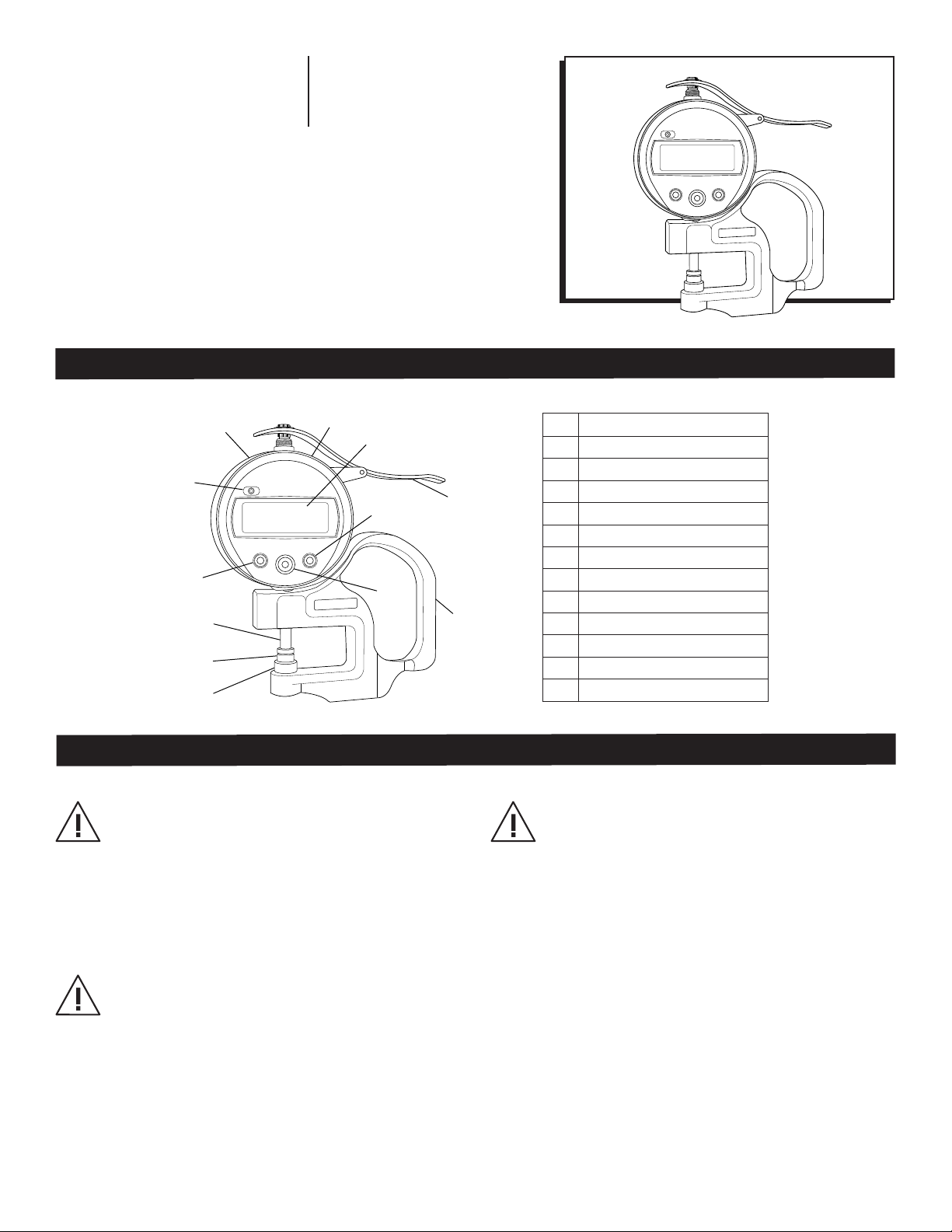

OVERVIEW OF COMPONENTS

12

1

7

8

10

11

+/–

in/mm ON/OFFORIGIN

9

2

3

4

IMPORTANT! Do not rotate the display unit of

this instrument. Doing so may damage the

display unit.

5

6

SAFETY

# DESCRIPTION

1 Indicator

2 Spindle

3 Contact Point

4 Anvil

5 Lifting Lever

6 Frame

7 On/Off Button

8 Origin Button

9 Inch/Millimeter Select Button

10 +/– Button

11 Output Connector

12 Battery Holder

IMPORTANT! Do not move the spindle too

quickly or apply excessive lateral force to the

spindle.

To use this instrument properly, read this user's manual

prior to use. Before using this instrument for the first time,

inspect all components to ensure proper performance.

OPERATING ENVIRONMENTS

IMPORTANT! Use this instrument in environments

where the temperature is between 32°-104°F

(0°-40°C) and the humidity is between 30% and

70% with no condensation.

• Use this instrument in places that are free from dust,

oil or oil mist and are not exposed to direct sunlight.

PAGE 1 OF 4 0616 IH-2781

• Check the performance and accuracy before use if

the instrument is dropped or sustains an impact.

• Check that the movement of the long hand, short

hand and spindle are smooth. Also check if the LCD

is working normally.

• Check that the contact point, anvil, back plate and

screws on the lever mount are not loose.

• Zero the instrument frequently using a master gauge

if used in a place with significant temperature

fluctuation.

Page 2

SAFETY CONTINUED

BATTERY-RELATED WARNINGS

WARNING! If the battery is misused or abused,

leaking or subject to extreme conditions,

explosion and/or fire can result. Observe the

following precautions to avoid instrument failure

or malfunction.

• Do not disassemble, deform, short-circuit, charge,

heat the battery to 212ºF or over or throw the battery

into a fire.

• Always insert the battery correctly according to the

polarities (+ and – ) marked on the battery and the

instrument.

• Always use the recommended battery.

• If the instrument will not be used for more than three

months, remove the battery and store it separately.

• When discarding or storing the battery, cover the

positive (+) and negative (–) terminals with insulating

tape to prevent contact with other metals. When

disposing of it, follow the ordinances or regulations

of the local government.

• Keep the battery away from direct sunlight, high

temperature, high humidity and out of the reach of

children.

• Do not swallow the battery. If swallowed, consult a

physician immediately.

• Should the content of the battery contact the

eyes or skin, or enter the mouth, rinse with water

immediately and consult a physician. Should it

adhere to clothing, wash the clothing with water.

DISPOSAL WARNINGS

WARNING! A liquid crystal display and a

silver oxide battery are used in this product.

When disposing of the instrument, follow

the ordinances and regulations of the local

government.

• The liquid crystal display contains an irritating

substance. Should the liquid content contact the

eyes or skin, or enter the mouth, consult a physician

immediately.

IMPORTANT! Do not strike the instrument or

allow it to be struck. Do not drop or apply

excessive force to it.

• Do not disassemble or modify.

• Do not use an electric engraving pen or other such

devices on the instrument. It may cause damage.

REPLACING BATTERY

Use a silver oxide battery (SR44).

1. Remove the battery holder using a screwdriver.

2. When replacing the battery, remove the spent battery.

3. Install a new battery into the battery holder with its

positive (+) side facing the front of the instrument.

4. Replace the battery holder into its original position.

IMPORTANT! A battery is not installed in this

instrument at the factory. Install the battery

before using.

• If the battery holder is not installed properly, the

instrument may not display the correct value or a

malfunction may result.

• If MEASUREMENT mode is not automatically entered

after executing the above procedure, reinstall the

battery.

SETUP

• When the battery is installed, nonsensical numbers

or an "E" may be displayed on the readout. This is

not a malfunction. Zero the instrument, then perform

the measurement.

• If the instrument will not be used for more than three

months, remove the battery and store it separately

to prevent damage by battery leakage.

NOTE: Do not use a sharp-pointed tool to

remove the battery holder and do not pry the

battery holder out.

• The supplied battery is used only to check the

functions and performance of the instrument.

It may not meet the battery life specification.

• If the battery is removed, zeroing is cancelled.

After installing the battery, perform the steps to zero

the instrument.

PAGE 2 OF 4 0616 IH-2781

Page 3

SETUP CONTINUED

ZEROING THE INSTRUMENT

Press and hold the ORIGIN button for more than one

second. The origin will be set, indicating "0.000/0.00mm"

or "0.00000/0.0000in" on the display.

TIPS

• Right after the battery is installed, nonsensical

numbers, or an "E" may be displayed in the readout.

This is not a malfunction. Zero the instrument, then

perform measurement.

• A rubber damper has been attached to the spindle

as a shock absorber. The elasticity of the damper

may cause the indicated value to not stabilize at

the bottom of the stroke, but this will not cause any

operational problems.

OPERATION

This thickness gauge is a measuring instrument for

quickly and accurately measuring the thickness or

outside diameter of an object.

1. To operate this instrument, first hold the frame and push

down the lifting lever by the thumb. (See Figure 1)

The spindle will move up and the contact point will

move away from the anvil, providing a space that

allows an object to be inserted.

• Also, the spindle may feel heavy at the bottom of

the stroke when this indicator is first used. This can

be resolved by pushing the spindle up once.

SETTING THE COUNT DIRECTION

The +/– button switches the count direction of display

values with respect to the spindle direction. The "▼" sign

appears in the upper left of the LCD if the indicator is set

so that it counts down when the spindle is retracted.

• The zero position may change due to thermal

expansion and contraction of the spindle, frame,

etc., caused by variations in ambient temperature.

Reduce temperature fluctuation during

measurement to a minimum. Zero the instrument

before using for the first time or when a significant

temperature fluctuation is unavoidable.

• This instrument may not be able to properly hold

large objects in position for measurement.

(See Figure 2)

Plastic

Spacer

Figure 1

2. Next, insert the object in the space, then slowly

release the spindle to see a reading on the

indicator.

IMPORTANT! Damage to the indicator or the

contact point may result if the spindle is moved

too quickly when measuring an object.

PAGE 3 OF 4 0616 IH-2781

Figure 2

• This may result in a fluctuation of indicator readings.

If the object is too large, hold it in your hand to

stabilize it.

Plastic

Spacer

NOTE: Plastic spacers have been inserted in

the lever slide unit. (See Figure 2) They are

used for assisting the lever operation. Never

remove the spacers.

Object to be

measured

Page 4

MAINTENANCE

IMPORTANT! Wipe off stains on the spindle

sliding face with a dry cloth or a cloth

dampened with a small amount of alcohol.

Do not lubricate the spindle at this time.

• Wipe off stains on the dial cover or the digital

display surface with a soft, dry cloth or a cloth

dampened with a small amount of neutral

detergent. Be sure to use only a neutral detergent.

• To clean the indicator, use a soft cloth soaked in

a diluted neutral detergent. Do not use organic

solvent (thinner or benzene). It may deform or

damage the indicator.

• Deterioration of instrument performance is

caused mostly by harsh operating conditions. It is

recommended that the instrument be periodically

inspected, the frequency being determined by the

amount of use, environment and the way in which the

instrument is used.

TROUBLESHOOTING

ERROR MESSAGE OPERATING ISSUE RECOMMENDATIONS

The battery is depleted. Replace the battery.

Err C

E

Water drops may have formed on the detector

unit due to sudden thermal change, or the

detector unit may be contaminated due to

other causes.

An ABS data composition error occurred while

the spindle was moving at high speed.

If this message still appears after two hours of thermal

stabilization, the instrument needs to be repaired.

Contact Uline Customer Service at 1-800-295-5510.

Continue using the instrument, since this error does not

affect measured values.

If this error occurs while the spindle is stopped, it

could be due to sensor failure. In this case, contact

Uline Customer Service at 1-800-295-5510.

If the problem persists, or if the troubleshooting section does not resolve or describe your problem, contact

Uline Customer Service at 1-800-295-5510.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

PAGE 4 OF 4 0616 IH-2781

uline.com

Loading...

Loading...