UBS Axcera LU6000AL Compiled External Amplifier Manual

INSTRUCTION MANUAL

Innovator

LX Series

Analog Power Amplifier

Assembly

AXCERA, LLC

103 FREEDOM DRIVE P.O. BOX 525 LAWRENCE, PA 15055-0525 USA

(724) 873-8100 • FAX (724) 873-8105

www.axcera.com • info@axcera.com

LX Series Power Amplifier Assembly Table of Contents

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

SECTION PAGE

1.1 Manual Overview ............................................................................ 1-1

1.2 Assembly Designation Numbers ......................................................... 1-1

1.3 Safety........................................................................................... 1-2

1.4 Contact Information..................................................................... 1-2

1.5 Material Return Procedure................................................................. 1-2

1.6 Limited One Year Warranty for Axcera Products..................................... 1-3

CHAPTER 2 AMPLIFIER ASSEMBLY DESCRIPTION, MAINTENANCE

& REMOTE CONTROL CONNECTIONS

2.1 LX Series Power Amplifier Chassis Assembly Overview........................... 2-1

2.1.1 Power Amplifier Chassis Configurations ....................................... 2-3

2.1.1.1 250 Watt Power Amplifier Chassis Configuration................... 2-3

2.1.1.2 500 Watt Power Amplifier Chassis Configuration................... 2-3

2.1.1.3 1 kW Power Amplifier Chassis Configuration ........................ 2-3

2.1.2 System Configurations............................................................. 2-3

2.1.2.1 250W, 500W or 1kW System Configurations........................ 2-4

2.1.2.2 2 kW System Configuration.............................................. 2-4

2.1.2.3 3 kW System Configuration.............................................. 2-5

2.1.2.4 4 kW System Configuration.............................................. 2-5

2.1.2.5 5 kW System Configuration.............................................. 2-6

2.1.2.6 6 kW System Configuration.............................................. 2-6

2.1.3 Power Amplifier Module Assembly, 250W ..................................... 2-8

2.1.4 Power Supply Module Assembly................................................2-10

2.1.5 Front Panel LCD Display Screens ..............................................2-10

2.2 System Operation ..........................................................................2-10

2.2.1 Principles of Operation ............................................................2-10

2.3 Maintenance.................................................................................2-12

2.4 Customer Remote Connections ...................................................2-12

CHAPTER 3 SITE CONSIDERATIONS, INSTALLATION AND SETUP PROCEDURE S

3.1 Site Considerations.......................................................................... 3-1

3.2 Unpacking the Chassis w/Modules, bandpass and trap filters .................... 3-5

3.3 Installing the Chassis w/Modules and filters.......................................... 3-5

3.4 AC Input ....................................................................................... 3-6

3.5 Setup and Operation........................................................................ 3-7

3.5.1 Input Connections .................................................................. 3-7

3.5.2 Initial Turn On ....................................................................... 3-9

3.5.2.1 Receiver Module LEDs on Front Panel ................................. 3-9

3.5.2.2 Modulator Module LEDs on Front Panel............................... 3-9

3.5.2.3 IF Processor Module LEDs on Front Panel ...........................3-10

3.5.2.4 Upconverter Module LEDs on Front Panel...........................3-10

3.5.2.5 Controller Module LEDs on Front Panel ..............................3-10

3.5.2.6 Power or Driver Amplifier Module LEDs on Front Panel ..........3-10

3.5.3 Front Panel Screens for the (Optional) Exciter Switcher Tray ..........3-10

3.5.4 Front Panel Screens for the Exciter/Amplifier Chassis Assembly ......3-13

3.5.5 Operation Pro cedure ..............................................................3-22

LX Series, Rev. 1 March 2, 2005 i

LX Series Power Amplifier Assembly Table of Contents

TABLE OF CONTENTS - (Continued)

SECTION PAGE

CHAPTER 4 CIRCUIT DESCRIPTIONS

4.1 Power Amplifier Module .................................................................... 4-1

4.1.1 UHF Phase/Gain Board ............................................................. 4-1

4.1.2 150 Watt Driver Pallet Assembly................................................ 4-2

4.1.3 150 Watt Driver, Dual Output Board........................................... 4-2

4.1.4 UHF Module Assembly, RF Module Pallet, Philips ........................... 4-2

4.1.5 2 Way UHF Combiner Assembly................................................. 4-3

4.1.6 Amplifier Control Board ............................................................ 4-3

4.2 Power Supply Assembly.................................................................... 4-5

CHAPTER 5 DETAILED ALIGNMENT PROCEDURES

5.1 Module Replacement ........................................................................ 5-1

5.1.1 Initial Test Setup .................................................................... 5-1

5.2 Innovator LX Series Exciter/Driver Chassis Assembly.............................. 5-1

5.2.1 (Optional) Receiver Module Assembly ......................................... 5-2

5.2.2 Modulator Module Assembly ...................................................... 5-2

5.2.3 IF Processor Module Assembly .................................................. 5-3

5.2.4 VHF/UHF Upconverter Module Assembly ...................................... 5-3

5.2.5 Setting up the Drive Level of the Transmitter ............................... 5-4

5.2.6 Changing the Channel on the Transmitter.................................... 5-4

5.2.7 Frequency Response Delay Equalization Adjustment ...................... 5-4

5.2.8 Linearity Correction Adjustment ................................................ 5-5

5.3 Bandpass Filter Assembly ................................................................. 5-6

5.4 (Optional) One or Two Section Trap Filter Assembly ............................... 5-7

5.4.1 Fine Tuning ........................................................................... 5-8

5.4.2 Major Tuning ......................................................................... 5-8

5.5 Calibration of Transmitter Forward Output Power Level........................... 5-9

5.6 Calibration of Transmitter Reflected Output Power Level ........................5-10

APPENDICES

APPENDIX A INNOVATOR LX SERIES SPECIFICATIONS

APPENDIX B DRAWINGS AND PARTS LISTS

APPENDIX C TRANSMITTER LOG SHEET

LX Series, Rev. 1 March 2, 2005 ii

LX Series Power Amplifier Assembly Table of Contents

LIST OF FIGURES

FIGURE PAGE

1-1 Brady Marker Identification Drawing............................................. 1-1

2-1 1kW Power Amplifier Assembly Racking Plan .................................. 2-3

3-1 1 kW Minimum Ventilation Configuration ....................................... 3-4

3-2 Front and Rear View Exciter/Driver .............................................. 3-5

3-3 Front and Rear View 76” Cabinet Typical 4kW Configuration.............. 3-6

3-4 AC Input Box Assembly ............................................................. 3-6

3-5 Rear View of LX Series Transmitter/Translator................................ 3-8

4-1 250 Watt UHF Amplifier Module ................................................... 4-2

5-1 Typical Red Field Spectrum......................................................... 5-5

5-2 Bandpass Filter........................................................................ 5-7

5-3 One Section Trap Filter.............................................................. 5-8

LX Series, Rev. 1 iii

LX Series Power Amplifier Assembly Table of Contents

LIST OF TABLES

TABLE PAGE

2-1 Typical LX Series Analog System Drawings and Parts Lists................ 2-3

2-2 Typical LX Series Dig ital System Drawings and Parts Lists................. 2-4

2-3 LX Series Power Amplifier Chassis Assemblies ................................ 2-8

2-4 Power Amplifier Status Indicators ................................................ 2-9

2-5 Power Amplifier Control Adjustments............................................ 2-9

2-6 Power Amplifier Sample ............................................................. 2-9

2-7 LX Series Customer Remote Connections...............................2-13

3-1 LX Series Transmitters AC Input and Current Requirements.............. 3-1

3-2 LX Series Transmitters AC Input and Current Requirements.............. 3-6

3-3 Rear Chassis Connections for LX Series Transmitter.........................3-8

(Optional) Exciter Switcher Menu Screens....................................................3-11

3-4 Exciter Switcher Menu 01 Splash Screen #1 .................................3-11

3-5 Menu 02 Splash Screen #2........................................................3-11

3-6 Menu 03 Exciter Switcher Control Screen, Automatic Operation.......3-11

3-7 Menu 04 Exciter Switcher Control Screen, Manual Operation...........3-11

3-8 Menu 05 Exciter Switcher Control Screen, Amps On Line................3-11

3-9 Menu 06 Exciter Switcher Control Screen, Cancel Auto Back up.......3-12

3-10 Menu 07 Exciter Switcher Control Screen, B Back up to A...............3-12

3-11 Menu 08 Exciter Switcher Control Screen, back up Changeover.......3-12

3-12 Menu 09 Exciter Switcher Control Screen, Ext Amp Status..............3-12

3-13 Menu 10 Exciter Switcher Control Screen, Ext Amp Status..............3-12

LX System Controller Menu Screens .............................................................3-13

3-14 Menu 01 Splash Screen #1........................................................3-13

3-15 Menu 02 Splash Screen #2........................................................3-13

3-16 Menu 10 Main Screen ..............................................................3-13

3-17 Menu 11 Error List Access Screen...............................................3-14

3-18 Menu 12 Transmitter Device Data Access Screen ..........................3-14

3-19 Menu 13 Transmitter Configuration Access Screen ........................3-14

3-20 Menu 20 Error List Display Screen ..............................................3-14

3-21 Menu 30 Transmitter Device Details Screen .................................3-15

3-22 Menu 30-1 System Details Screens ............................................3-15

3-23 Transmitter Device Parameters Detail Screens .............................3-15

3-24 Menu 40 Authorized Personnel Screen ........................................3-16

3-25 Menu 40-1 Transmitter Set Up: Power Raise/Lower Screen .............3-17

3-26 Menu 40-2 Transmitter Set Up: Model Select Screen .....................3-17

3-27 Menu 40-3 Transmitter Set Up: Receiver Channel Configuration......3-18

3-28 Menu 40-4 Transmitter Set Up: Upconverter Channel Select Screen .3-18

3-29 Menu 40-5 Transmitter Set Up: Serial Address Screen...................3-18

3-30 Menu 40-6 Transmitter Set Up: Station ID Screen..........................3-18

3-31 Menu 40-7 Transmitter Set Up: System Visual Power Cal. Screen......3-19

3-32 Menu 40-8 Transmitter Set Up: System Aural Power Cal. Screen.......3-19

3-33 Menu 40-9 Transmitter Set Up: System Rfltd. Power Cal. Screen ......3-19

3-34 Menu 40-10 Transmitter Set Up: Modulated Output Cal. Screen ........3-19

3-35 Menu 40-11 Transmitter Set Up: Aural Deviation Screen .................3-20

3-36 Menu 40-12 Transmitter Set Up: Fwrd Pwr Fault Threshold Screen....3-20

3-37 Menu 40-13 Transmitter Set Up: Refl Power Fault Threshold Screen ..3-20

3-38 Menu 40-14 Transmitter Set Up: DLC Control Screen......................3-20

3-39 Menu 40-15 Transmitter Set Up: Auto Standby Control Screen.........3-21

LX Series, Rev. 1 iv

LX Series Power Amplifier Assembly Table of Contents

LIST OF TABLES

TABLE PAGE

3-40 Menu 40-16 Transmitter Set Up: Receiver ALC Fault Set Up Screen...3-21

3-41 Menu 40-17 Transmitter Set Up: Inner Loop Gain Control Screen ......3-21

3-42 Menu 40-18 Transmitter Set Up: Optional System Control Screen .....3-21

3-43 Menu 40-19 Transmitter Set Up: Remote Command Control Screen...3-22

5-1 Typical Bandpass Values ............................................................ 5-6

5-2 Results of Tuning the Output Trap Filter........................................ 5-9

LX Series, Rev. 1 v

LX Series Power Amplifier Assembly Chapter 1, Introduction

Chapter 1

Introduction

1.1 Manual Overview

This manual explains the installation,

setup, alignment, and maintenance

procedures for the Power Amplifier

Assembly for the Innovator LX Series

transmitter. It is important that you

read all of the instructio ns, especially

the safety information in this chapter,

before you begin to install or operate

the unit.

This instruction manual is divided into

five chapters and supporting appendices.

Chapter 1, Introduction, contains

information on the assembly numbering

system used in the manual, safety,

maintenance, return procedures, and

warranties. Chapter 2, Amplifier

Assembly Description, Maintenance &

Remote Control Connections, describes

the amplifier assembly and includes

discussions on control and status

indicators and remote control

connections. Chapter 3, Site

Considerations, Installation and Setup

Procedures, explains how to unpack,

install, setup, and operate the power

amplifier assembly. Chapter 4, Circuit

Descriptions, contains circuit level

descriptions for boards and board level

components in the power amplifier.

Chapter 5, Detailed Alignment

Procedures, provides information on

adjusting the power amplifier and the

system for optimal operation. Appendix

A contains system specifications.

Appendix B contains assembly and

subassembly drawings and parts lists.

Appendix C contains a transmitter log

sheet.

1.2 Assembly Designators

Axcera has assigned assembly numbers,

such as Ax (x=1,2,3…), to all assemblies,

trays, and boards that are referenced in

the text of this manual and shown on the

block diagrams and interconnect

drawings provided in the appendices.

These supporting documents are

arranged in increasing numerical order in

the appendices. Section titles in the text

for assembly or tray descriptions or

alignment procedures contain the

associated part number(s) and the

relevant appendix that contains the

drawings for that item.

The cables that connect between the

boards within a tray or assembly and

that connect between the trays, racks

and cabinets are labeled using Brady

markers.

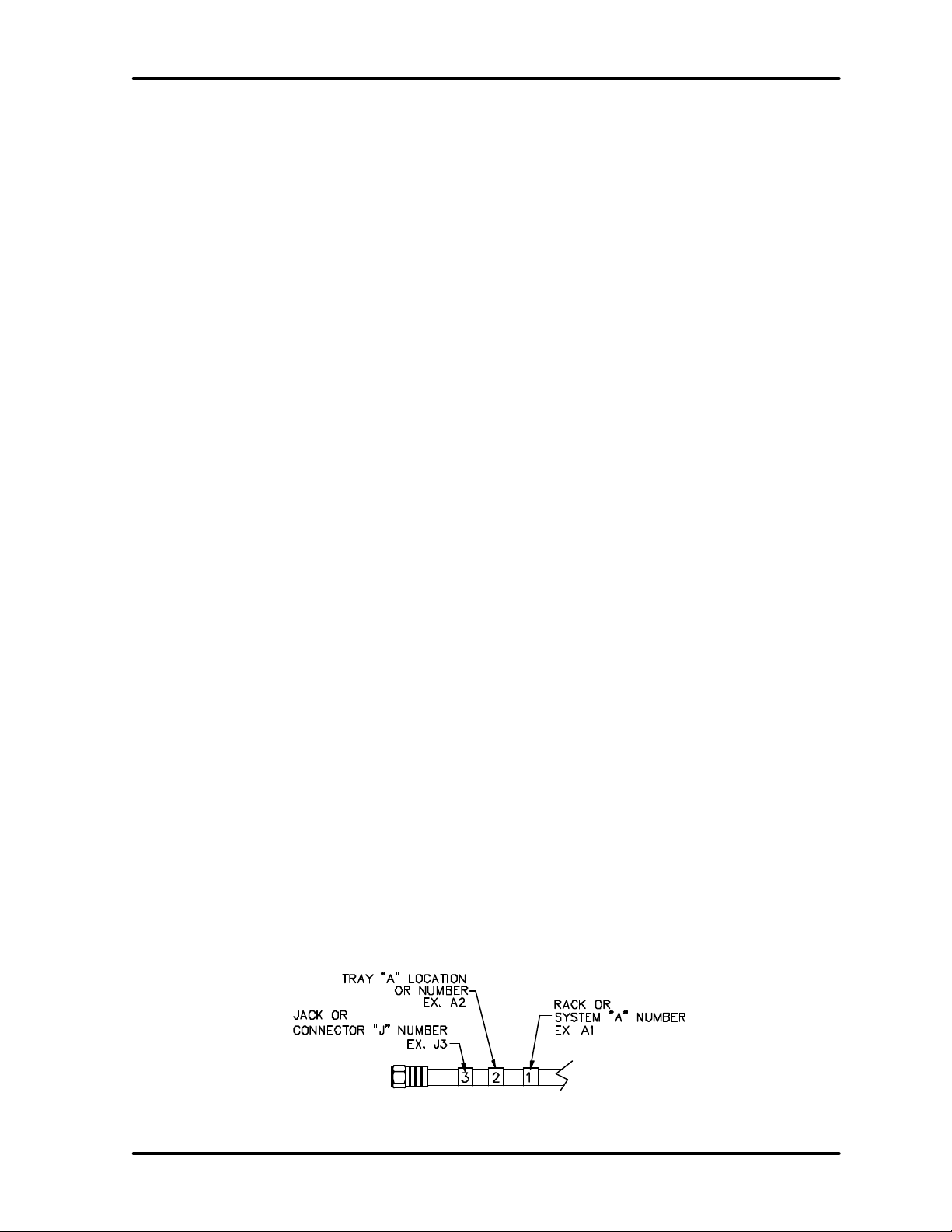

Figure 1-1 is an example of a Brady

marked cable. There may be as few as

two or as many as four Markers on any

one cable. These Brady markers are

read starting furthest from the

connector. If there are four Brady

Markers, this marker is the transmitter

number such as transmitter 1 or

transmitter 2. The next or the furthest

Brady Marker is the rack or cabinet

number on an interconnect cable or the

board number within a tray. The next

number on an interconnect cable is the

tray location or number. The Brady

marker closest to the connector is the

jack or connector number on an

interconnect cable or the jack or

connector number on the board within a

tray.

Figure 1-1 Brady Marker Identification Drawing

LX Series, Rev. 1 1-1

LX Series Power Amplifier Assembly Chapter 1, Introduction

1.3 Safety

The transmitters and associated power

amplifier assemblies manufactured by

Axcera are designed to be easy to use

and repair while providing protection

from electrical and mechanical hazards.

Listed throughout the manual are notes,

cautions, and warnings concerning

possible safety hazards that may be

encountered while operating or servicing

the transmitter. Please review these

warnings and familiarize yourself with the

operation and servicing procedures

before working on the assembly.

Read All Instructions – All of the

operating and safety instructions should

be read and understood before operating

this equipment.

Retain Manuals – The manuals for the

power amplifier assembly and the

transmitter should be retained at the

transmitter site for future reference. We

provide two sets of manuals for this

purpose; one set can be left at the office

while one set can be kept at the site.

Heed all Notes, Warnings, and

Cautions – All of the notes, warnings,

and cautions listed in this safety section

and throughout the manual must be

followed.

Follow Instructions – All of the

operating and use instructions for the

amplifier assembly should be followed.

Cleaning – Unplug or otherwise

disconnect all power from the equipment

before cleaning. Do not use liquid or

aerosol cleaners. Use a damp cloth for

cleaning.

Ventilation – Openings in the cabinets

and modules front panels are provided

for ventilation. To ensure the reliable

operation of the amplifier assembly, and

to protect the unit from overheating,

these openings must not be blocked.

Servicing – Do not attempt to service

this product yourself until becoming

familiar with the equipment. If in doubt,

refer all servicing questions to qualified

Axcera service personnel.

Replacement Parts – When

replacement parts are used, be sure that

the parts have the same functional and

performance characteristics as the

original part. Unauthorized substitutions

may result in fire, electric shock, or other

hazards. Please contact the Axcera

Technical Service Department if you have

any questions regarding service or

replacement parts.

1.4 Contact Information

The Axcera Field Service Department can

be contacted by phone at (724) 873-

8100 or by fax at (724) 873-8105.

Before calling Axcera, please be prepared

to supply the Axcera technicia n with

answers to the following questions. This

will save time and help ensure the most

direct resolution to the problem.

1. What are the Customers’ Name

and call letters?

2. What are the model number and

type of transmitter?

3. Is the transmitter digital or

analog?

4. How long has the transmitter

been on the air? (Approximately

when was the transmitter

installed.)

5. What are the symptoms being

exhibited by the transmitter?

Include the current control/power

supply LCD readings and the

status of LEDs on the front

panels of the modules. If

possible, include the

control/power supply LCD

readings before the problem

occurred.

1.5 Return Material Procedure

To insure the efficient handling of

equipment or components that have been

returned for repair, Axcera requests that

each returned item be accompanied by a

LX Series, Rev. 1 1-2

LX Series Power Amplifier Assembly Chapter 1, Introduction

Return Material Authorization Number

(RMA#).

An RMA# can be obtained from any

Axcera Field Service Engineer by

contacting the Axcera Field Service

Department at (724) 873-8100 or by fax

at (724) 873-8105. This procedure

applies to all items sent to the Field

Service Department regardless of

whether the item was originally

manufactured by Axcera.

When equipment is sent to the field on

loan, an RMA# is included with the unit.

The RMA# is intended to be used when

the unit is returned to Axcera. In

addition, all shipping material should be

retained for the return of the unit to

Axcera.

Replacement assemblies are also sent

with an RMA# to allow for the proper

routing of the exchanged hardware.

Failure to close out this type of RMA# will

normally result in the customer being

invoiced for the value of the loaner item

or the exchange assembly.

When shipping an item to Axcera, please

include the RMA# on the packing list and

on the shipping container. The packing

slip should also include contact

information and a brief description of why

the unit is being returned.

Please forward all RMA items to:

AXCERA, LLC

103 Freedom Drive

P.O. Box 525

Lawrence, PA 15055-0525 USA

For more information concerning this

procedure, call the Axcera Field Service

Department.

Axcera can also be contacted through email at info@axcera.com and on the

Web at www.axcera.com.

1.6 Limited One Year Warranty for

Axcera Products

Axcera warrants each new product that

it has manufactured and sold against

defects in material and workmanship

under normal use and service for a

period of one (1) year from the date of

shipment from Axcera's plant, when

operated in accordance with Axcera's

operating instructions. This warranty

shall not apply to tubes, fuses,

batteries, or bulbs.

Warranties are valid only when and if

(a) Axcera receives prompt written

notice of breach within the period of

warranty, (b) the defective product is

properly packed and returned by the

buyer (transportation and insurance

prepaid), and (c) Axcera determines, in

its sole judgment, that the product is

defective and not subject to any misuse,

neglect, improper installation,

negligence, accident, or (unless

authorized in writing by Axcera) repair

or alteration. Axcera's exclusive liability

for any personal and/or property

damage (including direct, consequential,

or incidental) caused by the breach of

any or all warranties, shall be limited to

the following: (a) repairing or replacing

(in Axcera's sole discretion) any

defective parts free of charge (F.O.B.

Axcera’s plant) and/or (b) crediting (in

Axcera's sole discretion) all or a portion

of the purchase price to the buyer.

Equipment furnished by Axcera, but not

bearing its trade name, shall bear no

warranties other than the special hours of-use or other warranties extended by

or enforceable against the manufacturer

at the time of delivery to the buyer.

NO WARRANTIES, WHETHER

STATUTORY, EXPRESSED, OR

IMPLIED, AND NO WARRANTIES OF

MERCHANTABILITY, FITNESS FOR

ANY PARTICULAR PURPOSE, OR

FREEDOM FROM INFRINGEMENT,

OR THE LIKE, OTHER THAN AS

SPECIFIED IN PATENT LIABILITY

ARTICLES, AND IN THIS ARTICLE,

SHALL APPLY TO THE EQUIPMENT

FURNISHED HEREUNDER.

LX Series, Rev. 1 1-3

LX Series Power Amplifier Assembly Chapter 1, Introduction

F WARNING!!!

× HIGH VOLTAGE Ø

DO NOT ATTEMPT TO REPAIR OR TROUBLESHOOT THIS EQUIPMENT UNLESS

YOU ARE FAMILIAR WITH ITS OPERATION AND EXPERIENCED IN

SERVICING HIGH VOLTAGE EQUIPMENT. LETHAL VOLTAGES ARE PRESENT

WHEN POWER IS APPLIED TO THIS SYSTEM. IF POSSIBLE, TURN OFF

POWER BEFORE MAKING ADJUSTMENTS TO THE SYSTEM.

« RADIO FREQUENCY RADIATION HAZARD «

MICROWAVE, RF AMPLIFIERS AND TUBES GENERATE HAZARDOUS RF

RADIATION THAT CAN CAUSE SEVERE INJURY INCLUDING CATARACTS,

WHICH CAN RESULT IN BLINDNESS. SOME CARDIAC PACEMAKERS MAY BE

AFFECTED BY THE RF ENERGY EMITTED BY RF AND MICROWAVE

AMPLIFIERS. NEVER OPERATE THE TRANSMITTER SYSTEM WITHOUT A

PROPERLY MATCHED RF ENERGY ABSORBING LOAD ATTACHED. KEEP

PERSONNEL AWAY FROM OPEN WAVEGUIDES AND ANTENNAS. NEVER LOOK

INTO AN OPEN WAVEGUIDE OR ANTENNA. MONITOR ALL PARTS OF THE RF

SYSTEM FOR RADIATION LEAKAGE AT REGULAR INTERVALS.

LX Series, Rev. 1 1-4

LX Series Power Amplifier Assembly Chapter 1, Introduction

EMERGENCY FIRST AID INSTRUCTIONS

Personnel engaged in the installation, operation, or maintenance of this equipment are urged to become

familiar with the following rules both in theory and practice. It is the duty of all operating personnel to be

prepared to give adequate Emergency First Aid and thereby prevent avoidable loss of life.

RESCUE BREATHING

1. Find out if the person is

breathing.

You must find out if the person

has stopped breathing. If you

think he is not breathing, place

him flat on his back. Put your ear

close to his mouth and look at his

chest. If he is breathing you can

feel the air on your cheek. You

can see his chest move up and

down. If you do not feel the air

or see the chest move, he is not

breathing.

2. If he is not breathing, open

the airway by tilting his head

backwards.

Lift up his neck with one hand

and push down on his forehead

with the other. This opens the

airway. Sometimes doing this will

let the person breathe again by

himself.

SKIN REDDENED: Apply ice cold water to burned

area to prevent burn from going deeper into skin

tissue. Cover area with clean sheet or cloth to keep

away air. Consult a physician.

SKIN BLISTERED OR FLESH CHARRED: Apply ice

cold water to burned area to prevent burn from

going deeper into skin tissue.

3. If he is still not breathing,

begin rescue breathing.

-Keep his head tilted backward.

Pinch nose shut.

-Put your mouth tightly over his

mouth.

-Blow into his mouth once every

five seconds

-DO NOT STOP rescue breathing

until help arrives.

LOOSEN CLOTHING - KEEP

WARM

Do this when the victim is

breathing by himself or help is

available. Keep him as quiet as

possible and from becoming

chilled. Otherwise treat him for

shock.

BURNS

Cover area with clean sheet or cloth to keep away

air. Treat victim for shock and take to hospital.

EXTENSIVE BURN - SKIN BROKEN: Cover area with

clean sheet or cloth to keep away air. Treat victim

for shock and take to hospital.

LX Series, Rev. 1 1-5

LX Series Power Amplifier Assembly Chapter 1, Introduction

dBm, dBw, dBmV, dBµV, & VOLTAGE

EXPRESSED IN WATTS

50 Ohm System

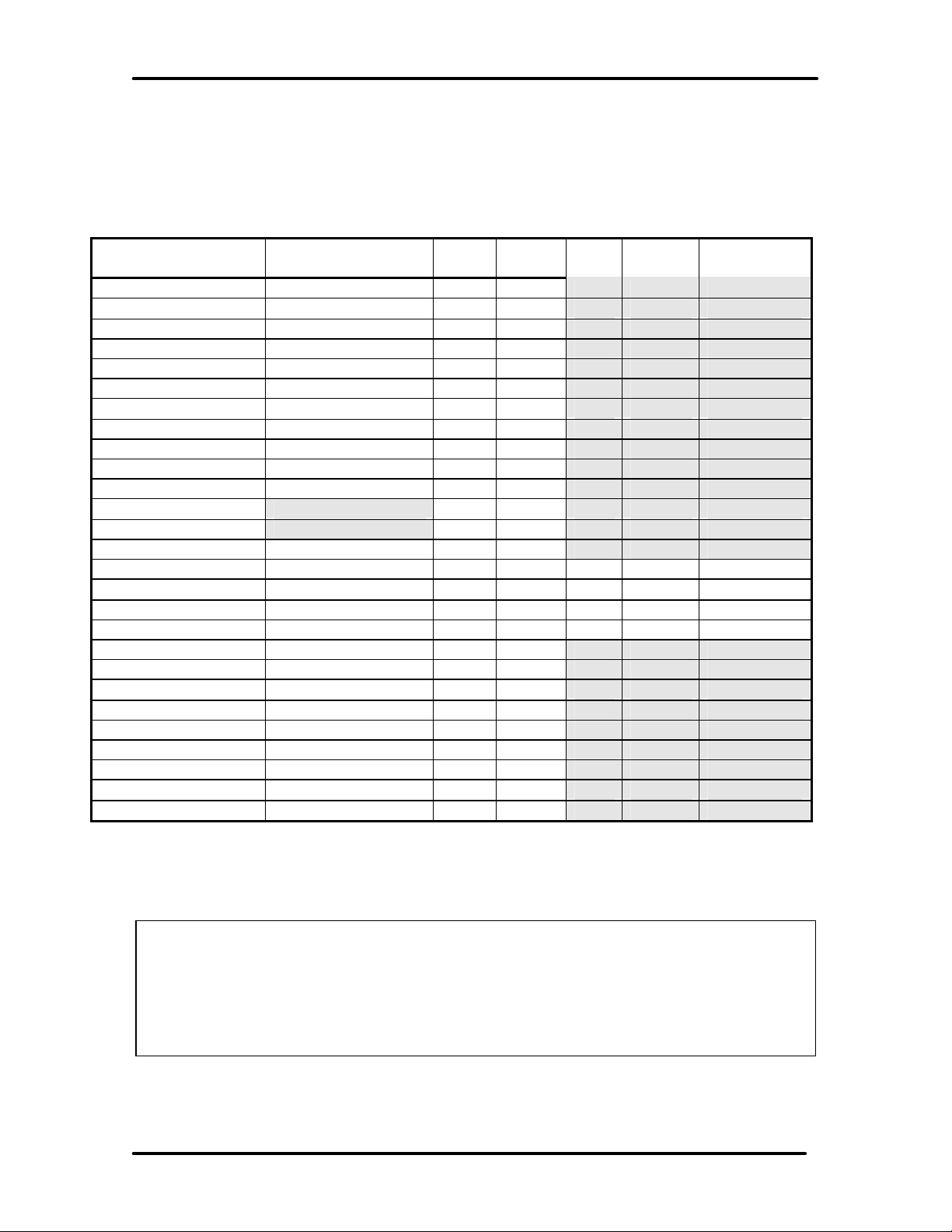

WATTS PREFIX dBm dBw dBm

V

1,000,000,000,000 1 TERAWATT +150 +120

100,000,000,000 100 GIGAWATTS +140 +110

10,000,000,000 10 GIGAWATTS +130 +100

1,000,000,000 1 GIGAWATT +120 + 99

100,000,000 100 MEGAWATTS +110 + 80

10,000,000 10 MEGAWATTS +100 + 70

1,000,000 1 MEGAWATT + 90 + 60

100,000 100 KILOWATTS + 80 + 50

10,000 10 KILOWATTS + 70 + 40

1,000 1 KILOWATT + 60 + 30

100 1 HECTROWATT + 50 + 20

50 + 47 + 17

20 + 43 + 13

10 1 DECAWATT + 40 + 10

1 1 WATT + 30 0 + 77 +137 7.07V

0.1 1 DECIWATT + 20 - 10 + 67 +127 2.24V

0.01 1 CENTIWATT + 10 - 20 + 57 +117 0.707V

0.001 1 MILLIWATT 0 - 30 + 47 +107 224mV

0.0001 100 MICROWATTS - 10 - 40

0.00001 10 MICROWATTS - 20 - 50

0.000001 1 MICROWATT - 30 - 60

0.0000001 100 NANOWATTS - 40 - 70

0.00000001 10 NANOWATTS - 50 - 80

0.000000001 1 NANOWATT - 60 - 90

0.0000000001 100 PICOWATTS - 70 -100

0.00000000001 10 PICOWATTS - 80 -110

0.000000000001 1 PICOWATT - 90 -120

dBµV VOLTAGE

TEMPERATURE CONVERSION

° F = 32 + [(9/5) °C]

° C = [(5/9) (°F - 32)]

LX Series, Rev. 1 1-6

LX Series Power Amplifier Assembly Chapter 1, Introduction

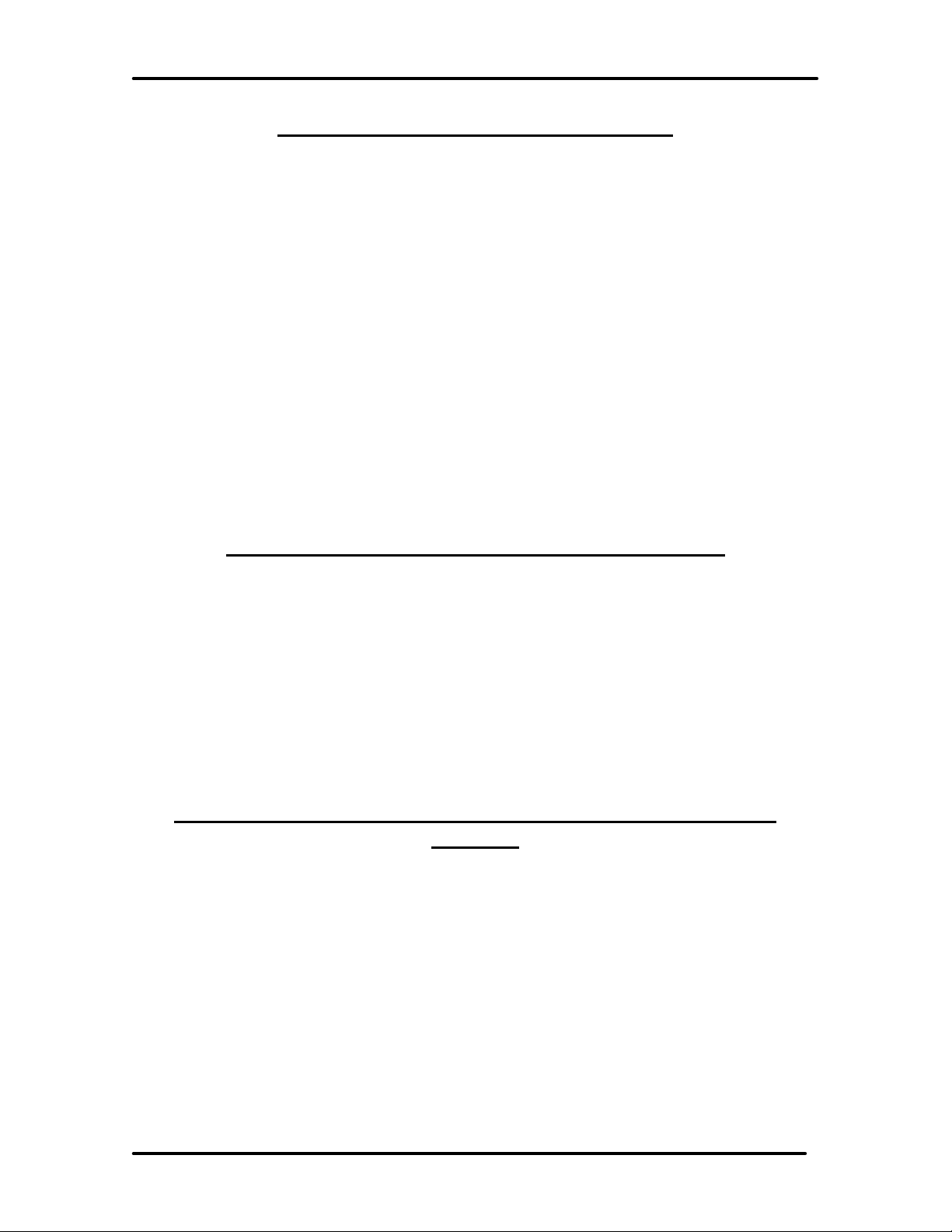

USEFUL CONVERSION FACTORS

TO CONVERT FROM TO MULTIPLY BY

mile (US statute) kilometer (km) 1.609347

inch (in) millimeter (mm) 25.4

inch (in) centimeter (cm) 2.54

inch (in) meter (m) 0.0254

foot (ft) meter (m) 0.3048

yard (yd) meter (m) 0.9144

mile per hour (mph) kilometer per hour(km/hr) 1.60934

mile per hour (mph) meter per second (m/s) 0.44704

pound (lb) kilogram (kg) 0.4535924

gallon (gal) liter 3.7854118

U.S. liquid

(One U.S. gallon equals 0.8327 Canadian gallon)

fluid ounce (fl oz) milliliters (ml) 29.57353

British Thermal Unit watt (W) 0.2930711

per hour (Btu/hr)

horsepower (hp) watt (W) 746

NOMENCLATURE OF FREQUENCY BANDS

FREQUENCY RANGE DESIGNATION

3 to 30 kHz VLF - Very Low Frequency

30 to 300 kHz LF - Low Frequency

300 to 3000 kHz MF - Medium Frequency

3 to 30 MHz HF - High Frequency

30 to 300 MHz VHF - Very High Frequency

300 to 3000 MHz UHF - Ultrahigh Frequency

3 to 30 GHz SHF - Superhigh Frequency

30 to 300 GHz EHF - Extremely High Frequency

LETTER DESIGNATIONS FOR UPPER FREQUENCY

BANDS

LETTER FREQ. BAND

L 1000 - 2000 MHz

S 2000 - 4000 MHz

C 4000 - 8000 MHz

X 8000 - 12000 MHz

Ku 12 - 18 GHz

K 18 - 27 GHz

Ka 27 - 40 GHz

V 40 - 75 GHz

W 75 - 110 GHz

LX Series, Rev. 1 1-7

LX Series Power Amplifier Assembly Chapter 1, Introduction

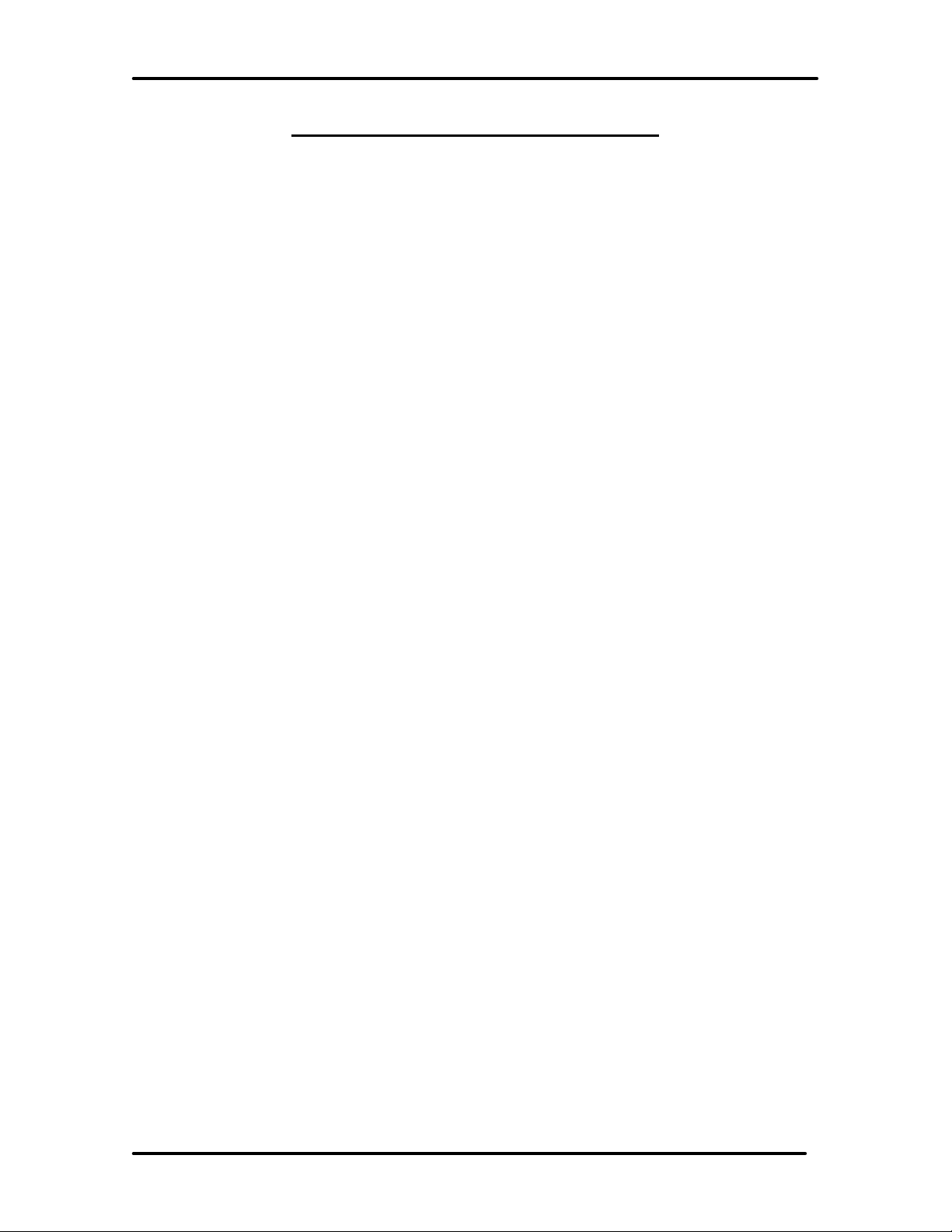

ABBREVIATIONS/ACRONYMS

AC Alternating Current

AFC Automatic Frequency Control

ALC Automatic Level Control

AM Amplitude modulation

AGC Automatic Gain Control

AWG American wire gauge

BER Bit Error Rate

BW Bandwidth

DC Direct Current

D/A Digital to analog

dB Decibel

dBm Decibel referenced to 1 milliwatt

dBmV Decibel referenced to 1 millivolt

dBw Decibel referenced to 1 watt

FEC Forward Error Correction

FM Frequency modulation

Hz Hertz

ICPM Incidental Carrier Phase Modulation

I/P Input

IF Intermediate Frequency

LED Light emitting diode

LSB Lower Sideband

MPEG Motion Pictures Expert Group

O/P Output

PLL Phase Locked Loop

PCB Printed circuit board

QAM Quadrature Amplitude Modulation

LX Series, Rev. 1 1-8

LX Series Power Amplifier Assembly Chapter 1, Introduction

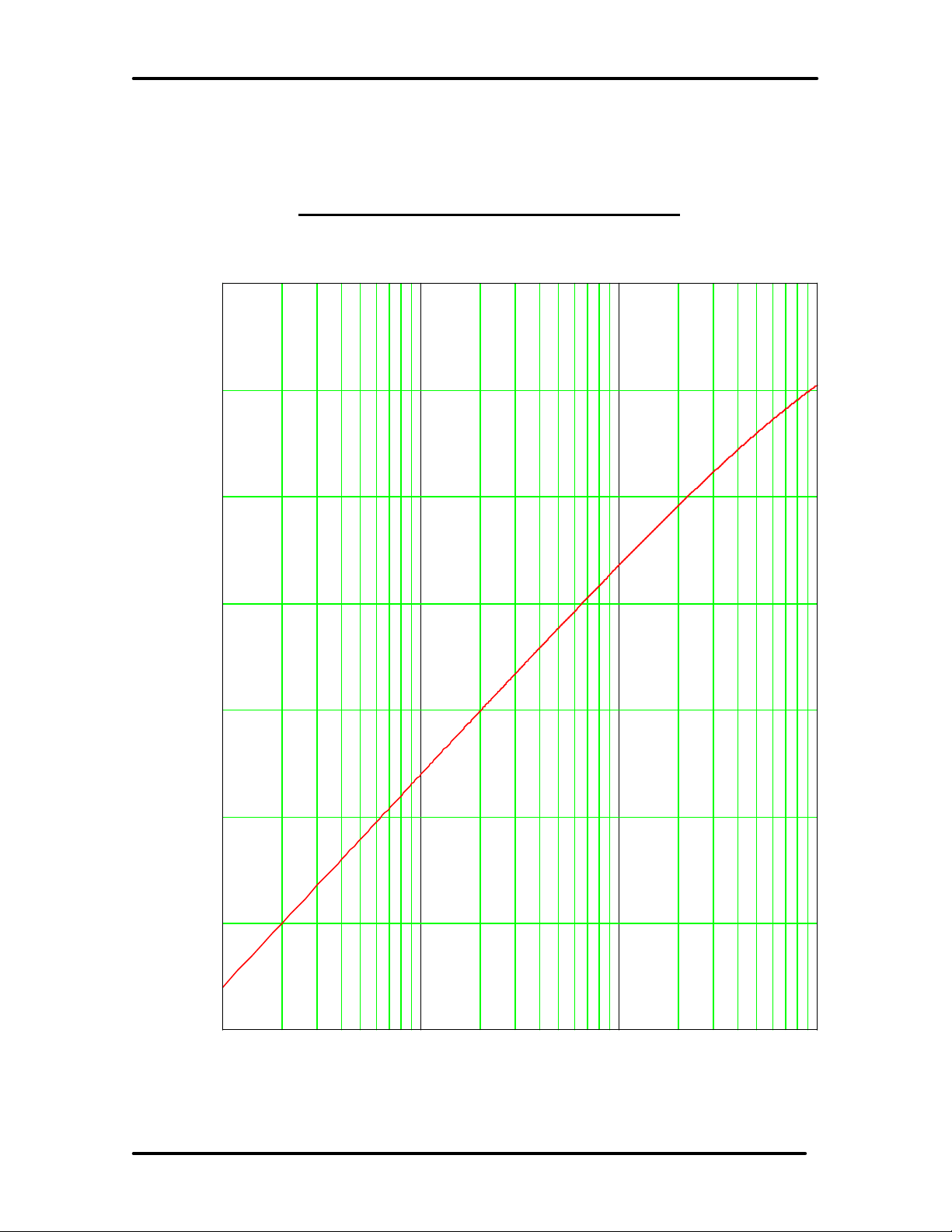

N

dB

RETURN LOSS VS. VSWR

0

-10

-20

R

E

T

U

R

L

O

S

S

-30

-40

-50

-60

-70

1.001 1.01 1.1 2.0

VSWR

LX Series, Rev. 1 1-9

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

Chapter 2

Amplifier Assembly Description, Maintenance

& Remote Control Connections

2.1 LX Series Power Amplifier Chassis

Assembly Overview

The power amplifier chassis assembly in

the LX Series contains modular television

amplifiers that slide into the assembly

each producing approximately 250 Watts

peak of sync output. There is also needed

one external Power Supply Module

Assembly for every two 250 Watt PA

modules, which also slide into the Power

Amplifier Chassis Assembly, under the PA

Modules. Four PA modules and two Power

Supply modules are the maximum

number of modules in one Power Amplifier

Chassis Assembly producing 1 kW analog

output power . Two Power Amplifier

Chassis Assemblies are required for 2 kW

analog output power, three Power

Amplifier Chassis Assemblies for 3 kW

analog, four Power Amplifier Chassis

Assemblies for 4 kW analog, five Power

Amplifier Chassis Assemblies for 5 kW

analog, and six Power Amplifier Chassis

Assemblies are required for 6 kW analog

output power.

In a 250W system the RF output of the

exciter/driver at the “N” connector J25

connects to the (A3) power amplifier

chassis assembly at the “N” connector

J201.

In a 500W or 1 kW system the RF output

of the exciter/driver at the “N” connector

J25 connects to the (A3) power amplifier

chassis assembly at the “N” connector

J200.

In a 2 kW system the RF output of the

exciter/driver connects to (A5) a 2 Way

Splitter Assembly. The two outputs of the

splitter connect to the (A3) and (A6)

power amplifier chassis assemblies at

J200.

In a 3 kW system the RF output of the

exciter/driver connects to (A5) a 4 Way

Splitter Assembly. Three outputs of the

splitter, the fourth at J5 is 5 Watt

terminated, connect to the (A3), (A6)

and (A13) power amplifier chassis

assemblies at J200.

In a 4 kW system there are two cabinet

assemblies (A1 and A2). The (A1)

cabinet assembly contains the (A1-A27)

exciter/driver assembly and the (A1-A6

and A1-A3) Power Amplifiers. The (A2)

cabinet assembly contains the (A2-A6

and A2-A3) Power Amplifiers. The RF

output of the exciter/driver connects to

(A1-A5) a 4 Way Splitter Assembly.

Three outputs of the splitter at J2, J4 and

J5 connect to the (A1-A3), (A2-A6) and

(A2-A3) power amplifier chassis

assemblies at J200. The fourth output of

the splitter at J1 is connected through

A1-A5-A1, a phase matching line, before

it is connected to the input of the

(A1-A6) Power Amplifier.

In a 5 kW system there are two cabinet

assemblies (A1 and A2). The (A1)

cabinet assembly contains the (A1-A27)

exciter/driver assembly and the (A1-A6

and A1-A3) Power Amplifiers. The (A2)

cabinet assembly contains the (A2-A6,

A2-A3 and A2-A13) Power Amplifiers.

The RF output of the exciter/driver at J25

connects to (A1-A5-A1) a 2 Way Splitter

Assembly. One output of the splitter

connects to (A2-A5) a 4 way splitter in

the (A2) cabinet and the other output

connects to (A1-A5-A2) a 4 way splitter

in the (A1) cabinet. Two of the outputs

of the (A1-A5-A2) splitter at J1 and J5

connect to the (A1-A6) and the (A1-A3)

power amplifier chassis assemblies at

J200. The RF outputs at J2 and J4 of the

(A1-A5-A2) splitter are terminated. The

other output of the (A1-A5-A1) splitter at

J2 connects to the (A2) cabinet at J3 of

(A2-A5) a 4 way splitter. Three of the

outputs of the (A2-A5) splitter at J1, J2

and J4 connect to the (A1-A6), (A1-A3)

LX Series, Rev. 1 2-1

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

and (A1-A13) power amplifier chassis

assemblies at J200. The other output of

the (A2-A5) splitter at J5 is terminated.

In a 6 kW system there are two cabinet

assemblies (A1 and A2). The (A1) cabinet

assembly contains the (A1-A27)

exciter/driver assembly and the (A1-A6,

A1-A3, and A1-A13) Power Amplifiers.

The (A2) cabinet assembly contains the

(A2-A6, A2-A3, and A2-A13) Power

Amplifiers. The RF output of the

exciter/driver at J25 connects to (A1-A5A1) a 2 Way Splitter Assembly. One

output of the splitter connects to (A2-A5)

a 4 way splitter in the (A2) cabinet and

the other output connects to (A1-A5-A2) a

4 way splitter in the (A1) cabinet. Three

of the outputs of the (A1-A5-A2) splitter

at J1, J2 and J4 connect to the (A1-A3),

(A1-A6) and (A1-A13) power amplifier

chassis assemblies at J200. The fourth

output of the (A1-A5-A2) splitter at J5 is

terminated. The other output of the (A1A5-A1) splitter at J2 connects to the (A2)

cabinet at J3 of (A2-A5) a 4 way splitter.

Three of the outputs of the (A2-A5)

splitter at J1, J2, and J4 connect to the

(A2-A3), (A2-A6), and (A2-A13) power

amplifier chassis assemblies at J200. The

other output of the (A2-A5) splitter at J5

is terminated.

Data and control inf ormation for the

system is fed through the system serial

cable. In a 250W, 500W or 1kW system,

the system serial cable connects from J34

on the exciter/driver assembly to J232 on

the (A3) Power Amplifier Assembly.

In a 2 kW system, the system serial cable

connects from J34 on the exciter/driver

assembly to J232 on the (A3) Power

Amplifier Assembly. The serial cable then

connects from J233 on the (A3) power

amplifier to J232 on the (A6) power

amplifier.

In a 3 kW system, the system serial cable

connects from J34 on the exciter/driver

assembly to J232 on the (A3) Power

Amplifier Assembly. The serial cable then

connects from J233 on the (A3) power

amplifier to J232 on the (A6) power

amplifier and from J233 on the (A6)

power amplifier to J232 on the (A13)

power amplifier.

In a 4 kW system, the system serial

cable connects from J34 on the

exciter/driver assembly to J232 on the

(A1-A3) Power Amplifier Assembly. The

serial cable then connects from J233 on

the (A1-A3) power amplifier to J232 on

the (A1-A6) power amplifier. The serial

cable next connects from J233 on (A1A6) to J233 on the (A2-A3) power

amplifier and then from J233 on the (A2A3) power amplifier to J232 on the (A2A6) power amplifier.

In a 5 kW system, the system serial

cable connects from J34 on the

exciter/driver assembly to J232 on the

(A1-A3) Power Amplifier Assembly. The

serial cable then connects from J233 on

the (A1-A3) power amplifier to J232 on

the (A1-A6) power amplifier. The serial

cable next connects from J233 on (A1A6) to J232 on the (A2-A3) power

amplifier. The serial cable next connects

from J233 on (A2-A3) to J232 on the

(A2-A6) power amplifier and then from

J233 on the (A2-A6) power amplifier to

J232 on the (A2-A13) power amplifier.

In a 6 kW system, the system serial

cable connects from J34 on the

exciter/driver assembly to J232 on the

(A1-A3) Power Amplifier Assembly. The

serial cable then connects from J233 on

the (A1-A3) power amplifier to J232 on

the (A1-A6) power amplifier. The serial

cable next connects from J233 on (A1A6) to J232 on the (A1-A13) power

amplifier. The serial cable next connects

from J233 on (A1-A13) to J232 on the

(A2-A3) power amplifier and then from

J233 on the (A2-A3) power amplifier to

J232 on the (A2-A6) power amplifier.

Finally the serial cable connects from

J233 on (A2-A6) to J232 on (A2-A13)

power amplifier.

LX Series, Rev. 1 2-2

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

2.1.1 Power Amplifier Chassis

Configurations

In the 250W power amplifier chassis

assembly the RF from J201 connects to

the OSP Jack J111 in the power amplifier

assembly. In the power amplifier chassis

assemblies above 250W, the RF from J200

connects to the SMA Jack J100 on the 4

way splitter assembly. The 4 outputs, in a

1 kW amplifier power amplifier assembly,

connect through the output SMA jacks to

OSP input jacks of the four slide in power

amplifier module assemblies. J101

connects to jack J111 on power amplifier

#1. J102 connects to jack J121 on power

amplifier #2. J103 connects to jack J131

on power amplifier #3. J104 connects to

jack J141 on power amplifier #4.

2.1.1.1 250 Watt Power Amplifier Chassis

Configuration

In a 250 Watt power amplifier chassis

assembly, the RF input at J201 is

connected to J111 on the power amplifier

module. The output of the power

amplifier at J112 connects to the RF

output jack J203 of the power amplifier

chassis assembly.

2.1.1.2 500 Watt Power Amplifier Chassis

Configuration

In a 500 Watt power amplifier chassis

assembly, Jacks J103 and J104, on the 4

way splitter assembly, are not used and

are terminated with 50O. Also, the power

amplifier modules #3 and #4 are not

2.1.2 System Configurations

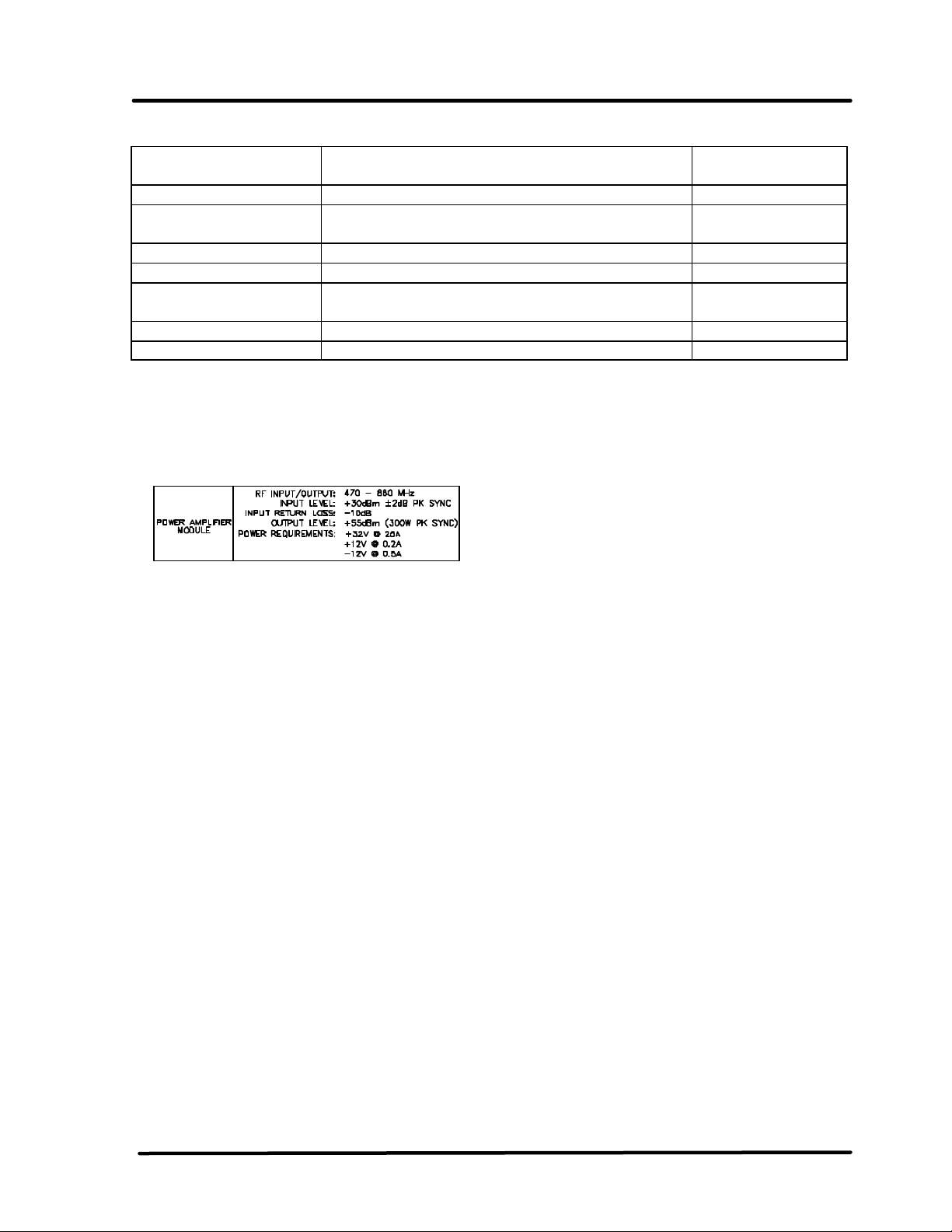

Table 2-1: Typical LX Series Analog System Configuration Drawings and Parts Lists

ANALOG SYSTEM

CONFIGURATIONS

250W 1303515 1303383

500W

1 kW

INTERCONNECT RACKING PLAN PARTS LIST

(Transmitter) 1303564

(Translator) 1303563

(Transmitter) 1303564

(Translator) 1303563

used. Finally a 2 way combiner is used in

place of the 4 way combiner.

2.1.1.3 1kW Power Amplifier Chassis

Configuration

In a 1 kW amplifier power amplifier

assembly, the output OSP jacks connect

to the OSP input jacks on the four way

combiner assembly. J112 connects to

J151 on the 4 way combiner. J122

connects to J152 on the 4 way combiner

power amplifier #2. J132 connects to

J153 on the 4 way combiner. J142

connects to J154 on the 4 way combiner.

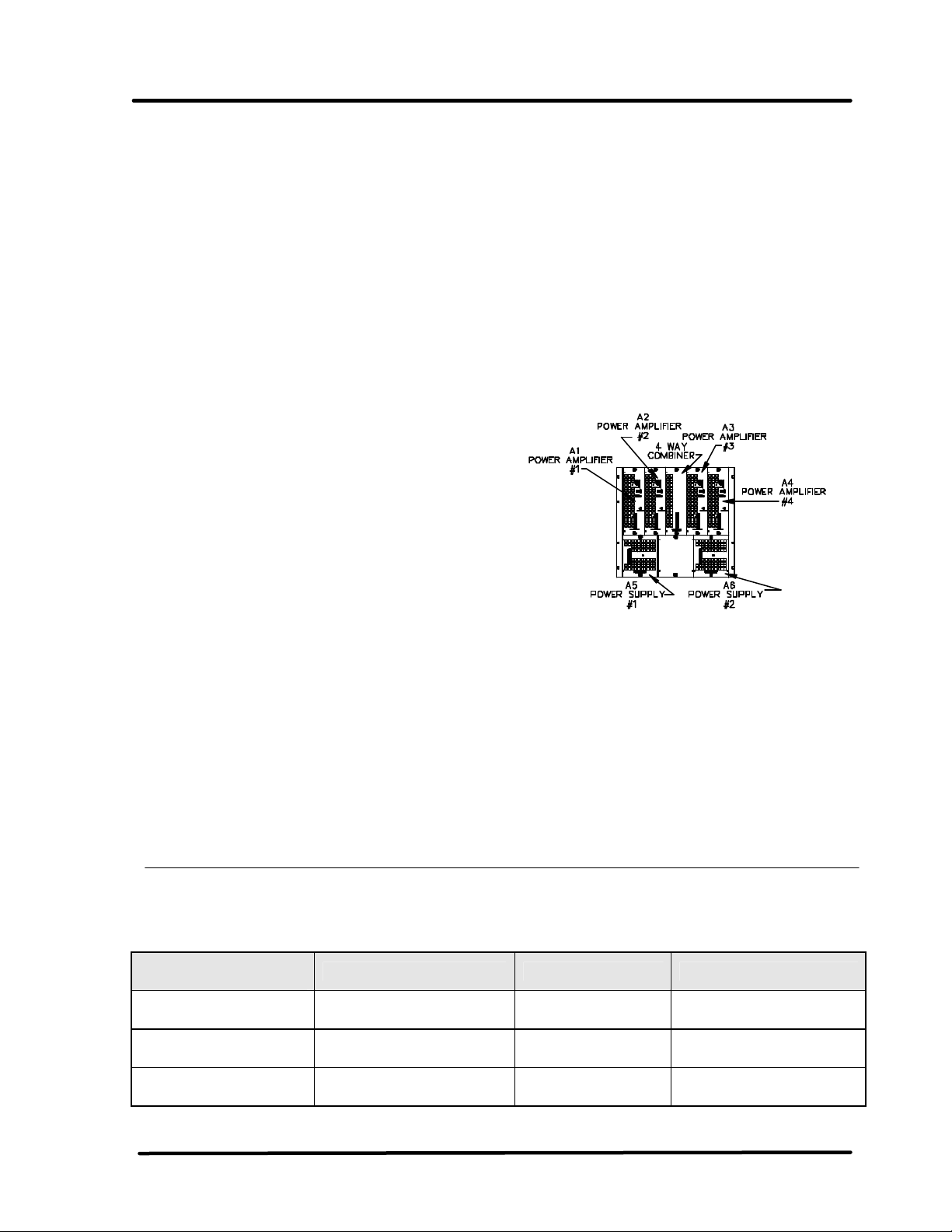

Figure 2-1. 1 kW Power Amplifier

Assembly Racking Plan

In a 1 kW amplifier power amplifier

assembly, the (A5) power supply #1

provides voltages to the (A1) power

amplifier #1 and the (A3) power

amplifier #3 assemblies and the (A6)

power supply #2 provides voltages to the

(A2) power amplifier #2 and the (A4)

power amplifier #4.

(Transmitter) 1303865

(Translator) 1303862

1303383

1303383

(Transmitter) 1303864

(Translator) 1303269

(Transmitter) 1303604

(Translator) 1303272

LX Series, Rev. 1 2-3

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

ANALOG SYSTEM

CONFIGURATIONS

2 kW 1303685 1303601

3 kW 1304066 1304075 (Transmitter) 1304068

4 kW 1304127 1304133 (Transmitter) 1304206

5 kW 1304278 1304277 (Transmitter) 1304276

6 kW 1304311 1304310 (Transmitter) 1304325

NOTE: Refer to Table 2-1 for the

Interconnect, Racking Plan and Parts

List Numbers for your system. The

actual drawings and parts lists are

located in Appendix B of this manual.

A Drawing List of the order the

drawings appear in the Appendix is

found at the beginning of the section.

2.1.2.1 250 Watt, 500 Watt or 1kW

Output System Configurations

In a 250 Watt system, the output of the

(A3) power amplifier chassis assembly at

the 7/16” connector J203 is cabled to (A9)

the bandpass filter for the system. In a

500 Watt or 1 kW system, the output of

the (A3) power amplifier chassis assembly

at the 7/16” connector J205 is also cabled

to the (A9) bandpass filter. The filtered

output connects either directly to (A11)

the output coupler or first to the Optional

1 section or 2 section trap filter if more

filtering is needed and then to the output

coupler. The (A11) coupler assembly

supplies a forward and a reflected power

samples to the (A4) Visual/Aural Metering

Board. The Visual/Aural Metering Board

supplies reflected, visual and aural output

power samples to the exciter/ driver for

metering purposes. The reflected sample

connects to TB31-13, the visual sample at

TB31-14 and the aural output power

sample at TB31-15. The RF output for the

transmitter is at J2 the 7/8” EIA connector

on the (A11) coupler assembly.

2.1.2.2 2 kW Output System

Configuration

In a 2 kW system, the output of the (A3)

and the (A6) power amplifier chassis

assemblies, at the “7/16” connectors

J205, are cabled to (A7) the hybrid

combiner for the system, mounted to the

INTERCONNECT RACKING PLAN PARTS LIST

(Transmitter) 1303866

(Translator) 1303828

input of the bandpass filter. A 500 Watt

reject load (A9) connects to J4 on the

hybrid combiner to dissipate reject

power. A thermal switch (A9-A1) is

mounted to the reject load and supplies

an overtemperature fault, at 175º F., to

the driver assembly, at TB30-7 & TB3015, if a problem occurs in the output

lines. NOTE: If an overtemperature fault

occurs, it must be manually reset on the

system controller after repairs are made.

The combined output of the hybrid

combiner at the “7/8” Jack J3 is

connected to J1 on the bandpass filter.

The filtered output of the bandpass filter

is either cabled directly to the (A11)

output coupler or first to the 1 or 2

section trap filter and then to the output

coupler. The (A11) coupler assembly

supplies a forward and a reflected power

samples to the (A4) Visual/Aural

Metering Board. The Visual/Aural

Metering Board supplies reflected, visual

and aural output power samples to the

exciter/driver for metering purposes.

The reflected sample connects to TB3113, the visual sample at TB31-14 and the

aural output power sample at TB31-15.

The RF output for the transmitter is at J2

the 7/8” EIA connector on the (A11)

coupler assembly.

2.1.2.3 3kW Output System

Configuration

In a 3 kW system, the outputs of A3, A6

and A13 power amplifier chassis

assemblies, at the “N” connectors J205,

are cabled to (A7) the hybrid combiner

for the system mounting facing the rear

of the cabinet. A 500 Watt reject load

(A18), mounted on the roof of the

cabinet, connects to J4 on the hybrid

combiner to dissipate reject power.

Another 500 Watt reject load (A9), also

LX Series, Rev. 1 2-4

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

mounted on the roof, connects to J5 on

the hybrid combiner to dissipate reject

power. Thermal switches (A9-A1 & A18A1) are mounted to the reject loads and

supply overtemperature faults, at 175º F.,

to the driver assembly at TB30-7 & 15, if

a problem occurs in the output lines.

NOTE: If an overtemperature fault occurs,

it must be manually reset on the system

controller after repairs are made.

The combined output of the hybrid

combiner is cabled to the externally

mounted assemblies, which consist of

(A8) the bandpass filter, (A12) the output

trap filter and (A11) the output coupler.

The output coupler assembly supplies a

forward and a reflected sample to the

(A44) Visual/Aural Metering Board. The

Visual/Aural Metering Board supplies

samples to the exciter/driver for metering

purposes. The reflected sample connects

to TB31-13, the visual sample to TB31-14

and aural output power sample to TB31-

15. The RF output for the transmitter is

at J2 the 3-1/8” EIA connector on the

(A11) output coupler assembly.

2.1.2.4 4kW Output System

Configuration

In a 4 kW system, the outputs of the four

power amplifier chassis assemblies must

be combined. This is accomplished by

combining two power amplifier chassis

assemblies, creating two outputs then

combing these into one output. In the

(A1) cabinet assembly, the outputs of the

(A1-A3 and A1-A6) power amplifiers at

the “7/16” connectors J205, are cabled to

the (A1-A7) hybrid combiner, mounted to

the input jack of the (A1-A8) bandpass

filter. A 1 kW reject load (A1-A9), that

dissipates reject power, is mounted on a

shelf inside the (A1) cabinet and is

connected to (J4) on the hybrid combiner.

A thermal switch (A1-A9-A1) is mounted

to the reject load and supplies an

overtemperature fault, at 175º F., to the

driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A1) amplifier cabinet. The combined

output at (A1-A7-J3) of the hybrid

combiner connects to the (A1-A8)

bandpass filter for filtering before it is

connected either directly to the “7/8”

Jack J1 on (A3) the 2 way combiner

assembly mounted on the roof of the

cabinets, or through the optional (A1A12) trap filter and then to the 2 way

combiner.

In the (A2) cabinet, the outputs of the

(A2-A3 and A2-A6) power amplifiers at

the “7/16” connectors J205, are cabled to

(A2-A7) hybrid combiner. A 1 kW reject

load (A2-A9) connects to (J4) on the

hybrid combiner to dissipate reject

power. A thermal switch (A2-A9-A1) is

mounted to the reject load and supplies

an overtemperature fault, at 175º F., to

the driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A2) amplifier cabinet. The combined

output at (A2-A7-J3) of the hybrid

combiner connects to the (A2-A8)

bandpass filter for filtering before it is

connected either directly to the “7/8”

Jack J2 on (A3) the 2 way combiner

assembly mounted on the roof of the

cabinets, or through the optional (A2A12) trap filter and then to the 2 way

combiner. The combined output of the

(A3) 2 way combiner at the 1-5/8”

connector (A3-J3) is connected to the

input of the (A4) output coupler. The

output coupler assembly supplies a

forward power sample at (A4-J3) and a

reflected sample at (A4-J6) to the (A44)

Visual/Aural Metering Board. The

Visual/Aural Metering Board supplies a

reflected power sample to TB31-13, a

visual power sample to TB31-14 and

aural power sample to TB31-15 on the

exciter/driver for metering purposes.

The RF output for the transmitter is at J2

the 1-5/8” connector on the A4 output

coupler assembly.

2.1.2.5 5kW Output System

Configuration

In a 5 kW system, the outputs of the five

power amplifier chassis assemblies must

be combined. This is accomplished by

combining three power amplifier chassis

assemblies, creating one combined

LX Series, Rev. 1 2-5

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

output, and combining the other two

power amplifier chassis assemblies,

creating another combined output. The

two combined outputs are then combined

into one output. In the (A1) cabinet

assembly, the outputs of the (A1-A6 and

A1-A3) power amplifiers at the “7/16”

connectors J205, are cabled to the J1 and

J2 input jacks of (A1-A7) a hybrid

combiner. A 500 Watt reject load (A1A18), that dissipates reject power, is

mounted near the top of the (A1) cabinet

and is connected to (J4) on the hybrid

combiner. A thermal switch (A1-A18-A1)

is mounted to the reject load and supplies

an overtemperature fault, at 175º F., to

the driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A1) amplifier cabinet. A 1.5 kW reject

load (A1-A9), that dissipates reject power,

is mounted beside the 500W load in the

(A1) cabinet and is connected to (A3-J4) a

2 way hybrid combiner. A thermal switch

(A1-A9-A1) is mounted to the reject load

and supplies an overtemperature fault, at

175º F., to the driver assembly at TB30-7

& 15, if a problem occurs in the output

lines for the transmitter. This fault is in

parallel with the other fault line. The

combined output of the A1 cabinet at (A1A7-J3) of the hybrid combiner connects to

(J2) one of the input jacks to (A3) the 2

way combiner mounted on the roof of the

cabinets.

In the (A2) cabinet, the outputs of the

(A2-A6, A2-A3 and A2-A13) power

amplifiers at the “7/16” connectors J205,

are cabled to (A2-A7) a hybrid combiner.

A 500W reject load (A2-A9) connects to

(J4) on the hybrid combiner to dissipate

reject power. A thermal switch (A2-A9A1) is mounted to the reject load and

supplies an overtemperature fault, at

175º F., to the driver assembly at TB30-7

& 15, if a problem occurs in the combining

of the power amplifiers in the (A2)

amplifier cabinet. A 500W reject load

(A2-A5) connects to (J5) on the hybrid

combiner to dissipate reject power. A

thermal switch (A2-A5-A1) is mounted to

the reject load and supplies an

overtemperature fault, at 175º F., to the

driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A2) amplifier cabinet. . These faults

are in parallel with the other fault lines.

The combined output of the A2 cabinet at

(A2-A7-J6) of the hybrid combiner

connects to the other input jack (J1) on

(A3) the 2 way combiner mounted on the

roof of the cabinets. J4 on the combiner

connects to a 1.5 kW reject load (A1-A9),

that dissipates reject power, which is

mounted inside the cabinet facing the

rear of the (A1) cabinet. A thermal

switch (A1-A9-A1) is mounted to the

reject load and supplies an

overtemperature fault, at 175º F., to the

driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A2) amplifier cabinet. This fault is in

parallel with the other overtemperature

fault lines.

The combined output of the (A3)

combiner at J3 connects to the (A8)

bandpass filter for filtering before it is

connected through the (A12) trap filter,

for additional filtering, to the input of the

(A11) output coupler. The outp ut coupler

assembly supplies a forward power

sample at (A1-A44-J1) and a reflected

sample at (A1-A44-J2) to the (A44)

Visual/Aural Metering Board, mounted in

the (A1) cabinet. The Visual/Aural

Metering Board supplies a reflected

power sample to TB31-13, a visual power

sample to TB31-14 and aural power

sample to TB31-15 on the exciter/driver

for metering purposes. The RF output for

the transmitter is at J2 the 3-1/8”

connector on the A11 output coupler

assembly.

2.1.2.6 6kW Output System

Configuration

In a 6 kW system, the outputs of the six

power amplifier chassis assemblies must

be combined. This is accomplished by

combining three power amplifier chassis

assemblies, creating one combined

output, and combining the other three

power amplifier chassis assemblies,

creating another combined output. The

two combined outputs are then combined

LX Series, Rev. 1 2-6

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

into one output. In the (A1) cabinet

assembly, the outputs of the (A1-A3, A1A6, and A1-A13) power amplifiers at the

“7/16” connectors J205, are cabled to the

J1, J2 & J3 input jacks of (A1-A7) a 3 way

hybrid combiner. A 500 Watt reject load

(A1-A9), that dissipates reject power, is

mounted on the roof of the (A1) cabinet

and is connected to (J5) on the hybrid

combiner. A thermal switch (A1-A9-A1) is

mounted to the reject load and supplies

an overtemperature fault, at 175º F., to

the driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A1) amplifier cabinet. Another 500 Watt

reject load (A1-A18), that dissipates reject

power, is mounted on the roof of the (A1)

cabinet and is connected to (J4) on the

hybrid combiner. A thermal switch (A1A18-A1) is mounted to the reject load and

supplies an overtemperature fault, at

175º F., to the driver assembly at TB30-7

& 15, if a problem occurs in the output

lines for the (A1) amplifier cabinet. This

fault is in parallel with the other fault line.

The combined output of the A1 cabinet at

(A1-A7-J6) of the hybrid combiner

connects to one of the input jacks (J1) on

(A3) the 2 way combiner mounted on the

roof of the cabinets.

In the (A2) cabinet, the outputs of the

(A2-A3, A2-A6, and A3-A13) power

amplifiers at the “7/16” connectors J205,

are cabled to (A2-A7) hybrid combiner. A

500 Watt reject load (A2-A9) connects to

(J4) on the hybrid combiner to dissipate

reject power. A thermal switch (A2-A9A1) is mounted to the reject load and

supplies an overtemperature fault, at

175º F., to the driver assembly at TB30-7

& 15, if a problem occurs in the output

lines for the (A2) amplifier cabinet.

Another 500 Wat t reject load (A2-A18),

that dissipates reject power, is mounted

on the roof of the (A2) cabinet and is

connected to (J4) on the hybrid combiner.

A thermal switch (A2-A18-A1) is mounted

to the reject load and supplies an

overtemperature fault, at 175º F., to the

driver assembly at TB30-7 & 15, if a

problem occurs in the output lines for the

(A2) amplifier cabinet.

The combined output of the A2 cabinet at

(A2-A7-J6) of the hybrid combiner

connects to the other input jack (J2) on

(A3) the 2 way combiner mounted on the

roof of the cabinets. J4 on the combiner

connects to a 1.5 kW reject load (A5),

that dissipates reject power, which is

mounted inside the cabinet facing the

rear of the (A2) cabinet. A thermal

switch (A5-A1) is mounted to the reject

load and supplies an overtemperature

fault, at 175º F., to the driver assembly

at TB30-7 & 15, if a problem occurs in

the output lines for the (A2) amplifier

cabinet. This fault is in parallel with the

other overtemperature fault lines. The

combined output of the (A3) combiner

connects to the (A8) bandpass filter for

filtering before it is connected through

the (A12) trap filter, for additional

filtering, to the input of the (A11) output

coupler. The output coupler assembly

supplies a forward power sample at (A1A44-J1) and a reflected sample at (A1A44-J2) to the (A44) Visual/Aural

Metering Board. The Visual/Aural

Metering Board supplies a reflected

power sample to TB31-13, a visual power

sample to TB31-14 and aural power

sample to TB31-15 on the exciter/driver

for metering purposes. The RF output for

the transmitter is at J2 the 3-1/8”

connector on the A11 output coupler

assembly.

NOTE: If an overtemperature fault

occurs in any system configuration, it

must be manually reset on the system

controller after re pairs are made.

The LX Series power amplifier assembly

is made up of the modules and

assemblies listed in Table 2-3.

LX Series, Rev. 1 2-7

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

ASSEMBLY

DESIGNATOR

ASSEMBLY NAME PART NUMBER

125W/250W/500 Watt Chassis Assembly 1303958

Table 2-3: Typical LX Series Power Amplifier Chassis Assemblies

Or 500W Upgradeable & 1 kW Chassis

Assembly

1303953

A3 & (Opt A6 & A13) Power Amplifier Assembly, 250 Watt 1302868

Power Supply Assembly 1302863

Opt A5 2 or 4 Way Splitter Assembly

1303567 (2 Way)

1303347 (4 Way)

A11 Coupler Assembly 450029

A4 or A44 Visual/Aural Metering Board 1265-1309

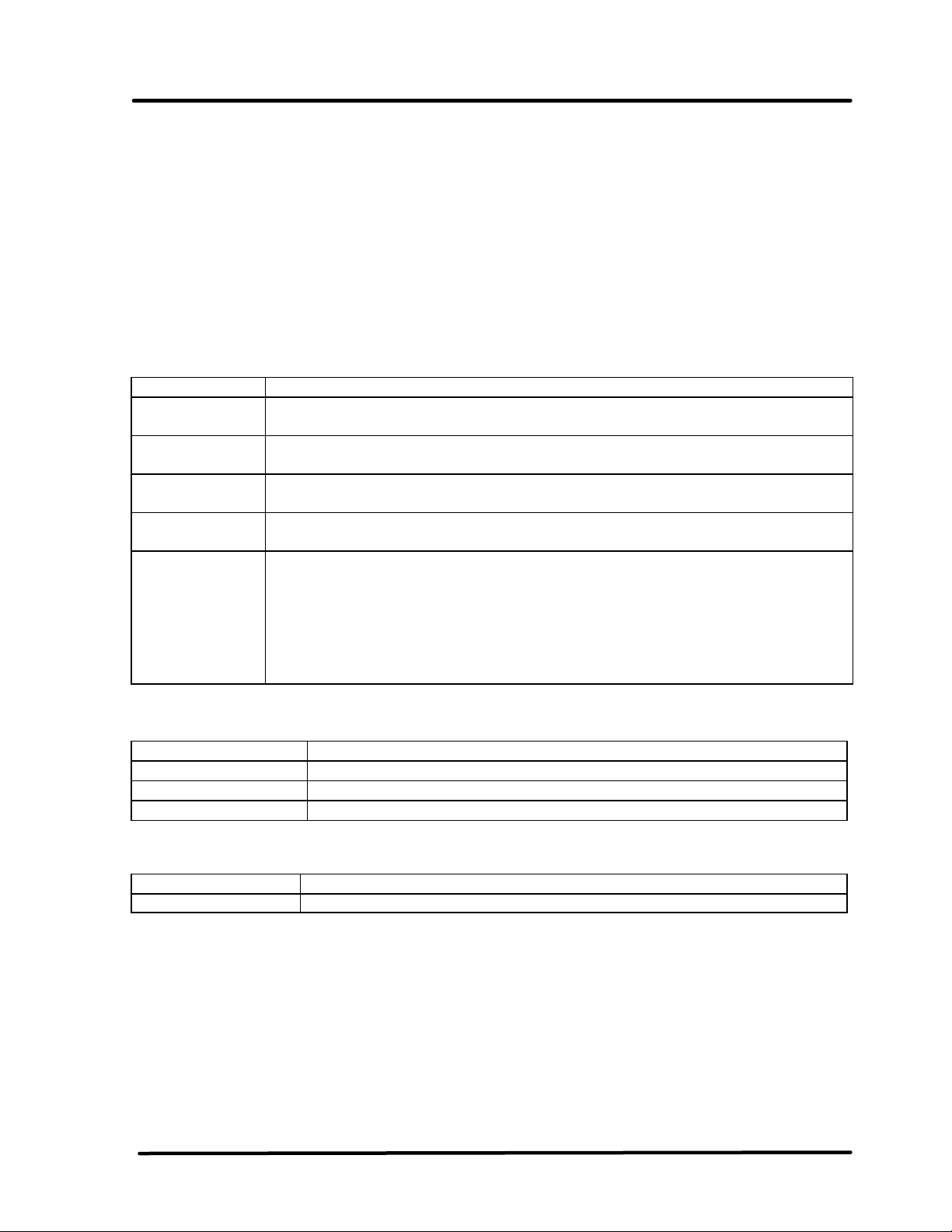

2.1.3 Power Amplifier Module

Assembly, 250 Watt (1302868;

Appendix B)

The Transmitter/Exciter Driver Power

Amplifier module and any External

Power Amplifier modules contain the

same control and monitoring board.

This board monitors RF output power,

RF reflected power, the current draw of

amplifier sections, the supply voltage,

and the temperature of the PA heat sink.

The RF power detector circuit outputs

The 250 Watt Power Amplifier Module

Assembly is made up of (A6) an Amplifier

Control Board (1303682, 1301962 or

1303702), (A1) a UHF Phase/Gain Board

(1303213), (A2) a 150 Watt Driver Pallet

Assembly (1303293), (A3 & A4) two RF

Module Pallets, Philips (1300116), and

(A5) a 2-Way Combiner Board

(1303208).

The Power Amplifier Module contains

Broadband LDMOS amplifiers that cover

the entire UHF band with no tuning

required. Each module amplifies the RF

to a nominal 300W output power. The

Power Amplifier assembly is used to

amplify the RF output of the

Transmitter/Exciter Driver. A cable,

located on the rear chassis, connects the

RF output from the Exciter/Driver at J25

to J200 the RF input to the PA Assembly.

This module contains RF monitoring

circuitry for both an analog and a digital

system. Control and monitoring lines to

the Power Amplifier module are routed

through the floating blind-mate

connector of the Control &

Monitoring/Power Supply module.

vary with operating frequency. These

circuits must be calibrated at their

intended operating frequency. The

following front panel potentiometers are

used to set the Power Amplifier

Calibrations in Analog Systems.

R201 Reflected Power Cal

R202 Forward Power Cal

R204 Meter Offset Zero

In analog systems, the Aural power of

an Exciter Driver Power Amplifier and

the Aural power of any external

amplifier will not be reported by the

system Control Monitoring module.

Additionally the Visual power of these

amplifiers, is reported as Forward Power

just like in digital systems. In analog

systems, aural and visual power will only

be reported for the final system RF

output.

If the Control Monitoring module is

monitoring a 10-100 Watt Analog

Transmitter, system power is measured

in the Power Amplifier module. The

wired connections are transferre d

through the power supply connector to

LX Series, Rev. 1 2-8

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

the backplane board on a five position

header. All four positions of control

board switch SW1 must be set on to

route these lines as the system's RF

power signals. In systems of output

power greater than 100 Watts, system

power is monitored by an external

module that is connected to TB31 and

control board SW1 switches must be set

off.

The Forward Power of the

Transmitter/Exciter Driver Power

Amplifier module is routed to the

Upconverter module as AGC #1. A

system over-drive condition is detected

when this value rises above 0.9 VDC.

When an over-drive condition is

detected, the Upconverter module

reduces its RF output level. For values

less than 0.9 VDC, the Upconverter uses

this voltage for automatic gain.

Table 2-4. Power Amplifier Status Indicator

LED FUNCTION

ENABLED

(Green)

DC OK

(Green)

TEMP

(Green)

MOD OK

(Green)

When lit Green, it indicates that the PA is in the Operate Mode. If a Mute

occurs, the PA will remain Enabled, until the input signal is returned.

When lit Green, it indicates that the fuse protected DC inputs to the PA

module are OK.

When lit Green, it indicates that the temperature of the heatsink

assembly in the module is below 78°C.

When lit Green, it indicates that the PA Module is operating and has no

faults.

If the Module OK LED is Red and blinking a fault is present.

1 Blink indicates Amplifier Current Fault.

MOD OK

(Red)

2 Blinks indicate Temperature Fault.

3 Blinks indicate +32V Power Supply Over Voltage Fault.

4 Blinks indicate +32V Power Supply Under Voltage Fault.

5 Blinks indicate Reflected Power Fault.

6 Blinks indicate +12V or –12V Power Supply Fault.

Table 2-5. Power Amplifier Control Adjustments

POTENTIOMETERS DESCRIPTION

RFL CAL Adjusts the gain of the Reflected Power monitoring circuit

VISUAL CAL Adjusts the gain of the Visual / Forward Power monitoring circuit

METER ZERO Adjusts the offset of the Forward Power monitoring circuit

Table 2-6. Power Amplifier Sample

DISPLAY FUNCTION

FWD SAMPLE RF sample of the amplified signal being sent out the module on J25.

LX Series, Rev. 1 2-9

LX Series Power Amplifier Assembly Chapter 2, Amplifier Assembly Description,

Maintenance & Remote Control Connections

2.1.4 Power Supply Module

Assembly, LX Series (1302863;

Appendix B)

The Power Supply Module Assembly is

made up of (A1) a +32V/2000W

Switching Power Supply and (A2) a

±12V/40W Switching Power Supply.

The power supply module provides the

+32 VDC and the +12 VDC and –12 VDC

to the power amplifier module assembly .

2.1.5 Front Panel Display Screens

NOTE: In systems with two exciters and

an exciter switcher, first perform the

following procedure with Exciter A as the

On Air Exciter then select Exciter B as

the On Air Exciter and repeat the

procedure. Switcher system must be in

Manual.

A 4 x 20 display located on the front of

the Control & Monitoring/Power Supply

Module is used in the LX Series

transmitter for control of the operation

and display of the operating parameters

of the entire transmitter. Refer to

Chapter 3 for detailed information on

the LCD menu screens.

2.2 System Operation

When the transmitter is in operate, as set

by the menu screen located on the

Control & Monitoring Module in the

exciter/driver assembly. The IF

Processor will be enabled, the mute

indicator on the front panel will be

extinguished. The +32 VDC stage of the

Power Supply in the Control & Monitoring

Module is enabled, the operate indicator

on the front panel is lit and the DC OK on

the front panel should also be green.

The enable and DC OK indicators on the

PA Module will also be green.

When the transmitter is in standby. The

IF Processor will be disabled, the mute

indicator on the front panel will be red.

The +32 VDC stage of the Power Supply

in the Control & Monitoring Module is

disabled, the operate indicator on the

front panel will be extinguished and the

DC OK on the front panel should remain

green. The enable indicator on the PA

Module is also extinguished.

If the transmitter does not switch to

Operate when the operate menu is

switched to Operate, check that all faults

are cleared and that the remote control

terminal block stand-by signal is not

active.

The transmitter can be controlled by the

presence of a modulated input signal. If

the input signal to the transmitter is lost;

the transmitter automatically cutbacks

and the input fault indicator on the IF

Processor module lights. When the video

input signal returns, the transmitter

automatically returns to full power and

the input fault indicator is extinguished.

2.2.1 Principles of Operation

Operating Modes

This transmit ter is either operating or in

standby mode. The sections below

discuss the characteristics of each of

these modes.

Operate Mode

Operate mode is the normal mode for

the transmitter when it is providing RF

power output. To provide RF power to

the output, the transmitter will not be in

mute. Mute is a special case of the

operate mode where the +32 VDC

section of the power supply is enabled

but there is no RF output power from

the transmitter. This condition is the

result of a fault condition that causes

the firmware to hold the IF Processor

module in a mute state.

LX Series, Rev. 1 2-10

Loading...

Loading...