Page 1

DL489

Commemorative Edition True RMS

Digital Clamp-On Meter

INSTRUCTION MANUAL

ENGLISH

CAT III

600V 600A

600V

CAT III

1000V

CAT II

NCV

μ

V

MAX/

H

z

MIN

PEAK

DL489

T

e

A

m

p

/

A

°

F

°

C

MFD

/

D

u

t

y

True RMS

T1

30V

T2

CATII 1000V

CATIII

600V

MAX

RANGE

INRUSH

TEMP

Zero

DC

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

TABLE OF CONTENTS

FEATURES .............................................................................................3

GENERAL SPECIFICATIONS

IMPORTANT SAFETY WARNINGS

CATEGORY DEFINITIONS

SYMBOLS .............................................................................................5

OVERVIEW

OPERATING INSTRUCTIONS

AC Amps: < 600A – Jaw ......................................................... 7

DC Amps: <600A – Jaw ............................................................8

Non-Contact Voltage ..................................................................8

Zero DC Amps ..............................................................................9

AC/DC Low Amps: <2000µA .......................................................9

Temperature F˚/C˚ ..................................................................... 10

Continuity ..................................................................................10

Resistance: < 60MΩ .................................................................11

Capacitance (MFD).....................................................................11

Diode .........................................................................................12

Min/Max/Peak ...........................................................................12

Voltage: AC 750V / DC 1000V ................................................ 13

Frequency (Hz) / Duty Cycle ......................................................14

Battery Replacement ................................................................14

LRA Inrush ..................................................................................15

Test Lead Notes .........................................................................15

WARRANTY .........................................................................................16

DISPOSAL

CLEANING

STORAGE

..................................................................................... 5 - 7

...........................................................................................16

...........................................................................................16

...........................................................................................16

.............................................................3

............................................ 3 - 4

...................................................................4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

FEATURES

• True RMS

• 600A AC/DC

• 750V AC/1000V DC

• Resistance 60MΩ

• Capacitance 2000µF

• AC/DC microamps 2000µA

• Frequency 99.99kHz

• Dual Temperature Differential

• Non-Contact Voltage

• LRA Inrush

• Data hold

• Min/Max

• Peak hold

• Visible high-voltage alert

• Manual ranging option

• Worklight/ back lit display

• Low battery indicator

• Auto power off

• Magnetic mount

• Dual display

• Input jack locks

• Detachable clamp head

GENERAL SPECIFICATIONS

• Operating Temperature: 32˚ to 122˚F (0˚ to 50˚C)

• Storage Temperature -4˚F to 140˚F (-20˚ to 60˚C)

• Operating Humidity: <80%

• Operating Altitude: 6,562 ft (2,000m)

• Pollution Degree: 2

• Display: 3 5/6 digits, 6,000 count

• Refresh Rate: 3/sec

• Over-range: “OL” is displayed

• Dimensions: 10.2” X 2.5” X 1.5”

• Item Weight: 1 lb.

• Calibration: Recommended annually

• CAT Rating: CAT III 600V/CAT II 1000V

• Certifications: cETLus 3rd Edition, CE Conformity, IEC 61010-1 3rd Edition,

IP42, 6’ Drop Protetion, RoHS,

• Battery Type: (AAA) X 6

• Test Leads: Test leads w/alligator clips CATIV 600V/CATII 1000V

IMPORTANT SAFETY WARNINGS

WARNING

Read entire Safety Notes section regarding potential hazard and proper

instructions before using this meter. In this manual the word “WARNING” is

used to indicate conditions or actions that may pose physical hazards to the

user. The word “CAUTION” is used to indicate conditions or actions that may

damage this instrument.

WARNING

To ensure safe operation and service of the tester, follow these instructions.

Failure to observe these warnings can result in severe injury or death.

WARNING

• Before each use, verify meter operation by measuring a known voltage

or current.

• Never use the meter on a circuit with voltages that exceed the category

based rating of this meter.

• Do not use this meter during electrical storms or in wet weather.

• Do not use the meter or test leads if they appear damaged.

• Ensure meter leads are fully seated and keep fingers away from the

metal probe contact when making measurements. Always grip the leads

behind the finger guards molded into the probe.

• Do not open the meter to replace batteries while the probes are

connected.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

IMPORTANT SAFETY WARNINGS (CONT.)

• Use caution when working with voltages above 60V DC or 25V AC RMS.

Such voltages pose shock hazards.

• To avoid false readings that can lead to electrical shock, replace

batteries if a low battery indicator appears.

• Unless measuring voltage or current, shut off and lockout power before

measuring resistance or capacitance.

• Always adhere to national and local safety codes. Use proper personal

protective equipment (PPE) to prevent shock and arc blast injury where

hazardous live conductors are exposed.

• Always turn off power to a circuit or assembly under test before cutting,

unsoldering or breaking the current path. Even small amounts of current

can be dangerous.

• Always disconnect the live test lead before disconnecting the common

test lead from the circuit.

• In the event of electrical shock, ALWAYS bring the victim to the

emergency room for evaluation, regardless of victim’s apparent recovery.

Electrical shock can cause unstable heart rhythms that may need

medical attention.

• If any of the following occurs during testing, turn off the power source to

the circuit being tested: arcing, flame, smoke, extreme heat, smell of

burning materials or discoloration melting of components.

WARNING

Higher voltages and currents require greater awareness of physical safety

hazards. Before connecting the test leads, turn off power to the circuit under

test, set meter to the desired function and range, connect the test leads to

the meter first, then connect to the circuit under test. Reapply power. If an

erroneous reading is observed, disconnect power immediately and recheck all

settings and connections.

WARNING

This meter is designed for trade professionals who are familiar with the

hazards of their trade. Observe all recommended safety procedures that

include proper lock-out utilization and use of personal protective equipment

that includes safety glasses, gloves and flame resistant clothing.

CATEGORY DEFINITIONS

Measurement

Category

II < 10 Circuits connected to mains socket

III < 50 Mains distributions parts of the building

IV > 50 Source of the mains installation in the

Short-Curcuit

(typical) kA

a

outlets and similar points in the MAINS

installation

building

Location in the

building installation

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

SYMBOLS

AC (Alternating current) DC (Direct current)

Negative DC AC/DC Voltage or Current

Auto-ranging

Auto power off Active Non-Contact Voltage

Low Battery Hold/Capture Value

Minimum measured value

displayed

Duty Cycle Hertz/Frequency

Voltage

Ohms/Resistance Diode

Capacitance mode in

nanofarads or microfarads

Degrees Fahrenheit Degrees Celsius

Continuity Mega (x106 or 1,000,000)

Milli (x10-3 or 0.001) Kilo (x103 or 1,000)

Nano (x10-9 or 0.000000001)

Microamps Warning or Caution

Ground Dangerous Levels

Double Insulation

(Protection to Class II)

Overload: Range Exceeded

Maximum measured value

displayed

Amperage

Microfarad

µF

Micro (x10-6 or 0.000001)

Safe for disconnect from

live conductors

OVERVIEW

C

A

600V 600A

NCV

A

μ

V

MAX/

H

z

/

D

MIN

PEAK

DL489

CATII 1000V

B

CAT III

T

e

A

m

p

/

°

F

°

C

MFD

u

t

y

True RMS

T1

30V

T2

CATIII

600V

MAX

TEMP

INRUSH

D

G

J

RANGE

DC

Zero

M

N

O

R

X

Y

S

U

W

Z

S/N

V

5

E

F

H

I

K

L

P

Q

T

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

OVERVIEW (CONT.)

A. Clamp: Measure inductive AC/DC current. Opens to 1.25” (31.7mm).

B. Conductor Alignment Marks: Use to aid the visual alignment of a conductor

when measuring inductive amperage. Greatest accuracy is achieved when the

conductor inside the clamp is centered at the intersection of these marks.

C. Wire Separation Tab/ NCV sensor: Use to isolate an individual wire from a

bundle for testing. NCV sensor detects live voltage.

D. Test Lead Holder: Used for hands-free use of the test probes.

E. Worklight: Lights clamp area in dark work environments.

F. Category Max Indicator: Maximum CAT Rating for clamp jaw.

G. Hand Guide: Used as a point of reference for the operator’s safety.

H. Clamp Lever: Opens and closes current clamp jaw.

NOTE: The clamp uses a high-tension spring to close the jaw. Do not allow

fingers or objects to become pinched in the base as the jaws close.

I. NCV Alert Light: Indicates voltage when in NCV mode and high-voltage alert.

J. Hold/Worklight/ Back light Button:

• Press to hold the reading on the display. Press again to return to live reading.

• Press and hold to turn on Worklight and Back light. Press and hold again to

turn off.

• Worklight and Backlight turn off after 60 seconds.

K. NCV Button: Press and hold for Non-contact voltage detection mode.

L. AC/DC Amps/ Microamps Button:

• Press to enter AC/DC Amps mode; (AC/DC Amps upper display)

• Press again to enter AC/DC Microamps (µA) mode; (AC/DC microamps lower

display),

M. Temperature Button:

• Press to enter temperature mode for T1 (upper temperature input jack).

• Press again to enter temperature mode for T2 (lower temperature input jack).

• Press again to enter temperature differential mode (T1-T2).

• Press and hold to change temperature scale.

N. Range Button:

• Press to toggle to between Auto and Manual Ranging modes. (AT will

appear on display when in Auto Ranging mode).

• Press repeatedly to cycle through manual ranges when in Manual Ranging

mode.

• Press and hold to return to auto ranging mode.

Note: Select range prior to MIN/MAX for best results.

O. Power Button: Press to turn on and off the meter.

P. Min/Max/ Peak Button:

• Press to enter Min/Max mode. Max is the default setting.

• Press repeatedly to cycle through Min/Max captured values.

• Press and hold to return to live readings.

• Press and hold to enter Peak mode.

• Press and hold again to return to live readings.

Q. AC/DC Volts/ Hertz (Hz)/ Duty Cycle Button:

• Press to enter AC Voltage mode.

• Press again to enter DC Voltage mode.

• Press and hold to enter Hertz (Hz)/Duty Cycle modes.

• Press to return to live readings.

R. Continuity/ Resistance/ Capacitance/ Diode Test Button:

• Press to enter Continuity mode.

• Press again to enter Resistance mode.

• Press again to enter Capacitance mode.

• Press again to enter Diode test mode.

• Press again to return to live readings.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

S. DC Zero/ Inrush Button:

RANGE

MAX/

MIN

PEAK

• Press to Zero the DC clamp reading.

• Press and hold to enter LRA Inrush mode (must be in AC amp mode first).

• Press and hold again to return to live readings.

T. Display:

• High contrast dual backlit display.

• Amps (AC/DC) reading will always display on upper display.

U. K-Type Temperature Probe Inputs: T1 (Upper) and T2 (Lower)

V: Input Jack Lock: Switch to use Temperature or Test lead inputs

W. Category Max Indicator: Maximum CAT Rating for input jacks.

• Multifunction Input Port: Used for measuring: AC or DC volts, resistance,

continuity, diode, capacitance, AC or DC amps, AC or DC µA or LRA Inrush.

• Use CATIII test leads or higher

X. Magnetic Mount: For hands-free work.

Y. Battery Cover: Easy access for replacing batteries without breaking

calibration seal.

Z. Serial Number

Apo: Auto power off after 30 minutes of use.

Detachable Clamp Head: Compatible with industry standard meter heads. ADP

will appear on display. Press DC Zero to zero the head reading.

AC Amps: < 600A – Jaw

Single

Conductor

CAT III

600V 600A

Only

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

T2

CATII 1000V

CATIII

600V

MAX

30V

TEMP

• Default = (upper)

• Press x1 = (lower)

• Press x2 = (lower)

µA

µA

• Press and hold = (upper)

• Center wire in guides for best accuracy.

• Opposing currents cancel each other (use line-splitter when necessary).

• Keep hands below guard when measuring high current levels.

• Do not attempt to measure more than 600A AC.

• 45Hz to 400Hz True RMS

• Minimum current for Clamp measurement: 0.3A

Features:

HOLD

Range Resolution Accuracy Overload Protection

60A 0.01A

600A 0.1A

±(2.0% +8 dgts) 600V RMS

Minimum current for Clamp measurement: 0.3A

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

DC Amps: <600A

RANGE

MAX/

MIN

PEAK

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

• Do not attempt to measure more than 600A DC.

Features:

HOLD

Range Resolution Accuracy Overload Protection

60A 0.01A

600A 0.1A

±(2.0% +8 dgts) 600V RMS

Minimum current for Clamp measurement: 0.3A

• Default = (upper)

• Press x1 = (lower)

• Press x2 = (lower)

µA

µA

• Press and hold = (upper)

Non-Contact Voltage

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

NCV Sensor in the tip.

• Press and hold the NCV button and move the tip of the clamp meter near

voltage source.

• Non-Contact Voltage Detection is used to detect power with sensor located

in the tip of the clamp head, indicates positive response with both an

Audible and Visual alert.

• Do not use Non-contact voltage detector to determine if there is current on

the wire. Detection operation could be affected by socket design, insulation

thickness, type or other factors.

• Voltage indictor light may also light when voltage (>AC/DC 30V) is present

on the meter’s input jack or from an external interference such as motors,

flashlights, etc.

On Voltage

Approx. 24V AC

MAX

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Zero DC Amps

RANGE

MAX/

MIN

PEAK

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

• Default = DC Zero

• Press and Hold = LRA Inrush

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

Select DC current.

• Press to zero any offset in Amps DC.

• Used to monitor change from present displayed value.

• Required during DC Amps measurement to establish a zero level.

WARNING

Do not use DC Zero mode at amps greater than 600A DC or 2000µA DC.

AC/DC Low Amps: <2000µA

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

MAX/

MIN

PEAK

DL489

V

H

z

/

D

CATII 1000V

u

t

y

True RMS

T1

30V

T2

CATIII

600V

MAX

C

DC

MFD

Zero

INRUSH

TEMP

• Default = (upper)

• Press x1 = (lower)

• Press x2 = (lower)

µA

µA

• Press and hold = (upper)

WARNING

• Do not attempt to measure more than 2000µA.

Features:

HOLD

Range Resolution Accuracy Overload Protection

600µA 0.1µA

2000µA 1µA

± (1.2% +3 dgts) 600V RMS

True RMS: 45Hz to 400Hz

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

MAX/

MIN

PEAK

Temperature F˚/C˚

T

e

m

p

/

°

F

°

C

MAX/

MIN

PEAK

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

TEMP

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

Range Resolution Accuracy Overload Protection

-328˚F to 999˚F

(-200˚ to 999˚C)

1000˚F to 2462˚F

(1000˚ to 1350˚C)

• Disconnect test lead probes from voltage source and meter.

• Move Input Jack Locks to “TEMP” setting.

• Use K-Type thermocouple temperature probes only.

0.1°F (0.1˚C)

1°F (1˚C)

• Stated accuracy does not account for themocople accuaracy.

Features:

HOLD

• Default = T1

• Press x1 = T2

• Press x2 = T1-T2

• Press and hold =

±(1.0% +3.6˚F)

±(1.0% + 2.0˚C)

30V RMS

Continuity

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

• Buzzer sounds at less than < 40Ω.

WARNING

• Do not measure resistance on a live circuit.

Features:

HOLD

Open Circuit V <1.00V Overload Protection

Threshold Appox. <40Ω 600V RMS

10

• Default =

• Press x1 =

• Press x2 =

• Press x3 =

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Resistance: < 60MΩ

RANGE

MAX/

MIN

PEAK

RANGE

MAX/

MIN

PEAK

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

MAX/

MIN

PEAK

DL489

V

H

z

/

D

u

t

y

True RMS

DC

MFD

Zero

INRUSH

• Default =

• Press x1 =

• Press x2 =

• Press x3 =

Features:

HOLD

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

Range Resolution Accuracy Overload Protection

600Ω 0.1Ω

6kΩ 1Ω

60kΩ 10Ω

600kΩ 100Ω

± (0.8% +3 dgts)

600V RMS

6MΩ 1kΩ

60MΩ 0.01MΩ ± (1.2% +3 dgts)

Capacitance (MFD)

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

MIN

PEAK

DL489

/

D

u

t

y

True RMS

Zero

INRUSH

• Default =

• Press x1 =

• Press x2 =

• Press x3 =

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

Features:

MAX

HOLD

Range Resolution Accuracy Overload Protection

10.00nF

100.0nF

1.000µF

10.00µF

100.0µF

2000µF

0.01nF

0.1nF

0.001µF

0.01µF

0.1µF

1µF

± (3.0% +5 dgts) 600V RMS

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

GOOD DIODE

MAX/

MIN

PEAK

Reverse Bias

Displays "OL"

Forward Bias

Displays approx.

voltage drop

BAD DIODE

600V 600A

NCV

μ

V

MAX/

H

z

MIN

PEAK

DL489

Diode

CAT III

T

e

A

m

p

/

A

°

F

°

C

MFD

/

D

u

t

y

True RMS

T1

30V

T2

CATII 1000V

CATIII

600V

MAX

• Default =

• Press x1 =

• Press x2 =

• Press x3 =

RANGE

DC

Zero

INRUSH

TEMP

Open Diode

Displays "OL"

or

Both directions

• Forward voltage drop if forward biased.

• “O.L.” if reverse biased.

Features:

HOLD

Diode Test

Range Open Circuit V Test Current Overload Protection

3.0V <3.2V DC 0.25mA 600V RMS

'0' Both directions

Min/Max/Peak

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

RANGE

MAX/

MIN

PEAK

Voltage: AC 750V / DC 1000V

CAT III

600V 600A

High

Voltage

Alert

WARNING

• Use CATIII rated test leads or higher.

• Do not attempt to measure more than 750V AC/1000V DC.

• Keep hands below line when measuring high current levels.

• Do not exceed 25 volts AC or DC – RMS at either the common or

multifunction input ports as measured from earth ground.

• Select AC or DC Voltage.

WARNING

• NCV LED will flash and audible alert over 600V AC/DC

• NCV LED will flash without audible alert over 30V AC/DC

Features:

AC Volts (45Hz to 400Hz)

Range Resolution Accuracy Overload Protection

600mV 0.1mV

6V 1mV

60V 10mV

600V 100mV

750V 1.0V

True RMS: 45Hz to 400Hz

HOLD

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MIN

PEAK

DL489

z

/

D

u

t

y

True RMS

MFD

Zero

INRUSH

• Default =

• Press x1 =

• Press and hold =

• Press and hold x1 =

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

± (1.0% +3 dgts) 1000V RMS

DC Volts

Range Resolution Accuracy Overload Protection

600mV 0.1mV

6V 1mV

60V 10mV

± (0.5% +4 dgts)

1000V RMS

600V 1000mV

1000V 1V ±(0.8% +5 dgts)

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

RANGE

MAX/

MIN

PEAK

Frequency (Hz) / Duty Cycle

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

Use CAT III rated leads or higher.

Press the AC/DC volts button to select AC voltage, press and hold the button

for Frequency and Duty Cycle modes.

WARNING

Do not attempt to measure more than 750V AC/1000V DC.

Features:

HOLD

Frequency

Range Resolution Accuracy Overload Protection

99.99Hz 0.01Hz

999.9Hz 0.1Hz

9.999kHz 1Hz

± (0.1% +3 dgts) 600V RMS

99.99kHz 10Hz

Duty Cycle

Range Resolution Accuracy Overload Protection

1.0 to 99.0% 0.1%

±(0.2% per kHz +

0.1% + 5dgts)

Frequency Sensitivity: 1.8Vrms

• Default =

• Press x1 =

• Press and hold =

• Press and hold x1 =

600V RMS

Battery Replacement

• When the batteries are too low for safe

operation, the Low Battery indicator will display

• Remove the scews from the battery cover.

Remove battery cover.

• Replace the old batteries with 6 new (AAA)

batteries.

• Replace the battery cover.

• Replace the screws.

S/N

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

LRA Inrush

4mm

CATIV

600V

CAT III

600V 600A

T

e

A

m

p

RANGE

NCV

/

A

°

μ

F

°

C

V

MAX/

H

DC

MFD

z

/

D

MIN

Zero

u

t

y

INRUSH

PEAK

DL489

True RMS

• Default = DC Zero

T1

30V

T2

TEMP

CATII 1000V

CATIII

600V

MAX

• Press and hold = LRA Inrush

The UEi LRA Inrush is programmed to properly capture the starting current for

compressor motors.

• Select AC Amps.

• Select the range capable of capturing the maximum value.

• Press and hold the DC Zero/ LRA Inrush button – INRUSH will now be shown

on the screen.

• Activate the compressor and read value on the display.

• Press and hold the DC Zero/ LRA Inrush button to return to live readings.

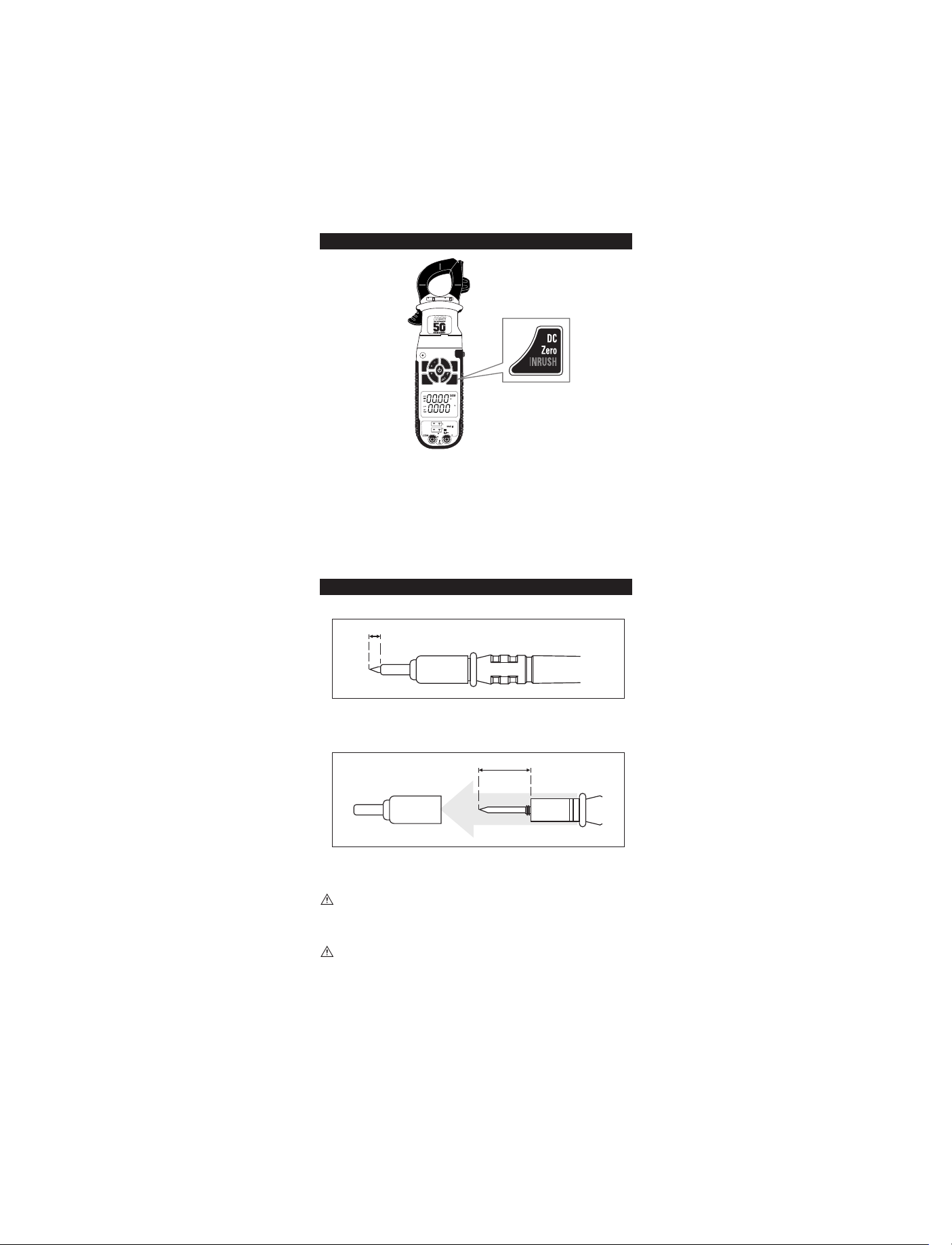

Test Lead Notes

Cat IV and CAT III Measurement Locations

4mm

CATIV

600V

• Ensure the test lead shield is pressed firmly in place. Failure to use the CAT

IV shield increases arc-flash risk.

CAT II Measurement Locations

18mm

CATIV

600V

CATII

1000V

• CAT IV shields may be removed for CAT II locations. This will allow testing

on recessed conductors such as standard wall outlets. Take care not to lose

the shields.

WARNING: Test Lead category protections apply only to test leads and

should not be confused with the meter’s specific CAT rating. Observe the

maximum category protection indicated on the meter the test leads are

plugged into.

CAUTION: If the test leads need to be replaced, you must use a new one

which should meet EN 61010-031 standard, rated CATIII 1000V or better.

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...