Ulco Medical AB800 Service manual

AB800 ABSORBER

AB800 ABSORBERAB800 ABSORBER

AB800 ABSORBER

USER MANUAL

USER MANUAL

USER MANUALUSER MANUAL

AB800 User Manual

This page intentionally left blank

2

AB800 User Manual

Copyright © 1993, 2005 by Ulco Medical

All rights reserved.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise,

without the written permission of the Ulco Medical.

All Ulco products are subject to a program of continuous development and the manufacturer reserves the right

to make alterations in design and equipment without prior notice.

Document Number: AB8-UM-001

Version: 1.3

3

AB800 User Manual

This page intentionally left blank

4

AB800 User Manual

Table of Contents

Table of Contents

Table of ContentsTable of Contents

1111 Introduction

Introduction ................................

IntroductionIntroduction

................................................................

................................................................

................................................................

................................................................

..................................

................................................................

.. 7777

....

1.1 Warranty Statement.......................................................................................................... 7

1.2 About this manual............................................................................................................. 7

1.3 Intended Use..................................................................................................................... 8

1.4 Device Classification......................................................................................................... 8

1.5 Background....................................................................................................................... 8

1.6 Safety Precautions............................................................................................................ 9

1.6.1 Before the first use............................................................................................... 9

1.6.2 Follow the Instructions for Use............................................................................. 9

1.6.3 Liability for proper function or damage................................................................ 9

1.6.4 Maintenance and Repairs.................................................................................... 9

1.6.5 Use of anaesthetic agents ................................................................................... 9

1.6.6 Power Connection ................................................................................................ 9

1.6.7 Monitoring and alarms....................................................................................... 10

2222 Using the Absorber

Using the Absorber ................................

Using the AbsorberUsing the Absorber

2.1 Background..................................................................................................................... 11

2.2 Mounting......................................................................................................................... 11

................................................................

................................................................

.....................................................

................................................................

..................... 11

..........................................

11

1111

2.3 Circle Circuits.................................................................................................................. 12

2.4 Physical Features............................................................................................................ 12

2.4.1 Scavenge Connector .......................................................................................... 13

2.4.2 Ventilator hose connector .................................................................................. 13

2.4.3 Identification Label............................................................................................. 13

2.4.4 Manual Bag Arm................................................................................................. 13

2.5 AB800 Front and top view components ......................................................................... 14

2.5.1 The 22 mm. Inspiratory and Expiratory male cones:.......................................... 14

2.5.2 The Bypass Control............................................................................................. 14

2.5.3 Canister Assembly.............................................................................................. 15

2.5.4 Canister locking system ..................................................................................... 15

2.5.5 The Mode Control Knob ..................................................................................... 15

2.5.6 The APL Valve..................................................................................................... 16

2.5.7 The Fresh Gas Connector................................................................................... 16

2.5.8 The Patient Pressure manometer connector ..................................................... 16

2.6 Circuits............................................................................................................................ 17

5

AB800 User Manual

2.6.1 Circle system ...................................................................................................... 17

3333 Care and Cleaning

Care and Cleaning ................................

Care and CleaningCare and Cleaning

3.1 Cleaning intervals ........................................................................................................... 19

3.2 Methods for cleaning the AB800 Absorber: ................................................................... 19

3.2.1 Method A ............................................................................................................ 19

3.2.2 Method B............................................................................................................ 19

4444 Servicing and Maintenance

Servicing and Maintenance ................................

Servicing and MaintenanceServicing and Maintenance

4.1 AB800-99 Service Kit ..................................................................................................... 25

4.2 Tools to be used ............................................................................................................. 25

4.3 Preparation to Service AB800 Absorber......................................................................... 26

4.4 Service Procedure........................................................................................................... 26

4.5 Test of AB800 absorber.................................................................................................. 34

5555 Technical Information

Technical Information ................................

Technical InformationTechnical Information

5.1 Principle of operation...................................................................................................... 35

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................................

................................................................

........................................

................................................................

.................................................

................................................................

...................... 19

............................................

................. 35

..................................

19

1919

........ 25

................

25

2525

35

3535

5.2 Control of excess gases.................................................................................................. 35

5.2.1 Automatic ventilation ......................................................................................... 35

5.2.2 Manual ventilation ............................................................................................. 35

5.3 Technical Specifications................................................................................................. 35

5.4 Test Standards................................................................................................................ 35

5.5 Symbols .......................................................................................................................... 36

6666 Assembly Drawings

Assembly Drawings................................

Assembly DrawingsAssembly Drawings

7777 Terms and conditions

Terms and conditions ................................

Terms and conditionsTerms and conditions

................................................................

................................................................

................................................................

................................................................

.....................................................

................................................................

.................................................

................................................................

..................... 37

..........................................

................. 44

..................................

37

3737

44

4444

6

AB800 User Manual

1111 Introd

Introduction

IntrodIntrod

1.1

1.1 Warranty Statement

1.11.1

All Ulco products are guaranteed to be free of defects of workmanship or material for a period of two years

from the date of delivery. The following are exceptions to this warranty:

1.

Defects caused by misuse, mishandling, tampering or by modifications not authorized by Ulco are not

covered.

2.

Rubber and plastic components and materials are warranted free of defects at the time of delivery.

Any product which proves to be defective in workmanship or material will be replaced, credited or repaired

with Ulco holding the option. Ulco is not responsible for deterioration, wear or abuse. In any case, Ulco will not

be liable beyond the original selling price.

Goods are subject to the terms of applicable warranty. Defective products will be accepted for return at Ulco's

discretion, and only during the warranty period. Application of this warranty is subject to the following

conditions:

1.

Ulco or its authorized agents must be promptly notified, in writing upon detection of the defective material

or equipment.

2.

Defective material or equipment, must be returned, shipping prepaid, to Ulco or its authorized agent.

3.

Examination by Ulco or its authorized agent must confirm that the defect is in fact covered by the terms of

this warranty.

4.

Ulco or its agent must receive notification in writing, of defective material or equipment no later than two

(2) weeks following expiration of this warranty.

In order to assume complete protection under this warranty, the installation and commissioning report, and/or

periodic manufacturer's service record (if applicable) must be returned to Ulco within 2 weeks of receipt of the

equipment.

The above is the sole warranty provided by Ulco. No other warranty expressed or implied is intended.

Representatives or agents of Ulco are not authorized to modify or amend the terms and conditions of this

warranty.

1.2

1.2 About this manual

1.21.2

This manual provides information for the preparation, assembly and maintenance of the AB800 CO2 circle

absorber, together with suitable equipment from the Ulco range. Although this equipment has been carefully

designed for simplicity of assembly and use, it is recommended that the contents of this manual be studied

before attempting preparation or maintenance of the equipment. Explanatory diagrams are provided in order

to help the reader understand the concepts described.

This manual is a supporting document for the operation and maintenance of the Ulco AB800 CO2 circle

absorber. It should be read in conjunction with other relevant information such as the manual(s) for the

vaporizer and anaesthesia machine (if applicable).

uction

uctionuction

Warranty Statement

Warranty StatementWarranty Statement

About this manual

About this manualAbout this manual

7

AB800 User Manual

1.3

1.3 Intended Use

Intended Use

1.31.3

Intended UseIntended Use

The AB800 CO2 Absorber is a circle rebreathing system for providing continuous gas inhalation anaesthesia for

human adults and children (above 5kg body weight).

The apparatus is intended for used solely in an operating or induction room.

The apparatus is intended to be used with hospital anaesthetic workstations and ventilators complying with

IEC 60601-2-13.

The apparatus is intended to be use under the continuous control of a person suitably trained and clinically

qualified in its use.

To comply with the Anaesthetic workstation station standard IEC 60601-2-13, the AB800 CO2 Absorber must

be used with adequate monitoring and alarms. The stated monitors and alarms can be found in Section 1.6.7

of this manual.

1.4

1.4 Device Classification

Device Classification

1.41.4

Device ClassificationDevice Classification

The AB800 CO2 Absorber is classified as follows:

•

Type CF applied part

1.5

1.5 Background

Background

1.51.5

BackgroundBackground

The forms the gas supply end of a circle rebreathing circuit for the purposes of anaesthetic gas delivery. It

provides the one-way valves which form the expiratory and inspiratory limbs of the circuit. It allows a means of

introducing fresh gas to the circuit via the inspiratory limb and provides means for controlled flow through a

soda-lime absorber canister on the expiratory limb of the circuit for the removal of CO2.

The system can be used with high flow, low flow or minimal flow of fresh gas for patient ventilation.

In addition, positive pressure ventilation may be delivered by means of a manual bag or a bellows system

driven by an anaesthetic ventilator (the ventilator is not part of the AB800). A manual switch controlled by the

user determines which of these positive pressure sources is connected to the circle system. The switch is

normally at the “bag” position for manual ventilation of the patient, and is switched to the “ventilator” position

when automatic ventilation is required.

The AB800 CO2 Absorber forms part of a semi-closed patient breathing system which employs a circle

absorber for the elimination of CO2. The system can be used with high flow, low flow or minimal flow of fresh

gas for patient ventilation.

The circle absorber section of the AB800 consists of a canister for the soda-lime absorbent and a machined

block containing the interconnections between the absorber system and the external connectors. The sodalime canister can accommodate up to 1 kg of soda-lime and is made of reusable polysulphone. The canister

fits to the under side of the AB800 system with a lever locking system.

The AB800 also employs a graduated lever control valve which allows the proportion of expired gas flowing

through the absorber to be controlled, allowing the patient's end tidal CO2 to be adjusted by the anaesthetist.

CO2 circle absorbers such as the AB800 are engineered to very high standards of design and finish and all

units are able to accommodate the most comprehensive specifications required in modern anaesthesia.

8

AB800 User Manual

The AB800 has been designed to be used in conjunction with the Signet 615 Anaesthetic Workstation, which

provides a mounting bracket suitable for attachment of the absorber.

1.6

1.6 Safety Precautions

Safety Precautions

1.61.6

Safety PrecautionsSafety Precautions

1.6.1

1.6.1 Before the first use

1.6.11.6.1

Before the first use

Before the first useBefore the first use

The unit must be connected to an anaesthesia machine and tested in accordance with the pre-use checklist

supplied with the machine. When using the AB8000 with conventional Boyle's type anaesthesia machines the

user must ensure that the correct ventilation mode (Manual or Automatic) is selected on the absorber prior to

commencing ventilation of the patient. Select VENTILATOR for mechanical ventilation or MANUAL BAG for hand

ventilation.

1.6.2

1.6.2 Follow the Instructions for Use

1.6.21.6.2

In order to use the equipment, these instructions must be fully read and understood and strictly followed. Any equipment

mentioned is only to be used for the intended purpose.

1.6.3

1.6.3 Liability for proper function or damage

1.6.31.6.3

This equipment is an adjunct to patient safety and it must in no way replace the normal monitoring by skilled personnel.

The manufacturers accept no responsibility for incidents arising from either incorrect use or malfunction of this

equipment.

If the equipment is serviced or repaired by persons not employed or authorised by Ulco, or if the equipment is not used

for the purposes for which it is intended, then the liability for the proper function of the equipment is transferred to the

owner/operator.

Where, the Signet 615 is assembled with other components of an anaesthetic system, such as ventilators or breathing

systems, and Ulco did not supply these components, then the personnel performing the assembly are responsible for

providing a checklist for the anaesthetic system.

1.6.4

1.6.4 Maintenance and Repairs

1.6.41.6.4

An authorised Ulco Technical Service Representative must perform maintenance of this equipment. Ulco products in

need of factory repairs must be sent to the nearest local agent or direct to Ulco.

Ulco recommends that anaesthesia products/equipment be serviced at intervals stated in Section Error! Reference

source not found.

source not found. of this manual. Periodic Manufacturer’s Service Contracts are available for products manufactured and

source not found.source not found.

or sold by Ulco. These agreements are available from Ulco Technical Services.

1.6.5

1.6.5 Use of anaesthetic agents

1.6.51.6.5

Explosive anaesthetic agents, such as ether or cyclopropane, must not be used due to the risk of fire. Ulco accepts no

liability if the wrong anaesthetic agent is used.

1.6.6

1.6.6 Power Connection

1.6.61.6.6

Ulco equipment is to be used only in rooms with mains power supply installations complying with national safety

standards.

Electrical connections for other equipment not listed here should only be made following consultations with the

respective manufacturers or other expert.

For full details of the electrical environment in which the Signet may be used see Section Error! Reference source not

found.

found. of this document.

found.found.

Follow the Instructions for Use

Follow the Instructions for UseFollow the Instructions for Use

Liability for proper function or damage

Liability for proper function or damageLiability for proper function or damage

Maintenance and Repairs

Maintenance and RepairsMaintenance and Repairs

Use of anaesthetic agents

Use of anaesthetic agentsUse of anaesthetic agents

Power Connection

Power ConnectionPower Connection

Error! Reference

Error! Reference Error! Reference

Error! Reference source not

Error! Reference source not Error! Reference source not

9

AB800 User Manual

1.6.7

1.6.7 Monitoring and alarms

1.6.71.6.7

If the unit alarms, check the patient. Establish that the patient is being ventilated correctly.

This unit must be used in conjunction with equipment providing the following alarms and monitoring capabilities:

These will help ensure patient safety, make precise ventilation possible and so achieve the best possible ventilator

parameters for the patient.

Monitoring and alarms

Monitoring and alarmsMonitoring and alarms

• Inspiratory oxygen concentration

• Anaesthetic agent concentration

• Airway pressure

• CO2 concentration

• Exhaled volume

• Breathing system integrity

• Continuing pressure

10

AB800 User Manual

2222 Using the A

Using the Absorber

Using the AUsing the A

2.1

2.1 Background

Background

2.12.1

BackgroundBackground

CO2 circle absorbers such as the AB800 are engineered to very high standards of design and finish and all

units are able to accommodate the most comprehensive specifications required in modern anaesthesia. Circle

absorbers such as the AB800 are designed to be used with anaesthetic machines such as the Signet 615

which provides a mounting bracket suitable for attachment of the absorber. The Signet 615 can also be

upgraded from its basic configuration with other optional accessories and attachments including a full range

of patient monitors to provide a comprehensive anaesthesia workstation.

2.2

2.2 Mounting

Mounting

2.22.2

MountingMounting

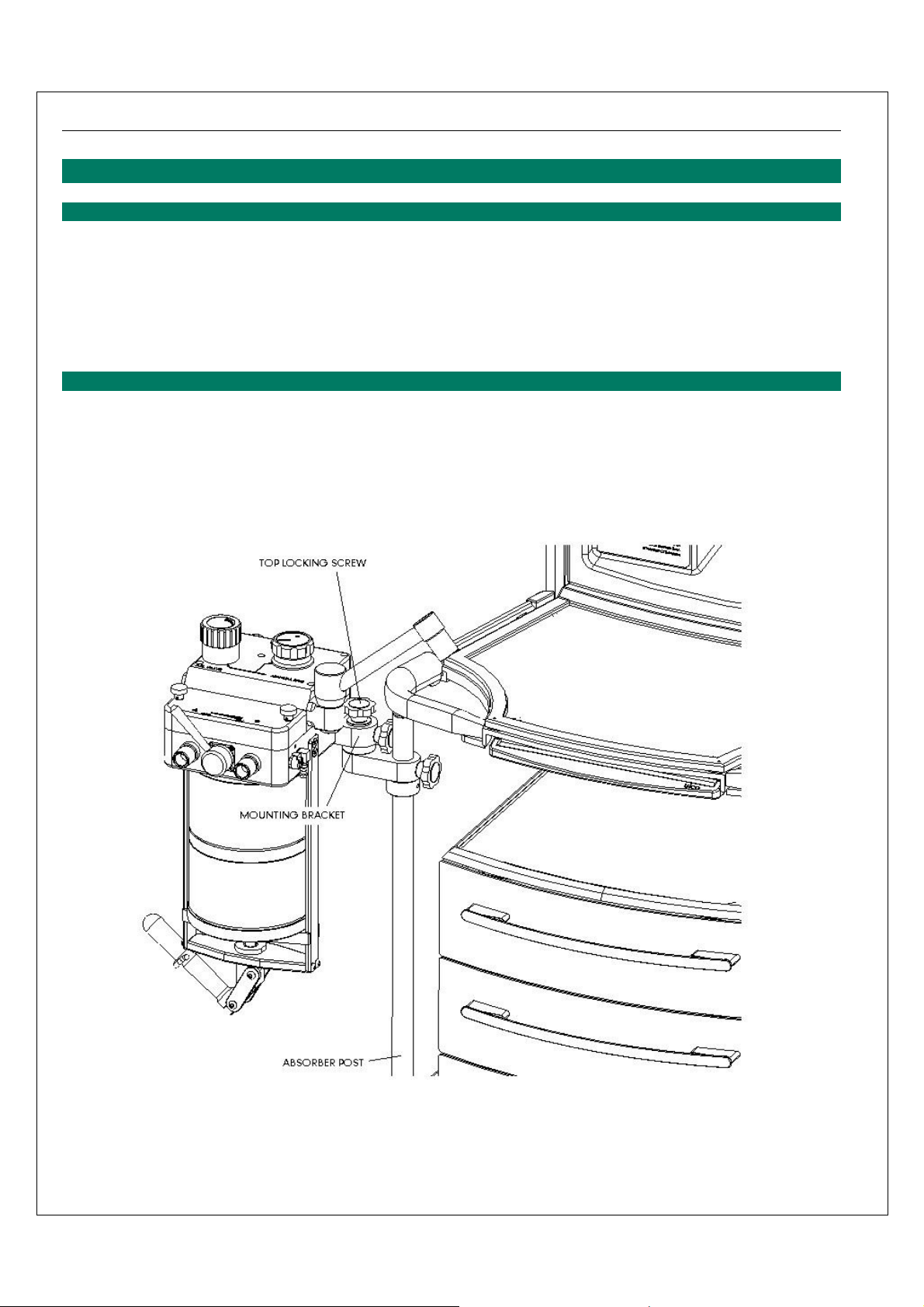

The soda-lime absorber mount bracket attaches to the post towards the front of the machine. The absorber

mount sits over the upright and should be allowed to seat itself into position. The top locking screw and side

locking screw can then be fastened to hold in position. The exhaust (Pink scavenge hose) can then be

attached to the 30mm exhaust valve scavenging outlet. The absorber fresh gas hose from the common gas

outlet can now be connected to the fresh gas inlet on the side of the absorber. This connection hose is made

from strong Polyurethane hose so it will not perish. No latex tubing is used in Ulco machines.

bsorber

bsorberbsorber

Figure 1: Mounting the AB800 absorber

11

AB800 User Manual

2.3

2.3 CCCCircle

2.32.3

For this the absorber fresh gas input is connected to the common gas outlet.

Ulco absorber 1 or 2kg model with bag/vent switch (Part No AB 800)

This version has separate limbs for the ventilator and manual bag. Selection is made by switching the knob,

either to the bag or ventilator position. This version eliminates the need to remove the manual bag from the

single limb to attach it to the ventilator.

2.4

2.4 Physical

2.42.4

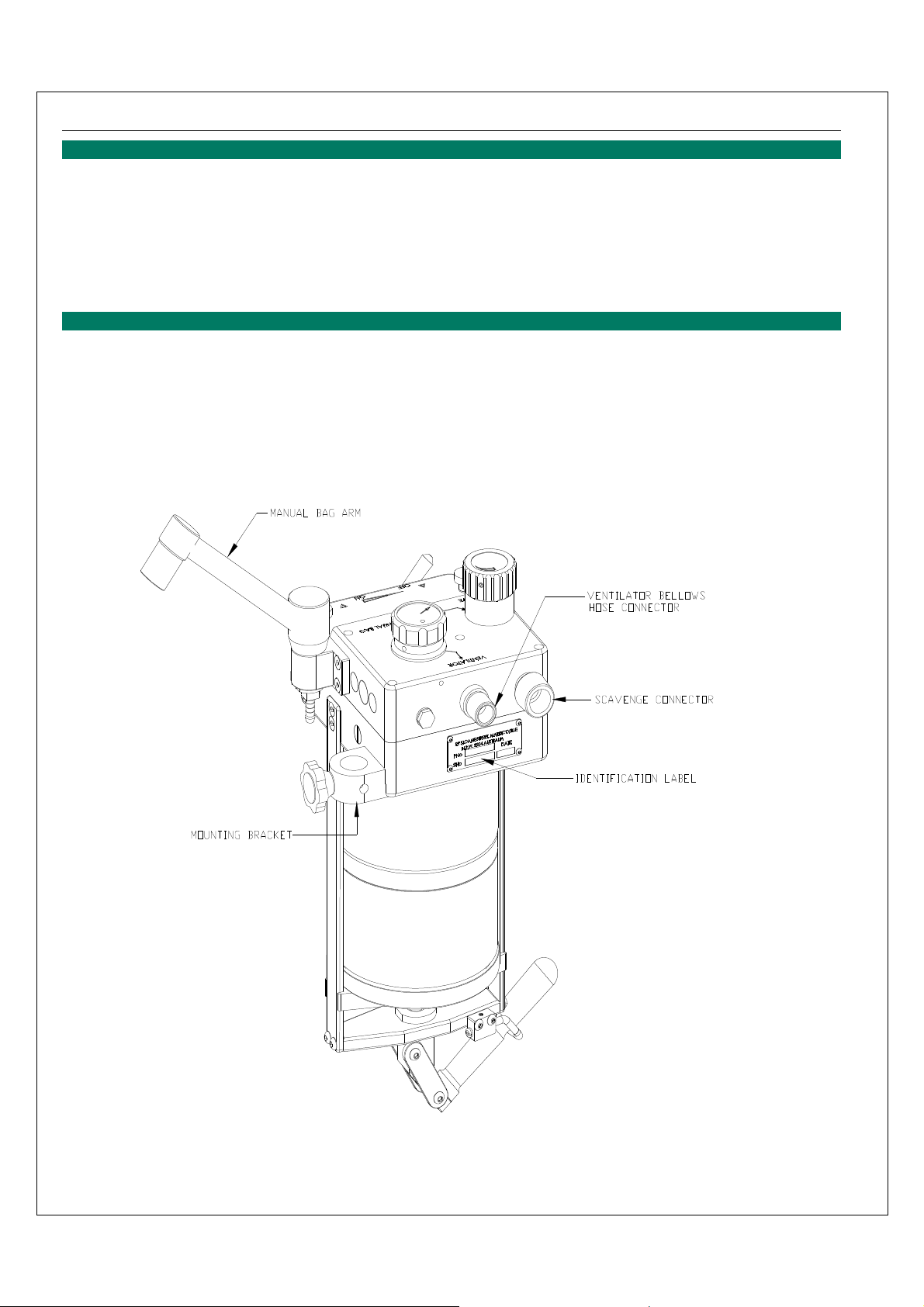

When viewed from the back the following can be seen:

ircle CCCCircuit

ircuitssss

ircle ircle

ircuitircuit

Physical FFFFeatures

Physical Physical

•

Scavenge connector 30mm Male cone

•

Ventilator bellows hose connector

•

Identification Label

•

Manual Bag Arm

eatures

eatureseatures

•

Figure 2: Rear view of AB800 absorber

12

AB800 User Manual

2.4.1

2.4.1 Scavenge Connector

2.4.12.4.1

Scavenge Connector

Scavenge Connector Scavenge Connector

The Pink scavenge hose connector is fitted with 2 different size connectors:

1 x 19 mm. Male connector

1 x 30 mm Female connector

The 19 mm male connector attaches to the Scavenge block of the anaesthetic machine and the 30 mm

female connector is connected to the absorber 30 mm male cone.

2.4.2

2.4.2 Ventilator hose connector

2.4.22.4.2

Ventilator hose connector

Ventilator hose connector Ventilator hose connector

The blue Ventilator Hose is connected to the 22 mm male cone at the back of the absorber and the other end

is connected to the ventilator patient 22 mm male cone.

2.4.3

2.4.3 Identification Label

2.4.32.4.3

Identification Label

Identification Label Identification Label

The Identification label has the name and address of the manufacturer as well as the serial number engraved.

The serial number must be stated when information regarding the unit is sought.

2.4.4

2.4.4 Manual Bag Arm

2.4.42.4.4

Manual Bag Arm

Manual Bag ArmManual Bag Arm

The manual re-breathing bag fitted with a male bag mount, is connected to the 22 mm. Female port on the

swivel arm.

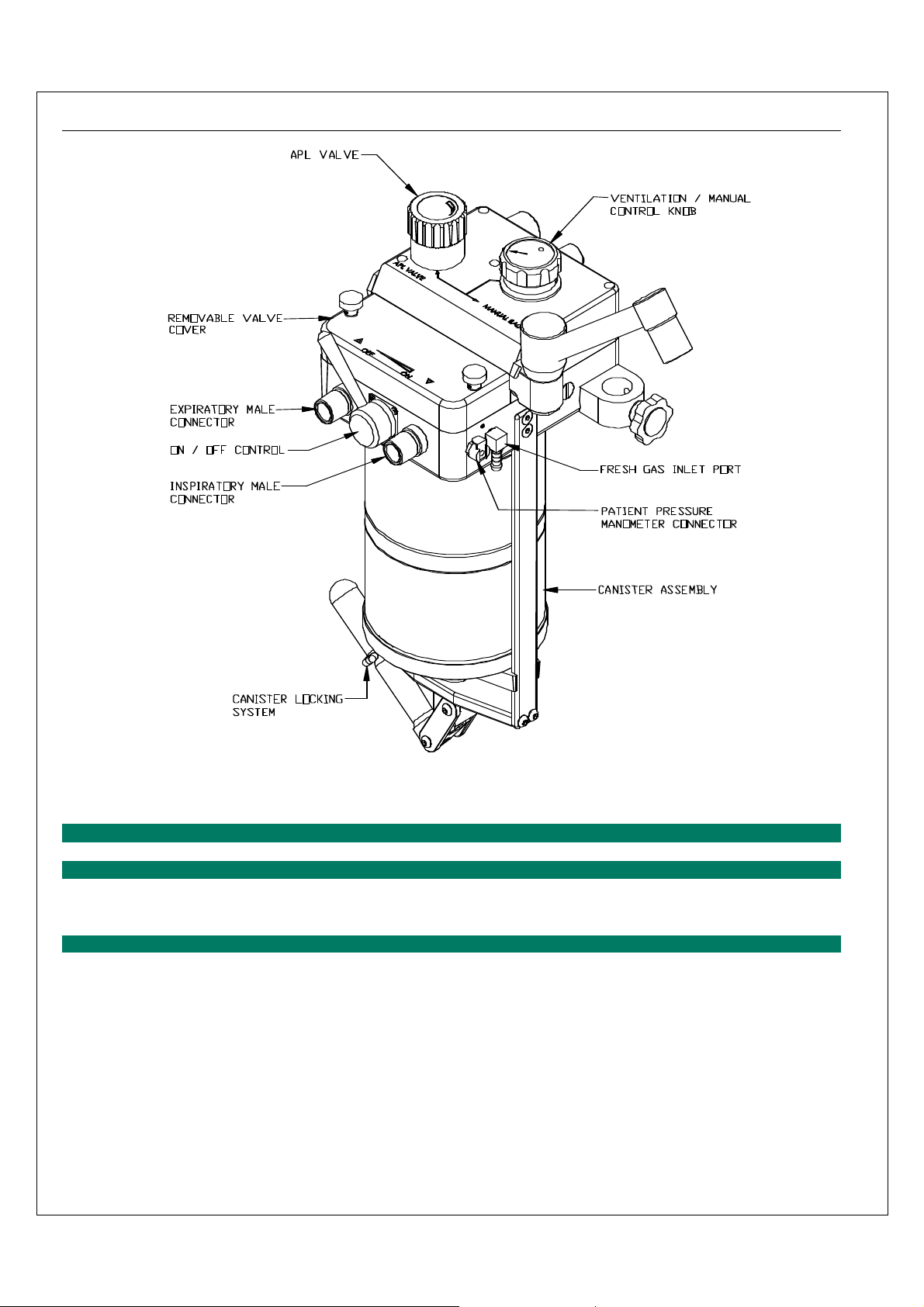

When viewed from the front and top the following can be seen:

•

22/15mm Inspiratory Male cone

•

ON / OFF Control

•

22/15mm Expiratory Male cone

•

Canister assembly

•

Canister support

•

Canister locking system

•

Ventilation Mode Control Knob

•

APL Valve (This valve also acts as a Pressure limiting valve and is factory set to max 80 cm/H2O but

can be set lower)

•

Removable valve cover

•

Silicone shutter unidirectional valves

•

Fresh Gas Connector

•

Patient Pressure manometer connector

13

AB800 User Manual

Figure 3: Front and side view of AB800 absorber

2.5

2.5 AB800 Front and top view components

AB800 Front and top view components

2.52.5

AB800 Front and top view componentsAB800 Front and top view components

2.5.1

2.5.1 The

2.5.12.5.1

The 22 mm. Inspiratory and Expiratory male cones:

22 mm. Inspiratory and Expiratory male cones:

TheThe

22 mm. Inspiratory and Expiratory male cones: 22 mm. Inspiratory and Expiratory male cones:

The white (clear) circuit hoses from the patient ‘Y’ piece are connected to these 2 cones.

2.5.2

2.5.2 The Bypass Control

2.5.22.5.2

The Bypass Control

The Bypass ControlThe Bypass Control

This control is used to bypass the soda lime absorber so that the patient re-breaths some of the exhaled gases

in order to raise the CO2 level. This control may be used in place of a reduced ventilation rate to elevate the

CO2 level, because when reducing the ventilator rate, the O2 level is also reduced; whereas using the bypass

control on the absorber, only the CO2 level is increased.

The amount of re-breathing may be increased, by turning the control to the left, or decreased by turning the

control to the right.

14

Loading...

Loading...