Page 1

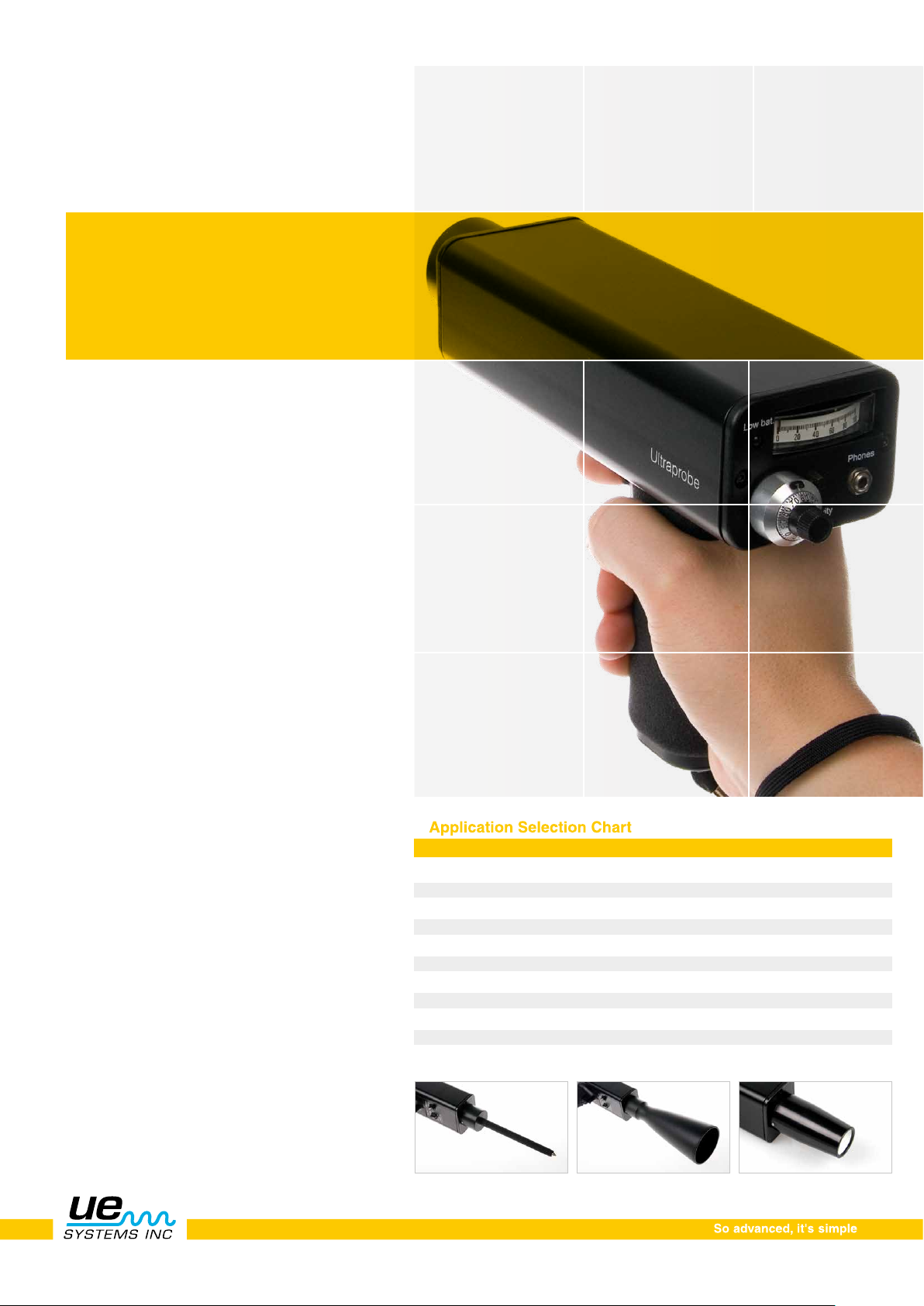

ULTRAPROBE® 2000

The ultimate analog ultrasonic inspection

The Ultraprobe® 2000 flexibility and

adaptability easily adjusts to meet a wide

range of testing demands. This intrinsically

safe instrument tests for leaks as well as

performs mechanical and electrical

inspections.

Flexible / Adaptable Recognizing that every test

environment is different, our engineers designed

the Ultraprobe with many user-friendly features,

which can be adapted to approach virtually any

inspection requirement.

Frequency Tuning allows the operator to select the

specific frequency of a problem sound while reducing interference from competing ultrasonic signals.

system for predictive maintenance

Bi-Modal Meter Switch has two meter functions:

1) Logarithmic Metering will provide instant ‘real time’

re-sponse for enhanced leak and fault detection.

2) Linear Mode provides a slow, averaging

response to stabilize readings for bearing and

mechanical monitoring.

A 10-turn Sensitivity Adjust Dial

provides a wide dynamic sensitivity range.

Trisonic

a patented transducer, consists of a phased array

of three transducers, which provides a level of

sensitivity beyond anything previously obtainable.

Acoustic Headphones:

• Noise isolating type for loud environments.

Intrinsically Safe:

• FM, CSA, ATEX rated

™

Scanning Module

APPLICATION KIT # UP20 00KT UP2000SC UP200 0C UP2000S

Pressure & Vacuum Leak Detection

Hydraulic Valve Bypass

Exhaust System Leaks

Heat Exchangers, Boilers, Condensers

Valve & Steam Trap Inspection

Bearing Testing

Gear/Gear Box Inspection

Cockpit Window/Hatch Leaks

General Mechanical Inspection

Tanks, Pipes, Leak Testing, etc.

Electrical Inspection

Stethoscope module Long range module Close focus module

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 2

Kit includes:

• Frequency Selection

(20 kHz – 100 kHz)

• Precision edgewise meter

• 3-way meter/auxiliary mode selector

• Numerically calibrated 10-turn

sensitivity dial

• Rechargeable battery with

lowlevel indicator light

• Anodized aluminum housing

• Trisonic™ Scanning Module

• Stethoscope/Contact Module

• Stethoscope Extension Kit

• Rubber Focusing Probe

• Warble Tone Generator

• Deluxe noise isolating headset

• Zero Halliburton aluminium

carrying case

• Instruction Manual and

Multimedia Training

Ultrasonic CD Training Series

is Included

This professionally produced series was

shot in actual plant environments enabling

you to see, hear and experience realistic

test examples along with practical solu-

tions. The training series is applicable for

all levels of ultrasonic testing experience

and is arranged in an organized format.

You’ll be taken step by step through each

application. The following sections are

included in the CD's:

Ultraprobe

Construction

Circuitry

Frequency

Response

Probes

Transmitter

Headset

Indicators

Battery

Features

Overall Size

Sensitivity

Threshold*

Warranty

Display Modes

®

2000 Specifications

Hand-held metered pistol type made with aluminum

and ABS plastic

Solid State heterodyne receiver with temperature compensation

Frequency Detect ultrasonic frequencies between 20 kHz and

100 kHz, continuously variable

Frequencies are converted to 50 kHz to 3 kHz audio

Scanning Module patented Trisonic plug-in type consisting of

a phased array of multiple transducers for airborne ultrasound.

This probe is shielded against RF interference.

Rubber Focusing Probe (flexible) slips over scanning module

to concentrate conical directivity and to shield reception of stray

ultrasound. Also fits over Stethoscope Module to shield against

high ambient ultrasound while unit isat maximum sensitivity.

Stethoscope Module – plug-in type, insulated probe with

RF shielding; 11.4 cm (4 1/2”) long stainless steel probe tip,

conically shaped for uniform surface contact. Stethoscope

Extension Kit: 3-piece, segmented metal rods to increase

stethoscope contact range for 50.8 cm (20”) and 76.2 cm (31”).

Patented warble tone transmission

Noise isolating type: Double headset wired monophonic.

Impedance16 ohms. Over 23 dB of noise attenuation.

Meets or exceeds ANSI specifications and OSHA standards.

For hard hat use.

Ballistic output meter; linear calibration scale of 0-100 for logging

relative measurements. Meter is accurate 1% throughout entire

scale. Low Level Battery LED indicator for main housing internal

power supply.

Self contained NiMH rechargeable.

RECHARGING SYSTEM: Standard 110V. Also available in 220V.

Frequency Tuning Adjustment Dial: 20-100 kHz with

"fixed band" position for ultra-narrow frequency response.

Bi-Modal Meter Switch

for logarithmic and linear meter scale adjustments.

Optional Auxiliary Mode

selection for chart recorder output: 0-50 mV.

Sensitivity Control – Precision 10-turn adjustment dial

with numerically calibrated sensitivity increments for finite

gain adjustment.

Spring loaded trigger switch

Complete kit in Zero Halliburton aluminum carrying case:

47 x 37 x 17 cm (18.5” x 14.5” x 6.5”)

Pistol unit: 0.9 kg (2 lbs.)

Complete carrying case: 6.4 kg (14 lbs.)

Detects 0.127 mm (0.005") diameter leak @ 0.34 bar (5 psi)

at a distance of 15.24 m (50 ft.)

–2

1 x 10

1-year parts/labor standard,

5 years with completed warranty registration card.

Logaritmic and linear

*depends on leak configuration

**specify Ex rating if needed at time of order

std. cc/sec to 1 x 10–3 std. cc/sec

• Introduction to Airborne Ultrasound

• Review of each Ultraprobe Feature

• Overview of the Specific Application

(Leak Detection, Mechanical and

Bearing Inspection, Heat Exchangers,

Boilers & Condensers, Steam Traps

& Valves, Electrical Inspection)

• Demonstration of Testing Techniques

• Problem Solving Techniques

©UE Systems, Inc. Made in U.S.A.

Ultraprobe 2000 Kit: Meets and exceeds ASTM E1002-2005 requirements for Leak Detection. Government Codes NSN: 6635-01-156-3927, FSCM (CAGE) Code: 59202.

Table of allowance #s: 788, 404, 576, 583, 607. Covered by one or more of the following patents: 0151115; 0303776; 0315199; 1206586; 1297576; 1881263; 2562758;

2689339; 4416145; 4823600; 5955670; 6122966; 6339961; 6341518; 6415645; 6655214; 6707762; 6804992 UE Systems is committed to continual product improvement;

therefore specifications are subject to change without notice. Warranty details are available by request.

**

www.uesystems.com

UE Systems Inc. • 14 Hayes St. • Elmsford, New York • USA 10523

T: +1 914 592 1220 • E: info@uesystems.com • www.uesystems.com

Loading...

Loading...