Page 1

1-800-547-5740 • Fax: (503) 643-6322

www.ueiautomotive.com • email: info@ueiautomotive.com

ACM6000

INSTRUCTION MANUAL

Page 2

• Even moderate amounts of current can cause ventricular fibrillation

• Use insulated tools and gloves to avoid electrical shock

• Disconnect wiring from supply voltage before performing

continuity tests

• Disconnect the negative battery terminal when removing and

replacing starters, alternators, and other components that have

direct connections to the battery

Multimeter Safety Precautions

When making resistance measurements, ensure no voltage is present

in the component or wire being tested. When making voltage or

current measurements, ensure you don’t exceed the maximum rating

of the ACM6000.

International Symbols

C o n t r ols and Indicators

1. Rotary Selector Knob: Switches measurement function.

2. ZERO button: In the DC AMP’s mode, this control zero’s the display,

so the user can get the most accurate DC current reading.

3. Test lead input terminals

• Positive input (red terminal) for:

• Voltage

• Temperature

• R e s i s t a n c e

• Negative input (black terminal) for: used as common, ground

or low-side input for all test lead measurements.

4. ON/OFF switch: Slide the switch forward to turn the instrument

on, slide it back to turn the instrument off.

5. HOLD button: Freezes the display.

Introduction

The ACM6000 DC/AC Clamp Meter instrument allows pocket sized

convenience for testing voltage, current flow, resistance, continuity

and temperature.

A voltage measurement does not always provide complete information

about the behavior of a circuit. A current measurement, in addition to

the voltage measurement, provides additional information to help you

make a correct diagnosis.

The instructions, recommendations and illustrations in this manual are

intended the basic information necessary to get you started on the path

to automotive electrical diagnostics.

State-of-the-art electronic test tools are not very effective without understanding basic automotive electrical diagnostics and basic electrical circuits. Training courses are usually available from local schools. For

additional information on domestic field training, contact the UEI

Automotive Field Training Center at (770) 476 -1431 (8-5 PM, EST).

Custom contract training can be provided in your area.

Safety Notes

Before using this meter, read all safety information carefully. In

this manual the word "WARNING" is used to indicate conditions

or actions that may pose physical hazards to the user. The word

"CAUTION" is used to indicate conditions or actions that may

damage this instrument.

WARNING!

Follow appropriate work area safety precautions

Automotive safety

When performing vehicle maintenance, work in a well-ventilated

area - route exhaust gases out of work area. Work in a well-lit

environment. Use supplemental work lights in service area.

• DO NOT wear jewelry (rings, watches, etc.) when

working on vehicles

• Wear approved safety eyewear at all times

• Avoid rotating fan blades, drive-belts and pulleys on

running engines

• Beware of electrical shock when working on vehicle wiring and

electrical systems

• Keep open flames and sparks away from batteries, engine fuels

and oils

ACM6000-MAN P. 1

1

2 3

5 4

Page 3

Clamp-on techniques for current testing

Traditional current measurement involves opening a suspect circuit and

connecting the meter in series. However, opening a circuit to perform a

current flow test creates its own set of problems such as:

• Accessing/removing/replacing a computer, module or other

device from a hard-to-get area

• Cutting and then repairing a wire

• Reprogramming data that was lost when a circuit was opened

The ACM6000 Clamp Meter allows the technician to quickly and easily

make a non-intrusive current flow measurement by clamping the jaw

around a wire.

AC and DC voltage testing

Automotive technicians routinely use a DMM to make voltage checks of

the battery and various circuits. The ACM6000 permits the user to make

standard AC/DC voltage tests, resistance and continuity tests, tempera t u r e

tests and non-intrusive current tests, while enjoying shirt pocket convenience.

• Use the DC Voltage Measurement capability ( V ) to test any

circuit or device that is powered by battery or regulated voltage

• Use the AC Voltage Measurement capability ( V ) to test any

circuit that generates its own voltage, such as a magnetic type

trigger pickup, ABS, or crank-sensor

Resistance measurement (Ohms - Ω) testing

The ACM6000 can be used to measure how much electrical resistance

is present in a circuit or across a connector. The meter sends a small

current through the circuit being tested to calculate resistance.

Continuity testing

In order to assist the technician who may not be able to see the

meter display at the same time he is making test lead connections,

the instrument sounds a buzzer when measured resistance is

approximately 25 Ohms or less, which indicates there is continuity

and not an open circuit.

ZERO adjustment

DC Current Measurement is most accurate when the instrument is

zeroed before making the measurement. By pressing the ZERO button

for one or two seconds, the display reading is reset to approximately

00.0. Note: Some flicker of the least significant digit – the rightmost

digit – is normal due to the presence of electrical and magnetic forces

present from shop lighting, wiring, and other live electrical sources

near the test area.

Data hold

• Press the HOLD button to freeze the display reading

• Press the HOLD button again to resume real time readings

Wire to be tested must

pass through the opening

when clamp-jaw is shut.

Press there to open

clamp-jaw.

Display

1. Battery Low Indicator: If the letters “BAT” are displayed, turn

off the meter and replace the battery.

2. Minus Sign (-): Indicates negative polarity.

3. Measurement Display: This meter can display numbers up

to 199.9 on the LCD. The units (ohms, volts, etc.) are displayed as

symbols to the right of the digital value.

NOTE: A 1 on the left side of the display indicates that the input

has exceeded the selected range.

Features

AC and DC current testing

Frayed wiring, corroded or degraded connections, failing switches, etc.

may test OK for voltage but may not allow sufficient current for the

circuit to function properly. Technicians can make better informed

diagnostic decisions when circuit current (amperage) is also tested.

The ACM6000 can be used to test for both AC and DC current. The user

selectable range switch allows for measurement up to 200 Amps.

ACM6000-MAN P. 2

2

1

3

Page 4

Low battery indicator

The LOW BATTERY i n d i c ator displayed in the upper left hand corner of

the display screen alerts the operator to replace the ACM6000 battery.

• See “Battery Replacement” for detailed instructions

Temperature measurement

Automotive repair and maintenance often involves checking the

temperature of A/C and heating duct air as well as engine coolant

temperature. The operator may read temperature by connecting any

standard K type thermocouple to the input jacks, through the supplied

temperature probe adapter.

Hand strap

A Hand Strap is provided to avoid accidentally dropping the ACM6000

Clamp Meter.

Pouch

A pouch is provided for storage of the ACM6000 Clamp Meter, the

accessories and the operator’s manual.

Operating Instructions

AC/DC current testing

The procedure for measuring current using the ACM6000 is different

from measuring voltage.

• To measure VOLTAGE, the meter leads are connected to the points

in the circuit being tested

• To measure CURRENT, the jaws of the Clamp Meter are placed

around a wire or cable to make the measurement (Ensure test

leads are not connected to the meter)

1. To measure high AC CURRENT: Turn the rotary

function switch to the 200 Amps AC setting (200A ).

To measure high DC CURRENT: Turn the rotary function switch

to the 200 Amps DC setting (200A ).

2. Slide the ACM6000 power switch to the ON position.

3. Press the ZERO button (DC current measurements, only).

This will zero the instrument for the most accurate reading.

4. Place the jaws of the ACM6000 around the conductor

being tested.

• Verify that the instrument and its strap do not

touch moving pulleys or belts

• Failure to obey the current flow polarity indicator

arrow located on the inner jaw face will result in a minus

sign to the left of the amps readout

• Be sure the jaws are closed, leaving no air gap between

the two jaws.

A. Remove the instrument from the conductor

B. Turn the rotary switch to the 20A scale

C. Follow steps 3 and 4

5. When testing is completed move the instrument power switch

to OFF.

Measuring AC voltage

NOTE: Observe safety rules.

WARNING!

• Be certain that wires and leads, as well as clothing and hands

are clear of moving parts

• When checking ABS wheel speed sensors be sure the wheels

are free to rotate and will not move the vehicle or cause damage

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to V.

3. Connect the test leads to the meter.

A. Plug the black lead into the COM input

B. Plug the red lead into the VΩ˚F input

4. Connect the probe tips to the circuit under test. For automotive

AC voltage measurements using a multimeter not necessary to

observe polarity.

NOTE: If the voltage readout is not stable, further evaluation of the

c i r cuit using a labscope is re c o m m e n d e d .

5. When testing is completed move the instrument power switch

to OFF.

Measuring DC voltage

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to V.

3. Connect the test leads to the meter.

A. Plug the black lead into the COM input

B. Plug the red lead into the VΩ˚F input

4. Connect the black COM probe tip to the ground (-) side of the

circuit under test.

5. Connect the red prove tip to the positive (+) side of the circuit.

• The voltage present in the circuit is shown on the display

panel readout

• Instrument will indicate the polarity of the red lead

connection displayed on the left side of the voltage readout

NOTE: If the voltage reading is not stable, further

evaluation of the circuit using a labscope, model ADL7000

or ADL7100, is recommended.

6. When testing is completed move the instrument power switch

to OFF.

Resistance measurement

• The ACM6000 supplies a small current to the circuit under

test which is used to determine the circuit’s resistance

• Displays circuit resistance in Ohms (W)

ACM6000-MAN P. 3

Page 5

WARNING!

The circuit being tested must be turned OFF!

(NO VOLTAGE PRESENT).

• Use the built-in DMM to verify that the circuit under test is

turned OFF and no voltage is present.

Measuring resistance (Ohms Ω)

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to Ω.

3. Connect the test leads to the meter.

A. Plug the black lead into the COM input

B. Plug the red lead into the VΩ˚F input

4. Verify that the circuit under test has no voltage applied.

5. Connect the test leads across the load or circuit to

be tested.

6. Read the circuit resistance displayed in Ohms.

7. When testing is completed move the instrument

power switch to OFF.

Testing continuity

Continuity is the measure of a circuit’s ability to conduct current as

opposed to resisting current flow.

• The Audible Continuity buzzer will sound when resistance

is under approximately 25Ω

• To set for continuity, follow the same procedures

prescribed for measuring resistance

• The same precautions apply

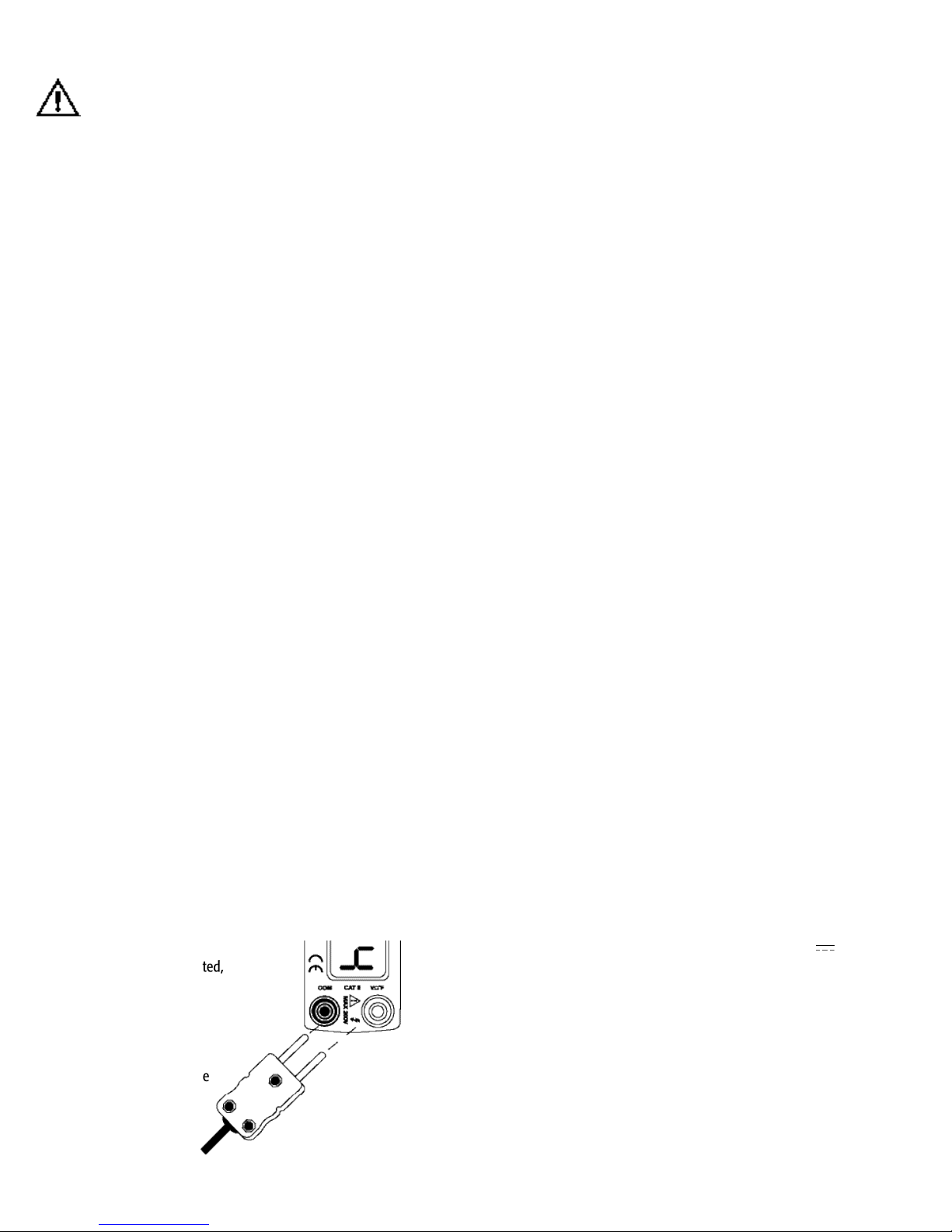

Measuring temperature

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to ˚F.

3. Connect the banana plugs of the thermocouple adapter

into the meter inputs (Fig. 1). Observe polarity.

4. Connect the K-type thermocouple to the

thermocouple adapter.

5. The temperature reading can be read on the

display panel.

6. When testing is completed,

move the instrument

power switch to OFF.

Plug the standard K-type

thermocouple into this

side of the adapter.

DC current testing

When investigating electrical circuit problems the tools most often

used by the automotive technician are the trouble light and the

volt/ohm meter or DMM. The trouble light is often the tool used to test

for current. However, most trouble lights have severe limitations:

1. The operator must guess at the amp draw based upon the

brightness of the bulb. Modern automotive circuits require precise

current loads. Accurate current measurements are crucial.

2. Many trouble lights require up to 2 amps to shine brightly.

If used to test a circuit designed for less amperage, the 2 amp

draw can over load the circuit resulting in damage.

3. Some DMMs have a built-in current testing feature. When using

most DMM’s to measure amps, it is necessary to open the system

under test and connect the DMM in series. While the test result is

accurate, the hook-up is time consuming and often impractical.

The ACM6000 Clamp Meter is a preferred alternative. By simply

placing the Clamp Meter around a power – or ground - wire of the

circuit being tested, the connection is made. No back probing or

intrusion of insulation is necessary. Additionally, the sensitivity and

resolution of the ACM6000 gives a precise amperage readout rather

than an estimate based upon bulb brightness. Because no direct

connection is required, there is no danger of overloading the circuit.

Re-connecting or reattaching wires is unnecessary.

NOTE: The ACM6000 Clamp Meter is designed to give accurate

measurement of continuous current flow. If the device being tested

is pulsed (like solenoids and relays) the readout will show the

average current.

For testing recommendations of pulsed circuits contact the UEi Training

Coordinator at 770/476-1431.

Starter current draw

Most starters draw several hundred amps initially, to start the crankshaft

turning. After about one half second the starter current will stabilize for

the duration of cranking. Typical starter current draw (after the initial

surge is):

• 4 cylinder - 120 amps

• 6 cylinder - 150 amps

• 8 cylinder - 180 amps

Test procedure:

1. Disable ignition or fuel, this is a cranking test.

2. Turn the ACM6000 rotary function switch to 200A .

3. Slide the instrument power switch to ON.

4. Verify that the vehicle ignition switch is in the OFF position.

5. Place the jaws of the ACM6000 around the starter cable and

be sure the jaws are closed.

6. Press the ACM6000 ZERO button. The display screen should

read approximately 00.0.

ACM6000-MAN P. 4

(Fig 1)

ATA1 Temp

Probe Adapter

Page 6

ACM6000-MAN P. 5

WARNING!

Observe proper safety procedure for step 7. Be certain the vehicle

cannot move during the cranking portion of the test.

7. Crank the engine while observing the meter reading.

CAUTION!

Avoid overheating the starter limit cranking time to 15 seconds.

8. When testing is completed move the instrument power switch

to OFF.

Abnormally high current can indicate:

• Over-advanced engine timing

• Seized engine

• Faulty starter

Abnormally low current can indicate:

• Low compression engine

• High resistance in starter circuit or connections

• Faulty battery - to check the condition of the battery, use

the voltmeter to perform a cranking voltage test

Parasitic load

Parasitic Load is the small amount of current drawn from the battery

after the ignition switch is turned OFF and the various electronically

controlled devices have phased from "Awake" to "Asleep" mode.

Typically, the parasitic load will be under 20 milliamps. In some

applications parasitic load will reach 40 milliamps and still be normal.

Check the vehicle service manual for exact specifications.

Test procedure:

1. Turn the ignition switch and all accessories OFF.

2. Disable the under-hood light.

3. Allow sufficient time for all the electronic devices to be asleep.

• Some devices take hours

• Refer to the vehicle service manual for exact time

4. Turn the ACM6000 rotary function switch to 20A .

5. Slide the instrument power switch to ON.

6. Press the ACM6000 ZERO button. The display should read

approximately 00.0.

7. Place the jaws of the ACM6000 around the battery positive

cable(s) or the battery negative cable(s). Either way will work.

Be sure the jaws are closed.

8. Because the display readout can vary up to 60mA, add 60mA

to the highest expected reading for parasitic load of the vehicle

under test. If the display readout exceeds that amount, further

testing is recommended.

Example: Normal highest parasitic load for vehicle under test is

40mA. Add 60mA to the expected 40mA for a total of 100mA. If

the display is 0.10A (100mA) the parasitic load can be considered

normal. However, a reading of 0.11 A (110mA) or more would

be too high.

Alternator output

Problems involving hard starting because of low battery current can be

caused by a faulty alternator. The alternator is responsible for keeping

the battery charged. The ACM6000 provides an easy way to check alternator current output.

Test procedure:

1. This test should be conducted with the battery fully charged.

• Charge the battery if necessary

2. Start engine and run at about 1800 RPM.

3. Allow sufficient time for all the electronic devices to be asleep.

4. Turn the ACM6000 rotary switch to 200A .

5. Slide the instrument power switch to ON.

6. Press the ACM6000 ZERO button. The display should read

approxiametly 00.0.

7. Using CAUTION to avoid moving belts, etc., place the jaws

of the ACM6000 around the alternator output wire. Be sure that

the jaws are closed.

8. Compare reading with manufacturers specifications.

9. When testing is completed move the instrument power switch

to OFF, and remove the meter from the wire.

Measuring amp output is only a partial indicator of alternator function

and ability to keep the battery charged. Performing a Regulator –

Operating Voltage test is also recommended.

Blower motor current draw

Modern automotive heating and air conditioning systems can be quite

complicated. Diagnosing these systems may require the use of a service

manual to help isolate the exact problem. However, it is often possible

to make quick work of pin-pointing some problems by using the

ACM6000 to measure current flow. Blown A/C fuses or insufficient

cooling/heating caused by a faulty blower motor are easy to find

using the ACM6000.

Test procedure:

1. To test the blower motor: disconnect the vehicles electrical

harness from the blower motor.

2. Connect a fused jumper lead set from the battery to the

blower motor.

3. Turn the ACM6000 rotary function switch to 200A .

4. Slide the instrument power switch to ON.

5. Press the ACM6000 ZERO button. The display should read

approximately 00.0.

6. Place the jaws of the ACM6000 around one of the two wires,

either one will work.

Page 7

ACM6000-MAN P. 6

7. Most blower motors draws about 25 amps at battery voltage.

Verify normal current draw specifications for the type of motor

you are testing.

• Excessive amperage indicates a faulty blower motor

probably due to an internal short

• Insufficient amperage indicates a faulty blower motor

probably due to high electrical resistance, either internally

or in the connector paths

8. When testing is complete move the instrument power switch to

OFF, and remove the meter from the wire.

Fuel pump current draw

Diagnosing fuel pump problems can sometimes be difficult. The

ACM6000 can be used to make a quick check for fuel pump current

draw during cranking. A fuel pump related problem possibly exists if

current flow is 2 amps or less during cranking. Additional testing may

be necessary if current flow is more than 2 amps.

Test procedure:

1. Disable the ignition system. This is a cranking test.

2. Turn the ACM6000 rotary function switch to 20A .

3. Slide the instrument power switch to ON.

4. Press the ACM6000 ZERO button. The display should read 00.0.

5. Place the jaws of the ACM6000 around the power wire to the

fuel pump. Be sure the jaws are closed.

WARNING!

Observe proper safety procedures for step 6. Be certain the vehicle

cannot move during the cranking portion of this test.

6. Observe the fuel pump current draw reading while an assistant

cranks the engine:

• Press the ACM6000 HOLD button to freeze the reading

• Press the HOLD button again to release the HOLD feature

7. When testing is complete, move the instrument power switch

to OFF.

Detailed evaluation of fuel pump performance can be made using the

Automotive Labscope.

Lamps, lights and electric motors

Devices such as headlamps, stop lights and interior lights as well as electric

motors (wiper, seat, mirror, etc.) draw current at a steady rate. The

ACM6000 can be used to verify the current flow powering these devices.

Measuring current in suspect circuit:

1. Turn the ACM6000 rotary function switch to 200A .

2. Slide the instrument power switch to ON.

3. Press the ACM6000 Z ERO button. The display should read

approximately 00.0.

4. Place the jaws of the ACM6000 around the positive (+) wire

of the circuit under test.

5. Note the display readout. Lights and motors should not draw

whole amps of current until switched ON.

6. Switch power to the suspect circuit ON and verify that current

draw does not exceed normal limits for that circuit.

7. When testing is complete, move the instrument power switch

to OFF, and remove the meter from the wire.

AC voltage testing

Some sensors produce their own voltage as an AC output. AC devices

include: The ABS Sensor, the Magnetic Crank Sensor, Magnetic

Distributor Pickup, and the Alternator. These devices operate at speeds

that are too fast for a meter to be able to give exact measurements of

each pulse. The meter reading is an averaged measurement. When

more detailed analysis of an AC device it is necessary, use a Labscope.

Measuring AC Voltage:

1. Slide the ACM6000 power switch to ON.

2. Turn the rotary function switch to V.

3. Connect the test leads to the meter.

A. Plug the black lead into the COM input

B. Plug the red lead into the VW˚F input

4. Connect the probe tips to the circuit under test. For AC sensor

voltage measurements with a multimeter, it is not necessary to

observe polarity.

WARNING!

• Be certain that wires and leads, as well as clothing and

hands are clear of moving parts

• When checking ABS wheel speed sensors be sure the wheels

are free to rotate and will not move the vehicle or cause damage

5. When testing is complete move the instrument power switch

to OFF.

Diagnostic tips:

• Heat and vibration can degrade sensor magnets, causing

reduced voltage or erratic voltage and current output

• Cracked magnets create unstable signals and erratic

computer responses

• Frayed wiring and poor connections frequently cause voltage

and current flow problems on AC sensors

• Check clearance between magnet and pickup against

manufacturer’s specifications

Page 8

ACM6000-MAN P. 7

DC voltage testing

Most electric/electronic devices in an automobile rely upon Direct

Current. Voltage will always have a direct relationship to current. It is

important that the voltage be appropriate for the need.

• When voltage is too low, insufficient power can cause problems Bulbs become dim, motors can slow down, and relays will

often malfunction

• When voltage is too high, devices are overpowered and bulbs

will burn out prematurely, motors can run too fast and fail early,

relays with fine wiring may overheat and fail

Use the DMM DC Voltage Testing capability of the ACM6000 to make

these important voltage tests.

NOTE: Modern automotive engine management systems utilize

computers and pulsed electronic solenoids in order to achieve the

best combination of power, fuel efficiency and low emissions. Those

pulsed devices are often on for only a few thousandths of a second

at a time. In some situations the on pulse lasts only a few millionth

of a second. The tool of choice to test pulsed circuits is a highperformance Labscope, like the ADL7000 or ADL7100. These

Labscopes sample the circuit millions of times per second.

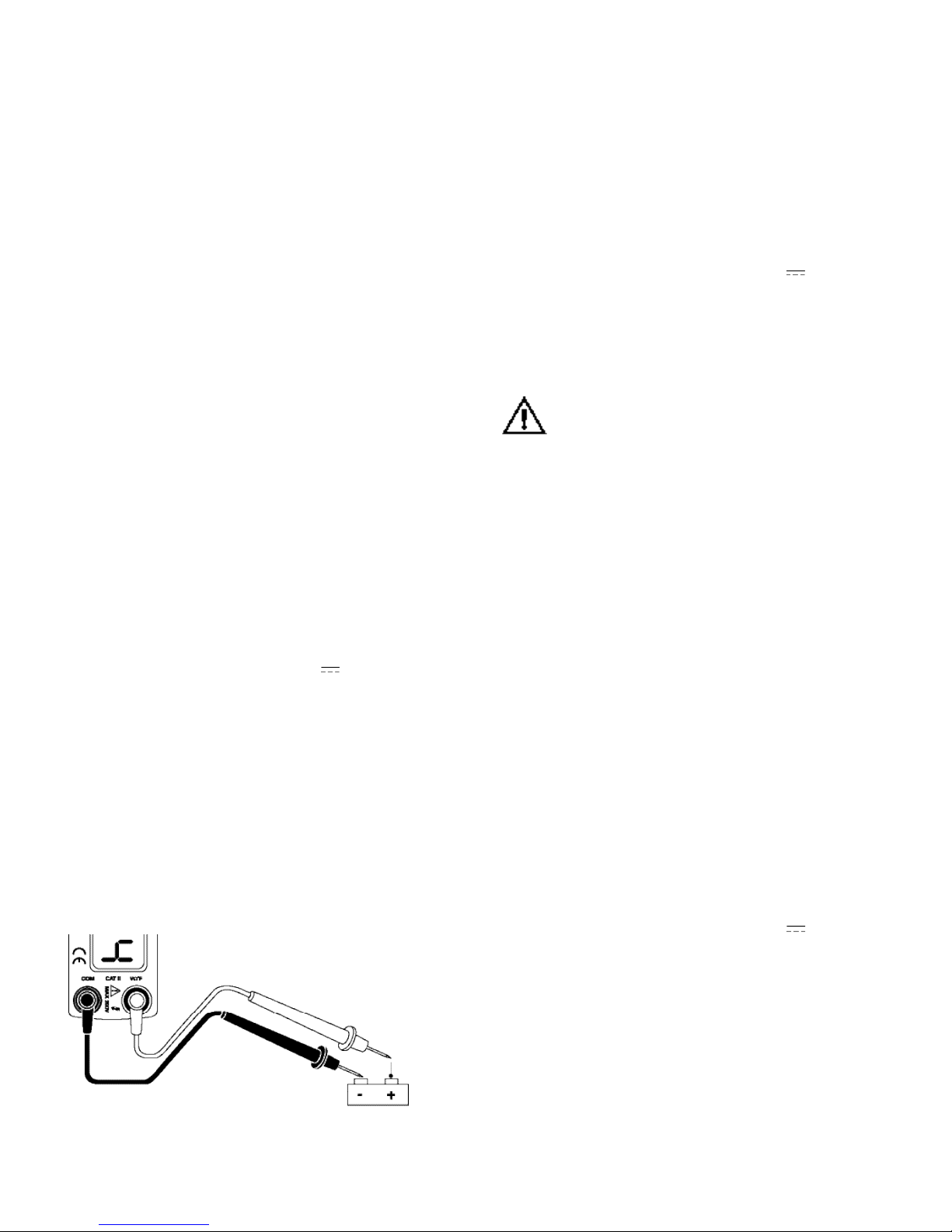

Battery - state of charge

When conducting starting and charging system tests the first step is to

verify that the battery is fully charged.

1. Place the vehicle ignition switch in the OFF position.

2. Turn the headlights ON for 30 seconds to dissipate the battery

surface charge.

3. Slide the ACM6000 power switch to the ON position.

4. Turn the ACM6000 rotary function switch to V.

5. Connect the test leads to the meter (Fig 2).

A. Connect the black COM lead probe tip to the battery

negative (-) post

B. Connect the red VW˚F lead probe tip to the battery

positive (+) post

• A fully charged battery will read 12.6 volts or more

• A reading of 12.4 to 12.5 is considered about 75% charged

• If the reading is 12.3 volts or less, charge the battery

before making further starting and charging system tests

6. When testing is complete, move the instrument power

switch to OFF, and disconnect the test leads.

Battery - cranking voltage

By comparing the Battery – Cranking Voltage test result with the Starter

Current Draw test result, the technician can determine if a battery

should be replaced.

Test procedure:

1. Verify that the battery state of charge is ok.

2. Disable ignition or fuel so the engine will crank but not run.

3. Slide the ACM6000 power switch to the ON position.

4. Turn the ACM6000 rotary function switch to V.

5. Connect the test leads to the meter.

A. Connect the black COM lead probe tip to the

battery negative (-) post

B. Connect the red VW˚F lead probe tip to the

battery positive (+) post

WARNING!

Observe safety procedures for step 7. Be certain the vehicle can not

move during the cranking portion of the test.

6. Crank the engine while observing the meter reading. To avoid

overheating the starter, limit cranking to 15 seconds.

• Look for a reading of 9.6 volts or higher when testing at 70˚F

• In colder conditions allowing 0.1 volt less for each 10˚F

drop in temperature is accepted practice

7. When testing is complete, move the instrument power switch

to OFF.

NOTE: If the cranking voltage drops below 9.0 volts (on 12 volts

systems) the vehicle will not start reliably.

Regulator - operating voltage

The voltage regulator must maintain sufficient voltage to keep the

vehicle battery properly charged. The Charging Voltage can be tested

using the ACM6000.

Test procedure:

1. Start the vehicle engine.

• All accessories OFF

• Run until engine is at operating temperature

2. Slide the ACM6000 power switch to the ON position.

3. Turn the ACM6000 rotary function switch to V.

4. Connect the test leads to the meter.

A. Connect the black COM lead probe tip to the battery

negative (-) post

B. Connect the red VW˚F lead probe tip to the battery

positive (+) post

Battery

(Fig 2)

Page 9

ACM6000-MAN P. 8

5. System voltage reading should be 13.1 volts to 14.2 volts.

• Check the vehicle service manual for exact specifica t i o n s

7. When testing is complete, move the instrument power

switch to OFF and disconnect the test leads.

NOTE: See the illustration on page 22 for test lead hookup instructions.

TIP: Low Voltage - Check connections, drive belt, faulty voltage re gu l a t o r .

High Voltage - Usually indicates a faulty voltage re gu l a t o r.

Potentiometer tests

Automotive computer engine management systems depend upon

signals from potentiometer to determine fuel distribution and ignition

timing. If these devices fail or become intermittently faulty, erroneous

data is fed to the computer resulting in poor fuel economy and

driveability complaints. A typical example of a potentiometer is the

Throttle Position Sensor (TPS). To test a throttle position sensor:

Test procedure:

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to V.

3. Connect the test leads to the meter.

A. Connect the black COM lead probe tip to the battery

negative (-) post

B. Connect the red VW˚F lead probe tip to the battery

positive (+) post

4. Turn the ignition switch on. DO NOT start the engine.

5. Look for a 5 volt reading. (Some vehicles may differ.

Verify the correct reference voltage for the vehicle being tested.)

• If the reference voltage is too high or low, look for a problem with the

wiring harness, connectors or the computer

6. After establishing that the reference voltage is OK, connect the

red lead probe tip to the TPS output wire.

7. Look for low voltage at idle position which should smoothly

increase as throttle is increased. Any erratic voltage readout

indicates a bad sensor. Verify the factory specs for the low voltage

(idle) setting. As little as one tenth of one volt off can make a

difference in vehicle performance. The high voltage (full throttle

voltage) should reach at least 80% of the reference voltage. For

example, it should reach at least 4 volts with a 5 volt reference.

8. Turn the vehicle switch OFF.

9. When testing is complete, move the instrument power switch

to OFF and disconnect the meter leads.

Measuring resistance

Resistance measurements are frequently made as a part of automotive

circuit and component testing. Additionally, continuity testing is used to

establish that a circuit is complete (no opens). Continuity testing is a quick

v e r i f i cation that resistance is below a certain level. Levels can vary from

meter to meter. A buzzer sounds when measured resistance is below

approximately 25 Ohms.

Ohms and audible continuity measurements:

1. Slide the ACM6000 power switch to the ON position.

2. Turn the rotary function switch to Ω .

3. Connect the test leads to the meter.

A. Plug the black lead into the COM input

B. Plug the red lead into the VΩ˚F input

4. Verify that the circuit under test is completely OFF.

5. Connect the test leads across the lead or circuit to be tested.

6. Read the circuit resistance, displayed in Ohms.

• If the display shows an over-range indication (“1” at the left

side of the display) the circuit resistance is either above the

meter’s 20 0 0Ω range, or the circuit is open

NOTE: The audible continuity feature allows the operator to do quick

resistance tests without looking at the meter display.

• The audible continuity buzzer will sound if resistance is under

approximately 25Ω

7. When testing is complete, move the instrument power switch

to OFF and disconnect the meter leads.

NOTE: A n y circuit tested that has a voltage applied will not provide an

a c c u r ate re a d i n g .

Temperature measurement

A standard accessory with the ACM6000 is a temperature

probe adapter and a K-Type thermocouple. Use the thermocouple probe

tip to contact the component to be measured. Additional probes for air,

fluids, and surface

contact measurements are available.

Air conditioning/heating duct temperature measurement:

1. Insert the thermocouple connector into the adapter.

Observe polarity.

2. Connect the banana plug thermocouple adapter to the ACM6000

black COM and red VΩ˚F inputs (Fig. 3). Observe polarity.

3. Turn the rotary function switch to ˚F.

4. Slide the instrument power switch to the ON position.

5. Position the probe tip in the airflow of an A/C-heating duct.

6. Start the engine and set the vehicle temperature controls

for the test. Look for the change in temperature to meet

manufacturers specifications.

Page 10

ACM6000-MAN P. 9

7. Because of the sensitivity and quick response time of the

ACM6000 and K-Type thermocouple the readings will reveal

higher highs and lower lows than are possible with dial

type thermometers.

8. When testing is complete move the instrument power switch to

OFF, and remove the thermocouple.

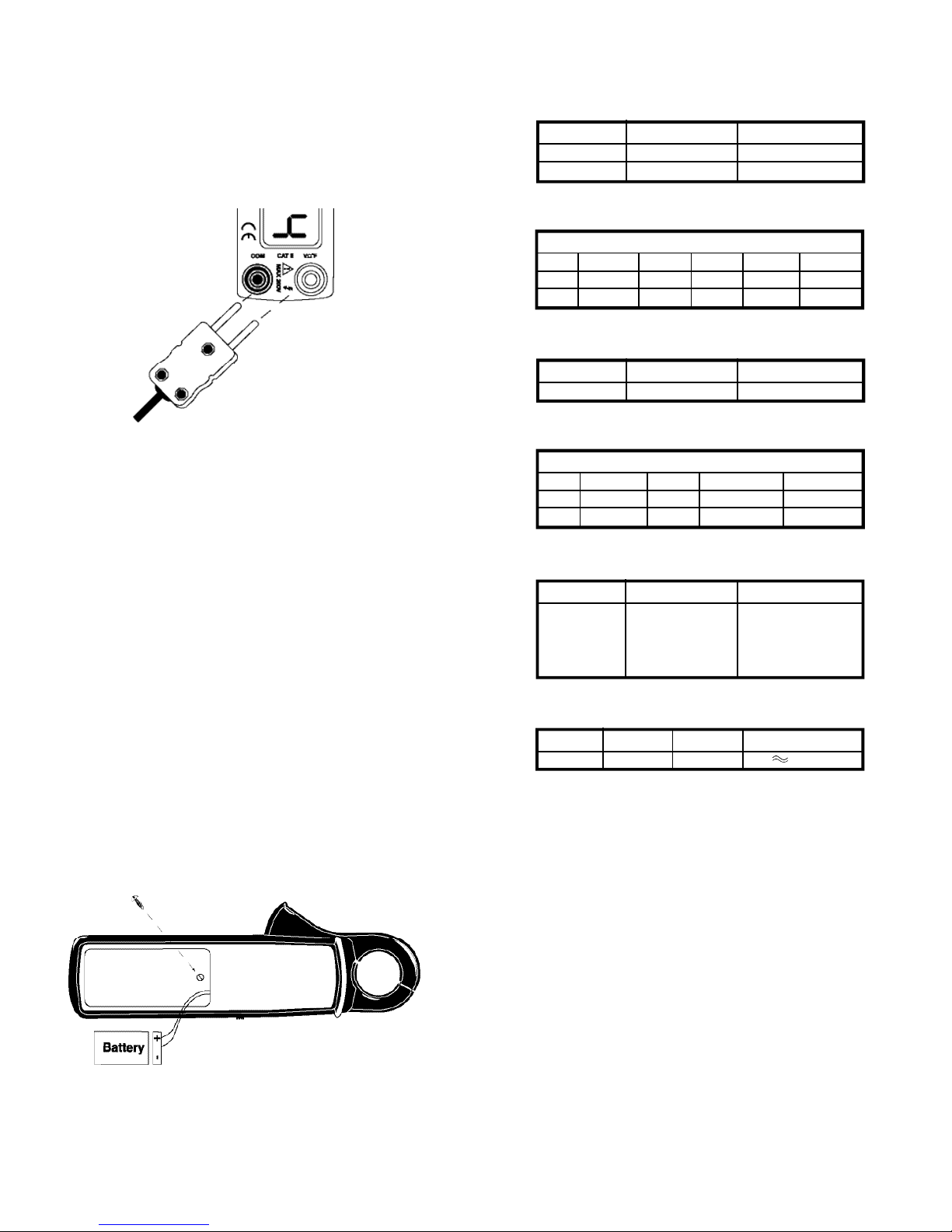

Battery replacement

When the low battery symbol is displayed on the LCD, replace the

battery with a new one.

Dispose of batteries in accordance with your local solid-waste disposal

regulations. Never expose batteries to high temperature or incineration.

1. Turn the ADM6000 power switch OFF.

2. Remove test leads from the meter.

3. Remove the battery cover screw (Fig. 4).

4. Remove the battery cover.

5. Remove the depleted battery.

6. Insert a fresh 9V NEDA1604, IEC6F22 Battery, observe polarity

markings in the battery compartment.

7. Replace the battery cover.

8. Replace and secure the battery cover screw.

9. Resume normal use of the instrument.

Specifications

1. DC current

2. AC current

3. DC Voltage

(Input impedance 10mΩ)

4. AC Voltage

5. Temperature

(K-Type thermocouple)

6. Resistance

Environmental operating conditions

This clamp meter was designed to be used in temperature and

humidity that remains within the range of 60˚ to 90˚F and 30 to 85%

Relative Humidity (RH). Excessive temperatures (hot or cold) or

excessive humidity can cause the meter to give erroneous readings.

If the humidity raises to the point of causing condensation on the

ACM6000, the meter can become dangerous to use and can give

erroneous readings. Most test equipment in use today use sensitive

digital electrical components. These components are extremely

sensitive to heat and humidity.

NOTE: Whenever the meter undergoes a rapid or ex t r eme change of

t e m p e r a t u r e or humidity, it should be left on for about 5 minutes to

allow the internal tempera t u re to stabilize. This will ensure that your

m e a s u r ements are as accurate as possible.

ATA1 Temp

Probe Adapter

(Fig 3)

Battery Compartment

(Fig 4)

Range Resistance Accuracy

20A 10mA ±3.5% ±6 digits

200A 100mA ±3.5% ±3 digits

Accuracy

Range Resolution 50-60Hz 60-100Hz 100-400Hz 100-400Hz

20A 10mA ± 3 % ± 4 d g t s ± 3 % ± 7 d gt s ± 3 % ± 10 d g t s ± 3 % ± 1 0 d g t s

20 0 A 20 0 m A ± 3 % ± 4 d g t s ± 3 % ± 7 d g t s ± 3 % ± 10 d g t s ± 3 % ± 10 d g t s

Range Resolution Accuracy

200V 0.1V ±1% ±2 digits

Accuracy

Range Resolution 50-60Hz 60-400Hz 400-1000Hz

200V 0.1V ±1.5% ±2.0%±10dgts ±3.0%

±3dgts ±25dgts

Range Resolution Accuracy

40˚F 1˚F ±3% ±6dgts(<302˚F)

to 1000˚F ±3%(>302˚F)

at 50-90˚F ambient

Temperature

Range Resistance Accuracy Continuity Tone

2000Ω 1Ω ±1%±2dgts <25Ω

Page 11

ACM6000-MAN P. 10

Standard and Optional Accessories

Standard

Soft carrying case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ACM6100P

Standard test lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATL55

Temperature probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATA1/ATH2329

Optional

Rigid temperature probes with handles

Surface probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATH2336

Liquid/Immersion probe . . . . . . . . . . . . . . . . . . . . .ATH2338

Air/Gas probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ATH2350

Screw on Alligator ends . . . . . . . . . . . . . . . . . . . . . . . . .AAC3

Extended test leads

7.5” leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ADL7100A107

11.5” leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ADL7100A108

Premium silicon test leads . . . . . . . . . . . . . . . . . . . . . . .ATL300

Page 12

Limited Warranty

The ACM6000 is warranted to be free from defects in materials and workmanship for a period

of one year from the date of purchase. If within the warra n ty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warra n ty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not

covered by warra n ty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired (when

r e p a i r able) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

Service: (800) 308-7709

www.ueiautomotive.com • Email: info@ueiautomotive.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

ACM6000

Low Amp Clamp-On DMM

Copyright © 2004 UEi Automotive ACM6000-MAN 4/04

Loading...

Loading...