Page 1

Digital-Servo 81 310

Charateristics

• For Märklin oder DCC Digital systems and Analogue operation

• Integrated Digital decoder

• Switchable by locomotive functions, solenoid or proportional to speed setting

• Configurable turning speed

• Up to four configurable stop positions

• Rotation angle up to 180°

• Configured by DCC CV programming or by a Motorola Digital center

• With mounting material, cam levers and control wires

2 x 0.4 mm and 1 x 0.6 mm, length 100 mm

• Torque 2 Ncm

• Dimensions 20.0 x 17.6 x 8.0 mm

Description

The digital servo with the integrated digital decoder is suitable for installation in vehicles, as well as for use

in stationary working models. The quiet, smooth running spoils even the fastidious Model railroader. The

servo moves the item with the enclosed control wire. In vehicles for example, pantographs or doors can be

moved. In fixed items for example, it can move turnouts, signal semaphores, boom gates, water cranes and

gates.

With the enclosed mounting material the servo can be installed in many different positions.

Connection

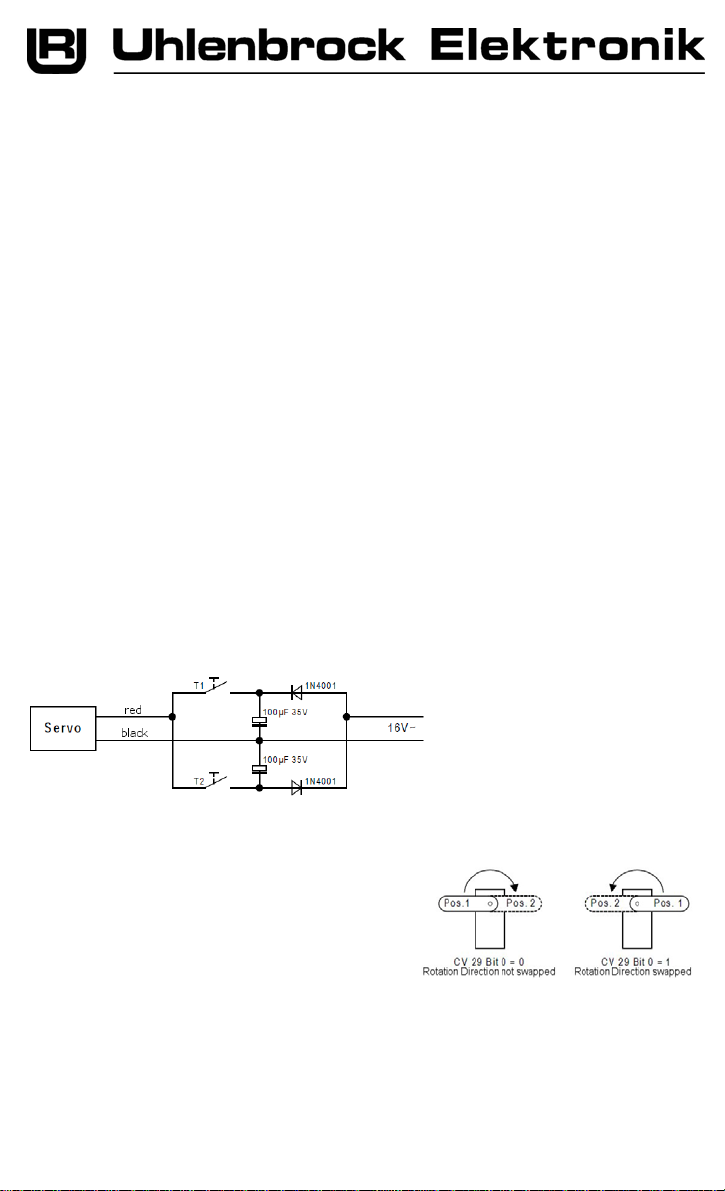

The digital servo has two connecting wires which are connected in an analogue operation as shown below

or in digital operation to the track power from the digital center or a Booster.

Attention: Manual turning of the servo cam will destroy the servo!

Example for connecting in Analogue Operation

Meaning for the connection:

Plus to red, Minus to black wire – the Servo moves to Position 1.

Plus to black, Minus to red wire – the Servo moves to Position 2.

Attention: The reversing pulse from a Märklin transformer will destroy the servo!

Analogue Operation

The Servo can be operated with DC or AC voltage between

10V und 20V. Depending on the polarity the servo moves

between two programmable end positions at a maximum

angle of 180°. These end positions can be programmed, for

use in an analogue system, with a digital center in CV261

for position 1 and CV262 for position 2 (see the section

“Programming “).

Bit 0 in CV 29 can be used to swap the rotation direction.

The servo operates for as long

as a key is pressed, up to the

stop position.

Important: Only one key can be

pressed at a time!

1

Page 2

Digital Operation

In the digital operation the servo can be controlled in five different operating modes. The appropriate

operating mode is specified in CV257 (see the section “Selection of Digital Format and Operating Mode”).

In all modes the operating speed between the end positions are adjustable (CV 258), as is a starting

delay (CV259). The brake delay is fixed

Up to four stop positions can be programmed in CVs 261 to 264. The value range is between 0 and 255

and corresponds to a total angle from 0 to 180°.

Bit 0 of CV29 can be used to swap the rotation direction in all operating modes (see Table “Calculating

the value for CV29 “).

The Locomotive address is either programmed in CV1 (short address DCC 1-127, Mot. 1-80) or in CVs 17

and 18 (long address DCC 128-9999). Bit 5 of CV29 determines if the short or the long address is to be

used (see Table “Calculating the value for CV29 “).

The Solenoid address (Operating modes 3 and 5) is always programmed into CVs 17 and 18 (only DCC

1-2000).

Operating Modes

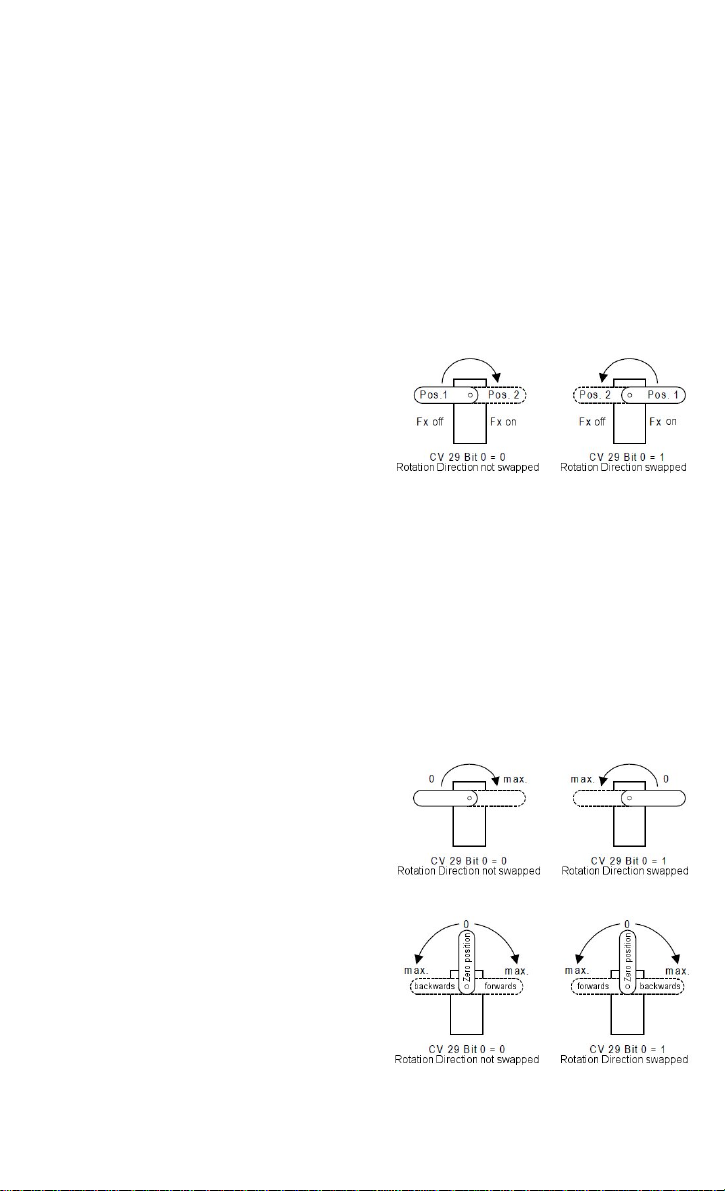

Operating Mode 1 – Control by Locomotive address and Spe cial function

The servo can be operated by any desired locomotive

special function of a programmable locomotive address

between two programmable stop positions through a

maximum angle of 180°.

If the locomotive special function is switched off, stop

position 1 from CV261 is approached. If the locomotive

special function is switched on, the stop position 2 from

CV262 is approached.

The locomotive special function number is entered into the CV265 (high order byte) and CV266 (low order

byte). If CV265 contains a value of 128 (factory setting) a value between 0 and 28 can be programmed into

CV266, where the value corresponds to the desired locomotive special function number f0 to f28.

If locomotive special functions between f29 and f32767 are to be used the values to be programmed into

CV265 and CV266 are calculated with the following formula:

Locomotive special function number = high order byte * 256 + low order byte

Example

The Servo is to be controlled by locomotive special function f300 of locomotive address 10.

Divide the locomotive special function number by 256 (300/256 = 1, remainder 44)

Enter the result (1) as the value of CV265.

Enter the remainder (44) as the value of CV 266.

The following CVs need to be programmed:

CV1 (short address) = 10, CV 265 = 1, CV 266 = 44

Operating Mode 2 - Control by Locomotive address and Speed St ep

The servo can be controlled proportional to the position

of the speed control from any locomotive address,

whereby speed step 0 is the extreme left of the servo’s

travel and the maximum speed step (14 or 28,

depending on the value of CV29) the extreme right

position of the servo’s travel. The desired end positions

are reached by the speed control over a maximum

angle of 180°.

Operating Mode 3 - Control by Locomotive address, Speed Step and Direction

The servo can be controlled proportional to the position

of the speed control from any locomotive address,

whereby speed step 0 brings the servo to its central

position. With the maximum speed step in the forward

direction driving the servo to its extreme right position,

and with the maximum speed step in reverse direction

to its extreme left position, the desired end positions

are reached by the speed control over a maximum

angle of 180°.

.

2

Page 3

Operating Mode 4 – Control by 1 Solenoid Address and 2 Stop Positions (DCC only)

Using one solenoid address the servo can travel

between two programmable stops through a maximum

angle of 180°.

When the solenoid address is switch to “round/red” stop

position 1 from CV261 is approached. When the

solenoid address is switch to “straight/green” stop

position 2 from CV262 is approached.

The solenoid address is programmed into CV17 (high order byte) and CV18 (low order byte) according to

the following formula:

Solenoid address = high order byte * 256 + low order byte

Example

Solenoid address 300 is to control the servo.

Divide the solenoid address by 256 (300/256 = 1, remainder 44)

Enter the result (1) as the value into CV17.

Enter the remainder (44) as the value into CV18.

The following CVs need to be programmed:

CV 17 = 1, CV 18 = 44

Operating Mode 5 - Control by 2 Solenoid Address and 4 Stop Positions (DCC only)

Using two solenoid addresses together the servo can

travel between four programmable stops through a

maximum angle of 180°.

When the first solenoid address is switched to

“round/red” the servo moves to stop position 1 from

CV261 and if it is switched to “straight/green” it moves

to stop position 2 from CV262. When the second

solenoid address is switched to “round/red” the servo

moves to stop position 3 from CV263 and if it is

switched to “straight/green” it moves to stop position 4 from CV264.

The first solenoid address is programmed into CV17 (high order byte) and CV18 (low order byte)

according the following formula:

Solenoid address = high order byte * 256 + low order byte

The second solenoid address corresponds to the first plus 1.

Example

Solenoid addresses 300 and 301 are to be used to control the Servo.

Divide the solenoid address by 256 (300/256 = 1, remainder 44)

Enter the result (1) as the value into CV17.

Enter the remainder (44) as the value into CV18.

The following CVs need to be programmed:

CV 17 = 1, CV 18 = 44

Since CV257 is set to operating mode 5 (Control by two Solenoid Address and four Stop Positions), the

next address (here 301) will control the servo stop positions 3 und 4.

Selection of Digital Format and Operating Mode

The settings for the digital servo are programmed into CV257, e.g. which data format is to be used and in

which mode the digital servo should.

Note: Only one of the five operations can be selected.

Calculating the value for CV257

The value to be entered is calculated from the CV-table by adding the values of the desired functions.

Example

The servo is to be controlled by one

solenoid address and to be used on the

DCC format.

One solenoid address Value = 4

Only DCC operation Value = 64

The Sum of the values is 68.

Value 68 is programmed into CV 257.

Note: If the functions “Only DCC operation” and “Only Motorola operation” are both programmed the Digital

servo will not operate and can only be programmed.

Function CV257 Value

Mode 1 – Locomotive address and Special function 1

Mode 2 – Locomotive address and Speed Step 2

Mode 3 – Locomotive address and Speed Step 3

Mode 4 – One Solenoid Address and two Stops 4*

Mode 5 – Two Solenoid Address and four Stops 5

Only DCC operation 64*

Only Motorola operation 128

3

Page 4

Programming

The basis for setting up all the digital servo’s options is the Configuration Variables, CVs for short. The

Digital servo can be programmed with Intellibox, DCC and Motorola Center.

Note: During Programming the servo moves to the central position. It moves slightly around this position

during every read and write operation.

Programming with the Intellibox

The Intellibox supports DCC programming with a user friendly embedded menu. Long addresses do not

need to be laboriously calculated. They can be entered directly. The Intellibox automatically calculates the

values for CV17aund CV18 and sets Bit 5 in CV29 so that the long address is actually used. In exactly the

same way as it can be read. See the appropriate chapter in the Intellibox Manual.

Programming with DCC devices

Use the programming menu of your DCC Center to program the servo CVs by Register, direct or Page

programming for reading and programming. The precise procedure is found in the Manual for your Center.

Help Register for “little” DCC Centers with max. 99 CVs

When using DCC Center which can only program a maximum of 99 CVs you use a Help register. If CV32

is programmed with a value of 1, 2, 3 or 4, you can use CVs 96, 97, 98 und 99 to program CVs above 256

with the following procedure:

CV 32 = 0 – help register inactive

CV 32 = 1 - CVs 96-99 program CVs 257-260

CV 32 = 2 - CVs 96-99 program CVs 261-264

CV 32 = 3 - CVs 96-99 program CVs 265-268

CV 32 = 4 - CVs 96-99 program CVs 269-272

Programming of long Addresses without Programming Menu

If the programming is done with a center which does not have an embedded programming menu the values

for CV17 and CV18 must be calculated. This shows how to program address 2000.

Divide the address value by 256 (2000/256 = 7 remainder 208).

Take the result (7) and add 192 to it.

Enter this result (199) as the value for CV17.

Enter the remainder (208) as the value for CV18.

Important: Set Bit 5 of CV29 to 1 so that the decoder actually uses the long address

Main Line Programming

The decoder can be programmed using locomotive main line programming (POM) in all its operating

modes. If the decoder is in operating mode 4 or 5 (controlled by solenoid address) the solenoid address

must be used as the “locomotive address” of the POM-command. The two CVs can then not be altered.

Attention: When main line programming, please consider when programming CVs smaller than 257 that

perhaps an existing locomotive with same address can unintentionally have its CVs programmed. For this

reason use main line programming only to change the stop positions of the servos (CV 261-264). Usually

locomotive decoders do not use these CVs.

Calculating the value for CV29 (DCC Configuration)

Example

The Servo is be controlled by a Locomotive

address in DCC format with 28 speed steps.

The address to be used is a long address from

CV 17/18.

DCC 28 speed steps Value = 2

Use a long address Value = 32

The Sum of the Values is 34.

This value is factory preset to CV29.

Programming with a Märklin Center

With a Märklin center all CVs can be programmed, but not read.

1. Switch Center off and on.

2. Select the address of the digital servo.

3. Operate the direction change-over 5 times in quick succession.

4. Set the speed controller to "zero". The servo moves sligh tl y.

5. Enter the number of the CV that are to be programmed.

6. Briefly operate the direction change-over. The servo moves slightly.

7. Enter the desired value for CV e.g. a locomotive address.

8. Briefly operate the direction change-over. The servo moves slightly.

Bit Function CV29 Value

Rotation direction not swapped

0

Rotation direction swapped

DCC 14 Speed steps

1

DCC 28 Speed steps

Only digital operation

2

Digital/Analogue automatic

Use short address from CV1

5

Use long address from CV 17/18

2*

32*

0

1

0

0

4

0

4

Page 5

If further CVs are to be programmed repeat points 5-8.

If programming is to be terminated switch the center to "STOP" or set the address to "80" and briefly

operate the direction change-over.

Note: Since a Motorola digital center from Märklin only accepts inputs of 01 to 80, the value "0" must be

added by entering the address as "80".

Page-Register inputting of CV-Numbers greater than 256

If CVs above 256 are to be programmed then for this a 4 must be programmed into the CV66 (page

register). Now CVs 257 to 272 can be programmed using CVs 1 to 16.

CV66 = 0, CVs 1 to 29 are programmed directly.

CV66 = 4, CVs 257 to 272 are programmed with CVs 1 to 16.

The value of CVs 261 to 264 for the four possible stop positions, whose value is larger than 80, is internally

automatically multiplied by 4, so that the input values used are 0-63.

Example

CV261 is to have a stop position 1 set to a value of 200:

CV 66 = 4 (CVs 1 to 16 are to program CVs 257 to 272)

CV 5 = 50 (CV5 now corresponds to CV261 and 50*4 = 200 is the desired value 200)

Offset-Register for inputting of CV-Value greater then 79 (only for CV257 and CV265)

If CV values larger than 79 are to be programmed into the CV257 or CV265, then CV65 (offset register)

must be programmed larger than 0. For all following programming processes the value from CV65 is

automatically multiplied by 4 and added to the given value and programmed into the appropriate CV.

When leaving Motorola, programming the offset register (CV65) is automatically set back to zero.

Example

CV257 is to be programmed to the function “Only Motorola Operation“ (Value 128).

CV66 = 4 (CVs 1-16 are used to program CVs 257-272)

CV65 = 25 (the following values are added to 25*4 = 100)

CV1 = 28 (CV1 now represents CV257 and 28+100 = 128 is the new value 128)

Note: If the digital servo is operating in mode 4 or 5 (Controlled by solenoid addresses) the Motorola

programming is blocked. The operating mode of the Servos must be changed with a DCC center, before it

can be programmed with a Motorola center.

Programming Protection (DCC and Motorola)

If several Digital servos in a model (e.g. multi-bay locomotive shed) are to be controlled with the same

locomotive address, but via different locomotive functions, the “decoder lock” function (programming

protection) can be used for programming. Before installing the Digital servos, connect it to the programming

track and program the locomotive address (CV1) and program CV16 with an index number which is

different for each installed servo.

If the CVs of an installed servo is to be changed, then program CV15 with the index number of the servo

that is to be programmed.

Note: The CVs of a Servo can only be programmed if the value in CV15 is the same as that in CV16. The

CV15 however can always be programmed. Afterwards only the CVs of this servo are changed by CV

programming (POM) and not the CVs of the other servo.

Table of CVs (Configuration Variables) of the Digital servos

CV Description Value range

Short Locomotive address

1

is only used when CV29 Bit 5=0 (factory setting)

Software version (The processor used can be updated)

7

Manufacturer ID

8

Decoder Lock (Programming protection)

15

Decoder Lock Index Number

16

Long address (1-9999) or Solenoid address (1-2000)

17

17 = Long address high byte

18

18 = Long address low byte

The long address is only used when CV29 Bit 5=1

DCC 1-127

Mot 1-80

- varies

- 85

0-255 0

0-255 0

192-231

0-255

Factory

default

3

0

1

5

Page 6

CV Description Value range

Configuration DCC Standard

29

Bit 0=0 Normal driving direction

Bit 0=1 Reversed driving direction

Bit 1=0 14 speed steps

Bit 1=1 28 speed steps

Bit 2=0 only digital operation

Bit 2=1 auto digital/analog detection

Bit 5=0 Short Address (CV 1)

Bit 5=1 Long Address (CV 17/18)

Index Register for “small” DCC Centers

32

0 = Help register inactive

1 = CVs 96-99 program CVs 257-260

2 = CVs 96-99 program CVs 261-264

3 = CVs 96-99 program CVs 265-268

4 = CVs 96-99 program CVs 269-272

Offset Register

65

for CV programming with a Motorola Center

Page Register

66

for CV programming with a Motorola Center

96-99

The factory default values are marked with *.

Index Register for “small” DCC Centers

96 for CVs 257,261, 265, 269

97 for CVs 258,262, 266, 270

98 for CVs 259,263, 267, 271

99 for CVs 260,263, 268, 272

for this the appropriate value must be set in CV32

Selection of Operating Mode and Digital Format

257

Control by locomotive address and special function

Control by locomotive address and speed steps

Control by locomotive address, speed step and direction

Control by one solenoid address with 2 stop positions

Control by two solenoid address with 4 stop positions

DCC operation only

Motorola operation only

Rotation Speed

258

Acceleration delay (Inertia)

259

Decoder Reset

260

Stop Position 1

261

Stop Position 2

262

Stop Position 3

263

Stop Position 4

264

Locomotive special function number

265

265 = high order byte

266

266 = low order byte

Value

0 *

1

0

2 *

0

4 *

0 *

32

Value

1 *

2

3

4

5

64

128

0-255 6

0-4 0

0-63 0

0, 4 0

- -

0-255 1

0-63 10

0-63 2

0, 1 0

0-255 15

0-255 220

0-255 100

0-255 150

0-128

0-255

Factory

default

128

1

Guarantee declaration

Each component is tested for its complete functionality before distribution. If a fault should arise within the

guarantee period of 2 years, we will repair the component free of charge upon production of proof of

purchase. The warranty claim is void if the damage was caused by inappropriate treatment.

The trade names mentioned are registered trade marks of the respective companies.

Our contact Details:

Service

In the event of a defect or failure send the unit

together with the invoice and a short

description of the fault back to us for repair.

We are available if you have any questions!

Your direct line to a technician:

Mon - Tue - Thu – Fri, 14:00~16:00 and Wed 16:00~18:00

Hotline

0 20 45 - 85 83 27

6

Uhlenbrock Elektronik GmbH

Mercatorstr. 6

D-46244 Bottrop

Made in Germany

Electronic devices do not

belong in household rubbish

Loading...

Loading...