Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

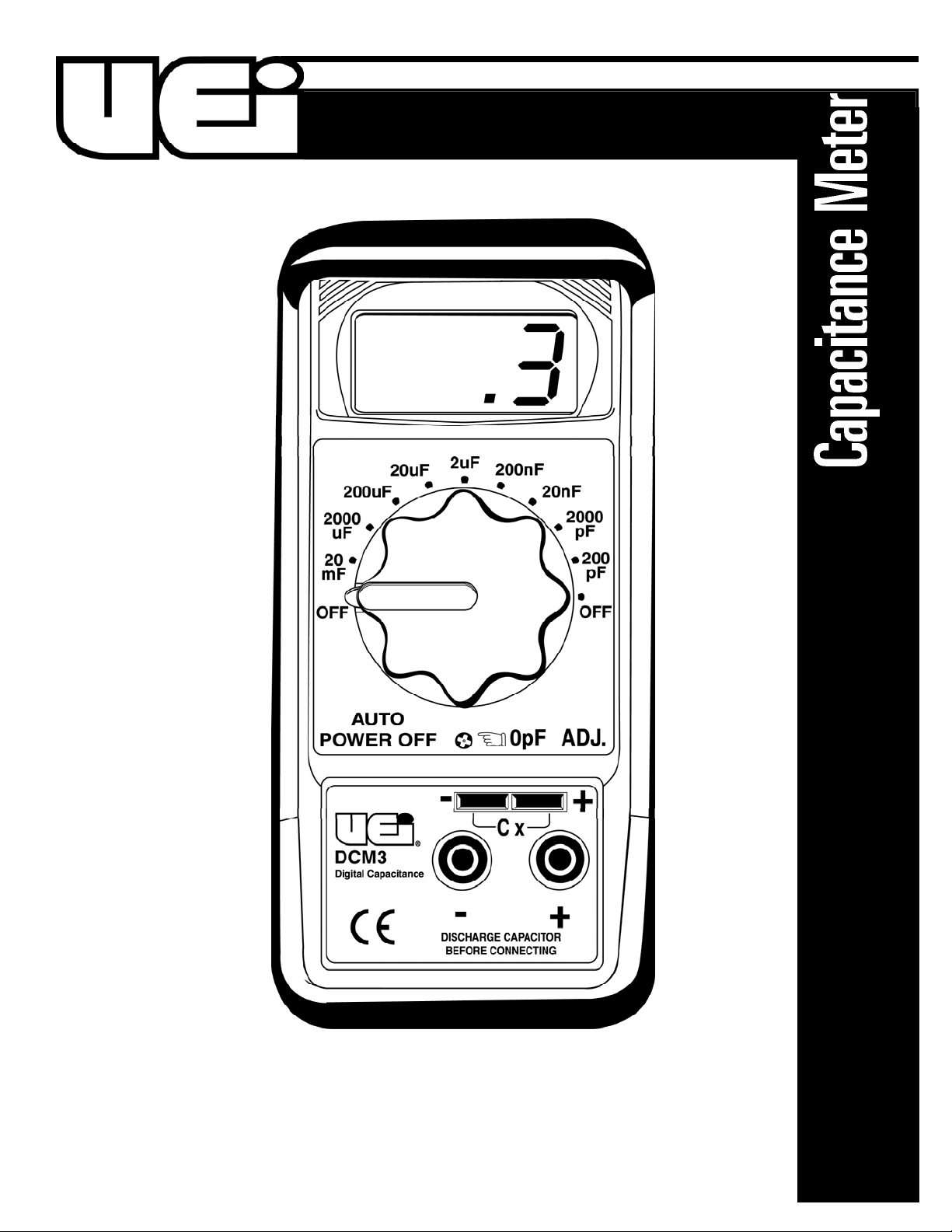

DCM3

INSTRUCTION MANUAL

Page 2

Introduction

The DCM3 Digital Capacitance Meter offers solid value in an industrial

quality meter. The wide range of inputs allows testing from the smallest

electronic components to large run/start capacitors. The rugged

design with protective boot and auto power off function keep your

meter working.

Features include

• 0.1% to 20 mF (20,000 µF)

• Zero adjustment (±20 pF for compensation of the measuring leads)

• Fuse protected input

Safety Notes

Before using this meter, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

Operating Instructions

WARNING!

To avoid electrical hazards, discharge the capacitor before measuring.

1. For capacitance measurement less than 200nF, it should make

"0-ADJ" for subtract the stray capacitance.

2. Set the range switch to the desired range.

3. Never apply an external voltage to the input terminals.

Damage to the meter may result.

4. Observe polarity when measuring polarized capacitors.

5. Insert the capacitor leads into the receptacle socket or directly connect

the test clip to the capacitor leads as required.

6. Read the capacitance direct from the display

Battery Replacement

Power is supplied by a 9 volt transistor battery. (NEDA 1604, IEC6F22). The

" " appears on the LCD display when replacement is needed. To replace the

battery, remove the two screws from the back of the meter and lift off the front

case. Remove the battery from battery contacts.

Fuse Replacement

If no current measurements are possible, check for a blown overload protection

fuse. There ia a fuse; F1 for the "Cx +" jack. For access to fuses, remove the two

screws form the back of the meter and lift off the front case. Replace F1 only

with the original type 0.25A/250V fuse.

M a i n t e n a n c e

Periodic service

WARNING!

Repair and service of this instrument is to be performed by qualified

personnel only. Improper repair or service could result in physical

degradation of the meter. This could alter the protection from

electrical shock and personal injury this meter provides to the

operator. Perform only those maintenance tasks that you are

qualified to do.

These guidelines will help you attain long and reliable service from

your meter:

1. Calibrate your meter annually to ensure it meets original

performance specifications.

2. Keep your meter dry. If it gets wet, wipe it dry immediately. Liquids

damage electronic circuits.

3. Whenever pra c t i cal, keep the meter away from dust and dirt, which

can cause premature wear.

4. Although your meter is built to withstand the rigors of daily use, it

can be damaged by severe impacts. Use reasonable caution when

using and storing the meter.

NOTE: When servicing the meter, use only the replacement parts specified.

Cleaning and Decontamination

Periodically clean your meter’s case using a damp cloth. DO NOT use

abrasives, cleaning solvents or strong detergents, as they may damage

the finish or affect the reliability of the structural components.

Battery Replacement

Always use a fresh replacement battery of the specified size and type.

Immediately remove the old or weak battery from the meter and

dispose of it in accordance with your local disposal regulations. Old or

defective batteries can leak chemicals that corrode electronic circuits.

WARNING!

To avoid electric shock, be sure to turn off the meter’s power and

disconnect both test leads from any equipment before you remove

or install batteries.

WARNING!

Under NO circumstance should you expose batteries to extreme heat or

fire as they may explode and cause injury.

NOTE: If you do not plan to use the meter for a month or more,

remove the battery and store it in an area that won’t be damaged by a

leaking battery.

DCM3-MAN P. 1

Page 3

C h a r a c t e r i s t i c s

Specifications

Auto power off: After meter operation approx. 10 minutes,

auto power off circuit

Test Voltage: <3.5 V

Input protection: 0.25 A/250 V fast action fuse

Zero adjust limited: ±20 pF approx

Shock proof: New structure, shock proof from 3 meter drop.

Display: 3 1/2 digit liquid crystal display (LCD) with maximum

reading of 1999

Polarity: Automatic, positive implied, negative polarity indica t i o n

Over range: [1] or [-1] is displayed

Zero: Automatic

Low battery indication: The " " is displayed when the battery voltage drops

b e l o w the operating level

Measurement rate: 2.5 times per second

Operation environment: 0˚C ~ 60˚C at 70% relative humidity

Storage temperature: -20˚C ~ 60˚C, 0 to 80% R.H. with battery removed

Accuracy: Stated accuracy at 23˚C ±5˚C, < 75% relative humidity

Power: Single standard 9 volt battery (NEDA 1604 pr JIS 006P)

Battery life: 200 hours typical with carbon-zinc

Dimension: 150 mm (H) x 70 mm (W) x 38 mm (D)

Weight: Approx. 170g including battery

Accessories: One pair test leads, 9V battery, operating instructions

DCM3-MAN P. 2

Range Resolution Accuracy Test Frequency

20 0 p F

0.1pF

20 0 0 p F

1pF

20 n F

10pF

20 0 n F

100pF ±1%rdg + 3dgt 820Hz

2 u F

1nF

20 u F

10nF 82Hz

20 0 u F

100nF

20 0 0 u F

1uF 2%rdg + 3dgt 8.2Hz

20 m F

10uF 4%rdg + 9dgt

Page 4

Limited Warranty

The DCM3 is warranted to be free from defects in materials and workmanship for a period

of one year from the date of purchase. If within the warra n ty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warra n ty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired

(when repairable) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

DCM3

Capacitance Meter

Copyright © 2007 UEi DCM3-MAN 1/07

PLEASE

RECYCLE

Loading...

Loading...