Page 1

Instruction Manual

Innovator,

LX Series

Digital UHF

Driver/Transmitter

AXCERA, LLC

103 FREEDOM DRIVE, P.O. Box 525 LAWRENCE, PA 15055-0525 USA

(724) 873-8100 • FAX (724) 873-8105

www.axcera.com • info@axcera.com

Page 2

Digital UHF Driver/Transmitter Table of Contents

i

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

SECTION PAGE

1.1: Manual Overview..................................................................................1-1

1.2: Assembly Designation Numbers.............................................................1-1

1.3: Safety.................................................................................................1-2

1.4: Contact Information ........................................................................ 1-2

1.5: Material Return Procedure.....................................................................1-2

1.6: Limited One Year Warranty for Axcera Products.......................................1-3

CHAPTER 2: SYSTEM DESCRIPTION & REMOTE CONTROL CONNECTIONS

2.0: System Overview................................................................................2-1

2.1: Exciter Amplifier Chassis Assembly ........................................................2-1

2.1.1: IF Processor Module....................................................................2-2

2.1.2: LO/Upconverter Module...............................................................2-4

2.1.3: Control & Monitoring/Power Supply Module....................................2-6

2.1.4: Driver Amplifier Module ...............................................................2-7

2.2: RF Output Assemblies...........................................................................2-9

2.3: Control and Status ...............................................................................2-9

2.3.1: Front Panel LCD Display Screen....................................................2-9

2.4: System Operation ................................................................................2-9

2.4.1: Principles of Operation.................................................................2-9

2.5: Maintenance......................................................................................2-11

2.6: Customer Remote Connections...................................................... 2-11

CHAPTER 3: SITE CONSIDERATIONS, INSTALLATION AND SETUP PROCEDURES

3.1: Site Considerations...............................................................................3-1

3.2: Unpacking the Chassis w/Modules..........................................................3-5

3.3: Installing the Chassis w/Modules ...........................................................3-5

3.4: AC Input .............................................................................................3-7

3.5: Setup and Operation ............................................................................3-7

3.5.1: Input Connections.......................................................................3-7

3.5.2: Initial Turn On ............................................................................3-9

3.5.2.1: DM8-R Digital Modulator Tray LEDs on Front Panel................3-9

3.5.2.2: IF Processor Module LEDs on Front Panel..............................3-9

3.5.2.3: LO/Upconverter Module LEDs on Front Panel.........................3-9

3.5.2.4: Controller Module LEDs on Front Panel.................................3-9

3.5.2.5: Driver Module LEDs on Front Panel ......................................3-9

3.5.3: Front Panel Screens for the Driver/Amplifier Chassis Assembly ......3-10

3.5.4: Operational Procedure...............................................................3-17

CHAPTER 4: CIRCUIT DESCRIPTIONS

4.1: IF Processor Module .............................................................................4-1

4.1.1: IF Processor Board......................................................................4-1

4.1.1.1: DM8 Modulator Selected.....................................................4-1

4.1.1.2: External Modulated IF Selected ...........................................4-1

4.1.1.3: Main IF Signal Path (Part 1 of 3)..........................................4-1

4.1.1.4: Input Level Detector Circuit ................................................4-2

4.1.1.5: Pin Diode Attenuator Circuit................................................4-3

4.1.1.6: Main IF Signal Path (Part 2 of 3)..........................................4-3

LX Series, Rev. 1 April 29, 2008

Page 3

Digital UHF Driver/Transmitter Table of Contents

ii

TABLE OF CONTENTS - (Continued)

SECTION PAGE

4.1.1.7: Amplitude and Phase Pre Correction Circuits.........................4-4

4.1.1.8: Main IF Signal Path (Part 3 of 3)..........................................4-5

4.1.1.9: ALC Circuit........................................................................4-5

4.1.1.10: Fault Command ...............................................................4-6

4.1.1.11: ±12 VDC Needed to Operate the Board..............................4-6

4.2: LO/Upconverter Module ........................................................................4-6

4.2.1: UHF Generator Board ..................................................................4-7

4.2.2: UHF Filters .................................................................................4-8

4.2.3: LO/Upconverter Board.................................................................4-8

4.2.3.1: Upconverter portion of the Board.........................................4-8

4.2.3.2: Automatic Gain portion of the Board ....................................4-9

4.2.3.3: The PLL and 10MHz Reference portion of the Board.............4-10

4.2.3.4: External 10MHz PLL and 10MHz Reference present Circuitry.4-10

4.2.3.5: Internal 10MHz Reference Circuitry....................................4-11

4.2.3.6: Selected 10MHz Reference Samples...................................4-11

4.2.3.7: Comparator Phase Lock Loop Circuit ..................................4-11

4.2.3.8: Lock Detector Circuit........................................................4-11

4.2.3.9: Voltage Requirements ......................................................4-12

4.3: Control Monitoring/Power Supply Module..............................................4-12

4.3.1: Power Protection Board..............................................................4-12

4.3.2: Control Board ...........................................................................4-13

4.3.2.1: Schematic Page 1 ............................................................4-13

4.3.2.2: Schematic Page 2 ............................................................4-14

4.3.2.3: Schematic Page 3 ............................................................4-14

4.3.2.4: Schematic Page 4 ............................................................4-15

4.3.2.5: Schematic Page 5 ............................................................4-15

4.3.3: Switch Board............................................................................4-16

4.3.4: Switching Power Supply Assembly ..............................................4-16

4.4: Driver Amplifier Module Assembly........................................................4-16

4.4.1: 1-Watt Amplifier Module Assembly..............................................4-17

4.4.2: 1-Watt UHF Amplifier Board .......................................................4-17

4.4.3: RF Amplifier Assembly...............................................................4-18

4.4.4: Coupler Board Assembly............................................................4-18

4.4.5: Amplifier Control Board..............................................................4-18

4.4.5.1: Schematic Page 1 ............................................................4-18

4.4.5.2: Schematic Page 2 ............................................................4-19

4.4.5.3: Schematic Page 3 ............................................................4-20

4.5: Dual Peak Detector Board ...................................................................4-21

CHAPTER 5: DETAILED ALIGNMENT PROCEDURES

5.1: System Preparation..............................................................................5-1

5.1.1: Module Replacement ...................................................................5-1

5.1.2: Initial Test Set Up .......................................................................5-1

5.2: LX Series Driver/Amplifier Chassis Assembly...........................................5-1

5.2.1: IF Processor Module Assembly......................................................5-2

5.3: Setting ALC Gain, AGC1, AGC2 and AGC Cutback ....................................5-2

5.4: Calibration of Output & Reflected Power .................................................5-3

5.4.1 Calibration of Forward Power.........................................................5-3

5.4.2 Calibration of Reflected Power .......................................................5-3

LX Series, Rev. 1 April 29, 2008

Page 4

Digital UHF Driver/Transmitter Table of Contents

iii

TABLE OF CONTENTS - (Continued)

SECTION PAGE

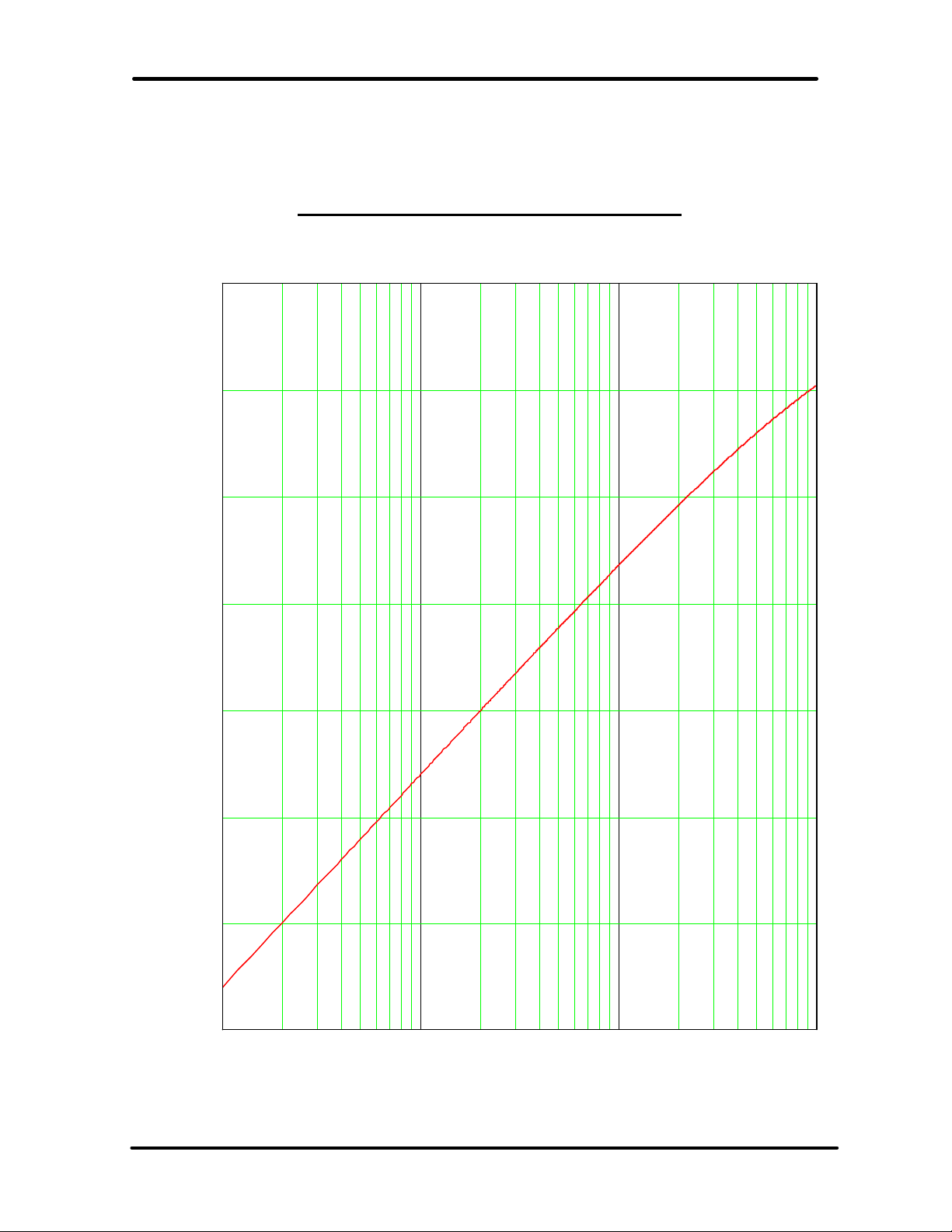

5.5: Linearity Correction Adjustment.............................................................5-4

5.6: Frequency Response Delay Equalization Adjustment ................................5-5

APPENDICES

APPENDIX A: TRANSMITTER SPECIFICATIONS

APPENDIX B: DRAWINGS LISTS

APPENDIX B: TRANSMITTER LOG SHEET

LX Series, Rev. 1 April 29, 2008

Page 5

Digital UHF Driver/Transmitter Table of Contents

iv

LIST OF FIGURES

FIGURE PAGE

1-1: Brady Marker Identification Drawing.................................................1-1

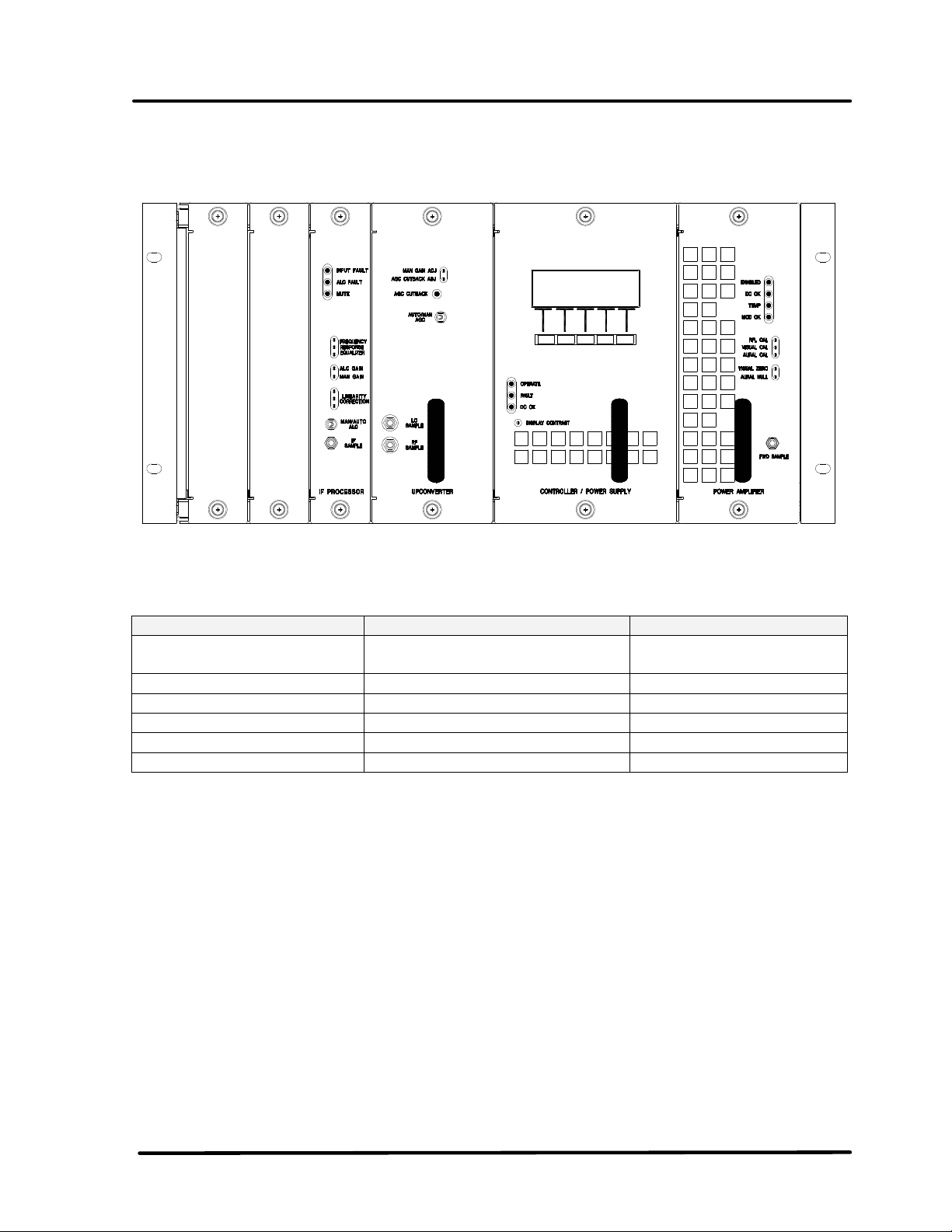

2-1: Digital LX Series Front View Modules and Assemblies .........................2-1

2-2: Rear View LX Series Driver/Amplifier Chassis Assembly....................2-11

3-1: 500 Watt Minimum Ventilation Configuration.....................................3-4

3-2: Tray Slide Cabinet Mounting Diagram...............................................3-6

3-3: Front and Rear View Reconnection Drawing.......................................3-6

3-4: Cabinet Front and Rear View Reconnection Drawing...........................3-6

3-5: AC Input Box Assembly...................................................................3-7

3-6: Rear View of Driver/Amplifier...........................................................3-8

4-1: 250 Watt UHF Amplifier Module .....................................................4-17

5-1: Typical Digital Spectrum .................................................................5-5

LX Series, Rev. 1

Page 6

Digital UHF Driver/Transmitter Table of Contents

v

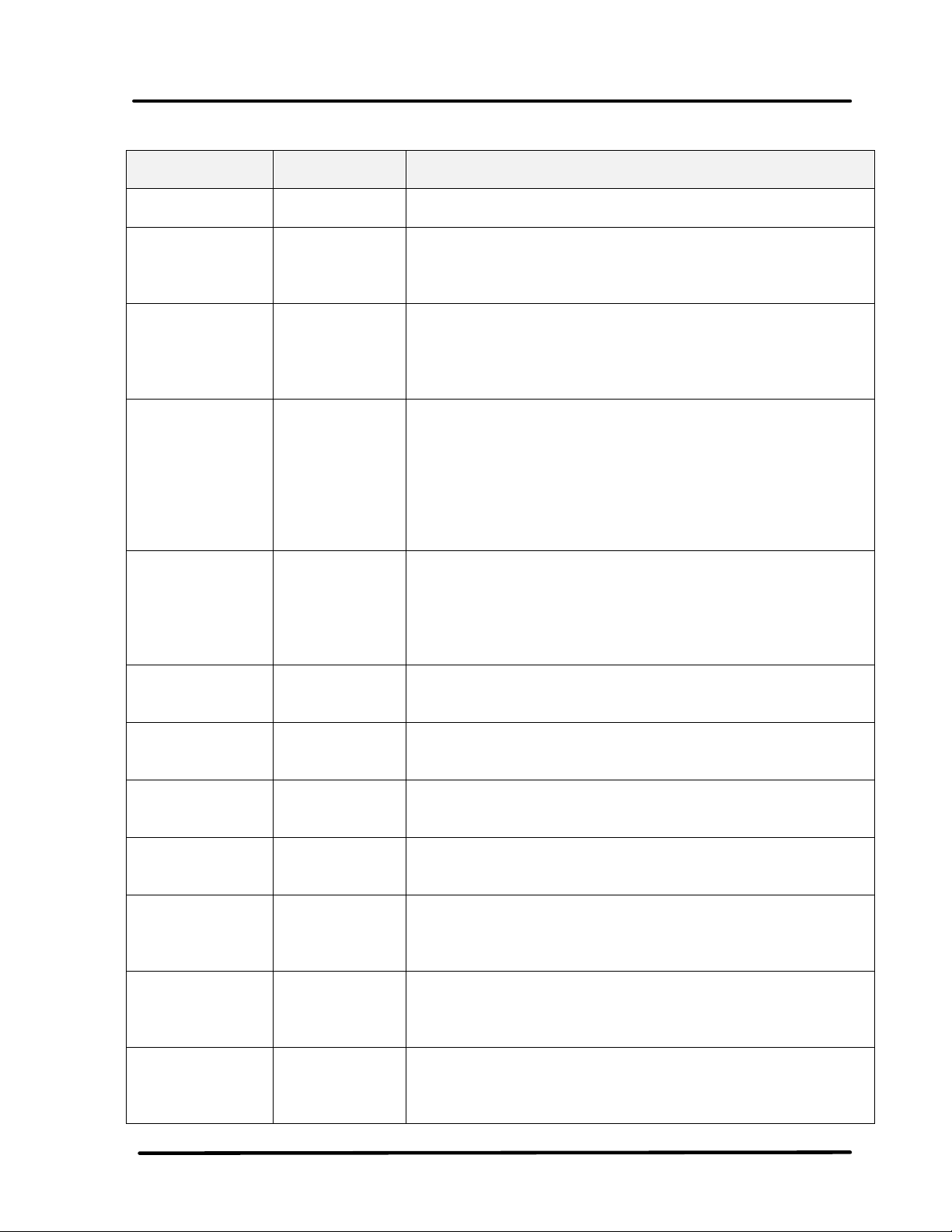

LIST OF TABLES

TABLE PAGE

2-1: Digital LX Series Modules and Assemblies .........................................2-1

2-2: IF Processor Front Panel Switch .......................................................2-3

2-3: IF Processor Front Panel Status Indicators ........................................2-3

2-4: IF Processor Front Panel Control Adjustments....................................2-3

2-5: IF Processor Front Panel Sample......................................................2-3

2-6: LO/Upconverter Front Panel Switch ..................................................2-5

2-7: LO/Upconverter Front Panel Status Indicators ...................................2-5

2-8: LO/Upconverter Front Panel Control Adjustments...............................2-5

2-9: LO/Upconverter Front Panel Samples................................................2-5

2-10: Controller/Power Supply Front Panel Display .....................................2-6

2-11: Controller/Power Supply Front Panel Status Indicators .......................2-6

2-12: Controller/Power Supply Front Panel Control Adjustments...................2-6

2-13: Driver Amplifier Front Panel Status Indicators....................................2-8

2-14: Driver Amplifier Front Panel Control Adjustments...............................2-8

2-15: Driver Amplifier Front Panel Sample.................................................2-8

2-16: LX Series Exciter Driver Customer Remote Connections.......... 2-12

3-1: LX Series Digital Transmitters AC Input and Current Requirements......3-1

3-2: Rear Chassis Connections for LX Series Digital Exciter/Driver..............3-8

Digital Driver/Amplifier System Controller Screens

3-3: Menu 01 Splash Screen #1............................................................3-10

3-4: Menu 02 Splash Screen #2............................................................3-10

3-5: Menu 10 Main Screen ...................................................................3-10

3-6: Menu 11 Error List Access Screen...................................................3-11

3-7: Menu 12 Transmitter Device Data Access Screen.............................3-11

3-8: Menu 13 Transmitter Configuration Access Screen...........................3-11

3-9: Menu 20 Error List Display Screen..................................................3-12

3-10: Menu 30 Transmitter Device Details Screen..................................3-12

3-11: Menu 30-1 System Details Screens..............................................3-12

3-12: Transmitter Device Parameters Detail Screens..............................3-13

3-13: Menu 40 Authorized Personnel Screen .........................................3-14

3-14: Menu 40-1 Transmitter Set Up: Power Control Screen ...................3-14

3-15: Menu 40-2 Transmitter Set Up: Model Select Screen .....................3-15

3-16: Menu 40-3 Transmitter Set Up: Upconverter Channel Select Screen 3-15

3-17: Menu 40-4 Transmitter Set Up: Serial Address Screen...................3-15

3-18: Menu 40-6 Transmitter Set Up: System Forward Power Cal. Screen.3-15

3-19: Menu 40-6 Transmitter Set Up: System Reflected Power Cal. Screen.3-16

3-20: Menu 40-7 Transmitter Set Up: Fwrd Pwr Fault Threshold Screen......3-16

3-21: Menu 40-8 Transmitter Set Up: Refl Power Fault Threshold Screen....3-16

3-22: Menu 40-10 Transmitter Set Up: Auto Standby Control Screen .........3-16

3-23: Menu 40-12 Transmitter Set Up: Inner Loop Gain Control Screen......3-17

3-24: Menu 40-13 Transmitter Set Up: Optional System Control Screen .....3-17

3-25: Menu 40-19 Transmitter Set Up: Amplifier Output Power Warning.....3-17

3-26: Menu 40-19 Transmitter Set Up: Remote Commands Control............3-17

4-1: Firmware Configuration Switch SW2 Operating Positions ..................4-15

LX Series, Rev. 1

Page 7

Digital UHF Driver/Transmitter Chapter 1, Introduction

Chapter 1:

Introduction

1.1: Manual Overview

This manual explains the installation,

setup, alignment, and maintenance

procedures for the LX Series modular

Digital UHF driver/transmitter. If your

transmitter contains external power

amplifier assemblies, then information

and drawings on the external amplifier

assemblies are contained in Volume 2.

This instruction manual is divided into

five chapters and supporting appendices.

Chapter 1: Introduction, contains

information on the assembly numbering

system used in the manual, safety,

maintenance, return procedures, and

warranties. Chapter 2: System

Description, maintenance and remote

control connections, describes the

transmitter and includes discussions on

system control and status indicators,

maintenance and remote control

connections. Chapter 3: Site

Considerations, installation and setup

procedures, explains how to unpack,

install, setup, and operate the

transmitter. Chapter 4: Circuit

Descriptions, contains circuit-level

descriptions for boards and board-level

components in the transmitter. Chapter

5: Detailed Alignment Procedures,

provides information on adjusting the

system assemblies for optimal operation.

Appendix A: contains drawings and

parts lists. Appendix B: contains a

transmitter log sheet

1.2: Assembly Designators

Axcera has assigned assembly numbers,

Ax designations such as A1, where

x=1,2,3…etc, to all assemblies, modules,

and boards in the system. These

designations are referenced in the text of

this manual and shown on the block

diagrams and interconnect drawings

provided in the appendices. The Block

Diagrams, Interconnects, Schematics,

Assembly Drawings and Parts Lists are

arranged in increasing numerical order in

the appendices. Section titles in the text

for assembly or module descriptions or

alignment procedures contain the

associated part number(s) and the

relevant appendix that contains the

drawings for that item.

The cables that connect between the

boards within a tray or assembly and

that connect between the trays, racks

and cabinets are labeled using Brady

markers. Figure 1-1 is an example of a

Brady marked cable. There may be as

few as two or as many as four Markers

on any one cable. These Brady markers

are read starting furthest from the

connector. If there are four Brady

Markers, this marker is the transmitter

number such as transmitter 1 or

transmitter 2. The next or the furthest

Brady Marker is the rack or cabinet

number on an interconnect cable or the

board number within a tray. The next

number on an interconnect cable is the

Tray location or number. The Brady

marker closest to the connector is the

jack or connector number on an

interconnect cable or the jack or

connector number on the board within a

tray.

LX Series, Rev. 1 1-1

Figure 1-1: Brady Marker Identification

Drawing

Page 8

Digital UHF Driver/Transmitter Chapter 1, Introduction

1.3: Safety

The UHF transmitter systems

manufactured by Axcera are designed to

be easy to use and repair while providing

protection from electrical and mechanical

hazards. Please review the following

warnings and familiarize yourself with the

operation and servicing procedures

before working on the transmitter

system.

Read All safety Instructions – All of

the safety instructions should be read

and understood before operating this

equipment.

Retain Manuals – The manuals for the

transmitter should be retained at the

transmitter site for future reference.

Axcera provides two sets of manuals for

this purpose; one set can be left at the

office while one set can be kept at the

site.

Heed all Notes, Warnings, and

Cautions – All of the notes, warnings,

and cautions listed in this safety section

and throughout the manual must be

followed.

Follow Operating Instructions – All of

the operating and use instructions for the

transmitter should be followed.

Cleaning – Unplug or otherwise

disconnect all power from the equipment

before cleaning. Do not use liquid or

aerosol cleaners. Use a damp cloth for

cleaning.

Ventilation – Openings in the cabinet

and module front panels are provided for

ventilation. To ensure the reliable

operation of the driver/transmitter, and

to protect the unit from overheating,

these openings must not be blocked.

Servicing – Do not attempt to service

this product yourself until becoming

familiar with the equipment. If in doubt,

refer all servicing questions to qualified

Axcera service personnel.

Replacement Parts – When

replacement parts are used, be sure that

the parts have the same functional and

performance characteristics as the

original part. Unauthorized substitutions

may result in fire, electric shock, or other

hazards. Please contact the Axcera

Technical Service Department if you have

any questions regarding service or

replacement parts.

1.4: Contact Information

The Axcera Field Service Department can

be contacted by phone at (724) 873-

8100 or by fax at (724) 873-8105.

Before calling Axcera, please be prepared

to supply the Axcera technician with

answers to the following questions. This

will save time and help ensure the most

direct resolution to the problem.

1. What are the Customers’ Name

and call letters?

2. What are the model number and

type of transmitter?

3. Is the transmitter digital or

analog?

4. How long has the transmitter

been on the air? (Approximately

when was the transmitter

installed.)

5. What are the symptoms being

exhibited by the transmitter?

Include the current control/power

supply LCD readings and the

status of LEDs on the front

panels of the modules. If

possible, include the

control/power supply LCD

readings before the problem

occurred.

1.5: Return Material Procedure

To insure the efficient handling of

equipment or components that have been

returned for repair, Axcera requests that

each returned item be accompanied by a

Return Material Authorization Number

(RMA#).

LX Series, Rev. 1 1-2

Page 9

Digital UHF Driver/Transmitter Chapter 1, Introduction

The RMA# can be obtained from any

Axcera Field Service Engineer by

contacting the Axcera Field Service

Department at (724) 873-8100 or by fax

at (724) 873-8105. This procedure

applies to all items sent to the Field

Service Department regardless of

whether the item was originally

manufactured by Axcera.

When equipment is sent to the field on

loan, an RMA# is included with the unit.

The RMA# is intended to be used when

the unit is returned to Axcera. In

addition, all shipping material should be

retained for the return of the unit to

Axcera.

Replacement assemblies are also sent

with an RMA# to allow for the proper

routing of the exchanged hardware.

Failure to close out this type of RMA# will

normally result in the customer being

invoiced for the value of the loaner item

or the exchanged assembly.

When shipping an item to Axcera, please

include the RMA# on the packing list and

on the shipping container. The packing

slip should also include contact

information and a brief description of why

the unit is being returned.

Please forward all RMA items to:

AXCERA, LLC

103 Freedom Drive

P.O. Box 525

Lawrence, PA 15055-0525 USA

For more information concerning this

procedure, call the Axcera Field Service

Department @ (724) 873-8100.

Axcera can also be contacted through email at info@axcera.com and on the

Web at www.axcera.com.

1.6: Limited One Year Warranty for

Axcera Products

Axcera warrants each new product that

it has manufactured and sold against

defects in material and workmanship

under normal use and service for a

period of one (1) year from the date of

shipment from Axcera's plant, when

operated in accordance with Axcera's

operating instructions. This warranty

shall not apply to tubes, fuses,

batteries, bulbs or LEDs.

Warranties are valid only when and if

(a) Axcera receives prompt written

notice of breach within the period of

warranty, (b) the defective product is

properly packed and returned by the

buyer (transportation and insurance

prepaid), and (c) Axcera determines, in

its sole judgment, that the product is

defective and not subject to any misuse,

neglect, improper installation,

negligence, accident, or (unless

authorized in writing by Axcera) repair

or alteration. Axcera's exclusive liability

for any personal and/or property

damage (including direct, consequential,

or incidental) caused by the breach of

any or all warranties, shall be limited to

the following: (a) repairing or replacing

(in Axcera's sole discretion) any

defective parts free of charge (F.O.B.

Axcera’s plant) and/or (b) crediting (in

Axcera's sole discretion) all or a portion

of the purchase price to the buyer.

Equipment furnished by Axcera, but not

bearing its trade name, shall bear no

warranties other than the special hoursof-use or other warranties extended by

or enforceable against the manufacturer

at the time of delivery to the buyer.

NO WARRANTIES, WHETHER

STATUTORY, EXPRESSED, OR

IMPLIED, AND NO WARRANTIES OF

MERCHANTABILITY, FITNESS FOR

ANY PARTICULAR PURPOSE, OR

FREEDOM FROM INFRINGEMENT,

OR THE LIKE, OTHER THAN AS

SPECIFIED IN PATENT LIABILITY

ARTICLES, AND IN THIS ARTICLE,

SHALL APPLY TO THE EQUIPMENT

FURNISHED HEREUNDER.

LX Series, Rev. 1 1-3

Page 10

Digital UHF Driver/Transmitter Chapter 1, Introduction

F WA RNING!!!

× HIGH VOLTAGE Ø

DO NOT ATTEMPT TO REPAIR OR TROUBLESHOOT THIS EQUIPMENT UNLESS

YOU ARE FAMILIAR WITH ITS OPERATION AND EXPERIENCED IN

SERVICING HIGH VOLTAGE EQUIPMENT. LETHAL VOLTAGES ARE PRESENT

WHEN POWER IS APPLIED TO THIS SYSTEM. IF POSSIBLE, TURN OFF

POWER BEFORE MAKING ADJUSTMENTS TO THE SYSTEM.

« RADIO FREQUENCY RADIATION HAZARD «

MICROWAVE, RF AMPLIFIERS AND TUBES GENERATE HAZARDOUS RF

RADIATION THAT CAN CAUSE SEVERE INJURY INCLUDING CATARACTS,

WHICH CAN RESULT IN BLINDNESS. SOME CARDIAC PACEMAKERS MAY BE

AFFECTED BY THE RF ENERGY EMITTED BY RF AND MICROWAVE

AMPLIFIERS. NEVER OPERATE THE TRANSMITTER SYSTEM WITHOUT A

PROPERLY MATCHED RF ENERGY ABSORBING LOAD ATTACHED. KEEP

PERSONNEL AWAY FROM OPEN WAVEGUIDES AND ANTENNAS. NEVER

LOOK INTO AN OPEN WAVEGUIDE OR ANTENNA. MONITOR ALL PARTS OF

THE RF SYSTEM FOR RADIATION LEAKAGE AT REGULAR INTERVALS.

LX Series, Rev. 1 1-4

Page 11

Digital UHF Driver/Transmitter Chapter 1, Introduction

EMERGENCY FIRST AID INSTRUCTIONS

Personnel engaged in the installation, operation, or maintenance of this equipment are urged to become

familiar with the following rules both in theory and practice. It is the duty of all operating personnel to be

prepared to give adequate Emergency First Aid and thereby prevent avoidable loss of life.

RESCUE BREATHING

1. Find out if the person is

breathing.

You must find out if the person

has stopped breathing. If you

think he is not breathing, place

him flat on his back. Put your ear

close to his mouth and look at his

chest. If he is breathing you can

feel the air on your cheek. You

can see his chest move up and

down. If you do not feel the air

or see the chest move, he is not

breathing.

2. If he is not breathing, open

the airway by tilting his head

backwards.

Lift up his neck with one hand

and push down on his forehead

with the other. This opens the

airway. Sometimes doing this will

let the person breathe again by

himself.

SKIN REDDENED: Apply ice cold water to burned

area to prevent burn from going deeper into skin

tissue. Cover area with a clean sheet or cloth to

keep away air. Consult a physician.

SKIN BLISTERED OR FLESH CHARRED: Apply

ice cold water to burned area to prevent burn from

going deeper into skin tissue.

3. If he is still not breathing,

begin rescue breathing.

-Keep his head tilted backward.

Pinch nose shut.

-Put your mouth tightly over his

mouth.

-Blow into his mouth once every

five seconds

-DO NOT STOP rescue breathing

until help arrives.

LOOSEN CLOTHING - KEEP

WARM

Do this when the victim is

breathing by himself or help is

available. Keep him as quiet as

possible and from becoming

chilled. Otherwise treat him for

shock.

BURNS

Cover area with clean sheet or cloth to keep away

air. Treat victim for shock and take to hospital.

EXTENSIVE BURN - SKIN BROKEN: Cover area

with clean sheet or cloth to keep away air. Treat

victim for shock and take to hospital.

LX Series, Rev. 1 1-5

Page 12

Digital UHF Driver/Transmitter Chapter 1, Introduction

dBm, dBw, dBmV, dBµV, & VOLTAGE

EXPRESSED IN WATTS

50 Ohm System

WATTS PREFIX dBm dBw dBmV dBµV VOLTAGE

1,000,000,000,000 1 TERAWATT +150 +120

100,000,000,000 100 GIGAWATTS +140 +110

10,000,000,000 10 GIGAWATTS +130 +100

1,000,000,000 1 GIGAWATT +120 + 99

100,000,000 100 MEGAWATTS +110 + 80

10,000,000 10 MEGAWATTS +100 + 70

1,000,000 1 MEGAWATT + 90 + 60

100,000 100 KILOWATTS + 80 + 50

10,000 10 KILOWATTS + 70 + 40

1,000 1 KILOWATT + 60 + 30

100 1 HECTROWATT + 50 + 20

50 + 47 + 17

20 + 43 + 13

10 1 DECAWATT + 40 + 10

1 1 WATT + 30 0 + 77 +137 7.07V

0.1 1 DECIWATT + 20 - 10 + 67 +127 2.24V

0.01 1 CENTIWATT + 10 - 20 + 57 +117 0.707V

0.001 1 MILLIWATT 0 - 30 + 47 +107 224mV

0.0001 100 MICROWATTS - 10 - 40

0.00001 10 MICROWATTS - 20 - 50

0.000001 1 MICROWATT - 30 - 60

0.0000001 100 NANOWATTS - 40 - 70

0.00000001 10 NANOWATTS - 50 - 80

0.000000001 1 NANOWATT - 60 - 90

0.0000000001 100 PICOWATTS - 70 -100

0.00000000001 10 PICOWATTS - 80 -110

0.000000000001 1 PICOWATT - 90 -120

TEMPERATURE CONVERSION

°F = 32 + [(9/5) °C]

°C = [(5/9) (°F - 32)]

LX Series, Rev. 1 1-6

Page 13

Digital UHF Driver/Transmitter Chapter 1, Introduction

USEFUL CONVERSION FACTORS

TO CONVERT FROM TO MULTIPLY BY

mile (US statute) kilometer (km) 1.609347

inch (in) millimeter (mm) 25.4

inch (in) centimeter (cm) 2.54

inch (in) meter (m) 0.0254

foot (ft) meter (m) 0.3048

yard (yd) meter (m) 0.9144

mile per hour (mph) kilometer per hour(km/hr) 1.60934

mile per hour (mph) meter per second (m/s) 0.44704

pound (lb) kilogram (kg) 0.4535924

gallon (gal) liter 3.7854118

U.S. liquid

(One U.S. gallon equals 0.8327 Canadian gallon)

fluid ounce (fl oz) milliliters (ml) 29.57353

British Thermal Unit watt (W) 0.2930711

per hour (Btu/hr)

horsepower (hp) watt (W) 746

NOMENCLATURE OF FREQUENCY BANDS

FREQUENCY RANGE DESIGNATION

3 to 30 kHz VLF - Very Low Frequency

30 to 300 kHz LF - Low Frequency

300 to 3000 kHz MF - Medium Frequency

3 to 30 MHz HF - High Frequency

30 to 300 MHz VHF - Very High Frequency

300 to 3000 MHz UHF - Ultrahigh Frequency

3 to 30 GHz SHF - Superhigh Frequency

30 to 300 GHz EHF - Extremely High Frequency

LETTER DESIGNATIONS FOR UPPER FREQUENCY

BANDS

LETTER FREQ. BAND

L 1000 - 2000 MHz

S 2000 - 4000 MHz

C 4000 - 8000 MHz

X 8000 - 12000 MHz

Ku 12 - 18 GHz

K 18 - 27 GHz

Ka 27 - 40 GHz

V 40 - 75 GHz

W 75 - 110 GHz

LX Series, Rev. 1 1-7

Page 14

Digital UHF Driver/Transmitter Chapter 1, Introduction

0 -10 -20 -30 -40 -50 -60

-70

N

dB

RETURN LOSS VS. VSWR

R

E

T

U

R

L

O

S

S

1.001 1.01 1.1 2.0

VSWR

LX Series, Rev. 1 1-8

Page 15

Digital UHF Driver/Transmitter Chapter 1, Introduction

ABBREVIATIONS/ACRONYMS

AC Alternating Current

AFC Automatic Frequency Control

ALC Automatic Level Control

AM Amplitude modulation

AGC Automatic Gain Control

AWG American wire gauge

BER Bit Error Rate

BW Bandwidth

DC Direct Current

D/A Digital to analog

DSP Digital Signal Processing

DTV Digital Television

dB Decibel

dBm Decibel referenced to 1 milliwatt

dBmV Decibel referenced to 1 millivolt

dBw Decibel referenced to 1 watt

FEC Forward Error Correction

FM Frequency modulation

FPGA Field Programmable Gate Array

Hz Hertz

ICPM Incidental Carrier Phase Modulation

I/P Input

IF Intermediate Frequency

LED Light emitting diode

LSB Lower Sideband

MPEG Motion Pictures Expert Group

O/P Output

PLL Phase Locked Loop

PCB Printed circuit board

QAM Quadrature Amplitude Modulation

SMPTE Society of Motion Picture and

Television Engineers

VSB Vestigial Side Band

LX Series, Rev. 1 1-9

Page 16

Digital UHF Driver/Transmitter Chapter 2, System Description,

A3 A5 A4 A6

Maintenance & Remote Control Connections

Chapter 2

System Description, Maintenance & Remote Control Connections

Figure 2-1: Driver/Amplifier Front View

Table 2-1: LX Series Modules and Assemblies

ASSEMBLY DESIGNATOR

TRAY/ASSEMBLY NAME PART NUMBER

Exciter Amplifier Chassis

Assembly, LX Series

Backplane Board 1301941

A3 IF Processor Module 1301938

A4 Control/Power Supply Module 1303229 (220 VAC)

A5 LO/Upconverter Module 1301930

A6 Driver Power Amplifier Module 1303874

2.0 System Overview

The digital transmitters in the Innovator

LX Series are complete UHF Digital

internally diplexed modular television

transmitters that operate at a nominal

DTV output power of 5 to 50 watts.

The LX Series can also be used as a

driver for external power amplifiers. The

output power of the driver is determined

by the level needed to attain the full

output power of the transmitter.

The Digital LX Series driver/transmitter is

made up of the modules and assemblies

as listed in Table 2-1.

1303228 (220 VAC)

2.1 Exciter Amplifier Chassis

Assembly, 220 VAC (1303228;

Appendix A)

The chassis assembly is factory set for

operation using 220 VAC. All of the

modules except the power amplifier

module and the power supply section of

the Control & Monitoring/Power Supply

Module, plug directly into a backplane

board. The backplane board provides

module to module interconnection as well

as interconnection to remote command

and control connectors.

LX Series, Rev. 1 2-1

Page 17

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

2.1.1 (A3) IF Processor Module

Assembly (1301938; Appendix A)

The (A3) IF Processor Assembly contains

the IF Processor Board (1301977). The IF

Processor provides pre-correction to

ensure broadcast quality output signal.

The pre-correction consists of amplitude

linearity correction, Incidental Carrier

Phase Modulation (ICPM) correction and

frequency response correction.

The IF Processor module is configured

either for an analog or digital system.

Pin 13C of the IF Processor module is

grounded in analog systems and left not

connected in digital systems. An IF

Processor Interlock signal is used to

report the presence of the IF Processor

module to the Control Monitoring board.

If the IF Processor interlock signal is not

present, the LX Series

Transmitter/Exciter Driver RF output is

Muted (turned off). If an analog IF

Processor module is installed and the

Modulation Present signal is not true,

the LX Series Transmitter/Exciter Driver

output is Muted (turned off).

The Control & Monitoring/Power Supply

module uses the IF Processor module for

System output power control. Through

the front panel display or a remote

interface, an operator can set the RF

output power level of the transmitter.

The range of RF power adjustment is

between 0% (full off) and 105% (full

power plus). A front panel IF Processor

module potentiometer sets the upper

limit of RF power at 120%. The

system's Control Monitoring board

compares the RF Power Monitoring

module RF power level with the desired

level and uses the IF Power Control PWM

line to correct for errors.

In digital systems, a digital level control

(DLC) voltage is generated on the IF

Processor module and sent to an

external digital modulator (DT1B/C). RF

power control is implemented by

changing the DLC voltage provided to

the external digital modulator. The 'RF

High' potentiometer sets the upper

adjusted range of RF control circuit

output to 120%.

The IF Processor module provides a

reference ALC voltage to the system's

Upconverter. When the ALC voltage

decreases, the Upconverter

automatically lowers the system output

power through the AGC circuits.

The IF Processor module has a front

panel switch to select Auto or Manual

ALC. When Manual ALC is selected, the

reference ALC voltage is set by a front

panel potentiometer. In this condition,

the RF power level control circuit is

removed from use. When the ALC select

switch is changed to Auto, the RF power

level control circuit will start at low

power and increase the RF output until

the desired output power is attained.

The IF Processor module Modulation

Present signal is monitored. If the

modulation level is too low or nonexistent, a Modulation Present Fault is

reported to the Control Monitoring

board. When the controller detects this

fault, it can be set to Automatically Mute

the transmitter or in Manual mode the

transmitter will continue to operate at

25% output.

The IF Processor module Input Signal

level is monitored. If the signal level is

too low or non-existent, an Input Fault

is reported on the Control Monitoring

board. When the IF Processor board

detects an Input Signal Fault it

automatically Mutes the transmitter.

The system controller does not Mute on

an IF Processor Input Fault.

LX Series, Rev. 1 2-2

Page 18

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

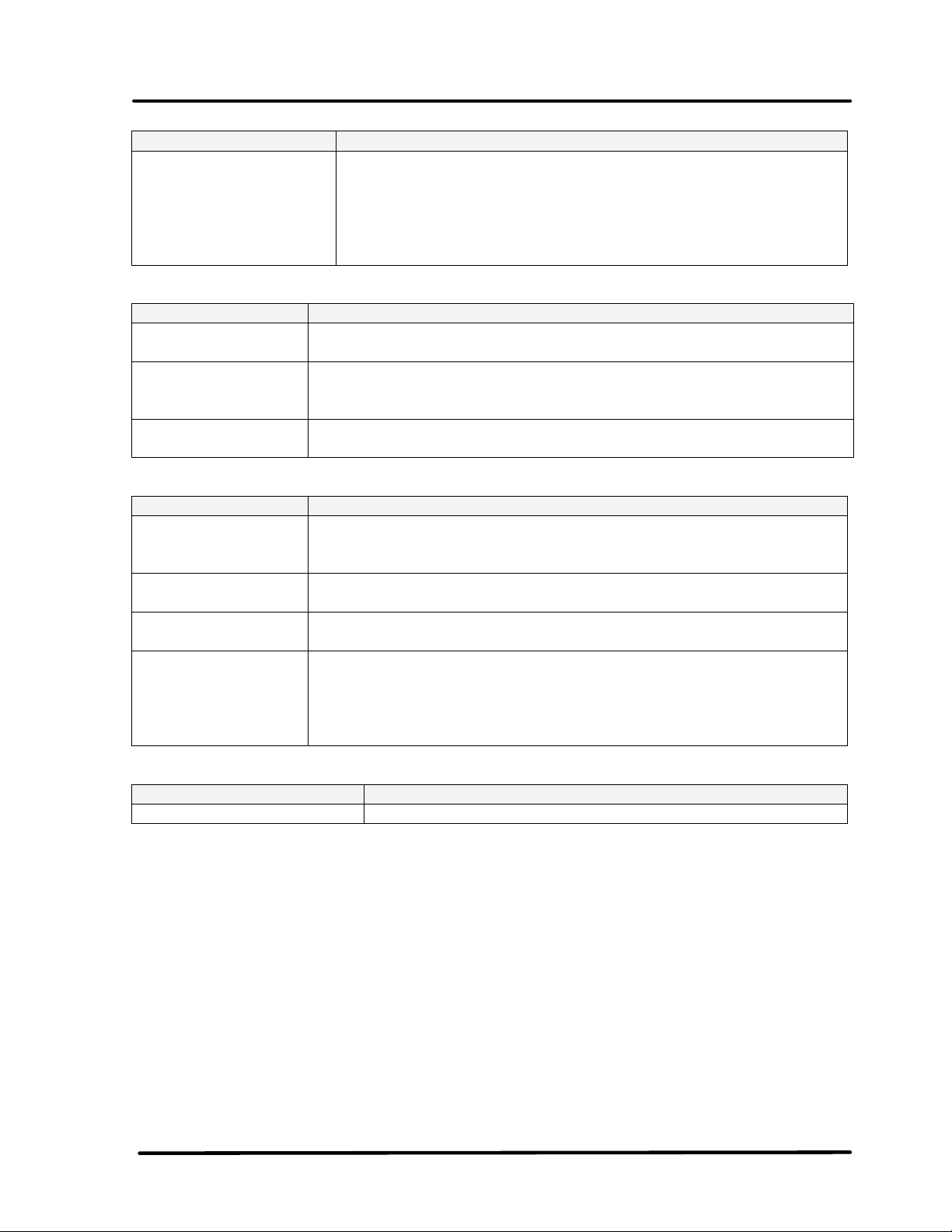

Table 2-2: IF Processor Front Panel Switch

SWITCH FUNCTION

When Manual ALC is selected, the reference ALC voltage is set

by the ALC Gain front panel potentiometer.

MAN/AUTO ALC

Table 2-3: IF Processor Front Panel Status Indicators

LED FUNCTION

INPUT FAULT (Red)

ALC Fault (Red)

MUTE (Red)

Table 2-4: IF Processor Front Panel Control Adjustments

POTENTIOMETERS

FREQUENCY

RESPONSE

EQUALIZER

ALC GAIN

MAN GAIN

LINEARITY

CORRECTION

Table 2-5: IF Processor Front Panel Sample

SMA CONNECTOR DESCRIPTION

IF SAMPLE Sample of the pre-corrected IF output of the IF Processor

When Auto ALC is selected, the IF level control circuit will

automatically increase the IF output until the desired output

power is attained.

When lit it indicates that there is a loss of the IF Input signal to the

IF Processor. Transmitter can be set to Mute on an IF Input Fault.

When lit it indicates that the required gain to produce the desired

output power level has exceeded the operational range of the ALC

circuit. The LED will also be lit when ALC is in Manual.

When lit it indicates that the IF input signal is cut back but the

enable to the Power Supply is present and the +32 VDC remains on.

DESCRIPTION

These three variable resistors, R103, R106 & R274, adjust the

depth of gain for the three stages of frequency response correction.

Adjusts the gain of the transmitter when the transmitter is in the

Auto ALC position.

Adjusts the gain of the transmitter when the transmitter is in the

Manual ALC position.

These three variable resistors adjust the threshold cut in for the

three stages of linearity pre-correction. R211 and R216, the top

two pots, are adjusted to correct for in phase amplitude distortions.

R 231, the bottom pot, is adjusted to correct for quadrature phase

distortions.

LX Series, Rev. 1 2-3

Page 19

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

2.1.2 (A5) LO/Upconverter Module

Assembly (1301930; Appendix A)

The (A5) LO/Upconverter Module

Assembly contains a front panel LED

display board (1303033), a UHF Filter

(1007-1101), a UHF Generator Board

(1585-1265) and a LO/Upconverter

Assembly (1303039). The

LO/Upconverter Assembly contains the

LO/Upconverter Board (1302132).

The LX Series Upconverter converts an

IF input signal to a RF output signal on

the desired channel frequency using a

high stability oven controlled oscillator

with very low phase noise and an

Automatic Level Control (ALC) for stable

output signal level.

Several control voltages are used for

transmitter power control. Automatic

gain control (AGC) circuits set the RF

output level of the transmitter system.

AGC #1 is provided by the

Transmitter/Exciter Driver Power

Amplifier module. This voltage is used

by the Upconverter to maintain a

constant RF output level at the Power

Amplifier module output. If this voltage

exceeds 0.9 VDC, the system is in an

over-drive condition. The 0.9 VDC overdriver threshold is set by a front panel

Upconverter module potentiometer.

When an over-drive condition is

detected, the Upconverter module

reduces it’s RF output level. For values

less than 0.9 VDC, the Upconverter uses

the AGC #1 voltage for automatic gain

control by setting it's RF output to

maintain AGC #1 equal to the AGC

voltage set by another front panel

potentiometer. When the Upconverter is

set for manual gain, the RF output of the

Upconverter is set by the front panel

AGC potentiometer. In manual gain

operation, the AGC #1 feedback voltage

from the PA is not used to adjust the RF

level unless an over-drive condition is

detected.

AGC #2 is provided by each of the

optional external amplifier modules.

Diodes are used in each of the external

amplifier forward power circuits to

capture the highest detected sample

voltage. This voltage is used by the

Upconverter to maintain a constant RF

output of the system. As with AGC #1,

the Upconverter module reduces its RF

output level if AGC #2 is too high. AGC

#1 and ACG #2 are diode ORed together

in the Upconverter gain circuit. Both

AGC voltages are first reduced by an onboard potentiometer before being

amplified. If an over-drive condition

does not exist, the higher of the two

AGC voltages is used to control the

Upconverter gain circuit. An AFC Voltage

is generated to control the VCXO of the

UHF Generator portion of the

Upconverter module. The typical AFC

voltage is 0.5 VDC but it can be as high

as +1.5 VDC.

The Upconverter can operate using

either the internal 10 MHz source or a

10 MHz external reference signal. When

an external 10 MHz source is present on

J10, it is automatically selected. An

external reference present signal is

provided to the controller for display

purposes. The selected 10 MHz signal

from the Upconverter is buffered then

sent to the backplane on two ports. One

port is sent to the Modulator module, if

present, and the other is routed to a

BNC connector (J11) on the backplane

for a system 10 MHz output signal.

A National Semiconductor frequency

synthesizer IC is used in the frequency

conversion of the IF signal to a RF

LX Series, Rev. 1 2-4

Page 20

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

signal. The frequency synthesizer IC

uses a 10 MHz reference frequency for

signal conversion. Typically the IF input

is a 0 dBm @ 44 MHz to the upconverter

through the backplane board is applied

to a mixer mounted on the first

conversion board.44 MHz for digital

systems. To obtain different output RF

frequencies, the synthesizer IC is serial

programmed by the Control Monitoring

board. The part is programmed to use a

5 kHz phase detection frequency. With

a 10 MHz input signal, the R counter is

set to 2000. With these settings the N

counter is set to the desired LO

frequency in kHz/5 kHz. The maximum

LO frequency setting with these

parameters is 1310.715 MHz.

Table 2-6: LO/Upconverter Front Panel Switch

SWITCH FUNCTION

When Manual AGC is selected, the reference AGC voltage is

set by the AGC Manual Gain front panel potentiometer.

MAN/AUTO AGC

Table 2-7: LO/Upconverter Front Panel Status Indicator

LED FUNCTION

AGC CUTBACK

(Red)

Table 2-8: LO/Upconverter Front Panel Control Adjustments

POTENTIOMETERS

MAN GAIN ADJ

AGC CUTBACK ADJ

(AGC OVERRIDE)

Table 2-9: LO/Upconverter Front Panel Samples

SMA CONNECTOR DESCRIPTION

LO SAMPLE

RF SAMPLE Sample of the On Channel RF Output of the Upconverter

When Auto AGC is selected, the RF power level control circuit

will automatically increase the RF output until the desired

output power is attained.

When lit it indicates that the required gain to produce the desired

output power level has exceeded the level set by the AGC Cutback

(Override) adjust. Transmitter will cut back power to 25%

Adjusts the gain of the transmitter when the transmitter is in the

Manual AGC position.

Adjusts the point at which the transmitter will cut back in power

when the Transmitter is in the Auto AGC position.

Sample of the LO signal to the Upconverter as generated by the

UHF Generator Board.

Example:

For a Frequency RF Out = 517.125 MHz,

N = 517125 kHz/5 kHz = 103425

An Upconverter PLL Lock indicator is

used to insure that the frequency control

circuits are operating properly. When

the Upconverter PLL is locked, the

frequency synthesizer IC is programmed

and the Power Amplifier module(s) can

be enabled.

The RF output of the LO/Upconverter

Module is at J23 on the rear chassis.

DESCRIPTION

LX Series, Rev. 1 2-5

Page 21

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

2.1.3 (A4) Control/Power Supply

Module Assembly, 220 VAC

(1303229; Appendix A)

The (A4) Control & Monitoring/Power

Supply Assembly is configured at the

factory for operation at 110 VAC or 220

VAC. The assembly made up of a Control

Board (1302021), a Power Protection

Table 2-10: Controller/Power Supply Display

DISPLAY FUNCTION

A 4 x 20 display providing a four-line readout of the internal

LCD

Table 2-11: Controller/Power Supply Status Indicator

LED FUNCTION

OPERATE

(green)

FAULT

(red or green)

DC OK

( red or green )

Table 2-12: Controller/Power Supply Control Adjustments

POTENTIOMETERS

DISPLAY CONTRAST Adjusts the contrast of the display for desired viewing of screen.

functions, external inputs, and status. See Chapter 3,

Controller/Power Supply Display Screens, for a listing of displays.

When lit it indicates that the transmitter is in the Operate Mode. If

transmitter is Muted the Operate LED will stay lit, the transmitter

will remain in Operate, until the input signal is returned.

Red indicates that a problem has occurred in the transmitter. The

transmitter will be Muted or placed in Standby until the problem is

corrected.

Green indicates that the switchable fuse protected DC outputs that

connect to the modules in the transmitter are OK.

Board (1302837) and a Switch Board

(1527-1406). The Assembly also

contains a switching power supply that

provides ±12 VDC to the rest of the

modules in the chassis and +32 VDC to

the Power Amplifier module.

The Assembly provides all transmitter

control and monitoring functions. The

Front panel LCD allows monitoring of

system parameters, including forward

and reflected power, transistor currents,

module temperatures and power supply

voltages.

DESCRIPTION

LX Series, Rev. 1 2-6

Page 22

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

2.1.4 (A6) Driver Amplifier Module

Assembly (1303874; Appendix A)

The (A6) Power Amplifier Module

Assembly is made up of a Coupler Board

Assembly (1227-1316), an Amplifier

Control Board (1303682), a 1 Watt

Module Assembly (1302891), a 40W UHF

Module (1304490) and a RF Module Pallet

(1300116).

The Driver Power Amplifier Module

contains Broadband LDMOS amplifiers

that cover the entire UHF band with no

tuning required. They amplify the RF to

the power level, 3.5 Watts Average is

maximum, that is needed to drive the

external amplifiers to the output power

level of the transmitter.

The Driver Power Amplifier is used to

amplify the RF output of the

Upconverter module. A cable, located on

the rear chassis, connects the RF output

from the Upconverter at J23 to J24 the

RF input to the driver PA Assembly. This

module contains RF monitoring circuitry

for both an analog and a digital system.

Control and monitoring lines to the

Driver Power Amplifier module are

routed through the floating blind-mate

connector of the Control &

Monitoring/Power Supply module.

The Driver Power Amplifier module and

any External Amplifier modules contain

the same control and monitoring board.

This board monitors RF output power,

RF reflected power, the current draw of

amplifier sections, the supply voltage,

and the temperature of the PA heat sink.

The RF power detector circuit outputs

vary with operating frequency. These

circuits must be calibrated at their

intended operating frequency. Front

panel adjustment potentiometers are

used to calibrate the following:

Power Amplifier Calibration Adjustments

R201 Reflected Power Cal

R202 Forward Power Cal

R203 (NOT USED) Aural Power Cal

R205 (NOT USED) Aural Null

The Forward power of an Exciter Driver

Power Amplifier and the Forward power

of any external amplifiers, are reported

by the system Control Monitoring

module.

If the Control Monitoring module is

monitoring a 5-50 Watt Transmitter,

system power is measured in the Power

Amplifier module. The wired

connections are transferred through the

power supply connector to the

backplane board on a five position

header. All four positions of control

board switch SW1 must be set on to

route these lines as the system's RF

power signals. In systems of output

power greater than 50 Watts, system

power is monitored by an external

module that is connected to TB31. In

this configuration switches SW1 on the

control board must be set off.

The Forward Power of the Exciter Driver

Power Amplifier module is routed to the

Upconverter module as AGC #1. A

system over-drive condition is detected

when this value rises above 0.9 VDC.

When an over-drive condition is

detected, the Upconverter module

reduces its RF output level.

For values less than 0.9 VDC, the

Upconverter uses this voltage for

automatic gain.

LX Series, Rev. 1 2-7

Page 23

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

Table 2-13: Driver Amplifier Status Indicator

LED FUNCTION

ENABLED

(Green)

DC OK

(Green)

TEMP

(Green)

MOD OK

(Green)

When lit Green, it indicates that the PA is in the Operate Mode. If a Mute

occurs, the PA will remain Enabled, until the input signal is returned.

When lit Green, it indicates that the fuse protected DC inputs to the PA

module are OK.

When lit Green, it indicates that the temperature of the heatsink

assembly in the module is below 78°C.

When lit Green, it indicates that the PA Module is operating and has no

faults.

If the Module OK LED is Red and blinking a fault is present, as indicated

below by the number of blinks and a pause then a repeat of the number

of blinks and a pause.

MOD OK

(Red)

1 Blink indicates Amplifier Current Fault.

2 Blinks indicate Temperature Fault.

3 Blinks indicate +32V Power Supply Over Voltage Fault.

4 Blinks indicate +32V Power Supply Under Voltage Fault.

5 Blinks indicate Reflected Power Fault.

6 Blinks indicate +12V or –12V Power Supply Fault.

MOD OK

(Amber)

A blinking Amber Mod OK LED indicates the power output of the amplifier

module is below 65%. (NOTE: Only in Amplifier Code Versions 3.7A or

later & System Controller Code Versions 3.9C or later.)

Table 2-14: Driver Amplifier Control Adjustments

POTENTIOMETERS

DESCRIPTION

REFLECTED CAL Adjusts the gain of the Reflected Power monitoring circuit

FORWARD CAL Adjusts the gain of the Forward Power monitoring circuit

AURAL CAL (NOT USED) Adjusts the gain of the Aural Power monitoring circuit

AURAL NULL

(NOT USED) Adjusts the offset of the Forward Power monitoring

circuit based on the Aural signal level.

Table 2-15: Driver Amplifier Sample

DISPLAY FUNCTION

FWD SAMPLE RF sample of the amplified signal being sent out the module on J25.

LX Series, Rev. 1 2-8

Page 24

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

2.2 RF Output Assemblies

The RF output from the exciter power

amplifier is at the RF output jack, an “N”

connector J25, PA RF Output, of the

chassis assembly. If this assembly is

used as a driver the output connects to

the input of the PA Assembly or a splitter

for multiple PA Assemblies, mounted

beneath the Exciter Assembly. If this

assembly is used as a 5W to 50W

transmitter, then the output connects

directly to the bandpass filter for the

system.

The RF output of the transmitter is

typically connected to a low pass and

DTV mask filters mounted on the rear or

top of the cabinet assembly. The low

pass and DTV mask filters are tuned to

eliminate unwanted sideband and

harmonic frequencies.

2.3 Control and Status

The control and status readings of the

exciter/amplifier Chassis assembly are

found by operating the front panel

display screen on the front of the

assembly. Detailed information on the

use of the screens is found in chapter 3.

2.3.1 Front Panel Display Screens

A 4 x 20 display located on the front of

the Control & Monitoring/Power Supply

Module is used in the LX Series

transmitter for control of the operation

and display of the operating parameters

of the transmitter. Refer to Chapter 3

for descriptions of the screens.

2.4 System Operation

When the transmitter is in operate, as set

by the menu screen located on the

Control & Monitoring Module, the

following occurs. The IF Processor will be

enabled and the mute indicator on the

front panel will be extinguished. The

+32 VDC stage of the Power Supply in

the Control & Monitoring Module is

enabled, the operate indicator on the

front panel is lit and the DC OK on the

front panel should also be green. The

enable and DC OK indicators on the PA

Module will also be green.

When the transmitter is in standby, the

IF Processor will be disabled, and the

mute indicator on the front panel will be

red. The +32 VDC stage of the Power

Supply in the Control & Monitoring

Module is disabled, the operate indicator

on the front panel will be extinguished

and the DC OK on the front panel should

remain green. The enable indicator on

the PA Module is also extinguished.

If the transmitter does not switch to

Operate when the operate menu is

switched to Operate, check that all faults

are cleared and that the remote control

terminal block stand-by signal is not

active.

The transmitter can be controlled by the

presence of an input signal. If the input

signal to the transmitter is lost, the

transmitter automatically cuts back and

the input fault indicator on the IF

Processor module lights. When the input

signal returns, the transmitter

automatically returns to full power and

the input fault indicator is extinguished.

2.4.1 Principles of Operation

Operating Modes

This transmitter is either operating or in

the standby mode. The sections below

discuss the characteristics of each of

these modes.

Operate Mode

Operate mode is the normal mode for

the transmitter when it is providing RF

power output. To provide RF power to

the output, the transmitter is not in

mute. Mute is a special case of the

LX Series, Rev. 1 2-9

Page 25

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

operate mode where the +32 VDC

section of the power supply is enabled

but there is no RF output power from

the transmitter. This condition is the

result of a fault that causes the firmware

to hold the IF Processor module in a

mute state.

Operate Mode with Mute Condition

The transmitter will remain in the

operate mode but will be placed in mute

when the following fault conditions

exists in the transmitter.

• Upconverter is unlocked

• Upconverter module is not present

• IF Processor module is not present

Entering Operate Mode

Entering the operate mode can be

initiated a few different ways by the

transmitter control board. A list of the

actions that cause the operate mode to

be entered is given below:

• A low on the Remote Transmitter

Operate line.

• User selects "OPR" using switches

and menus of the front panel.

• Receipt of an “Operate CMD” over

the serial interface.

There are several fault or interlock

conditions that may exist in the

transmitter that will prevent the

transmitter from entering the operate

mode. These conditions are:

• Power Amplifier heat sink

temperature greater than 78°C.

• Transmitter is Muted due to

conditions listed above.

• Power Amplifier Interlock is high

indicating that the amplifier is not

installed.

Standby Mode

The standby mode in the transmitter

indicates that the output amplifier of the

transmitter is disabled.

Entering Standby Mode

Similar to the operate mode, the

standby mode is entered using various

means. These are:

• A low on the Remote Transmitter

Stand-By line.

• Depressing the “STB” key on

selected front panel menus.

• Receipt of a “Standby CMD” over the

serial interface.

Auto Standby Mode

The FCC requires that certain

transmitters automatically switch to

standby operation on loss of input. The

LX Series transmitter incorporates this

feature as a user configurable setting.

When Auto Stand-By on input loss is

selected in the set-up menus, the

transmitter temporarily switches to

standby after ten seconds of input loss.

When the input signal, as reported by

the IF Processor module, is again

present, the transmitter automatically

returns to the Operate mode. This

feature is implemented in transmitter

software versions 1.4 and above.

RF System Interlock

A RF System Interlock signal is provided

through TB30-5. When this signal's

circuit is completed to ground such as

through a wire between TB30-5 and

TB30-15, the transmitter is allowed to

operate. If this circuit is opened, the

transmitter switches to a Mute condition.

This circuit may be completed through

coax relay contacts and reject load

contact closures to assure the RF output

system is available to receive the

transmitter's output RF signal. This

LX Series, Rev. 1 2-10

Page 26

Digital UHF Driver/Transmitter Chapter 2, System Description,

TB30

TB31

Maintenance & Remote Control Connections

feature is implemented in transmitter

software versions 1.4 and above.

2.5 Maintenance

The Innovator LX Series

Driver/Transmitter is designed with

components that require little or no

periodic maintenance except for the

routine cleaning of the fans and the front

panels of the modules.

The amount of time between cleanings

depends on the conditions within the

transmitter room. While the electronics

have been designed to function even if

covered with dust, a heavy buildup of

dust, dirt, or insects will affect the

cooling of the components. This could

lead to a thermal shutdown or the

premature failure of the affected module.

When the front panels of the modules

become dust covered, the module should

be pulled out and any accumulated

foreign material should be removed.

NOTE: In the power amplifier module the

two cables must be removed from the

rear of the module before attempting to

pull out. A vacuum cleaner, utilizing a

small, wand-type attachment, is an

excellent way to suction out the dirt.

Alcohol and other cleaning agents should

not be used unless you are certain that

the solvents will not damage components

or the silk-screened markings on the

modules and boards. Water-based

cleaners can be used, but do not saturate

the components. The fans and heatsinks

should be cleaned of all dust or dirt to

permit the free flow of air for cooling

purposes.

It is recommended that the operating

parameters of the driver/transmitter be

recorded from the LEDs on the modules

and the LCD system metering on the

control/monitoring module at least once

a month. It is suggested that this data be

retained in a rugged folder or envelope.

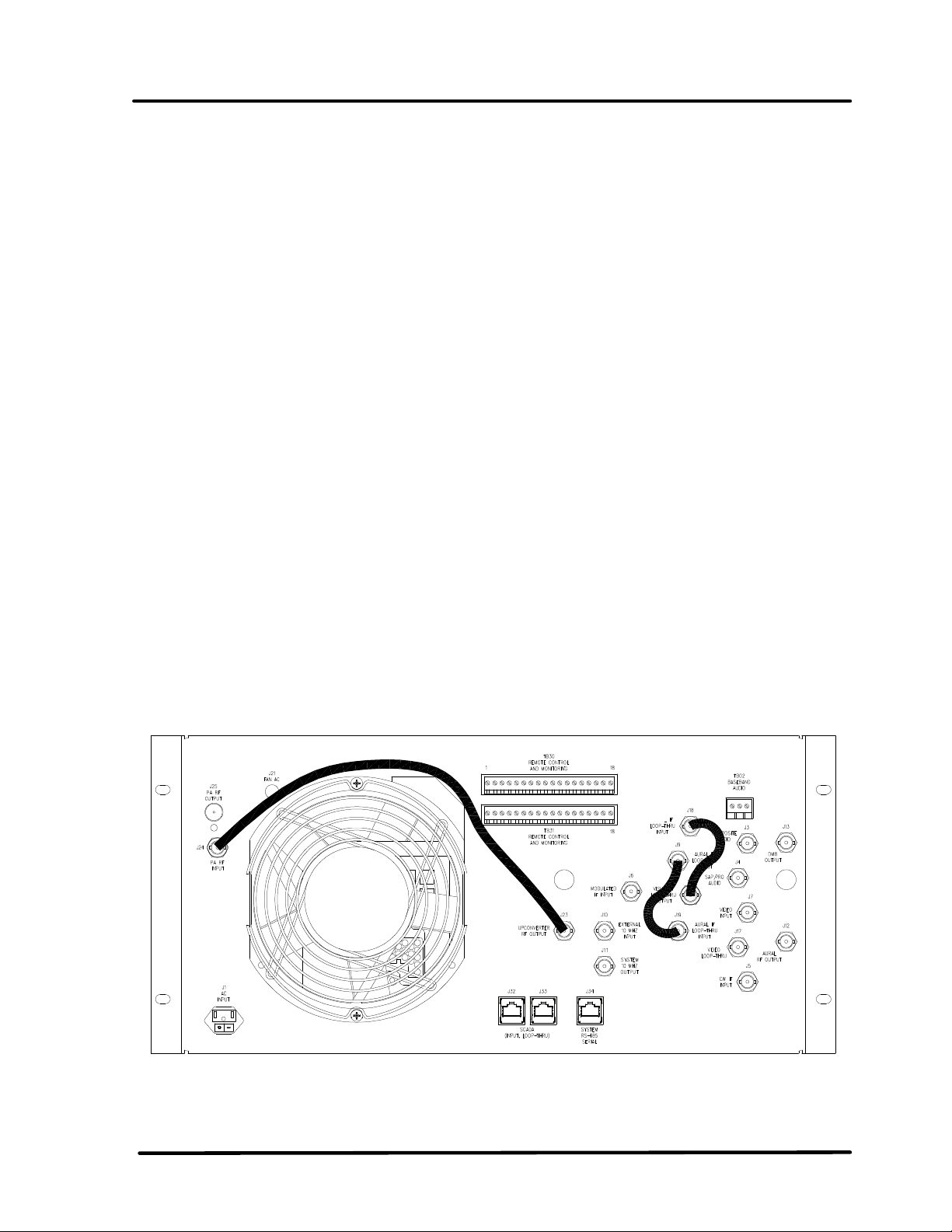

2.6 Customer Remote Connections

The remote monitoring and operation of

the transmitter is provided through jacks

TB30 and TB31 located on the rear of the

chassis assembly. If remote connections

are made to the transmitter, they must

be made through plugs TB30 and TB31

at positions noted on the transmitter

interconnect drawing and Table 2-16.

Figure 2-2: Exciter/Driver Chassis Assembly Rear View

LX Series, Rev. 1 2-11

Page 27

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

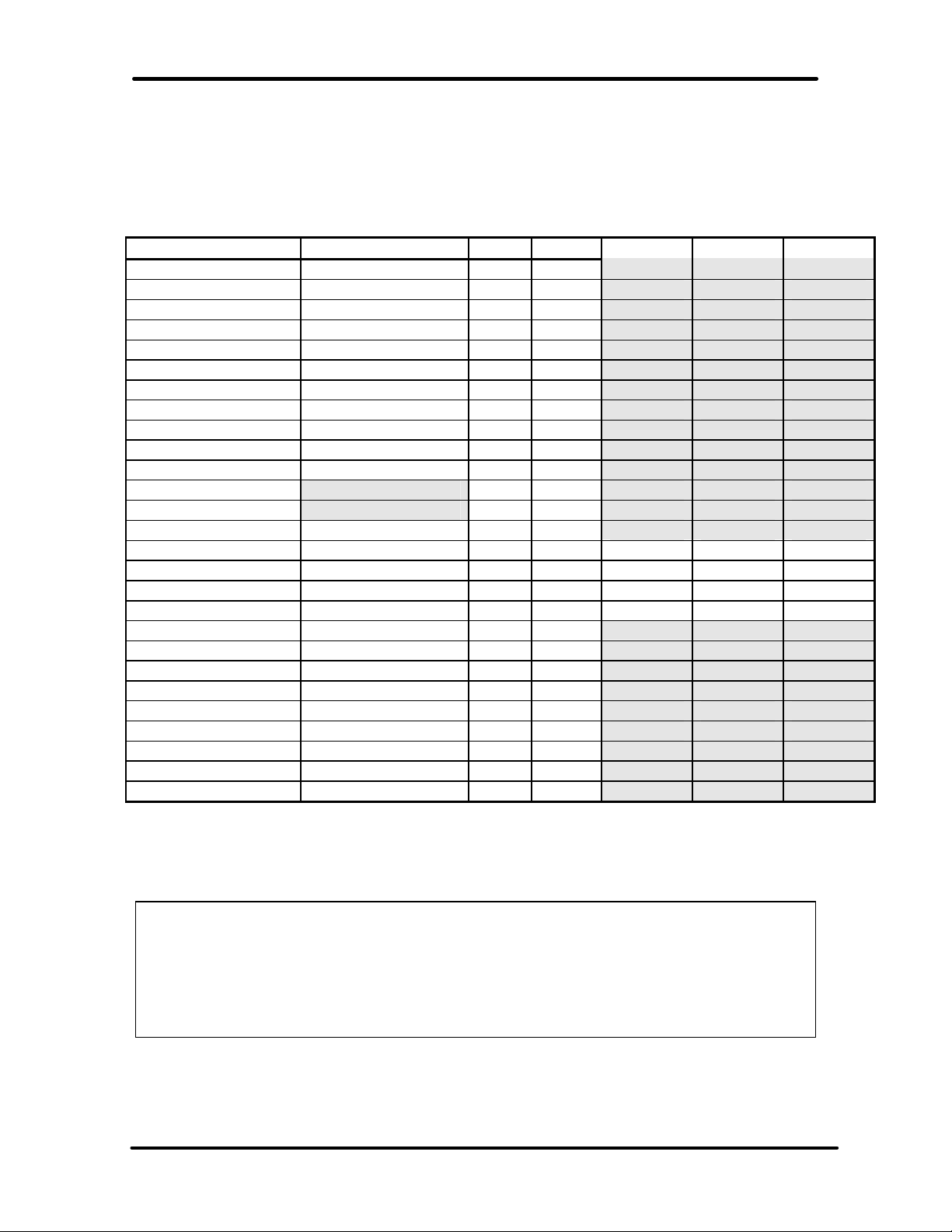

Table 2-16: LX Series Chassis Assembly Hard Wired Remote Interface Connections to

TB30 or TB31, 18 pos. Terminal Blocks Located on the Rear of the Assembly

Signal Name

RMT Transmitter

State

RMT Transmitter

Interlock

RMT Transmitter

Interlock

Isolated Return

RMT AUX IO 1 TB30-4

RMT RF System

Interlock

RMT

Transmitter

Operate

RMT

Transmitter

Stand-By

RMT Power

Raise

RMT Power

Lower

RMT

System Reflect

Power

RMT System

Visual/Forward

Power

RMT

System Aural

Power

Pin

Designations

TB30-1

TB30-2

TB30-3

TB30-5

TB30-6

TB30-7

TB30-8

TB30-9

TB30-10

TB30-11

TB30-12

Signal Type/Description

Discrete Open Collector Output - A low indicates that the

transmitter is in the operate mode.

Discrete Open Collector Output - A low indicated the

transmitter is OK or completes an interlock daisy chain.

When the transmitter is not faulted, the interlock circuit

is completed.

Ground - Configurable ground return which can be either

jumpered directly to ground or it can be the “source” pin

of an FET so that the transmitter interlock can be daisy

chained with other transmitters. This signal does not

directly interface to the microcontroller.

Discrete Open Collector Inputs, Discrete Open Drain

Outputs, or 0 - 5 VDC Analog Input - When used as an

output, this line is pulled to +5 VDC with a 1.0 kO

resistor for logic high and pulled to ground for a low. A

diode allows this line to be pulled up to 12 VDC. When

used as a digital input, this line considers all values over

2 Volts as high and those under 1 volt as low. As an

analog input, this line is protected by a 5.1 zener diode.

When this signal's circuit is completed to ground the

transmitter is allowed to operate. Typically, a jumper is

connected from TB30-5 and TB30-15. If this circuit is

opened, the transmitter switches to a Mute condition.

Implemented in transmitter software versions 1.4 and

above. (See note at end of table)

Discrete Open Collector Input - A pull down to ground on

this line indicates that the transmitter is to be placed into

the operate mode.

Discrete Open Collector Input - A pull down to ground on

this line indicates that the transmitter is to be placed into

the standby mode.

Discrete Open Collector Input - A pull down to ground on

this line indicates that the transmitter power is to be

raised.

Discrete Open Collector Input - A pull down to ground on

this line indicates that the transmitter power is to be

lowered.

Analog Output (0 to 4.0 V). This is a buffered loop

through of the calibrated “System Reflected Power” and

indicates the transmitter's reflected output power. The

scale factor is 25%/3.2V.

Analog Output (0 to 4.0 V). This is a buffered loop

through of the calibrated “System Visual/Avg. Power”.

Indicates the transmitter's Visual / Average power. Scale

factor is 100%/3.2V.

Analog Output (0 to 4.0 V). This is a buffered loop

through of the calibrated “System Aural Power”.

Indicates the transmitter's forward Aural output power.

The scale factor is 100%/3.2V.

LX Series, Rev. 1 2-12

Page 28

Digital UHF Driver/Transmitter Chapter 2, System Description,

Maintenance & Remote Control Connections

Signal Name

RMT Spare 1 TB30-13 Remote connection to spare module - Use is TBD.

RMT Spare 2 TB30-14 Remote connection to spare module - Use is TBD.

System Reflect

Power

System Visual /

Forward Power

System Aural

Power

IF Processor

IF Signal Select

IF Processor

DLC Voltage

UC AGC #2

Voltage

RMT Ground

RMT Ground

RMT +12 VDC

RMT -12 VDC

NOTE: The Remote RF System Interlock, at TB30-5, provides the customer with a

means of connecting the transmitter to protection circuits, for the loads, thermal

switches, combiners, or the antenna, in the output of your system, that Mutes

the transmitter if the protection circuit opens. If the interlock is not used in the

system, a jumper from TB30-5 to TB30-15, which is ground, needs to be

connected to TB30. This jumper provides the RF System Interlock, which allows

the transmitter to go to operate. Without the jumper, the transmitter will remain

Muted.

\

Pin

Designations

TB31-13

TB31-14

TB31-15

TB31-3

TB31-4

TB31-5

TB30-15, and

17

TB31-1, 2, 6

to 12, and 17

TB30-16

TB31-16

TB30-18

TB31-18

Signal Type/Description

Analog Input (0 to 1.00 V). This is the input of the

“System Reflected Power” indicating the transmitter's

reflected output power. The scale factor is 25%/0.80V.

Analog Input (0 to 1.00 V). This is the input of the

“System Visual / Forward Power” indicating the

transmitter's forward Visual / Forward output power. The

scale factor is 100%/0.80V.

Analog Input (0 to 1.00 V). This is the input of the

“System Aural Power” indicating the transmitter's

forward Aural output power. The scale factor is

100%/0.80V. (Not used in digital)

Discrete Open Collector Input - A low indicates that the

modulator IF source is to be used by the IF Processor

module. When floating an analog IF Processor module

may use the Modulated IF Input if the IF Processor sled

is so configured.

Analog Output (0 to 5.00 V). This is the input of IF

Processor module for digital system RF output power

control.

Auxiliary Analog Input (0 to 1V). This voltage is used by

the Upconverter for gain control. Linear signal with

display resolution of 0.01 %. Primary signal source is

J34-1.

Ground pins available through Remote

Ground pins available through Remote

+12 VDC available through Remote w/ 2 Amp re-settable

fuse

-12 VDC available through Remote w/ 2 Amp re-settable

fuse

LX Series, Rev. 1 2-13

Page 29

Digital UHF Driver/Transmitter Chapter 3, Site Considerations,

Installation and Setup Procedures

Chapter 3:

Site Considerations, Installation and Setup Procedures

Table 3-1: LX Series Digital Transmitters/Drivers AC Input and Current Requirements.

Transmitter/

Driver

5 Watt 117/220 VAC 5 Amps

50 Watt 117/220 VAC 10 Amps

125 Watt 220 VAC 10 Amps to the Exciter/Amplifier Cabinet

250 Watt 220 VAC 15 Amps to the Exciter/Amplifier Cabinet

500 Watt 220 VAC 25 Amps to the Exciter/Amplifier Cabinet

1000 Watt 220 VAC 45 Amps to the Exciter/Amplifier Cabinet

1500 Watt 220 VAC 65 Amps to the Exciter/Amplifier Cabinet

2000 Watt

2500 Watt

3000 Watt

3.1: Site Considerations

There are special considerations that

need to be taken into account before the

LX Series digital driver/transmitter can

be installed. For example, if the

installation is completed during cool

weather, a heat-related problem may not

surface for many months, suddenly

appearing during the heat of summer.

This section provides planning

information for the installation and set up

of the transmitter.

The AC input and current requirements

for LX Series digital transmitters are

shown in Table 3-1.

NOTE: This 1000 Watt transmitter is

typically operating at 220 VAC @ 45

Amps to the Exciter/Amplifier Cabinet.

The LX Series Digital Transmitters are

designed and built to provide long life

with a minimum of maintenance. The

environment in which they are placed is

important and certain precautions must

be taken. The three greatest dangers to

the transmitter are heat, dirt, and

moisture. Heat is usually the greatest

problem, followed by dirt, and then

Voltage Current

220 VAC 45 Amps to the Exciter/Amplifier Cabinet

220 VAC 40 Amps to the Amplifier Cabinet

220 VAC 45 Amps to the Exciter/Amplifier Cabinet

220 VAC 60 Amps to the Amplifier Cabinet

220 VAC 65 Amp to the Exciter/Amplifier Cabinet

220 VAC 60 Amps to the Amplifier Cabinet

moisture. Over-temperature can cause

heat-related problems such as thermal

runaway and component failure. Each

amplifier module in the transmitter

contains a thermal interlock protection

circuit that will shut down that module

until the temperature drops to an

acceptable level.

A suitable environment for the

transmitter can enhance the overall

performance and reliability of the

transmitter and maximize revenues by

minimizing downtime. A properly

designed facility will have an adequate

supply of cool, clean air, free of airborne

particulates of any kind, and no

excessive humidity. An ideal environment

will require temperature in the range of

40° F to 70° F throughout the year,

reasonably low humidity, and a dust-free

room. It should be noted that this is

rarely if ever attainable in the real world.

However, the closer the environment is

to this design, the greater the operating

capacity of the transmitter.

The fans are designed and built into the

transmitter will remove the heat from

within the modules, but additional means

are required for removing this heat from

LX Series, Rev. 1 3-1

Page 30

Digital UHF Driver/Transmitter Chapter 3, Site Considerations,

Installation and Setup Procedures

the building. To achieve this, a few issues

need to be resolved. The first step is to

determine the amount of heat to be

removed from the transmitter room.

There are generally three sources of heat

that must be considered. The first and

most obvious is the heat from the

transmitter itself. This amount can be

determined for a 50W digital transmitter

by subtracting the average power to the

antenna (50 watts) from the AC input

power (650 watts) and taking this

number in watts (600) and then

multiplying it by 3.41. This gives a result

of 2,046, the BTUs to be removed every

hour. 12,000 BTUs per hour equals one

ton. Therefore, a 1/4-ton air conditioner

will easily cool a 50W digital transmitter.

The second source of heat is other

equipment in the same room. This

number is calculated in the same way as

the equation for BTUs. The third source

of heat is equally obvious but not as

simple to calculate. This is the heat

coming through the walls, roof, and

windows on a hot summer day. Unless

the underside is exposed, the floor is

usually not a problem. Determining this

number is usually best left up to a

qualified HVAC technician. There are far

too many variables to even estimate this

number without reviewing the detailed

drawings of the site that show all of the

construction details. The sum of these

three sources is the bulk of the heat that

must be removed. There may be other

sources of heat, such as personnel, and

all should be taken into account.

Now that the amount of heat that must

be removed is known, the next step is to

determine how to accomplish this. The

options are air conditioning, ventilation,

or a combination of the two. Air

conditioning is always the preferred

method and is the only way to create

anything close to an ideal environment.

Ventilation will work quite well if the

ambient air temperature is below 100° F,

or about 38° C, and the humidity is kept

at a reasonable level. In addition, the air

stream must be adequately filtered to

ensure that no airborne particulates of

any kind will be carried into the

transmitter. The combination of air

conditioning for summer and ventilation

during the cooler months is acceptable

when the proper cooling cannot be

obtained through the use of ventilation

alone and using air conditioning

throughout the year is not feasible.

Caution: The use of air conditioning

and ventilation simultaneously is not

recommended. This can cause

condensation in the transmitters.

The following precautions should be

observed regarding air conditioning

systems:

1. Air conditioners have an ARI

nominal cooling capacity rating. In

selecting an air conditioner, do not

assume that this number can be

equated to the requirements of