1

Gantry Crane 1:87

Description

This gantry crane was built in large numbers and can still be found at many load tracks today.

This finished model is constructed very finely in detailed plastic. Quiet miniature motors with me tal

transmissions lift and lower the crane hook and move the trolley. The crane has two adjustable

outputs e.g. for lighting, lifting magnet or grip arm.

The model is equipped with a digital decoder, so that all functions can be controlled with either a DCC

or Märklin Motorola Digital Center. Using the key connections, analog operation is also possible.

Packing contents

x Gantry crane fully assembled

x Roof with two bearers for optional mounting

x Instructions

x Adhesive label

Unpacking

Remove the upper foam material and then

the lower foam material block from the

packing. Hold the gantry crane by the base

plate and carefully remove the middle

foam block from the packing. The middle

foam block consists of two sections

between which the crane hook is located.

Tip: In order to avoid damage we

recommend that you only transport the

gantry crane in this packing.

Roof assembly

If desired glue the enclosed bearers to the

intended location under the roof.

The roof should either be placed or only

loosely fixed so that the trolley remains

accessible in the case of service.

Note: During installation or in the case of

transport the crane hook must be raised

completely so that the rope cannot jump

off the pulleys.

2

Connections

Put the gantry crane on your work area so that the terminals of the decoder point upwards. Make sure

that the motors and transmission are free.

In the decoder which is centrally installed under the base plate you will find a 11-way terminal block as

well as 5 free soldering connections.

Allocation of terminals

1: Key 1 Crane Hook

2: Key 2 Crane Hook

3: Key 3 Crane trolley

4: Key 4 Crane trolley

5: Key 5 Output A1 on/off

6: Key 6 Output A2 on/off

7: Key 7 Output A3 on/off

8: Key 8 Output A4 on/off

9: Common return for the Keys

10 + 11 : Transformer (Analog operation) or Digital power (Digital operation)

Allocation of Solder connections

The solder pads connect to outputs A1 to A4, as well as +20V common return. Loads such as lighting,

lifting magnet etc. can be connected here. These can then be switched by keys 5 to 8 in analog

operations and special function keys f1 to f4 in digital operations.

3

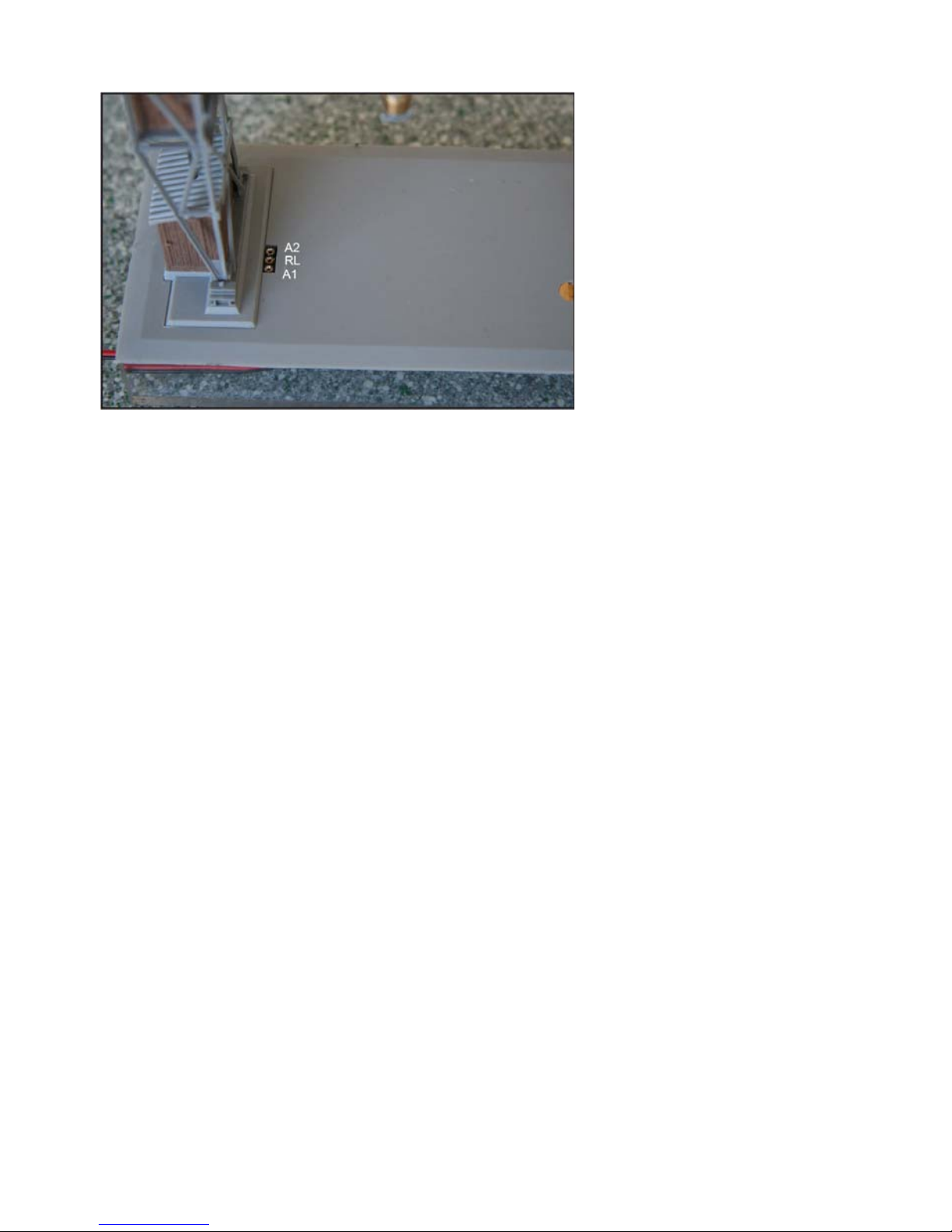

3 pole socket in the Base plate

The 3 pole socket provides outputs A1 and a2 as well as the common return RL. Loads such as

lighting, lifting magnet etc. can be connected here. The outputs can then be switched by keys 5 and 6

in analog operations and special function keys f1 and f2 in digital operations

Installation

Firstly saw a cutout of 124 x 53 mm in the layout’s base board under the shipping track. There is a

suitable template at the end of this description.

Attach sufficiently long cables to the appropriate connecting terminals.

Insert the gantry crane into the cutout by firstly passing the cables through it. You can use a

commercial adhesive to attach the base plate of the gantry crane on the layout board.

Operating

Analog Operation

After the crane is installed the keys and transformer are connected. Use a 16V~ model railway

transformer. Should you wish to operate loads on the A1 to A4 outputs connect them at this stage in

accordance with above connection allocation. The gantry crane is now operational.

The crane hook can be operated by keys 1 and 2 and the trolley by keys 3 and 4. Should the end

positions be reached without the respective motor being stopped the engine output is automatically

switched off (overload protection).

Note: The overload protection automatically switches the motor output off whenever the end positions

are reached, if the motor is not stopped.

Using Keys 5 to 8 outputs A1 to A4 can now also be controlled as described above.

For finer settings in the analog operations the crane decoder can be programmed with a digital cente r.

The rotating speeds for the 4 motor movements, the starting inertia with analog key press, as well as

the brake inertia when the key is released, can be adjusted.

Digital Operation

After the crane is installed connect the digital power (track power). Should you wish to operate loads

on the A1 to A4 outputs connect them at this stage in accordance with above connection allocation.

The gantry crane is now operational.

To operate the crane, call up locomotive address 3 on your digital center. Set locomotive address 3 to

DCC data format with 14 speed steps on the center (if possible) or operate address 3 in Motorola

format.

Attention: The crane decoder works only in 14 speed step mode!

4

If light function (f0) is switched off the crane hook can be controlled with the speed control. When light

function (f0) is switched on you can control the trolley with the speed control. The adjusted speed step

remains after switching the light function. If the end positions should be reached without having

stopped the relevant motor the motor output is automatically switched off (overload protection).

Note: The overload protection automatically switches the motor output off whenever the end positions

are reached, if the motor is not stopped.

By reversing the travel direction the speed is set to 0 and the motor output is reactivated (emergency

stop without starting/brake inertia).

If outputs A1 to A4 have loads attached they can be switched by special function keys f1 to f4. The

loads on A1 to A4 must operate on approximately +20V. The key terminals are not functional in the

digital operations.

Programming

In factory default state all decoder options are changed using configuration variables (CVs) according

to the DCC standard. The decoders can be pro grammed by an Intellibox, DCC Centre and Moto rola

Centre.

Programming with the Intellibox

Irrespective of the format to be driven later we recommend that the decoder be programmed via the

programming menu for DCC decoders.

The Intellibox supports DCC programming with a simple input menu. Long addresses do not have to

be laboriously calculated, they can be entered directly. The Intellibox automatically calculates the

values for CV17 and CV18.

For the exact process please read the appropriate chapter in the Intellibox manual.

Special case Motorola Locomotive addresses 80 to 255

In Motorola format the Intellibox supports an address range 255. Addresses 1 to 80 can also be

programmed easily using DCC programming mode. If an address above 80 is to be programmed, it

must, however, be done as described in the chapter “Programming with a Märklin Centre”.

After this programming technique CV 1 will be set to 0 and the decoder will use the Motorola address

higher than 80.

Programming of long Addresses without Pro gramming Menu

For programming with a centre which does not support prog ramming with an input menu, the value for

CV17 and CV18 must be calculated. Here is an example for programming the address 2000.

x Divide the addresses by 256 (2000:256 = 7 remainder 208).

x Take the result (7) and add it to 192.

x Program this value (199) into CV17.

x Program the remainder (208) into CV18.

x Important: Set Bit 5 of CV 29 to 1, so the decoder uses the long address.

Calculating the CV value

With CV29 and CV49 various characteristics of the decoder may be established.

The required values are easily calculated using the CV table and simple addition.

Example CV 49

Motorola off Value = 1

DCC on Value = 0

f1 toggle A1/A2 Value = 64

+20V on RL Value = 0

The Sum of all values is 65.

This value is programmed into CV 49.

Bit Function CV 49 Value

0 Motorola on

Motorola off

0

1

1 DCC on

DCC off

0

2

6 f1 switch A1 and f2 switch A2

f1 toggle A1/A2

0

64

7 +20V for Function outputs on RL (Base plate)

Expansion module supplies RL (Base plate)

0

128

5

Programming with a Märklin Center

With a Märklin center all CVs can be programmed, but not read.

Note: Before programming, the crane trolley must be driven into the center of the gantry.

1. Switch Center off and on.

2. Select the address of the decoder and switch the light on.

3. Change the direction of travel 5 times in quick succession, until the motor jerks briefly.

4. Set the speed controller to "zero".

5. Enter the nu m ber of the CV that is to be programmed.

6. Briefly operate the reversing switch. The motor jerks briefly.

7. Enter the desired value for CV e.g. a locomotive address.

8. Briefly operate reversing switch. The motor jerks briefly.

If further CVs are to be programmed repeat points 5-8.

If programming is to be terminated switch the center to "STOP" or set the address to "80" and briefly

operate the eversing switch.

Note: Since a Motorola digital center from Märklin only accepts inputs of 01 to 80, the value "0" must

be entered by entering the address as "80".

Page-Register for inputting CV-Numbers greater than 79

CV addresses larger than 79 can only be programmed with the help of the page register, CV66. If

CV66 has a value higher than 0, then the contents of CV66 times 64 will be added to every address

entered. The entered value must lie in the range 1 to 64.

When leaving the Motorola programming mode, the page register (CV66) is automatically reset to

zero.

Offset-Register for entering CV values greater than 79

CV values larger than 79 can only be programmed with the help of the offset register. The offset

register is CV65. If CV65 contains a value > 0, then all the following programmed values are

calculated by multiplying the contents of CV65 by 4 and adding the result to the entered value.

When leaving the Motorola programming mode the offset register (CV65) is automatically reset to

zero.

Example

CV49 is to be programmed with a value of 131, then CV65 must first be programmed with the value of 25.

Subsequently, CV49 can be programmed with a value of 31. The decoder places the value 4 * 25 + 31 into

CV49.

Note: When programming CV65 and CV66 the contents of the offset and page registers have no

effect.

6

Table of individual CVs (Configuration Variables)

CV Description Value Range Factory Default

1 Short Locomotive Address 1-127 3

2 Minimum Speed 1-63 5

3 Start Inertia 1-63 2

4 Brake Inertia 1-63 2

5 Maximum Speed

Must be greater than CV2

1-63 20

6 Maximum Motor Voltage

Must not be changed

1-255 64

7 Software Version

The processor used can be updated

- Varies

8 Manufacturer - 85

17

18

Long Locomotive Address

17 = High Byte

18 = Low Byte

1-9999

192-231

0-255

2000

199

208

29 Configuration of both motors in DCC standard

Bit 0=0 Driving direction not swapped

Bit 0=1 Driving direction swapped

Bit 1=0 14 Speed steps

Bit 5=0 Short Address (CV 1)

Bit 5=1 Long Address (CV 17/18)

Value

0 *

1

0 *

0 *

32

0-33 0

49 Decoder Configuration

Bit 0=0 Motorola on

Bit 0=1 Motorola off

Bit 1=0 DCC on

Bit 1=1 DCC off

Bit 6=0 f1 switches A1 and f2 switches A2

Bit 6=1 f1 toggles A1/A2 (switches between A1 and A2)

f1 off: A1 off und A2 on

f1 on: A1 on und A2 off

Bit 7=0 +20V for Function output RL on the base plate socket

Bit 7=1 Extension module provides RL for the base plate socket

Note: If the Motorola data format is switched off in bit 3 and the DCC data format is switched off

in bit 4, the decoder will not receive any more driving instructions and can only be programmed.

Value

0 *

1

0 *

2

0 *

64

0*

128

1-195 0

65 Motorola Programming Offset 0-255 0

67 Maximum Speed for Key 1 (Analog Operation) 0-255 40

68 Maximum Speed for Key 2 (Analog Operation) 0-255 40

69 Maximum Speed for Key 3 (Analog Operation) 0-255 50

70 Maximum Speed for Key 4 (Analog Operation) 0-255 50

71 Starting Inertia for Key 1 (Analog Operation) 0-255 5

72 Starting Inertia for Key 2 (Analog Operation) 0-255 5

73 Starting Inertia for Key 3 (Analog Operation) 0-255 5

74 Starting Inertia for Key 4 (Analog Operation) 0-255 5

75 Braking Inertia for Key 1 (Analog Operation) 0-255 1

76 Braking Inertia for Key 2 (Analog Operation) 0-255 1

77 Braking Inertia for Key 3 (Analog Operation) 0-255 1

78 Braking Inertia for Key 4 (Analog Operation) 0-255 1

79 Maximum Motor Voltage in Analog operation 0-255 180

98 Timed switching of Outputs A1 + A2

0 = both Outputs not timed

1 = only A1 timed switching

2 = only A2 timed switching

3 = A1 and A2 timed switching

0-3 3

99 Maximum ’On’ time in Seconds

for timed outputs as in CV 98

0-255 45

The factory default values are marked with an *.

7

Gantry Crane Template

Guarantee declaration

Each component is tested for its complete functionality before distribution. If a fault should arise within

the guarantee period of 2 years, we will repair the component free of charge upon production of proof

of purchase. The warranty claim is void if the damage was caused by inappropriate treatment.

The trade names mentioned are registered trade marks of the respective companies.

8

02045

8583-27

If you have any questions call us. Hotline times are:

Mon - Tue - Thu - Fri, 14:00-16:00 and Wednesdays 16:00-18:00

Our products are covered by a two year warrantee. If it is defective send decoder

along with the receipt of purchase to the following address:

Uhlenbrock Elektronik GmbH * Mercatorstr. 6 * 46244 Bottrop

Tel: 02045-8583-0 * Fax: 02045-8684-0 * www.uhlenbrock.de

Loading...

Loading...