Page 1

Technical Manual

Innovator,

CHV400BTD,

ATSC VHF High Band Transmitter

Axcera, LLC

103 Freedom Drive, P.O. Box 525, Lawrence, PA 15055-0525, USA

PHONE: 724-873-8100 • FAX: 724-873-8105

www.axcera.com • info@axcera.com

Page 2

RESTRICTIONS ON USE, DUPLICATION OR DISCLOSURE

OF PROPRIETARY INFORMATION

This document contains information proprietary to Axcera, to its affiliates or to a third party to

which Axcera may have a legal obligation to protect such information from unauthorized

disclosure, use or duplication. Any disclosure, use or duplication of this document or any of the

information herein for other than the specific purpose for which it was disclosed by Axcera is

expressly prohibited, except as Axcera may otherwise agree in writing. Recipient by accepting this

document agrees to the above stated conditional use of this document and this information

disclosed herein.

Copyright © 2010, Axcera

Page 3

Innovator CHV400BTD ATSC Transmitter Table of Contents

Table of Contents

Introduction ......................................................................................................1

Manual Overview ............................................................................................1

Assembly Designators .....................................................................................1

Safety ...........................................................................................................1

Contact Information ........................................................................................3

Return Material Procedure ...............................................................................3

Limited One Year Warranty for Axcera Products..................................................4

Unpacking and Installation ................................................................................11

Unpacking ...................................................................................................11

Installation ..................................................................................................11

Tray Slide Installation ................................................................................12

AC Input Connections .......................................................................................13

Input and Output Connections ...........................................................................14

Initial On Site Turn On Procedure.......................................................................17

Typical System Operating Parameters ................................................................18

Typical Problems, Indications and Causes in CHV200B Tray...................................19

LCD Display and Front Panel LED Indicators ........................................................19

System Remote Connections .............................................................................21

LCD Front Panel Screens...................................................................................22

Operation Screens ........................................................................................24

Set Up Screens ............................................................................................31

System Description ..........................................................................................37

(Optional) Innovator CHVB Series Web Ethernet Interface ....................................41

(Optional) Innovator CHVB Series SNMP Ethernet Interface...................................47

Circuit Descriptions of Boards in the CHV200B System .........................................49

(A1) 8 VSB Demodulator Board (1308275) - Only used with BRD operation .........49

Overview..................................................................................................49

Microcontroller Functions............................................................................49

Jumper and DIP Switch Settings..................................................................49

(A2) Digital Modulator Board (1304883), Part of the Digital Modulator ................50

w/Power Conditioner (1309629) .....................................................................50

SMPTE-310 Input ......................................................................................50

Channel Coder ..........................................................................................50

Analog Output Section ...............................................................................50

Pilot Frequency Generation.........................................................................50

Voltage Requirements ................................................................................51

(A3) IF Pre-Corrector Board (1308796) ...........................................................51

Pin-Diode Attenuator Circuit ........................................................................52

In Phase and Quadrature Corrector Circuits ..................................................52

Frequency Response Corrector Circuit ..........................................................53

ALC Circuit ...............................................................................................53

Input Fault and Modulation Fault Circuitry ....................................................54

±12 VDC, +6.8 VDC, and VREF needed to operate the Board .........................55

(A4) Frequency Agile Upconverter Board (1309695) .........................................55

(A5) ALC Board, Innovator CX Series (1308570) ..............................................56

(A6) Amplifier Assembly (1313959) – Used in the CHV20B Tray .........................57

(A6-A1) VHF HB Pre-Driver Assembly (1313899) ..........................................57

(A6-A2) 50 Watt Amplifier Pallet, Italmec (1313484) .....................................58

(A6) 200 Watt Driver Amplifier Assembly (1313912) – Used in the CHV200B .......58

(A6-A1) 50 Watt Amplifier Pallet, Italmec (1313484) .....................................58

(A6-A2) 500 Watt Amplifier Pallet, Italmec (1313581) ...................................58

(A7) Output Metering Detector Board (1313747) ..............................................58

(A8) Control Card, Innovator CX (1312543) .....................................................59

Technical Manual, Rev. 0 i January 7, 2010

Page 4

Innovator CHV400BTD ATSC Transmitter Table of Contents

(A9 & A10) Power Supplies used in CHV20B, CHV200B, and Driver for CHV400B &

higher power ...............................................................................................59

Circuit Description of External System Metering Board which is only used in

Transmitters with multiple external Amplifier Trays ..............................................60

(A5) System Metering Board (1312666) ..........................................................60

Circuit Descriptions of Boards in the CHV400, 400 Watt ATSC Amplifier Tray ........... 61

(A7) Amplifier Control Board (1312260) ..........................................................61

(A10) Current Metering Board (1309130) ........................................................61

(A5) 2 Way Splitter Board (1313941), in CHV400B ...........................................62

(A2 & A3) 500 Watt Amplifier Pallets (1313581) ...............................................62

(A6) 2 Way Combiner Board (1313969), in CHV400B ........................................62

(A8 & A9) CHV400B, 500 Watt, 750 Watt and 1000 Watt Amplifier Tray Power

Supplies ......................................................................................................62

(Optional) ASI to S310 Converter Module ...........................................................63

ASI Motherboard (1311179) .......................................................................63

ASI to 310 Conversion Board, Non-SFN (1311219).........................................63

ASI to 310 Conversion Board, SFN (1309764)................................................64

System Set Up Procedure .................................................................................65

Set Up of the LO1 and LO2 Samples on Upconverter Board ................................ 65

Set Up of the IF Precorrector Board in the System ............................................66

ALC Board Set-Up, Forward and Reflected Power Calibration for CHV200B Systems

..................................................................................................................67

Forward and Reflected Power Calibration of CHV400B and Higher Power Systems

with one or more External Amplifier Trays .......................................................68

Linearity Correction Adjustment (Non-Linear Distortions) ..................................70

Linearity Correction Adjustment (Linear Distortions) .........................................71

APPENDIX A

Innovator,

CHV400BTD..........................................................................................................1

Innovator CHV400BTD Transmitter System

Drawing List .........................................................................................................1

APPENDIX B

Innovator,

CHV20BTD, ..........................................................................................................1

Innovator CXB Series Transmitter

CHV20BTD Driver Tray,

Subassemblies & Boards Drawing List ......................................................................1

APPENDIX C

Innovator,

CHV400B, ............................................................................................................1

Innovator CXB Series Transmitter

CHV400B Amplifier Tray,

Subassemblies & Boards Drawing List ......................................................................1

Technical Manual, Rev. 0 ii January 7, 2010

Page 5

Innovator CHV400BTD ATSC Transmitter Introduction

Introduction

Manual Overview

This manual contains the description of the Innovator CHV400BTD ATSC Transmitter and

the circuit descriptions of the boards, which make up the system. The manual also

describes the installation, setup and alignment procedures for the system.

Appendix A of this manual contains the system level drawings and parts lists for the

Innovator CHV400BTD ATSC Transmitter System. Appendix B contains the Tray,

subassemblies and boards drawings and parts lists for the CHV200BTD Driver Tray.

Appendix C contains the Tray, subassemblies and boards drawings and parts lists for

the CHV400B Amplifier Tray. NOTE: Information and drawings on the Axciter, if part of

your system, are contained in the separate Axciter Instruction Manual.

Assembly Designators

Axcera has assigned assembly numbers, Ax designations such as A1, where x=1,2,3…etc,

to all assemblies, modules, and boards in the system. These designations are referenced

in the text of this manual and shown on the block diagram and interconnect drawings

provided in Appendix A.

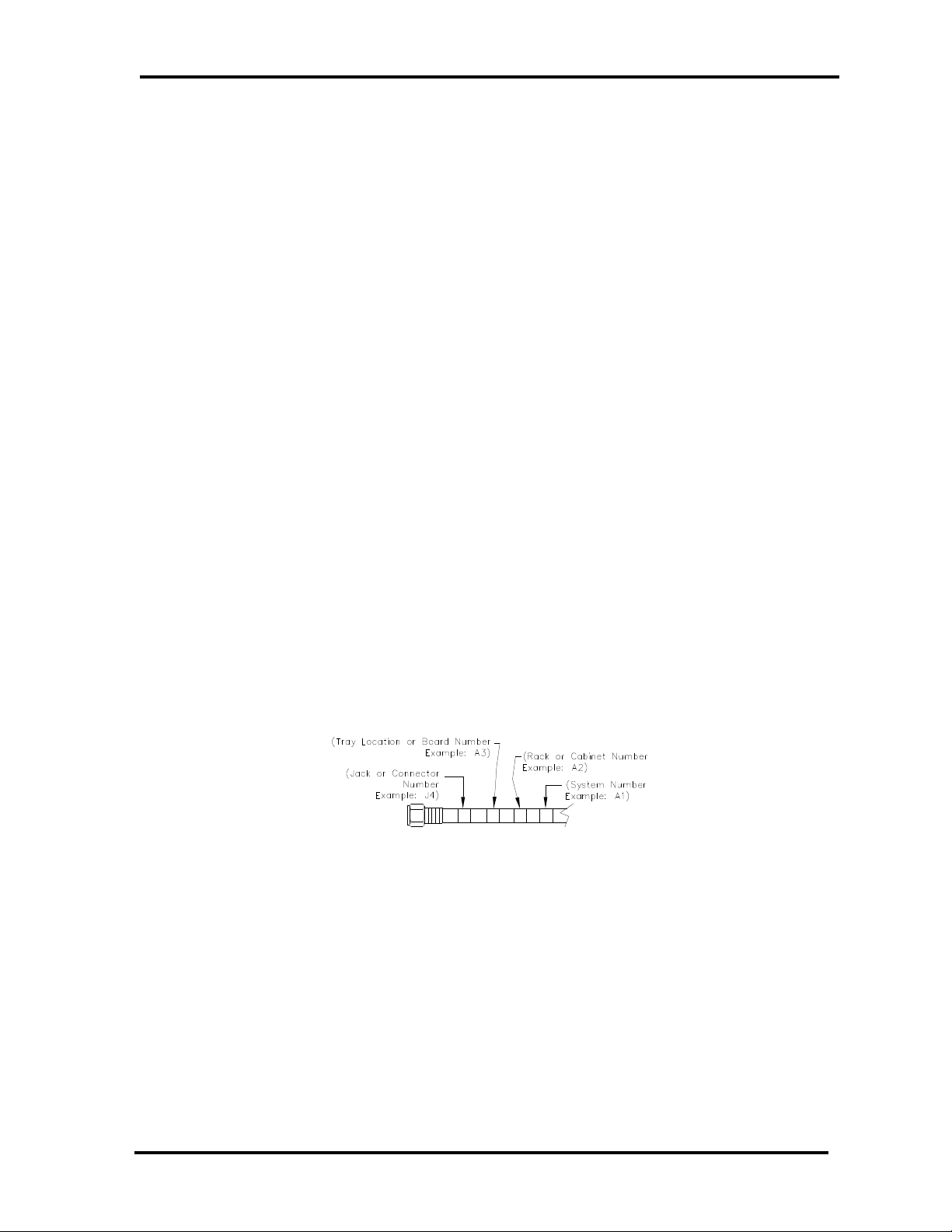

The cables that connect between the boards within a tray or assembly and that connect

between the trays, racks and cabinets are labeled using markers. Figure 1 is an

example of a marked cable. There may be as few as two or as many as four Markers on

any one cable. These markers are read starting farthest from the connector. If there

are four Markers, the marker farthest from the connector is the system number such as

system 1 or transmitter 2. The next or the farthest Marker is the rack or cabinet “A”

number on an interconnect cable or the board “A” number when the cable is within a

tray. The next number on an interconnect cable is the Tray location or Board “A”

number. The marker closest to the connector is the jack or connector “J” number on an

interconnect cable or the jack or connector “J” number on the board when the cable is

within a tray.

4 3 2 1

Marker Identification Drawing

Safety

The Innovator CHV400BTD ATSC Transmitter systems manufactured by Axcera are

designed to be easy to use and repair while providing protection from electrical and

mechanical hazards. Please review the following warnings and familiarize yourself with

the operation and servicing procedures before working on the system.

Hazardous Accessibility – Axcera has made attempts to provide appropriate

connectors, wiring and shields to minimize hazardous accessibility.

Circuit Breakers and Wiring – All circuit breakers and wire are UL and CE certified and

are rated for maximum operating conditions.

Technical Manual, Rev. 0 1

Page 6

Innovator CHV400BTD ATSC Transmitter Introduction

Single Point Breaker or Disconnect - The customer should provide a single point

breaker or disconnect at the breaker box for the main AC input connection to the

transmitter.

Transmitter Ratings - The transmitter ratings are provided in the text of this manual

along with voltage and current values for the equipment.

Protective Earthing Terminal – A main protective earthing terminal is provided for

equipment required to have protective earthing.

Read All safety Instructions – All of the safety instructions should be read and

understood before operating this equipment.

Retain Manuals – The manuals for the system should be retained at the system site for

future reference. Axcera provides two manuals for this purpose; one manual can be left

at the office while the other can be kept at the site.

Heed all Notes, Warnings, and Cautions – All of the notes, warnings, and cautions

listed in this safety section and throughout the manual must be followed.

Follow Operating Instructions – All of the operating and use instructions for the

system should be followed.

Cleaning – Unplug or otherwise disconnect all power from the equipment before cleaning.

Do not use liquid or aerosol cleaners. Use only a damp cloth for cleaning.

Ventilation – Openings in the cabinet and module front panels are provided for

ventilation. To ensure the reliable operation of the system, and to protect the unit from

overheating, these openings must not be blocked.

Servicing – Do not attempt to service this product yourself until becoming familiar with

the equipment. If in doubt, refer all servicing questions to qualified Axcera service

personnel.

Replacement Parts – When replacement parts are used, be sure that the parts have the

same functional and performance characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other hazards. Please contact the

Axcera Technical Service Department if you have any questions regarding service or

replacement parts.

Technical Manual, Rev. 0 2

Page 7

Innovator CHV400BTD ATSC Transmitter Introduction

Contact Information

The Axcera Field Service Department can be contacted by PHONE at 724-873-8100 or by

FAX at 724-873-8105.

Before calling Axcera, please be prepared to supply the Axcera technician with answers to

the following questions. This will save time and help ensure the most direct resolution to

the problem.

1. What are your Name and the Call Letters for the station?

2. What are the model number and type of system?

3. Is the system digital or analog?

4. How long has the system been on the air? (Approximately when was the system

installed?)

5. What are the symptoms being exhibited by the system? Include the current front

panel LCD readings and what the status LED is indicating on the front panel of

the tray. If possible, include the LCD readings before the problem occurred.

Return Material Procedure

To insure the efficient handling of equipment or components that have been returned for

repair, Axcera requests that each returned item be accompanied by a Return Material

Authorization Number (RMA#). The RMA# can be obtained from any Axcera Field

Service Engineer by contacting the Axcera Field Service Department at 724-873-8100 or

by Fax at 724-873-8105. This procedure applies to all items sent to the Field Service

Department regardless of whether the item was originally manufactured by Axcera.

When equipment is sent to the field on loan, the RMA# is included with the unit. The RMA#

is intended to be used when the unit is returned to Axcera. In addition, all shipping

material should be retained for the return of the unit to Axcera.

Replacement assemblies are also sent with the RMA# to allow for the proper routing of the

exchanged hardware. Failure to close out this type of RMA# will normally result in the

customer being invoiced for the value of the loaner item or the exchanged assembly.

When shipping an item to Axcera, please include the RMA# on the packing list and on the

shipping container. The packing slip should also include contact information and a brief

description of why the unit is being returned.

Please forward all RMA items to:

AXCERA, LLC

103 Freedom Drive

P.O. Box 525

Lawrence, PA 15055-0525 USA

For more information concerning this procedure, call the Axcera Field Service Department

at 724-873-8100.

Axcera can also be contacted through e-mail at info@axcera.com and on the Web at

www.axcera.com.

Technical Manual, Rev. 0 3

Page 8

Innovator CHV400BTD ATSC Transmitter Introduction

Limited One Year Warranty for Axcera Products

Axcera warrants each new product that it has manufactured and sold against defects in

material and workmanship under normal use and service for a period of one (1) year

from the date of shipment from Axcera's plant, when operated in accordance with

Axcera's operating instructions. This warranty shall not apply to tubes, fuses, batteries,

bulbs or LEDs.

Warranties are valid only when and if (a) Axcera receives prompt written notice of

breach within the period of warranty, (b) the defective product is properly packed and

returned by the buyer (transportation and insurance prepaid), and (c) Axcera

determines, in its sole judgment, that the product is defective and not subject to any

misuse, neglect, improper installation, negligence, accident, or (unless authorized in

writing by Axcera) repair or alteration. Axcera's exclusive liability for any personal

and/or property damage (including direct, consequential, or incidental) caused by the

breach of any or all warranties, shall be limited to the following: (a) repairing or

replacing (in Axcera's sole discretion) any defective parts free of charge (F.O.B. Axcera’s

plant) and/or (b) crediting (in Axcera's sole discretion) all or a portion of the purchase

price to the buyer.

Equipment furnished by Axcera, but not bearing its trade name, shall bear no warranties

other than the special hours-of-use or other warranties extended by or enforceable

against the manufacturer at the time of delivery to the buyer.

NO WARRANTIES, WHETHER STATUTORY, EXPRESSED, OR IMPLIED, AND NO

WARRANTIES OF MERCHANTABILITY, FITNESS FOR ANY PARTICULAR

PURPOSE, OR FREEDOM FROM INFRINGEMENT, OR THE LIKE, OTHER THAN AS

SPECIFIED IN PATENT LIABILITY ARTICLES, AND IN THIS ARTICLE, SHALL

APPLY TO THE EQUIPMENT FURNISHED HEREUNDER.

Technical Manual, Rev. 0 4

Page 9

Innovator CHV400BTD ATSC Transmitter Introduction

HIGH VOLTAGE

DO NOT ATTEMPT TO REPAIR OR TROUBLESHOOT THIS EQUIPMENT UNLESS

YOU ARE FAMILIAR WITH ITS OPERATION AND EXPERIENCED IN

SERVICING HIGH VOLTAGE EQUIPMENT. LETHAL VOLTAGES ARE PRESENT

WHEN POWER IS APPLIED TO THIS SYSTEM. IF POSSIBLE, TURN OFF

POWER BEFORE MAKING ADJUSTMENTS TO THE SYSTEM.

RADIO FREQUENCY RADIATION HAZARD

MICROWAVE, RF AMPLIFIERS AND TUBES GENERATE HAZARDOUS RF

RADIATION THAT CAN CAUSE SEVERE INJURY INCLUDING CATARACTS,

WHICH CAN RESULT IN BLINDNESS. SOME CARDIAC PACEMAKERS MAY BE

AFFECTED BY THE RF ENERGY EMITTED BY RF AND MICROWAVE

AMPLIFIERS. NEVER OPERATE THE TRANSMITTER SYSTEM WITHOUT A

PROPERLY MATCHED RF ENERGY ABSORBING LOAD OR THE ANTENNA

ATTACHED. KEEP PERSONNEL AWAY FROM OPEN WAVEGUIDES AND

ANTENNAS. NEVER LOOK INTO AN OPEN WAVEGUIDE OR ANTENNA.

MONITOR ALL PARTS OF THE RF SYSTEM FOR RADIATION LEAKAGE AT

REGULAR INTERVALS.

WARNING!!!

Technical Manual, Rev. 0 5

Page 10

Innovator CHV400BTD ATSC Transmitter Introduction

EMERGENCY FIRST AID INSTRUCTIONS

Personnel engaged in the installation, operation, or maintenance of this equipment are

urged to become familiar with the following rules both in theory and practice. It is the

duty of all operating personnel to be prepared to give adequate Emergency First Aid and

thereby prevent avoidable loss of life.

RESCUE BREATHING

1. Find out if the person is

breathing.

You must find out if the

person has stopped breathing.

If you think he is not

breathing, place him flat on

his back. Put your ear close to

his mouth and look at his

chest. If he is breathing you

can feel the air on your

cheek. You can see his chest

move up and down. If you do

not feel the air or see the

chest move, he is not

breathing.

2. If he is not breathing,

open the airway by tilting his

head backwards.

Lift up his neck with one

hand and push down on his

forehead with the other. This

opens the airway. Sometimes

doing this will let the person

breathe again by himself.

3. If he is still not breathing,

begin rescue breathing.

-Keep his head tilted

backward. Pinch nose shut.

-Put your mouth tightly over

his mouth.

-Blow into his mouth once

every five seconds

-DO NOT STOP rescue

breathing until help arrives.

LOOSEN CLOTHING - KEEP

WARM

Do this when the victim is

breathing by himself or help

is available. Keep him as

quiet as possible and from

becoming chilled. Otherwise

treat him for shock.

BURNS

SKIN REDDENED: Apply ice cold water to

burned area to prevent burn from going

deeper into skin tissue. Cover area with a

clean sheet or cloth to keep away air. Consult

a physician.

SKIN BLISTERED OR FLESH CHARRED:

Apply ice cold water to burned area to

prevent burn from going deeper into skin

tissue.

Cover area with clean sheet or cloth to keep

away air. Treat victim for shock and take to

hospital.

EXTENSIVE BURN - SKIN BROKEN: Cover

area with clean sheet or cloth to keep away

air. Treat victim for shock and take to

hospital.

Technical Manual, Rev. 0 6

Page 11

Innovator CHV400BTD ATSC Transmitter Introduction

dBm, dBw, dBmV, dBµµµµV, & VOLTAGE

EXPRESSED IN WATTS

50 Ohm System

WATTS PREFIX dBm dBw dBmV dBµV VOLTAGE

1,000,000,000,000 1 TERAWATT +150 +120

100,000,000,000 100 GIGAWATTS +140 +110

10,000,000,000 10 GIGAWATTS +130 +100

1,000,000,000 1 GIGAWATT +120 + 99

100,000,000 100 MEGAWATTS +110 + 80

10,000,000 10 MEGAWATTS +100 + 70

1,000,000 1 MEGAWATT + 90 + 60

100,000 100 KILOWATTS + 80 + 50

10,000 10 KILOWATTS + 70 + 40

1,000 1 KILOWATT + 60 + 30

100 1 HECTROWATT + 50 + 20

50 + 47 + 17

20 + 43 + 13

10 1 DECAWATT + 40 + 10

1 1 WATT + 30 0 + 77 +137 7.07V

0.1 1 DECIWATT + 20 - 10 + 67 +127 2.24V

0.01 1 CENTIWATT + 10 - 20 + 57 +117 0.707V

0.001 1 MILLIWATT 0 - 30 + 47 +107 224mV

0.0001 100 MICROWATTS - 10 - 40

0.00001 10 MICROWATTS - 20 - 50

0.000001 1 MICROWATT - 30 - 60

0.0000001 100 NANOWATTS - 40 - 70

0.00000001 10 NANOWATTS - 50 - 80

0.000000001 1 NANOWATT - 60 - 90

0.0000000001 100 PICOWATTS - 70 -100

0.00000000001 10 PICOWATTS - 80 -110

0.000000000001 1 PICOWATT - 90 -120

TEMPERATURE CONVERSION

°°°°F = 32 + [(9/5) °°°°C]

°°°°C = [(5/9) (°°°°F - 32)]

Technical Manual, Rev. 0 7

Page 12

Innovator CHV400BTD ATSC Transmitter Introduction

USEFUL CONVERSION FACTORS

TO CONVERT FROM TO MULTIPLY BY

mile (US statute) kilometer (km) 1.609347

inch (in) millimeter (mm) 25.4

inch (in) centimeter (cm) 2.54

inch (in) meter (m) 0.0254

foot (ft) meter (m) 0.3048

yard (yd) meter (m) 0.9144

mile per hour (mph) kilometer per hour(km/hr) 1.60934

mile per hour (mph) meter per second (m/s) 0.44704

pound (lb) kilogram (kg) 0.4535924

gallon (gal) liter 3.7854118

U.S. liquid

(One U.S. gallon equals 0.8327 Canadian gallon)

fluid ounce (fl oz) milliliters (ml) 29.57353

British Thermal Unit watt (W) 0.2930711

per hour (Btu/hr)

horsepower (hp) watt (W) 746

NOMENCLATURE OF FREQUENCY BANDS

FREQUENCY RANGE DESIGNATION

3 to 30 kHz VLF - Very Low Frequency

30 to 300 kHz LF - Low Frequency

300 to 3000 kHz MF - Medium Frequency

3 to 30 MHz HF - High Frequency

30 to 300 MHz VHF - Very High Frequency

300 to 3000 MHz UHF - Ultrahigh Frequency

3 to 30 GHz SHF - Superhigh Frequency

30 to 300 GHz EHF - Extremely High Frequency

LETTER DESIGNATIONS FOR UPPER FREQUENCY BANDS

LETTER FREQ. BAND

L 1000 - 2000 MHz

S 2000 - 4000 MHz

C 4000 - 8000 MHz

X 8000 - 12000 MHz

Ku 12 - 18 GHz

K 18 - 27 GHz

Ka 27 - 40 GHz

V 40 - 75 GHz

W 75 - 110 GHz

Technical Manual, Rev. 0 8

Page 13

Innovator CHV400BTD ATSC Transmitter Introduction

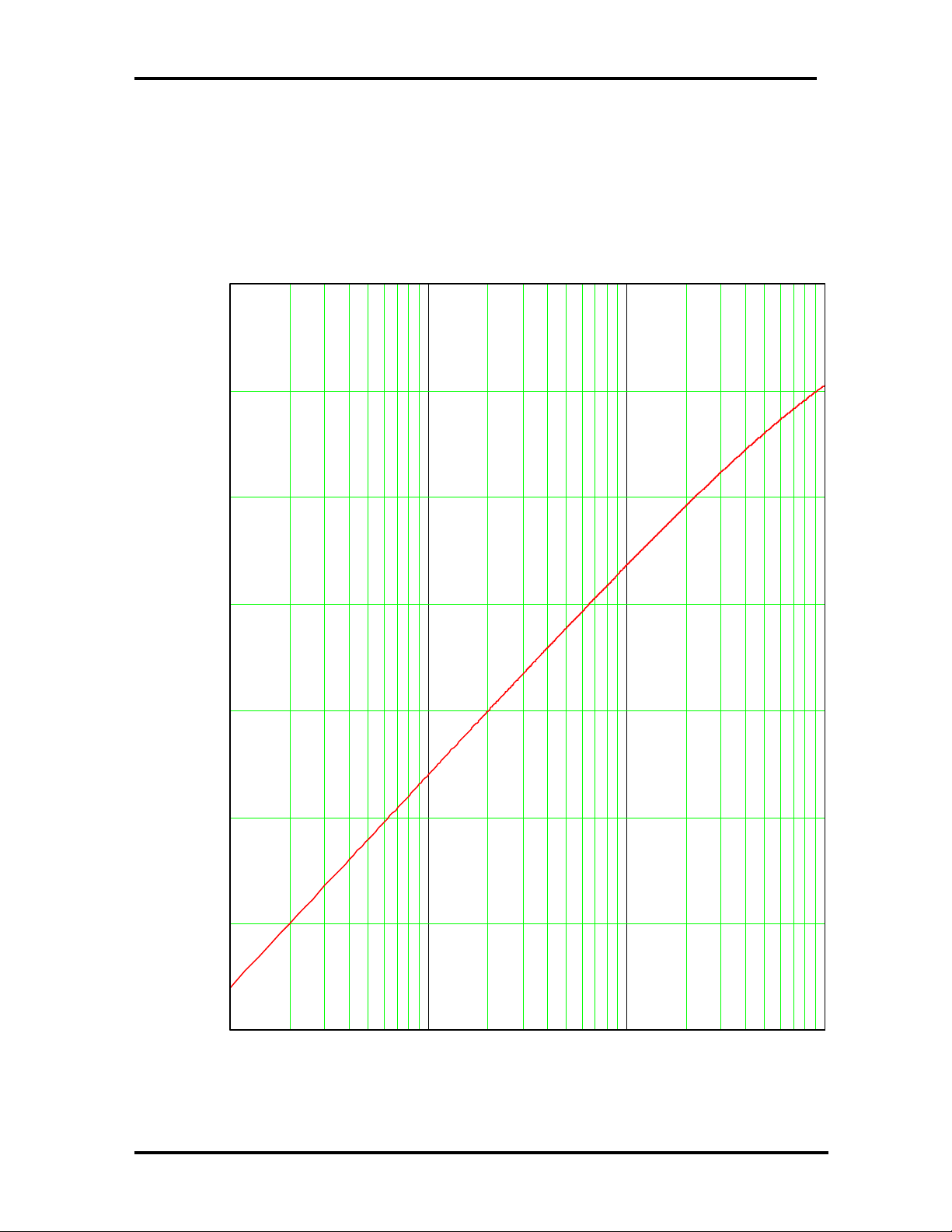

0

-10

-20

-30

-40

-50

-60

-70

S

dB

RETURN LOSS VS. VSWR

R

E

T

U

R

N

L

O

S

1.001 1.01 1.1 2.0

VSWR

Technical Manual, Rev. 0 9

Page 14

Innovator CHV400BTD ATSC Transmitter Introduction

ABBREVIATIONS/ACRONYMS

AC Alternating Current

AFC Automatic Frequency

Control

ALC Automatic Level Control

AM Amplitude Modulation

AGC Automatic Gain Control

ARD A-line, Regenerative

Translator, Digital

ATD A-line, Transmitter,

Digital

ATSC Advanced Television

Systems Committee (Digital)

AWG American Wire Gauge

BER Bit Error Rate

BRD B-line, Regenerative

Translator, Digital

BTD B-line, Transmitter,

Digital

BW Bandwidth

COFDM Coded Orthogonal Frequency

Division Multiplexing

modulation scheme

DC Direct Current

D/A Digital to Analog

DSP Digital Signal Processing

DTV Digital Television

dB Decibel

dBm Decibel referenced to

1 milliwatt

dBmV Decibel referenced to

1 millivolt

dBw Decibel referenced to 1 watt

FEC Forward Error Correction

FM Frequency Modulation

FPGA Field Programmable Gate

Array

Hz Hertz

ICPM Incidental Carrier Phase

Modulation

I/P Input

IF Intermediate Frequency

LED Light emitting diode

LSB Lower Sideband

LDMOS Lateral Diffused Metal Oxide

Semiconductor Field Effect

Transistor

MPEG Motion Pictures Expert

Group

NTSC National Television

Systems Committee (Analog)

O/P Output

PLL Phase Locked Loop

PCB Printed Circuit Board

QAM Quadrature Amplitude

Modulation

SMPTE Society of Motion Picture

and Television Engineers

VSB Vestigial Side Band

Technical Manual, Rev. 0 10

Page 15

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

Unpacking and Installation

Unpacking

Axcera certifies that upon leaving our facility all equipment was undamaged and in proper

working order. It is imperative that all packages be inspected immediately upon arrival to

verify that no damage occurred in transit to the site. Inspect all packages for exterior

damage and make note of any dents, broken seals, or other indications of improper

handling. Carefully open each package and inspect the contents for damage. Verify that all

materials are enclosed as listed on the packing slip. Report any shortages to Axcera. In the

event any in transit damage is discovered, report it to the carrier. Axcera is not responsible

for damage caused by the carrier. If the equipment is not going to be installed

immediately, return all items to their original packaging for safe storage. Save all packing

material for future use. If equipment is ever removed from the site, the original packaging

will ensure its safe transport.

The (Optional) UPS is

located behind this blank

panel

A1

Exciter/Driver

A2

Power Amplifier

A3

Power Amplifier

Figure 1: CHV1000BTD Front View Typical Racking Plan

Installation

The Innovator CXB Series transmitters are designed for simple installation. Expensive test

equipment is not required for installation and set up and to keep a system operational. An

information decal, with Voltage Range, Current Range, Manufacturer, Model and ratings is

attached to the rear panel of the stand alone tray or if mounted in a cabinet, to the top of

the frame above the door facing the rear of the cabinet. Prior to installing the product,

review the following items. Check that they been installed, tested and/or inspected.

Building Structure

Electrical Systems

Heating and Air Conditioning

Receive Antenna or Satellite Dish and input cabling

Optional ASI to S310 Converter, if needed

Transmit Antenna and output transmission line

Technical Manual, Rev. 0 11

Page 16

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

The Innovator CXB Series systems are 17” (43.2cm) wide standard rack mountable trays.

They are supplied with side mounted Tray Slides for ease of installation and removal. The

CHV200 system is 3 RU, 5.25” (13.3cm), high. The CHV400 and CHV500 systems are 9 RU,

15.75” (40cm) high, which is 3 RU, 5.25” (13.3cm) for the driver and 6 RU, 10.5” (26.7cm)

for the 400 watt Innovator CHVB Series amplifier tray. The CHV1000 systems are 15 RU,

26.25” (66.7cm) high, which is 3 RU, 5.25” (13.3cm) for the driver and 12 RU, 21” (53.4cm)

for the two Innovator CHVB Series amplifier trays. The CHV1500 systems are 15 RU, 26.25”

(66.7cm) high, which is 3 RU, 5.25” (13.3cm) for the driver and 12 RU, 21” (53.4cm) for the

two Innovator CHVB Series amplifier trays. The CHV2000 systems are 21 RU, 36.75”

(93.3cm) high, which is 3 RU, 5.25” (13.3cm) for the driver and 18 RU, 31.5” (80cm) for the

three Innovator CHVB Series amplifier trays. The CHV3000 systems are 27 RU, 47.25”

(120cm) high, which is 3 RU, 5.25” (13.3cm) for the driver and 24 RU, 42” (106.7cm) for the

four Innovator CHVB Series amplifier trays. In all the systems just described, if the Axciter

is also part of the system, another 3 RU, 5.25” (13.3cm) must be added to the rack space

for the Axciter tray.

Also needed for FCC compliance operation is an ATSC filter on the broadcast channel that

connects to the output of the CHV200 thru CHV3000 systems. Space must be provided for

the ATSC filter, and in some systems, for the circulator, splitter, combiner, reject load, and

low pass filter, whose dimensions will vary depending on manufacturer and channel. Refer

to the vendor supplied information included with your ATSC filter and low pass filter for

specific dimensions. Make sure that the space provided for the CX Series equipment is

sufficient and includes the circulator, splitters, combiners, reject load and external filters.

Check that any additional equipment, which is included in the system that extends above or

to the side of the mounting rack, has sufficient clearance space. Refer to the custom

racking plan for the system, if prepared, for detailed information.

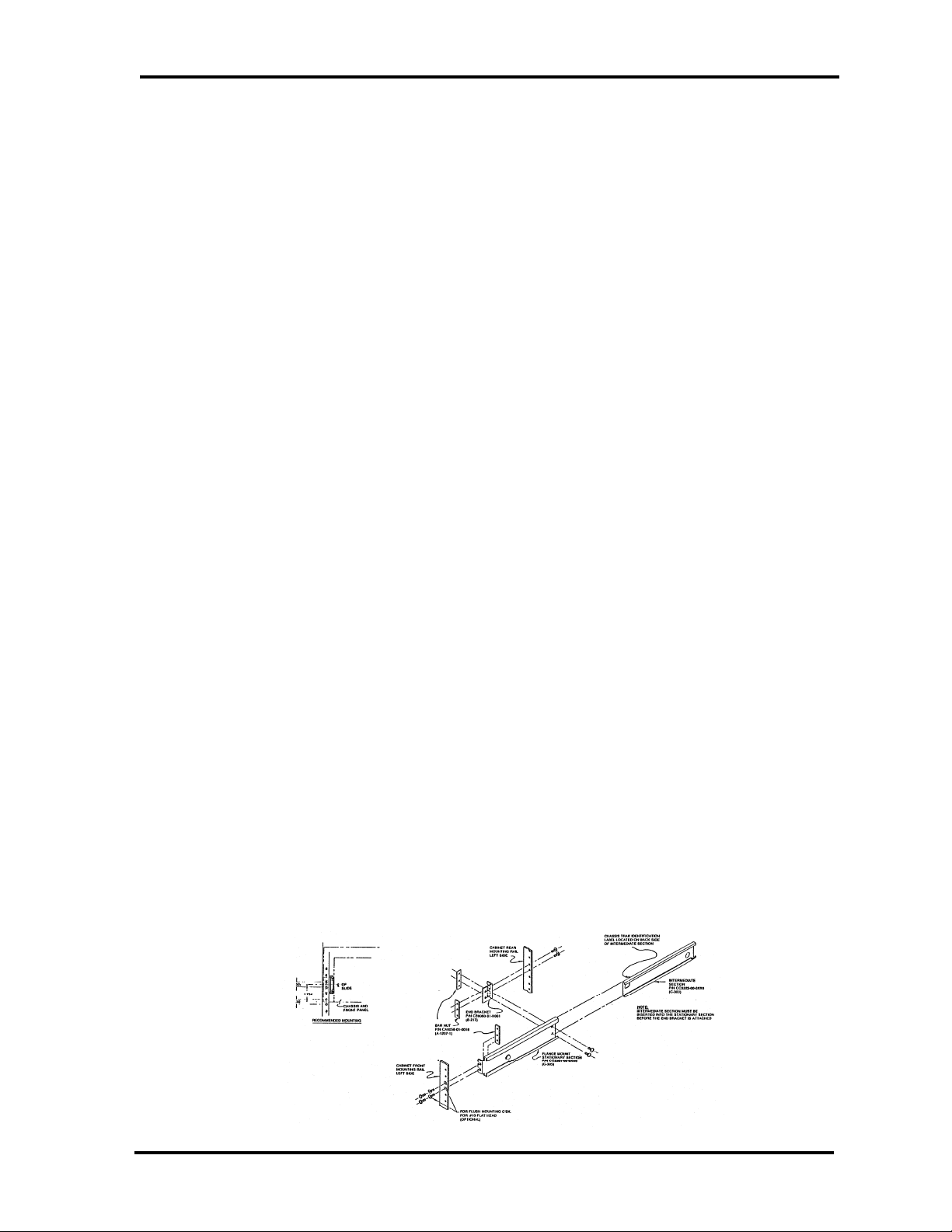

Tray Slide Installation

If the system is pre-mounted in a cabinet skip this section. Locate the tray slides included in

the installation material for your system. See Figure 2 and the manufacturers instructions,

included with the tray slides, for the cabinet mounting instructions of the tray slides. Install

the left tray slide into the left side of the cabinet (as viewed from the rear). Allow 3 RU, 5.25”

(13.3cm) of space between the trays for a CHV200B system. In high power systems, allow a

space of 3 RU, 5.25” (13.3cm) for the driver and 6 RU, 10.5” (26.7cm) for each of the

Innovator CHVB Series amplifier trays in higher power systems. Space must also be

provided for the splitter, combiner, ATSC filter and low pass filter, if present, whose

dimensions will vary depending on the manufacturer and the output channel. Secure the

left tray slide by connecting it to the front and rear mounting bars using No. 10 screws and

the bar nuts that have been provided. Install the tray slide on the right side of the cabinet

(as viewed from the rear) making sure that it is aligned with the tray slide on the left side.

Secure the slide by connecting it to the front and rear mounting bars using No. 10 screws and

the bar nuts that have been provided. Repeat this process for any other trays if purchased.

With both slides in place, slide the tray or trays into the cabinet.

Figure 2: Cabinet Slides

Technical Manual, Rev. 0 12

Page 17

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

AC Input Connections

The CHV200B single tray systems will operate with an input voltage of 185-253VAC. The

customer should provide a single point disconnect for the main AC input connection to the

transmitter. Check that the AC switch, located on the rear of the tray above the AC power

jack, is OFF. Connect the AC power cord supplied with the tray from J6 on the rear of the

tray to the AC source. If your system has the optional ASI to S310 Converter, check that it

is connected to the AC source.

If your system is a CHV400B or CHV500B, it also contains one amplifier tray. In CHV1000

and higher power systems, multiple amplifier trays are included. Each amplifier tray is

configured for 230 VAC operation only. Check that the ON/OFF circuit breaker or circuit

breakers in the amplifier, located on the rear panel on either side of the AC power jack, are

OFF. Connect the AC power cord supplied with the tray from J10 on the rear of the tray to

the 230 VAC source. Refer to Table 1 for the typical voltage and current requirements for

CHVB Systems.

If the system is mounted in a rack, an AC distribution box wired to a quad receptacle box is

used to connect the AC to the individual trays. The AC distribution box is mounted on the

upper right side of the rack accessed through the back of the rack. The main AC input for a

CHXBTD transmitter is, 195-235VAC, at least 10Amps, 50/60Hz. The customer should

provide a single point disconnect for the main AC input that connects to the transmitter. The

AC input lines connect inside the AC distribution box by first removing the two screws that

hold the cover plate to the front of the AC distribution box. Then connect the three wire main

AC input to the input lugs, L1 to L1, L2 to L2 and Ground to Ground. The power amplifier tray

and the quad receptacle box connect through AC power cords directly to the AC distribution

box. The AC power to the optional receiver tray and the exciter/driver tray are connected

through AC power cords that plug into the quad receptacle box.

If the system is mounted in a cabinet, an AC distribution panel is supplied to connect the AC

to the individual trays. The AC distribution panel is mounted facing the rear of the cabinet

and accessed through the back of the cabinet. The main AC input for a CHV1000BTD

transmitter is, 195-235VAC, at least 30Amps, 50/60Hz. The customer should provide a single

point disconnect for the main AC input that connects to the transmitter. The AC input lines

connect to the AC distribution panel by first removing the four #8 screws that hold the cover

plate to the front of the AC distribution panel. Then connect the three wire main AC input to

the input lugs located at the top left of the AC distribution panel, L1 to L1, L2 to L2 and

Ground to the Ground lug on the left. The AC distribution panel in a CHV1000BTD has three

circuit breakers that distribute the AC to the individual trays, which are the Exciter and the

two power amplifier trays. The circuit breakers, which are accessed through the rear door of

the cabinet, supply the AC though AC line cords, that connect to the AC input jacks mounted

on the rear panels of the trays. CB1 is a 30 Amp circuit breaker which supplies the AC to the

(A2), top, Power Amplifier A tray. CB2 is a 30 Amp circuit breaker which supplies the AC to

the (A3), bottom, Power Amplifier B tray. CB3 is a 10 Amp circuit breaker which supplies the

AC to the (A1) Exciter/Driver tray. A maximum of four 30 Amp circuit breakers for four

amplifier trays and two 10 Amp circuit breakers for two Exciter/Driver trays can be installed in

the AC Distribution Panel.

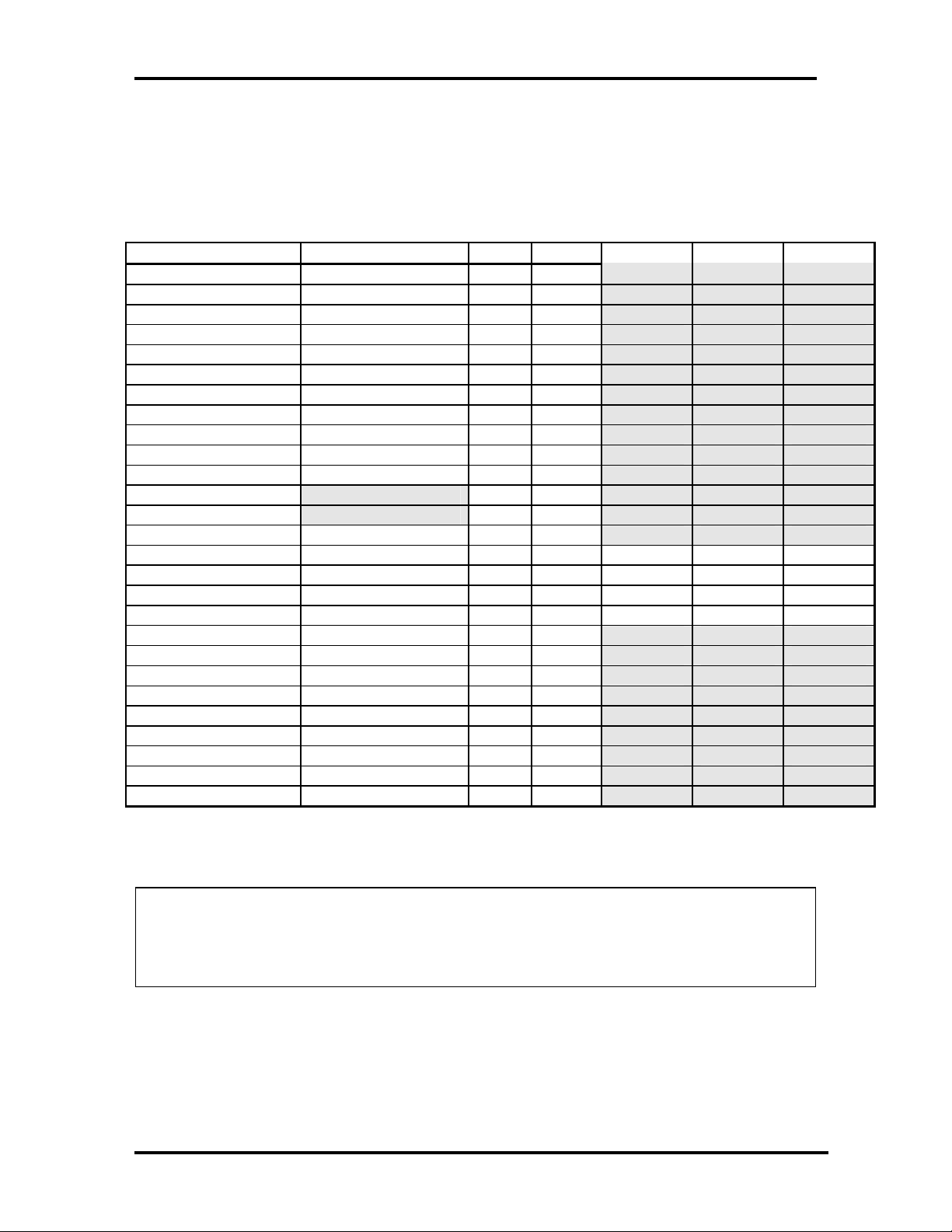

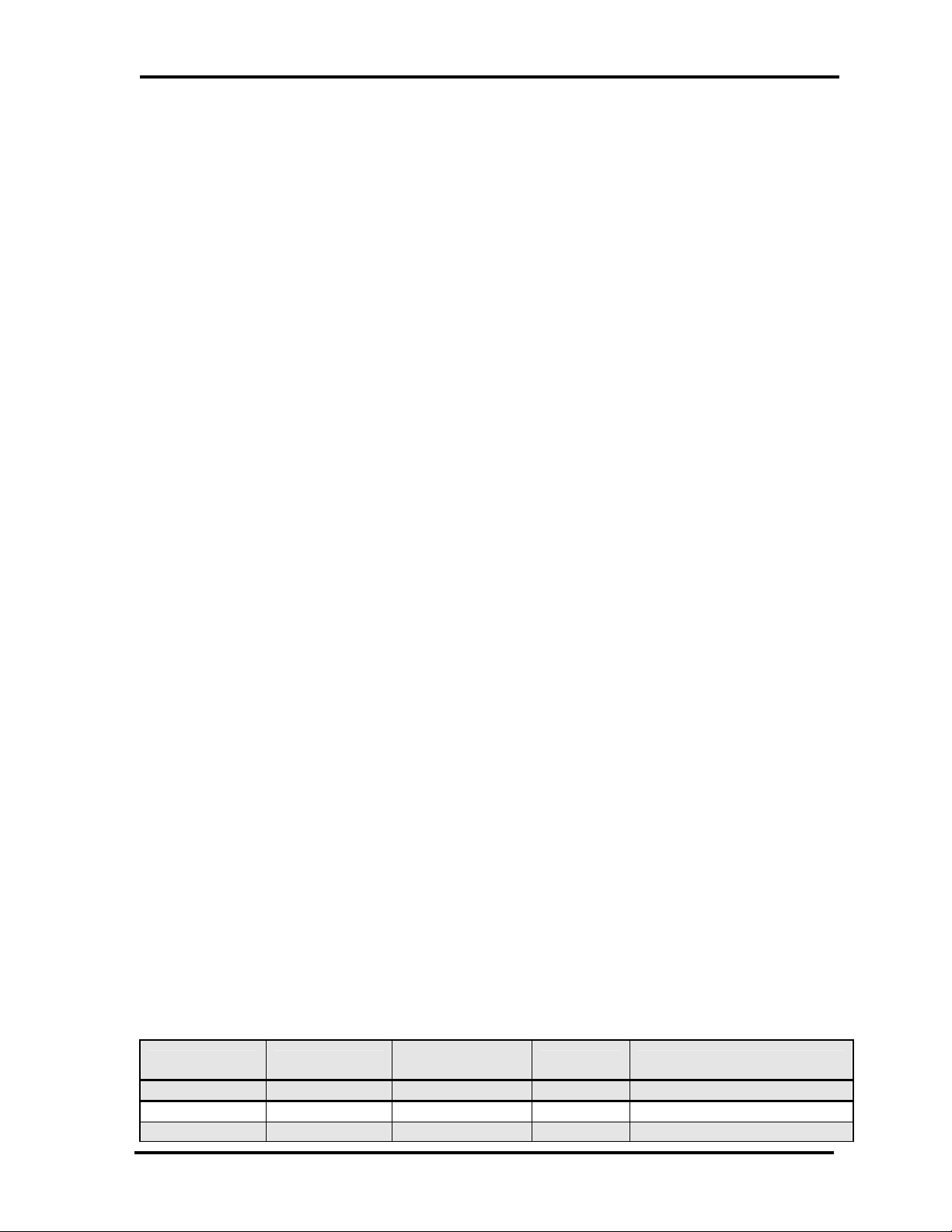

Table 1: CXB Series Digital Systems Typical AC Input and Current Requirements.

System O/P Power

Power

Consumption

Voltage Current

CHV200B 200 Watts 1000 Watts 230 VAC 4.4 Amps to the Cabinet

CHV400B 400 Watts 2200 Watts 230 VAC 9.6 Amps to the Cabinet

CHV500B 500 Watts 2700 Watts 230 VAC 11.8 Amps to the Cabinet

Technical Manual, Rev. 0 13

Page 18

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

J1

J11

J12

J10

J6

J9

J7

J4

J13

J5

CHV1000B 1000 Watts 5100 Watts 230 VAC 22.2 Amps to the Cabinet

CHV1500B 1500 Watts 7200 Watts 230 VAC 31.3 Amps to the Cabinet

CHV2000B 2000 Watts 10000 Watts 230 VAC 43.5 Amps to the Cabinet

CHV3000B 3000 Watts 14700 Watts 230 VAC 63.9 Amps to the Cabinet

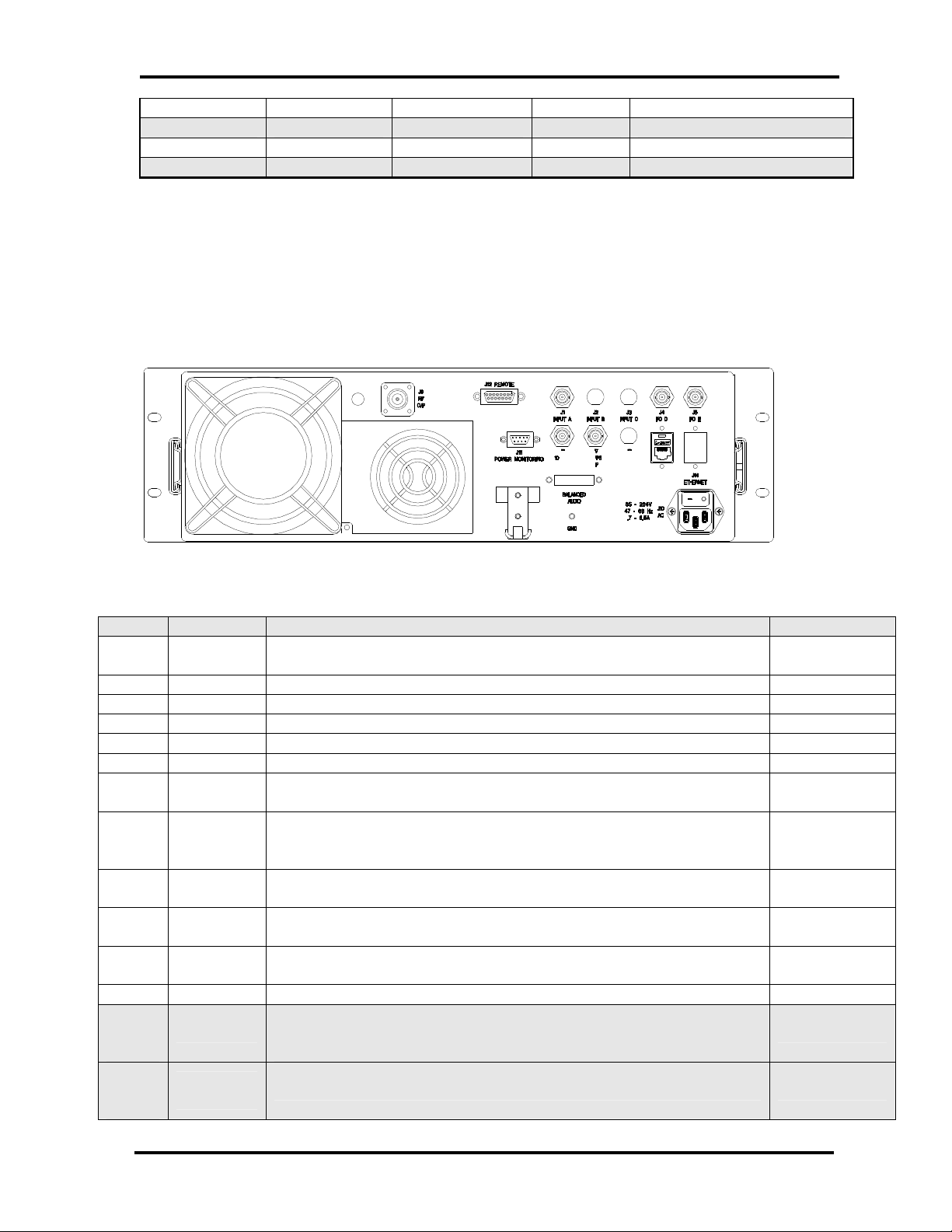

Input and Output Connections

The input and output connections to the system are made to the jacks mounted on the rear

panels of the CHV200B systems, the drivers for the CVH400B and high power systems, and

to the 500 Watt, 750 Watt and 1000 Watt amplifier trays. The CHV200B systems and the

drivers for the CVH400B and higher power systems accept an On Channel RF signal (BRD)

or a SMPTE-310 (BTD) input and output a digital RF ON Channel signal. Refer to Figure 3

and to Table 2 that follow for the locations and information on the jacks and connectors.

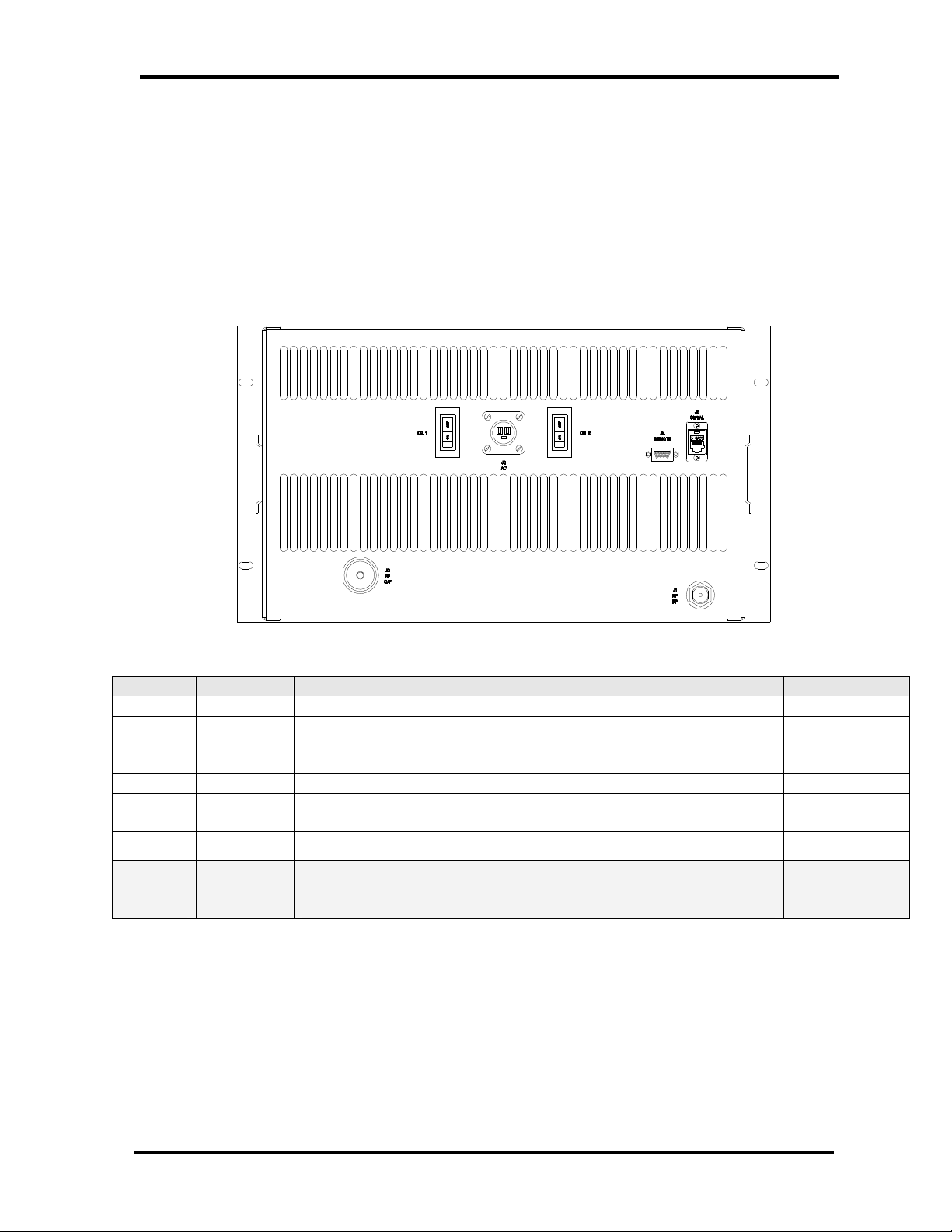

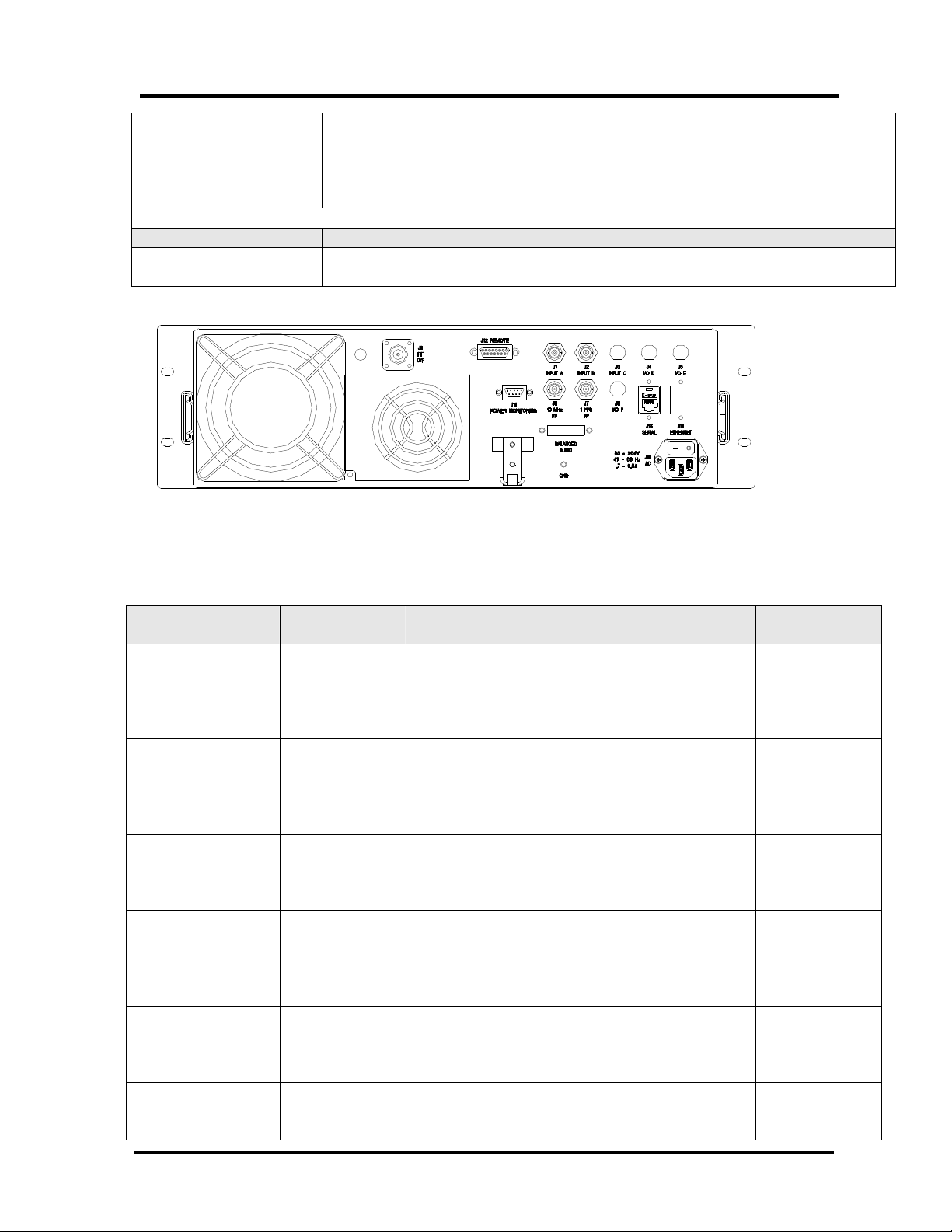

Figure 3: Rear View CHV200B and the driver for the CHV400B & higher power systems

Table 2: Connections for the CHV200B and the driver for the CHV400B & higher

power Systems

Port Type Function Impedance

J1 BNC

Input A: On Channel RF Input (BRD) –78 to –8 dBm or

SMPTE-310 Input (BTD)

50 Ohms

J4 BNC SMPTE-310 Output (BRD Only) Normally jumpered to J5 50 Ohms

J5 BNC SMPTE-310 Input (BRD Only) Normally jumpered to J4 50 Ohms

J6 BNC 10 MHz Input: Optional External 10 MHz Reference Input 50 Ohms

J7 BNC 1 PPS Input: Optional External 1 PPS Reference Input 50 Ohms

J9 N RF Output: On Channel RF Output 50 Ohms

J10 IEC

J11

J12

9 Pos

Male D

15 Pos

Female D

J13 RJ-45

J14 RJ-45

AC Input: AC input connection to 85-264VAC Source and

On/Off circuit breaker

Power Monitoring: Interface to System and external amplifier

trays, if present. Also provides an interlock for the Reject

Load (if used).

Remote: Remote control and status indications. Refer to

Table 7 on pages 21 & 22 for information on the connections.

Serial: Provides communication to System and to external

amplifier trays, if present.

Ethernet: Optional Ethernet connection. May not be present

in your tray.

N/A

N/A

N/A

N/A

N/A

J15

Front

Panel

J16

Front

Panel

BNC

9 Pos

Female D

RF Sample: Output Sample from Output Detector Board.

In a CHV200B the sample level at J15 is approximately 60dB

50 Ohms

down from the output power level of the tray.

Serial: Used to load equalizer taps into the modulator. N/A

Technical Manual, Rev. 0 14

Page 19

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

J1

J3

J4

J2

CB1

CB2

NOTES: If your CHVBTD system contains an Optional ASI to S310 Converter, connect the

ASI output of the STL to the ASI in jack on the rear panel of the converter.

Connect the SMPTE-310 Output from the SMPTE 310 Out jack on the rear panel of

the converter module to the input jack J1 on the rear panel of the CHV200B and

the driver tray for the CHV400B and higher power systems.

If your CHVBTD system contains an Optional KTECH receiver, connect the RF to the

input jack J1 on the rear panel of the receiver. Connect the SMPTE-310 Output

from the SMPTE 310 Out jack J2 on the rear panel of the receiver to the input jack

J1 on the rear panel of the CHV200B and the driver tray for the CHV400B and

higher power systems.

J5

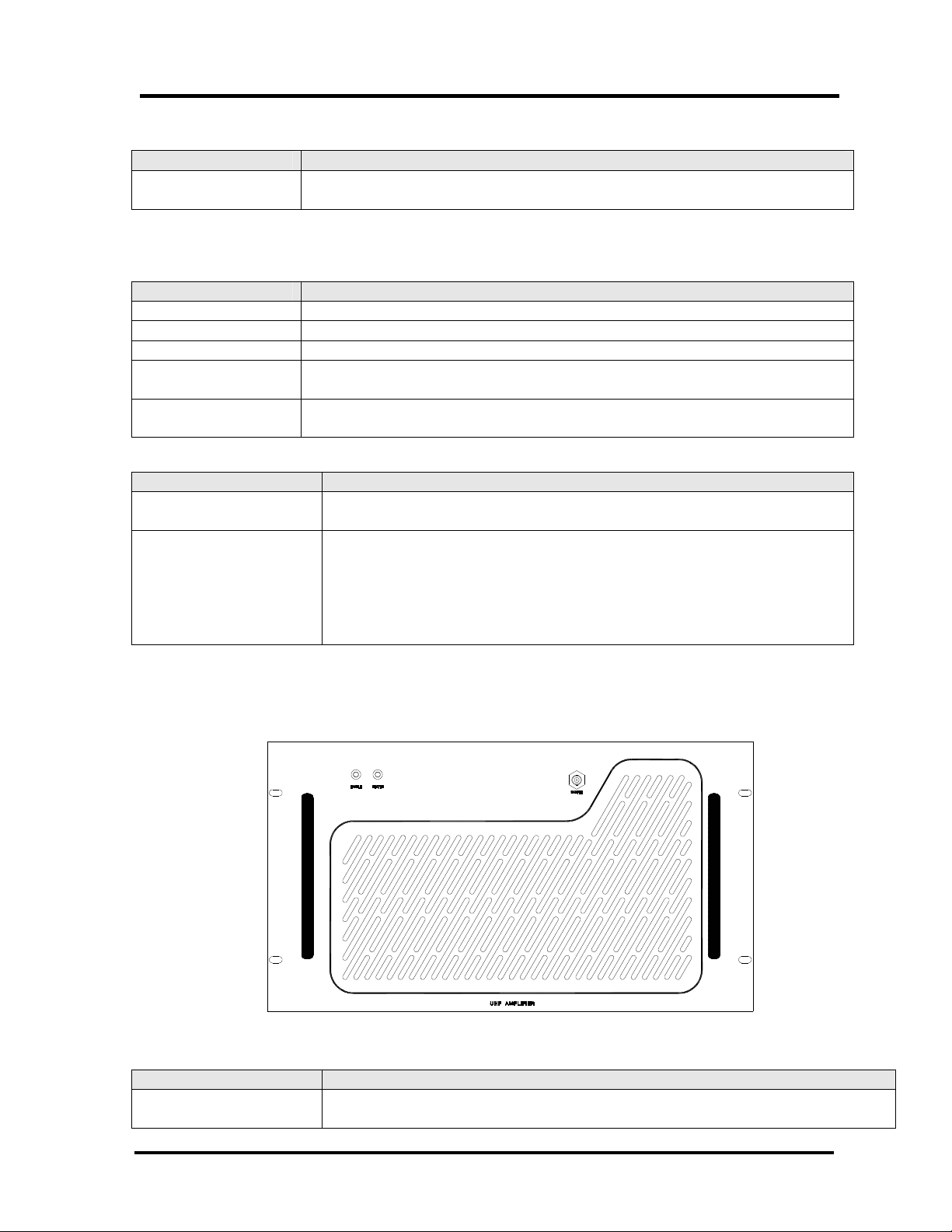

Figure 4: Rear View CHV500, CHV750 and CHV1000 Amplifier Tray

Table 3: Connections for the CHV500, CHV750 and CHV1000 Amplifier Tray

Port Type Function Impedance

J1 N RF Input: On Channel RF from CHVB driver tray 50Ω

7/16”

J2

(1.1cm)

RF Output: On Channel RF Output 50Ω

Din

J3 IEC AC Input: AC input connection to 230VAC Source N/A

J4 9 Pos D

Remote: Amplifier Control Interface

(Connects to J11 on the exciter/driver tray)

N/A

J5 RJ-45 Serial data N/A

J8

Front

Panel

BNC

RF Sample: Output Sample from Combiner thru Control

Board. In a CHV500B, the sample level is approximately

70dB down from the output power level of the tray.

50Ω

Refer to Figures 3 and 4, and Tables 2 and 3 for detailed information on the jacks and

connectors. Connect the On Channel RF Input (BRD), –78 to –8 dBm, or the SMPTE-310

Input (BTD), to the 50Ω BNC input jack J1, located on the rear panel of the CHV200B and

the driver tray for CHV400B and higher power systems. The input to J1 can be from the

ASI to S310 converter, the Axciter Tray or any other source of a SMPTE-310 signal.

If used, connect the external 10 MHz reference input to the 50Ω BNC 10 MHz input jack J6

located on the rear panel of the CHV200B and the driver tray for CHV400B and higher

power systems. If used, connect the external 1 PPS reference input to the 50Ω BNC 1 PPS

input jack J7 located on the rear panel of the CHV200B and the driver tray for CHV400B and

higher power systems.

Technical Manual, Rev. 0 15

Page 20

Innovator CHV400BTD ATSC Transmitter Unpacking and Installation

In Translator (BRD) systems there is a SMPTE-310 loop-thru from the output of the

Demodulator Board at J4, mounted on the rear panel of the transmitter or driver tray, to

the input to the Modulator Board at J5, mounted on the rear panel of the transmitter or

driver tray. There is a jumper installed from J4 to J5. To feed SMPTE-310 directly to the

Modulator Board, remove the jumper and insert SMPTE-310 into J5. This is only used in

Translator (BRD) systems not Transmitter (BTD) systems.

The digital RF ON Channel output of the CHV200B and the driver tray for CHV400B and

higher power systems is at J9 the 50Ω “N” connector RF output jack located on the rear

panel. In the CHV200B system the output of the tray at J9 connects to the low pass, digital

mask filter and then to the antenna for your system. In CHV400B and higher power

systems the output of the driver tray at J9 is connected to J1 the 50 Ohm “N” connector RF

input jack located on the rear panel of the 500 Watt, 750 Watt, 1 kW amplifier tray or to a

splitter in multiple amplifier systems. In CHV200B systems, check that the system power

metering interface cable is connected from J11 the 9 position “D” connector located on the

rear panel of the driver tray to J4 the 9 position “D” connector located on the rear panel of

the amplifier tray. This cable provides the control, status and operating parameters of the

amplifier tray to the driver tray. In CHV1000B or higher power systems, the output of the

driver tray is split and connected to J1 the “N” type connector RF input jack on the amplifier

trays. Check that the system power metering interface cable is connected from J11 the 9

position “D” connector located on the rear panel of the driver tray to J9 the 9 position “D”

connector located on the System Metering Board. Also check that the serial connection is

cabled from the RJ-45 connector J13 on the driver tray to the RJ-45 connector J1 on the

system metering board. The system metering board provides serial RJ-45 connections at J2

and J5 that are cabled to the RJ-45 serial port J5 on the rear panel of the amplifier trays.

These cables provide the control, status and operating parameters of the amplifier trays to

the driver tray through the System Metering Board.

The digital RF ON Channel output of the amplifier tray is at J2 the 50Ω “7/16” (1.1cm) Din

connector RF output jack located on the rear panel that connects directly to the digital mask

filter, the low pass filter and then to the antenna for your system in single amplifier

systems. In multiple amplifier tray systems the outputs of the trays connect to a combiner

and then the digital mask filter, the low pass mask filter, the output coupler and finally to

the antenna for your system. The output coupler provides a forward and a reflected power

sample that are cabled to the System Metering Board at J8 reflected and J3 forward. Also

connected to the system metering board at J10-6 & 9, is the output of the overtemperature

switch mounted to the reject load that is used as the reject interlock by the system. The

samples and interlock are fed through J9 on the system metering board to J11 on the driver

tray.

This completes the connections of the system.

Technical Manual, Rev. 0 16

Page 21

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Initial On Site Turn On Procedure

After the Innovator CHVB Series tray or trays are installed and all input, output and AC

connections are made, the system is ready for the initial on site turn on. Check that the

output of the CHV200B tray is connected to an appropriate rated load or to the digital mask

filter, low pass filter and the antenna for your system. If your system is a CHV400B and

higher power system, check that the output of the amplifier tray or the combiner assembly is

connected to an appropriate rated load or to the digital mask filter, low pass filter and the

antenna for your system. Check that the main AC power to the System is ON. If your system

contains an optional ASI to S310 converter module or KTECH receiver tray, check that they

have AC connected to them and that they are turned ON. NOTE: If your system is mounted in

a cabinet and contains an Optional UPS, push On the ON/OFF button, located on the left side of

the top panel of the UPS. The UPS is mounted behind the removable blank panel, located

immediately above the exciter/driver tray, which is held in place by four #10 Phillips head

screws.

If you have a CHV200B system, push ON the switch located on the rear panel of the tray

above the AC power jack. The large fan mounted on the rear panel of the tray should

operate. If your system is a CHV400B and higher power system, switch ON the ON/OFF

circuit breaker(s), located on the rear panel of the amplifier tray(s), mounted on each side of

the AC input power jack. The two fans mounted in the amplifier tray should operate.

The Operate/Standby LED and Status LEDs on the CHV200B should be Green indicating the

system is in Operate and performing normally. The Operate/Standby LED showing Amber

indicates the System is in Standby. The Status LED showing a blinking Red LED indicates an

Event (Fault) is occurring now. The Status LED showing Amber indicates that an Event (Fault)

occurred since the last time the Event (Fault) indications were reset.

If your system is a CHV400B and higher power, the Enable LED and Status LEDs on the 500,

750 or 1000 Watt Amplifier Tray should be Green indicating the system is in Operate and

performing normally. The Enable LED showing Amber indicates the System is in Standby. The

Status LED should be Green indicating no Events (Faults) in the system. If the

Operate/Standby LED shows Amber it indicates that the System is in Standby. If the Status

LED is blinking Red it indicates an Event (Fault) is occurring now. If the Status LED shows

Amber it indicates that an Event (Fault) occurred since that last time the Event (Fault)

indications were reset. The output power is factory set according to customer request and

does not need adjusted. If a problem occurs, call Axcera field support at 724-873-8100 for

information on modifying the power level of the system.

NOTE: The RF System Interlock is provided on J11, a D connector, located on the rear panel

of the CHV200B tray. The RF System Interlock at J11-5 provides the customer with a

means of connecting the system to protection circuits, for the loads, thermal switches,

combiners, or the antenna, in the output of your system, that will place the system in

Standby if the protection circuit opens. The Reject Load Interlock at J11-6 provides

the customer with a means of connecting the system to protection circuits, for the

reject load in multiple amplifier systems, which will place the system in Standby if the

protection circuit opens. If the interlocks are not used in your system, a plug with a

jumper from J11-5 to J11-9, ground, for RF system Interlock and another plug with a

jumper from J11-6 to J11-9, for Reject Load Interlock, need to be connected. These

jumpers provide the RF System and Reject Load Interlocks, which allow the system to

go to operate. Without the jumpers, the system will remain in Standby.

Technical Manual, Rev. 0 17

Page 22

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Typical System Operating Parameters

Typical Operating Parameters for a CHV20

Parameter Typical Reading

Forward Power 100%

Reflected Power <5%

Power Supply Voltage 42 Volts

Heatsink Temperature 20º to 30º F above ambient temperature

Pin Attenuator Voltage 1 Volt to 5 Volts

Typical Operating Parameters for a CHV20 used as driver

Parameter Typical Reading

Forward Power 20-70% (Depending on output power level of system)

Reflected Power <5%

Power Supply Voltage 42 Volts

Heatsink Temperature 20º to 30º F above ambient temperature

Pin Attenuator Voltage 1 Volt to 5 Volts

Typical Operating Parameters for a CHV200

Parameter Typical Reading

Forward Power 100%

Reflected Power <5%

Power Supply Voltage 42 Volts

Heatsink Temperature 20º to 30º F above ambient temperature

Pin Attenuator Voltage 1 Volt to 5 Volts

Typical Operating Parameters for a CHV200 used as a Driver

Parameter Typical Reading

Forward Power 20-70% (Depending on output power level of system)

Reflected Power <3%

Power Supply Voltage 42 Volts

Heatsink Temperature 20º to 30º F above ambient temperature

Pin Attenuator Voltage 1 Volt to 5 Volts

Typical Operating Parameters for the external Amplifier Tray(s)

in a CHV400 or higher power System

Parameter Typical Reading

Forward Power 100%

Reflected Power <5%

Power Supply Voltage 42 Volts

Heatsink Temperature 20º to 30º F above ambient temperature

Technical Manual, Rev. 0 18

Page 23

Innovator CHV400BTD ATSC Transmitter Initial On Site

Operate/Standby

Status LED

Enter Button

Operate/Standby

Up/Down Buttons

J11 Serial Port

J15 RF Sample

Turn On Procedure

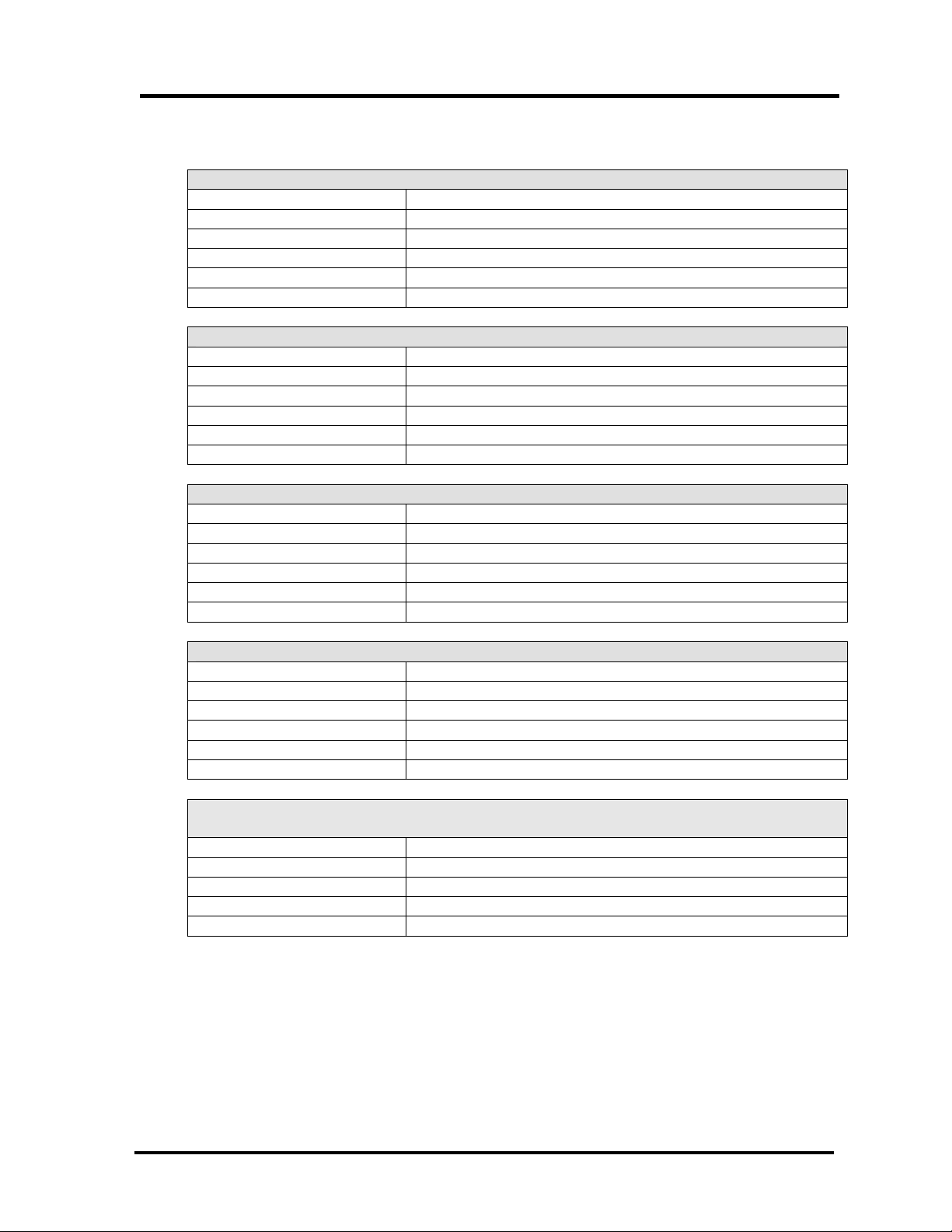

Typical Problems, Indications and Causes in CHV200B Tray

Problem Indication Cause

AC power cord not connected.

No power to

tray

Operate/Standby and Enable LED

indicators and LCD display are Off

Main AC to System missing.

On/Off switch on back of tray

Off. 10 Amp fuse (F1) blown*.

Power supply (A9) not operating

On the 8VSB Modulator S310

MPEG Input Selection Set Up

Screen, the Input is currently set

incorrectly to “from Internal

Source”. Set to “from External

No Output

Signal

Front Panel Status LED is Amber

and blinking with no events, faults

indicated.

Source”.

Loss of Input

Signal

Loss of Input on Modulator Menu Loss of input signal.

Any Event, Fault, which Mutes

Loss of

Output

Signal

Amber Operate/Standby LED.

Blinking Red Status LED.

the output. Including Input

Fault, VSWR Cutback, Overdrive,

Overtemperature and

Overvoltage.

Loss of 42V

Loss of ±12V

or 5V

Power Supply Fault on Power

Supply Menu

Operate/Standby and Enable LED

indicators and LCD display are Off

Power supply (A10) not

operating

Power supply (A9) not operating

NOTE: *A spare 10 Amp fuse is provided in the blank fuse holder under the active

fuse.

If there is an Event (Fault) occurring in the system, the Status LED on the front panel will

flash RED as long as the Event (Fault) is present. In addition, the menu will jump to the

current Event (Fault) on the display and blink the Event (Fault) continuously, if the Jump to

Fault screen is set to Yes. When the Event (Fault) is corrected, the tray will turn the Status

LED to AMBER to indicate that there was a Fault and the menu will still display the Fault but it

will not flash. This gives the user the knowledge that there was an Event (Fault) and what

type of Event (Fault) occurred. Before clearing the fault, check if there were other Events

(Faults) by stepping through the menus. To reset the indication of previous Events (Faults)

the user must push the Enter button with the Event (Fault) Reset Screen displayed. This will

reset all previous Events (Faults).

LCD Display and Front Panel LED Indicators

Left/Right Buttons LCD Display

LED

Buttons

Figure 5: Front View CHV200B and the driver for the CHV400B & higher power systems

Technical Manual, Rev. 0 19

Page 24

Innovator CHV400BTD ATSC Transmitter Initial On Site

Enable LED

Turn On Procedure

Table 4: Innovator CXB Series LCD Display

DISPLAY FUNCTION

LCD

Provides a two line readout of the input received channel, internal

functions, status, and Fault (Event) conditions.

The front panel has seven pushbuttons, two for the control of the system, Operate & Standby,

and five for control of the displayed menus, Left, Right, Up, Down & Enter.

Table 5: Innovator CXB Series Control Pushbuttons

PUSHBUTTON FUNCTION

OPR When pushed switches the system to Operate.

STBY When pushed switches the system to Standby.

ENTER Selects the changes made in the menus and submenus.

Up & Down Arrow

Left & Right Arrow

Scrolls through the main menus and after entering the Main Menu

Steps through submenus of the main menu when they are present.

Used to exit from main menus and submenus of the main menu

when they are present.

Table 6: Innovator CXB Series Operate/Standby and Status Indicators

LED FUNCTION

OPERATE/STANDBY

(Green/Amber)

A Green LED indicates that the system is in Operate. An Amber

LED indicates that the system is in Standby.

A Green LED indicates that the system is functioning normally. A

STATUS

(Green/Red/

Amber)

flashing Red LED indicates an Event (Fault) is occurring at this

time. An Amber LED indicates an Event (Fault) occurred since

the last time the Event (Fault) indications were reset but the

system is now operating normally. Amber LED Blinking, with no

Events (Faults) indicates the MPEG input is set to Internal Source.

NOTE: J15 is a Front Panel BNC RF Sample Jack 50Ω that provides an RF output sample from

the output detector board in the tray. In a CHV200B, the sample level at J15 is

approximately 60dB down from the output power level of the tray.

Status LED Sample

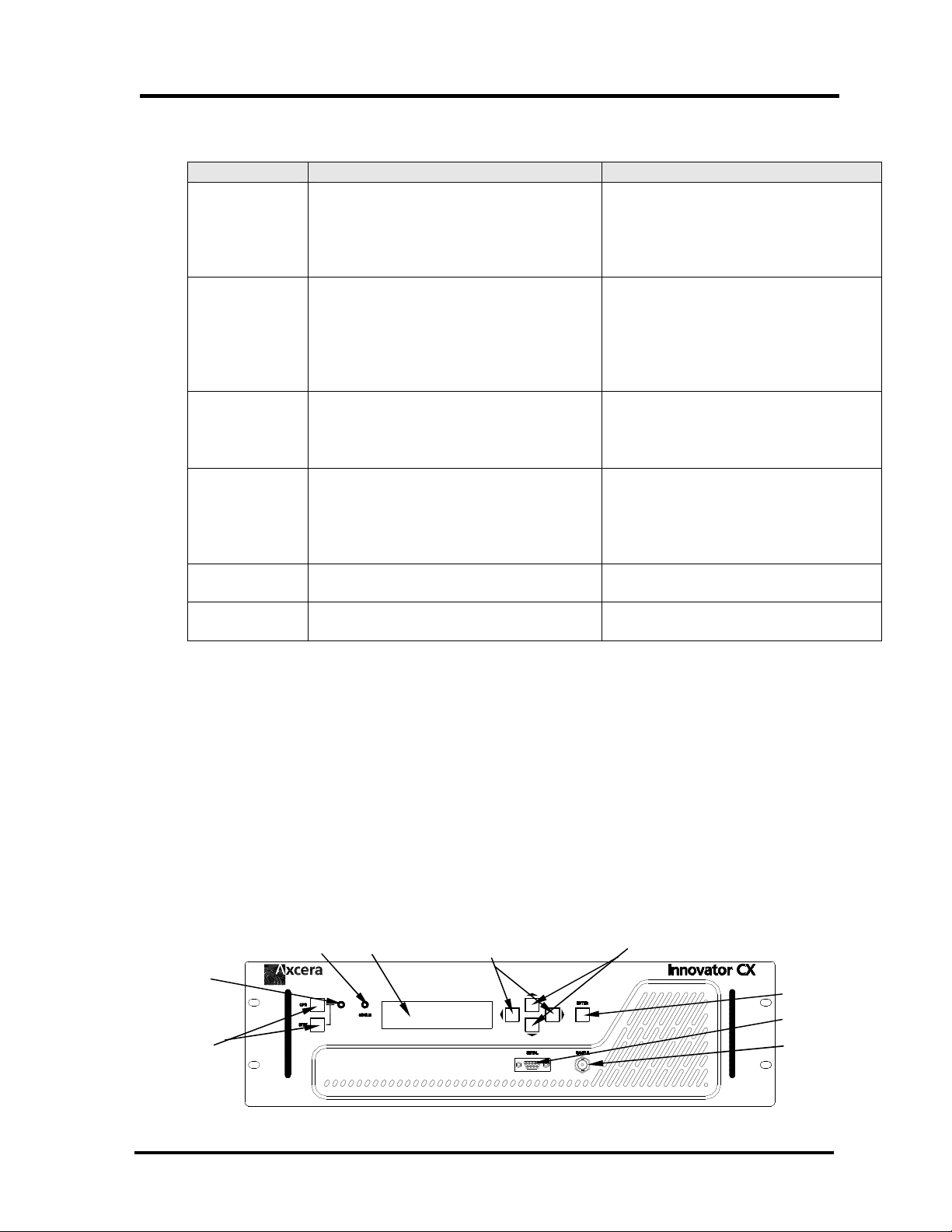

Figure 6: Front View Amplifier Tray in CHV400B and higher power systems

Table 7: Innovator CHVB Amplifier Tray LED Indicators and Sample Jack

LED FUNCTION

ENABLE

(Green/Amber)

A Green LED indicates that the system is in Operate and operating

normally. An Amber LED indicates that the system is in Standby.

Technical Manual, Rev. 0 20

Page 25

Innovator CHV400BTD ATSC Transmitter Initial On Site

J12

Turn On Procedure

A Green LED indicates that the system is functioning normally with no

STATUS

(Green/Red/

Amber)

faults. A flashing Red LED indicates an Event (Fault) is occurring at

this time. An Amber LED indicates an Event (Fault) occurred since the

last time the Event (Fault) indications were reset but the system is now

operating normally.

JACK FUNCTION

SAMPLE

J6

Typical sample value is 65dB down from the output power level of the

tray. (500 Watts output power = -8dBm sample level)

System Remote Connections

Figure 7: Rear View CHV200B and the driver for the CHV400B & higher power systems

The remote connections for the Innovator CHXB Series system are made to the Remote 15

Pos Female “D” connector Jack J12 located on the rear panel of the tray.

Table 7: Remote Connections to J12, 15 Pos Female D Connector, for CXB Series system

Remote Signal

Name

Pin

Designation

Signal Type Description

Discrete Open Collector Input - A pull

down to ground on this line indicates that

System Operate J12-1

the System is to be placed into the

Command

operate mode.

(Low = Activate : Floating = No Change)

Discrete Open Collector Input - A pull

down to ground on this line indicates that

System Standby J12-2

the System is to be placed into the

Command

standby mode.

(Low = Activate : Floating = No Change)

Discrete Open Collector Input - A pull

Power Raise J12-3

down to ground on this line indicates that

the Power of the System is to be Raised.

Command

(Low = Activate : Floating = No Change)

Discrete Open Collector Input - A pull

down to ground on this line indicates that

Power Lower J12-4

the Power of the System is to be

Command

Lowered.

(Low = Activate : Floating = No Change)

Discrete Open Collector Input - A pull

System Interlock J12-5

down to ground on this line indicates that

the Interlock is present.

(Low = OK : Floating = Fault)

Set to

Modulation Type

J12-6

Discrete Open Collector Input. - Sets the

Modulation type of the system.

(Low = Analog : Floating = Digital)

Command

Technical Manual, Rev. 0 21

Page 26

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Remote Signal

Name

Pin

Designation

Signal Type Description

Discrete Open Collector Input. – Selects

one of two possible Channel Setups of the

Set Channel

(Set Up 1 or Set

Up 2)

J12-7

system.

(Low = Set Up 2, CH 2 : Floating = Set

Up 1, CH 1) NOTE: The Set Up 1 & Set

Command

Up 2 settings are displayed and changed

in the Upconverter Set Up Menus.

Ground J12-8 Ground

Analog Output - 0 to 4.0 V. - This is a

System Forward

Power Level

J12-9

buffered loop through of the calibrated

“System Forward Power”. Indicates the

System Forward power.

Metering

Scale factor is 100 % = 2.0V.

Analog Output - 0 to 4.0 V. - This is a

System Aural

Power Level

J12-10

buffered loop through of the calibrated

“System Aural Power”. Indicates the

System Aural power. Scale factor is

Metering

100 % = 2.0V. (Not used in Digital)

Analog Output - 0 to 4.0 V. - This is a

System Reflected

Power Level

J12-11

buffered loop through of the calibrated

“System Reflected Power”. Indicates the

System Reflected power.

Metering

Scale factor is 25 % = 2.0V.

Report Input

Status

J12-12

Discrete Open Collector Output. Indicates if input to system is Normal or

Not. (Low = OK : Floating = Fault)

Status

Discrete Open Collector Output. -

Report Fault

Status

J12-13

Indicates if system is Operating Normally

or has a Fault.

Status

(Low = OK : Floating = Fault)

Discrete Open Collector Output. –

Report Operate

Status

J12-14

Indicates whether system is in Operate or

Standby.

Status

(Low = Operate : Floating = Standby)

Ground J12-15 Ground

LCD Front Panel Screens

A LCD display, located on the front of the Innovator CHXB Series systems, displays, on

screens, the current operating status of the system. When the tray is powered On, the LCD

will initially display two splash screens. The first splash screen will be displayed for a few

seconds, then the second splash screen will be displayed for a few seconds and finally the RF

Power Display default screen will be displayed. See examples of the screens below. The RF

Power Display default screen will be the screen displayed if no buttons are pushed to access

other screens. While viewing the RF Power Display default screen, pushing the Left and Right

arrow buttons together will also access the splash screens.

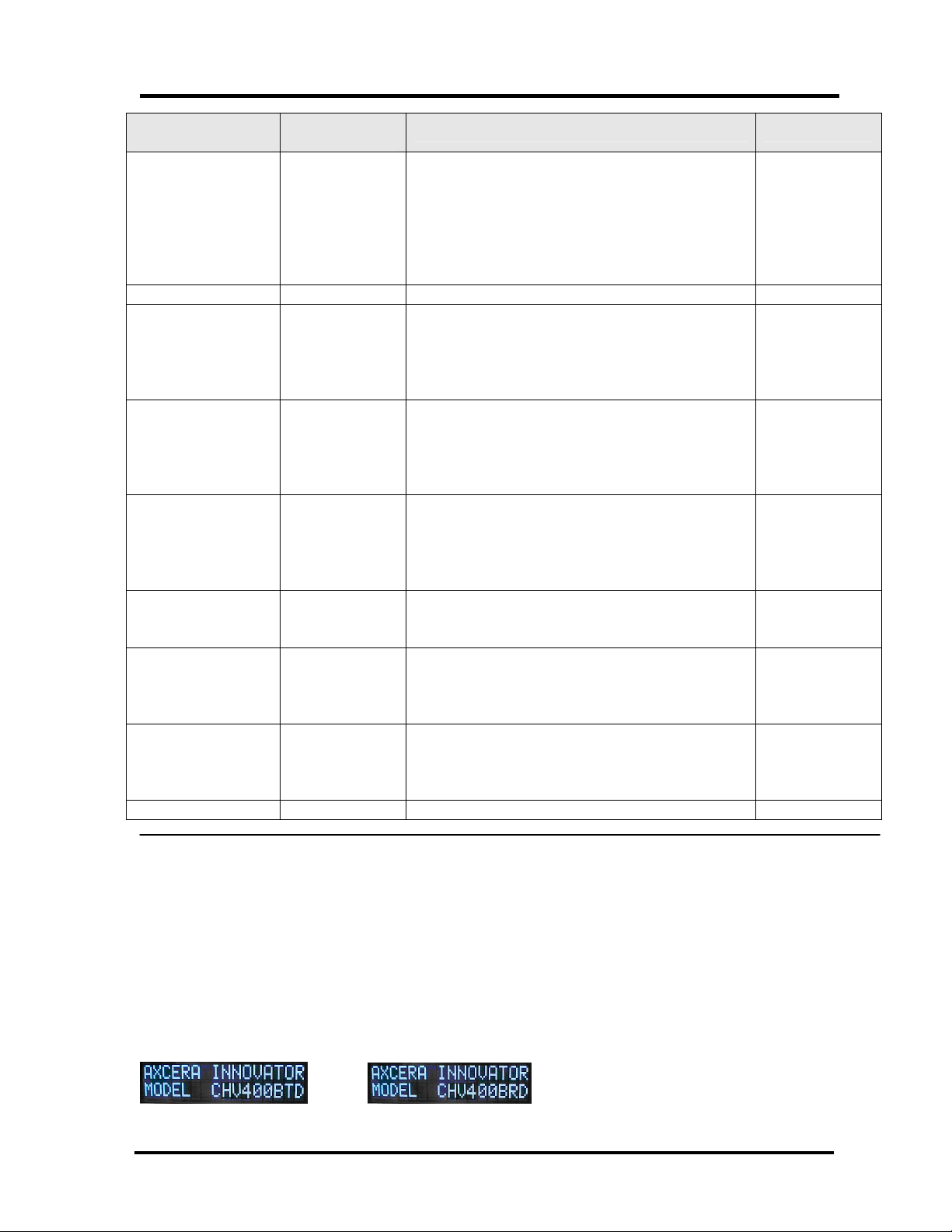

Splash Screen Number 1

The first splash screen displayed indicates the manufacturer, type and the model number.

Technical Manual, Rev. 0 22

Page 27

Innovator CHV400BTD ATSC Transmitter Initial On Site

Left/Right Buttons

Enter Button

Up/Down Buttons

Turn On Procedure

Splash Screen Number 2

The second splash screen indicates the Firmware and Version Numbers of the software used

in the system. The example shown is Firmware number 1312423: Version number 4.2/2.4.

The final screen is the RF Power default screen which indicates the Forward Power and

Reflected Power for the system.

The following screens are scrolled through using the buttons to the right of the display. Pushing

and releasing the Up & Down Arrows will scroll you through the Main Menus, which are shown

on the following pages aligned on the left side of the page. The Submenus of the Main Menus

are accessed by pushing and releasing the ENTER button. Once in the Submenus, pushing and

releasing the Up & Down Arrows will scroll you through the submenus of the Submenus. The

Submenus are shown on the following pages indented under the Main Menus and the submenus

of the Submenus are indented under the Submenu in which they are contained. In the SET UP

Menus, changes are made to the display by Pushing and releasing the ENTER button which

causes the item to be changed to blink, then using the left and right arrow buttons to display

the desired changed item, finally, pushing the ENTER button will accept the changes made upon

exit of the Set Up Menu.

NOTE: An example of accessing and changing an item using the Set Up Menus is as follows.

This procedure is to set the Off Air Receive Channel to the desired channel. Push and

release the DOWN Arrow button until the SYSTEM SET UP Main Menu is displayed.

Push and release the ENTER button. The Authorization Warning screen is displayed.

Push and release the ENTER button again and the ENTER BUTTON SETS TO CHANGE

MODE screen is displayed. Push and release the ENTER button again and the first set

up menu, which is the SET UP MENUS OF CHASSIS VALUES screen is displayed. Push

and release the DOWN Arrow button until the SET UP 8VSB DEMODULATOR screen is

displayed. Push and release the ENTER button to display the submenus under the SET

UP 8VSB DEMODULATOR menu. Push and release the DOWN Arrow until the 8VSB

DEMODULATOR USE OFF AIR CHxx is displayed. Push and release the ENTER button

and the XX, which indicates the Channel Number, will blink. Push and release the UP

or DOWN Arrow button until the desired new channel number is displayed. Push and

release the ENTER button, and the PUSH ENTER TO ACCEPT CHANGES menu is

displayed. Push and release the ENTER button again to accept the changes made.

The channel is now changed. Push and release the LEFT Arrow to exit to the SET UP

8VSB DEMODULATOR screen. Push and release the LEFT Arrow again to exit to the

SYSTEM SET UP Main Menu. Push and release the UP or DOWN arrows to browse the

main menus.

Technical Manual, Rev. 0 23

Page 28

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

The following screens are typical of an operating system. The values indicated on the screens

in your system may vary from those shown below.

Operation Screens

NOTE: The following Operation screens provide operating information only. No adjustments

are available using these screens.

Table 8: Transmitter/Translator RF Power Screen (BTD/BRD)

This is the default screen that is displayed after the splash screens are displayed. This screen

provides an indication of the Forward Output Power of the system in terms of Percent.

(Typically 100%). The screen also provides an indication of the Reflected Power of the

system in terms of Percent. (Typically less than 5%). Push the DOWN Arrow to view the next

main menu, which is the Transmitter Event Log Main Menu.

Table 9: Transmitter/Translator Event Log Main Screen (BTD/BRD)

This is the Transmitter Event Log Main Screen. Push the ENTER button to access the Event

List submenu. Push the DOWN Arrow to view the next main menu, which is the Transmitter

Details Main Menu.

Table 9.1: Transmitter/Translator Event List Screen (BTD/BRD)

When events occur, they will be displayed on this screen. The Up and Down arrow will

page you through the different entries in the event log. The above screen indicates

the 001 event of 013 total events that have occurred in the Transmitter. The number

in the parenthesis on the top right, is this case 01, indicates the number of times the

displayed event has occurred. The bottom line scrolls to indicate the event that

occurred, in this case RF Interlock Fault, and the time the event occurred after the

prior event. Push the LEFT Key to exit to the Transmitter Event Log Main Menu

screen. Pushing the RIGHT Key will access the Event Reset Screen.

Table 9.2: Transmitter/Translator Event Reset Screen (BTD/BRD)

This screen allows the resetting of events, after they are observed or corrected.

NOTE: Resetting the events on an amplifier may cause the transmitter to momentarily

mute.

Table 10: Transmitter/Translator Details Main Screen (BTD/BRD)

This is the System Details Main Screen. Push the ENTER button to access the Device Details

Chassis Values Main Sub Screen or push the DOWN Arrow to view the next main menu, which

is the System Set Up Main Menu.

Technical Manual, Rev. 0 24

Page 29

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Table 10.1: Transmitter/Translator Device Details Exciter Values Screen

(BTD/BRD)

This is the System Device Details Exciter Values Main Sub Screen. Push the ENTER

button to access the Device Details Exciter Values submenus or push the DOWN Arrow

to view the next main submenu, which is the 8VSB Demodulator Sub Menu.

Table 10.1.1: Transmitter/Translator Driver Forward/Reflected Power Details

Screen (BTD/BRD)

This screen provides an indication of the Output Forward Power of the Driver

Tray in terms of Percent, typically 20-70%. This screen also provides an

indication of the Reflected Output Power of the Driver Tray in terms of Percent,

Typically less than 3%.

Table 10.1.2: Heatsink Temperature Details Screen (BTD/BRD)

This screen indicates the temperature of the amplifier heatsink assembly,

mounted in the system or driver tray, in degrees Fahrenheit. If the

temperature is below the trip point, 194º F, it will indicate OK. If an

overtemperature Event (Fault) occurs, it will reset at 176º F.

(Typically 20º to 30º F. above ambient temperature)

Table 10.1.3: Power Supply Voltage Details Screen (BTD/BRD)

This screen indicates the power supply voltage in the system or driver tray. If

the power supply voltage is below the trip point, it will indicate OK. The fault

limit is the nominal supply voltage as set in the Exciter Setup Screen ±10%.

Table 10.1.4: RF System Interlock Details Screen (BTD/BRD)

This screen indicates if the external RF system interlock is present in your

system. (Typically Present. Must be present or system will remain in Standby.)

Table 10.1.5: Reject Load Interlock Details Screen (BTD/BRD)

This screen indicates if the external Reject Load interlock is present in your

system. (Typically Present. Must be present or system will remain in Standby.)

Table 10.1.6: AGC Details Screen (BTD/BRD)

This menu indicates if the AGC circuit has an input.

Technical Manual, Rev. 0 25

Page 30

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Table 10.1.7: AGC Overdrive Details Screen (BTD/BRD)

This menu indicates if the AGC circuit is operating within its range.

Table 10.1.8: AGC Auto/Manual Details Screen (BTD/BRD)

This menu indicates if the AGC circuit is operating in Auto or Manual.

Table 10.1.9: ALC Voltage Level Details Screen (BTD/BRD)

This menu indicates the Auto ALC voltage setting. (Typically 1 to 5 V)

Pushing the Left Arrow will display the System Device Details Exciter Values

Main Sub Screen and then pushing the Down arrow will access the System

Device Details 8VSB Demodulator Main Sub Screen.

Table 10.2: Translator 8VSB Demodulator Details Screen (BRD)

This is the System Device Details 8VSB Demodulator Main Sub Screen. Push the

ENTER button to access the Device 8VSB Demodulator submenus or push the DOWN

Arrow to view the next main menu, which is the Device Details 8VSB Modulator Main

Sub Menu.

Table 10.2.1: System Input Details Screen (BRD)

This screen provides the user information on the signal to noise ratio and signal

strength of the received signal. The signal to noise ratio is provided on this

menu to indicate to the user the quality of the receive signal. This reading also

assists the user in the positioning of the antenna. The signal strength ranges

from 0 to 100% and typically should be above 40% for reliable operation. The

signal strength allows the user to optimize the position of the receive antenna.

Table 10.2.2: Demodulator Details Screen (BRD)

This menu indicates whether there is a signal present at the demodulator.

Table 10.2.3: Demodulator Phase Lock Loop Details Screen (BRD)

This menu indicates whether the Phase Lock Loop is locked in the demodulator.

Table 10.2.4: Receive Input Channel Details Screen (BRD)

This menu indicates the input channel to the Demodulator circuit.

Technical Manual, Rev. 0 26

Page 31

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Pushing the Left Arrow will display the System Device Details 8VSB

Demodulator Values Main Sub Screen and then pushing the Down arrow will

access the System Device Details 8VSB Modulator Main Sub Screens.

Table 10.3: Transmitter/Translator 8VSB Modulator Details Screen

(BTD/BRD)

This is the System Device Details 8VSB Modulator Main Sub Screen. Push the ENTER

button to access the Device 8VSB Modulator submenus or push the DOWN Arrow to

view the next main menu, which is the Device Details IF Processor Main Sub Menu.

Table 10.3.1: Transmitter/Translator S310 Input Details Screen (BTD/BRD)

This menu indicates if the modulator has locked to the SMPTE-310 signal

coming from the demodulator.

Table 10.3.2: Modulator Phase Lock Loop A Details Screen (BTD/BRD)

This menu indicates if the Phase Lock Loop A in the modulator is locked.

Table 10.3.3: Modulator Phase Lock Loop B Details Screen (BTD/BRD)

This menu indicates if the Phase Lock Loop B in the modulator is locked.

Table 10.3.4: Modulator Linear Equalization Details Screen (BTD/BRD)

This menu indicates if the Linear Equalization is being used.

Table 10.3.5: Modulator Non Linear Equalization Details Screen (BTD/BRD)

This menu indicates if the Non Linear Equalization is being used.

Pushing the Left Arrow will display the System Device Details 8VSB Modulator

Values Main Sub Screen and then pushing the Down arrow will access the

System Device Details IF Processor Main Sub Screen.

Table 10.4: Transmitter/Translator IF Processor Details Screen (BTD/BRD)

This is the System Device Details IF Processor Main Sub Screen. Push the ENTER

button to access the Device IF Processor submenus or push the DOWN Arrow to view

the next main menu, which is the Device Details Upconverter Main Sub Menu.

Technical Manual, Rev. 0 27

Page 32

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Table 10.4.1: IF Processor Input Details Screen (BTD/BRD)

This menu indicates if there is an input signal to the IF Processor.

Table 10.4.2: IF Processor Modulation Present Details Screen (BTD/BRD)

This menu indicates if there is Modulation on the signal to the IF Processor.

Pushing the Left Arrow will display the System Device Details IF Processor

Values Main Sub Screen and then pushing the Down arrow will access the

System Device Details Upconverter Main Sub Screen.

Table 10.5: Upconverter Device Details Screen (BTD/BRD)

This is the System Device Details Upconverter Main Sub Screen. Push the ENTER

button to access the Device Upconverter submenus or push the DOWN Arrow to view

the next main menu, which is the Device Details Downconverter Main Sub Menu.

Table 10.5.1: Upconverter Phase Lock Loop 1 Details Screen (BTD/BRD)

This menu indicates if the Phase Lock Loop 1 in the upconverter is locked.

Table 10.5.2: Upconverter Phase Lock Loop 2 Details Screen (BTD/BRD)

This menu indicates if the Phase Lock Loop 2 in the upconverter is locked.

Table 10.5.3: Upconverter 10 MHz Phase Lock Loop Details Screen (BTD/BRD)

This menu indicates if the 10 MHz Phase Lock Loop in the upconverter is locked.

Table 10.5.4: Upconverter 10 MHz Details Screen (BTD/BRD)

This menu indicates if the 10 MHz reference used is generated internally or

provided by an external reference source.

Table 10.5.5: Upconverter System Channel Details Screen (BTD/BRD)

The upconverter transmit channel screen indicates the channel that the

upconverter is currently set and the center frequency of that channel.

Displayed above is CH: 7 that has a Center Frequency of 177MHz.

Pushing the Left Arrow will display the System Device Details Upconverter

Values Main Sub Screen and then pushing the Down arrow will access the

System Device Details Downconverter Main Sub Screen, if present.

Technical Manual, Rev. 0 28

Page 33

Innovator CHV400BTD ATSC Transmitter Initial On Site

Turn On Procedure

Table 10.6: Downconverter Device Details Screen (BTD/BRD)

NOTE: This screen is only used with an Axciter.

This is the System Device Details Downconverter Main Sub Screen. Push the ENTER

button to access the Device Downconverter submenus or push the DOWN Arrow to go