Page 1

USER GUIDE

RIGHT PRODUCT. RIGHT PLACE. RIGHT TEMPERATURE. SINCE 1962.

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

2000 Series • 2224ZWC • 24" Wine Captain® Model

Page 2

USER GUIDE

u-line.com

Contents

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Intro

Installation

Integrated Panel Dimensions

Integrated Grille / Plinth Dimensions

Integrated Panel Installation

Grille / Plinth Installation

Page 3

USER GUIDE

u-line.com

WELCOME TO U-LINE

Congratulations on your U-Line purchase. Your product comes from a company with over five decades and three generations

of premium modular ice making, refrigeration, and wine preservation experience. U-Line continues to be the American

leader, delivering versatility and flexibility for multiple applications including residential, light commercial, outdoor and marine

use. U-Line’s complete product collection includes modular Wine Captain

Crescent Ice Makers, Glass & Solid Door Refrigerators, Drawer Models, Freezers, and Combo® Models.

U-Line has captivated those with an appreciation for the finer things with exceptional functionality, style, inspired innovations

and attention to even the smallest details. We are known and respected for our unwavering dedication to product design,

quality and selection. U-Line is headquartered in Milwaukee, Wisconsin and has shipped product to five continents for over

two decades and is proud to have the opportunity to ship to you.

PRODUCT INFORMATION

Looking for additional information on your product? User Guides, Quick Reference Guides, CAD Drawings, Compliance

Documentation, and Product Warranty information are all available for reference and download at u-line.com.

®

Models, Beverage Centers, Clear Ice Machines,

PROPERTY DAMAGE / INJURY CONCERNS

In the unlikely event property damage or personal injury is suspected related to a U-Line product, please take the following

steps:

1. U-Line Customer Care must be contacted immediately at +1.800.779.2547.

2. Service or repairs performed on the unit without prior written approval from U-Line is not permitted. If the unit has been

altered or repaired in the field without prior written approval from U-Line, claims will not be eligible.

SERVICE INFORMATION

Answers to Customer Frequently Asked Questions are available at u-line.com under Customer Care or you may contact our

Customer Care group directly, contact information below.

GENERAL INQUIRIES

U-Line Corporation

8900 N. 55th Street

Milwaukee, Wisconsin 53223 USA

Monday - Friday 8:00 am to 4:30 pm CST

T: +1.414.354.0300

F: +1.414.354.7905

Email: sales@u-line.com

u-line.com

SERVICE & PARTS ASSISTANCE

Monday - Friday 8:00 am to 5:30 pm CST

T: +1.800.779.2547

F: +1.414.354.5696

Service Email: onlineservice@u-line.com

Parts Email: onlineparts@u-line.com

CONNECT WITH US

Designed, engineered and assembled in WI, USA

Introduction 1

Page 4

USER GUIDE

NOTICE

NOTICE

NOTICE

BACK SURFACE MUST HAVE AMPLE FLAT SURFACE

TO MOUNT OVERLAY FRAME FLAT AND WITHOUT

INTERFERENCE

2-3/4" MIN

(70 mm MIN)

Integrated Frame

3/4"

(20 mm)

23-1/2"

(595 mm)

30"

(762 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

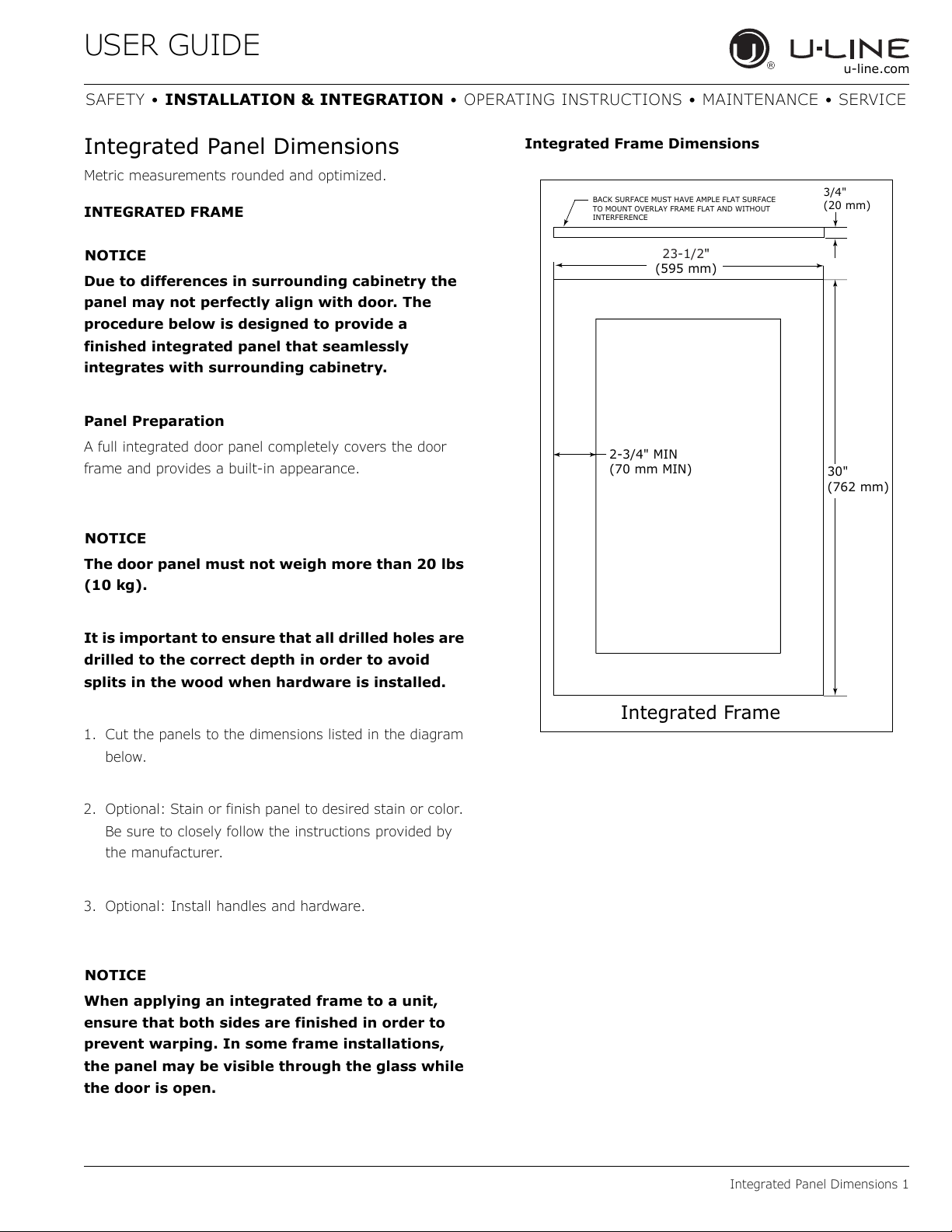

Integrated Panel Dimensions

Metric measurements rounded and optimized.

INTEGRATED FRAME

Due to differences in surrounding cabinetry the

panel may not perfectly align with door. The

procedure below is designed to provide a

finished integrated panel that seamlessly

integrates with surrounding cabinetry.

Panel Preparation

A full integrated door panel completely covers the door

frame and provides a built-in appearance.

The door panel must not weigh more than 20 lbs

(10 kg).

Integrated Frame Dimensions

It is important to ensure that all drilled holes are

drilled to the correct depth in order to avoid

splits in the wood when hardware is installed.

1. Cut the panels to the dimensions listed in the diagram

below.

2. Optional: Stain or finish panel to desired stain or color.

Be sure to closely follow the instructions provided by

the manufacturer.

3. Optional: Install handles and hardware.

When applying an integrated frame to a unit,

ensure that both sides are finished in order to

prevent warping. In some frame installations,

the panel may be visible through the glass while

the door is open.

Integrated Panel Dimensions 1

Page 5

USER GUIDE

NOTICE

NOTICE

Cutout

Integrated Frame

Main Panel

Wooden Insert

Top Design

and Insert Notch

Attach Wooden Insert

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

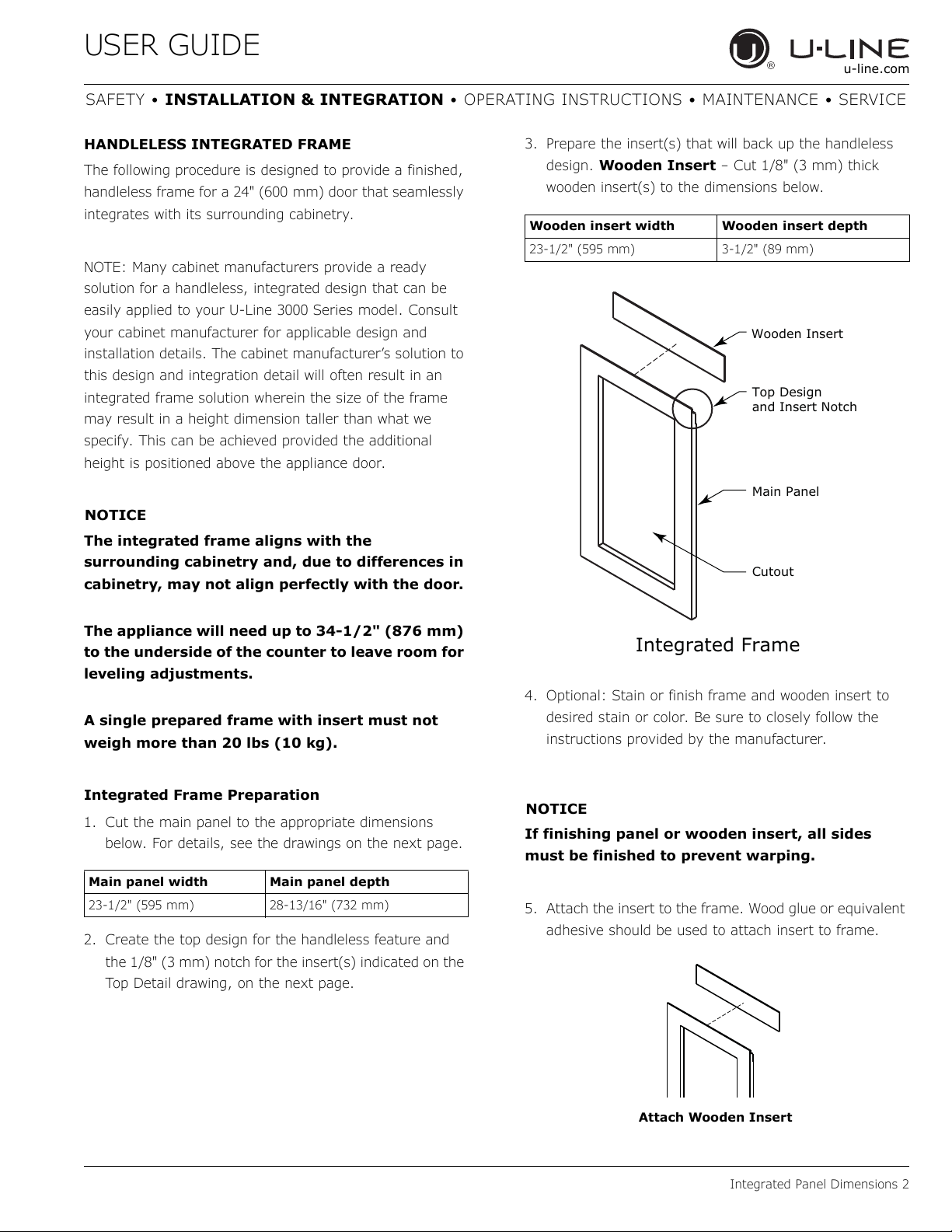

HANDLELESS INTEGRATED FRAME

The following procedure is designed to provide a finished,

handleless frame for a 24" (600 mm) door that seamlessly

integrates with its surrounding cabinetry.

NOTE: Many cabinet manufacturers provide a ready

solution for a handleless, integrated design that can be

easily applied to your U-Line 3000 Series model. Consult

your cabinet manufacturer for applicable design and

installation details. The cabinet manufacturer’s solution to

this design and integration detail will often result in an

integrated frame solution wherein the size of the frame

may result in a height dimension taller than what we

specify. This can be achieved provided the additional

height is positioned above the appliance door.

The integrated frame aligns with the

surrounding cabinetry and, due to differences in

cabinetry, may not align perfectly with the door.

3. Prepare the insert(s) that will back up the handleless

design. Wooden Insert – Cut 1/8" (3 mm) thick

wooden insert(s) to the dimensions below.

Wooden insert width Wooden insert depth

23-1/2" (595 mm) 3-1/2" (89 mm)

The appliance will need up to 34-1/2" (876 mm)

to the underside of the counter to leave room for

leveling adjustments.

A single prepared frame with insert must not

weigh more than 20 lbs (10 kg).

Integrated Frame Preparation

1. Cut the main panel to the appropriate dimensions

below. For details, see the drawings on the next page.

Main panel width Main panel depth

23-1/2" (595 mm) 28-13/16" (732 mm)

2. Create the top design for the handleless feature and

the 1/8" (3 mm) notch for the insert(s) indicated on the

Top Detail drawing, on the next page.

4. Optional: Stain or finish frame and wooden insert to

desired stain or color. Be sure to closely follow the

instructions provided by the manufacturer.

If finishing panel or wooden insert, all sides

must be finished to prevent warping.

5. Attach the insert to the frame. Wood glue or equivalent

adhesive should be used to attach insert to frame.

Integrated Panel Dimensions 2

Page 6

USER GUIDE

3/4" (20 mm)

28-13/16"

(732 mm)

2-3/4"

(70 mm)

2-3/4"

(70 mm)

R 5/8"

(R 16 mm)

1/8"

(3 mm)

1/4" (6 mm)

Wooden Insert

Notch Depth: 1/8" (3 mm

2-3/8"

(60 mm)

7/8" (22 mm)

Ref.

Cutout

for Frame

Units

Top Detail

Insert Notch

Top Design

1/8" (3 mm)

3-1/2" (89 mm)

23-1/2"

(595 mm)

Wooden Insert Dimensions

23-1/2"

(595 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Handleless Integrated Frame Dimensions

Integrated Panel Dimensions 3

Page 7

USER GUIDE

NOTICE

NOTICE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

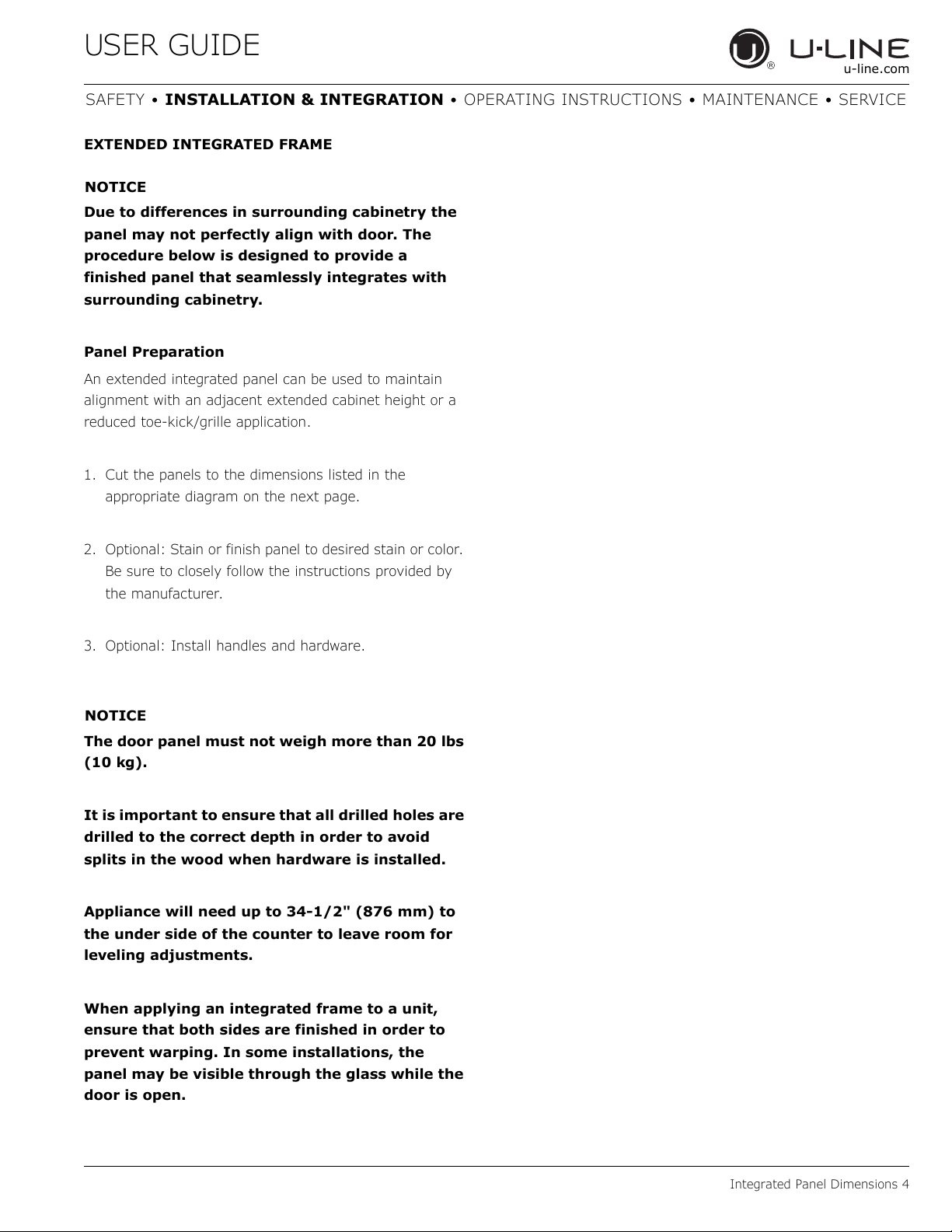

EXTENDED INTEGRATED FRAME

Due to differences in surrounding cabinetry the

panel may not perfectly align with door. The

procedure below is designed to provide a

finished panel that seamlessly integrates with

surrounding cabinetry.

Panel Preparation

An extended integrated panel can be used to maintain

alignment with an adjacent extended cabinet height or a

reduced toe-kick/grille application.

1. Cut the panels to the dimensions listed in the

appropriate diagram on the next page.

2. Optional: Stain or finish panel to desired stain or color.

Be sure to closely follow the instructions provided by

the manufacturer.

3. Optional: Install handles and hardware.

The door panel must not weigh more than 20 lbs

(10 kg).

It is important to ensure that all drilled holes are

drilled to the correct depth in order to avoid

splits in the wood when hardware is installed.

Appliance will need up to 34-1/2" (876 mm) to

the under side of the counter to leave room for

leveling adjustments.

When applying an integrated frame to a unit,

ensure that both sides are finished in order to

prevent warping. In some installations, the

panel may be visible through the glass while the

door is open.

Integrated Panel Dimensions 4

Page 8

USER GUIDE

3-5/16" (89 mm)

to

4-5/16" (114 mm)

U-Line

Unit

U-Line

Unit

Integrated Panel

Integrated Panel/Integrated Frame

Front Side

Front Side

3-5/16" (89 mm)

to

4-5/16" (114 mm)

Floor

Cabinet

> 3-5/16"

(> 89 mm)

3-5/16" (89 mm)

to

1" (25 mm)**

U-Line

Unit

Extended Integrated Panel/Extended Integrated Frame

Floor

Cabinet

3-5/16" (89 mm)

to

1" (25 mm)**

*

U-Line

Unit

Integrated Panel

* Panel can extend beyond the door

frame.

** A minimum of 1" (25 mm) from

the floor is required for proper

ventilation.

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Integrated Panel Dimensions 5

Page 9

USER GUIDE

NOTICE

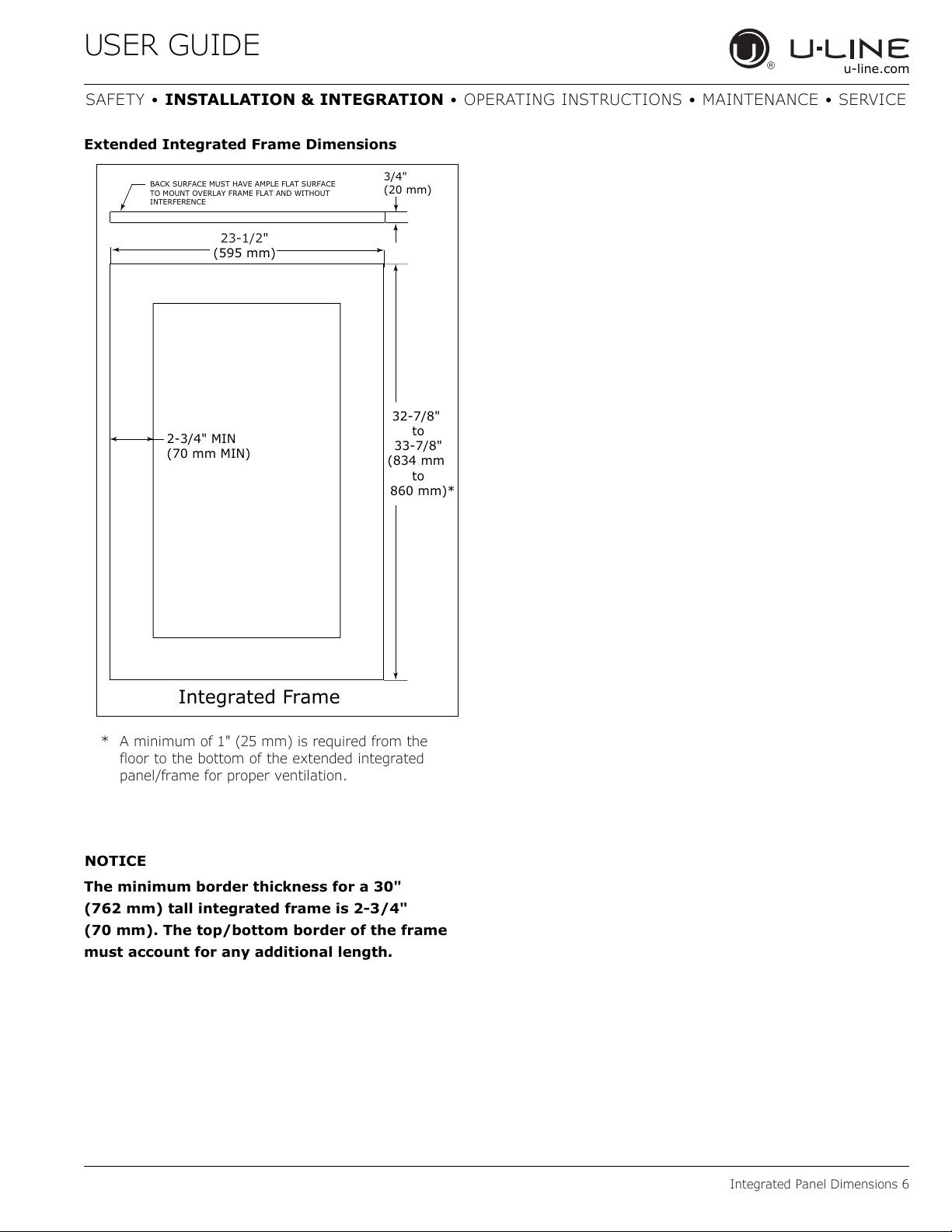

BACK SURFACE MUST HAVE AMPLE FLAT SURFACE

TO MOUNT OVERLAY FRAME FLAT AND WITHOUT

INTERFERENCE

2-3/4" MIN

(70 mm MIN)

Integrated Frame

3/4"

(20 mm)

23-1/2"

(595 mm)

32-7/8"

to

33-7/8"

(834 mm

to

860 mm)*

* A minimum of 1" (25 mm) is required from the

floor to the bottom of the extended integrated

panel/frame for proper ventilation.

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Extended Integrated Frame Dimensions

The minimum border thickness for a 30"

(762 mm) tall integrated frame is 2-3/4"

(70 mm). The top/bottom border of the frame

must account for any additional length.

Integrated Panel Dimensions 6

Page 10

USER GUIDE

Apply Tape To Shaded Area

23-3/4"

(605 mm)

20-5/8"

(525 mm)

1-9/16"

40 mm)

1-9/16"

(40 mm)

1" (25 mm)

3-5/16"

(84 mm)

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Integrated Grille - Plinth

Dimensions

PREPARE AND INSTALL INTEGRATED GRILLE

(PLINTH STRIP/BASE FASCIA)

1. Use the dimensions provided in the diagram to cut and

shape your integrated grille (plinth strip/base fascia)

panel. Recommended panel thickness is between 1/4"

(6 mm) and 3/8" (9 mm).

2. Finish or stain your grille (plinth strip/base fascia)

panel to match your surrounding furniture. Finish

front, back and edges to prevent warping. Carefully

follow the manufacturer’s recommendations for finish

application and cure times.

3. Apply double sided tape to the backside of the

integrated grill (plinth strip/base fascia). Use the

diagram below for reference. U-Line recommends

3M

™ VHB™ tape, a high strength bonding tape.

INTEGRATED GRILLE (PLINTH STRIP/BASE

FASCIA) DIMENSIONS

4. Remove backing paper from double sided tape.

5. Carefully align grille (plinth strip/base fascia) over

integrated panel and press into position.

Integrated Grille - Plinth Dimensions 1

Page 11

USER GUIDE

NOTICE

NOTICE

NOTICE

Wood

Panel

Door/Drawer

Bar

Clamp

Bar

Clamp

Integrated Panel

Integrated Panel

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Integrated Panel Installation

1. Fully open door.

2. Starting at corner, pull

gasket away from door.

3. Continue to pull gasket

free from gasket channel.

4. Upon removal, lay gasket down on a flat surface.

5. Align top of panel with top edge of door. Center panel

on door. (For 3036/3090 models, align panel on the

hinge side-edge of door.)

Due to differences in floor construction or

surrounding cabinetry, the panel may not sit

flush with the top of the door.

It is important to ensure that all drilled holes are

drilled to the correct depth in order to avoid

splits in the wood when hardwood is installed.

8. Locate 6 of the #6x 1-1/2" (38 mm) screws provided

with your unit.

9. Using a Phillips screwdriver, place one screw into each

of the 6 pilot holes and screw down. Do not overtighten

screws.

10.Ensure the screws sit flush against the bottom of the

channel.

6. Secure integrated

panel to door using

clamps. A robust

tape may also be

used. U-Line

recommends the

use of bar clamps

to secure the panel

to the door. If using

tape, be certain the

tape will not

damage panel finish

upon removal.

7. Using a 7/64"

(3 mm) drill bit, drill

6 pilot holes into

the wood panel 1/2"

(12 mm) deep using

the holes in

frame as a guide.

the door

11.Remove clamps from door.

If panel requires additional adjustment after

removing clamps, slightly loosen each screw and

adjust panel as necessary. Tighten screws upon

completion.

12.Starting at the corners, re-install the gasket into the

gasket channel in the frame. Make sure the gasket is

fully seated.

Integrated Panel Installation 1

Page 12

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Grille - Plinth Installation

REMOVING AND INSTALLING GRILLE

(PLINTH STRIP/BASE FASCIA)

WARNING

!

Disconnect electric power to the unit before

removing the grille (plinth strip/base fascia).

When using the unit, the grille (plinth strip/base

fascia) must be installed.

WARNING

!

DO NOT touch the condenser fins. The condenser

fins are SHARP and can be easily damaged.

Removing the grille

(plinth strip/base fascia)

1. Disconnect power to the unit.

2. Loosen the two screws (1).

3. Remove grille (plinth strip/base fascia) (2) from unit.

Installing the grille

1. Align cabinet and grille holes and secure, but do not

over tighten grille (plinth strip/base fascia) screws (1).

2. Reconnect power to the unit.

1

2

Grille - Plinth Installation 1

Loading...

Loading...