Page 1

C165+

Residential/Commercial Combustion Analyzer

INSTRUCTION MANUAL

ENGLISH

BACKED BY

10

C

o

m

CO/CO2

C165+

b

u

s

t

O2/EFF

AUX

STATUS

LINK

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

TEMP/PRS

EXCH TEST

ROOM CO

v3

S

R

P

P

M

E

T

2

O

C

O

C

r

e

z

y

l

a

n

i

A

o

n

8

Page 2

TABLE OF CONTENTS

Functions .............................................2

Features ..............................................2

General Specifications ................................3

Important Safety Warnings ............................3

Symbols ..............................................4

Analyzer Overview ..................................4-5

Overview

Pre Test Checklist

Setting Inlet Temperature

Analyzer Connections

Emptying & Cleaning the In-Line Water Trap

Changing The Particle Filter

Quick Start

Fresh Air Purge

CO Over-range Protection Pump

Measuring Flue Gases

Using The Menu

Combustion Test

- Optional Nitric Oxide Sensor

Heat Exchange Integrity Test

Room CO Test

Printing

Printouts

iOS App Guide

Kane Wireless Printer App Home iOS Screen ............15

Kane Wireless Printer App Settings Screen .............15

Android App Guide

Kane Wireless Printer App iOS Settings Screen ..........16

Kane Wireless Printer App Android Settings Screen ......16

Kane Wireless Printer App Android Personal

Details Screen .....................................16

Temperature Testing

...........................................6

...................................7

...........................7

...............................7

........7

.........................7

..........................................7

......................................8

.....................8

...............................8

..................................9-11

.................................11-12

.....................11

.......................12

......................................12

............................................14

...........................................14

.....................................15

.................................16

...............................17

Temperature/Pressure Testing

Pressure Measurement Good Practice

Large Bore Tubing Issues

Analyzer Specification

Certification

Electromagnetic Compatibility

Where To Test

What Results Are Generally Acceptable

Powering Off

Post Test

General Maintenance

Cold Weather Precautions

Replacing The Batteries

Annual Recertification

Recertification Services

Returning Your Analyzer

Where To Send Your Analyzer

Other Important Factors Relating To Combustion

Combustion Measurement Terms

Disposal

Storage

End Of Life Disposal

Warranty

........................................19

...................................20-21

.......................................22

...........................................22

............................................26

.............................................26

...........................................26

..........................18-19

..............................22

............................23

.............................23

............................24

................................26

.....................17

..............17

...........................17

......................19

............21

..........................22

............................24

......................24

...................25

...25

• Flue temperature: 32° to 1112°F

• Inlet temperature: Internal/ External sensor 32° to 112°F

• O2: 0 - 21%

• CO: 2000 ppm

• CO2: 0 - 20 %

•

EOS Technology

•

Pre-programmed fuels: Nat Gas, H Oil, Pellets, L Oil, LPG,

Butane, Propane, Town Gas, Coke Gas, Bio Gas, Bio Fuel

•

Memory Positions: 45

•

6 line backlit display

FUNCTIONS

• Efficiency: Nett/Gross 99.9%

• Efficiency: High (calculated) 119.9%

• Excess air: 250%

• CO/CO2 ratio: 0.99%

• Differential pressure

FEATURES

•

High altitude compensation

•

User customizable parameter views

•

Individual report printouts

•

Real-time clock

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

GENERAL SPECIFICATIONS

• Operating Temperature: 32° to 112°F (0° to 45°C)

• Storage Temperature: 0° to 120°F (-18° to 50°C)

• Operating Humidity: 10% to 90% R.H.

• Back light: Yes

• Dimensions: 7.87 x 1.77 x 3.5 inch

• Item Weight: 1.375 lbs

IMPORTANT SAFETY WARNINGS

Read entire Safety Notes section regarding potential hazard and proper instructions before using this analyzer. In this manual the

word “WARNING” is used to indicate conditions or actions that may pose physical hazards to the user. The word “CAUTION” is used to

indicate conditions or actions that may damage this instrument.

WARNING

To ensure safe operation and service of the tester, follow these instructions. Failure to observe these warnings can result in severe

injury or death.

WARNING

• Do not use this analyzer during electrical storms or in wet weather.

• To avoid false readings, charge batteries if a low battery indicator appears.

• Always adhere to national and local safety codes. Use proper personal protective equipment (PPE)

• Calibration: Recommended Annually

• Certification: CE Conformity, RoHS, REACH Compliant,

AHRI 1260 standard, FCC

• Battery Size: Alkaline or NiMH AA 3

• Accuracy: ± (% of reading + # of least significant digits)

WARNING

This analyzer extracts combustion gases that may be toxic in relatively low concentrations. These gases are exhausted from the back

of the analyzer.

This analyzer must only be used in well-ventilated locations by trained and competent persons after due consideration of all

potential hazards.

Users of portable gas detectors are recommended to conduct a “bump” check before relying on the unit to verify an atmosphere is free

from hazard. A ‘bump” test is a means of verifying that an instrument is working within acceptable limits by briefly exposing to a known

gas mixture formulated to change the output of all the sensors present.

NOTE: This is different from a calibration where the instrument is also exposed to a known gas mixture but is allowed to settle to a

steady figure and the reading adjusted to the stated gas concentration of the gas of the test gas.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

SYMBOLS

LINK

Low Battery Degrees Fahrenheit

Degrees Celsius Menu

LINK Pump Off & Pump On

Pump Start Pump Stop

Navigate Down Navigate Up

Enter Key Wireless/Store/Print

ANALYZER OVERVIEW

A. Infrared Printer Port

B. On/ Off (Power) Button

C. 6 Line Backlit Display

• Press any button to turn Back light on.

D. Pump Toggle Button: short press is data hold, long press turns pump on and off

E. UP Button

• Short press to navigate “UP”

F. Wireless/Store/Print Button: short press print, long press store

G. Down Button:

• Short press to navigate “DOWN”

H. ENTER Button: short press works as enter, long press turns on work light

I. Rotary Dial

J. Particle Filter (inside water trap)

K. Water Trap

L. LED Water Trap Indication

M. Protective Rubber Boot with Magnets

N. Serial Number QR Code: (Serial Number viewable under Protective Boot)

O. Sensors Fitted: (label under Protective Boot) Sensors that can be fitted in unit when shipped (CO-H2, CO, CO2, NO, O2)

P. Battery Compartment: (under Protective Boot)

Q. Grip Indentation: Indentation for fingers to grip analyzer

R. Water Trap Drain Plug (Red plug; take caution NOT to damage plug when removing protective boot)

S. Battery Charge USB Adapter Connection

T. Temperature Connections

• Flue Probe Temperature: T1

• Inlet Temperature: T2

U. Flue Gas Inlet Connection

V. Pressure Connections

• Pressure: P1

• Differential Pressure: P2

W. Infrared Printer Port

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

C

o

m

b

u

s

t

i

o

n

A

n

a

l

y

z

e

r

C165+

C

O

C

O

2

T

E

M

P

P

R

S

STATUS

LINK

v3

AUX

O2/EFF

CO/CO2

TEMP/PRS

EXCH TEST

ROOM CO

ANALYZER OVERVIEW (CONT.)

A

B

C

N

UEi TEST INSTRUMENTS

www.ueitest.com

Tel: 1-800-547-5740

Serial No.

D

E

F

G

H

I

J

K

L

M

CO-H

CO

O

Sensors

2

Fitted:

CO

NO

2

O

2

P

Q

R

S

T

Narrow Pin MUST be on the

T2

P2

T1

P1

Right hand side.

U

V

Flue Probe Temperature Plug

(Plugs into T1)

Red Connector

(plugs into Flue

Gas Inlet)

[BOTTOM]

Flue Probe

Gas Inlet Plug

W

[TOP]

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

OVERVIEW

The C165+ Combustion Analyzer measures CO, CO2, differential temperature and differential pressure.

CO2 is set to zero in fresh air automatically after the initial countdown.

It is important that re-zeroing is done in outside fresh air as indoor CO2 levels are affected by human breath.

It calculates oxygen (O2), CO/CO2 ratio, Losses, Combustion Efficiency (Gross, Nett, Gross Condensing, or Nett Condensing).

The C165+ Combustion Analyzer can also measure CO levels in ambient air - useful when a CO Alarm is triggered. It can also perform a Room CO Test

for 30 minute duration.

A low flow detection system warns of low flow and switches the pump off. This also helps to prevent water ingress from overfilled water traps.

The analyzer has a protective rubber boot with magnets for hands-free operation and is supplied with a probe with an integral temperature sensor.

A large 6 line display provides the user with relevant information. All data can be printed via the infrared printer or Wireless Printer App.

The C165+ uses a new data storage system allowing the user to store the maximum number of logs of interest to them, rather than be restricted to

an allowance of particular logs.

The memory can store up to 45 logs of any combination of Combustion, AUX, Temperature, Heat Exchange, Room CO.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

PRE TEST CHECKLIST

T2

T1

P2

P1

• Clean particle filter

• Water trap and probe line are empty of water

• Power on and zero

• All hose and thermocouple connections are properly secured

• Flue gas probe is sampling ambient FRESH air

• Water trap is fitted correctly to the instrument

• Flue temperature plug is connected

• Ensure water trap plug is inserted correctly

SETTING INLET TEMPERATURE

• Turn on and zero the analyzer, without the flue probe connected, to use ambient temperature

• Connect the flue probe thermocouple to T1 during zero countdown use for inlet ducted system

• Connect a thermocouple to T2 to measure second temp source

ANALYZER CONNECTIONS

WARNING

Turning the pump off while the probe is in the flue will leave toxic gases inside the analyzer. Once

data has been printed or copied, it is advisable to purge the unit with fresh air as soon as possible.

To do this remove the probe from the flue and turn ON pump. Always allow the readings to return to

zero (20.9% for O2) prior to shutting the unit off. The meter will not switch off until the CO reading is

below 20 ppm.

CAUTION

The probe will be hot from flue gases. Remove the probe from the flue and allow it to cool naturally.

Do not immerse the probe in water, as this will be drawn into the analyzer and damage the flue

probe and the pump and sensors.

NOTE: Take care when

inserting the temperature

probes as the pins are

polarized. Insert with the

smaller pin (+) to the right.

EMPTYING & CLEANING THE IN-LINE WATER TRAP

• Remove the rubber plug

• Allow the water to drain out

• Re-insert the rubber plug

CHANGING THE PARTICLE FILTER

• Remove the protective rubber boot

• Slide the water trap unit from the analyzer

• Remove the particle filter from its’ spigot and replace

• Slide the water trap back into position and replace the protective rubber boot

QUICK START

Turn on the analyzer by pressing the On/Off Button for 2 seconds until the unit activates. As described the analyzer will perform a 60

second turn on purge. Once completed simply select the reading desired by the position of the rotary dial.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

FRESH AIR PURGE

NOTE

Each time the analyzer is turned on it will perform a 60 second air purge, this is to clear the gas

sampling path (including probe, if connected). For these reasons it is very important that the analyzer

be in outside fresh air when powered on.

CO OVER-RANGE PROTECTION PUMP

The analyzer’s intelligent protection system will automatically activate the protection pump once an over-gas condition is detected

(see specification table for detection limits). When activated the main sampling pump will be shut down, allowing the sample system

to be purged with fresh air. Once readings have returned to a safe level, the protection pump will shut down and the main pump will

reactivate.

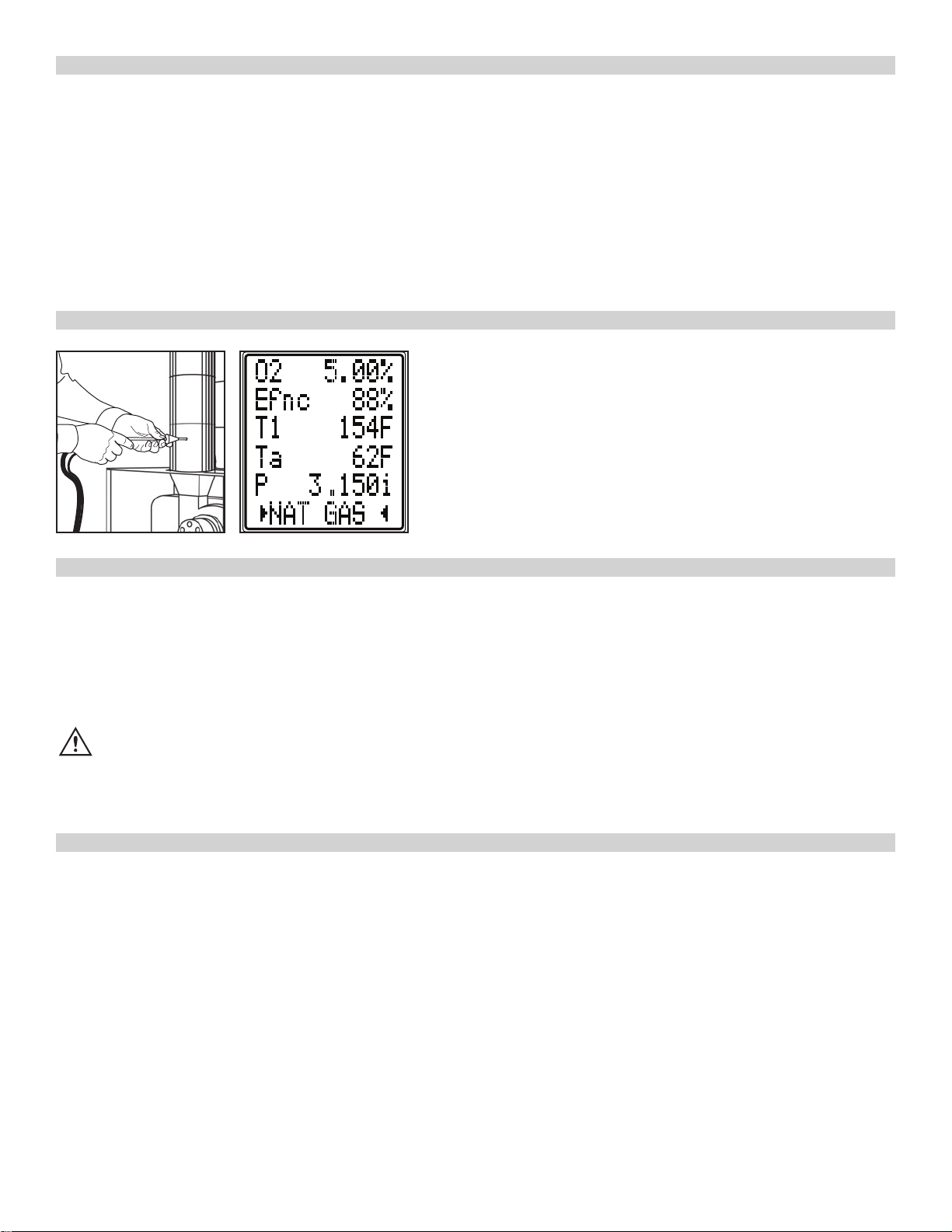

MEASURING FLUE GASES

After the initial countdown is finished and the analyzer is properly setup, put its’ flue probe in the appliance’s sampling point. The tip of

the probe should be at the center of the flue. Use the flue probes depth stop cone to set the position.

With balanced flues, make sure the probe is positioned into the flue so no air can “back flush” into the probe.

CAUTION!: Ensure the flue probe handle does not get hot!

Boiler

Flue

20”

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

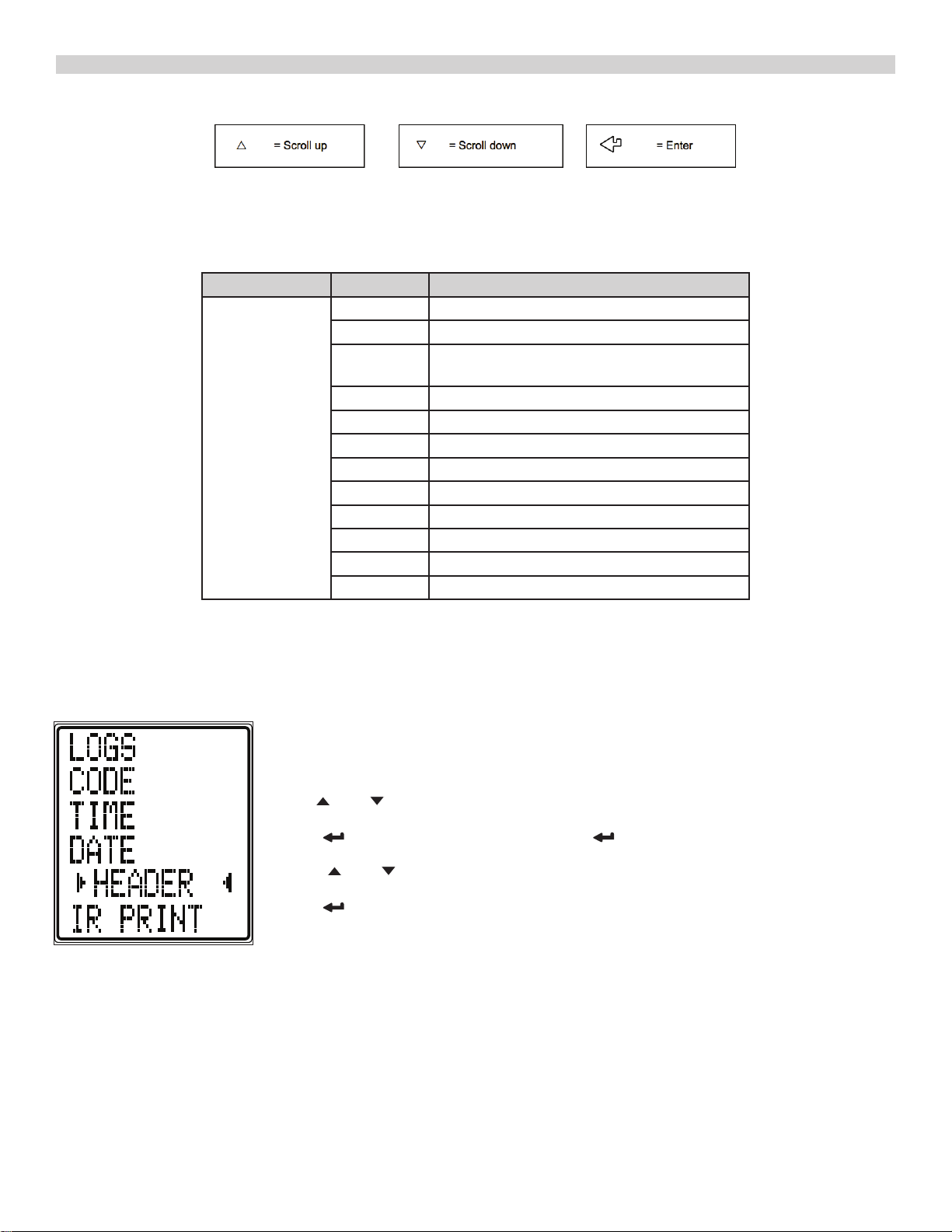

USING THE MENU

Select “Menu” on the rotary switch and navigate using the function buttons:

NOTE: To “EXIT” the “MENU” at any time simply move the rotary switch to any position other than “Menu”. Any changes that have not been

“entered” will be ignored.

MENU SCREEN

MENU OPTIONS/COMMENTS

LOGS VIEW, EXIT, DELETE ALL

CODE 000000 (PASSWORD PROTECTED FOR AUTHORIZED

SERVICE PERSONAL ONLY

TIME HH:MM:SS

DATE MM:DD:YY

HEADER LINE 1, LINE 2, BACK

IR PRINT KMIRP, IRP-2/3

˚C/˚F ˚C or ˚F

GAS UNIT ppm, mg/kWh, mmg/m3

LANGUAGE ENGLISH, FRANCAIS, ESPANOL

EFF GROSS, NETT

O2 REF CO %

The Menu position on the Rotary Dial allows for the customization of the default settings for the analyzer as per the user’s

requirements. Navigation through the Menu system is via the dedicated user’s interface buttons (Up, Down, Enter).

As you navigate up or down through the Menu, the items will scroll accordingly, eventually back to the beginning.

Rotate Selector Dial to MENU to set up or customize your settings.

Selected parameter are centered, highlighted with arrow icons on either side.

Use

Press to a select a parameter to edit. Press button to scroll fields to change.

Press and buttons to change field contents.

Press to enter content selected.

The analyzer will perform a 60 second purge in Rotary Dial setting of AUX, O2/Eff, CO/CO2. This should be done in fresh air.

and buttons to scroll menu options.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

COMBUSTION TESTS

Insert the tip of the flue probe into the center of the flue. The readings will stabilize within 60 seconds assuming the system conditions are stable.

The rotary switch can be used to display the following information:

O2/Eff

Fuel type can be changed via “STATUS” setting.

Carbon Dioxide (%)

Oxygen (%) left after combustion. Should be 20.9% ± 0.3% in fresh air.

Gross efficiency

Flue temperature (°F).

Inlet temperature (°F). Normally set by flue probe during fresh air purge.

Press to print a full combustion test, (or send to Smart Device via optional Wireless module).

Hold

CO/CO2

Fuel type can be changed via “STATUS” setting.

Carbon monoxide (ppm).

COa is CO ambient

Losses calculated

Excess air %

Pressure reading

Press

Hold

AUX display

The AUX (auxiliary) display can be customized via “MENU” / “SCREEN” / “AUX”.

The parameters displayed on lines 1, 2, 3, 4 and 5 can be set by the user.

They remain the AUX parameters until changed by the user.

Press to print a full combustion test, (or send to Smart Device via optional Wireless module).

Hold for 2+ seconds to log a full combustion report.

for 2+ seconds to log a full combustion report.

to print a full combustion test, (or send to Smart Device via optional Wireless module).

for 2+ seconds to log a full combustion report.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

COMBUSTION TEST - OPTIONAL NITRIC OXIDE SENSOR

Instructions for C165+ Analyzers fitted with optional Nitric Oxide (NO) sensors

Displaying the Nitric Oxide (NO) reading

Select “Menu” on the rotary switch and navigate using the function buttons:

Select SCREEN and then select AUX

Choose a line to display the required readings as below

AUX display

The AUX (auxiliary) display can be customized via MENU / SCREEN / AUX.

The parameters displayed on lines 1, 2, 3, 4, 5 and 6 can be set by the user.

They remain the AUX parameters until changed by the user.

NOTE: To EXIT the MENU at any time simply move the rotary switch to any position other than MENU.

Any changes that have not been “entered” will be ignored.

Use and to navigate to the main menu option SCREEN Press .

Use and to navigate to the sub menu option AUX Press .

PRINTING and STORING

The NO readings are printed and stored in the same way as the other combustion gas readings. On the

printouts the NO readings appear directly below the flue CO readings or AUX

The dial needs to be in O2/Eff, CO/CO2 or AUX position to print or store. When the dilution pump is operating to protect the CO sensor the NO readings are also affected by an unspecified amount. The screen

typically will show: ----

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

HEAT EXCHANGE INTEGRITY TEST

There are many methods to test heat exchange integrity. One of these is to observe the Excess Air, O2 and CO readings both before and

after the blower turns on. If the heat exchanger is sealed, your O2 and CO readings should remain fairly stable. A breach in the heat

exchanger may allow fresh air to be forced into the flue after the blower turns on due to pressure increase in the plenum. The result

may be a rise in the measured O2 in the stack gas and an increase in Excess Air. In some sealed systems the fresh air drawn in through

the breach may reduce the combustion air available leading to an increase in the CO reading. If either of these situations are present it

is probable there is a problem with the Heat Exchanger which may require additional testing and inspections.

NOTE: Many cracks are invisible to borescopes or the naked eye, and only open or separate from pressure or temperature changes

during operations. Rotate dial to “EXCH TEST” Rotate test selector to “EXCH TEST”. Call for heat on the system. Observe and wait for

O2 readings to stabilize.

No probes or hose connections are required for this test.

Rotate selector dial to Room CO

Press Enter Button to select GENERAL test type

CO readings will be logged every minute for 30 minutes.

Readings will be saved once the 30 minute test is completed.

Test results and LOG number will be displayed.

Press Print Button to Print the test results.

This LOG will be saved in the LOGS/ROOM CO MENU screen.

ROOM CO TEST

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

PRINTING

Rotate selector Dial to Menu Position.

Use or Arrow Buttons to select Printer.

Press button.

Use or Arrow Buttons to select Printer type (KMIRP, IRP-2/3)

Wireless Printer App

Please see pages 15 and 16

To Go to LINK setting on Rotary Dial

Use Up or Down arrows

Select App to print

[IRP2] [KMIRP2]

PRINTOUTS

O2/Eff CO/CO2 AUX PRS/TEMP HEAT EXCHANGE

07/15/21

07/15/21

07/15/21 07/15/21

07/15/21

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

WPC2 DTHA2

PRINTOUTS (CONT.)

07/15/21

07/15/21

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Printer

12:00 PM

100%

12:00 PM

100%

ANALYSER TYPE

Select the analyser model you’re

connecting to.

Select Analyser

TEXT CAPTURE STYLE

Select what test processing style

you’d like to use.

YOUR NAME

Provide your name to use for

correspondence from the App...

Your Name

YOUR COMPANY NAME

Provide your Company name for

correspondence from the App...

Your Company

Printer

Settings

Print out

Connect to Analyser

iOS APP GUIDE

Install the App

• Free download from Apple® App store

• Search for “Kane Wireless Printer” and install

Upon opening App the first time, it will ask you a series of questions:

• Allow access to device location (GPS)

• Allow access to contacts (for emailing)

Kane Wireless Printer App Home iOS Screen

Pairing the Kane Wireless Printer app with your Analyzer

Turn on your analyzer allowing a complete startup

In the App Press PRINTOUT

Select CONNECT TO ANALYZER

• Your Analyzer’s serial number, proceeded by a “K”, should appear

• Select your analyzer to pair

Kane Wireless Printer App Settings Screen

Print to App from Analyzer

• When testing in the AUX, O2/Eff, CO/CO2, PRS/TEMP, HEAT EXCH screen

• Press FILE (Wireless) Button to enter print menu

• Scroll ARROW Button to select Wireless

• Press Button to print to App

To Disconnect an analyzer

• Select disconnect from Printout screen

Adding Notes & Emailing from the Kane Wireless Printer App

In PRINTOUT screen, Select EMAIL PRINTOUT

• A message window will open

• Enter email address

• Add message/notes to Printout

• Send message

Select CLEAR CONSOLE to delete a Printout

• Press to Confirm deletion

To print Saved LOGS from Analyzer to App

To print Saved LOGS from Analyzer to App

• Rotate Selector dial to MENU

• Press or Arrow Buttons to select LOGS. Press Button

• In the LOGS screen. Press Button to VIEW.

• Press or Arrow Buttons to select LOGS VIEW you want. Press Button

Email Printout

Clear Console

Find Quality Products Online at: sales@GlobalTestSupply.com

15

www.GlobalTestSupply.com

Page 16

24%

12:00 Provider

KANE Wireless Printer

24%

12:00 Provider

24%

12:00 Provider

Connected to AUTOplus 051717..

AUTOplus V1 . 08

SERIAL No. 051717568

YOUR COMPANY NAME &

PHONE NUMBER HERE

DATE

TIME

Enable NightMode function

11/04/18

09:19:52

SW No.: 19086

SW ver: 1.4.5

ANDROID APP GUIDE

Installing the App

• Free download from Google Play

• Search for “Kane Wireless Printer” and install

Upon opening App the first time, it will ask you a series of questions:

• Allow access to device location (GPS)

• Allow access to contacts (for emailing)

Kane Wireless Printer App Home Android Screen

Start up

• Press the Menu icon in top left of screen

• Press Settings

A. Select “Your Name”, enter name and Press “OK”

B. Select “Your Company Name”, enter name and Press “OK”

C. Select “Analyser Type” select “Other Kane Analyser”

Kane Wireless Printer App Android Settings Screen

Pairing the Kane Wireless Printer app with your Analyzer

• Turn on your analyzer and allow it to complete its startup

• Touch the Kane Wireless Printer banner of the home page

• From the “Pick a device” screen, touch “Scan For Devices” at the bottom of the page

• Your Analyzer’s serial number, proceeded by a “K”, appears of the list. Select it to pair

Settings

Help

Feedback

Share this app

Visit Kane

on YouTube

on Twitter

on Facebook

Personal Details

Your Name

Provide your name to automatically use in correspondence

Your Company Name

Provide your company name to automatically use in

correspondence

Application Settings

Analyser Type

Select the analyser model you’re connecting to

Printout Font Scaling

Change the font scale so your printout fits better on-screen

Print to App from Analyzer

• When testing in AUX, O2/Eff, CO/CO2, PRS/TEMP, HEAT EXCH screen

• Press FILE (Wireless) Button to enter print menu

• Scroll Arrow Button to select Wireless

• Press Button to print to App

To Disconnect an analyzer

• Select disconnect from Printout screen

Adding Notes & Emailing from the Kane Wireless Printer App

-After a report is on the app, Press the Pen icon on the top right of the app screen.

• Press “Write your note here” and you can type your notes for the report. Press “OK”

icon when done and it will save the note under the report.

• Press the “3 vertical dots” icon on the right side of the screen

• From that drop-down menu, Press “Email” icon

• Find and select your email app from the list. The email app will open to a new message and

your report will be attached

Kane Wireless Printer App Android Personal Details Screen

To print Saved LOGS from Analyzer to App

• Rotate Selector dial to MENU

• Press or Arrow Buttons to select LOGS. Press Button

• In the LOGS screen. Press Button to VIEW.

• Press or Arrow Buttons to select LOGS VIEW you want. Press Button

GPS Tagging

Tag printouts with gps location

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

PRESSURE/TEMPERATURE TESTING

Select the Temperature Rotary Dial position.

Use the T1 connection for the Flue Probe temperature sensor

Use the T2 connection for the Inlet temperature sensor

Real time temperature difference

Real time pressure reading

WARNING

NEVER ATTEMPT TO TAKE A PRESSURE READING WITHOUT KNOWING THE MAXIMUM PRESSURE THAT MIGHT BE PRESENT. THIS

INSTRUMENT’S PRESSURE TRANSDUCER IS RATED AT 1.1 PSI WITH A MAXIMUM OVER RANGE OF 5.8 PSI.

Select “TEMP/PRS”. The pump stops automatically. Using the black connectors and manometer hose, connect to P1 for single

pressure or P1 and P2 for differential pressure.

Pressure units can be selected via “MENU”.

Eg Flow Temp

Eg Return Temp

Differential Temp

Press

Hold

WARNING

Before using the UEi C165+ to measure the pressure of a gas/air ratio valve, read the manufacturer’s manual thoroughly. If in doubt,

contact the manufuctuer.

After adjusting a gas/air ratio valve, it is essential the CO, CO2 are within the manufacturer’s specified limits.

If using larger bore tubing when performing pressure tests:

Push tubing over the rim of the This may not produce a gas tight seal.

spigot to ensure a gas tight seal.

to print a full pressure test, (or send to Smart Device via optional Wireless module).

for 2+ seconds to log a pressure report.

PRESSURE MEASUREMENT GOOD PRACTICE

LARGE BORE TUBING ISSUES

Connecting WPC2 or DTHA2 to FGA

Select Menu option with Rotary Dial in LINK position

Options are APP or LINK

In LINK option

Press ENTER button to select choice

ADD, REMOVE, STATUS, BACK use Up or Down arrow button to

select option

Select a device (WPC2, DTHA2) use Up or Down arrow button to

select device

Enter WPC2 or DTHA2 serial number

Serial Number if more than 10

digits, use only last 10 digits

Serial Number if less than 10

digits add 000 (i.e., 0002001228)

All WPC2 serial number start

with 01AF2

NOTE: WPC2 will require

adding serial number for each

clamp

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

17

Page 18

ANALYZER SPECIFICATIONS

PARAMETER RANGE RESOLUTION ACCURACY

Temp Measurement

Flue Temperature

Inlet Temperature

(Internal sensor)

Inlet Temperature

(External sensor)

Flue Gas Measurement

2

*

Oxygen

Carbon monoxide

Carbon dioxide

Efficiency (Net or Gross)

Efficiency High (C)

Excess Air

*

CO/CO2 ratio

1

*

1

*

2

2

*

2

*

2

*

32°-1112°F

32°-122°F

32°-1112°F

0-21%

0 to 2000ppm

2000 to 9999ppm

Above 9999ppm

Purge pump

operates

0-20%

0-99.9%

0-119.9%

0-250%

0-0.999

0.1°F

0.1°F

0.1°F

0.1%

1ppm

0.1%

0.1%

0.1%

0.1%

0.0001

±3.6°F

±0.3% reading

±3.6°F

±0.3% reading

±3.6°F

±0.3% reading

±0.3%

±3ppm or ±5% of rdg

±10% of rdg

unspecified

±0.3% volume

±1.0% reading

±1.0% reading

±0.2% reading

±5% reading

Nitric Oxide Sensor

0 to 100ppm

1ppm + 2ppm <30ppm

(optional)

Overrange to 1500ppm

Pressure (differential)

±80mbar 0.1mbar ±0.5% FSD

Pre-programmed Fuels NAT GAS, H OIL, PELLLETS,OIL, LPG, BUTANE, PROPANE

User programmed Fuels 5 user defined fuels

Storage Capacity 45 Total Tests

*1 Using dry gases at STP

*2 Calculated

1

*

1

+5ppm <100ppm

*

+5% reading >100ppm

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

ANALYZER SPECIFICATIONS CONT.

Carbon Dioxide resolution is 0.01% below 1% measured value.

Ambient Operating Range 32° to 113°F (0° to 45°C) 10% to 90% RH

Storage Temperature Range 0° to 120°F (-18° to 50°C)

Battery Type / Life 3 AA cells

>8 hours using Alkaline AA cells

Chargers (optional) 100-240v charger, for NiMH batteries only

Dimensions

Probe: 7.87 x 1.77 x 3.5 in (200 x 45 x 90mm)

11.8 in (300mm) long including handle.

2.3 dia. x 9.4 in (6mm dia. x 240mm) long stainless-steel shaft with 6.5ft

(2m) long neoprene hose. Type K thermocouple

CO Protection Pump: Operates at 2000ppm measured CO.

The C165+ is in conformity with the relevant Union harmonization legislation listed below:

Directive Title

201430EU Electromagnectic Capability

201165EU Restriction of use of certain hazardous substances in electrical

and electronic equipment (RoHS)

The following harmonized standards and technical specifications have been applied:

CERTIFICATION

The UEi C165+ is TUV-tested and certified to EN 50379, Parts 1, 2 & 3 in accordance to 1st German Federal Emission Control Ordinance

(BlmSchV)

EMC

EN507270:2015

Safety

EN61010-1:2010

RoHS

IEC62321-2:2013, IEC62321-1:2013; IEC62321-3-1;2013, IEC63321-5:2013, IEC623321-4:2013, IEC62321-7-2:2017, IEC62321-7-1:2015,

IEC62321-6:2015, AHRI 1260

FCC

ELECTROMAGNETIC COMPATIBILITY

European Council Directive 89/336/EEC requires electronic equipment not to generate electromagnetic disturbances exceeding defined levels and

have adequate immunity levels for normal operation. Specific standards applicable to this analyzer are stated below.

As there are electrical products in use pre-dating this Directive, they may emit excess electromagnetic radiation levels and, occasionally, it may be

appropriate to check the analyzer before use by:

Use the normal start up sequence in the location where the analyzer will be used.

Switch on all localized electrical equipment capable of causing interference.

Check all readings are as expected. A level of disturbance is acceptable.

If not acceptable, adjust the analyzer’s position to minimize interference or switch off, if possible, the offending equipment during your test.

At the time of writing this manual (November 2020) UEi Test Instruments is not aware of any field-based situation where such interference has

occurred, and this advice is only given to satisfy the requirements of the Directive. This product has been tested for compliance with the following

generic standards and is certified to be compliant.

EN 61000-6-3 : 2011

EN 61000-6-1 : 2007

Specification EC/EMC/KI/C165+ details the specific test configuration, performance and conditions of use.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

WHERE TO TEST

Air Conditioning / Heat Pump

Suction Line:

• Temperature

Verify proper:

• Static Duct Pressures

• Temperature Differential

• Static Pressure Drop Across Coils

to condensing unit

Boiler & Water Heaters & High Efficiency Modulating Hot Water Systems

Boiler

Verify proper combustion:

• O

• CO2

• CO Air Free

• Stack Temp

• Stack Draft

2

Water Heater

Draft

Verify proper combustion:

• O

• CO2

• CO

• Stack Temp

• Efficiency

2

HE Boiler Instant Water

Heaters

Draft

Verify proper

combustion:

• O

• CO2

• CO

• Stack Temp

• Efficiency

Hi / Low fire

Gas Pressure

Supply and Return Water temp

2

Furnaces: 80% Furnaces: 90%

80% Furnace

Verify proper combustion:

• O

• CO2

• CO

• Stack Temp

• Vent Pressure

• Efficiency

2

90%+ Furnace

Verify proper combustion:

• O

2

• CO2

• CO

• Stack Temp

• Vent Pressure

• Efficiency

Verify/Set Up

• Gas Pressure

Test

• Limit Switch

• Pressure Switch

Verify proper operation:

• Static Duct Pressure

• Temperature Rise

• AC side Static Pressure

Drop across coils

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Verify/Set Up

• Gas Pressure

Test

• Limit Switch

• Pressure Switch

Verify proper operation:

• Static Duct Pressure

• Temperature Rise

• AC side Static Pressure

Drop across coils

Page 21

WHERE TO TEST (CONT.)

Furnaces (continued): Atmospheric, Gas & Oil

Atmospheric Furnace

Draft

Verify proper

• Temperature Rise

• AC side Static Pressure

Drop across coils

Verify proper combustion:

• O

• CO2

• CO

• Stack Temp

• Efficiency

2

Oil Furnace

Verify proper combustion:

• O

• CO2

• CO

• Stack Temp

• Stack Draft

• Efficiency

2

Natural Gas & Propane

Verify proper combustion:

• O

• CO2

• CO

• Stack Temp

• Vent Pressure

• Efficiency

Test

• Limit Switch

• Pressure Switch

Set Up

• Gas Pressure

Verify proper:

• Static Duct Pressure

• Temperature Rise

• AC side Static Pressure

Drop across coils

2

Test & Verify:

• Smoke

Set Up

• Over Fire Draft

Verify proper

• Static Duct Pressure

• Temperature Rise

• AC side Static Pressure

Drop across coils

WHAT RESULTS ARE GENERALLY ACCEPTABLE

Atmospheric Gas

Fixed Burners

Gas Fired Burners Oil Fired burners

(#2 Oil Fuel)

Positive Overfire Gas

& Oil

Oxygen 7 to 9% O2 3 to 6% O2 4 to 7% O2 3 to 9% O2

Stack temperature 325˚ to 500˚F 275˚ to 500˚F 325˚ to 600˚F

Draft (Water Column Inches) -.02 to -0.4 InWC -.02 to -0.4 InWC -.04 to - 0.6 InWC -.02 to -0.4 InWC

Carbon Monoxide (parts per million) <100 ppm <100 ppm <100 ppm <100 ppm

Overfire Draft (Water Column Inches) -.02 InWC -0.2 InWC 0.4 to 0.6 InWC

Smoke 0 (manufacturer's

recommendation)

NOTE: Follow manufacturer guidelines for the specific equipment being serviced

Typical Excess Air Levels

O2% (measured) Excess Air %

Natural Gas 3% 16.7%

LIGHT Oil 5% 31%

Coal 8% 62%

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

POWERING OFF

When you power off the C165+, there is a 45 second purge when in O2/Eff, CO, CO2, AUX screens.

Make sure you do not exceed the analyzer’s operating specifications. In particular:

• Do not exceed the flue probes maximum temperature (1112˚F)

• Do not exceed the analyzer’s internal temperature range

• Do not put the analyzer on a hot surface

• Do not exceed the water trap’s level

• Do not let the particle filter become dirty and blocked

View the displayed data to ensure that the stable operating conditions have been achieved and the readings are within the expected

range.

POST TEST

Remove the probe from the flue and allow analyzer to purge with fresh air

until readings return to zero. O2 to 20.9%, CO to Zero (Be careful the probe

tip will be HOT).

GENERAL MAINTENANCE

• Re-certify your instrument annually to ensure it meets original performance specification

• Keep your instrument dry, if it gets wet, wipe dry immediately. Liquids can degrade electronic circuits

• Whenever practical, keep the instrument away dust and dirt that cause premature wear

• Although your instrument is built to withstand the rigors of daily use, it can be damaged by severe impacts.

• Use reasonable caution when using and storing this meter

PERIODIC SERVICE

WARNING

Repair and service of this instrument is to be performed by qualified personnel only. Improper repair or service could result in physical

degradation of the instrument. This could alter the protection from personal injury this meter provides to the operator. Perform only those

maintenance tasks that you are qualified to do.

It is important you keep your flue gas analyzer in a warm and dry place overnight

Electronic devices that become really cold, by being left in a vehicle overnight, suffer when taken into a warm room the next

morning. Condensation may form which can affect the analyzer’s performance & cause permanent damage. See operating and storage

temperature specifications.

Electrochemical sensors used in flue gas analyzers can be affected by condensation or water being sucked into the analyzer, as the

small apertures on top of sensors can become blocked with water, stopping sensors seeing flue gas. When this happens, oxygen or

carbon dioxide reading will display as “—” & sensors may be permanently damaged

COLD WEATHER PRECAUTIONS

If you think that your analyzer is affected by condensation or water ingress, it may be possible to rectify the problem yourself. Simply

leave the analyzer running in a warm place, with the pump ‘ON’ sampling fresh air for a few hours (use mains adapter/battery charger if

needed). If, after doing this, you still experience problems please contact our Service Center.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

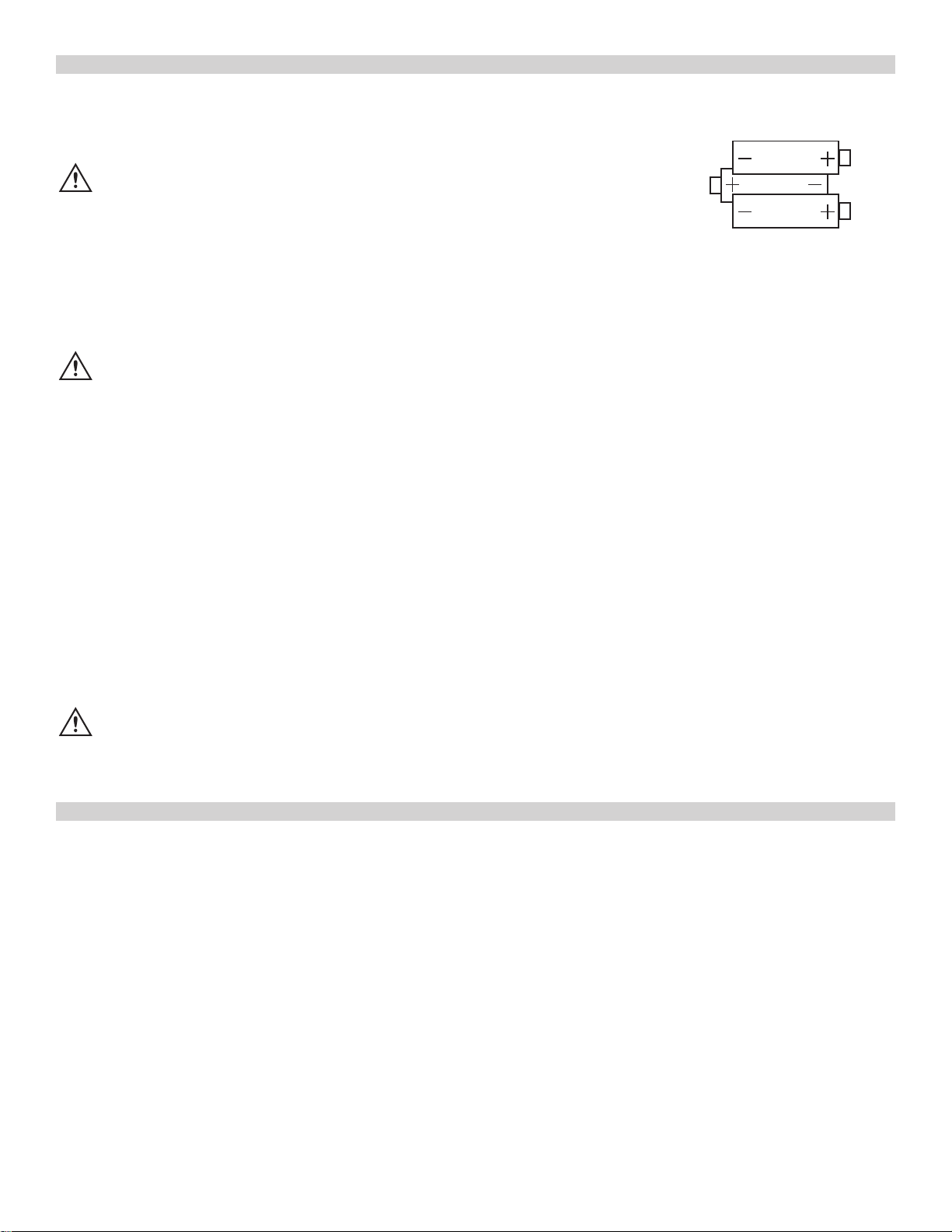

REPLACING THE BATTERIES

This meter has been designed for use with both Alkaline or rechargeable Nickel Metal Hydride (NiMH) batteries. No other types are

recommended and will void warranty. The analyzer is supplied with 3 (AA) size NiMH rechargeable batteries. These should be installed

into the instrument.

CAUTION

Take great care when installing the batteries to observe correct polarity. Always check the meter

for operation immediately after installing new batteries.

Using Rechargeable Batteries

The battery charger must only be used when NiMH batteries are fitted. Alkaline batteries are not rechargeable. Attempting to recharge

alkaline batteries may result in damage to the product and create a fire risk.

When changing the batteries, the time and date will need setting.

WARNING

Do not try and charge the unit with Alkaline batteries fitted. Do not mix NiMH cells of different capacities from different

manufacturers, all cells must be identical.

Turn over the analyzer, remove the protective rubber boot and fit 3 “AA” batteries in the battery compartment. Take great care to

ensure they are fitted with the correct battery polarity. Replace the battery cover and the protective rubber boot.

Time and Date

When changing the batteries, the time and date will need setting.

Battery Disposal

Always dispose of depleted batteries using approved disposal methods that protect the environment.

Battery Charging

Ensure that you use the correct charger. This unit uses a 5V regulated charger. Ensure the batteries are fitted in the correct manner,

and charge for at least 16 hours. Subsequent charges should be overnight. NiMH batteries may be charged at any time, even for short

periods to conduct testing.

WARNING

Under NO circumstances should you expose batteries to extreme heat or fire as they may explode and cause injury. Always dispose of

old batteries promptly in a manner consistent with local disposal regulations.

CANADIAN ANNUAL RECERTIFICATION SERVICES

KANE CANADA MEASUREMENT SOLUTIONS

All Canadian customers needing annual recertification services should...

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

BACKED BY

10

8

USA ANNUAL RECERTIFICATION SERVICES

Complete care for your C160 series combustion analyzer.

When you:

Request Recertification or Service Online

Within 1 Year of Purchase or Last Service

UEi will:

10 Year Warranty: All UEi combustion analyzers have a standard 1-year

warranty. Each recertification extends the warranty for 1 more year for up to 10

years from the date of purchase.

Contractors who book recertification of a C160 series analyzer at

within 12 months from either the date of

purchase or the date of the last recertification will receive reduced

service pricing that lowers the cost of ownership and 2 additional

benefits:

Same Day Service: All qualifying analyzers received for recertification through

UEi Service+ are returned on the same business day.*

*Analyzers that include the additional NO (Nitric Oxide) sensor requires 48-hour turnaround.

PRODUCT REGISTRATION

Register Online

Registering you analyzer online is quick and easy. Just log in or setup an account, it only takes a couple of minutes. Once logged in you

can register you analyzer by providing some product information and uploading a proof-of-purchase.

When it’s time to request recertifcation, just log into your account, select the analyzer, select the service and place your order.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

OTHER IMPORTANT FACTORS RELATING TO COMBUSTION

The three T’s of combustion

• Time: Amount of time that the fuel and oxygen are together in the combustion chamber

• Temperature: How high the temperature is determines the rate of oxidation, or spread of combustion

• Turbulence: How well the fuel and air are mixed

These three factors are all interrelated and will move your results along the combustion curves.

COMBUSTION MEASUREMENT TERMS

Other parameters measured include Net temperature, draft and efficiency.

Net Temperature

Net temperature is the difference between the combustion air entering the combustion chamber and the flue gas temperature past

the heat exchange. This is used to determine how efficient the system is extracting heat from the combustion process in addition to

the performance of the combustion process. On sealed systems that have ducted inlet air for combustion air, the Net temperature

must compare this air stream temperature with the flue gases. If the appliance simply uses room air for the combustion air, our

analyzers have an internal temperature sensor, so it will use this temperature when calculating Net temperature. The most accurate

results for efficiency are obtained when measuring flue gases at the point where flue temperature (not flame temperature) is the highest.

Draft

Draft is the difference between the ambient pressure level and the pressure level in the flue.

This is created either by the natural buoyancy of the hot gases created in combustion lifting, or by an inducer fan that assists the flow

of flue gases up the stack. Most combustion equipment will specify the amount of draft that is required for proper operation. Draft

helps draw combustion air into the combustion chamber, and also helps in mixing the fuel and oxygen. Without proper draft, the

combustion process can spill poisonous by-products into the space where the appliance is located. This can be a risk to those in the

area, or create a danger to residents or employees working near the combustion equipment.

Efficiency

Efficiency is a measure of how well the fuel is burned to create heat, and how well the generated heat is captured for the intended

use. The information used to create this value are based on the fuels heating value, the heat lost up the flue and the gas components

in the flue gas. The original method to determine efficiency included many manual methods and lookup charts. As an example you

would measure the CO2 level and the stack temperature and then reference a slide scale that would give you the relative efficiency

number. UEi’s electronic combustion analyzers perform the measurements on a continuous basis, and can calculate the efficiency as

adjustments are being made. Combine this with a printout and you are able to provide a before and after comparison of the combustion equipment in relatively little time as part of normal servicing. Combustion efficiency is not the same as AFUE (annual fuel usage

efficiency). AFUE is not measurable with any portable flue gas analyzer.

Combustion Efficiency Calculations

This identifies three sources of loss associated with fuel burning:

• Losses due to flue gases:

Dry Flue gas loss, moisture and hydrogen,

Sensible heat of water vapor, Unburned gas

• Losses due to refuse:

Combustible in ash, riddling and dust

• Other losses:

Radiation, convection, conduction other unmeasured losses

Net efficiency calculations assume that the energy contained in the water vapor (formed as a product of combustion and from wet

fuel) is recovered and the wet loss term is zero. Gross efficiency calculations assume that the energy contained in the water vapor

is not recovered. Since the fuel air mixture is never consistent there is the possibility of unburned/partially unburned fuel passing

through the flue. This is represented by the unburned carbon loss. Losses due to combustible matter in ashes, riddling, dust and grit,

radiation, convection and conduction are not included.

CO Air Free

Certain standards (ANSI Z21.1) for Carbon Monoxide are stated in terms of air-free. Air-free refers to the concentration of CO in

combustion gases undiluted with flue, or other gases containing little CO. This value is computed using an equation that takes into

account the O2 concentration of the flue gas.

• If 5% O2 is measured (O2m) in the flue then the CO gas value will be recalculated as if 0% were measured. The equation for

air-free is as follows:: COaf = CO PPM x [(20.9) / (20.9 - O2m)]

• In our example if a reading of 325 PPM were measured then the air-free value would be calculated as follows:

COaf = 325 PPM x [(20.9) / (20.9 - 5)] COaf = 325 PPM x [(20.9) / (15.9)] COaf = 427

We may be given a limit on our gas range by the local authority, which stated that we must not emit more than 400-PPM Carbon

Monoxide air-free. In the example we would be breaking the limit and corrective action should be taken to reduce the level of CO.

Air-free values prevent false readings being submitted, e.g. allowing more air into the boiler will increase the oxygen level in the flue

and dilute any toxic gas reading. Air-free referencing gives readings as if they were undiluted.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

DISPOSAL

Caution: This symbol indicates that equipment and its accessories shall be subject to separate collection and correct disposal.

STORAGE

Remove the batteries when instrument is not in use for a prolonged period of time. Do not expose to high temperatures or humidity.

After a period of storage in extreme conditions exceeding the limits mentioned in the General Specifications section, allow the

instrument to return to normal operating conditions before using it.

END OF LIFE DISPOSAL

The Waste Electrical or Electronic Equipment (WEEE) Directive requires countries in the EU to maximize collection and environmentally responsible

processing of these items. Products are now labelled with a crossed out wheeled bin symbol to remind you that they can be recycled.

Note: Batteries used in this instrument should be disposed of in accordance with current legislation and local guidelines.

WARRANTY

The C165+ are warranted to be free from defects in materials and workmanship for a period of 1 year from the date of purchase. If

within the warranty period your instrument should become inoperative from such defects, the unit will be repaired or replaced at UEi’s

option. This warranty covers normal use and does not cover damage which occurs in shipment or failure which results from alteration,

tampering, accident, misuse, abuse, neglect or improper maintenance. Batteries and consequential damage resulting from failed batteries are not covered by warranty.

Any implied warranties, including but not limited to implied warranties of merchantability and fitness for a particular purpose, are

limited to the express warranty. UEi shall not be liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or economic loss. A purchase receipt or other proof

of original purchase date will be required before warranty repairs will be rendered. Instruments out of warranty will be repaired (when

repairable) for a service charge

This warranty gives you specific legal rights. You may also have other rights, which vary from state to state.

Copyright ©2022 Kane USA Inc. All Rights Reserved. IOS® and Android™ are property of their respective owners. 202005B 0922

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...