Page 1

Para Español, vea páginas 4-6.

Pour le français, consulter les pages 7-9.

π H-2722

ALL-TERRAIN

PALLET TRUCK

1-800-295-5510

uline.com

TECHNICAL DATA

MODEL H-2722

Capacity (12" load center) 2,000 lbs.

Capacity (15" load center) 1,5 00 lb s.

Fork Length 32"

Fork Width 4"

Fork Thickness 2⁄"

Max. Fork Height 9"

Min. Fork Height 3"

Overall Length 49"

Overall Width 65½"

Overall Height 50½"

Diameter of the Front Wheels 16" Pneumatic

Diameter of Steering Wheels 10" Pneumatic

Weight 309 lbs.

WARNINGS

• Please read and understand instruction manual

before using the pallet truck.

• Do not place hands or feet under the pallet truck at

any time.

• Always wear appropriate safety shoes.

• Do not operate loaded pallet truck on ramps or

inclines.

• Do not tip loaded pallet truck forks. This may cause

damage to the forks and personal injury.

• Never leave a loaded pallet truck unattended in the

raised position. Always lower load to the floor.

PAGE 1 OF 9 0715 IH-2722

• Do not load pallet truck beyond it’s rated capacity.

• Secure load before transporting.

• To prevent accidental tipping, make sure load is

centered on the forks.

• Do not move a loaded pallet truck by means other

than manual force.

• Failure to comply with these warnings may result in

personal injury and/or property damage.

Page 2

OPERATION

To raise the forks, place handle in the UP position

(bottom part of the handle slot). (See Figure 1)

To lower forks, pull lever handle to DOWN position

(upper part of the slot). (See Figure 1)

To freely move the handle, set the lever in NEUTRAL

position (center notch of slot). (See Figure 1)

TO LIFT A LOAD

1. Lower forks to lowest position.

2. Insert forks under load, or into pallet.

3. Place lever in UP position.

4. Move handle up, and down until forks reach

desired height.

TO MOVE A LOAD

1. Place lever in NEUTRAL position.

2. Pull or push pallet truck to desired location.

Down

Neutral

Up

Figure 1

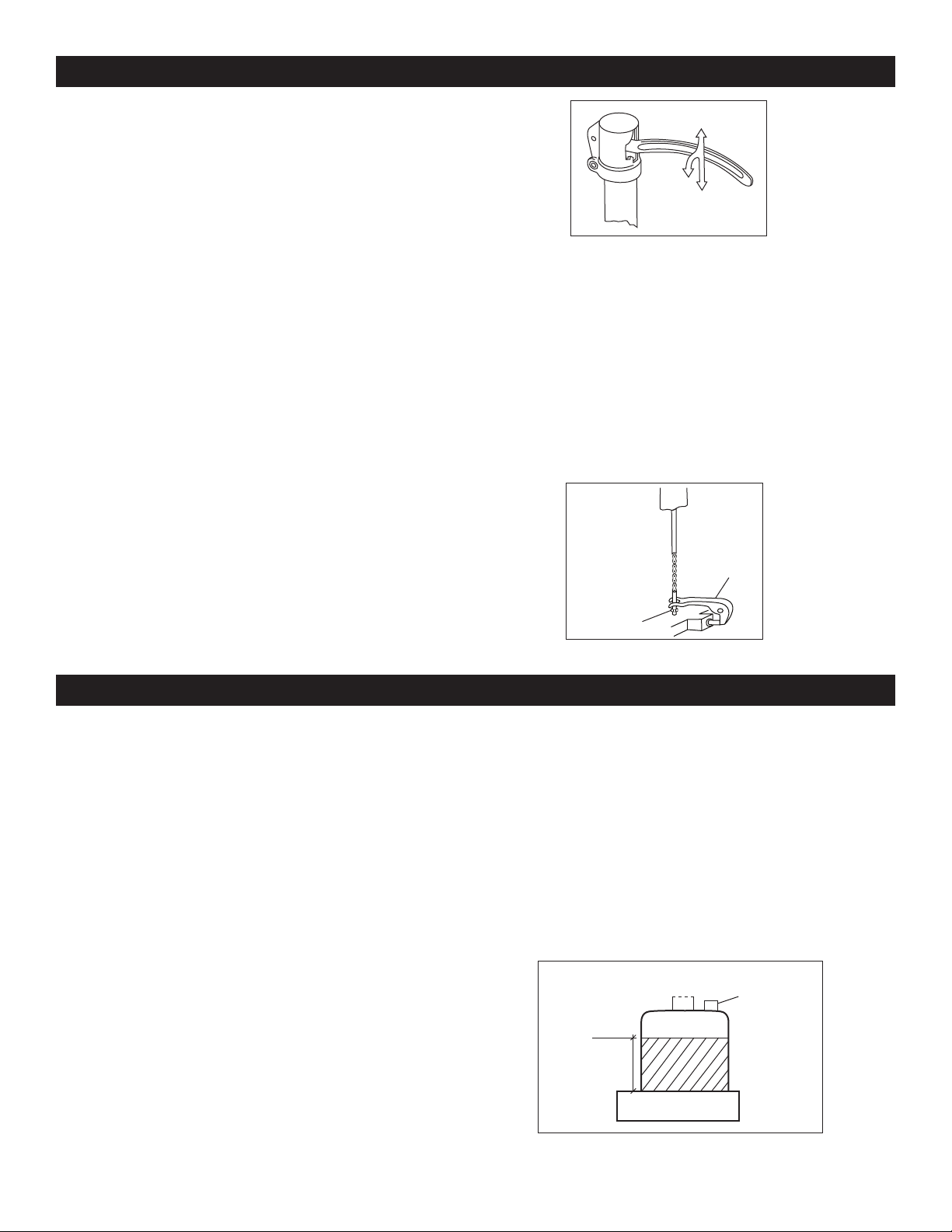

UP-DOWN CAM ADJUSTMENT

1. Set the lever in the NEUTRAL position.

2. Alternate turning the cam nut and pumping the

handle. (See Figure 2)

3. When lifting stops, give the nut one more turn.

4. The cam nut is properly adjusted when pumping

the handle in the NEUTRAL position causes no

movement of the hydraulic ram.

TO LOWER A LOAD

1. Pull lever to the DOWN position.

2. Pull forks away from load.

Cam Nut

Figure 2

Cam

MAINTENANCE

CLEANING THE RELEASE VALVE

(BLEED THE PUMP)

Over time, the hydraulic pump assembly may

become clogged with debris, air bubbles, and

not function properly. To clean the release valve and

bleed the pump:

1. Pump handle quickly, raising pallet truck to max

height. While continuing pumping action, pull

lever to down position.

2. When forks reach total down position, valve is

flushed. Repeat if necessary.

LUBRICATION

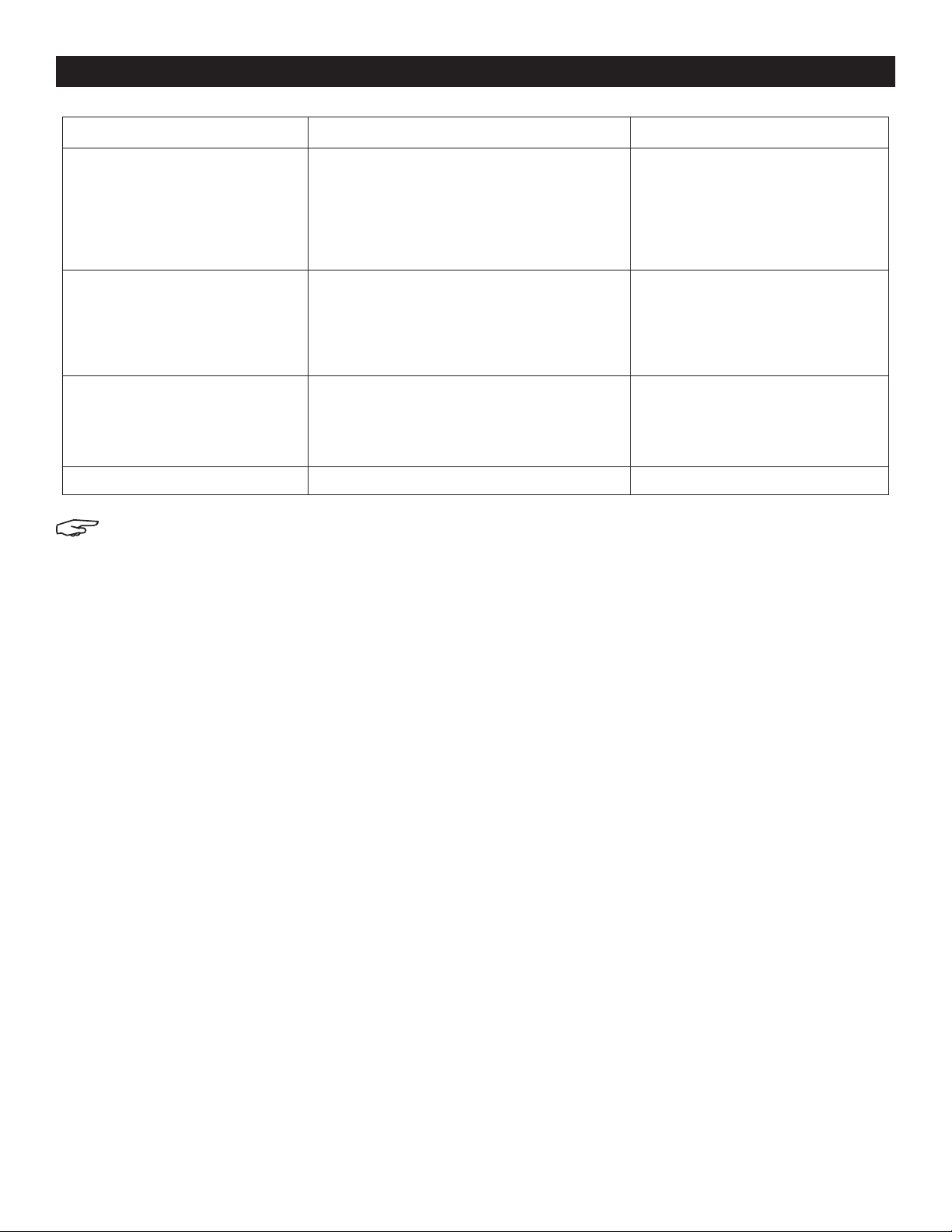

Check the oil level annually by removing the oil plug

(Part #28 on the Pump Diagram) found on the top of the

pump housing. When changing or adding oil, fill the

tank through the oil plug screw hole to 80% capacity

with hydraulic jack oil, about 2" deep in pump housing.

(See Figure 3)

PAGE 2 OF 9 0715 IH-2722

Please use Shell Tellus Oil: No. 22 or 27, Turbine Oil:

No. 22, or Texaco Regal: No. 32. Grease the rear and

front wheels annually or as needed.

Do not use any other type of oil. There is one grease

fitting located on the table (Part #43 on the Pump

Diagram). Lubricate this point on a semi-annual basis or

as needed. Wheel bearings are sealed and require no

lubrication. Crank shaft features oil light bushings that also

require no lubrication. Lightly oil all other moving parts.

Pump

Housing

2 inches

deep

Figure 3

Oil Plug

Oil

80%

Capacity

Page 3

TROUBLESHOOTING

OPERATING ISSUE CAUSES RECOMMENDATIONS

Hydraulic unit does not lift. Oil low in tank.

Steel ball not seated in hydraulic unit.

Worn O-ring in ram cylinder.

Once lifted, truck lowers by itself. Steel ball or relief valve not seated correctly.

Worn O-ring in ram cylinder.

Oil leakage from each valve.

Fork does not lower. Cam chain broken.

Up-down cam nut out of adjustment.

Broken fork rods and linkage.

Lever does not set at NEUTRAL position. Up-down cam nut out of adjustment. Adjust cam nut (As noted in Operation).

Make sure there is no oil leakage from

valve and add oil.

Clean release valve (As noted in

Maintenance).

Replace O-ring.

Clean release valve (As noted in

Maintenance).

Replace O-ring.

Tighten plug of each valve.

Replace cam chain.

Adjust cam nut (As noted in Operation).

Replace broken parts.

NOTE: Do not attempt to repair the pallet truck unless you are trained and authorized to do so.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

PAGE 3 OF 9 0715 IH-2722

uline.com

Page 4

π H-2722

PATÍN HIDRÁULICO

TODO TERRENO

MODELO H-2722

Capacidad (centro de carga de 12") 907 kg (2,000 lbs.)

Capacidad (centro de carga de 15") 680 kg (1,500 lbs.)

Longitud de Horquilla 81.3 cm (32")

Ancho de la Horquilla 10.2 cm (4")

Grosor de la Horquilla 6 cm (2⁄")

Altura Máx. de Horquilla 22.9 cm (9")

Altura Mín. de Horquilla 7.6 cm (3")

Largo General 124.5 cm (49")

Ancho Total 166.4 cm (65½")

Altura Total 128.3 cm (50½")

Diámetro de las Llantas Delanteras Neumáticas de 40.6 cm (16")

Diámetro de las Llantas de Dirección Neumáticas de 25.4 cm (10")

Peso 140 kg (309 lbs.)

01-800-295-5510

uline.mx

INFORMACIÓN TÉCNICA

ADVERTENCIAS

• Por favor, lea y comprenda el manual de

instrucciones antes de usar el patín hidráulico.

• No ponga las manos ni los pies debajo del patín

hidráulico en ningún momento.

• Lleve siempre zapatos de seguridad apropiados.

• No utilice el patín hidráulico en rampas o

superficies con inclinación.

• No vuelque las horquillas del patín hidráulico

cuando estén cargadas. Esto podría dañar las

horquillas y ocasionar lesiones personales.

• Nunca deje un patín hidráulico cargado sin

supervisión en posición elevada. Baje siempre la

carga al suelo.

PAGE 4 OF 9 0715 IH-2722

• No cargue el patín hidráulico por encima de su

capacidad establecida.

• Fije la carga antes de transportarla.

• Para evitar vuelcos accidentales, asegúrese de que

la carga esté centrada en las horquillas.

• No mueva un patín hidráulico cargado por otro

medio que no sea la fuerza manual.

• No seguir estas advertencias puede causar lesiones

personales y/o daños a la propiedad.

Page 5

FUNCIONAMIENTO

la Leva

Para subir las horquillas, coloque el asa en la posición UP

(SUBIR) (parte inferior de la ranura del asa). (Vea Diagrama 1)

Para bajar las horquillas, estire del asa de la palanca y

colóquela en la posición DOWN (BAJAR)

(parte superior de la ranura). (Vea Diagrama 1)

Para mover el asa libremente, coloque la palanca en

la posición NEUTRAL (NEUTRO) (muesca central de la

ranura). (Vea Diagrama 1)

PARA SUBIR UNA CARGA

1. Baje las horquillas hasta la posición más baja.

2. Inserte las horquillas debajo de la carga o en la tarima.

3. Coloque la palanca en la posición UP (SUBIR).

4. Mueva el asa hacia arriba y hacia abajo hasta que

las horquillas alcancen la altura deseada.

PARA MOVER UNA CARGA

1. Coloque la palanca en la posición NEUTRAL (NEUTRO).

2. Empuje o jale el patín hidráulico para colocarlo en

la ubicación deseada.

PARA BAJAR UNA CARGA

1. Jale la palanca para colocarla en la posición

DOWN (BAJAR).

2. Quite las horquillas de la carga.

Bajar

Neutro

Subir

Diagrama 1

AJUSTE DE LA LEVA ARRIBA/ABAJO

1. Coloque la palanca en la posición NEUTRAL (NEUTRO).

2. Alterne entre girar la tuerca de la leva y bombear

con el asa. (Vea Diagrama 2)

3. Cuando deje de subir, gire la tuerca una vez más.

4. La tuerca de la leva estará bien ajustada cuando

al bombear con el asa en la posición NEUTRAL

(NEUTRO) no se produzca movimiento alguno en el

martillo hidráulico.

Horquilla

Tuerca de

Diagrama 2

MANTENIMIENTO

LIMPIEZA DE LA VÁLVULA DE DESCARGA

(DRENAJE DE LA BOMBA)

Con el paso del tiempo, el ensamble de la bomba

hidráulica podría obstruirse con suciedad o burbujas

de aire y no funcionar correctamente. Para limpiar la

válvula de descarga y drenar la bomba:

1. Bombee el asa rápidamente, elevando el patín

hidráulico a su altura máxima. Continuando con la

acción de bombeo, jale la palanca

para colocarla en la posición DOWN (BAJAR).

2. Cuando las horquillas alcancen la posición

más baja, la válvula estará drenada. Repita la

operación en caso de ser necesario.

LUBRICACIÓN

Verifique el nivel de aceite anualmente quitando el

tapón de aceite (Parte #28 del diagrama de la bomba),

ubicado en la parte superior de la cubierta de la

bomba. Al agregar o cambiar el aceite, llene el tanque

a través del orificio del tapón de aceite hasta el 80%

de su capacidad con aceite para gatos hidráulicos, a

una profundidad de unos 5 cm (2") en la cubierta de la

bomba. (Vea Diagrama 3)

PAGE 5 OF 9 0715 IH-2722

Favor de usar aceite Shell Tellus: N.º 22 o 27, aceite para

turbinas: N.º 22 o Texaco Regal: N.º 32. Engrase las llantas

delanteras y traseras anualmente o cuando sea necesario.

No

use ningún otro tipo de aceite. Hay un conector

para grasa ubicado en la placa (Parte #43 del

diagrama de la bomba). Lubrique este punto dos

veces al año o cuando sea necesario. Los baleros de

las llantas están sellados y no requieren lubricación. El

eje de la manivela cuentan con casquillos ligeros que

tampoco requieren lubricación. Engrase ligeramente

todas las demás partes móviles.

Cubierta de

la bomba

5 cm

(2 pulgadas)

de profundidad

Diagrama 3

Tapón de

Aceite

80%

Capacidad

de Aceite

Page 6

SOLUCIÓN DE PROBLEMAS

PROBLEMA DE FUNCIONAMIENTO CAUSAS RECOMENDACIONES

La unidad hidráulica no se eleva. Bajo nivel de aceite en el tanque.

La bola de acero no está bien asentada en la

unidad hidráulica.

Anillo-O desgastado en el cilindro del martillo.

Una vez arriba, el patín se baja solo. La bola de acero o la válvula de descarga no

Las horquillas no se bajan. La cadena de la leva está rota.

La palanca no se asienta en la

posición NEUTRAL (NEUTRO).

están bien asentadas.

Anillo-O desgastado en el cilindro del martillo.

Hay una fuga de aceite en cada válvula.

La tuerca de la leva que permite subir y bajar está

desajustada.

Las varillas y los eslabones de la horquilla están

rotos.

La tuerca de la leva que permite subir y bajar está

desajustada.

Asegúrese de que no haya ninguna fuga

de aceite que proceda de la válvula y

agregue aceite.

Limpie la válvula de liberación.

(Como se indica en Mantenimiento).

Reemplace el anillo-O.

Limpie la válvula de descarga.

(Como se indica en Mantenimiento).

Reemplace el anillo-O.

Apriete el acople de cada una de las

válvulas.

Reemplace la cadena de la leva.

Ajuste la tuerca de la leva.

(Como se indica en Funcionamiento).

Reemplace las partes rotas.

Ajuste la tuerca de la leva.

(Como se indica en Funcionamiento).

NOTA: No intente reparar el patín hidráulico a menos que esté capacitado y autorizado para hacerlo.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

01-800-295-5510

PAGE 6 OF 9 0715 IH-2722

uline.mx

Page 7

π H-2722

TRANSPALETTE

TOUT-TERRAIN

1-800-295-5510

uline.ca

DONNÉES TECHNIQUES

MODÈLE H-2722

Capacité [centre de la charge de

30,5 cm (12 po)]

Capacité [centre de la charge de

38,1 cm (15 po)]

Longueur de la fourche 81,3 cm (32po)

Largeur de la fourche 10,2cm (4po)

Épaisseur de la fourche 6cm (2 ⁄po)

Hauteur max. de la fourche 22,9cm (9 po)

Hauteur min. de la fourche 7,6 cm (3po)

Longueur totale 1,24 m (49 po)

Largeur totale 1,66m (65½po)

Hauteur totale 1,28m (50½po)

Diamètre des roues avant Pneumatiques, 40,6 cm (16 po)

Diamètre des roues directrices Pneumatiques, 25,4 cm (10 po)

Poids 140,2kg (309lb)

907,2 kg (2000lb)

680,4 kg (1500 lb)

AVERTISSEMENTS

• Lisez bien le mode d'emploi avant d'utiliser le

transpalette.

• Ne placez jamais vos mains ou vos pieds sous le

transpalette.

• Portez toujours des chaussures de sécurité

appropriées.

• N'utilisez pas le transpalette chargé sur des rampes

ou des pentes.

• Ne faites pas basculer la fourche du transpalette

chargé. Cela peut endommager la fourche et

causer des blessures corporelles.

• Ne laissez jamais un transpalette chargé dans la

position élevée sans surveillance. Abaissez toujours

la charge au sol.

PAGE 7 OF 9 0715 IH-2722

• Ne chargez pas le transpalette au-delà de sa

capacité nominale.

• Fixez la charge avant de la transporter.

• Pour éviter tout basculement accidentel, assurezvous que la charge est centrée sur la fourche.

• Ne déplacez pas un transpalette chargé par des

moyens autres que la force manuelle.

• Le défaut de suivre ces avertissements pourrait

entraîner de graves blessures corporelles ou des

dommages matériels.

Page 8

FONCTIONNEMENT

Pour soulever la fourche, placez la poignée en position

MONTÉE (partie inférieure de la fente de la poignée).

(Voir Figure1)

Pour abaisser la fourche, tirez la poignée en position

DESCENTE (partie supérieure de la fente). (Voir Figure1)

Pour déplacer librement la poignée, placez le levier en

position NEUTRE (encoche centrale de la fente).

(Voir Figure1)

POUR SOULEVER UNE CHARGE

1. Abaissez la fourche jusqu'à la position la plus basse.

2. Insérez la fourche sous la charge, ou dans la palette.

3. Placez le levier en position MONTÉE.

4. Déplacez la poignée vers le haut et le bas jusqu'à

ce que la fourche atteignent la hauteur souhaitée.

POUR DÉPLACER UNE CHARGE

1. Placez le levier en position NEUTRE.

2. Tirez ou poussez le transpalette à l'endroit désiré.

Descente

Neutre

Montée

Figure1

RÉGLAGE DE LA CAME DE COMMANDE

MONTÉE-DESCENTE

1. Placez le levier en position NEUTRE.

2. Tournez l'écrou de la came tout en pompant la

poignée. (Voir Figure2)

3. Lorsque le levage s'arrête, tournez l'écrou d'un autre tour.

4. L'écrou de la came est correctement réglé lorsque

le pompage de la poignée en position NEUTRE ne

provoque aucun mouvement du vérin hydraulique.

POUR ABAISSER UNE CHARGE

Came

1. Placez le levier en position DESCENTE.

2. Éloignez la fourche de la charge.

Écrou de

came

Figure2

ENTRETIEN

NETTOYER LA VALVE DE VIDANGE

(PURGER LA POMPE)

Après un certain temps, l'ensemble de la pompe

hydraulique peut devenir obstrué par des débris, des

bulles d'air, et ne plus fonctionner correctement. Pour

nettoyer la valve de vidange et purger la pompe:

1. Pompez rapidement la poignée pour soulever le

transpalette à la hauteur maximale. Tout en continuant

de pomper, placez le levier en position DESCENTE.

2. La valve est vidée lorsque la fourche atteint la position

la plus basse. Répétez l'opération si nécessaire.

LUBRIFICATION

Vérifiez le niveau d'huile chaque année en retirant

le bouchon d'huile (pièce n°28 sur le schéma de la

pompe) qui se trouve sur le dessus du boîtier de pompe.

Lors d’un changement ou d'un remplissage d'huile

hydraulique, remplissez le réservoir par le trou de la

vis du bouchon d'huile jusqu'à 80% de sa capacité,

environ 5cm (2po) de profondeur du boîtier de pompe.

(Voir Figure3)

PAGE 8 OF 9 0715 IH-2722

Veuillez utiliser de l'huile Shell Tellus n° 22 ou n° 27, de

l'huile turbine n° 22, ou Texaco Regal n° 32. Graissez les

roues arrière et avant annuellement ou au besoin.

N'utilisez aucun autre type d'huile. Un raccord de

graissage se trouve sur la plaque (pièce n°43 sur le

schéma de la pompe). Lubrifiez ce point deux fois

par année ou au besoin. Les roulements des roues

sont scellés et ne nécessitent aucune lubrification. Le

vilebrequin dispose de bagues d'huile qui ne nécessitent

également aucune lubrification. Graissez légèrement

toutes les autres pièces mobiles.

Boîtier de

pompe

2 pouces

de

profondeur

Figure3

Bouchon

d'huile

80 % de la

capacité

en huile

Page 9

DÉPANNAGE

PROBLÈME CAUSES RECOMMANDATIONS

L'unité hydraulique ne se soulève pas. Faible niveau d'huile dans le réservoir.

La bille d'acier n’est pas appuyée dans l'unité

hydraulique.

Le joint torique est usé dans le vérin à piston

plongeur.

Une fois relevé, le transpalette

s'abaisse par lui-même.

La fourche ne s'abaisse pas. La chaîne de la came est brisée.

Le levier ne se place pas en position

NEUTRE.

La bille d'acier ou la soupape de surpression n'est

pas appuyée correctement.

Le joint torique est usé dans le vérin à piston

plongeur.

De l'huile fuit de chaque valve.

L'écrou de la came de commande montéedescente est déréglé.

Les tiges de la fourche et la tringlerie sont

endommagées.

L'écrou de la came de commande montéedescente est déréglé.

Assurez-vous qu'il n’y a pas de fuite

d'huile en provenance de la valve et

ajoutez de l'huile.

Nettoyez la valve de vidange (de

la façon indiquée dans la section

Entretien).

Remplacez le joint torique.

Nettoyez la valve de vidange (de

la façon indiquée dans la section

Entretien).

Remplacez le joint torique.

Serrez le bouchon de chaque valve.

Remplacez la chaîne de la came.

Réglez l'écrou de la came (de la

façon indiquée dans la section

Fonctionnement).

Remplacez les pièces endommagées.

Réglez l'écrou de la came (de la

façon indiquée dans la section

Fonctionnement).

REMARQUE: Ne tentez pas de réparer le transpalette à moins d'être formé ou autorisé pour le faire.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

PAGE 9 OF 9 0715 IH-2722

uline.ca

Loading...

Loading...