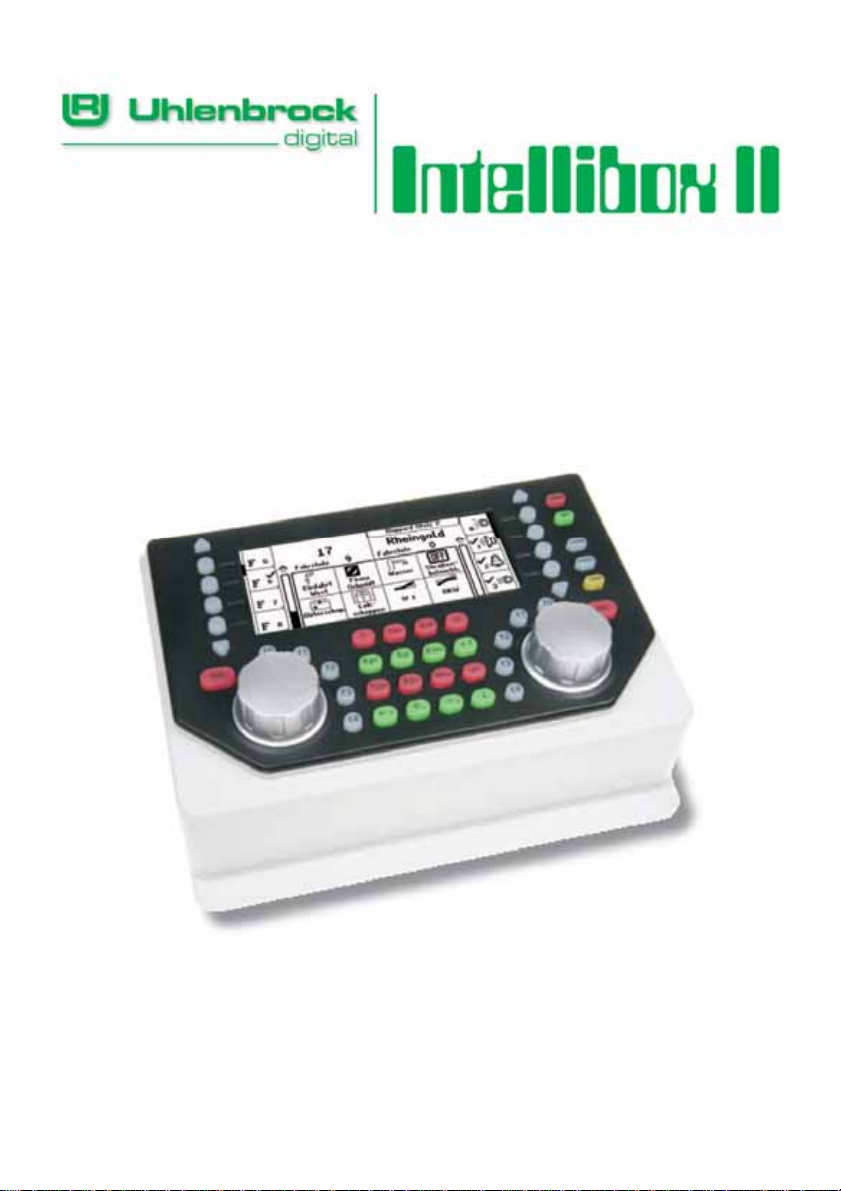

Page 1

The shortest connection

between technology

and pleasure

Manual for Software Version 1.0

Page 2

Intellibox II

2

Page 3

Intellibox II

Table of Contents

1. The Digital Center Intellibox II...................................................................................6

1.1 Description............................................................................................................................ 6

1.2 Quick guide........................................................................................................................... 9

1.3 Overview of the Commands................................................................................................ 10

1.4 Technical Data.................................................................................................................... 11

2. The Intellibox II Connections...................................................................................12

2.1 Definition of the individual Sockets..................................................................................... 12

2.2 Connecting Transformer, Track and Programming Track................................................... 12

2.3 Connecting LocoNet ........................................................................................................... 13

2.4 USB Computer Interface.....................................................................................................13

2.5 Connecting DCC Boosters.................................................................................................. 14

2.6 Connecting Märklin Boosters.............................................................................................. 14

2.7 Connecting s88 Modules .................................................................................................... 15

2.8 Connecting IRIS Receivers................................................................................................. 15

3. The Operating Elements.......................................................................................... 17

3.1 Overview of the Operating Elements.................................................................................. 17

3.2 The Display with the Display keys ...................................................................................... 18

3.3 The Controller ..................................................................................................................... 19

3.4 Menu Operation.................................................................................................................. 19

3.5 Entry of Numerals ............................................................................................................... 21

3.6 Entry of Names ................................................................................................................... 21

4. Basic Settings Menu ................................................................................................23

4.1 Menu Item Operation.......................................................................................................... 23

4.1.1 Speed Display.......................................................................................................... 23

4.1.2 Throttle..................................................................................................................... 25

4.2 “Language” Submenu ......................................................................................................... 27

4.3 ”Locomotive Data Format” Menu ........................................................................................ 28

4.4 “Turnout settings” Menu......................................................................................................29

4.4.1 General Data format................................................................................................. 29

4.4.2 Switching Times....................................................................................................... 30

4.5 “Hand Controller” Menu ......................................................................................................31

4.6 “Display” Menu....................................................................................................................32

4.7 “Programming Track” Menu................................................................................................ 34

4.8 “Interface” Menu.................................................................................................................. 35

4.9 “s88 Setting” Menu.............................................................................................................. 35

4.10 “Special Options” Menu .................................................................................................... 37

4.11 “Software-Version” Menu.................................................................................................. 38

4.12 “Start Mode” Menu............................................................................................................ 38

4.13 “Database” Menu .............................................................................................................. 39

4.14 “Reset” Menu .................................................................................................................... 41

5. The Control Desk......................................................................................................43

5.1 Operating Elements ............................................................................................................ 43

5.2 Locomotive Addresses und Names.................................................................................... 44

5.2.1 Locomotive selection................................................................................................ 45

5.3 Throttle................................................................................................................................45

5.4 Light and Special functions.................................................................................................46

5.5 The LokPosi Display........................................................................................................... 47

5.6 The Loco Menu................................................................................................................... 48

5.6.1 Multi-traction............................................................................................................. 48

5.6.2 Last called up Locomotive........................................................................................ 52

5.6.3 Controlling All Functions........................................................................................... 53

5.6.4 Dispatching Locomotives ......................................................................................... 55

3

Page 4

Intellibox II

5.6.5 Edit a Loco dataset................................................................................................... 56

5.6.6 FRED Hand Controller ............................................................................................. 66

6. The Switch Panel Mode............................................................................................69

6.1 Description.......................................................................................................................... 69

6.2 Select Switch Panel Mode.................................................................................................. 69

6.3 Operating a Switch Panel ................................................................................................... 70

6.4 Configuring the Switching times.......................................................................................... 71

6.5 Select a Switch Panel......................................................................................................... 71

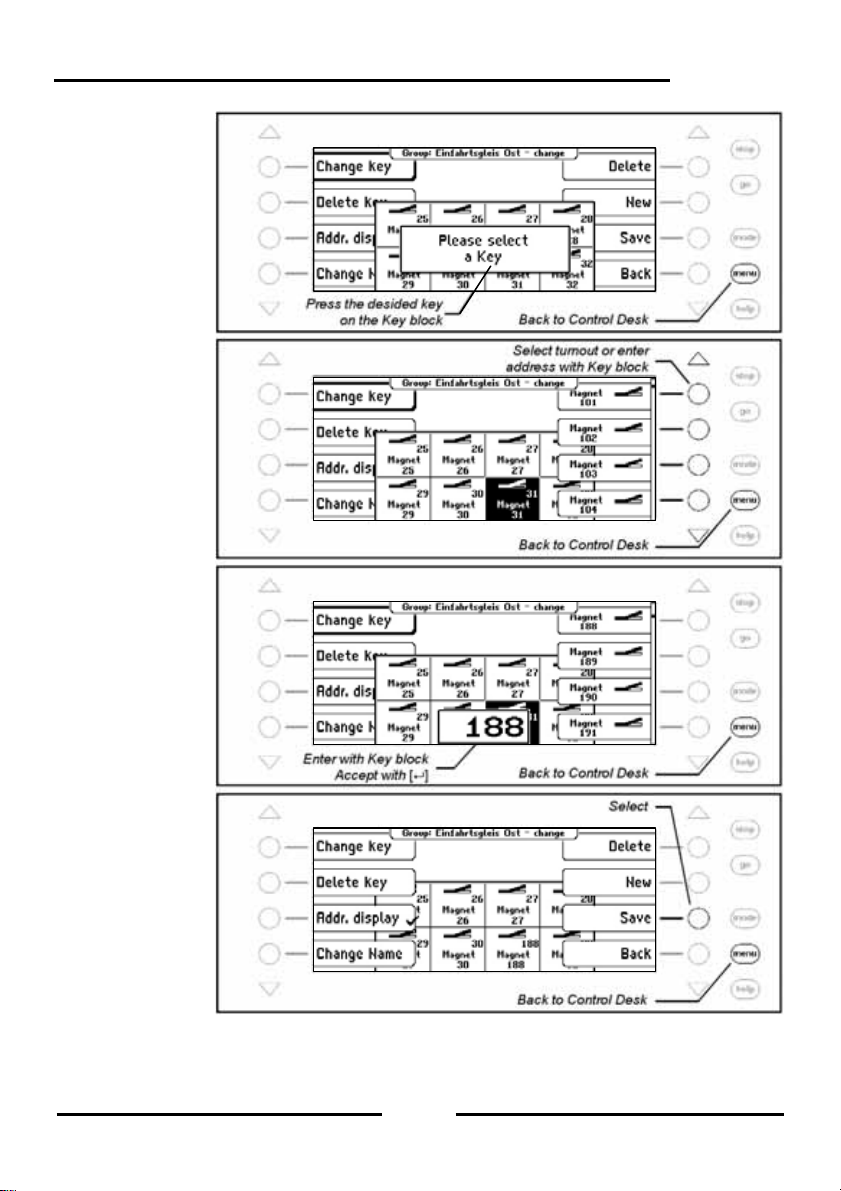

6.6 Setup and Edit a Switch Panel............................................................................................ 72

6.6.1 Setup a new Switch Panel........................................................................................ 72

6.6.2 Edit Switch Panel ..................................................................................................... 74

6.6.3 Delete Switch Panel................................................................................................. 76

6.6.4 Switch Address Display on/off.................................................................................. 77

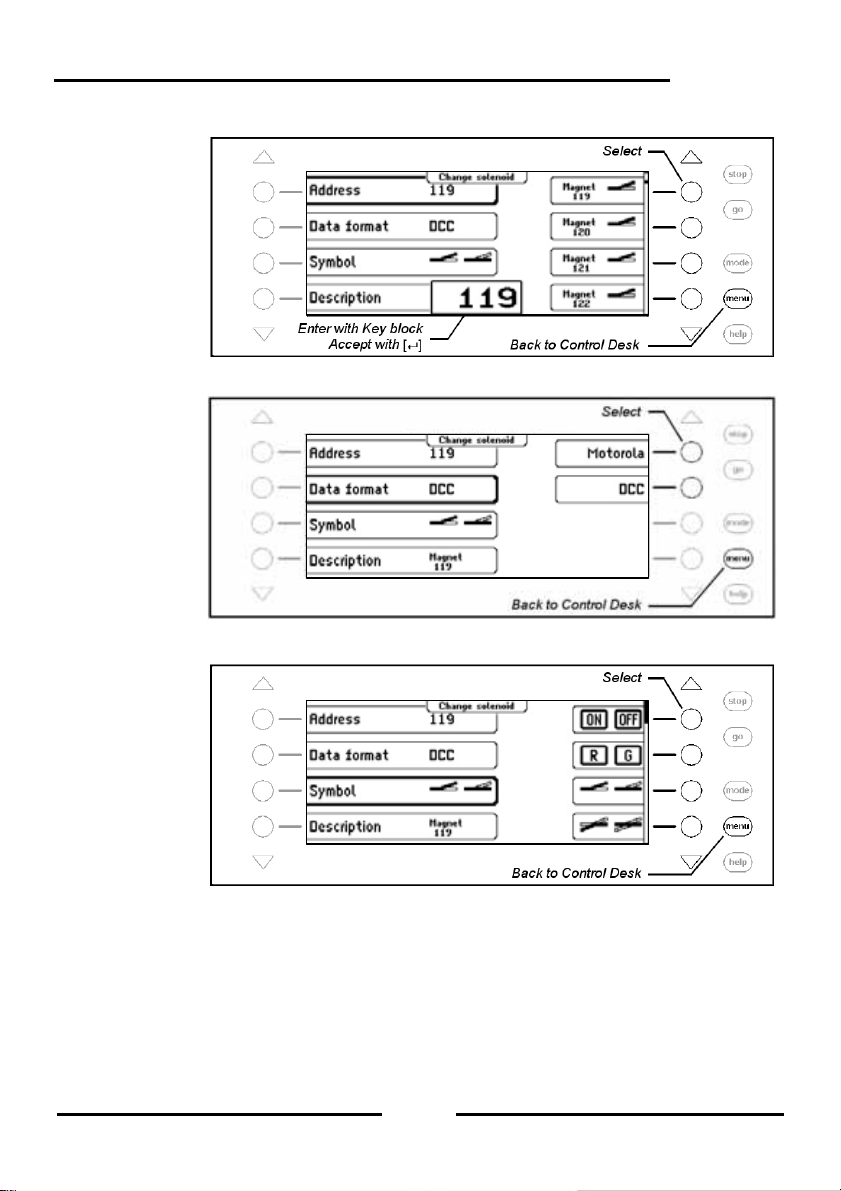

6.7 Set Name, Symbol and Data format of Solenoid addresses............................................... 78

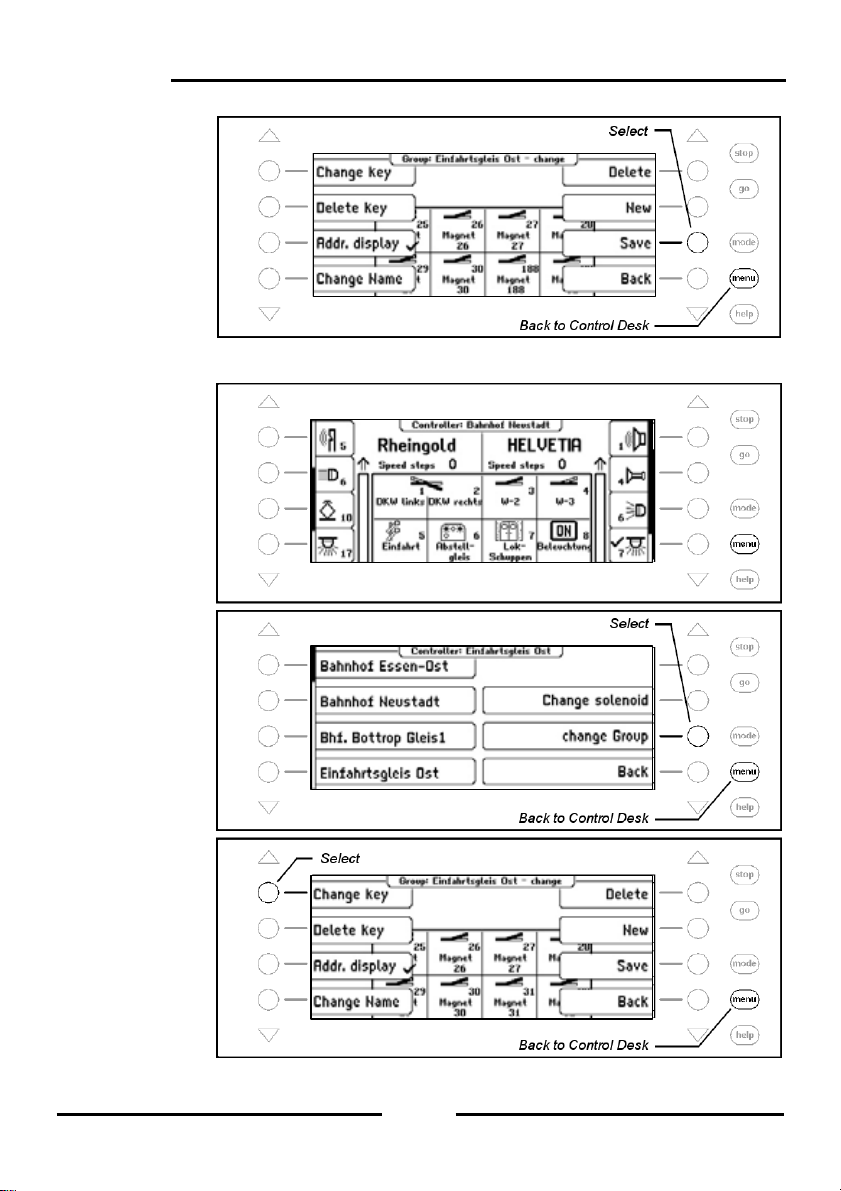

7. The Route Mode .......................................................................................................81

7.1 Description.......................................................................................................................... 81

7.2 Selecting Route Mode......................................................................................................... 81

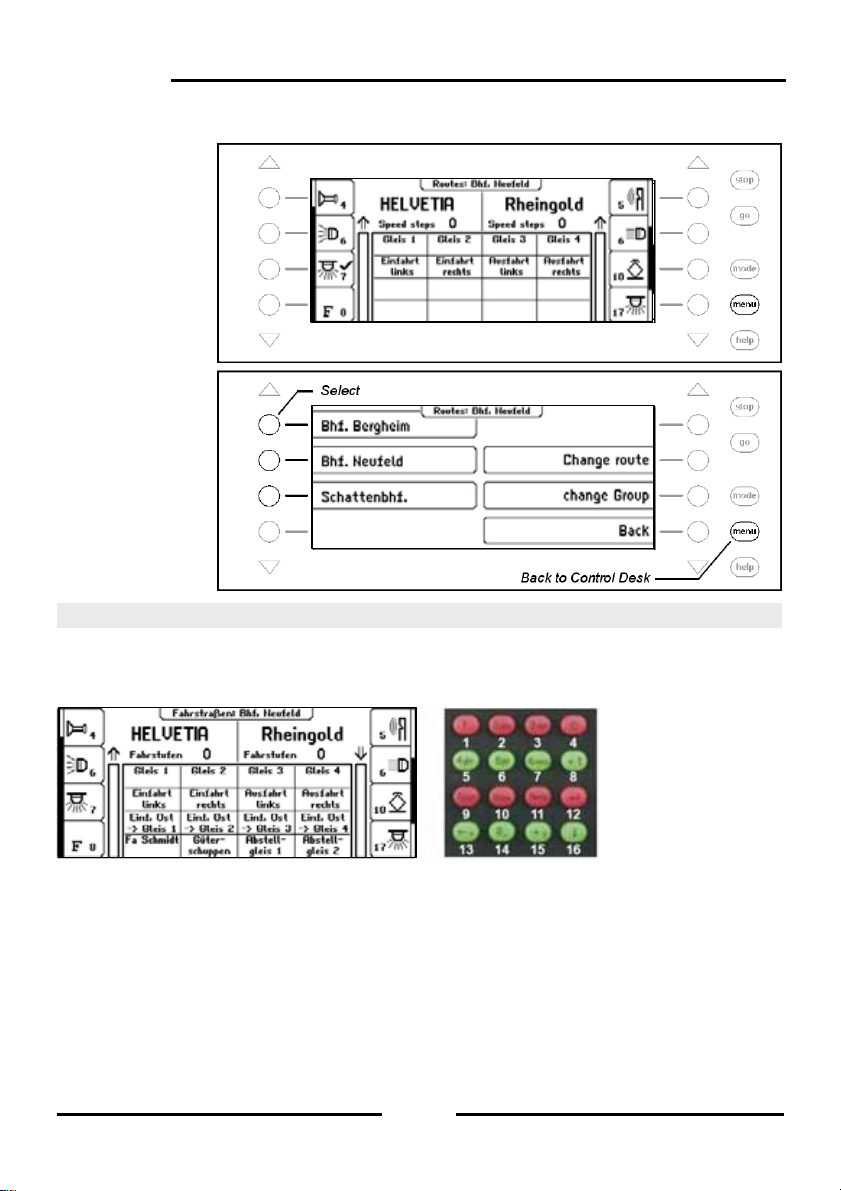

7.3 Selecting a Route Group.....................................................................................................81

7.4 Switching Routes................................................................................................................ 82

7.5 Entering and Changing Route Groups................................................................................ 83

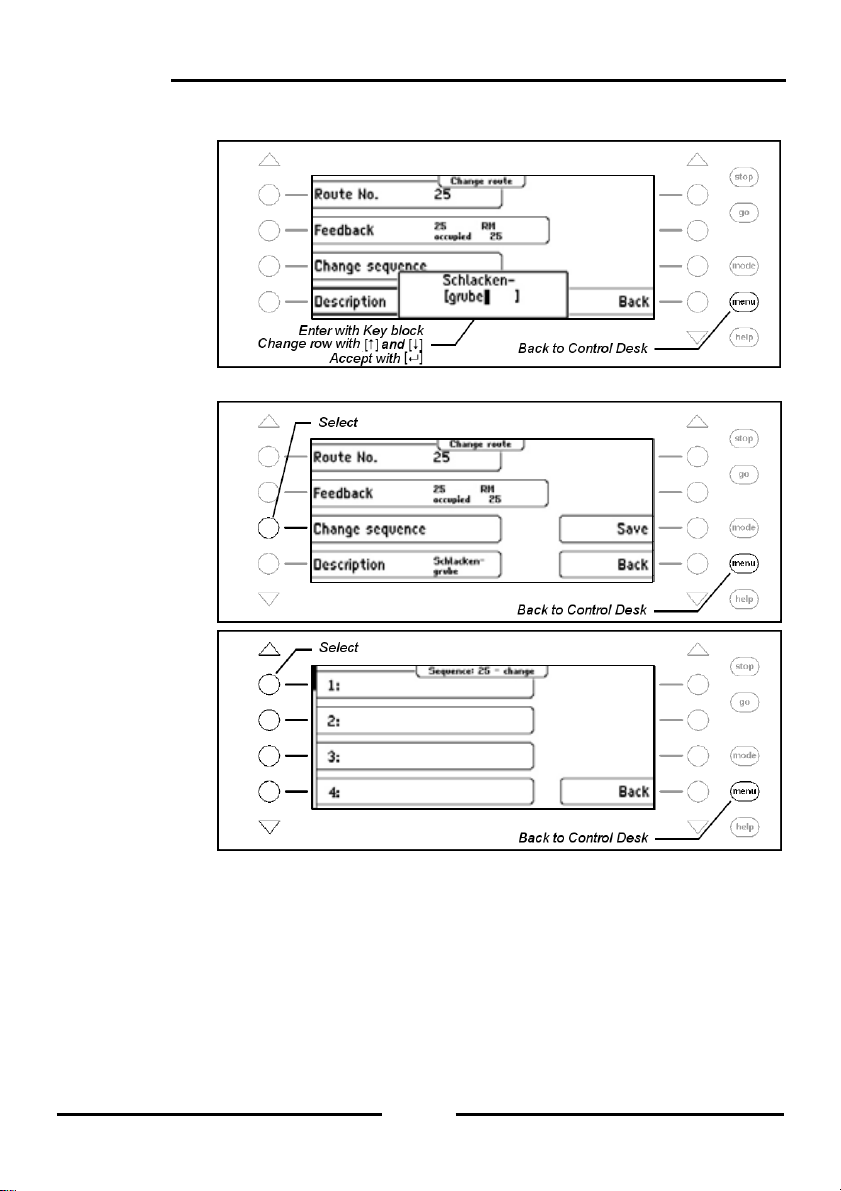

7.5.1 Entering a new Route............................................................................................... 83

7.5.2 Change a Route Group............................................................................................ 85

7.5.3 Delete a Route Group .............................................................................................. 86

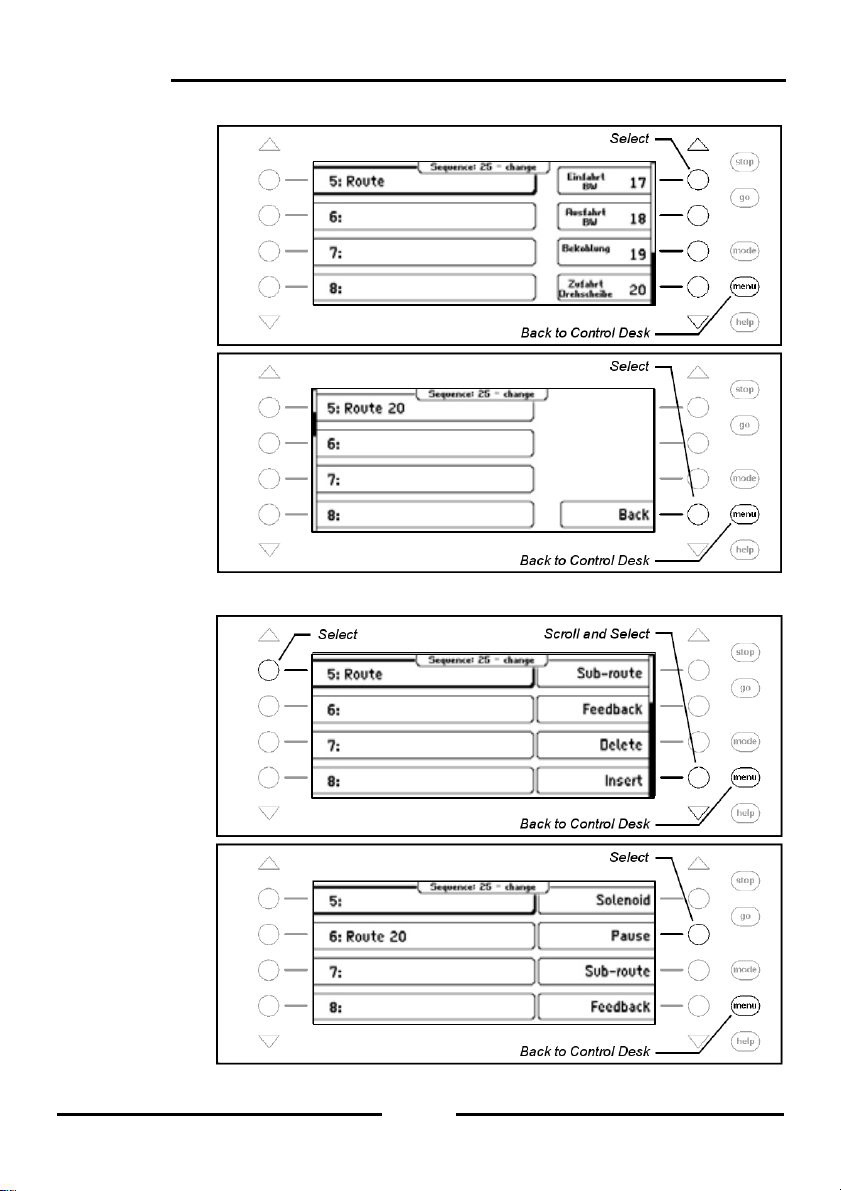

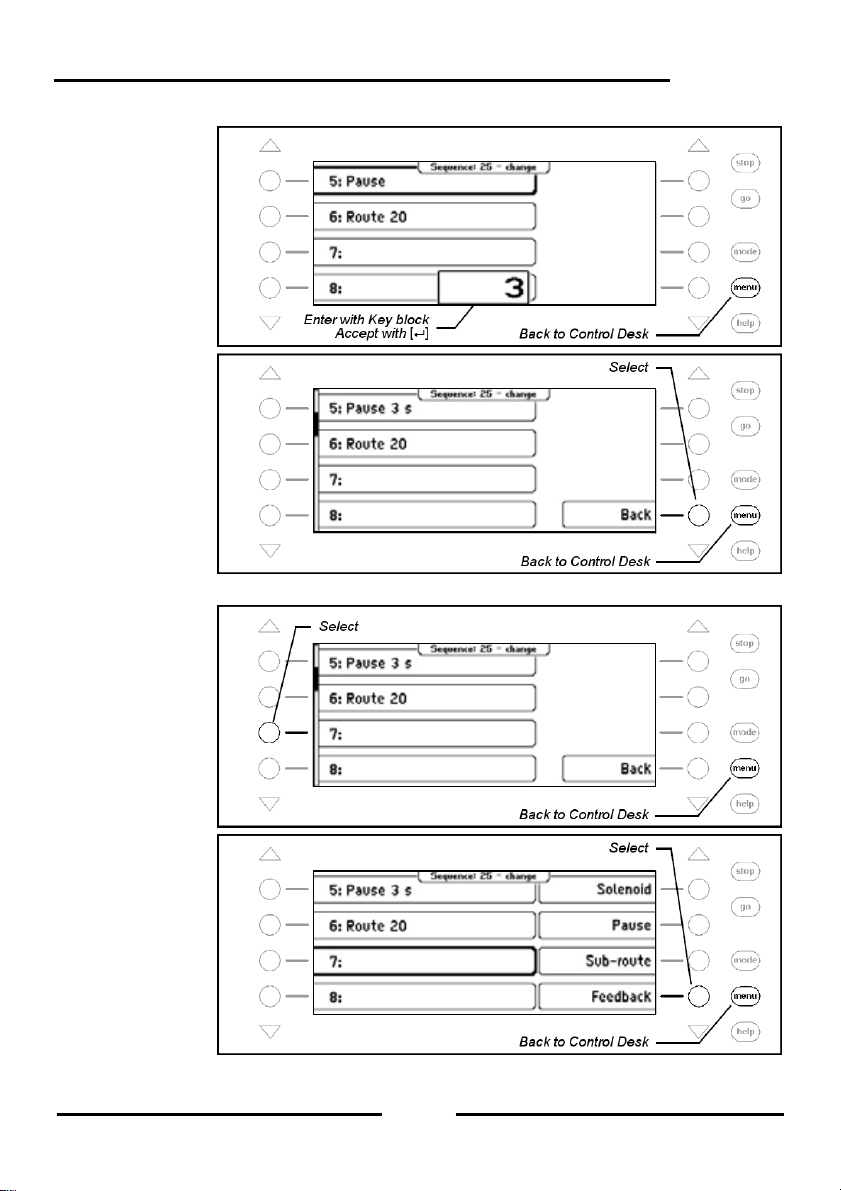

7.6 Programming Routes..........................................................................................................87

7.7 Using Routes from an External Device............................................................................... 97

7.8 Automatically activate a Route when the Intellibox starts up............................................ 100

7.9 Processing two or more Routes in succession................................................................. 101

8. The Feedback Mode...............................................................................................104

8.1 LocoNet Feedbacks.......................................................................................................... 104

8.2 s88-Feedback ................................................................................................................... 104

8.3 Selecting a Feedback Module........................................................................................... 104

8.4 The Display....................................................................................................................... 105

8.5 Selecting a Feedback Group ............................................................................................ 106

8.6 Adding and Changing Feedback Groups.......................................................................... 106

8.7 Setting the Name and Symbol of a Feedback .................................................................. 113

8.8 Triggering Feedback Message ......................................................................................... 115

9. The LISSY Mode .....................................................................................................116

9.1 Description........................................................................................................................ 116

9.2 Selecting LISSY Mode...................................................................................................... 116

9.3 The Display in LISSY Mode.............................................................................................. 116

9.3 The Display in LISSY Mode.............................................................................................. 117

9.4 Selecting the Displayed Group ......................................................................................... 117

9.5 Adding a new or Changing a Group.................................................................................. 118

9.5.1 Adding a new Group............................................................................................... 118

9.5.2 Changing a Group.................................................................................................. 120

9.5.3 Deleting a Group.................................................................................................... 122

9.5.4 Switching the Address display on/off...................................................................... 123

9.6 Assigning a Name to a Train Category and LISSY Receiver............................................ 124

9.7 DirectDrive........................................................................................................................ 126

10. The Infrared Remote Control IRIS.......................................................................127

10.1 Description of the Infrared Remote Control .................................................................... 127

10.1.1 Function Mode...................................................................................................... 127

10.1.2 Operating controls................................................................................................ 127

10.1.3 Locomotive Control .............................................................................................. 128

4

Page 5

10.1.4 Solenoid control.................................................................................................... 129

10.1.5 Activating a Route................................................................................................ 131

10.1.6 Power on/off......................................................................................................... 131

10.2 Intellibox Display Mode IRIS........................................................................................... 131

10.2.1 Selecting IRIS Mode............................................................................................. 131

10.2.2 Selecting the Transmission Channel.................................................................... 132

10.2.3 The Displays......................................................................................................... 132

Intellibox II

11. Model Time Clock.................................................................................................136

11.1 Description...................................................................................................................... 136

11.2 Selecting the Clock Mode............................................................................................... 136

11.3 Clock Settings................................................................................................................. 136

11.3.1 Special Settings.................................................................................................... 137

12. The Programming Mode ......................................................................................140

12.1 Programming Track ........................................................................................................ 140

12.2 Activating Programming Mode........................................................................................ 140

12.3 Programming of DCC and Multi-protocol Decoders........................................................ 141

12.3.1 Reading and programming CV Plain text............................................................. 141

12.3.2 Programming and reading individual CVs............................................................ 143

12.3.3 Mainline Programming ......................................................................................... 146

12.3.4 Register programming and reading...................................................................... 147

12.3.5 Paged programming and reading......................................................................... 147

12.3.6 Error message during Programming of DCC Decoders....................................... 147

12.4 Programming of Märklin Motorola or mfx Decoders ....................................................... 148

13. LocoNet Programming.........................................................................................150

14. The Interface.........................................................................................................154

14.1 Interface Characteristics................................................................................................. 154

14.2 Interface in Betrieb nehmen............................................................................................ 154

14.3 Communication PC - LocoNet (only for Experts)............................................................ 154

15. Operation as Auxiliary Device.............................................................................155

15.1 Operation ........................................................................................................................ 155

15.2 Setting the Operating Mode............................................................................................ 155

15.3 Connect as Auxiliary Device........................................................................................... 155

16. Software Update...................................................................................................157

Appendix.....................................................................................................................158

List of Special options............................................................................................................. 159

Converting bits to bytes .......................................................................................................... 161

Module address table for feedback channels ......................................................................... 163

Coding table for solenoid decoder.......................................................................................... 164

Tips and Tricks........................................................................................................................ 165

HOTLINE ................................................................................................................................ 168

5

Page 6

Intellibox II

1. The Digital Center Intellibox II

The Intellibox II is not only a Digital Center, but a complete S ystem in a Box. It has all the

functions which previously one had to labouriously assembled, and with all that it is

efficient and compact.

With the Intellibox II it does not matter whether you control your digital model r ailway in

Motorola, DCC or Selektrix format. The Intellibox II utilise the various data formats

simultaneously, on the same track, and is therefore a genuine multi-protocol digital center.

1.1 Description

Large, high resolution Display

The high resolution display is 98 x 42 mm (visible diagonal 105 mm) and allo ws a detailed

representation of information in plain text or as symbols.

Night design

The Display and the keys have backlighting with which you can also see during the night

phase when using an IntelliLight.

Two Throttles

Two locomotives can be controlled independently with the two large rotary controls. When

the locomotive is changed these clever throttle controls without end stops automatically

restore the saved speed of the selected locomotive. They c an be operated in DC and AC

throttle mode.

The display shows the locomotive name or number, the speed (absol ute and relative to the

highest speed) and the direction of both the locomotives that are actually being controlled

by the throttles.

The light and 4 special functions can be switched by the function keys. In DCC operati on

up to 28 special functions can be switched by the keys beside the display.

Booster

The high performance Booster has an output capacity of 3A and is short circuit protected.

Switch panel

The Intellibox II can control 320 Märklin and/or 2048 DCC sole noids. Groups of 8 or 16 in

each case can be directly accessed by the key block. The state of turnouts and signals is

indicated with the appropriate symbols in the centre of the display.

Route control

The Intellibox II internal route memory can hold up to 80 routes with 24 entries each.

These can be called up by feedback c ontacts. Further routes that are stored in external

devices can be called up by the Intellibox or merged into internal routes.

Feedback Mode

Up to 2048 feedbacks in groups of 8 or 16 are shown in the centre of the display by

selectable symbols. Feedbacks can also be triggered directly from the key block.

6

Page 7

Large Locomotive Database

The empty locomotive data base can store one’s own locomotive data records. Data

entered can be address, name, data format, symbols for special functions and the setting

for the maximum speed in km/h.

Locomotive Position Indication

In conjunction with the Individual Locomotive Control System “LISSY” the actual position of

the locomotive can be displayed at top the display when it is called up.

DirectDrive

Control of a locomotive can be taken over by a throttle with a simple key press and without

entering the locomotive address or name, when it passes a selected LISSY receiver in

LISSY-Mode.

Infrared Receiver

The integrated Infrared receiver allows wireless control of model railway layouts with our

IRIS infrared remote control. If desired, in difficult space arrangements, 2 additional

external receivers can be connected.

Model Time Clock

The Intellibox II integrated model clock can be blended i nto the middle part of the display. It

indicates the time and weekday. The model time can be accelerated relative to the real

time by factors between 1 and 127. This provides possibil ities such as timetabled tri ps and

the synchronization of further LocoNet clocks, like in the LocoNet display 63450, Intelli Light

28000 and SoundDircetor 38000.

Locomotive Programmer

The Intellibox II provides simple menu driven programming of DCC, Motorola and mfx

locomotive decoders. For DCC compatible decoders there is not only simple plain text

programming, but also CV programming, main track programming, register programming

and CV paged programming.

Motorola decoders are programmed using Motorola CV programming.

• Various Data Formats

The Intellibox II can control a mixture of makes of locomotive, function and turnout

decoders on a layout.

The following data formats can be transmitted simultaneously:

• Motorola Data Format

Uhlenbrock, Märklin, Viessmann

• Extended Motorola Data Format (Spur I)

Uhlenbrock, Märklin AC Spur I format

• DCC Data Format

Uhlenbrock, Märklin Gleichstrom, Arnold, Digitrax, Lenz, LGB, Roco and all DCC

compatible decoders.

• Selectrix Data Format

Trix, Rautenhaus

Intellibox II

7

Page 8

Intellibox II

9999 Decoder Addresses, 128 Speed Steps

Intellibox II supports all addresses and speed steps of the individual decoder makes.

• Märklin Motorola Decoder

80 addresses, 14 Speed steps

• Märklin mfx Decoder

255 addresses, 14 Speed steps

• Uhlenbrock Motorola Decoder

255 addresses, 14 Speed steps

• Uhlenbrock DCC Decoder

9999 addresses, 128 Speed steps

• DCC compatible Decoder

9999 addresses, 14, 28, 128 Speed steps, depending on model

• Trix Selectrix Decoder

112 addresses, 31 Speed steps

Extended Locomotive Special Functions

For each Locomotive address 32767 special functions (for some DCC decoders) are

available for switching of lights, sound etc.

With USB Interface

The Interface at 115200 Baud offers the fast connection to the computer. It not only makes

it possible to use PC programs to control the model railway layout but also serves for data

protection of the Intellibox II and for updating system software.

With Help Function

The context sensitive help function almost makes a manual redundant. Help for the

current operating situation is directly available at any time.

Non-volatile Memory

All settings which have been carried out on the Intellibox II remain p ermanent even when

the equipment is switched off.

Updatable System Software

The Intellibox II system software can be updated anytime via the integrated USB Interface.

Compatible with many other devices

On the back of the Intellibox II, besides the sockets for transformer, track and programming

track, there are sockets for DCC booster, Märklin Motorola booster, LocoNet, s88-feedback

modules, IRIS auxiliary receiver, and also the USB computer.

Operation as Auxiliary Device

The Intellibox II can be connected at another LocoNet center (Intellibox II, Intellibox IR,

Intellibox Basic, IB-COM or TwinCenter) as an accessory device and then takes on the

functions of a control desk, 3A booster and Loco Net power feed. In addition a further s88

feedback input and a USB Port are available.

8

Page 9

Intellibox II

1.2 Quick guide

Important! Please use this quick guide only in the beginning if you want to try out the

Intellibox. Please read the entire manual to be fully informed about all functions and

options of the device.

Connecting the Cable

The 16V AC from a 70 VA transformer and the Track are connected to the 6 way screw

terminal plug as described in Chapter 2.

NOTE! Incorrect connection can destroy the device because connecting additional digital

components can cause a short circuit between the transformer power and digital output.

Connecting the Device

If the plug is inserted into the Intellibox and the transformer power is s witched on the gr een

[go]-key at the top right of the Intellibox II will light up after approximately 5 seconds and

indicating that the device is in the ready state.

Presets

Ex-factory the Intellibox II has the following settings:

Speed display Speed steps indication

Throttle AC throttle

Default data format for Locos Motorola

Default data format for turnouts Motorola

If the configuration for your layout is correct you place the first locomotive onto the track.

Alternatively you must look in the “Basic Settings” Menu and make the necessary changes.

A complete description of the operation as well as all setti ngs can be found in Chapters 3

and 4.

Calling up a Locomotive

• Press the left or right [lok]-Key

• Use the numeric keys to enter the locomotive address

• Confirm with the [ ]-key

Controlling a Locomotive

• Increase the speed by turning the knob to the right

• Decrease the speed by turning the knob to the left

• Press on the control knob when the locomotive is stationary to change direction

Switching Light

The [f0]-key switches the Light on or off

9

Page 10

Intellibox II

Switching Special functions

• Press one of the Special function keys [f1] [f2] [f3] [f4]

• If you press the context sensitive key beside the display you operate functions f0 to f28

on DCC decoders (see Chapter 5.4).

Note: All entries must be made on the controller on which the loco motive address or name

was originally entered!

Changing the data for a single Locomotive

• Press the [lok]-key of the right or left controller twice

• With the Scroll key scroll down to the "Change Loco data entry" item

• Confirm the selection with the Select Key (Auswahltaste)

• Then make change to the desired setting for this locomotive address

Switching Turnouts

Turnouts are switched from the key block. With the eight pairs of keys the turnouts or

signals with addresses 1 to 8 can be switched. The respe ctive position is indicated by a

turnout symbol in the middle part of the display. The allocation of the keyboard can be

easily changed at any time (see Chapter

6.5).

1.3 Overview of the Commands

Very important! Use this brief description only if you want a quick reference to a little

information. Please read the entire manual to be fully informed about all functions and

options of the device.

Switch off track power

• [stop]

Switch on track power

• [go]

Select Locomotive by Address

• [lok] + Address entry + [ ]

Select Locomotive by Name

• [lok] + Select key

Change Speed

• Turn the throttle knob

Change Direction

• With locomotive stationary press on the controller knob

Emergency stop of the controlled locomotive

• Press on the controller knob

Switch the Light function

• The [f0]-key switches the light on or off

Switch Special functions f1-f4

• [f1] [f2] [f3] [f4]

Switch Special functions f0-f28

• Press the context sensitive keys beside the display

Active functions are indicated with a tick.

10

Page 11

Selecting the Device Mode

• Press [mode]-key

• Select with the keys on the right of the Display

Change Control Panel Mode Key Assignment

• Press [mode]-key

• Select panel with the keys on the right of the Display

• [menu] + Number 1 Key + [ ] (Factory setting 1)

Change Feedback Mode Key Assignment

• Press [mode]-key

• Select feedback with the keys on the right of the Display

• [menu] + Number 1 Key + [ ] (Factory setting 1)

Configure the Data format individual Decoder

• [lok] + address entry + [ ] or [lok] + Select key

• Press [lok]-key x2 + with Scroll key scroll to "Change Loco Data"

• "Change Loco Data" + select "Change Data format"

• Select the desired Data format + "Save"

Change Basic Setting

• Press [mode]-key

• Select Basic Settings with the Select key on the left side of the display

• Confirm the setting with Select key

• Return control mode with [menu]-key

1.4 Technical Data

• Input power

Maximum allowable of 18V AC

• Maximum Power loading

3.5 A to the layout track

0.5 A on LocoNet B output

0.5 A on LocoNet T output

All outputs have short circuit protection!

• Maximum number of Feedback modules

A total of 2048 feedback contacts can be connected.

• Locomotive Address range

DCC Data format: 1-9999, Motorola-Data format: 1-255

• Turnout Address range

DCC Data format: 1-2048, Motorola Data format: 1-320

• Usable Transformer

16-18V AC, 52-70VA, e.g. Uhlenbrock 70VA Transformer 20070

• Dimensions

180 x 136 x 80 mm

Intellibox II

11

Page 12

Intellibox II

2. The Intellibox II Connections

The following section describes Intellibox II Connections and what must be noted when the

devices are connected.

2.1 Definition of the individual Sockets

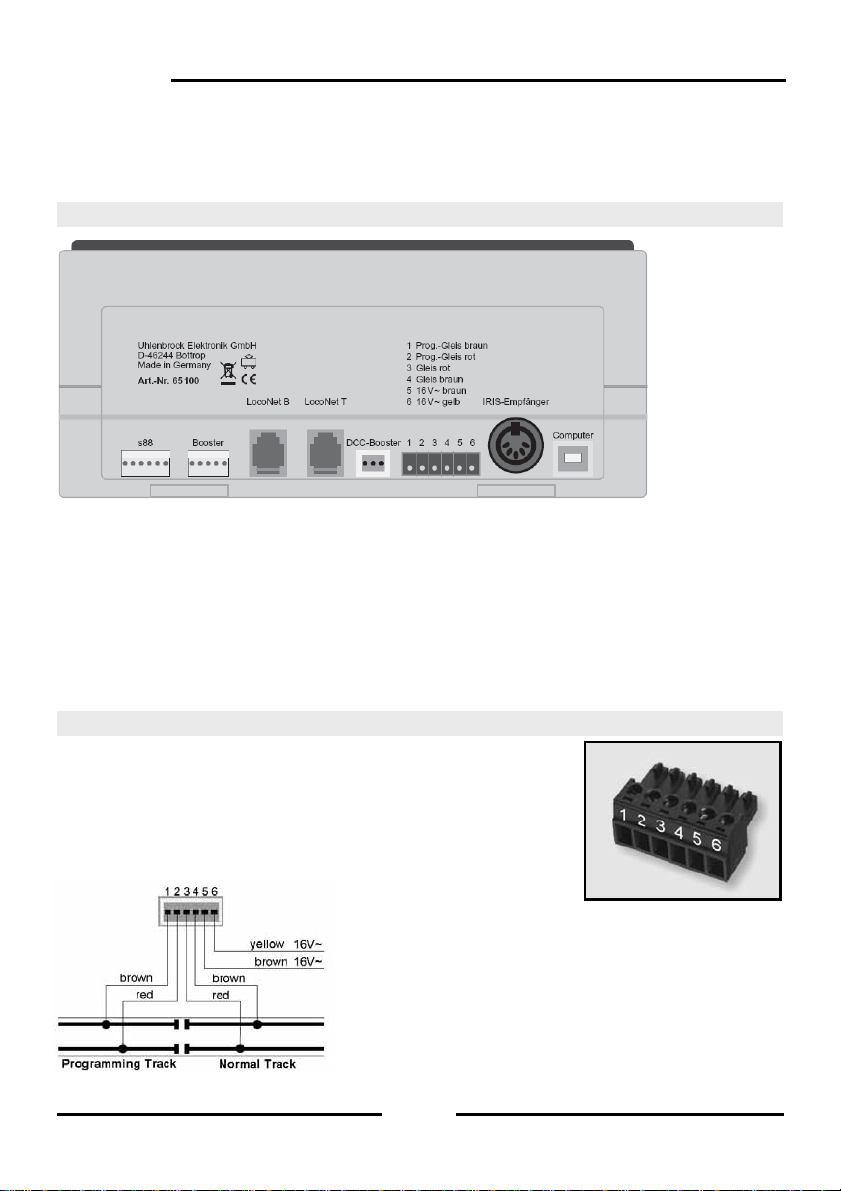

Figure 2.11 The rear view of the Intellibox II with its connections

6-way Header: s88-Feedback

5-way Header: Märklin Booster

RJ12 Socket: LocoNet B (Booster)

RJ12 Socket: LocoNet T (Throttle)

3-way Header: DCC Booster

6-way Header: Transformer, Track, Programming Track

5-way DIN Socket: additional IRIS receiver

USB Socket: USB Computer connection

2.2 Connecting Transformer, Track and Programming Track

The included 6-way plug for connecting the transformer, Track

and Programming Track is a screw terminal plug, to which the

wires are connected by tightening the screws.

The image to the right shows the assignment of the terminal s of

the plug.

The terminal assignment of the 6-way connector is

shown in the diagram on the left.

Note: For the transformer and track connection you

should use wire with as large a cross sections as

possible (at least 0.5 mm²). The connection to the track

should be made at several locations of the layout. We

recommend feed points with a separation of approx. 1m

for H0.

12

Page 13

Transformer

For trouble free operation a transformer of min. 52VA and 16V A C is required. With full

loading we recommend the Uhlenbrock transformer 20 070 with 70VA. The transformer

output potential should not exceed 18V ~.

The transformer’s AC potential is connected to terminal 5 (brown) and 6 ( yellow) of the 6way connecting plug.

Important: Incorrect connection ca n destroy the device because additional digit al devices

may cause a short circuit between the transformer output and the digital power.

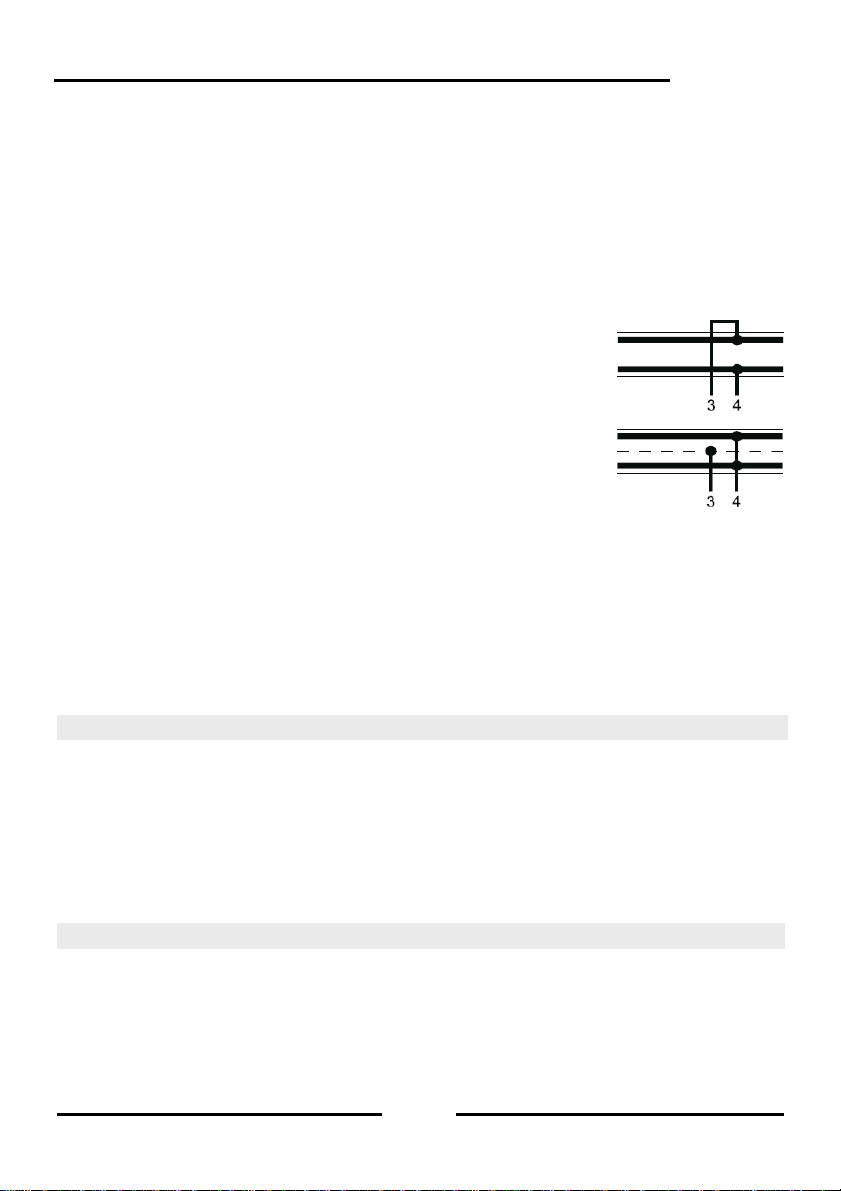

Track

2-Rail track is connected to terminals 3 and 4 of the 6-way

connecting plug.

For 3- Rail track (Märklin) the centre rail is connected to ter minal 3

(red Märklin cable) and the track body to terminal 4 (bro wn Märklin

cable) of the 6-way connecting plug.

Programming Track

The Programming track is a section of track is specially setup for programming and reading

of locomotive decoders.

This track is connected to terminal 1 (brown) and 2 (red) of the 6-way connecting plug.

Important: The track must definitely be isolated on both sides - with Märklin track it is

essential to isolate the centre rail and outer rails. During progr amming the isolation point

must not be bridged (e.g. by bogie or lighted wagon).

Note: The programming track can be used for programming and reading of decoders. It

can equally be used for normal train traffic when the Intellibox is not in programming mode.

Intellibox II

2.3 Connecting LocoNet

The Intellibox supports all devices which have a LocoNet interface.

LocoNet boosters such as Power 2, 4 and 7 are connected to LocoNet B since the digital rail

signal is available here. Connection LocoNet T is only suitable for manual control devices and

devices that do not need a digital rail signal. We recommend connecting LocoNet boosters on

large layouts to the LocoNet B socket only.

All other devices can be connected to LocoNet T.

Note: Behind a LocoNet power feed unit no track signal is available even if its input is

connected to the LocoNet B socket.

2.4 USB Computer Interface

Attention: Before the Intellibox II is connected to the PC the driver software for the

interface must be installed (see Chapter 15.3). The driver software can be found on the

included CD.

13

Page 14

Intellibox II

plug

For connecting the Intellibox to a computer you us e a USB lead with type A and B plugs,

Part No. 61070. This type of cable is also used for connecting the com puter with a USB

printer.

The Intellibox USB interface is set to a data transmission rate of 115200 Baud.

2.5 Connecting DCC Boosters

Boosters with DCC Booster interface can be connected to the DCC booster socket. Both

the DCC and the Motorola data format are output.

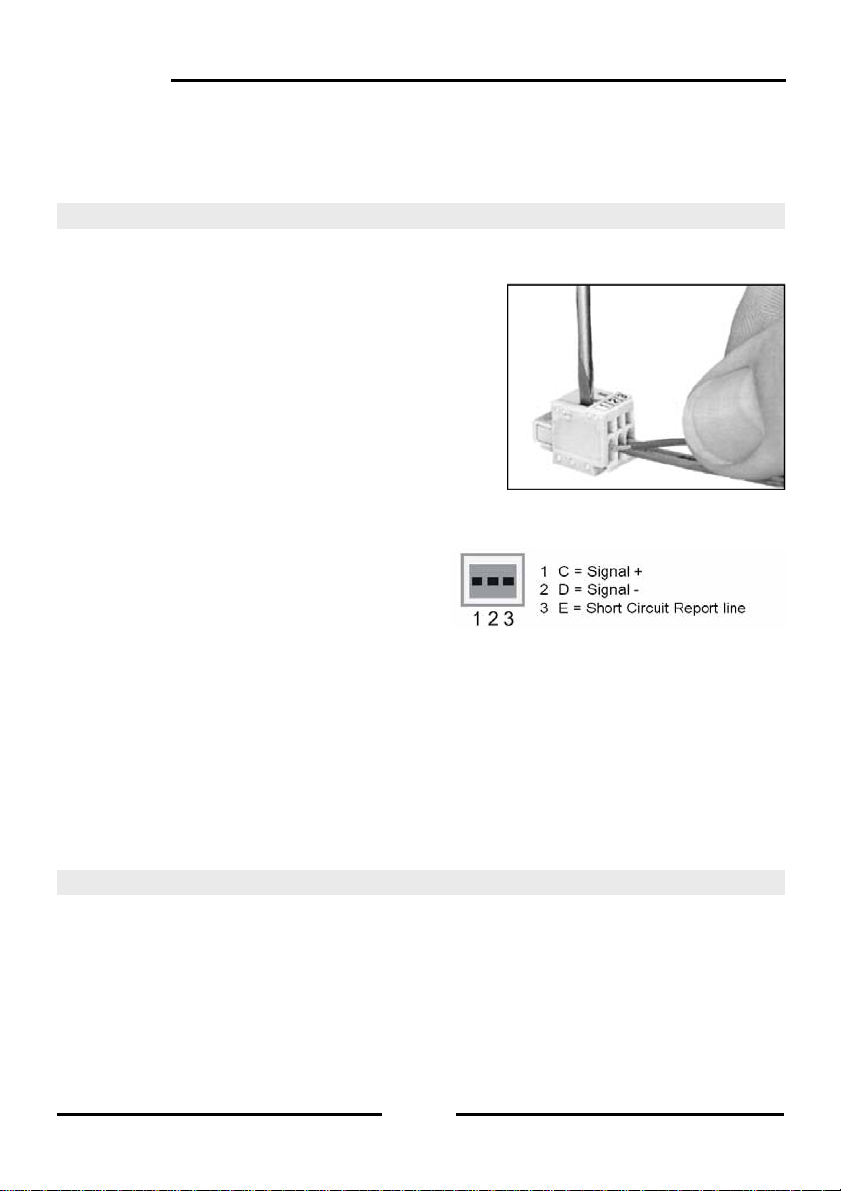

A 3-way clamp connector is provided for connecting

to the device. The cables of braid or wire to be

attached are stripped approx. 6 mm, carefully twisted,

and tinned if possible.

Using a narrow screw driver (2 mm) which fits in the

opening of the plug apply light pressure to open the

clamp terminal contacts. The stripped end of the

cable is inserted into the clamp terminal plug. When

pressure from the screw driver is released the cable is

fixed to that contact.

Lenz Booster

Both signal lines C and D as with the short

circuit line E are connected to the 3-way clamp

terminal plug.

Other DCC Boosters

Other DCC Boosters normally have two connecting cables which are connected to

terminals 1 and 2 of the 3-way clamp terminal plug.

Note: Because of the missing short circuit line “E“, these boosters have no way of

reporting a short circuit to the Intellibox. They are normally equipped with there own short

circuit protection.

Märklin and Arnold Digital= Boosters

Märklin Digital= Booster (6016) and Arnold Digital= Booster (86015) ar e connected with the

help of the Uhlenbrock Adapters 61 030 to the DCC Booster socket.

Figure 2.51 Attaching the cable to the clamp

Bild 2.51 Fixierung der Kabel

im Klemmstecker

Figure 2.52 Assignment of the contacts of the 3-way

connector (Cable side)

2.6 Connecting Märklin Boosters

Märklin boosters (6015/6017) and all boosters using the Motorola format that have a

Märklin booster compatible connection can be attached to the Märklin booster socket.

Connect the booster with the Märklin booster socket of the Intellibox II using the enclos ed

flat strip cable (see the booster operating instructions).

14

Page 15

The plugs must be connected to the so that the cable on

the Intellibox and the Booster 6017 go to th e top and on

the Booster 6015 to the bottom (as shown in the

diagram).

Note: If the Booster Power 4 (Part No. 63 240) is to

transmit the Selectrix Format it must be connected to the

Intellibox Märklin Booster socket.

Tip: The Märklin Booster outputs the DCC Format when Special option 901 is set to “3“

(Setting see Chapter 4.10), otherwise the Intellibox will report the error „Short Circuit“ as

soon as the Märklin Booster is connected and the DCC Format is output.

Figure 2.61 Connection of the flat cable

Intellibox II

2.7 Connecting s88 Modules

Feedback modules serve to monitor track sections and trains in automatic operations on a

model railway layout.

All feedback modules that conform to the Märklin s88 standard c an be used on the s88

feedback input.

The flat cable supplied with the module is used to

connect the module to the Intellibox s88 input socket.

On both devices the plug must be connected so that

the flat cable goes downwards.

more modules are used the flat cable is c onnected from output of the la st module to the

If

input of the next module so that all modules are daisy chained and con nected to the s88

feedback bus (see also the manual of the particular module).

Figure 2.71 Connection of flat cables

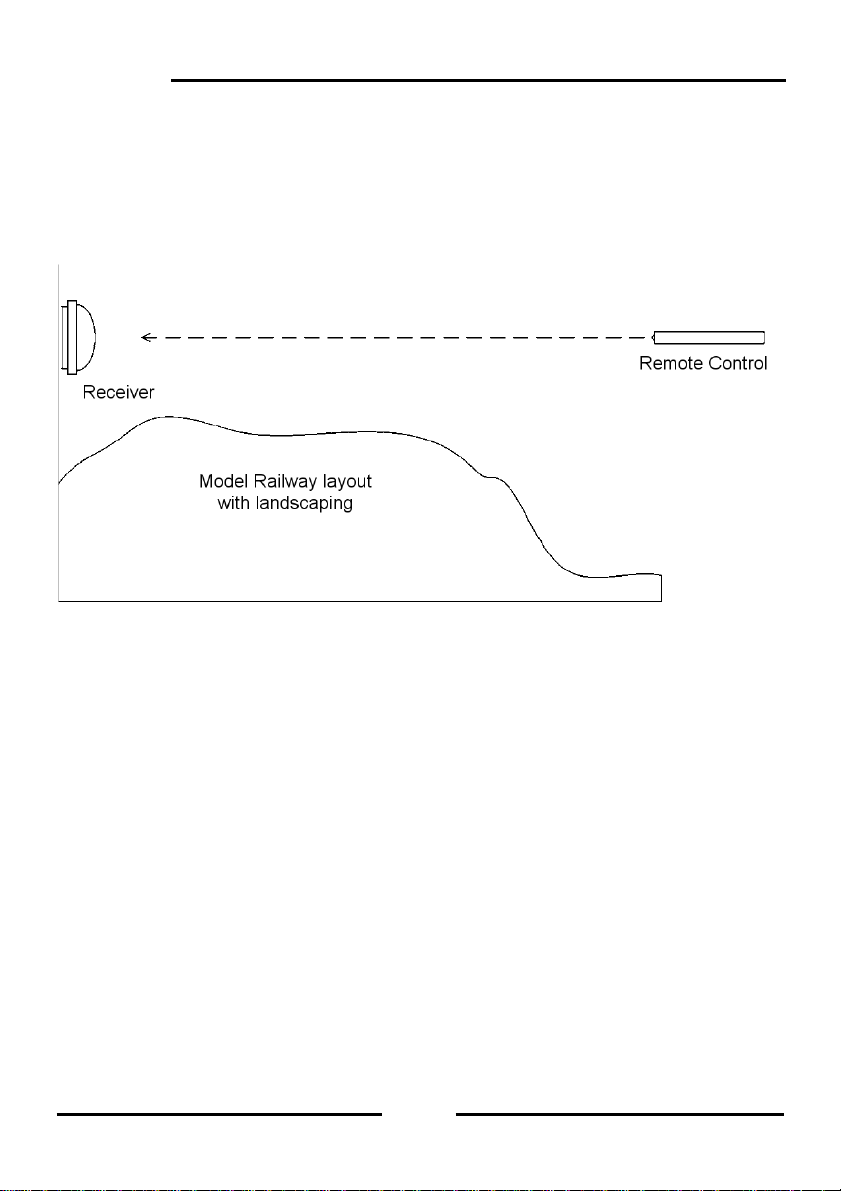

2.8 Connecting IRIS Receivers

Receiver

The built-in receiver is located under the front panel

to the right of the [C]-key. During operation the

remote control IRIS (Part No. 66510) should always

be held in the direction of the receiver (see

illustration).

In difficult situations such as a model railway la yout in

two rooms, two further external receivers can be

used.

Auxiliary Receiver

Auxiliary receivers (Part No. 66520) are connected to

the 5-pole DIN-socket, designated “IRIS receiver“. A

single auxiliary receiver can be connected directly.

When two auxiliary receivers are used they are

connected to the Intellibox via a Y-cable.

15

Page 16

Intellibox II

The receiver is attached to the back wall of the model railway layout using the provided

double sided adhesive pad. As shown in the sketch, the are a bet ween the receiver an d the

transmitter must be free from obstacles. For trouble-free operation, the receiver must

always “see” the transmitter so that trouble free operation is possible. The most sensitive

direction of the receiver is perpendicular to the center of the cov er dome to the rear wall of

the receiver.

During operations the remote control should be always held toward a receiver. A red

control LED under the transparent dome of the receiver blinks when the receiver has

received the infrared signal from a remote control.

16

Page 17

3. The Operating Elements

3.1 Overview of the Operating Elements

Intellibox II

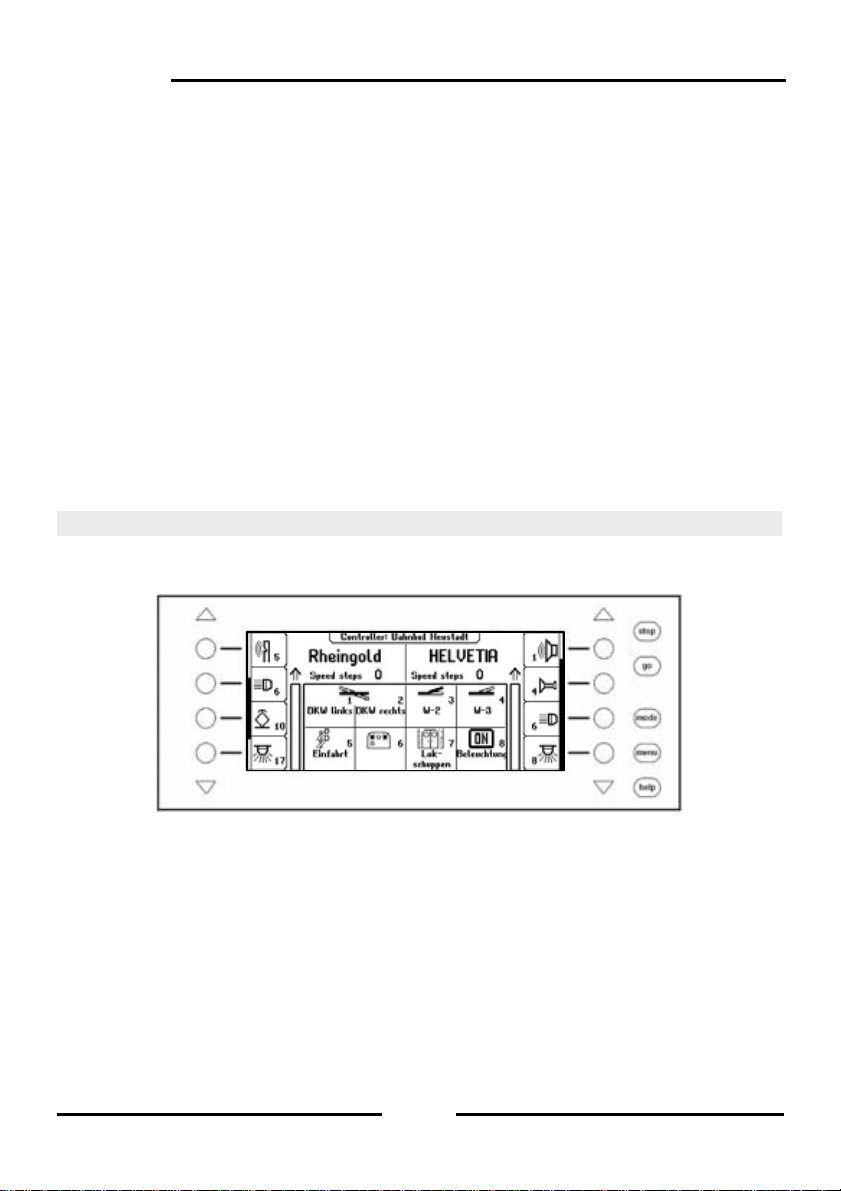

A. Backlit LCD with associated display keys with information about locom otive address or

name, speed and driving direction and the current operati ng mode, e.g. in control desk

mode shows turnout or signal status. The display ke ys are for selecting entries from the

lists which are shown down the side of the display, e.g. in the control desk mode the list

of special functions

B. Key area with operational status indicator, main control keys and help function

C. Left Controller with function keys and locomotive selection key

D. Right Controller with function keys and locomotive selection key

E. Key block with telep hone keyboard and special keys

stop/go

Operating status and key for interrupting and restarting of running operations

mode

Selection of the operating mode e.g. operating desk mode, feedback mode, route mode,

LISSY mode, programming mode, etc.

menu

Setting options related to the current operating mode and return to the operating desk

mode from each submenu

help

Help for every operating situation

17

Page 18

Intellibox II

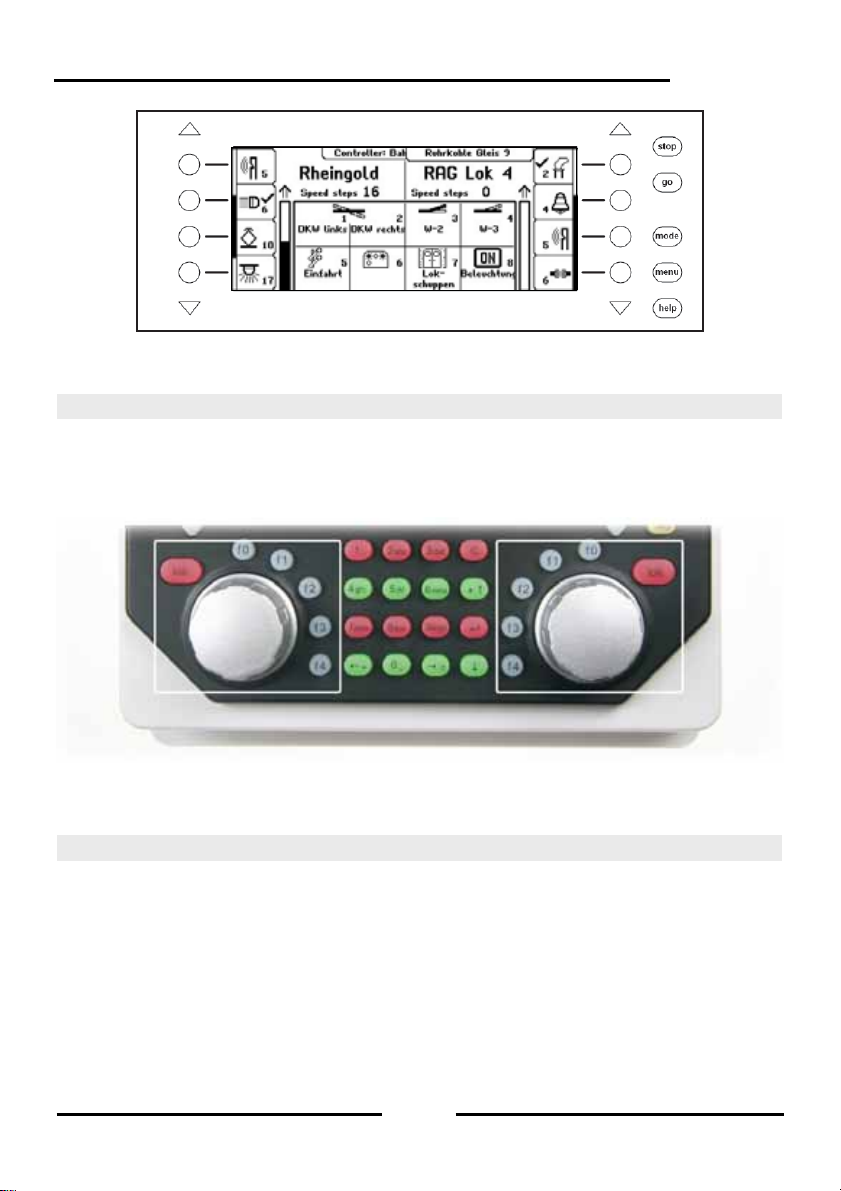

Left Controller

With endless rotary control, direction switch, f0 for switching light function , 4 function keys

and locomotive selection key.

Right Controller

With endless rotary control, direction switch, f0 for switching light function , 4 function keys

and locomotive selection key.

Centre Key block

Telephone key pad for entering digits and characters. With special keys for easy entry of

addresses and working in the individual modes.

LCD Display

The large backlit LCD Display provides information about both currently controlled

vehicles, currently selected operating mode (e.g. in control desk mode, display of turnout

or signal status) and the assignment of the display keys, which always match the in dividu al

operating situations.

Display keys

For selecting entries from the lists which are shown down the side of the displa y, e.g. in the

control desk operation the list of the spec ial functions or the selection of individual menu

items.

3.2 The Display with the Display keys

The large backlit LCD Display is clearly arranged on the panel. The three part display

provides a clear overview of the current running status at all times.

The top area shows the current selected vehicle for each of the controllers along with their

speed and driving direction.

The special functions are switched by the round display keys beside the display. If the

controlled locomotive has more than 4 special functions, then the scrollbar in dicates the

active items in the list. The triangular keys (= Scroll k e ys) can p age thro ugh this list up ward

or downward. Their background light indicates the possible direction.

If the LISSY system is connected to the Intellibox the messages indicating the current state

of the locomotive is shown above the locomotive name. This information is stor ed in the

Intellibox and displayed again when the locomotive is next called. The display is updated

whenever the locomotive passes another place on the layout that is being monitored by the

LISSY system.

18

Page 19

The middle has information about the current operating mode, e.g. in the control desk

mode the state of turnouts or signals.

Intellibox II

3.3 The Controller

Locomotives can be called and controlled by the control desk. The Intellibox has two

independent integrated controllers. They are on the left and right side of the unit.

Digital decoders with different data formats can be controlled simultaneously.

The controllers are also operational during programming or while changing presets.

Each control desk consists of the throttle control knob for changing locomotive speed and

driving direction as well as of the f0 to f4 special function keys. The [lok]-key on each

control desk serves to select new locomotives on the controller.

3.4 Menu Operation

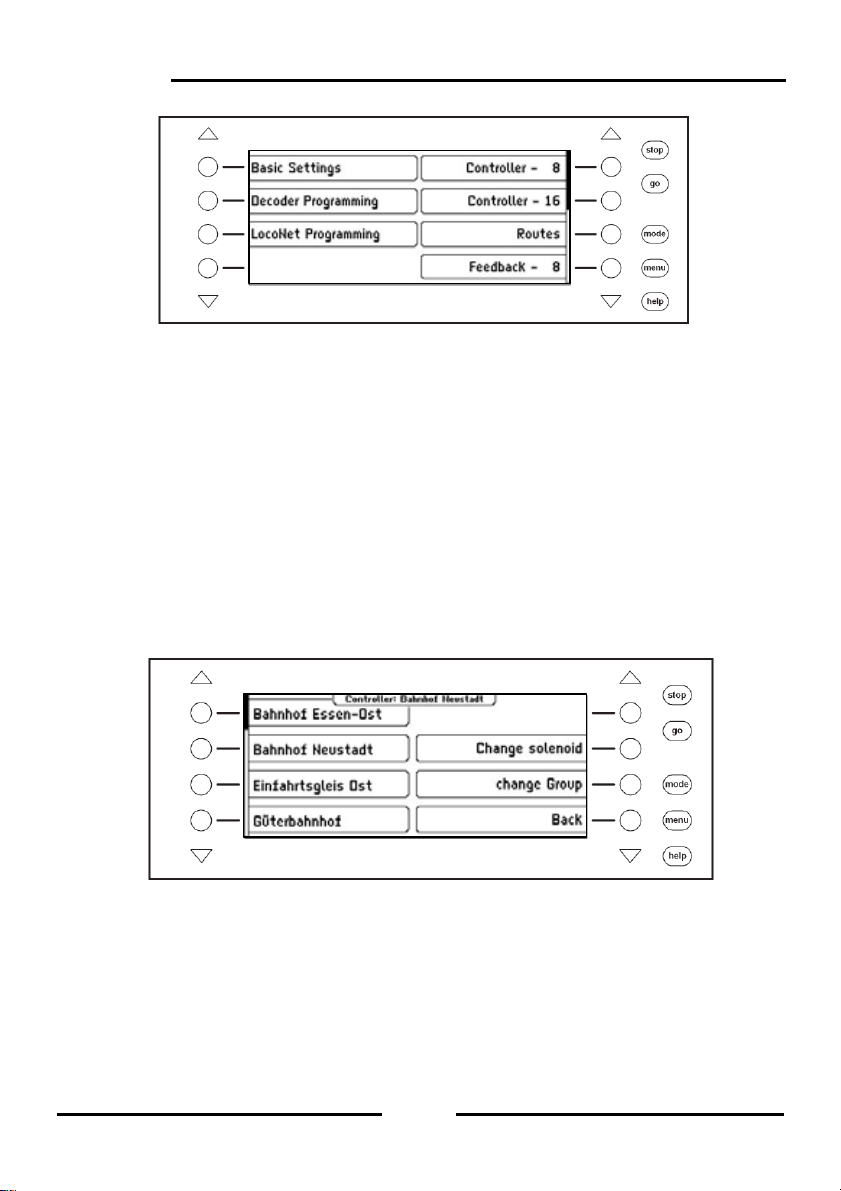

The Intellibox is operated by three main control keys [mode], [menu] and [help]. [Mode]-key

switches between the device modes. If it is pressed the main selection menu appears a nd

shows all the modes. On the left side are the modes that fully utilize the displ ay and on the

right are the modes which represent the control desk in the display in combination with

other control elements (control desk, routes, etc.) in the middle display area.

19

Page 20

Intellibox II

The [Menu]-key leads to selection or configuration menus, which belong to each device

mode. In the control desk mode e.g. a new control desk is selecte d or a solenoid is linked

with a name and a symbol. A further press of the [menu]-key returns back to the Co ntrol

Desk.

The [help]-key can be call context sensitive help at any time.

The individual menus are always navigated with the display ke ys besid e the left and on th e

right the display. Depending upon the operation the dis play gives the meaning of these

keys. If more than four options are available the triangul ar scroll keys light up. A scrollbar

indicates if different options are still present above or below the four represented. These

other options can be accessed with the triangular scroll keys.

The menus are constructed in such a way that the left side has the main options. T he right

side shows associated control steps or a submenu which belong to one of the options on

the left side. Here one often also finds the “Back” key to exit the menu or with which to

return to a parent menu. For example the control desk menu:

20

Page 21

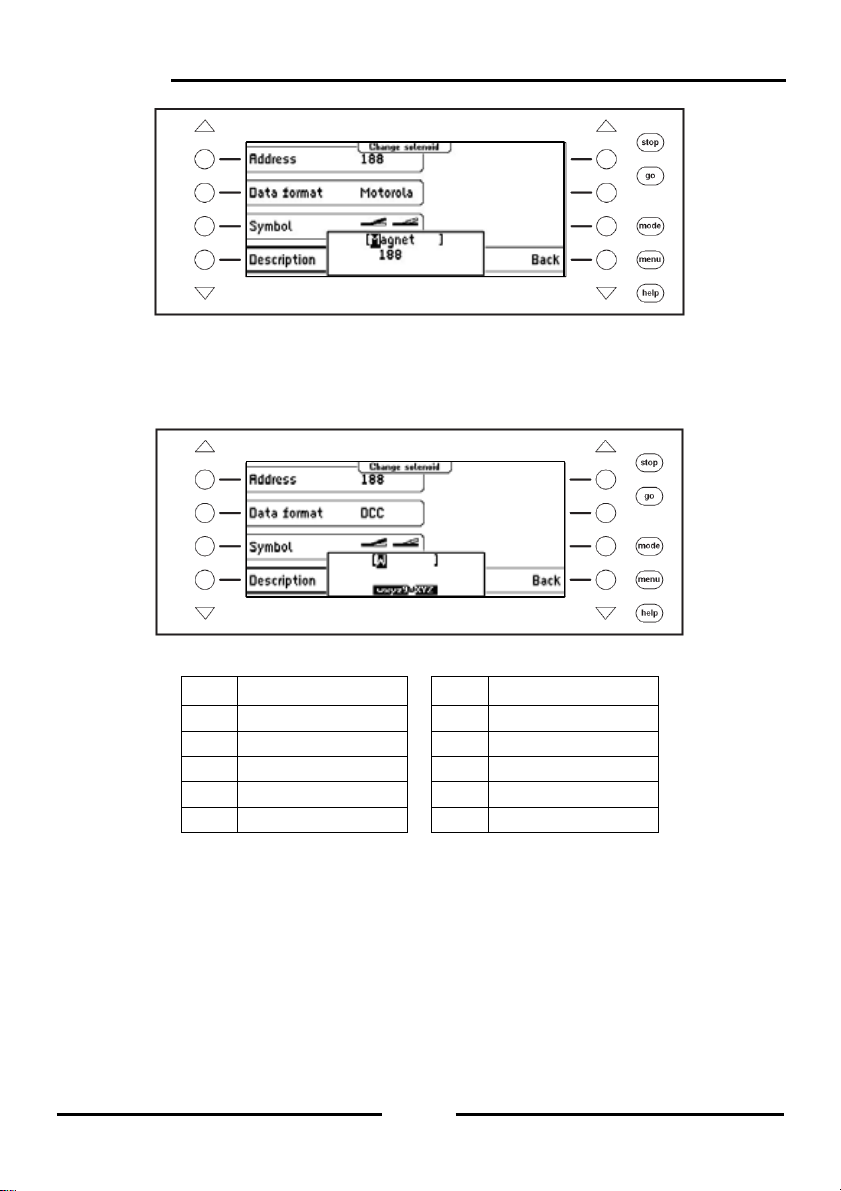

If an option on the left side is activated by key press, this is repres ented by a frame around

the menu element, e.g.:

The right side now shows options for this point. In this example the data format for

solenoids can be set. The submenu is faded out again by another operation of the left

selection key. If a selection key on the right is pressed the selection for this parameter

(here the data format) is accepted and indicated left.

Intellibox II

3.5 Entry of Numerals

If during the course of operating the device input of a number of s equences is required to

enter a locomotive or a solenoid address it is done with the alphanumeric ke yboard in the

centre of the unit (key block). As soon as a digit key is pressed an input field appears. The

input can be completed in the field and confirmed with []-key. The last entered digit can be

deleted with the [C]-key. The [+]-key increments the number in the input field by one,

while []-key decrements the number by one.

3.6 Entry of Names

While operating the device input of names may be necessarily to provide a locomotive or a

turnout with a name. This input can be done with the alphanumeric keyboard in the centre

of the unit (key block). As soon as a change of name is selected, depending upon context,

a one or two line input field appears.

The actual line in which the text can be entered is marked by square brackets. The Curser

position at which next character will be changed is s hown inverted. The arrow keys [] and

[] can move the cursor within the line. The arrow keys [] and [] can be changed

between the lines. The [C]-key will delete the character at the input position.

The character input is ended with the []-key.

21

Page 22

Intellibox II

pq

g

When an alphanumeric key is pressed a list of characters which can be inserted appears.

As is the case for mobile phones repeated pressing of the key selects characters from this

list. If the key is then released for a short time or if another key is pr essed the character at

the cursor position is used.

Here are the symbols assigned to the alphanumeric keys 0-9:

Key Assignment Key Assignment

1 -1.,()<>_:+*/#! 6 mno6MNOöÖ

2 abc2ABCäÄ 7

3 def3DEF 8 tuv8TUVüÜ

4

hi4GHI 9 wxyz9WXYZ

5 jkl5JKL 0 (space)0

Note: Key [0] will overwrite the existing character at the cursor positi on either with a blank

or the number “0” inserted.

rs7PQRSß

22

Page 23

Intellibox II

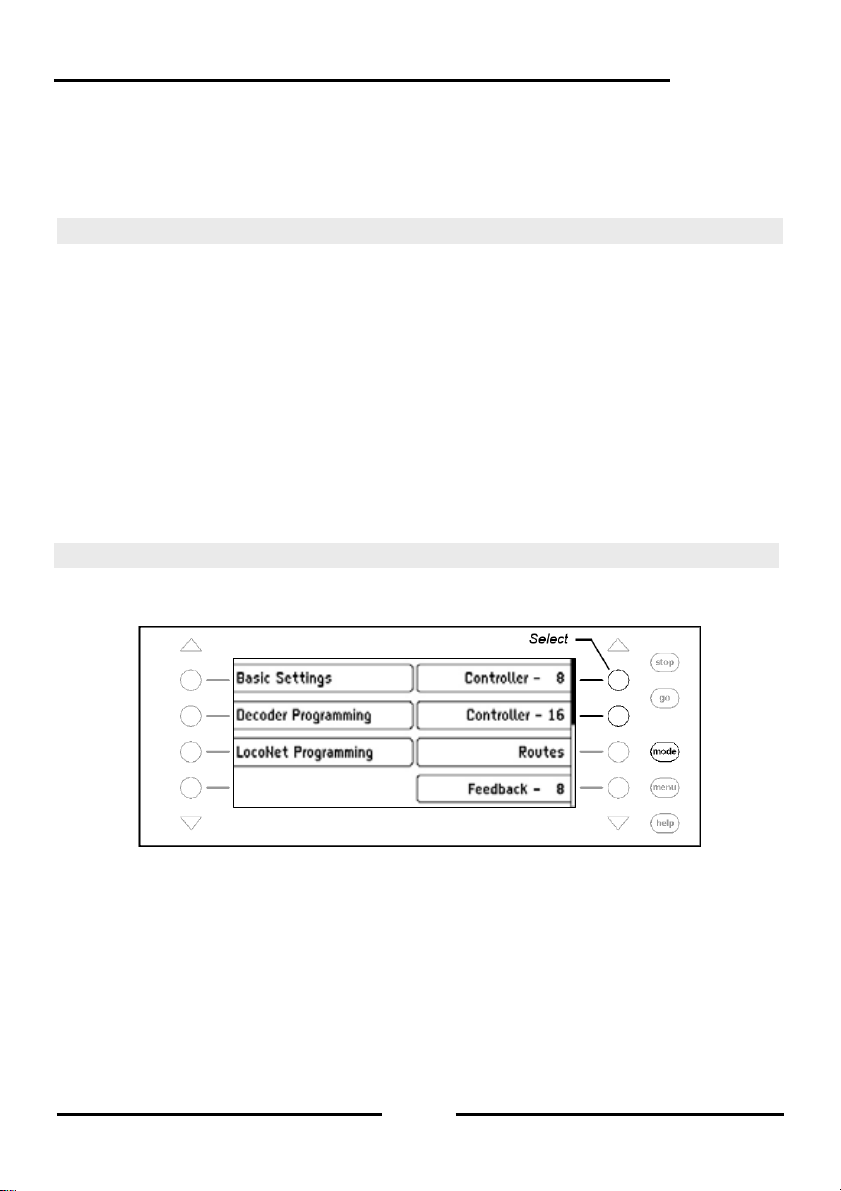

4. Basic Settings Menu

The Basic Setting of the Intellibox II can be changed by menu driven options and are the n

saved to non-volatile memory.

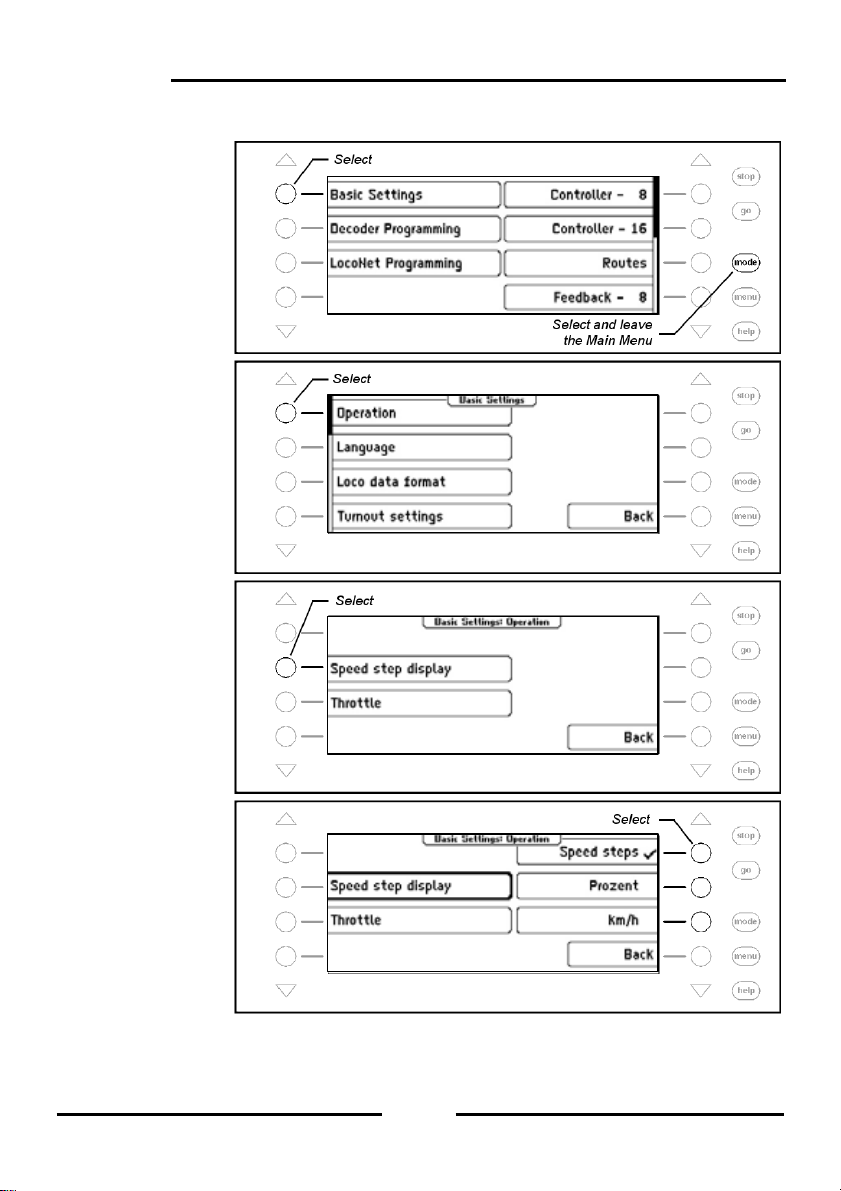

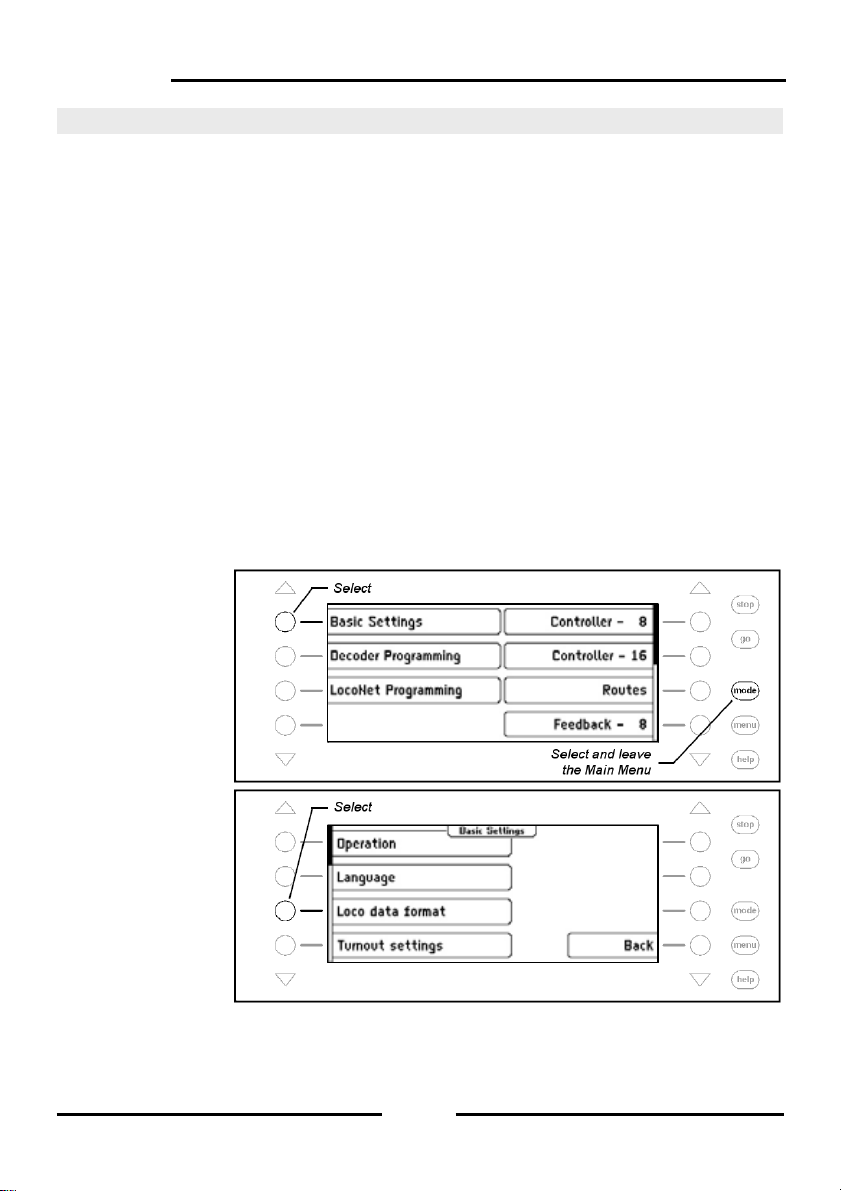

The Basic Settings Menu is reached by pressing the [mode]-key and selecting “Basic

Settings” submenu.

The Basic Settings Menu has the following items:

• Operation

• Language

• Loco data format

• Turnout setting

To leave the main menu press the [mode]-key.

4.1 Menu Item Operation

4.1.1 Speed Display

The display of the vehicle speed can be in one of three ways.

Speed Step display

The display is directly in speed steps according to the decoder data format 0-14, 0-28, 0-31

or 0-126 speed steps.

Percent Display

The display is in percent of the maximum speed irrespective of the data format being used.

Display in km/h

If the individual locomotive address in the database has a top s peed assigned to it (see

Chapter 5.6.5) the speed can be calculated and displayed in km/h.

The display is preset to “Speed Step display”.

• Hand Control

• Display

• Programming track

• Interface

• s88-Settings

• Special options

• Software Version

• Start mode

• Database

• Feedback

23

Page 24

Intellibox II

Procedure:

Step 1

Step 2

Step 3

Step 4

24

Page 25

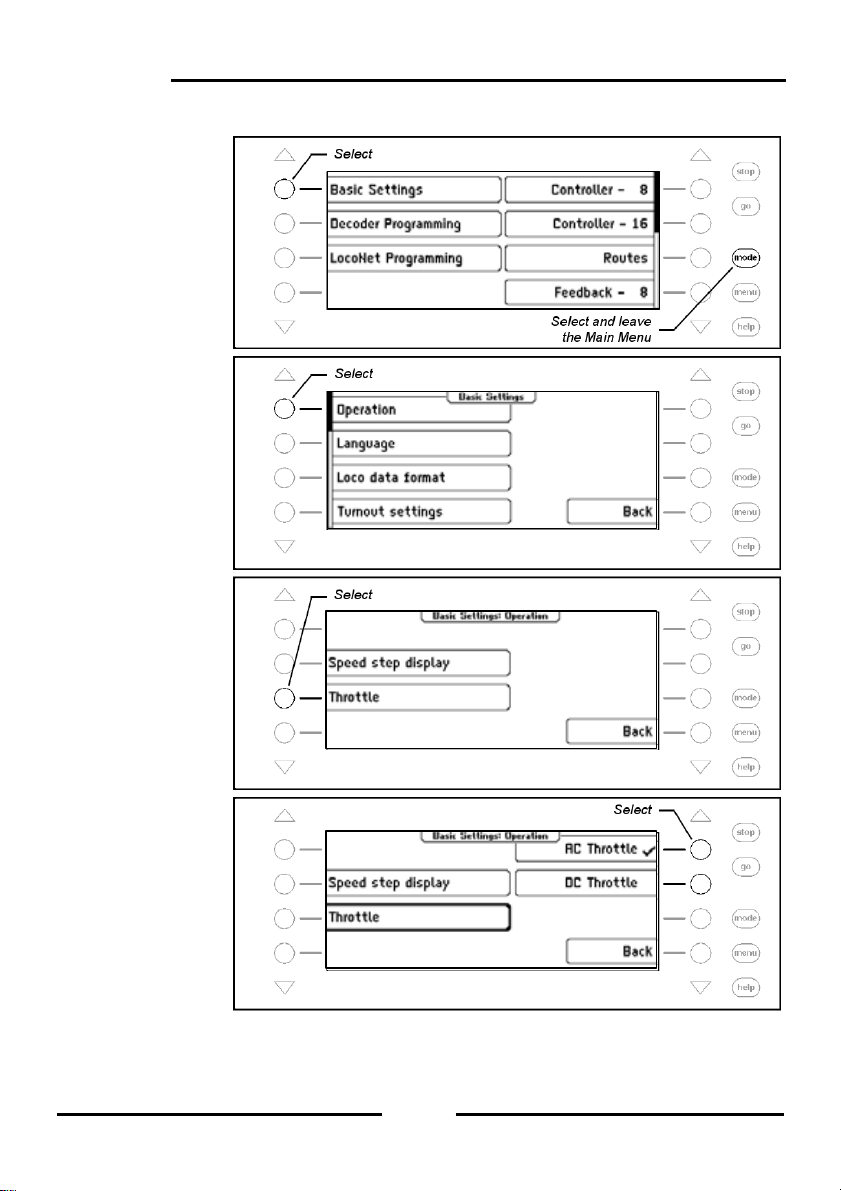

4.1.2 Throttle

The throttle controls on the Intellibox II can be selected to operate like a DC throttle or an

AC throttle.

The factory default setting is “AC throttle”.

AC Throttle Mode

The AC Throttle Mode is set up to control locomotives like the AC transformers in 3-r ail

systems.

Figure 4.1.2.1 Principle of an AC throttle

In this operating mode the speed increases by turning the knob to the ri ght and decreases

by turning the knob to the left. When either the maximum speed or the zero speed is

reached further rotation in the same direction of the knob has no effect. In this operating

mode the direction is switched with a light pressure on the throttle knob.

If the reversing switch is activated while the vehicle is running the vehicle will firstly stop

and only then switch the direction over. It depends on the decoder data format if this

causes an emergency (Motorola, DCC) or stops using the setup deceleration (Selectrix).

DC Throttle Mode

The DC Throttle Mode controls the locomotives as is common in the 2-rail DC systems.

Intellibox II

Figure 4.1.2.2 Pr inciple of a DC throttle

In DC operating mode a right turn of the control knob, starting from speed step zer o, the

locomotive will move in a direction. When the control is turned back the speed is re duced

until the loco stops. A further turn to the left will cause the locomotive to accelerate in the

opposite direction.

If the maximum speed of the loco is reach further turns in that direction has no effect. In

this operating mode a light pressure on the control k nob will cause the vehicle to stop. It

depends on the decoder data format if this causes an emer gency ( DCC) o r stops using t he

setup deceleration (Motorola, Selectrix).

25

Page 26

Intellibox II

Procedure:

Step 1

Step 2

Step 3

Step 4

26

Page 27

Intellibox II

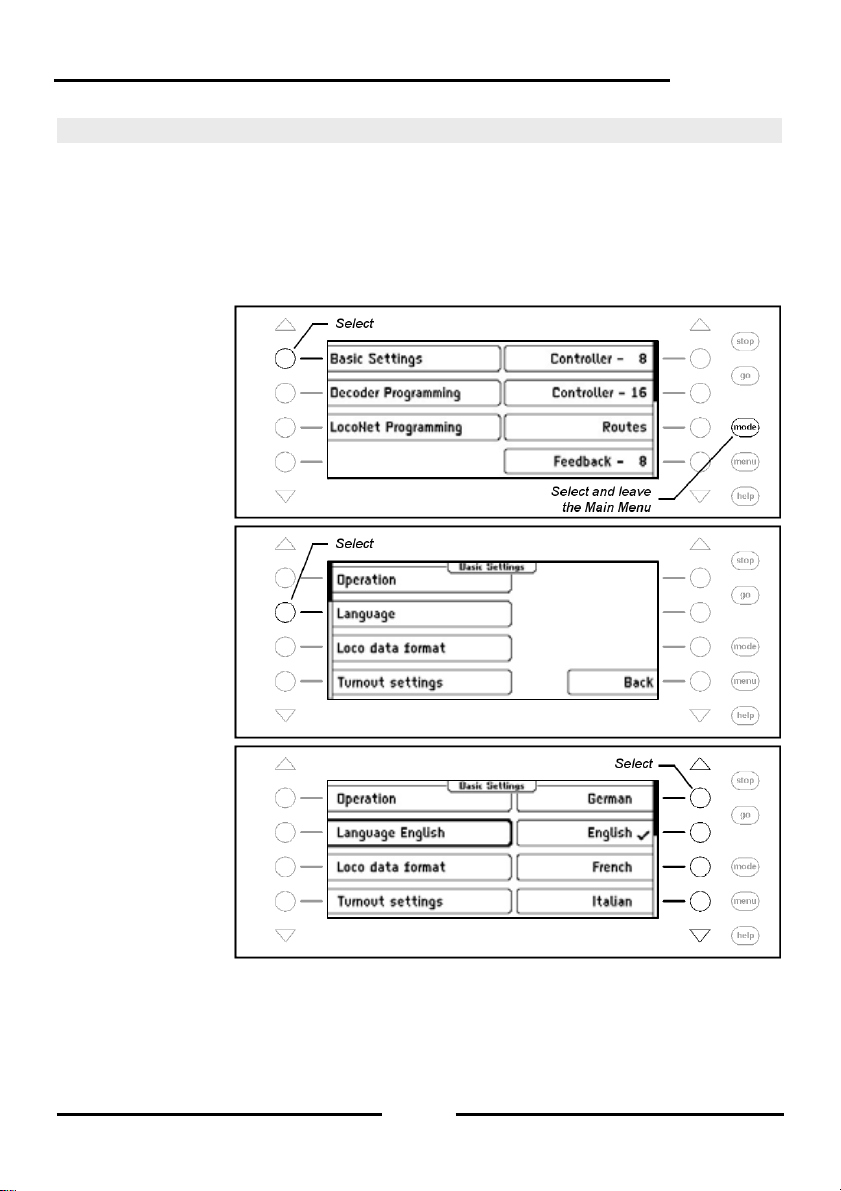

4.2 “Language” Submenu

For the language of the text on the display the following languages can be selected:

• German

• English

• French

The preset is “German“.

Procedure:

Step 1

Step 2

Step 3

• Italian

• Dutch

• Swedish

• Spanish

• Portuguese

• Danish

27

Page 28

Intellibox II

4.3 ”Locomotive Data Format” Menu

Sets the locomotive data format that will be used for decoder the first time they are called

up and when an individual data format is not assigned to it.

The data format you will use most should be set up here before the first time you use the

Intellibox II. The preset value is the new Motorola data format.

Possible settings are:

Motorola - old

old Motorola Data format

Locomotive decoder with 14 speed steps, without special functions

Function decoder controls with special functions keys f1 to f4

Motorola - new

also Spur-I-Format with 14 speed steps, with locomotive special functions f1 to f4

DCC 14-28-128

DCC Format with 14, 28 or 128 speed steps, up to 32767 special functions

Selectrix

Trix Selectrix with 31 speed steps and 4 special functions

Note: The format of individual decoders can eas ily be change d at any time indep endent of

the locomotive data format in the “Change Loco Data” Option.

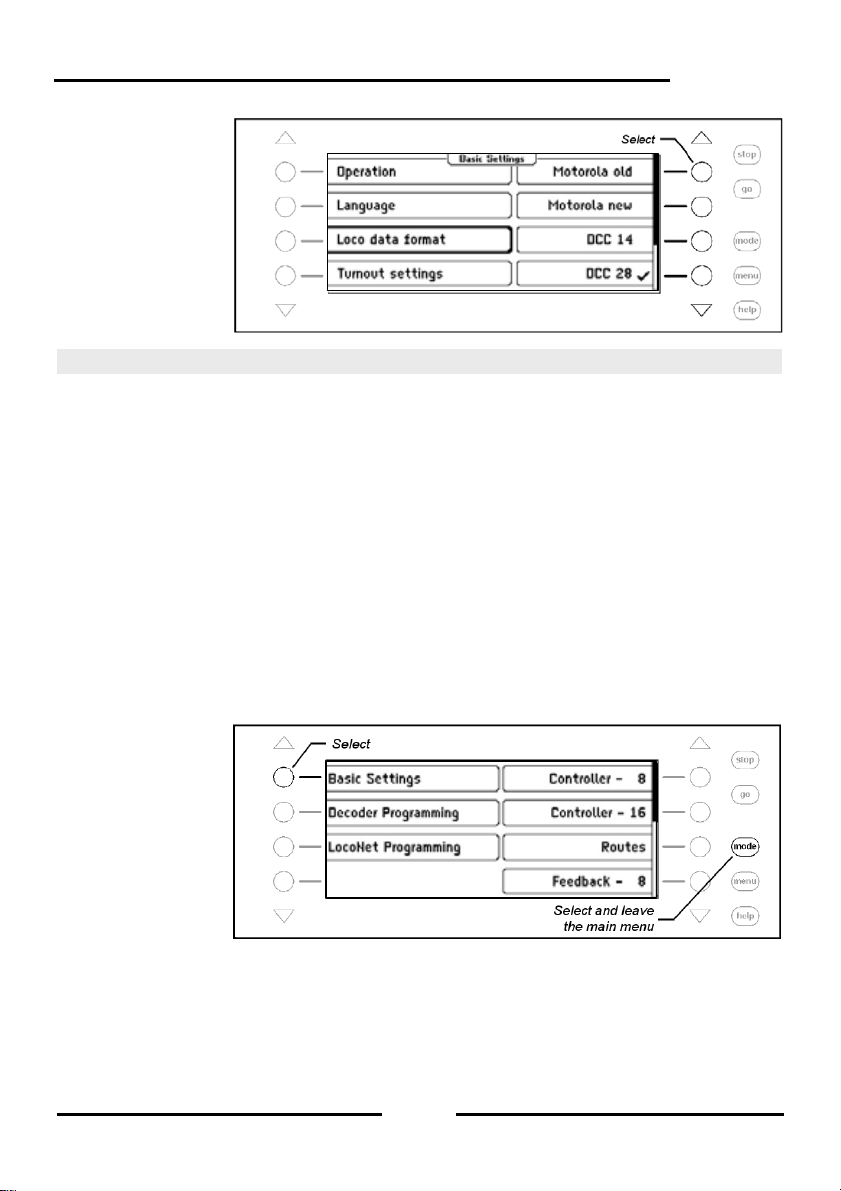

Procedure:

Step 1

Step 2

28

Page 29

Step 3

Intellibox II

4.4 “Turnout settings” Menu

Attention: Turnout decoders from Märklin and Viessmann for the Motorola data format

each control four turnouts. The address selected by the DIP switch on the decod er is not

identical to the turnout addresses of the turnouts connected to the decoder.

All setting menus in the Intellibox II use turnout addresses and not turnout decoder

addresses.

The appendix has a Table showing the relationship of the DIP switch position and the

turnout addresses and also the assignment of the Märklin Keyboards.

4.4.1 General Data format

Sets the turnout data format that will be used for decoders the first time they are called up

and when an individual data format is not assigned to them as outlined in Chapter 6.7.

The data format you will use most should be set up here before the first time you use the

Intellibox II.

The preset value is the Motorola Data format.

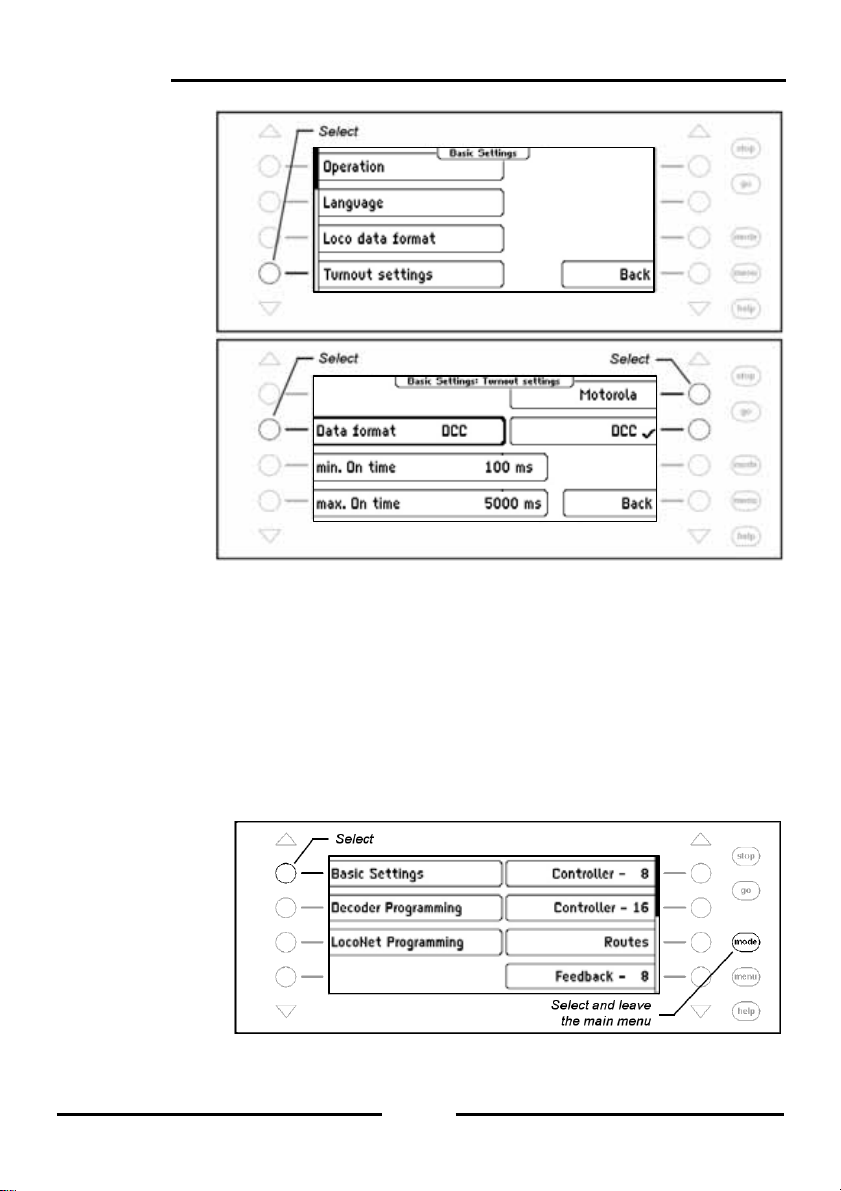

Procedure:

Step 1

29

Page 30

Intellibox II

Step 2

Step 3

4.4.2 Switching Times

The switching pulse that is generated when a control key is pressed norm ally lasts as l ong

as the key is held. To ensure that the switching function s till works with a very short key

press and the solenoid is not damaged by a long activation the Intellibox II has a minimum

and maximum switching time. The factory defaults for the switching time is 100 ms (0.1

sec.) minimum time and 5000 ms (5 sec.) for the maximum time.

Valid vales are between 0 and 9999 ms.

Note: In DCC decoders the switching times can only be set for turnout decoders that are

not configured for “continuous” operation.

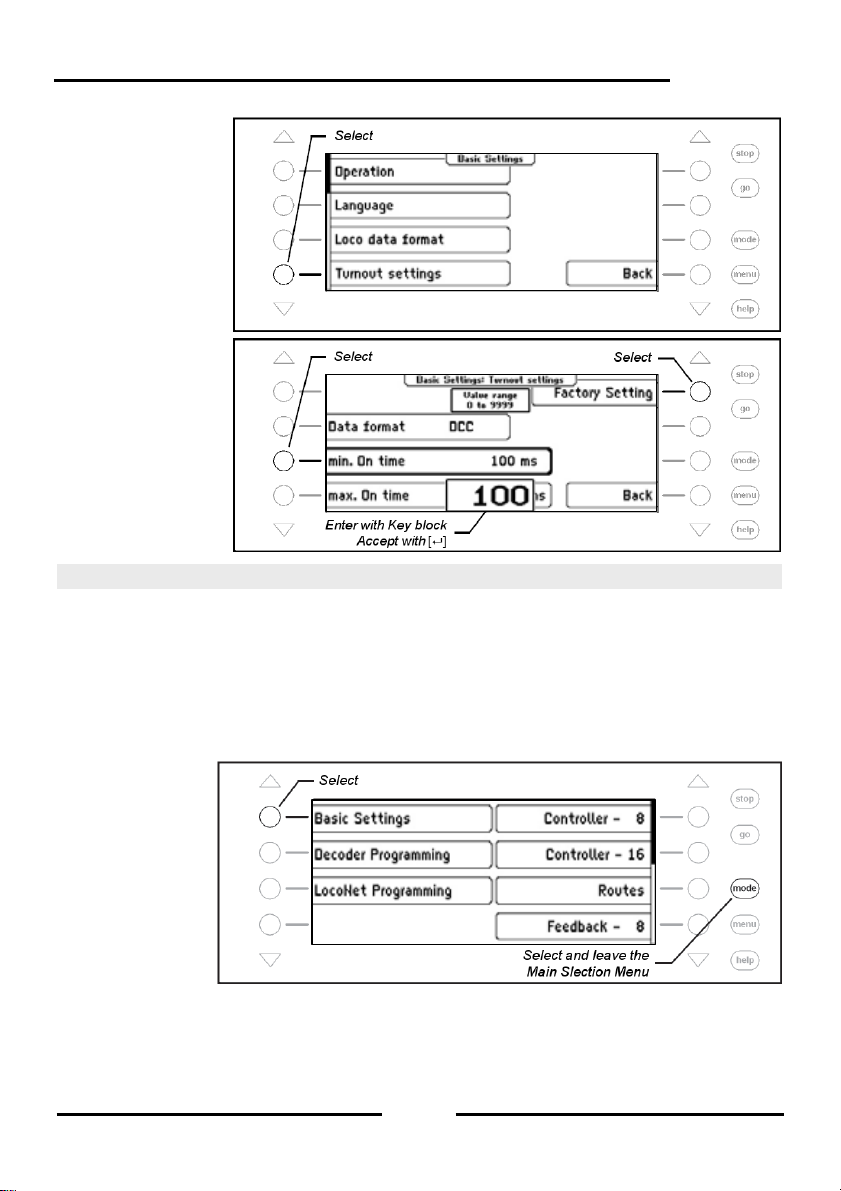

Procedure:

Step 1

30

Page 31

Step 2

Step 3

Intellibox II

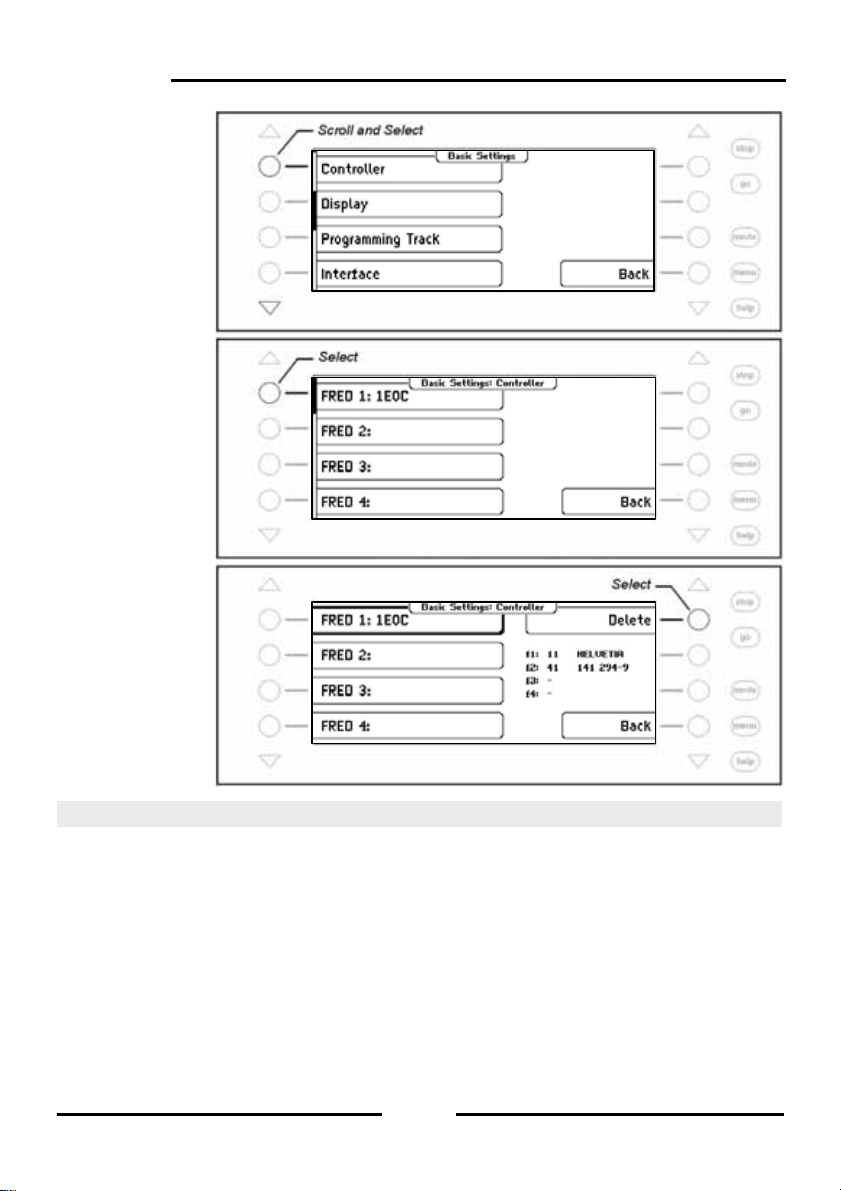

4.5 “Hand Controller” Menu

When an Uhlenbrock FRED hand controller is connected to Intellibox Loc oNet for the first

time, the center will automatically assign an internal Identification number (ID) to the

FRED. The center can forward locomotive addresses to the FRED under this hand

controller number.

The Hand controller Menu can be used to display the assignment of the FRED number and

matching ID and individual FREDs can be deleted.

Procedure:

Step 1

31

Page 32

Intellibox II

Step 2

Step 3

Step 4

4.6 “Display” Menu

The Display Menu is used to set the brightness and Contrast of the display.

Procedure:

32

Page 33

Step 1

Step 2

Step 3

Intellibox II

Step 4

33

Page 34

Intellibox II

4.7 “Programming Track” Menu

It is possible to select whether the connections for the programmi ng track provides only

programming power or if the output automatically switches between normal digital po wer

and programming power.

Only Programming Track

There is no power on the programming track output, it is only fed with programming power

during read and write operations.

Automatic

During normal running the programming track output provides normal digital po wer. It is

automatically switched over to programming track power as soon as the Programming

Menu is selected. That way a model railway layout can setup a siding to be the

programming track and also a normal siding.

Very important: The track segment must be isolated on both sides. It must not have an y

electrical connection with the rest of the layout and must be exclusively provided with

power from the programming track output. The isolations must not be bridged by a vehic le

during programming operations (bogie, lit wagon).

The preset value for the programming track is “automatic”.

Procedure:

Step 1

Step 2

34

Page 35

Intellibox II

4.8 “Interface” Menu

This menu is used to change the baud rate of the Intellibox II. The preset value is 115200

bit/s.

Procedure:

Step 1

Step 2

4.9 “s88 Setting” Menu

Unlike in other digital centers the Intellibox II stores the feedback signals.

To process this polling as fast as possible the Intellibox II needs to know how many s88

feedback modules are connected to the s88 feedback bus.

Using a Start address the s88 feedback modules are configured to use these feedback

addresses in ascending order.

35

Page 36

Intellibox II

Procedure:

Step 1

Step 2

Step 3

Step 4

36

Page 37

Intellibox II

4.10 “Special Options” Menu

The Intellibox II has various special options which affect the operation of the devic e and

can differ between software versions. Each special option can be selected with an

identification number. The individual special options can be obta ined in a separate list for

the particular software. With later software changes a file containing the relevant

explanation is included in the update package.

Procedure:

Step 1

Step 2

Step 3

37

Page 38

Intellibox II

Step 4

The right display keys can be used to set special option bits to 1 or 0.

4.11 “Software-Version” Menu

Use this Menu item to find the serial number of your device and the Version number of the

System software.

Procedure:

Step 1

Step 2

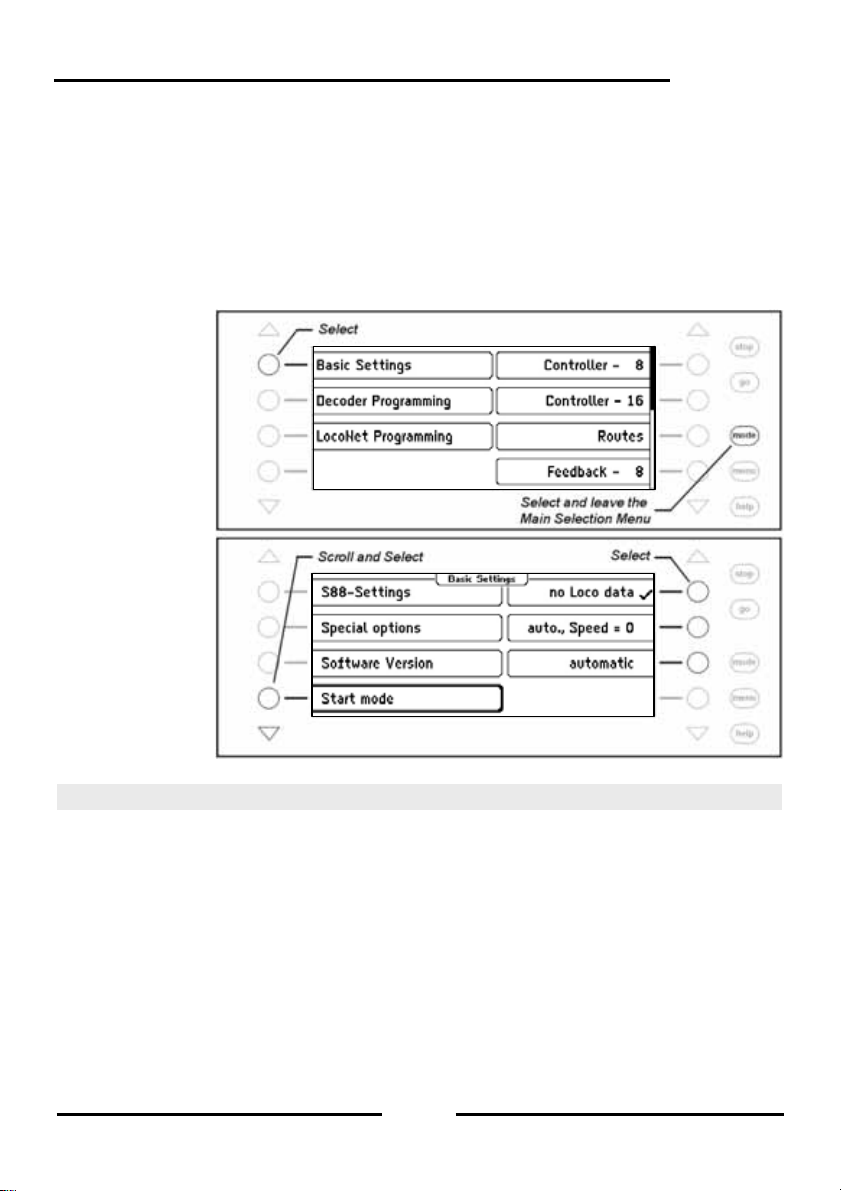

4.12 “Start Mode” Menu

When the playing is finished the Intellibox II saves all the data. The Start Mode Menu can

be used to configure which of the data will be restored at the next start.

no Loco data

No data from the previous play session is to be restored.

38

Page 39

auto, Speed = 0

All data from the last operation about locomotives and Multi-traction with their direction and

the state of their special functions are recovered from the last use.

automatic

In addition to the data about direction and special function s the speed of all locomotives is

restored. That way the entire operation continues on from when it was last switched off.

Note: A safety question appears if all locomotives are definitely to run at their old speed.

Procedure:

Step 1

Step 2

Intellibox II

4.13 “Database” Menu

The Intellibox has a database in which all user settings for locomotiv es, turnouts, feedback

units, Routes, LISSY receivers and booster are saved. The assigned names and symbols

for the individual elements are saved. Two memory buffers are available for the active

database and for a copy

The “Database” Menu has the following options:

Make Copy

A copy of the active database is made into the copy buffer.

Swap with Copy

The data is swapped between the active database and the cop y buffer. The data from the

copy buffer are put into the active data buffer and active data buffer is placed into the co py

buffer.

.

39

Page 40

Intellibox II

Delete

The active data buffer is flushed. Subsequently all names are rep laced with the relevant

addresses and basic symbols are used for functions, turnouts and feedbacks.

Demo Database

A Demo database with preset values of names and symbols is loaded.

Procedure:

Step 1

Step 2

Step 3

40

Page 41

Step 4

Intellibox II

4.14 “Reset” Menu

This submenu is used to reset the Intellibox II back to factory defaults.

Intellibox

The entire device does a reset and start afresh like when the operating power is turned on.

Configuration

All changes under Basic Settings are erased. All changes to speci al option are reversed.

The selected language remains.

Locomotive Data format

The entries made for individual locomotive decoder in “Change Loco Data” submenu

(Chapter 5.6.5), are erased. The general data format for locomotive decoders (Chapter

4.3) is selected for the respective decoder addresses.

Turnout Data format

The entries for the individual turnout decoders made in submenus “Name, Symbol and

Data format of solenoid settings” (Chapter 6.7) are erased. The general data format for

turnout decoders is used for the respective decoder addresses.

Procedure:

Step 1

41

Page 42

Intellibox II

Step 2

Step 3

Step 4

42

Page 43

Intellibox II

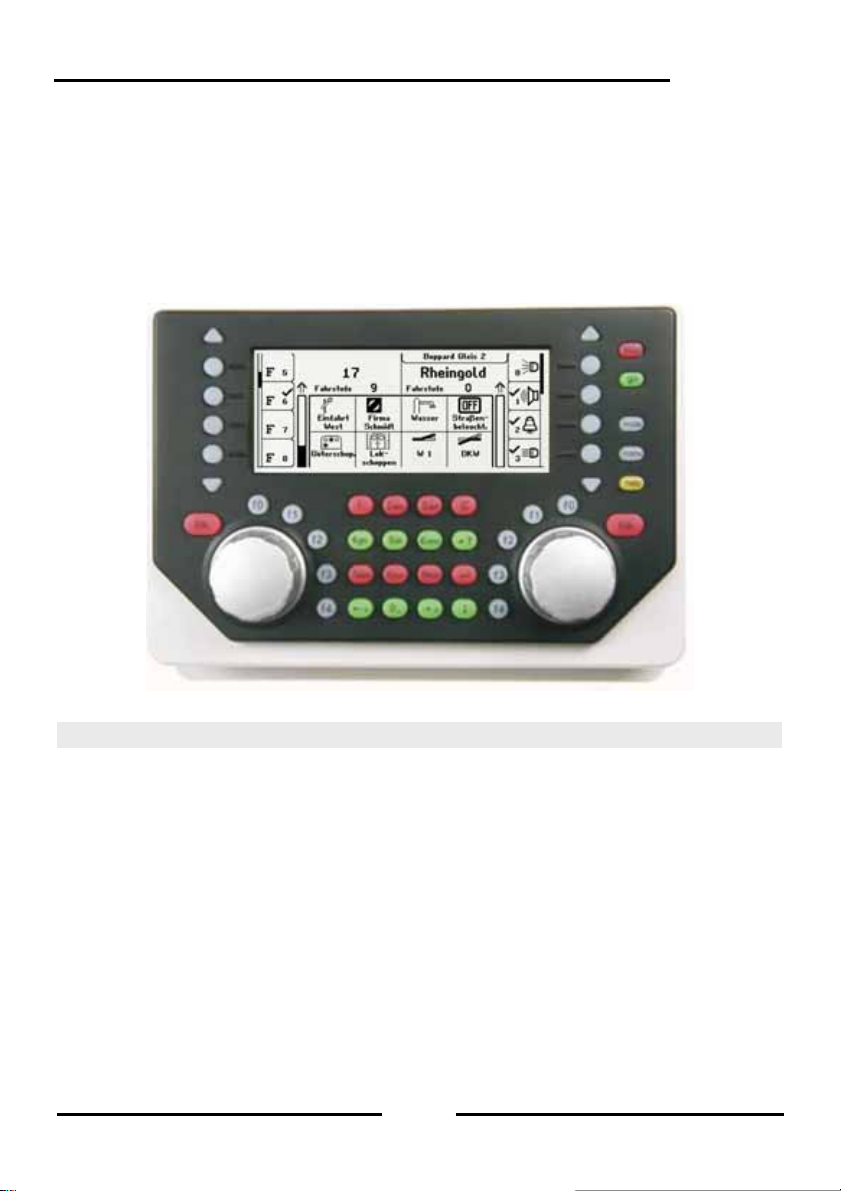

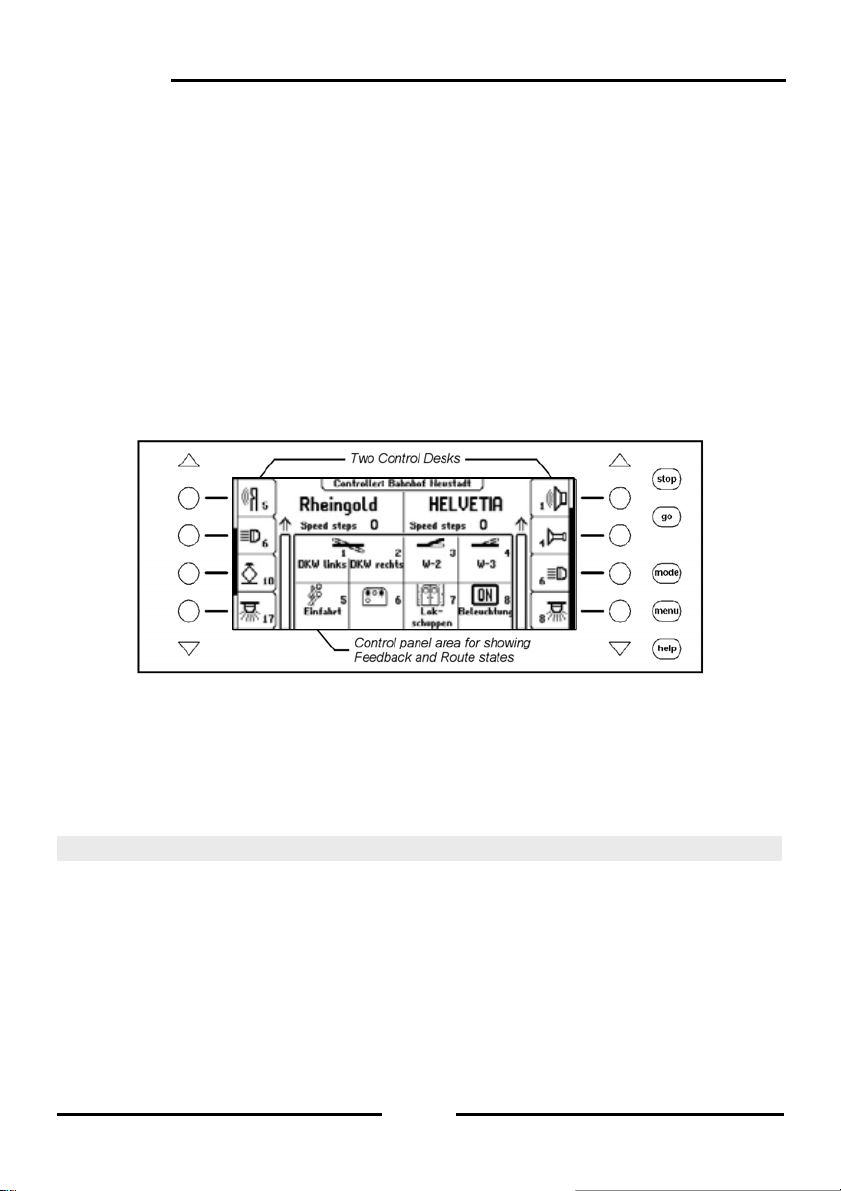

5. The Control Desk

Locomotives can be called up and controlled with a control desk. The Intellibox has two

built-in, independent from one-another control desks. They are located on the left and rig ht

side of the device control panel.

Digital decoders with different data formats can be controlled simultaneously.

The Control desks are also operational during programming and while changes are made

to the presets.

Figure 5.11 The Front view of the Intellibox

5.1 Operating Elements

Each control panel has the following elements:

The [stop]-key

The [stop]-key turns the power off to the main line and the track sections powered by

connected boosters. The “STOP – no track power” message is then shown in the display.

This key is used by both control desks.

The [go]-key

The [go]-key turns the power on to the main line and the track sections are p owered by

connected boosters. It is used by both control desks.

Note: If during normal running the [go]-key is pressed and held, the [stop]-key is also

pressed or when the power is off (red LED beside the [stop]-key is lit) the [stop]-key is

pressed and held, and the [go]-key is also pressed the Intellibox II switches to the Halt

Mode. During the Halt Mode all locomotives are stopped, the track power remai ns on so

turnouts and signals can still be switched. After pressing the [go]-key all locomotives r un

with their previous speed.

43

Page 44

Intellibox II

The keys [f0] [f1] [f2] [f3] [f4]

These keys switch locomotive special functions such as Light, Special lighting, Horn or

Smoke unit.

The [lok]-key

starts the selection of the wanted locomotive for respective control desk.

If a vehicle is already selected then pressin g the [lok]-key twice will enter the Loc o Menu.

Here you can build a Multi-traction, assign locomotive to a hand controller or edit

locomotive data.

The Throttle knob

The throttle knob is used to change the locomotive speed and direction. The rotating

throttle without end stop on the Intellibox II automatically restores the saved speed when a

new locomotive is selected.

The Display

The large backlit LCD display always gives you an exact overview of the running status.

The display of the used locomotive, running speed and direction of actually controlled

vehicles are shown separately for each controller. The display keys at the sides are

assigned with loco special functions. If the controlled locomotive has more than 4 special

functions the triangular scroll keys, top and bottom can be used scroll through further

functions. If it is possible to scroll up or down the corresponding scroll key is lit up.

The scrollbar diagrammatically shows at which point in the selection ran ge the displ a y keys

are.

5.2 Locomotive Addresses und Names

In a digital control system an individual locomotive is selected by an address. This is a

sequence of digit, which are installed in the individual locomotive decoder for identification.

Each decoder is set to its own address so that the locomotive can be addressed by this

particular address.

In order to simplify locomotive selection each locomotive can be assig ned a name. If the

assignment is done once the Intellibox II saves it permanently.

In every new locomotive selection it can be selected from a list by name.

44

Page 45

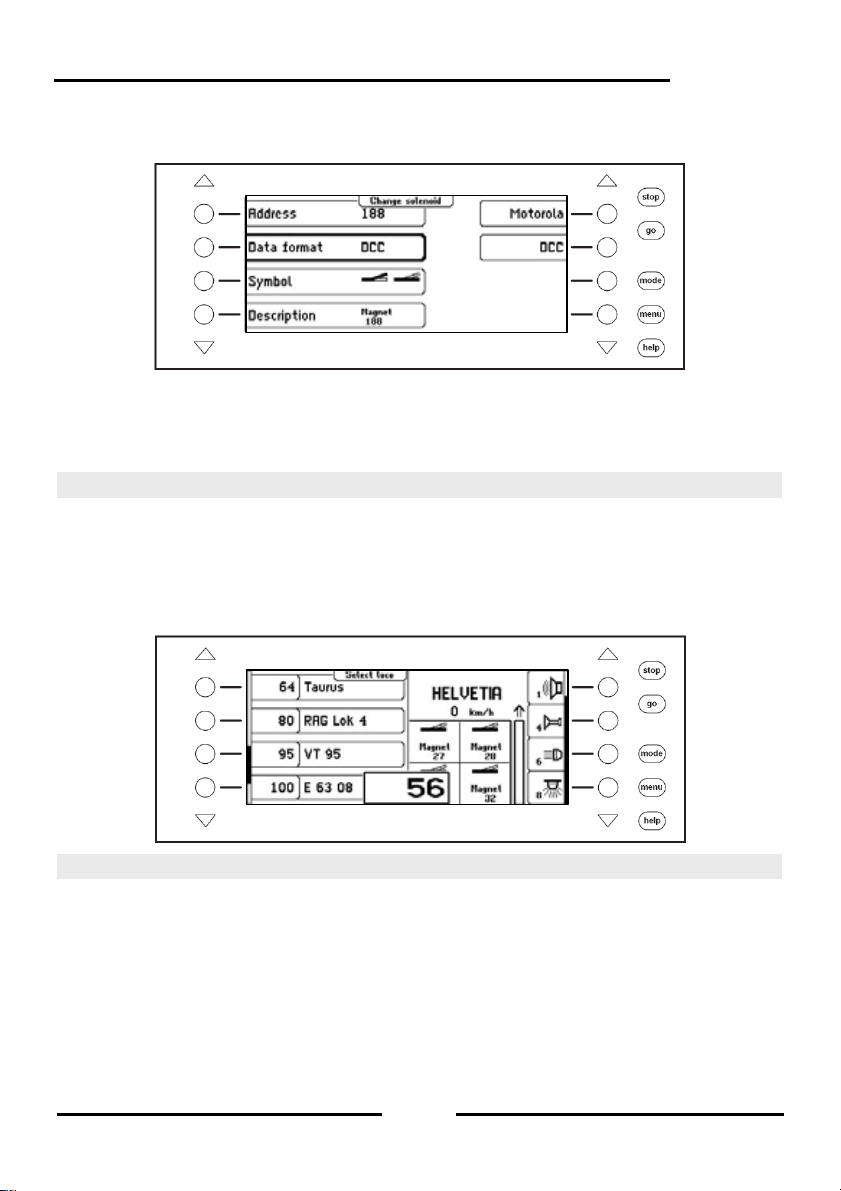

5.2.1 Locomotive selection

If a vehicle is to be controlled with the Intellibox II it must be called under the decoder

address or under the assigned name.

Locomotive selection is started by pressing the [lok]-key. The display shows a list of

locomotive addresses and names. The desired locomotiv e is selected with the selection

keys. If more then 4 locomotives are available the scrollbar appears and the triangular

scroll keys can be used to scroll through the list. The [mode]-ke y can be used to switch

between sorting by locomotive address or by name.

If the locomotive is not on the list its address can be entered numerically. After pressing the

digit an input field appears to verify the digit inputs. The [C]-key can be used to delete the

last digit and the [ ]-key to confirm the entry.

Note: If the loco being called up is already being c ontrolled by another throttle control the

Intellibox II will inform you with message: “The selected loco is already under co ntrol!”. Th e

vehicle can then be controlled with both throttles.

Intellibox II

5.3 Throttle

The throttle is for changing the speed of the locomotive and its direction. The rotary control

without endpoints automatically restores the save speed of a newly selected locomotive.

The throttle has two operating modes:

AC Throttle Mode

The AC Throttle Mode is set up to control locomotives like the AC transformers in 3-r ail

systems.

In this operating mode the speed increase b y turning the knob to the right and decreas es

by turning the knob to the left.

When either the maximum speed or the zero spe ed is reached further r otation in the same

direction of the knob has no effect. The maximum speed or zero speed then remains.

The direction is changed by lightly pressing on the control.

Figure 5.31 Principle of an AC throttle

45

Page 46

Intellibox II

If the reversing switch is activated while the vehicle is running the vehicle will firstly stop

and only then switch the direction over. It depends on the decoder data format if this

causes an emergency (Motorola, DCC) or stops using the setup deceleration (Selectrix).

DC Throttle Mode

The DC Throttle Mode controls the locomotives as is common in the 2-rail DC systems.

In DC operating mode a right turn of the control knob, starting from speed step zer o, will

move the locomotive in a direction. When the control is turned back the speed is reduc ed

until the loco stops. A further turn to the left will cause the locomotive to accelerate in the

opposite direction.

If the maximum speed of the loco is reached further turns in that direction has no effect.

In this operating mode a light pressure on the control knob will cause the vehicle to stop. It

depends on the decoder data format if this causes an emer gency ( DCC) o r stops using t he

setup deceleration (Motorola, Selectrix).

Preset

In factory default setting the AC Throttle Mode is active. This can be changed in the

Intellibox Basic Settings Menu (See Chapter 4.1).

Figure 5.32 Principle of a DC throttle

5.4 Light and Special functions

The function keys beside the throttle control knob can be used to switch the light and

special functions f0 to f4 of locomotive and function decoders.

The special functions f0 to f28 (DCC) for a locomotive are shown in the display and can be

switched with the selection keys. Active functions are indicated by a tick. If more than 4

functions are available, the triangular scroll keys can be used to scroll through the list.

46

Page 47

Intellibox II

5.5 The LokPosi Display

The LokPosi Display in conjunction with the LISSY System shows the position of a loco.

The Intellibox II gets information from the LISSY System about which locomotive is at

which position on the layout. This information about the location of a locomotive is saved

by the Intellibox II. If a locomotive is called up its location is displayed in the LokPosi field.

If the loco moves the indication is deleted because the locomotive has departed the last

location. If the loco enters another track section that is controlled by a LISSY receiver the

new location is displayed in the LokPosi field.

The LokPosi field either contains the number of the LISSY receiver, at which the loco is

located or the name of that track section in the event that the LISSY receiver has been

assigned a name. How a name can be assigned to a LISSY receiver is outlined in Chapter

9.6.

47

Page 48

Intellibox II

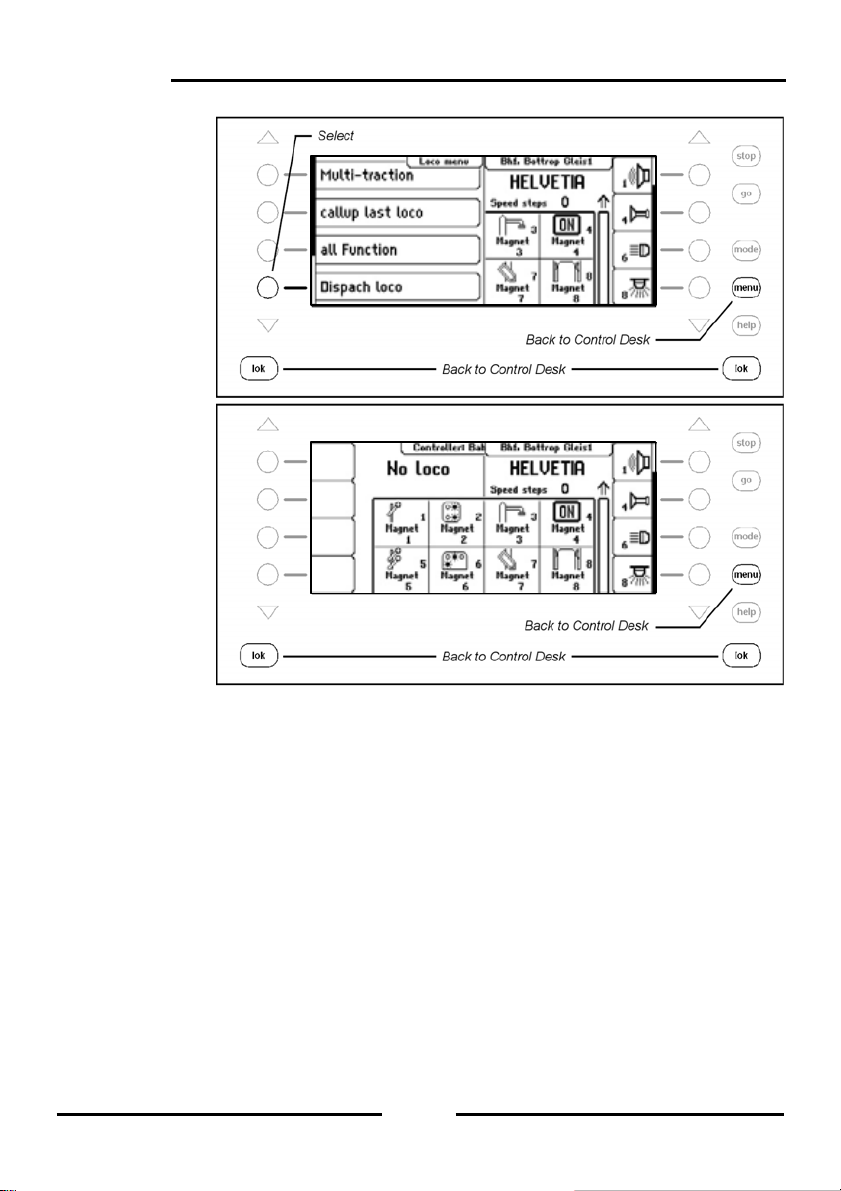

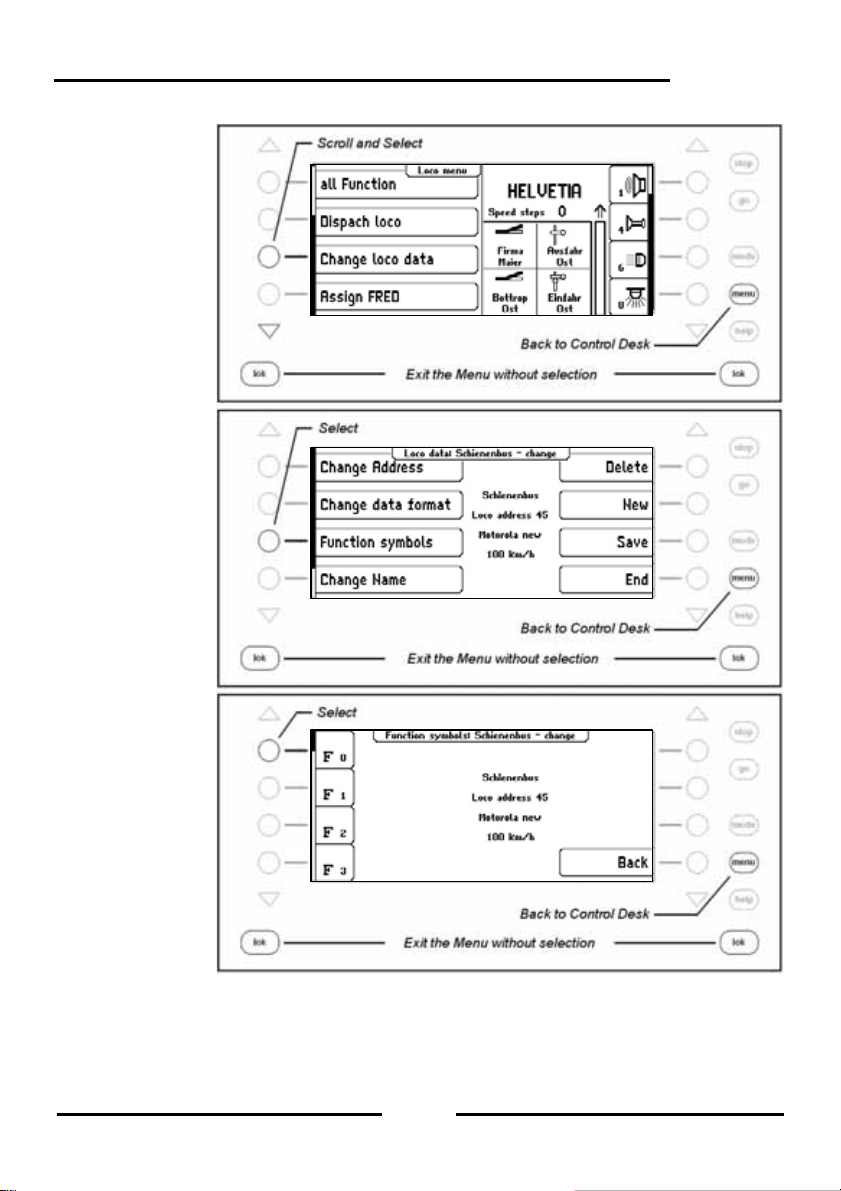

5.6 The Loco Menu

The key sequence [lok] and [menu] or 2x [lok] calls up the Loco Menu for the currently

controlled locomotive. Here you can reach following functions:

• Multi-traction

• Call up last locomotive

• Switch all functions

• Dispatch locomotives

• Edit locomotive data

• FRED assignment

5.6.1 Multi-traction

The Intellibox II can control up to 4 locomotives together with the one controller. A

locomotive can be added to a Multi-traction either by its decoder address or its name. A

total of up to eight different Multi-traction are possible.

Building a Multi-traction

Note: The combination of [lok] and [+] keys goes directly into Multi-traction Menu for

adding and removing locos.

Step 1

48

Page 49

Step 2

Step 3

Step 4

Intellibox II

49

Page 50

Intellibox II

Step 5

Deleting a Multi-traction

Step 1

Step 2

50

Page 51

Step 3

Step 4

Behaviour of Multi-traction Locomotives

A Multi-traction can only be called up under the address or name of the “base locomotive”.

If a traction locomotive is called under its own address Multi-traction appears in the display

in place of the speed indication, but no direct ion indic ation. The direction of this locom otive

can however be changed so that at the start of the Mu lti-traction operation al l vehicles can

run in the same direction.

Note: The direction can only be change if the entire Multi-traction is stationery. The speed

step must be set to “0” under the address of the base locomotive.

The special functions of a coupled loco in a Multi-traction can be individually controlled

under its own address and independent of the base locomotive.

If locomotives having decoders with different number of speed ste ps are coupled into a

Multi-traction the group is controlled according to the locomotive with the lowest number of

speed steps. If for example a decoder with 28 speed steps is coupled with a decoder with

14 speed steps, the decoder with 28 speed steps will change its speed with every notch of

the throttle, but the one with 14 speed steps only with every second notch. It therefore

makes sense to use the locomotive with the least number of speed steps as the base

locomotive.

Intellibox II

51

Page 52

Intellibox II

Important: For troubl e free operation of multiple locomotiv es in a Multi-traction it must be

ensured that coupled locomotives have the same minimum and maximum speed.

Note: The setting of the minimum and maximum speeds must be programmed into the

locomotive with the appropriate parameters. Details for this are in the particular decoder

manual.

5.6.2 Last called up Locomotive

The Intellibox II notes the last 4 locomotives called up by a control desk. The 4 locom otiv es

can be quickly recalled via the Loco Menu.

Procedure:

Step 1

Step 2

52

Page 53

Step 3

5.6.3 Controlling All Functions

The Intellibox II can control function decoders which can be switched with a function

address up to 32767. Directly accessible from the loco control panel ar e special function

light (f0) and special functions f1 to f28. These special functions can be switched with

symbols and by the keys beside the display. T o switch the higher functions (>28) the Loc o

Menu must be used. Special functions from f0 to f32767 which are accessible via a

locomotive address can be switched from the submenu “All Functions”

Procedure:

Step 1

.

Intellibox II

53

Page 54

Intellibox II

Step 2

Step 3

Step 4

54

Page 55

Step 5

Intellibox II

While the “All Functions” Menu is open the loc omotive can be controlled by the controller

as normal. The locomotive speed and direction are shown in the display.

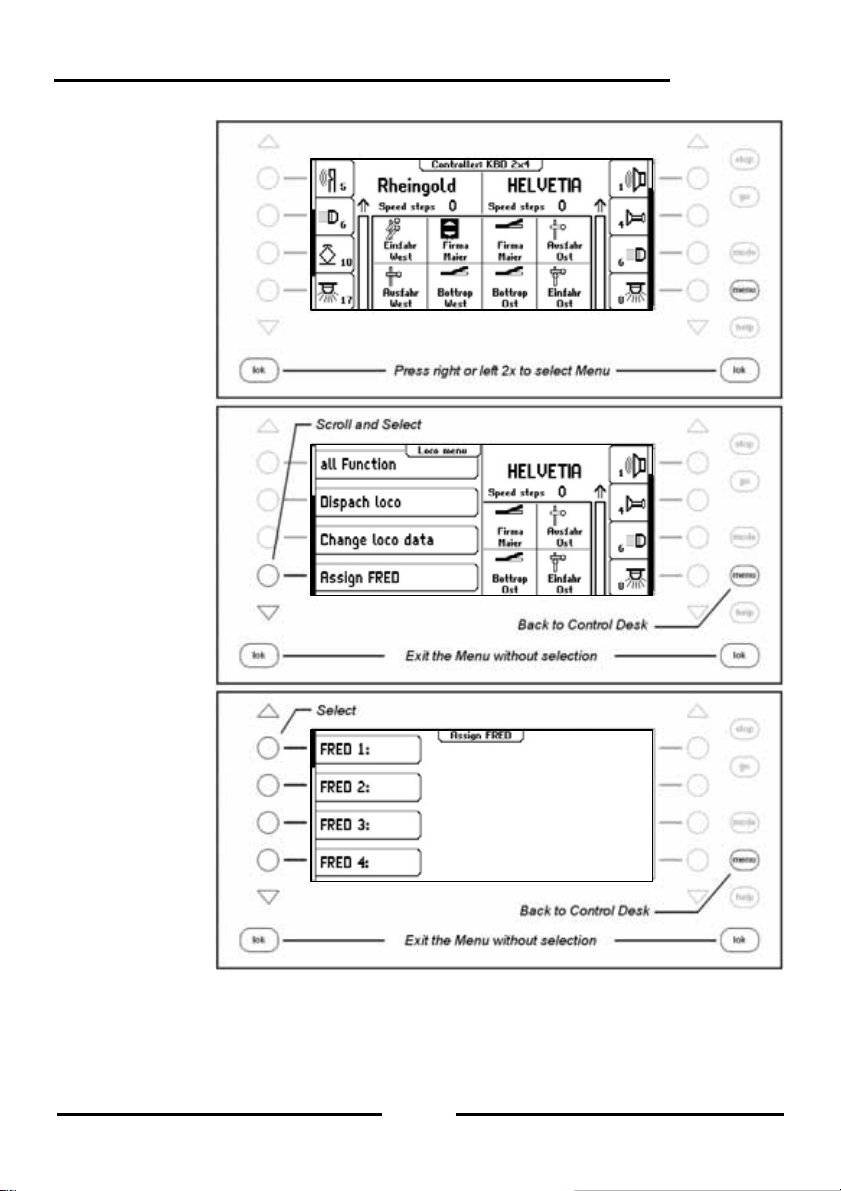

5.6.4 Dispatching Locomotives

If a vehicle that is being controlled by an Intellibox II controll er is to be taken over by a

controller which does not have the capability of entering the locomotive address (e.g.

FRED hand controller from Uhlenbrock, BT-2 hand controll er from Digitrax) the locomotive

address must be placed into the dispatch buffer. After that the Hand cont rollers without an

address input can take over the address. The manual for the particular Hand controller will

describe the key combination is used to take over the address from the Intellibox II, after it

has been “dispatched”.

Procedure:

Step 1

55

Page 56

Intellibox II

Step 2

Step 3

The locomotive (here the “Rheingold”) is no w in the dispatch buffer and can be taken b y a

Hand Controller.

Note: The key sequence [lok] – [C] – [lok] likewise dispatches a locomotive (no Multitraction locomotives).

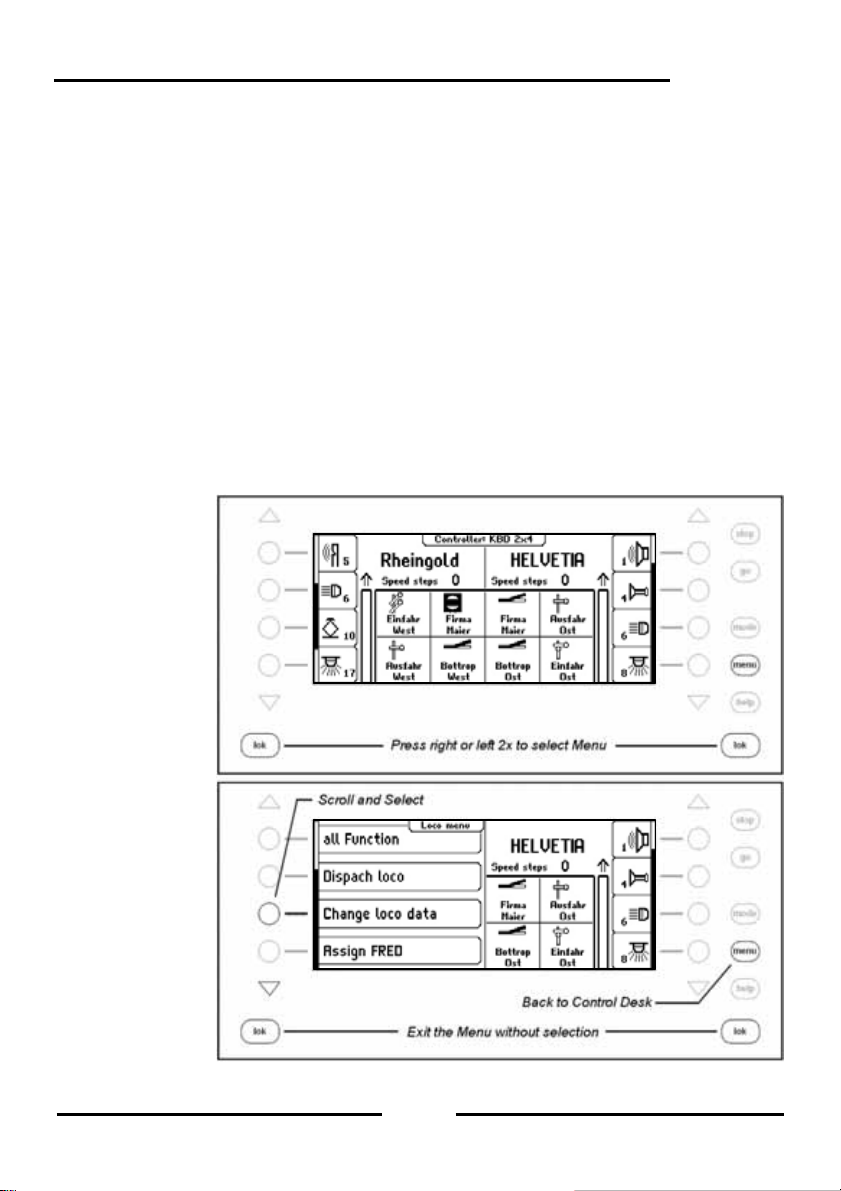

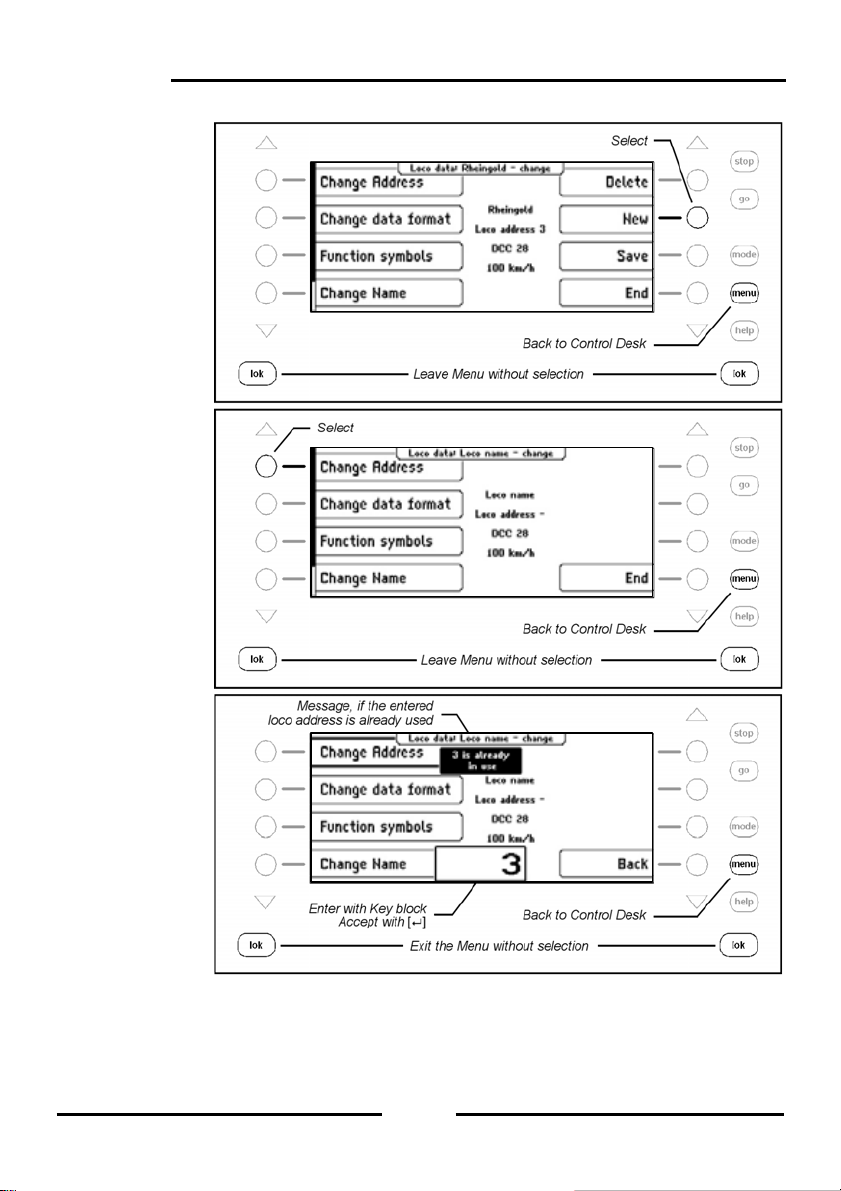

5.6.5 Edit a Loco dataset

Every locomotive in the Intellibox II has an associated dataset. This can have the foll owing

entries:

Change Address

Should a vehicle receive a new address with a new deco der it is simp le th e quickly change

the address without having to discard the dataset or enter a new one.

Set Data format

Every new decoder is firstly addressed by the general dat a format selected in the Basic

Settings (Setting see Chapter 4.3). If desired however each locomotive address can be

assigned its individual data format.

56

Page 57

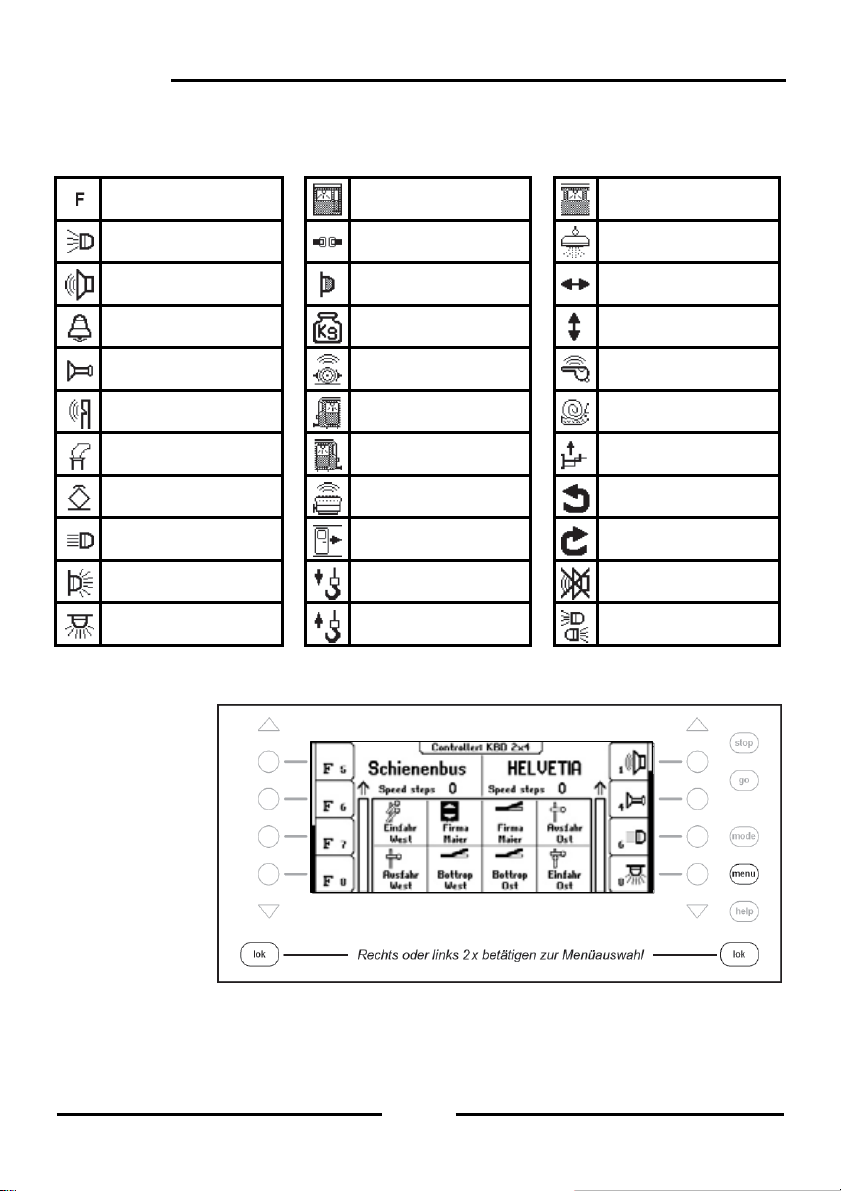

Assign Symbols to Functions

The list of special functions in the display can have a maximum of 28 entries (for som e

DCC decoders). The standard indication “F” for function can be replaced b y a symbol that

represents the particular function for a better oversight. For non-assigned special functions

the display can be hidden.

Assign a Name

A name can be assigned to every locomotive address. As soon as a name is assigned for

a locomotive it is shown in the display in place of the address. Both the name and the

address are used in the Loco selection menu for the throttle controls.

Define Maximum Speed

To display a vehicle speed in km/h at the top speed of the individual locomotive ad dresses

must be entered in the Locomotive database.

The top speed is shown when a locomotive runs at the top speed step.

The speed display of the intermediate speed steps are calculated in proportion.

Procedure:

Enter a new Loco dataset

Step 1

Step 2

Intellibox II

57

Page 58

Intellibox II

Step 3

Step 4

Step 5

58

Page 59

Step 6

Step 7

Step 8

Intellibox II

59

Page 60