Page 1

Servo decoder 67 800

For connection 4 Servos

Characteristics

• For Märklin and DCC Digital systems

• Switchable like a solenoid decoder

• Switching address for each servo freely selectable

• Adjustable stop positions

• Adjustable rotating speed

• 4 stopping positions via 2 addresses in the DCC operation

• Backlash function, e.g. for boom gates or semaphore signals

• Configurable via the turnout keys of digital systems

or by DCC CV programming

• Powered from the track or separate transformer

• Very low power usage by integrated regulator

• Servo output with overload protection

Description

The servo decoder allows you to use Servos, as commonly employed in modeling, to solve

mechanical control problems on the model railway layout. For example, with the appropriate

mechanics the Servos can change turnout positions, move water cranes in, open doors of

locomotive sheds, operate boom gates and much more.

Up to four Servos can be connected to a servo decoder and operated independently of each

other. The servo decoder works like a turnout decoder and in a digital system is assigned a

solenoid address for each servo. By using digital systems, the solenoid controlling the servo

can be brought to two stop positions. The servo decoder operates with all DCC and Motorola

Digital systems.

The Servos’ stops for the two solenoid positions "red" and "green" can be independently

configured. The speed with which the servo moves between the two stops can also be

adjusted.

For special applications each of the attached servos can have two additional independent

stops by assigning two additional solenoid addresses. This way mechanical items like water

cranes can be moved between four positions via two solenoid addresses.

The servo decoder also has a “rocker” function which can be used for boom gates or

semaphore signals. If the servo reaches a stop it then bounces a little before it stops

completely. The rocker movement amplitude and speed can be adjusted.

1 Address, both stops and the rotating speed for each servo are separately setup with simple

key programming from Motorola and DCC centers.

In the case of use of a DCC center like the Intellibox all parameters can be programmed by

CV programming. That way, 2 addresses, their stops, the rotating speed and the rocker

function can be separately setup for each servo.

Page 2

Installation of Servo decoders 67 800

Connecting the Servo decoder

The terminals labeled “Gleis” (track) are connected with the track terminals of a DCC or

Motorola Digital center. In this case the decoder is supplied via the track power.

Note: Since most Servos move uncontrolled, when supply voltage is switched on (this is a

servo characteristic and is not produced by the servo decoder), we recommend that the

decoder is also connected to a 16V model railway transformer via the "trafo" terminals. The

uncontrolled movements of the Servos then only occur when the entire layout is switched on.

Connecting the Servos to the Servo Decoder

Each servo decoder has four 3-pin headers for connecting a maximum of four Servos. The

Servo’s plugs are plugged onto the appropriate header so that the earth wire (usually black

or brown) is at the front edge of the circuit board.

Header pin assignment

Earth - PCB front edge

5V - middle

Control wire - back

Tip: If the distance from the servo to the servo decoder is too far you can extend the lead

without any difficulty. Servo cables with plug and socket are available in specialized

electronics outlets.

Programming

From a DCC center, the decoder can be programmed by keys and solenoid instruction or by

using CV programming.

With key programming not all items can be used.

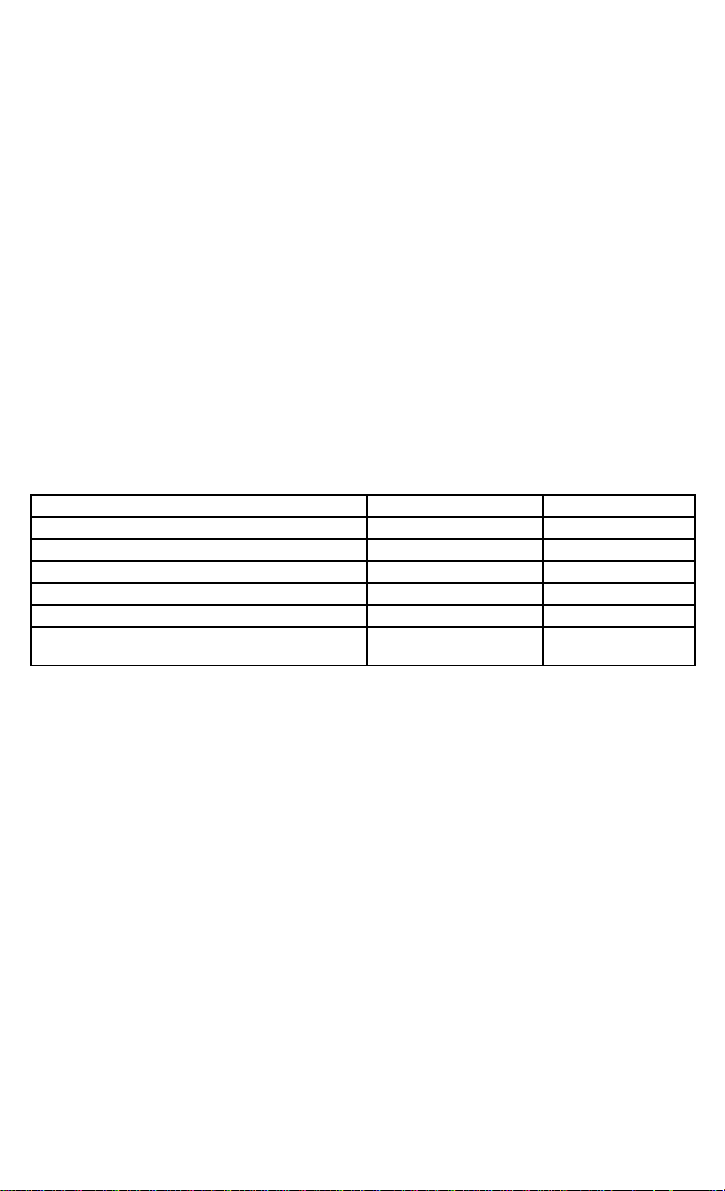

Item Key programming CV Programming

Data format X X

Addresses 1 2

Stop positions 2 4

Switching time X X

Whip function - X

Selection whether the servo is always to be switched

on or only during servo movement

Programming by Key and Solenoid Command

All settings for the stops and the servo speed are easily set by the digital center, or another

control device, with which one can control solenoids.

The desired servos should be connected to the outputs that are to be programmed since the

servo decoder acknowledges the setting of the servo parameters, during programming, with

a movement of the respective servo.

1. Activating Programming Mode

Press the key on the decoder and keep it pressed. The control LED blinks.

2. Selecting Data Format

The LED blinks alternately at flashing rate A and flashing rate B for 5 seconds in each case.

Meaning:

Blinking rate A = __ __ __ = selection DCC format

Blinking rate B = _ _ _ _ _ _ = selection Motorola format

If the key is released during the appropriate blinking rate then the appropriate data format is

selected.

Note: If the decoder no longer reacts to key inputs from the input device, the wrong data

format was selected! Programming must be repeated.

- X

Page 3

3. Specify servo output to progra m

When the key is released the servo on connector 1 briefly moves back and forth. If the key is

pressed again the servo at connector 2 briefly moves back and forth. Further operation

changes to output 3 and 4. If the key is then operated again, programming mode is

terminated.

Operate the key repeatedly until the servo on the output to be programmed moves briefly.

4. Specifying the solenoid address for the selected servo output

On digital center or another control device which can switch solenoids, operate one of the

two keys (red or green) which are to move this servo later. The servo decoder acknowledges

the key press as the servo briefly moves back and forth.

5. Selecting solenoid keys for [+] and [-] keys

In order to be able to set up stops and the speed of the servo during programming, two keys

must be specified which will be used as [+] and [-] key.

From the digital center, or another control device which can switch solenoids, press the key

which is to be used as [+]-key. The solenoid address of this key must not be the same as the

previously selected solenoid address. The servo decoder acknowledges the key press by

briefly moving the servo back and forth.

In the same way, the key which is to be the [-]-key is determined.

Note: After programming, this allocation is deleted so that these keys can be used on the

layout as normal.

6. Setting the stop positions of the Servos

Using the address setup in step 4, the servo can now be moved to stop position “red” with

the red solenoid key. With the help of the [+] and [-] keys, specified in step 5, the stop

position of the Servos is adjusted accordingly. For this the [+] or [-]-key is repeatedly pressed

until the desired retaining position is reached. With the green solenoid move the servo to the

stop position "green" as described above.

When desired positions are fixed, the servo must be switched to the "red" and "green" sto p

positions 3 times (thus red-green-red-green-red-green) without changing the setting, in order

to go to the next programming step (keys in accordance with step 4).

7. Setting the speed of the Servos

The servo now independently moves back and forth with the set speed between the two stop

positions. The speed of the movement can be increased or decreased with the [+]and [-]

keys, specified in step 5.

8. Terminate Programming

When the desired speed is adjusted, one of the two keys which change the servo position is

operated, (keys in accordance with step 4).

Programming for this servo output is complete and the servo decoder is ready for the

programming of the next output. The selected settings are permanently stored.

Note: If the programming is terminated prematurely, as if the track power is switched off,

then the selected settings are stored.

Page 4

CV Programming with DCC Devices

p

The decoder can be programmed with the Intellibox and any DCC center that permits 3 digit

numerical values. Use the programming menu of your DCC center to select and program

the decoder CVs. The exact process will be outlined in the center’s manual.

Connection of the servo decoder for programming

For programming the servo decoder it must be individually connected to a programming

track. The desired servos are connected to outputs which are to be programmed.

Configuration of the servo decoder

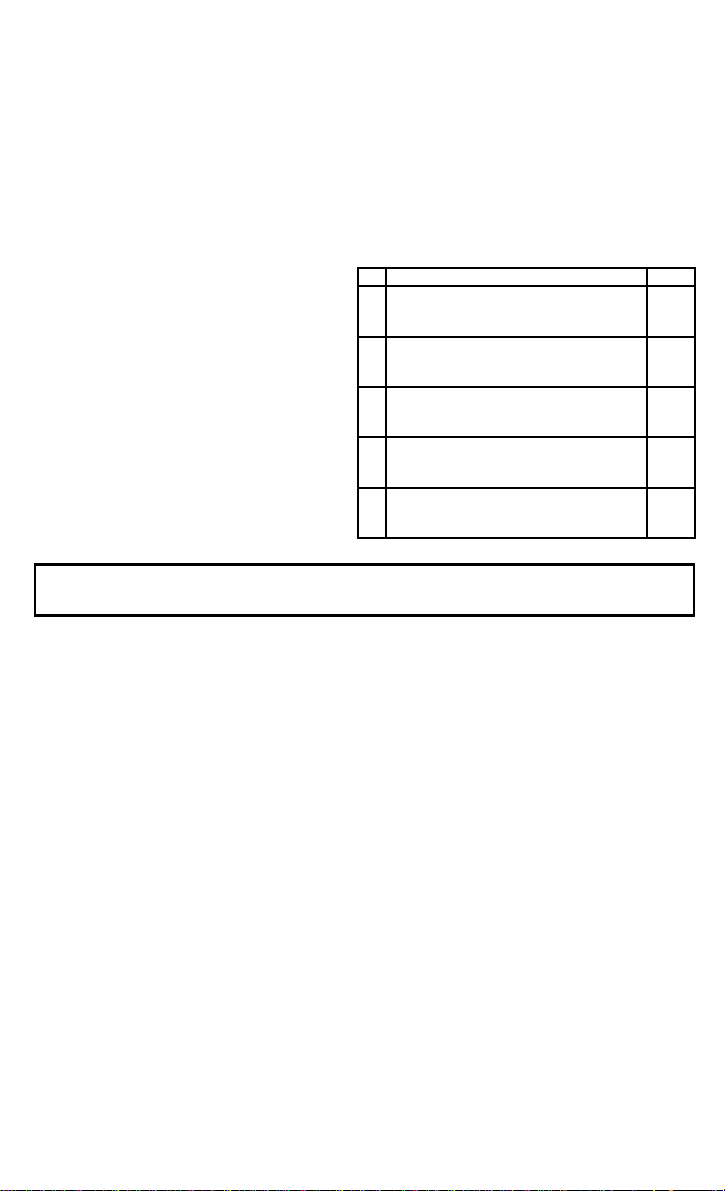

CV 119 is used to specify different decoder settings.

If the power on the different servo outputs is always switched on or only during servo

operation and if the operating mode is Motorola or DCC:

The entered value is calculated from the

CV table in which the values of the desired

functions are added.

Example

Output 1 power always on value = 1

Output 2 power always on value = 2

Output 3 power always on value = 4

Output 4 power always on value = 8

Operating mode DCC value = 0

Sum of all values is always 15.

This value is preset in CV 119 by the

factory.

Configuration of the Servo Outputs

Bit Function of CV 119 Value

0 Power output 1

only switched on during servo operation

always switched on

1 Power output 2

only switched on during servo operation

always switched on

2 Power output 3

only switched on during servo operation

always switched on

3 Power output 4

only switched on during servo operation

always switched on

7 Operating mode

DCC

Motorola

0

1*

0

2*

0

4*

0

8*

0

128*

Note: In the following we always refer to the CVs for the servo output 1.

The CVs for out

uts 2 to 4 can be taken from the CV table.

Address 1 and 2 (CV 120 and 121, 160 and 161)

The addresses for each servo output can be freely selected. The valid range of address is

1-2048.

The servo is brought to the stop by the Address 1 in accordance with CV122 (red) and

CV123 (green).

Address 2 brings the servo to stop positions in accordance with CV162 (red) and CV163

(green).

Note: Address 2 can be configured by CV programming.

Addresses to 255 can be entered directly as values in the CV for the Low byte (e.g.

CV121). CV for the High byte (e.g. CV 120) remains at value 0 (factory setting).

Addresses from 256 the values for the High byte and the Low byte must be calculated. For

example, programming of the address 2000 is as follows.

• Divide the address value by 256 (2000/256 = 7 remainder of 208).

• Register the integer result (7) as value in CV for the High byte (e.g. CV 120).

• Register the remainder (208) as value in CV for the Low byte (e.g. CV 121).

Setting Stop positions (CV 122 and 123, 162 and 163)

The setting of the stops is done by numerical values between 0 and 127.

CV value = 0 maximum value for stops 1 and 3 (CV 122, 162)

CV value = 127 maximum value for stops 2 and 4 (CV 123, 163)

Setting time (CV 124)

Time constant by which servo position is incremented or decremented in 1 ms steps.

Process time = (difference between "red" and "green" values) * setting time * 1 ms

Setting time = (desired procedure time in seconds) * 1000 difference of the values for

retaining position "red" and "green"

Page 5

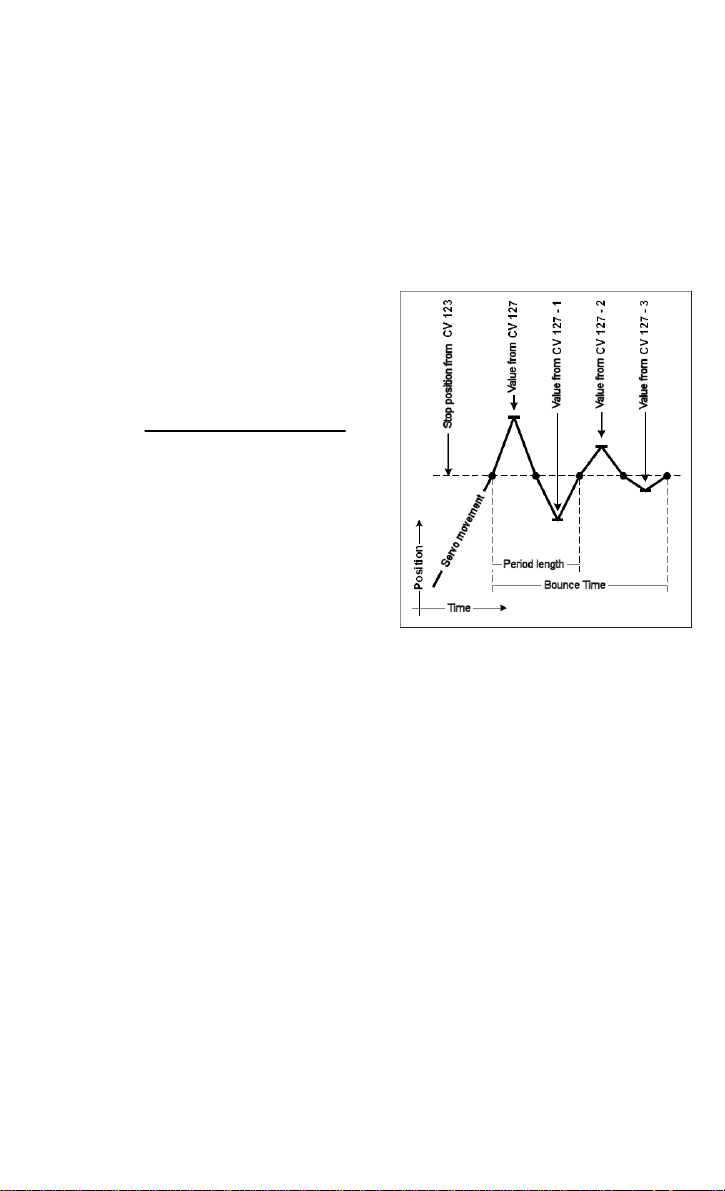

Bounce function (CV 125 to 128)

For both stops of the 1st Address of all four servo outputs, the bounce function can be

activated as it appears in boom gates and semaphore signals. For this the bounce distance

must not be 0 in CV 125 and CV 127.

Attention: In this case the programmed stop position of the Servo must be less than or

equal to the end stop minus the bounce distance.

Note: The stops for the 2nd Address are then no longer used.

With the bounce function active, the servo will, after reaching the respective "red" or "green"

stop, be beyond the stop by the amount of the bounce distance.

Now the motion direction is reversed and the servo again proceeds beyond the stop.

However this time only by the bounce distance minus 1.

With every subsequent reversal of direction that the servo movement approaches the

desired stop, the bounce distance is reduced by

one in each case.

After several movements the bounce distance is

0 and the Servo’s stop is reached.

The period length of the bounce function is set by

the bounce time in CV 126 and CV 128:

Bounce time =

Example

In this example the bounce amplitude was set to

"green” (CV 127) to the value 4.

The first bounce corresponds exactly to this

value. With each successive bounce the value is

reduced by 1.

Note: The programmed stop of the Servos plus

the bounce amplitude must be less than or equal

to the end stop (= possible position).

period length

4 * bounce amplitude * 1 ms

Technical data

Addresses: 2

Address range: 1-2048 digital

Format: DCC, Motorola

Servo outputs: 700 mA each

Total load: 700 mA

Accessories

Transformer 45 VA Part No. 20 040

The transformer has an output voltage of 16 V. A maximum current of 2.8 A. The

transformer has 2 quick connect terminals on the low voltage side.

Servos

With accessories, mounting material and control wire, 2 x 0.4 mm and 1 x 0.6 mm, length

100 mm.

Mini servo Part No. 81 410

Used in restricted space conditions, for applications which do not require high torque.

Size 20.0 x 17.6 x 8.0 mm, torque 4 Ncm.

Standard servo Part No. 81 420

For general use, e.g. turnouts. Size 22.2 x 20.0 x 11.1 mm, torque 13 Ncm.

Precision servo Part No. 81 430

Very quiet and precise. Size 22.2 x 21.3 x 11.1 mm, torque 14 Ncm.

Page 6

CV Table (Configuration Variables) of Servo decoder 67 800

Configuration of Decoders

Value

CV Description

112 Software version (the processor used can be updated) - varies

113 Manufacturer code - 85

119 Decoder Configuration

Bit 0=0 Power Output 1 only on during servo movement

Bit 0=1 Power Output 1 always

Bit 1=0 Power Output 1 only on during servo movement

Bit 1=1 Power Output 1 always

Bit 2=0 Power Output 1 only on during servo movement

Bit 2=1 Power Output 1 always

Bit 3=0 Power Output 1 only on during servo movement

Bit 3=1 Power Output 1 always

Bit 4-6 Not used

Bit 7=0 DCC operation

Bit 7=1 Motorola Operation

The asterisk * denotes the factory default value

Value

0

1*

0

2*

0

4*

0

8*

-

0*

128

Factory

Range

Default

0-255 15

Configuration of Servo outputs

CV for servo output Factory defaults

1 2 3 4

120 130 140 150 1. Address high byte 0-8 0 0 0 0

121 131 141 151 1. Address low byte 0-255 1* 3* 5* 7*

122 132 142 152 Stop position “red” Address 1 0-127 30 30 30 30

123 133 143 153 Stop position “green” Address 1 0-127 95 95 95 95

124 134 144 154 Switchover time 0-255 40 40 40 40

125 135 145 155 Bounce distance setting “red” 0-127 0 0 0 0

126 136 146 156 Bounce duration setting “red” 0-255 0 0 0 0

127 137 147 157 Bounce distance setting “green” 0-127 0 0 0 0

128 138 148 158 Bounce duration setting “green” 0-255 0 0 0 0

160 170 180 190 2. Address high byte 0-8 0 0 0 0

161 171 181 191 2. Address low byte 0-255 0 0 0 0

162 172 182 192 Stop position “red” Address 2 0-127 0 0 0 0

163 173 183 193 Stop position “green” Address 2 0-127 0 0 0 0

*) When a Motorola center is used the factory programmed addresses are not usable and must be adjusted by the user via

key programming.

Description Value

Range

1 2 3 4

Guarantee declaration

Each component is tested for its complete functionality before distribution. If a fault should

arise within the guarantee period of 2 years, we will repair the component free of charge

upon production of proof of purchase. The warranty claim is void if the damage was caused

by inappropriate treatment.

Please note that, according to EMV regulation the component may only be installed in

vehicles which carry the CE logo.

The trade names mentioned are registered trade marks of the respective companies.

Our contact Details:

In the event of a defect or failure send the unit together

with the invoice and a short description of the fault back

We are available if you have any questions!

Your direct line to a technician:

Mon - Tue - Thu – Fri, 14:00~16:00 and Wed 16:00~18:00

Service

to us for repair.

Hotline

0 20 45 - 85 83 27

Uhlenbrock Elektronik GmbH

Mercatorstr. 6

D-46244 Bottrop

Made in Germany

Electronic devices do not

belong in household rubbish

Not suitable for children

under age 10.

Part No. 67 800

Loading...

Loading...