Page 1

INSTRUCTION MANUAL

DT835A

DIGITAL

UHF TRANSMITTER

AXCERA, LLC

103 FREEDOM DRIVE P.O. BOX 525 LAWRENCE, PA 15055-0525 USA

(724) 873-8100 • FAX (724) 873-8105

www.axcera.com • info@axcera.com

Page 2

Digital UHF Transmitter Table of Contents

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

Section Page

1.1 Manual Overview..................................................................................1-1

1.2 Safety.................................................................................................1-1

1.3 Maintenance ........................................................................................1-2

1.4 Material Return Procedure .....................................................................1-2

1.5 Limited One-Year Warranty for Axcera Products.......................................1-3

CHAPTER 2 SYSTEM DESCRIPTION AND CUSTOMER REMOTE CONNECTIONS

2.1 System Overview .................................................................................2-1

2.1.1 Single UHF Exciter Assembly ........................................................2-1

2.1.2 (Optional) 10 MHz Reference Distribution Amplifier Tray..................2-2

2.1.3 DM8-R Modulator Tray.................................................................2-2

2.1.4 Amplifier Array Assemblies...........................................................2-2

2.1.5 Transmitter Output Assemblies.....................................................2-3

2.1.6 Control and Status ......................................................................2-3

2.1.7 Metering Panel............................................................................2-4

2.1.8 UHF Exciter Tray .........................................................................2-5

2.1.9 Variable Gain/Phase Tray .............................................................2-6

2.1.10 UHF Amplifier Tray .....................................................................2-6

2.1.11 Modulator front panel menus and indicators ..................................2-7

2.1.12 Main AC Input............................................................................2-8

2.1.13 Customer Remote Interface Connections.............................. 2-8

CHAPTER 3 INSTALLATION AND SETUP PROCEDURES

3.1 Site Considerations................................................................................3-1

3.2 Unpacking the Cabinets and Trays...........................................................3-4

3.3 Installing the Cabinets and Trays ............................................................3-4

3.3.1 DM8-R Modulator Installation ........................................................3-5

3.4 Main AC Inputs......................................................................................3-6

3.5 Output Connections...............................................................................3-6

3.6 Setup and Operation Procedures.............................................................3-7

3.6.1 DM8-R Modulator Setup Procedures ...............................................3-8

CHAPTER 4 CIRCUIT DESCRIPTIONS

4.1 UHF Exciter Assembly ............................................................................4-1

4.1.1 Control and Status .......................................................................4-1

4.1.2 Digital Input and Remote Connections............................................4-1

4.1.3 AC Input .....................................................................................4-2

4.2 DM8-R Modulator Tray...........................................................................4-2

4.2.1 DM8 Digital Modulator Board .........................................................4-2

4.2.2 DM8-R Front Panel Board..............................................................4-3

4.3 UHF Exciter Tray ..................................................................................4-3

4.3.1 UHF Filter...................................................................................4-3

4.3.2 UHF Generator Board...................................................................4-4

4.3.3 (Optional) 10-MHz Reference Oscillator Board ................................4-4

DT835A, Rev. 1 i July 23, 2003

Page 3

Digital UHF Transmitter Table of Contents

TABLE OF CONTENTS

CHAPTER 4 CIRCUIT DESCRIPTIONS - Continued

Section Page

4.3.4 PLL Board...................................................................................4-5

4.3.5 Power Entry Module.....................................................................4-7

4.3.6 IF Phase Corrector Board .............................................................4-7

4.3.7 ALC Board ..................................................................................4-9

4.3.8 Visual/Aural Metering Board .......................................................4-15

4.3.9 UHF Upconverter Board..............................................................4-16

4.3.10 Transmitter Control Board .........................................................4-17

4.3.11 +12V(4A)/-12V(1A) Power Supply Board....................................4-22

4.3.12 5-Section Delay Equalizer Board ................................................4-23

4.4 Variable Phase/Gain Tray ....................................................................4-23

4.4.1 Variable Gain/Phase Board ..........................................................4-23

4.4.2 Metering Board ..........................................................................4-24

4.4.3 Power Entry Module....................................................................4-24

4.4.4 +15V/-12V Power Supply Board ..................................................4-24

4.5 Metering Panel ...................................................................................4-24

4.5.1 Splitter Board ............................................................................4-25

4.5.2 Visual/Aural Metering Board ........................................................4-25

4.5.3 Dual Peak Detectors ...................................................................4-25

4.5.4 Detector Threshold Board............................................................4-26

4.5.5 Power Entry Module....................................................................4-26

4.5.6 +/-12V Power Supply Board........................................................4-26

4.6 AC Distribution Assembly, UHF Exciter..................................................4-27

4.7 2-3kW Amplifier Array.........................................................................4-27

4.8 UHF Amplifier Trays............................................................................4-29

4.8.1 UHF Filter.................................................................................4-29

4.8.2 1-Watt Amplifier Board Assembly................................................4-29

4.8.3 1-Watt Amplifier Board ..............................................................4-30

4.8.4 Single Stage Amplifier Assembly.................................................4-30

4.8.5 Coupler Board...........................................................................4-34

4.8.6 Dual Peak Detector Enclosure.....................................................4-34

4.8.7 Dual Peak Detector Board ..........................................................4-34

4.8.8 4-Way Splitter Assembly............................................................4-35

4.8.9 4-Way Splitter Board .................................................................4-35

4.8.10 Dual Stage Amplifier Assembly...................................................4-35

4.8.11 Amplifier Protection Board .........................................................4-39

4.8.12 Amplifier Control Board.............................................................4-40

4.8.13 Variable Gain/Phase Enclosure...................................................4-42

4.8.14 Variable Gain/Phase Board ........................................................4-42

4.8.15 4-Way Combiner Assembly........................................................4-43

4.9 AC Distribution Assembly, Single Phase Amplifier Array..........................4-44

4.10 AC Distribution Assembly, Three Phase Amplifier Array..........................4-45

4.11 Combiner Reject Load Assembly..........................................................4-45

4.11.1 Combiner Reject Load Board......................................................4-46

DT835A, Rev. 1 ii July 23, 2003

Page 4

Digital UHF Transmitter Table of Contents

TABLE OF CONTENTS - (continued)

Section Page

CHAPTER 5 DETAILED ALIGNMENT PROCEDURES

5.1 DM8-R Modulator ..................................................................................5-1

5.1.1 DM8-R Modulator Board Configuration .........................................5-1

5.2 UHF Exciter Tray ...................................................................................5-2

5.2.1 Delay Equalization Adjustment......................................................5-3

5.2.2 IF Phase Corrector Adjustment .....................................................5-3

5.2.3 UHF Generator Board...................................................................5-3

5.2.4 10-MHz Reference Generator Board ..............................................5-4

5.2.5 PLL Board...................................................................................5-4

5.3 UHF Amplifier Trays...............................................................................5-4

5.3.1 Variable Gain/Phase Board ...........................................................5-4

5.3.2 1-Watt UHF Amplifier Board .........................................................5-4

5.3.3 UHF Filter...................................................................................5-4

5.3.4 Single Stage Amplifier Assembly...................................................5-4

5.3.5 Coupler Board.............................................................................5-4

5.3.6 Dual Stage Amplifier Assembly .....................................................5-5

5.3.7 4-Way Splitter Assembly..............................................................5-5

5.3.8 Dual Stage Amplifier Assembly .....................................................5-5

5.3.9 4-Way Combiner Assembly...........................................................5-6

5.3.10 Circulator...................................................................................5-6

5.3.11 Dual Peak Detector Board............................................................5-6

5.3.12 Amplifier Protection Board ...........................................................5-6

5.3.13 Amplifier Control Board...............................................................5-6

5.3.14 Switching Power Supply ..............................................................5-6

5.3.15 Calibration of Output and Reflected Power and VSWR Cutback ........5-6

5.4 Phase and Gain Adjustment of the UHF Amplifier Trays in each Array..........5-7

5.5 Calibration of the Side A and Side B Arrays Forward Output Power .............5-7

5.6 Calibration of the Side A and Side B Arrays Reflected Output Power............5-7

5.7 Phase and Gain Adjustment for the entire Amplifier Array..........................5-8

5.8 Calibration of the Forward Output Power Level of the Transmitter...............5-8

5.9 Calibration of the Reflected Output Power Level of the Transmitter .............5-8

5.10 Calibration of the Reject Output Power Level of the Transmitter................5-9

APPENDICES

APPENDIX A SAMPLE LOG REPORT SHEET

APPENDIX B TYPICAL OPERATIONAL READINGS

APPENDIX C ASSEMBLY DRAWINGS AND PARTS LISTS

APPENDIX D SUBASSEMBLY DRAWINGS AND PARTS LISTS

APPENDIX E DT835A SYSTEM SPECIFICATIONS

DT835A, Rev. 1 iii July 23, 2003

Page 5

Digital UHF Transmitter Table of Contents

LIST OF FIGURES

2-1 Exciter Remote Interface Assembly ................................................2-10

2-2 Amplifier Array Remote Interface Panel ..........................................2-14

3-1 1 kW Minimum Ventilation Configuration...........................................3-4

3-2 Tray Installation Instructions...........................................................3-6

5-1 Typical Digital Spectrum ...............................................................5-12

DT835A, Rev. 1 iv July 23, 2003

Page 6

Digital UHF Transmitter Table of Contents

LIST OF TABLES

2-1 DT835A Major Assemblies ...............................................................2-1

2-2 Metering Panel Meters.....................................................................2-4

2-3 UHF Exciter Tray Meters..................................................................2-5

2-4 UHF Exciter Tray Switches...............................................................2-5

2-5 UHF Exciter Tray Fault Indicators .....................................................2-5

2-6 UHF Exciter Tray Samples ...............................................................2-6

2-7 Variable Phase/Gain Tray Meters......................................................2-6

2-8 Variable Phase/Gain Tray Sample.....................................................2-6

2-9 UHF Amplifier Tray Meters...............................................................2-6

2-10 UHF Amplifier Tray Status Indicators ................................................2-7

2-11 UHF Amplifier Tray Control Adjustments ...........................................2-7

2-12 UHF Amplifier Tray Sample..............................................................2-7

2-13 Modulator Front Panel LEDs.............................................................2-8

2-14 Customer Remote Control Interface Connections.................... 2-12

3-1 MPEG and 10 MHz Input Information................................................3-6

3-2 Jumper Positions in the Gain 1 and Gain 2 Circuits

For an Input Level of Between –6 and –26 dBm.................................3-8

4-1 Fuses, Idling Currents and Voltage Settings for Amplifier Devices......4-42

5-1 8-VSB Modulator Connections..........................................................5-1

5-2 Jumper Configurations for the Symbol Generator Board......................5-3

5-3 Jumper Configurations for the VSB Filter Board .................................5-5

5-4 DIP Switch Settings........................................................................5-6

5-5 Jumper Positions on the 6 dB Pad ..................................................5-10

5-6 Center Frequencies for the Delay Equalizer Sections.........................5-11

5-7 PLL Board Switch Positions............................................................5-13

5-8 Switch Positions for Channel Frequencies........................................5-14

DT835A, Rev. 1 v July 23, 2003

Page 7

Digital UHF Transmitter Chapter 1, Introduction

Chapter 1

Introduction

This manual explains the installation,

setup, alignment, and maintenance

procedures for the DT835A Digital UHF

Transmitter. It is important that you

read all of the instructions, especially

the safety information in this chapter,

before you begin to install or operate

the unit.

1.1 Manual Overview

This instruction manual is divided into

four chapters and supporting appendices.

Chapter 1, Introduction, contains

information on safety, maintenance,

return procedures, and warranties. The

Chapter 2, System Description and

Customer Remote Interface Connections,

describes the transmitter and includes

discussions of system control and status

indicators and remote control

connections. Chapter 3, Installation and

Set up Procedures, explains how to

unpack, install, setup, and operate the

transmitter. Chapter 4, Circuit

Descriptions, provides information on the

boards and subassemblies that make up

the DT835A. Chapter 5, Detailed

Alignment Procedures, provides

information on adjusting the system

assemblies for optimal operation The

appendices contain sample log sheets,

typical operational readings, assembly

and subassembly drawings and parts list,

and system specifications.

1.2 Safety

The digital UHF transmitters

manufactured by Axcera are designed for

ease of use and repair while providing

protection from electrical and mechanical

hazards. Listed throughout the manual

are notes, cautions, and warnings

concerning possible safety hazards that

may be encountered while operating or

servicing the transmitter. Please review

these warnings and familiarize yourself

with the operation and servicing

procedures before working on the

transmitter.

Read All Instructions – All of the

operating and safety instructions should

be read and understood before operating

this equipment.

Retain Manuals – The manuals for the

transmitter should be retained at the

transmitter site for future reference. We

provide two sets of manuals for this

purpose; one set can be left at the office

while one set can be kept at the site.

Heed Notes, Warnings, and

Cautions – All of the notes, warnings,

and cautions listed in this safety section

and throughout the manual must be

followed.

Follow Instructions – All of the

operating and use instructions for the

transmitter should be followed.

Cleaning – Unplug or otherwise

disconnect power from the equipment

before cleaning. Do not use liquid or

aerosol cleaners. Use a damp cloth for

cleaning.

Ventilation – Openings in the cabinets

and tray front panels are provided for

ventilation. To ensure reliable operation,

and to protect the unit from overheating,

these openings must not be blocked.

Servicing – Do not attempt to service

this product yourself until becoming

familiar with the equipment. If in doubt,

refer all servicing questions to qualified

Axcera service personnel.

Replacement Parts – When

replacement parts are used, be sure that

the parts have the same functional and

performance characteristics as the

original part. Unauthorized substitutions

may result in fire, electric shock, or other

DT835A, Rev. 1 1-1

Page 8

Digital UHF Transmitter Chapter 1, Introduction

hazards. Please contact the Axcera

Technical Service Department if you have

any questions regarding service or

replacement parts.

1.3 Maintenance

The DT835A is designed with

components that require little or no

periodic maintenance except for the

routine cleaning of the fans and the front

panels of the trays.

The amount of time between cleanings

depends on the conditions within the

transmitter room. While the electronics

have been designed to function even if

covered with dust, a heavy buildup of

dust, dirt, or insects will affect the

cooling of the components. This could

lead to a thermal shutdown or premature

failure of the affected trays.

When the front panels of the trays

become dust covered, the top covers

should be removed and any accumulated

foreign material removed. A vacuum

cleaner, utilizing a small wand-type

attachment, is an excellent way to

suction out the dirt. Alcohol and other

cleaning agents should not be used

unless you are certain that the solvents

will not damage components or the silkscreened markings on the trays and

boards. Water-based cleaners can be

used, but do not saturate the

components. The fans and heatsinks

should be cleaned of all dust or dirt to

permit the free flow of air for cooling

purposes.

It is recommended that the operating

parameters of the transmitter be

recorded from the meters on the trays

and the system metering control panel at

least once a month. It is suggested that

this data be retained in a rugged folder

or envelope. A sample format for a log

sheet is provided in Appendix A.

Photocopies of the log sheet should be

made for continued data entries.

1.4 Material Return Procedure

To insure the efficient handling of

equipment or components that have been

returned for repair, Axcera requests that

each returned item be accompanied by a

Material Return Authorization Number

(MRA#).

An MRA# can be obtained from any

Axcera Field Service Engineer by calling

the Axcera Field Service Department, at

(724) 873-8100. This procedure applies

to all items sent to the Field Service

Department regardless of whether the

item was originally manufactured by

Axcera.

When equipment is sent to the field on

loan, an MRA# is included with the unit.

The MRA# is intended to be used for the

return of the unit to Axcera. In addition,

all shipping material should be retained

for the return of the unit to Axcera.

Replacement assemblies are also sent

with an MRA# to allow for the proper

routing of the exchanged hardware.

Failure to close out this type of MRA# will

normally result in invoicing for the value

of the loaner item or the exchange

assembly.

When shipping an item to Axcera, please

include the MRA# on the packing list and

on the shipping container. The packing

slip should also include contact

information and a brief description of why

the unit is being returned.

Please forward all MRA items to:

Axcera

103 Freedom Drive

P.O. Box 525

Lawrence, PA 15055-0525 USA

For more information concerning this

procedure, call the Axcera Field Service

Department, at (724) 873-8100 or by

fax at (724) 873-8105.

Axcera can also be contacted through email at service@axcera.com and on the

Web at www.axcera.com.

DT835A, Rev. 1 1-2

Page 9

Digital UHF Transmitter Chapter 1, Introduction

1.5 Limited One-Year Warranty for

Axcera Products

Axcera warrants each new product that

it has manufactured and sold against

defects in material and workmanship

under normal use and service for a

period of one (1) year from the date of

shipment from Axcera's plant, when

operated in accordance with Axcera's

operating instructions. This warranty

shall not apply to tubes, fuses,

batteries, or bulbs.

Warranties are valid only when and if

(a) Axcera receives prompt written

notice of breach within the period of

warranty, (b) the defective product is

properly packed and returned by the

buyer (transportation and insurance

prepaid), and (c) Axcera determines, in

its sole judgment, that the product is

defective and not subject to any misuse,

neglect, improper installation,

negligence, accident, or (unless

authorized in writing by Axcera) repair

or alteration. Axcera’s exclusive liability

for any personal and/or property

damage (including direct, consequential,

or incidental) caused by the breach of

any or all warranties, shall be limited to

the following: (a) repairing or replacing

(in Axcera’s sole discretion) any

defective parts free of charge (F.O.B.

Axcera’s plant) and/or (b) crediting (in

Axcera’s sole discretion) all or a portion

of the purchase price to the buyer.

Equipment furnished by Axcera, but not

bearing its trade name, shall bear no

warranties other than the special hoursof-use or other warranties extended by

or enforceable against the manufacturer

at the time of delivery to the buyer.

NO WARRANTIES, WHETHER

STATUTORY, EXPRESSED, OR

IMPLIED, AND NO WARRANTIES OF

MERCHANTABILITY, FITNESS FOR

ANY PARTICULAR PURPOSE, OR

FREEDOM FROM INFRINGEMENT,

OR THE LIKE, OTHER THAN AS

SPECIFIED IN PATENT LIABILITY

ARTICLES, AND IN THIS ARTICLE,

SHALL APPLY TO THE EQUIPMENT

FURNISHED HEREUNDER.

DT835A, Rev. 1 1-3

Page 10

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

Chapter 2

System Description and Customer Remote Connections

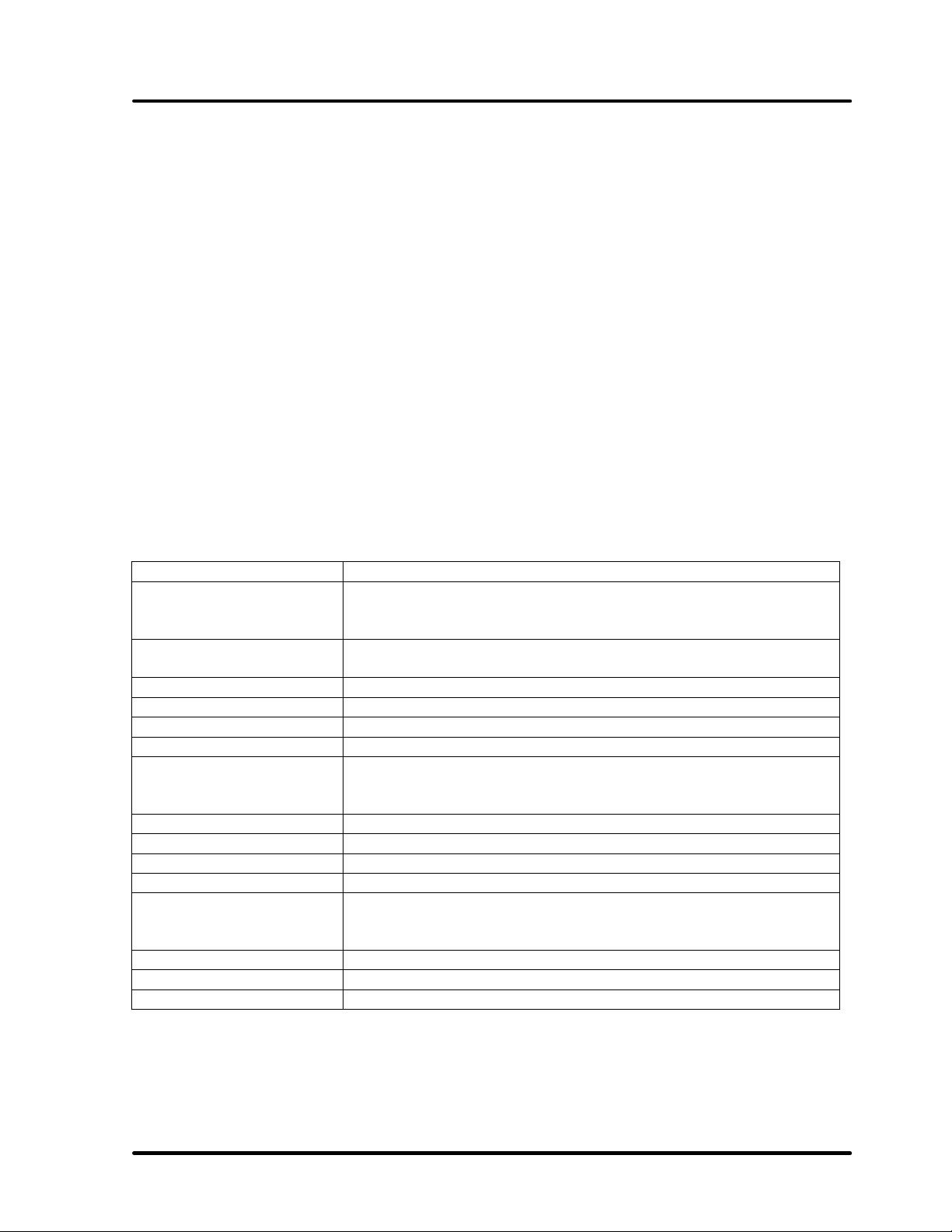

MAJOR ASSEMBLY NUMBER TRAY/ASSEMBLY NAME

A1 Single UHF exciter assembly

A2 and A3 two 2-3kW amplifier array assemblies

A4 Hybrid combiner assembly

A7 Directional coupler assembly

Output coupler assembly

DM8-R digital modulator tray

Table 2-1: DT835A Major Assemblies

2.1 System Overview

The DT835A is a complete UHF solidstate television transmitter that operates

at an output power of 2000 watts to

3000 watts digital, depending on the

digital application. The DT835A is made

up of three cabinets: a UHF exciter

cabinet and two amplifier array cabinets.

The DT835A is made up of the trays and

assemblies shown in Table 2-1.

2.1.1 (A1) Single UHF Exciter

Assembly

The single UHF exciter assembly

contains (A1) a UHF exciter tray, a DM8R digital modulator tray, (A10) an

(Optional) 10 MHz reference generator

tray, (A3) a splitter, (A4 and A5) two

variable phase/gain trays, (A6) a

metering panel, (A8) an AC distribution

assembly, and (A9) a remote interface

assembly.

The DM8-R modulator tray can have an

external 10 MHz reference connected to

J3 on the rear panel or it will generate

and internal 10 MHz reference if no

external reference is supplied. The

Digital input connects to J2 on the

remote interface assembly that is cabled

to J2 on the DM8-R modulator. The

Output from the DM8-R modulator at J4

connects to J6 on the rear of the UHF

exciter tray. The Digital IF is wired to

J18 on the 5 section delay equalizer

board, 44 MHz (1072090). The

processed digital IF signal is then cabled

to the J32 on the ALC board (1265-

1305). The digital IF input must be

selected as the input. This is

accomplished by connecting the jumper

W11 on J29 between pins 2 and 3 on the

ALC board. The digital IF is wired

through the K3 and K4 relays to the rest

of the ALC board. The LED DS5, digital

IF modulator enable, should be lit. The

ALC board has the capability of

switching between two different IF

inputs, but in this case only the digital IF

input is used.

The output of the ALC board (-10 dBm)

connects to (A11) the UHF upconverter

board (1265-1310) in the upconverter

section of the UHF digital exciter. The

upconverter takes the LO and

heterodynes it with the IF; the signal is

then filtered to produce the RF onchannel output.

The (A15-A1) UHF generator board

(1565-1109) is mounted in the UHF

Generator Enclosure (1519-1144) for EMI

and RFI protection. The board contains a

VCXO circuit and additional circuitry to

multiply the VCXO frequency by eight.

The output is split and provides an input

to the x8 multiplier circuitry as well as a

sample for the PLL board. The amplified

eighth harmonic is then fed to the SMA

output jack of the board at J3. Typical

output level of the signal is +16 dBm

nominal.

The (Optional) (A14-A1) 10-MHz

reference generator board (1519-1126)

DT835A, Rev. 1 2-1

Page 11

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

is located in the (Optional) (A10) 10-MHz

reference kit (1286-1108). The board

contains a high-stability crystal oscillator

that provides a 10-MHz output that is

used as reference frequency for the

transmitter. The board is mounted within

an enclosed assembly that helps to

maintain the operating temperature of

the oscillator board.

The (A13) PLL board (1286-1104) is part

of the phase lock loop (PLL) circuit, which

provides the automatic frequency control

(AFC) voltage, that connects to the VCXO

assembly, on the UHF Generator board,

and maintains the accurate output

frequency of the VCXO. The AFC is

generated by comparing a sample of the

10-MHz reference to a sample of the

VCXO frequency. The PLL board uses an

external 10-MHz signal as the reference

unless it is missing, then an internally

generated 10-MHz signal is used. A

sample of the signal from the UHF

generator board connects to SMA jack J9,

the sample input on the board. The signal

is amplified by U8 and coupled to U9, a

divide by 20/21 IC. A sample of the

signal at the output of U8 is connected to

J10, the sample output jack on the

board, which is typically connected to the

front panel of the tray.

The selected 10-MHz reference connects

to amplifier IC U1 whose output is split.

A sample of the 10-MHz reference is

cabled to jack J3, the 10-MHz output

jack, which is connected to J5 on the rear

of the tray.

If the 50 kHz from the 10-MHz reference

and the 50-kHz from the UHF generator

board become unlocked, the red Unlock

LED, lights and the Lock LED, located on

the LED display board, is extinguished.

The RF output of the UHF exciter at J15

is split two ways by the (A3) splitter.

The RF output #1 connects to the input

of (A4) one of the variable phase/gain

trays and the RF output #2 connects to

the input of (A5) the other variable

phase/gain tray. The output of the (A4)

variable phase/gain tray connects to

(A2) the side A amplifier array

assembly. The output of the (A5)

variable phase/gain tray connects to

(A3) the side B amplifier array

assembly.

2.1.2 (Optional) 10 MHz Reference

Distribution Amplifier Tray

The (Optional) 10 MHz reference

distribution amplifier tray provides a 10

MHz reference at a suitable output level

for distribution.

The system is made up of an internal 10

MHz reference source, a reference

distribution amplifier, and splitter kit(s)

without precise offset IF to distribute the

reference signal to each transmitter.

The reference distribution amplifier tray

utilizes an internal 10 MHz reference

generator assembly to generate a 10

MHz reference signal. This signal is then

divided into five equivalent signals and

then amplified and delivered to the

output of the tray.

2.1.3 DM8-R Digital Modulator Tray

The DM8-R modulator Tray is an ATSC

compliant 8 VSB modulator that mounts

in a standard 19” rack. The DM8-R

modulator accepts a SMPTE-310 MPEG

data stream and outputs a 6 MHz wide

IF output centered at 44 MHz with a

pilot carrier at 46.69 MHz. The DM8-R

modulator provides linear and nonlinear

correction capability for the transmission

path as well as internal test sources that

are used during initial transmitter

installation. All of the functions of the

DM8-R modulator are controlled from

the LX Controller LCD display and

pushbuttons.

2.1.4 Amplifier Array Assemblies

The amplifier array assemblies each

contain (A9-A1) an 8-way splitter

(ZFSC-8-43) with four to six connections

used depending on the power level of

the transmitter, four to six (A1, A2, A3,

DT835A, Rev. 1 2-2

Page 12

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

A4, A5 & A6) UHF amplifier trays, (A7) a

4 to 6-way combiner, (A8) an output

coupler, (A10) an AC distribution

assembly, and (A11) an interface panel.

The RF input from the variable

phase/gain tray connects to J1 on (A11)

the interface panel in the amplifier array

assembly. The RF is connected to the

COM input of the 8-way splitter, which

splits it eight ways, with six of the

outputs connected to J1, the RF input on

each of the UHF amplifier trays and the

other two outputs terminated with 50Ω.

The UHF amplifier trays amplify the RF

signals to the power needed to produce

a maximum of 300 watts 64 QAM or 8VSB digital per tray.

The outputs of the four, five or six UHF

amplifier trays are combined in the 4, 5

or 6-way combiner. This provides

approximately half of the power needed

to generate the full 8-VSB digital output

of the transmitter. The RF output is

connected to the output coupler

assembly. The output coupler assembly

supplies a forward and a reflected power

sample of the output from the amplifier

assembly to the metering panel in the

single exciter assembly.

In each UHF amplifier tray, the forward

power and reflected power samples from

the 4-way combiner board are

connected to the dual peak detector

board, single supply, that provides peak

detected samples to the amplifier control

board. The amplifier control board then

supplies DC voltages to the front panel

meter of the UHF amplifier tray. Before

exiting each UHF amplifier tray, the RF

is fed through a circulator for the

protection of the tray from high VSWR

conditions.

2.1.5 Transmitter Output

Assemblies

The outputs of the amplifier array

assemblies connect through (A5 and A6)

1-5/8” to 3-1/8” adapters to (A4) a

hybrid combiner (55223A) that

combines the output from the amplifier

assemblies into a single output. The

reject output of the hybrid combiner is

connected to (A7) an output coupler that

provides a reject sample from J3 to the

metering panel in the single UHF exciter

assembly for monitoring purposes. The

output of the (A7) directional coupler

connects to (A8) a 2500-watt reject load

that dissipates any reject power

produced during the combining process.

A (A8-A1) thermal switch is mounted on

the 2500-watt reject load that connects

to the overtemperature fault circuit on

the transmitter control board in the UHF

exciter tray. This fault circuit shuts down

the transmitter if an overtemperature

fault occurs. The overtemperature is

normally caused by a large reject power

being dissipated by the reject load due

to the malfunctioning of one of the

amplifier arrays.

The output of the (A4) hybrid combiner

at J3 is fed to (A11) the output coupler

assembly. The filtered signal is

connected to (A11) an output coupler

assembly that provides combined

forward and reflected power samples to

the metering panel in the single UHF

exciter assembly. The forward sample is

processed to provide peak detected

visual and aural power output samples

to the front panel meter on the metering

panel. The reflected power sample is

also peak detected and wired to the

front panel meter.

2.1.6 Control and Status

Information on the control and status of

the transmitter is provided by the

indicators on the metering panel and the

variable phase/gain trays. There are also

control, status, and LED indicators on

the front panel of the UHF exciter tray.

The functions of these control and status

indicators are shown in the following

tables. The switches and LED indicators,

which are mounted so that the switches

and LEDs can be operated or viewed

from the front panel of the UHF exciter,

are part of the transmitter control board.

DT835A, Rev. 1 2-3

Page 13

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

On the UHF exciter tray, switch (S1) is

an Operate/Standby switch that

provides the Operate command

(Enable), when in Operate, to the each

of the amplifier arrays. The Enable to

each amplifier array is split four, five or

six ways and then applied to the UHF

amplifier trays. The Enable is needed to

turn on the switching power supplies

located in the UHF amplifier trays.

When the UHF exciter is in Operate, the

green LED (DS2) is on and when the

exciter is in Standby, the amber LED

(DS1) is on.

NOTE: If the transmitter does not

switch to Operate when S1 is switched

to Operate, check that a dummy jumper

plug, with a jumper between pins 1 and

2, is connected to jack J7 on (A9) the

remote interface assembly in the single

UHF exciter assembly. This jumper

provides the interlock needed for the

operation of the transmitter. If the

interlock is present, the green LED

(DS5) on the transmitter control board

should be lit.

The operation of the transmitter is

controlled by the front panel switches on

the UHF exciter tray. During normal

operation of the transmitter, switch S2

should be in the Auto position. The front

panel of the UHF exciter also has LEDs

that indicate a Modulation Fault (Loss),

red LED (DS9), and a VSWR Cutback,

amber LED (DS7).

2.1.7 Metering Panel

Table 2-2: Metering Panel Meters

METER FUNCTION

Combination meter

(A13)

Displays power in terms of a percentage of the calibrated

transmitter output level on the scale; a full-scale reading is

120%

Switch (S1), meter Selects the desired % Forward, % Reject, or % Reflected

reading.

% Forward (0 - 120 %) Displays the output power level (≈100%)

% Reject (0 - 120 %) Displays the % Reject Output Power (<5%)

% Reflected (0 - 120 %) Displays the % Reflected Output Power (<5%)

Power meter side A

(A15)

Displays power in terms of a percentage of the calibrated

amplifier array output level on the scale; a full-scale reading

is 120%

Switch (S2), meter Selects the desired % Forward or % Reflected reading

Forward (0 - 120 %) Displays the output level of the array (≈ 95%)

% Reflected (0 - 120 %) Displays the % Reflected Output Power of the array (<5%)

Power meter side B

(A16)

Displays power in terms of a percentage of the calibrated

amplifier array output level on the scale; a full-scale reading

is 120%

Switch (S3), meter Selects the desired % Forward or % Reflected reading

Forward (0 - 120 %) Displays the output level of the array (≈ 95%)

% Reflected (0 - 120 %) Displays the % Reflected Output Power of the array (< 5%)

DT835A, Rev. 1 2-4

Page 14

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

2.1.8 UHF Exciter Tray

Table 2-3: UHF Exciter Tray Meters

METER FUNCTION

Meter (A18) Displays power in terms of a percentage of the calibrated

exciter output level on the upper scale. The voltage level is

read on one of the two bottom scales. A full-scale reading on

the top scale is 120%. 100% equals +10 dBm 8-VSB digital.

Also reads the ALC voltage level.

Switch (S3), meter Selects the desired % Exciter or the ALC voltage reading

ALC (0 - 1 V) Displays the ALC voltage level (≈0.85 VDC)

% Exciter Displays the % Exciter Output Power. This is the level needed

to attain (0 -100) which is the desired output power of the

transmitter (≈ 30 %).

Table 2-4: UHF Exciter Tray Switches

SWITCH FUNCTION

Transmitter (S1)

Operate/Standby

Mode Select (S2)

Auto/Manual

FAULT INDICATOR FUNCTION

Modulation loss (DS9

red)

VSWR cutback (DS7

amber)

The momentary contact switch (S1) applies a ground to K1, a

latching relay, on the transmitter control board. K1 will switch

either to Operate or to Standby depending on which direction

S1 is pushed. When switched to Operate, a low, Enable

command, is applied to the UHF amplifier trays mounted in the

amplifier arrays. These Enables will turn on the UHF amplifier

trays. The opposite occurs when the transmitter is switched to

Standby.

The momentary contact switch (S2) applies a ground to K2, a

latching relay, on the transmitter control board. K2 will switch

the transmitter to Automatic or Manual depending on which

direction S2 is pushed. In Automatic, the Modulation Fault

command from the ALC board will control the operation of the

transmitter. The transmitter will switch to Standby, after a

slight delay, if the input modulation is lost and will quickly

switch back to Operate when the modulation is restored. In

Manual, the transmitter is controlled by the operator using the

front panel Operate/Standby switch or by remote control.

Table 2-5: UHF Exciter Tray Fault Indicators

Indicates that the input has been lost to the transmitter. The

fault is generated on the ALC board in the UHF exciter tray.

Indicates that the reflected power level of the transmitter

has increased above 20%. This will automatically cut back

the output power level to 20%. The fault is generated on the

transmitter control board in the UHF exciter tray.

DT835A, Rev. 1 2-5

Page 15

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

Table 2-6: UHF Exciter Tray Samples

SAMPLE DESCRIPTION

f(s) A sample of the channel oscillator output taken from

the sample jack of the PLL board

Exciter O/P An output power sample of the exciter taken from the

UHF upconverter board

2.1.9 Variable Phase/Gain Trays

Table 2-7: Variable Phase/Gain Tray Meters

METER FUNCTION

Switch (S1), meter Selects the desired % Power or the ALC voltage

reading

% Output Power Displays the % Output Power of the amplifier array

(100%=+15 dBm 8- VSB digital ≈45%)

ALC Displays the ALC voltage from the UHF exciter that

connects to the amplifier trays in the amplifier array

(.6 - 1 VDC typical)

Table 2-8: Variable Phase/Gain Tray Sample

SAMPLE DESCRIPTION

Output (J4), (0 dBm) A front panel sample of the RF output of the

phase/gain tray, which connects to the amplifier

array, taken from the variable gain/phase board

2.1.10 UHF Amplifier Trays

Table 2-9: UHF Amplifier Tray Meters

METER FUNCTION

Meter (A9) Displays power in terms of a percent of the calibrated power

output value. A full-scale reading is 100%, which is equivalent to

300 watts 8-VSB digital. Also reads % Reflected Power, power

supply voltage levels, and AGC voltage levels.

Switch (S2),

meter

% Output pwr Displays the % Output Power of the tray (100%=300 watts 8-VSB

% Refl

(Reflected)

Power supply Displays the power supply voltage, +26.5 VDC, on the middle

AGC voltage Displays the AGC voltage level, +1 - +2 VDC, on the bottom scale

Selects the desired % Power or the voltage reading

digital)

Displays the % Reflected Output Power of the tray (<5% with all

amplifier trays operating as measured on the top scale)

scale

DT835A, Rev. 1 2-6

Page 16

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

Table 2-10: UHF Amplifier Tray Status Indicators

INDICATOR FUNCTION

Enable (DS4 green) Indicates that an Enable, Operate command, is

applied to the UHF amplifier tray from the selected

UHF exciter tray

Overdrive (DS2 red) Indicates that the level of the drive is too high. The

protection circuit will limit the drive to the set

threshold. The fault is generated on the amplifier

control board.

VSWR cutback (DS1 red) Indicates that the reflected power level of the tray has

increased above 50%. This will automatically cut back

the output power level to 50%. The fault is generated

on the amplifier control board.

Overtemp (DS3 red) Indicates that the temperature of (A5-A6- A3 and A5-

A6-A4), one or both of two thermal switches mounted

on the heatsink assembly for the output amplifiers, is

above 175° F. When this fault occurs, the Enable to

the switching power supply in the affected amplifier

tray is immediately removed and it will shut down.

Input fault (DS5 red) Indicates that the input RF level to the amplifier trays

dropped below the 0 dBm range

Table 2-11: UHF Amplifier Tray Control Adjustments

ADJUSTMENT FUNCTION

Phase (A10-R5) Adjusts the phase of the RF output by approximately

70°

Gain (A11-R6) Adjusts the gain of the RF output when the amplifier

control board is in the AGC mode

Table 2-12: UHF Amplifier Tray Sample

SAMPLE DESCRIPTION

Module O/P (0 dBm) A sample of the combined output of the four dual-

stage amplifier boards taken from the dual-peak

detector board

2.1.11 DM8-R Modulator Front Panel LED Indicators

The front panel LEDs are described in Table 2-13.

Table 2-13: Modulator Front Panel LEDs

LED Indicator Function

PWR Indicates that the DC power supply is operating

MPEG

LED

PLL A

LED

PLL B

LED

Indicates the presence of a valid MPEG stream at the

J1-2B input

Indicates that the DM8 symbol clock is locked to the

frequency of the 10 MHz reference.

Indicates that the pilot frequency is locked to the

incoming 10 MHz reference.

DT835A, Rev. 1 2-7

Page 17

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

2.1.12 Main AC Input

The transmitter needs an AC input of

208/240 VAC at 100 amps for each

amplifier array assembly and at 20 amps

for the exciter assembly.

The 208/240 VAC input to each amplifier

assembly connects to (A10) the AC

distribution assembly, amplifier array

(1278-1200), on the right, center of

each cabinet. The assembly contains the

terminal block (TB1) that connects to

the 208/240 VAC. Line 1 is connected to

TB1-1A, line 2 to TB1-3A, and safety

ground to TB1-4A.

The distribution assembly contains nine

circuit breakers that supply the AC to

the rest of the amplifier assembly. The

input AC from TB1 is connected to (CB1)

the main AC circuit breaker (100 amps)

that distributes the 208/240 VAC to the

other eight circuit breakers. The output

of CB1 has three MOVs, VR3, VR4, and

VR6, mounted to it: VR4 is connected

from line 1 to ground, VR6 is connected

from line 2 to ground and VR3 is

mounted across the two lines. The

switched input AC is wired through the

six circuit breakers, CB2-CB7, to the six

UHF amplifier trays in the amplifier

cabinets. CB2 is a 20-amp circuit

breaker that supplies the AC voltage to

the (A1) UHF amplifier tray. CB3 is a 20amp circuit breaker that supplies the AC

voltage to the (A2) UHF amplifier tray.

CB4 is a 20-amp circuit breaker that

supplies the AC voltage to the (A3) UHF

amplifier tray. CB5 is a 20-amp circuit

breaker that supplies the AC voltage to

the (A4) UHF amplifier tray. CB6 is a 20amp circuit breaker that supplies the AC

voltage to the (A5) UHF amplifier tray.

CB7 is a 20-amp circuit breaker that

supplies the AC voltage to the (A6) UHF

amplifier tray. The circuit breakers CB8

and CB9 control the AC to the A12-A3

and A12-A5 fans mounted on the

(optional) (A12) reject load assembly

that only used as part of the 2.5 and 3

kW amplifier array assemblies.

The 208/240 VAC input to the single

UHF exciter assembly connects to (A8)

the AC distribution assembly, single UHF

exciter assembly (1245-1500), in the

right, center rear of the cabinet. The

assembly contains the terminal block

(TB1) that connects to the 208/240

VAC. Line 1 is connected to TB1-1A, line

2 to TB1-3A, and ground to TB1-2A. The

AC distribution panel contains (CB1) the

main circuit breaker (20 amps) that

supplies the AC to the rest of the single

exciter assembly. The output of CB1 has

three MOVs, VR1, VR2, and VR3,

connected to it: VR1 from line 1 to

ground, VR3 from Line 2 to ground and

VR2 across the two lines. The AC output

of CB1 connects to A1 and A2, the IEC

outlet strips, into which the external

trays connect. The (A1) UHF exciter tray

and the (A4) variable phase/gain tray

plug into the (A1) IEC outlet strip. The

(A5) variable phase/gain tray, the (A6)

metering panel, the (optional) (A7)

receiver tray, the 8 VSB modulator tray

or other optional trays plug into the (A2)

IEC outlet strip. When the circuit

breaker CB1 on the single UHF exciter

assembly is switched on, +12 VDC from

the UHF exciter tray is supplied to each

of the amplifier array cabinets. The +12

VDC is split six ways in the amplifier

array and connected to each of the UHF

amplifier trays to operate the LED status

indicators in the tray. Also +12V is

connected to the (Optional) external

exhaust kit, if present.

2.1.13 Customer Remote Interface

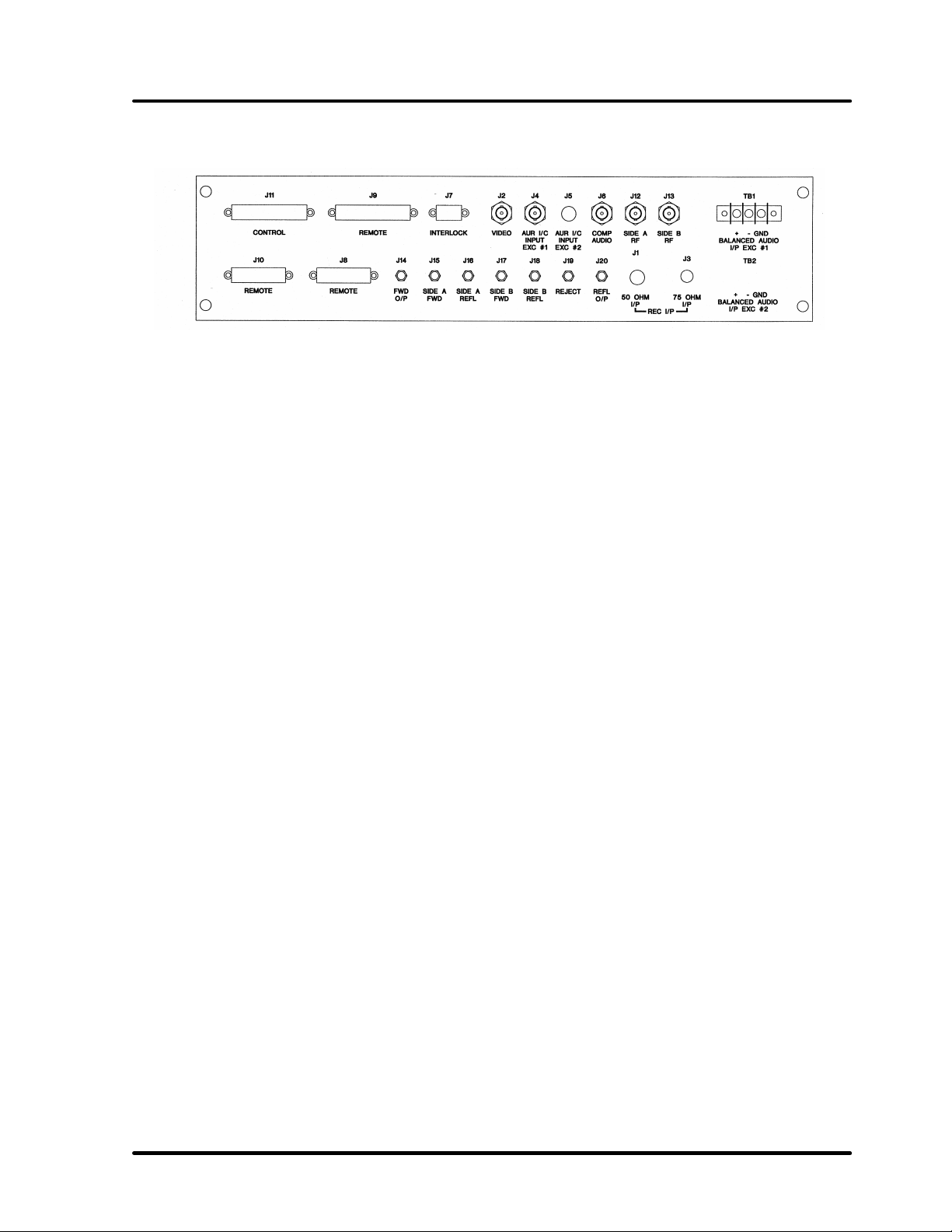

Connections

The remote monitoring and operation of

the transmitter is provided through the

jacks (J8, J9, and J10) on (A9) the

remote interface assembly mounted on

the rear of the single UHF exciter

assembly (see Figure 2-1).

DT835A, Rev. 1 2-8

Page 18

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

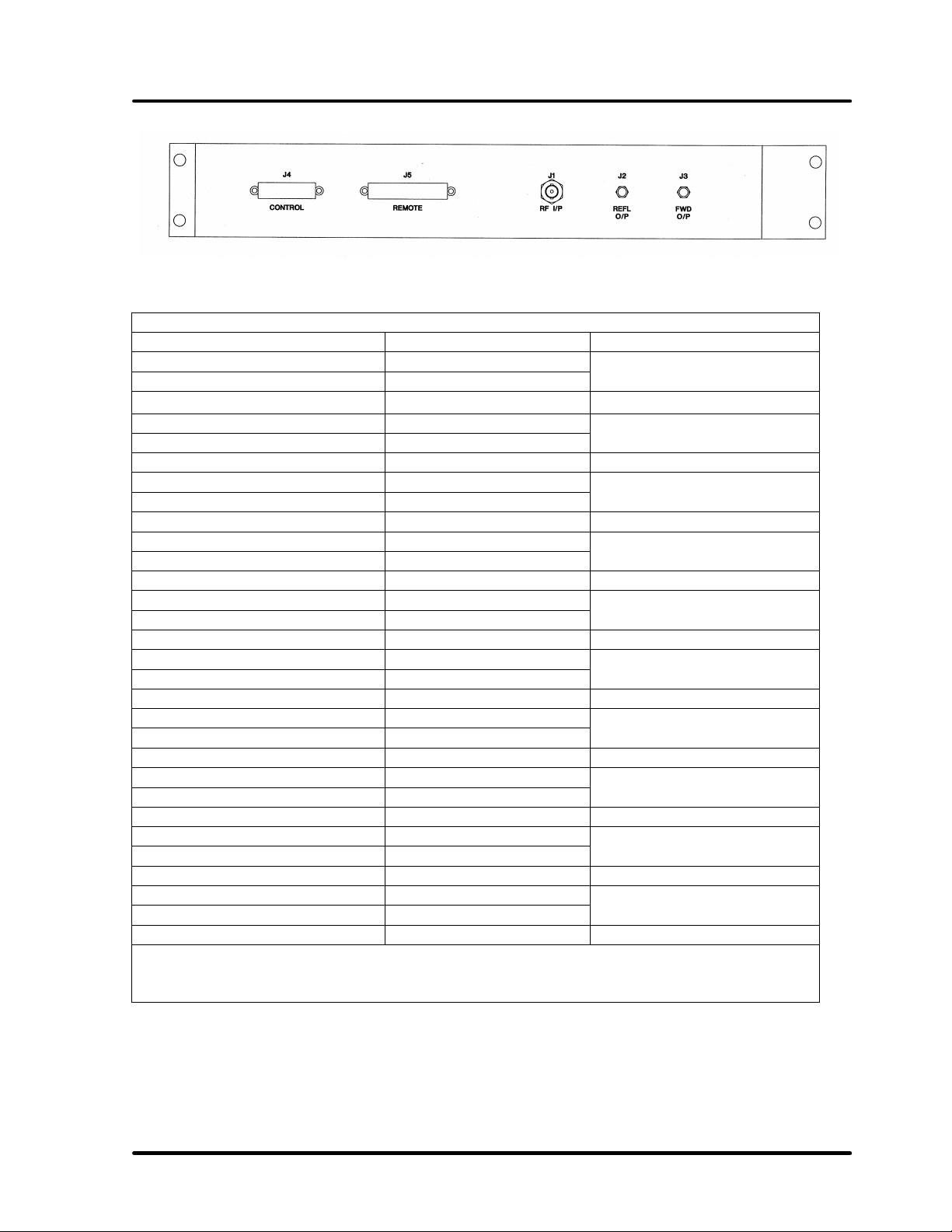

Figure 2-1: Exciter Remote Interface Assembly

Jack (J7) should have a dummy plug

connected to it, with a jumper

connected between pins 1 and 2, to

provide the interlock to the exciter

needed to operate the transmitter. If the

jumper is missing, the transmitter will

not switch to Operate. If remote

connections are made to the

through the plugs provided in the

installation material for the transmitter

and wired as indicated on the

interconnect drawing for the single UHF

exciter assembly (11056919). The

remote control interface connections for

this transmitter are shown in

Table 2-14.

transmitter, they should be made

DT835A, Rev. 1 2-9

Page 19

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

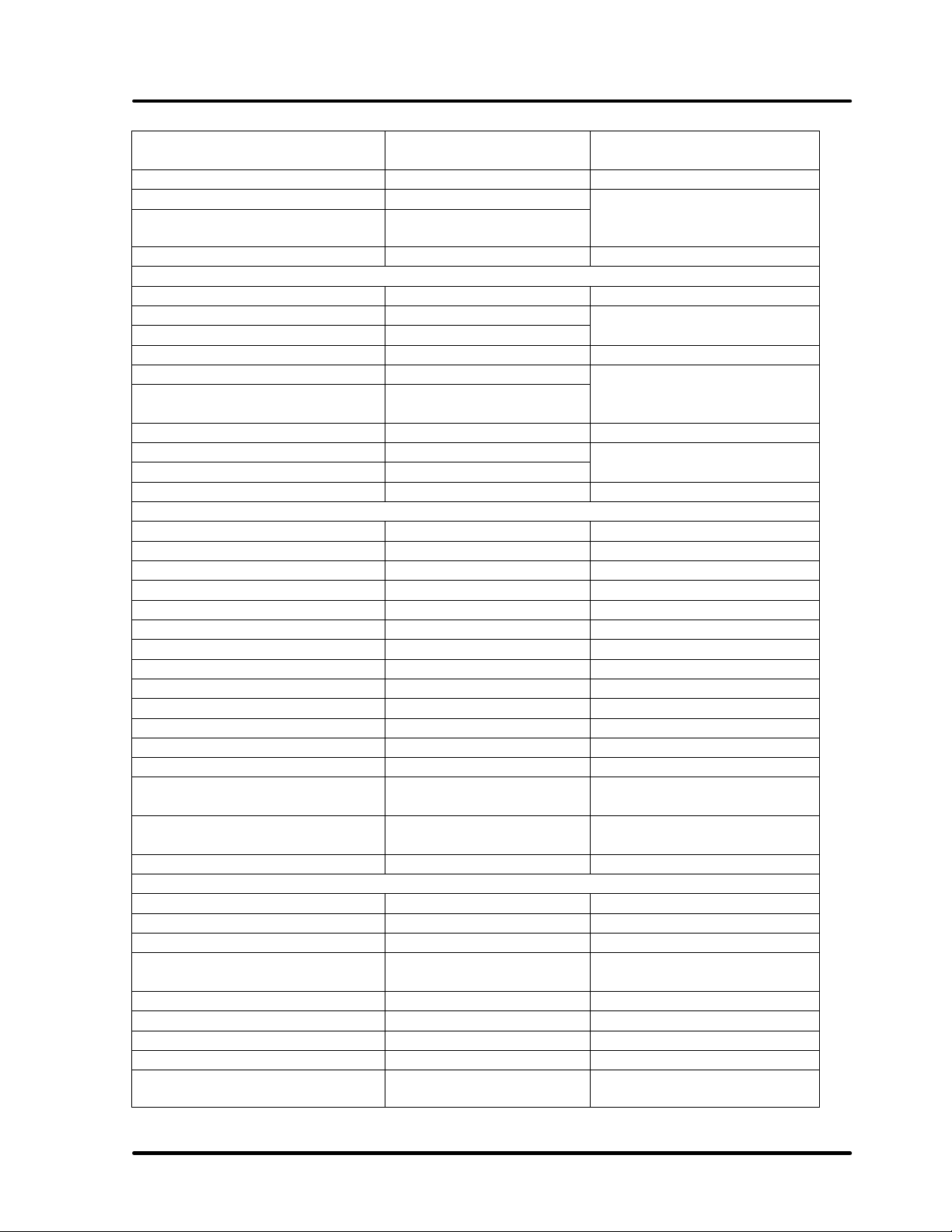

Table 2-14: Remote Control Interface Connections

FUNCTION

Exciter Enable Interlock J7-1

Exciter Enable Interlock Rtn J7-2

Transmitter Remote Metering

Combined Output Power J10-7

Combined Output Power Rtn J10-8

Combined Reflected Power J10-9

Combined Reflected Power

Rtn

Exciter Output J9-26

Exciter Output Rtn J9-27

Exciter Remote Control Commands

Exciter Operate (Enable) J8-3 Contact closure

Exciter Standby/Operate Rtn J8-2

Exciter Standby (Disable) J8-1 Contact closure

Exciter Auto J8-6 Contact closure

Exciter Auto/Manual Rtn J8-5

Exciter Manual J8-4 Contact closure

Power Raise (optional) J9-6 Contact closure

Raise/Lower Rtn (optional) J9-5

Power Lower (optional) J9-4 Contact closure

Exc Modulator Select

(optional)

Exc Modulator Select Rtn

(optional)

Exciter Remote Status Indications

Exciter Auto Mode Indicator J9-30 50 mA max current sink

Auto/Manual Mode Ind Rtn J9-31

Exciter Manual Mode

Indicator

Operate Indicator J9-1 50 mA max current sink

Operate/Standby Ind Rtn J9-2

Standby Indicator J9-3 50 mA max current sink

REMOTE JACK/PIN

NUMBER

J10-10

J8-10 Contact closure

J8-11

J9-32 50 mA max current sink

INTERFACE TYPE

J7-1 and 2 must be

jumpered together for

normal operation.

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

DT835A, Rev. 1 2-10

Page 20

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

FUNCTION

Exciter VSWR Cutback

Indicator

Video Loss Indicator J9-7 50 mA max current sink

Video Loss Indicator Rtn J9-8

Exc Receiver Fault Ind

(optional)

Side A Driver Remote Metering

Side A Driver Output Power J10-1

Side A Driver Output Power

Rtn

Side B Driver Remote Metering

Side B Driver Output Power J10-3

Side B Driver Output Power

Rtn

Side A Forward Power J10-14

Side A Forward Power Rtn J10-15

Side A Reflected Power J10-16

Side A Reflected Power Rtn J10-17

Side B Forward Power J10-20

Side B Forward Power Rtn J10-21

Side B Reflected Power J10-18

Side B Reflected Power Rtn J10-19

Side A + B Remote Metering

Reject Power J10-11

Reject Power Rtn J10-12

The above connections are made to jack (J9), the 37-position “D” connector; to jack

(J10), the 25-position “D” connector; to jack (J8), the 25-position “D” connector; or

to jack (J7), the 9-position “D” connector on (A9) the remote interface assembly

mounted at the top, rear of the single UHF exciter cabinet.

REMOTE JACK/PIN

NUMBER

J8-7 50 mA max current sink

J8-9 50 mA max current sink

J10-2

J10-4

Side A Remote Metering

Side B Remote Metering

INTERFACE TYPE

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ

source resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ

source resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

DT835A, Rev. 1 2-11

Page 21

Digital UHF Transmitter Chapter 2, System Description and

Customer Remote Connections

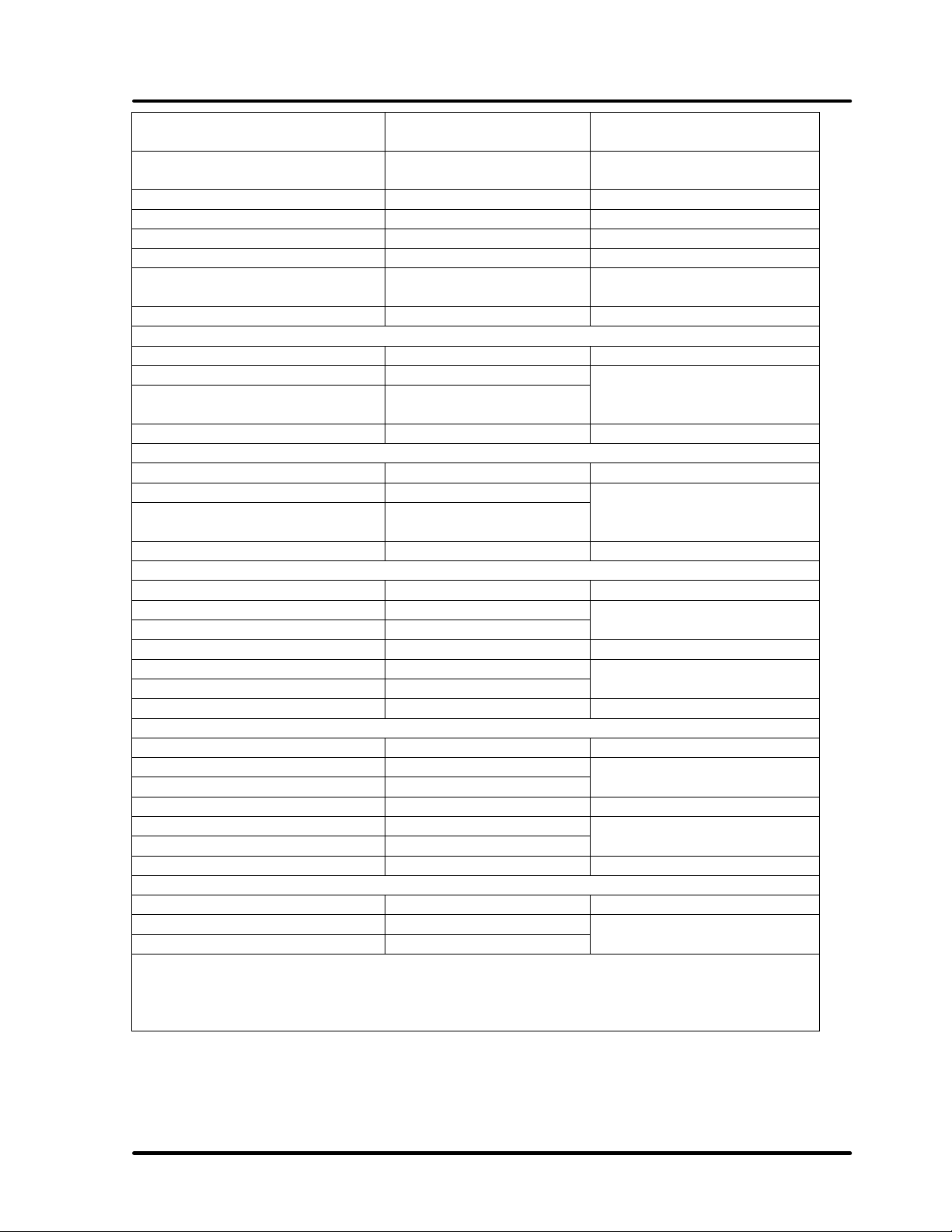

Figure 2-2: Amplifier Array Remote Interface Panel

Amplifier Array Assembly Remote Metering

(A1) UHF Amp Tray Refl Pwr J5-2

(A1) Reflected Power Rtn J5-1

(A1) UHF Amp Tray Fwrd Pwr J5-4

(A1) Forward Power Rtn J5-3

(A2) UHF Amp Tray Refl Pwr J5-6

(A2) Reflected Power Rtn J5-5

(A2) UHF Amp Tray Fwrd Pwr J5-8

(A2) Forward Power Rtn J5-7

(A3) UHF Amp Tray Refl Pwr J5-9

(A3) Reflected Power Rtn J5-10

(A3) UHF Amp Tray Fwrd Pwr J5-11

(A3) Forward Power Rtn J5-12

(A4) UHF Amp Tray Fwrd Pwr J5-13

(A4) Forward Power Rtn J5-14

(A4) UHF Amp Tray Refl Pwr J5-15

(A4) Reflected Power Rtn J5-16

(A5) UHF Amp Tray Fwrd Pwr J5-18

(A5) Forward Power Rtn J5-17

(A5) UHF Amp Tray Refl Pwr J5-21

(A5) Reflected Power Rtn J5-20

The above connections are made to jack (J5), the 37-position “D” connector on

(A11) the remote interface panel (Figure 2-2) mounted at the top, rear of each of

the amplifier array cabinets.

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

1V full scale at 1kΩ source

resistance

DT835A, Rev. 1 2-12

Page 22

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

Chapter 3

Installation and Setup Procedures

There are special considerations that

need to be taken into account before the

DT835A can be installed. For example, if

the installation is completed during cool

weather, a heat-related problem may not

surface for many months, suddenly

appearing during the heat of summer.

This section provides planning

information for the installation and set up

of the transmitter.

3.1 Site Considerations

The transmitter requires an AC input line

of 220 VAC with a rating of 20 amps for

the exciter cabinet and 100 amps for

each amplifier cabinet. Make sure that

the proposed site for the transmitter has

the voltage requirements that are

needed.

The DT835A is designed and built to

provide long life with a minimum of

maintenance. The environment in which

it is placed is important and certain

precautions must be taken. The three

greatest dangers to the transmitter are

heat, dirt, and moisture. Heat is usually

the greatest problem, followed by dirt,

and then moisture. Over-temperature

can cause heat-related problems such as

thermal runaway and component failure.

Each amplifier tray in the transmitter

contains a thermal interlock protection

circuit that will shut down that tray until

the temperature drops to an acceptable

level.

A suitable environment for the

transmitter can enhance the overall

performance and reliability of the

transmitter and maximize revenues by

minimizing down time. A properly

designed facility will have an adequate

supply of cool, clean air, free of airborne

particulates of any kind, and no

excessive humidity. An ideal environment

will require temperature in the range of

40° F to 70° F throughout the year,

reasonably low humidity, and a dust-free

room. It should be noted that this is

rarely if ever attainable in the real world.

However, the closer the environment is

to this design, the greater the operating

capacity of the transmitter.

The fans and blowers designed and built

into the transmitter will remove the heat

from within the trays, but additional

means are required for removing this

heat from the building. To achieve this, a

few considerations should be taken into

account. The first step is to determine

the amount of heat to be removed. There

are generally three sources of heat that

must be considered. The first and most

obvious is the heat from the transmitter

itself. This can be determined by

subtracting the average power to the

antenna (1500 watts) from the AC input

power (15,000 watts). This number in

watts (13,500) is then multiplied by

3.41, which gives 46,035, the BTUs to be

removed every hour. 12,000 BTUs per

hour equals one ton, so a 4-ton air

conditioner will cool a 1.5 kW digital

transmitter.

The second source of heat is other

equipment in the same room. This

number is calculated in the same way as

the equation for BTUs. The third source

of heat is equally obvious but not as

simple to calculate. This is the heat

coming through the walls, roof, and

windows on a hot summer day. Unless

the underside is exposed, the floor is

usually not a problem. Determining this

number is usually best left up to a

qualified HVAC technician. There are far

too many variables to even estimate this

number without detailed drawings of the

site showing all construction details. The

sum of these three sources is the total

amount of heat that must be removed.

There may be other sources of heat, such

as personnel, and all should be taken into

account.

DT835A, Rev. 0 3-1

Page 23

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

Now that the amount of heat that must

be removed is known, the next step is to

determine how to accomplish this. The

options are air conditioning, ventilation,

or a combination of the two. Air

conditioning is always the preferred

method and is the only way to create

anything close to an ideal environment.

Ventilation will work quite well if the

ambient air temperature is below 100° F,

or about 38° C, and the humidity is be

kept at a reasonable level. In addition,

the air stream must be adequately

filtered to ensure that no airborne

particulate of any kind will be carried into

the transmitter. The combination of air

conditioning for summer and ventilation

during the cooler months is acceptable

when the proper cooling cannot be

obtained through the use of ventilation

alone and using air conditioning

throughout the year is not feasible.

Caution: The operation of air

conditioning and ventilation

simultaneously is not recommended.

This can cause condensation in

transmitters. For tube type

transmitters, this can be especially

serious if the condensation forms in

the tube cavity and creates

damaging arcs.

The following precautions should be

observed regarding air conditioning

systems:

1. Air conditioners have an ARI

nominal cooling capacity rating. In

selecting an air conditioner, do not

assume that this number can be

equated to the requirements of

the site. Make certain that the

contractor uses the actual

conditions that are to be

maintained at the site in

determining the size of the air

conditioning unit. With the desired

conditioned room temperature

under 80° F, the unit must be

derated, possibly by a substantial

amount.

2. Do not have the air conditioner

blowing directly onto the

transmitter. Condensation may

occur on, or worse in, the

transmitter under certain

conditions.

3. Do not isolate the front of the

transmitter from the back with the

thought of air conditioning only

the front of the unit. Cooling air is

drawn in at the front of all

transmitters and in the front and

back of others. Any attempt to

isolate the front from the rear will

adversely affect the cooling air

flow.

4. Interlocking the transmitter with

the air conditioner is

recommended to keep the

transmitter from operating without

the necessary cooling.

5. The periodic cleaning of all filters

is a must.

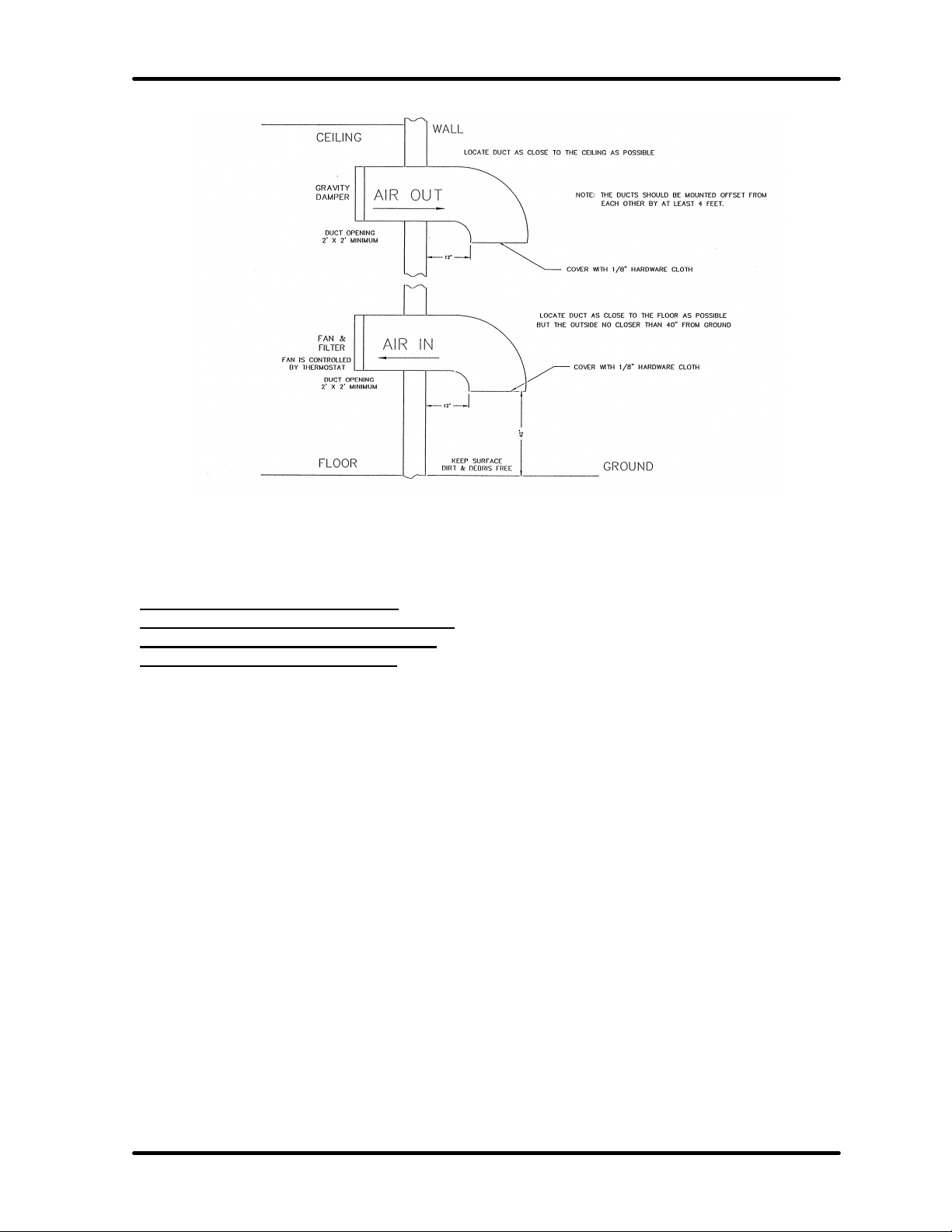

When using ventilation alone, the

following general statements apply:

1. The blower, with attendant filters,

should be on the inlet, thereby

pressurizing the room and

preventing dirt from entering the

transmitter.

2. The inlet and outlet vents should

be on the same side of the

building, preferably the leeward

side. As a result, the pressure

differential created by wind will be

minimized. Only the outlet vent

may be released through the roof.

3. The inlet and outlet vents should

be screened with 1/8" hardware

cloth (preferred) or galvanized

hardware cloth (acceptable).

4. Cooling air should enter the room

as low as practical but in no case

higher than four feet above the

floor. The inlet must be located

DT835A, Rev. 0 3-2

Page 24

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

where dirt, leaves or snow will not

be carried in with the cooling air.

5. The exhaust should be located as

high as possible. Some ducting is

usually required to insure the

complete flushing of heated air

with no stagnant areas.

6. The filter area must be adequate

to insure a maximum air velocity

of 300 feet per minute through the

filter. This is not a conservative

number but a never-exceed

number. In a dusty or remote

location, this number should be

reduced to 150 CFM.

7. The inlet and outlet(s) must have

automatic dampers that close any

time the ventilation blower is off.

8. In those cases in which

transmitters are regularly off for a

portion of each day, a

temperature-differential sensor

that controls a small heater must

be installed. This sensor will

monitor inside and outside

temperatures simultaneously. If

the inside temperature falls to

within 5° F of the outside

temperature, the heater will come

on. This will prevent condensation

when the ventilation blower comes

on and applies even in the

summer.

9. A controlled-air bypass system

must be installed to prevent the

temperature in the room from

falling below 40° F during

transmitter operation.

10. The blower should have two

speeds, which are thermostatically

controlled, and interlocked with

the transmitter.

11. The blower on high speed must be

capable of moving the required

volume of air into a half inch of

water pressure at the required

elevation. The free air delivery

method must not be used.

12. Regular maintenance of any filters

can not be overemphasized.

13. Tube transmitters should not rely

on the internal blower to exhaust

cooling air at elevations above

4000 feet. For external venting,

the air vent on the cabinet top

must be increased to an 8"

diameter for a 1 kW transmitter

and to 10" for 5 kW and 10 kW

transmitters. An equivalent

rectangular duct may be used but,

in all cases, the outlet must be

increased in area by 50% through

the outlet screen.

14. It is recommended that a site plan

be submitted to Axcera for

comments before installation

commences.

In calculating the blower requirements,

filter size, and exhaust size, if the total

load is known in watts, 2000 CFM into

1/2" of water will be required for each

5000 watts. If the load is known in BTUs,

2000 CFM into 1/2" of water will be

required for each 17,000 BTUs. The inlet

filter must be a minimum of seven

square feet, larger for dusty and remote

locations, for each 5000 watts or 17,000

BTUs. The exhaust must be at least four

square feet at the exhaust screen for

each 5000 watts or 17,000 BTUs.

The information presented in this section

is intended to serve only as a general

guide and may need to be modified for

unusually severe conditions. A

combination of air conditioning and

ventilation should not be difficult to

design (see Figure 3-1). System

interlocking and thermostat settings

should be reviewed with Axcera. As with

any equipment installation, it is always

good practice to consult the

manufacturer when questions arise.

Axcera can be contacted at

(724) 873-8100.

DT835A, Rev. 0 3-3

Page 25

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

Figure 3-1. 1 kW Minimum Ventilation Configuration

3.2 Unpacking the Cabinets and

Trays

Note: Air conditioning and any

related heat exhaust ducts should be

in place before continuing with the

installation of the transmitter.

Thoroughly inspect the cabinets and all

other materials upon their arrival. Axcera

certifies that upon leaving our facility the

equipment was undamaged and in proper

working order. The shipping containers

should be inspected for obvious damage

that indicates rough handling. Check for

dents and scratches or broken switches,

meters, or connectors. Any claims

against in-transit damage should be

directed to the carrier. Inform Axcera as

to the extent of any damage as soon as

possible.

Remove the cabinets, trays, hybrid

combiner, bandpass filter, trap filter, and

output couplers, along with any

installation material, from the crates and

boxes. Remove the straps that hold the

cabinets to the shipping skids and slide

the cabinets from the skids. Remove the

plastic wrap and foam protection from

around the cabinets. Do not remove any

labeling or tags from any cables or

connectors. These are identification

markers that make reassembly of the

transmitter much easier.

3.3 Installing the Cabinets and Trays

There are three cabinets: (A1) the single

UHF exciter assembly, (A2) the side A

amplifier array assembly, and (A3) the

side B amplifier array assembly. With the

operator facing the cabinets, they should

be arranged from left to right with the

single UHF exciter cabinet on the left, the

side A amplifier cabinet in the center, and

the side B amplifier cabinet on the right.

The cabinets should be positioned with

consideration given to adequate air

intake and exhaust, the opening of the

rear door, access to the trays (including

sliding them out for testing), the AC

hookup, and the installation of the output

transmission line. The cabinets should be

grounded using copper strapping

material and should also be permanently

mounted to the floor of the site using the

holes in the bottom of the cabinets.

DT835A, Rev. 0 3-4

Page 26

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

If trays are pre-mounted in the exciter

cabinet, remove the two L-brackets,

mounted on the front panel rails of the

single exciter cabinet, which hold the

trays in place during shipment. The UHF

amplifier trays are shipped separately

from the amplifier array cabinets because

of the weight of each tray. The trays are

mounted in the cabinet using Chassis

Trak cabinet slides. The tray slides are on

the top and bottom of the UHF amplifier

trays and on the sides of the UHF exciter

tray and the variable phase/gain trays.

Inspect the trays for any loose hardware

or connectors, tightening where needed.

Open the rear door; the key to unlock

the door, if the door has the optional

lock, is found in a tan envelope taped to

the door. Inspect the interior for packing

material and carefully remove any

packing material that is found. Slowly

slide each tray in and out to verify that

they do not rub against each other and

have no restrictions to free movement.

Note: The UHF amplifier trays must

be placed into the cabinets in the

proper location, and according to the

labeling on each tray, or the gain and

the phasing will not be maximized.

The UHF amplifier trays are labeled to

indicate where they are positioned in the

side A or the side B amplifier cabinets.

They are mounted in each cabinet from

bottom left to top right, with A1 the

bottom, left tray and A6 (if used) the top,

right tray. Locate the tray labeled A1 and

slide it into the side A cabinet in the

bottom, left position. Locate the tray

labeled A2 and slide it into the side A

cabinet in the bottom, right position.

Locate the tray labeled A3 and slide it

into the side A cabinet in the middle, left

position. Locate the tray labeled A4 and

slide it into the side A cabinet in the

middle, right position. Locate the tray

labeled A5 and slide it into the side A

cabinet in the top, left position.

Locate the UHF amplifier tray labeled B1

and slide it into the side B cabinet in the

bottom, left position. Locate the tray

labeled B2 and slide it into the side B

cabinet in the bottom, right position.

Locate the tray labeled B3 and slide it

into the side B cabinet in the middle, left

position. Locate the tray labeled B4 and

slide it into the side B cabinet in the

middle, right position. Locate the tray

labeled B5 and slide it into the side B

cabinet in the top, left position. All of the

amplifier trays should now be installed.

Slowly slide each tray in and out to verify

that they do not rub against each other

and have no restrictions to free

movement.

Caution: Each UHF amplifier tray has

a hard-line coaxial cable connected

to the rear panel. The tray will not

slide out without first removing this

connection.

In order to pull out the tray for test

purposes or other reasons, use the test

cable included in the installation material

kit for connections from the tray to the

output cable.

It may be necessary to make

adjustments to the positions of the trays.

This can be accomplished by loosening

the cabinet slide mounting bolts that hold

the front of the slide to the mounting

frame of the cabinet and moving the tray

up or down or left or right, as needed, to

correct for any misalignment.

3.3.1 DM8-R Modulator Installation

1. If not pre-mounted, remove the

modulator tray from the shipping box

and inspect it for any damage that

may have occurred during shipment.

Remove all packing material used to

protect the unit during shipment.

2. The tray mounts using four clearance

holes into a standard 19" rack or

cabinet. Mount the tray into the

cabinet and adjust or align the tray

so that it does not interfere with

cabling or other trays.

DT835A, Rev. 1 3-5

Page 27

Digital UHF Transmitter Chapter 3, Installation and Setup Procedures

3. Verify that the circuit breaker (CB1),

located on the rear of the tray, and

the main circuit breaker for the

system are off.

4. Connect the AC power cord, provided

in the installation kit, to J1, the AC

input jack on the rear of the tray.

5. Connect the MPEG input to J2, the IF

output from J4, and the 10 MHz

reference input, if supplied, to J3 on

the rear of the tray.

6. Connect the IF output at J4 to the

digital IF input to the upconverter of

the system.

This completes the installation procedure

for the DM8-R modulator.

3.4 Main AC Inputs

Once the cabinets are in place, and the

trays have been checked for damage and

alignment, the main AC hookup is ready

to be made.

Caution: Before connecting the

208/240 VAC, make certain that all

of the circuit breakers associated

with the transmitter are switched

off.

There are three AC input circuits to the

DT835A transmitter: one is 20 amps and

the two others are 100 amps single

phase. The input AC to the exciter

cabinet should be a 20 amp, 208/240

VAC line. The input AC to each amplifier

cabinet should be a single-phase, 100

amp, 208/240 VAC line.

The 20-amp, 208/240 VAC input

connections are made to the terminal

block A1-TB1, part of the AC distribution

assembly, exciter cabinet (1245-1500),

near the center, right-hand side, rear

portion of cabinet #1. Connect terminal 1

to line 1, terminal 3 to line 2 (208/240

VAC), and terminal 2 to the chassis

ground.

For single phase - Connect one of the

100-amp, 208/240 VAC inputs to the

terminal block A3-TB1, part of the AC

distribution assembly, amplifier

assembly (1278-1100), near the center,

right-hand side, rear portion of cabinet

#2. Connect line 1 to TB1-1A, line 2 to

TB1-3A and the safety ground to TB14A. Follow the same procedure for

cabinet #3.

3.5 Output Connections

The RF output of the (A2) amplifier

assembly connects through (A5) a 1-5/8"

to 3-1/8" adapter to J1 on (A4) the

hybrid combiner. The RF output of the

(A3) amplifier assembly connects

through (A6) a 1-5/8" to 3-1/8" adapter

to J2 on (A4) the hybrid combiner. The

reject output of the combiner at J4

connects through (A12) a 1-5/8” to 31/8” adapter to (A7) a directional coupler

(1016-1043) and then to (A8) the 2500watt reject load. The combined RF output

of the combiner at J3 connects through

(A9) the bandpass filter to (A10) the

output trap filter assembly. The filtered

output connects through (A11) the

output coupler assembly (1020-1002) to

the transmission line that is connected to

the antenna.