Page 1

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

Chapter 2

System Description

The 840A (1064941) is a complete 10kW UHF internally diplexed television

transmit ter that operates at a nominal

visual output power of 10,000 watts peak

sync visual and an average aural output

power of 1000 watts with a 10 dB

aural/vis ual ratio.

2.1 System Overview

The 840A is made up of three cabinet

assemblies: the (A1) dual 250-watt

driver/amplifier assembly (1064946);

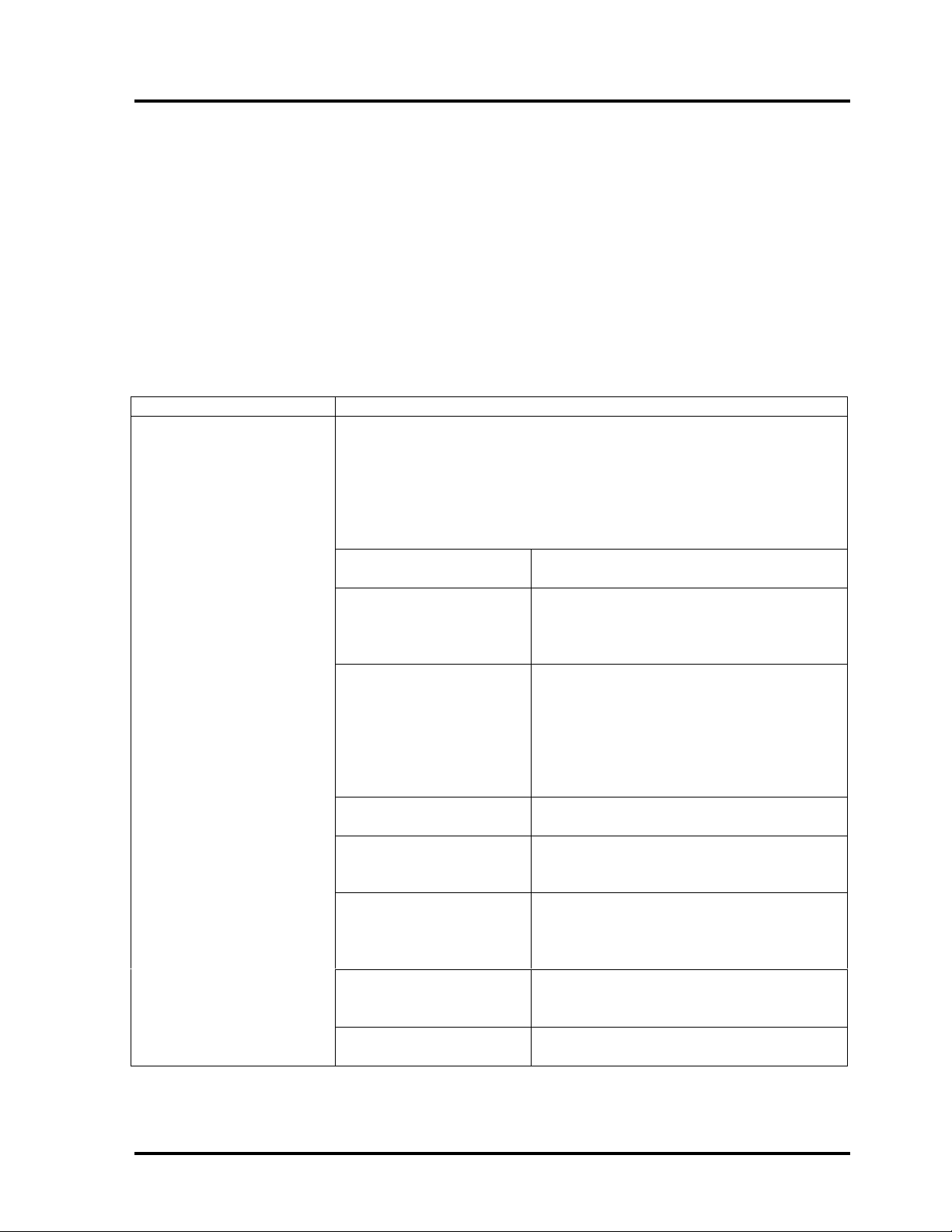

Table 2-1. Driver/Amplifier Assembly Assemblies and Trays

DESIGNA TIO N NUMBE R TRAY/ASS EMB LY NAME DRAWING NUMB E R

A2 AC distribution assembly 1265-1600

A4 UHF exciter tray 1063301

A9 3-wa tt am p lifi er tra y 10682 03

A6 and A7 250-watt amplifier trays

A14 Bandpass filter assembly --

(A2) the 10-kW ampl ifier assembly

(1299-1100); and (A3) the high-voltage

power suppl y assembly, 208/240 VAC

(1068022).

2.1.1 (A1) Dual 250-Watt

Exciter/ Amplifier Asse m bly

(1064946; Appendix A)

The dual 250-watt d river/amplifier

assembly is made up of the assemblies

and trays shown in Table 2-1.

10440 27, low -b a nd ;

1044028, mid-band;

10440 29, h igh-b a nd

The exciter/amplifier assembly

(1064946) is connected to the baseband

video and aural inputs. The assembly

also provides connections for the remote

monit oring and operation of the

exciter/amplifier assembly. The UHF

exciter tray (1063301) takes the

baseband aural and video inputs and

produces the visual and aural RF signals

on the channel frequencies. The

combined visual and aural RF output (+7

dBm) of the exciter feeds the 3-watt

amplifier tray (1068203). The 3-watt

amplifier tray contains an automatic gain

control circuit and two 3-watt amplifier

boards. The tray generates the output

level needed to drive the 250-watt

amplifier trays (1044027, low-band;

1044028, mid-band; and 1044029, highband).

The output from the 3-watt tray is fed to

the (A10) RF hyb rid spli tte r SMA

connection J1. The RF hybrid splitter

output f eeds the RF signal to one of the

250-watt amplifiers directly and, through

(A5) the line stretcher, to the other 250wa tt amplifier. The line stretcher gives

the operator the ability to control the

phase of the output signal that is fed to

one of the 250-watt trays. Each of the

250-watt amplifier trays contains an

amplifier enclosure and feedforward

circuits to achieve an output of 250-watts

peak visual power and 25 watts of aural

power.

In the 250-watt amplifier tray, a forward

power samp le from the UHF coupler is

connected to the dual peak detector

board; this board provides a peakdetected fo rward sample to the amplifier

control board for metering purposes.

Before exiting the 250-watt amplifier

tray, the RF is fed through a circulator for

the protection of the tray from high

VSWR conditions. The reject port of the

circulator is cabled to the reject

840A, Rev. 0 2-1

Page 2

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

load/coupler board; this board supplies

the reflected sample to the dual peak

detector board, single supply. This signal

is then sent to the amplifier control board

for metering purposes. The output of the

250-watt visual amplifier trays is

combined in a UHF tee combiner, and fed

through (A14) a bandpass filter and

(A11) a directional coupler, before being

connected with1/2" heliax to the RF input

jack (A2-A1-J1) of the tube cavity

assembly in the 10-kW am plifier

assembly cabinet. The combined output

of the 250-watt visual amplifier trays

(350 watts) is t he level needed to drive

the 10-kW amp lifi er to 10,0 00 watts

peak sync visual output.

The ma in AC input to t he

exciter/amplifier assembly is (A2) the AC

distribution panel assembly (1265-1600).

The AC distribution panel assembly

contains a terminal block (TB1) that

connects to the main AC input (208/240

VAC). The terminal block has four metaloxide varistors (MOVs) connected across

the i nput lines for surge and transient

protection. The AC distribution panel

contains CB1, the 40-amp main AC

circuit breaker that distributes the AC

through the circuit breakers CB2 to C B7

to the exciter and amplifier trays.

2.1.2 (A2) 10-kW Diacrode Amplifier

(1299-1100; Appendix A)

The (A11) metering control panel (1293-

1308) on the amplifier assembly provides

the operator with front panel metering

for all voltage (M1 using S1) and current

(M2 using S3) readings that apply to the

tube. The metering control panel also

provides the aural, visual, and reflected

output power readings for the transmitt er

using meter M3 with switch S4. The front

panel assembly contains the switches

that control the Operate/Standby (S5)

and Automatic/Manual (S6) operation of

the 10-kW amp lifie r. When sw itch ed to

Operate, the panel supplies the driv er

enable (Operate command) to the

exciter/amplifier assembly. The

Automatic/Manual switch selects either

the automatic operation of the

transmitter, which uses the video input

to control the on/off state of the

transmitter, or the Normal front panel

control, manual operation, of the

transmitter. The metering control panel

also provides front panel c ontrol, through

switch S8, of the Visual Output Power

level. High-Volta ge Enable/Disable switch

S7 controls the high-voltage power

supply from the front panel of the 10-kW

diacrode amplifier. Normal/Exciter Test

switch S10, when in the Exciter Test

position, gives the o perator the ability to

operate the exciter/am plifier assembly

without operating the 10-kW amplifier.

Note: The exciter/amplifier assembly

output must be terminated into a

dummy load prior to using this

function

The metering control panel also has LEDs

on the f ront panel for a visual indication

of the operating status of the

transmitter: Operate/Standby,

Auto/Manual, High Voltage

Enable/Disable, Driver Mode

Norma l/Test, 3-Fau lt wit h Fault Rese t

Switch (S9), Fault Status Overtemp, and

VSWR Cutback. The front panel has

command status LEDs that indicate,

when they are lit, tha t the comm and has

been given. I n addition, the front panel

has Operate status LEDs that indicate,

when they are lit, tha t the comm and has

been carried out.

The metering control panel of the (A10)

remote control and cabinet interface

assembly provides intercabinet control

and mo nitoring for the exciter and highvoltage cabinets. The remote control and

cabinet interface assembly also provides

remote access to the transmitter for

monit oring and control purposes.

The (A6) screen power supply assembly,

60 Hz (1293-1321), in the rear

compartment of the amplifier cabinet,

produces the 500 VDC at 60 mA for the

tube. The (A5) control and bias power

supply assembly (1181-1402) contains

.

840A, Rev. 0 2-2

Page 3

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

two separate power supplies: the control

power supply and the bias power supply.

The control power supply produces the

±12 VDC to the metering circui ts (peak

detectors) in the 10-kW amplifier as well

as the fault sensing boards, differential

buffer boards, and control logic boards in

the metering control panel. The bias

power supply produces the -80 VDC bias

voltage to the tube. R1, the bias voltage

adjustment, is located behind the

metering control panel. It sets up the

idling current (1.5 amps), no RF drive, by

adjusting the bias voltag e. The (A3)

filament power supply assembly (1299-

1107) produces the 5.2 VDC to the

filament of the tube. The 10-kW

assembly also has (A16) a blower

assembly (1293-1325) that provides the

coolant air flow to the tube mounted in

the cavity assembly.

The RF output of the 10-kW amplifier at

(A2- A1-J2) is fed th rough a 3-1/ 8"

hardline to (A2) an output coupler (1020-

1043) that provides a reflected power

sample for fault and VSWR cutback

protection. The output at (A2-A2-J2)

connects to two UHF trap filters. The trap

filters screen out the -3.58-MHz, -4.5MHz, +8.08-MHz, and +9.00-MHz

intermodulation products as well as the

second visual harmonic frequency. The

output of the trap filter is fed through

(A1 8 ) the output coupler (1020-1002)

that provides a reflected and forward

power sample to (A19) the visual/aural

mete ring assembly (1162-1402) for

metering purposes. The output of the

couple r is then fed to the ante nna.

2.1.3 (A3) High-Voltage Power

Supply Assembly, 208/240 VAC

(1068022; Appendix A)

The (A3) high-voltage power supply

assembly, 208/240 VAC (1068022),

provides the 10-kW amplifier, through

TB4, with the AC voltage that the

assembly needs to operate. It also

supplies the AC needed to operate the

blower assembly, through TB6, and the

hig h-voltage, usi ng 18 AW G 29- k V

rubb er insu la te d wi res , need e d to

operate the tube in the 10-kW amplifier.

The high-voltage power supply produces

the 50 00 VDC a t 4.00 a mp s , ma ximum

current (black picture), or 1.5 amps

idling current (no RF drive applied) for

the plate (anode) of the tube. The

assembly contains (A1) the high-voltage

transformer (1293-6103), (A5, A6, and

A7) the thre e high -voltage rectifier

boards (1293-1101), (A8, A19, A22, and

A23) filter capacitors, and (A16) the

choke tha t genera te the high vol tag e.

The high-voltage power supply assembly

also contains the power supply metering

boards, the isolation relay boards, the

circuit breakers needed to supply highvoltage metering, high voltage-on sense,

the power-on sequence, the switching on

and off, and the protection of the high

voltage. The high-voltage power supply,

at TB2, is connected to the 10-kW

assembly that provides the +12 VDC for

metering, switching, and the Enable to

the high-voltage power supply.

2.1.4 (A19) Visual/Aural Metering

Assembly (1162-1402; Appendix A)

The visual/aural metering assembly

consists of (A1) a single peak detector

board (1162-1403) for the reflected

output metering. It also contains (A2) a

visual/ aural metering board (1161-1103

or 1161-1115) for aural output and visual

output power levels and reflected power

level for VSWR protection.

840A, Rev. 0 2-3

The visual/aural metering assembly takes

the forward and reflected power samples

from the (A2-A2) and the (A18) output

couplers. The assembly provides the

metering control panel on the front panel

meters with visual, aural, and refle cted

levels for remote monitoring and VSWR

protection.

The visual/aural metering assembly

consists of (A1) a single peak detector

board (1162-1403) for the reflected

Page 4

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

output metering. It also contains (A2) a

visual/ aural metering board (1161-1103

or 1161-1115) for aural output and visual

output power levels and reflected power

levels for VSWR protection.

2.2.1 Exciter/Driver Cabi net

2.2.1.1 UHF Exciter Tray

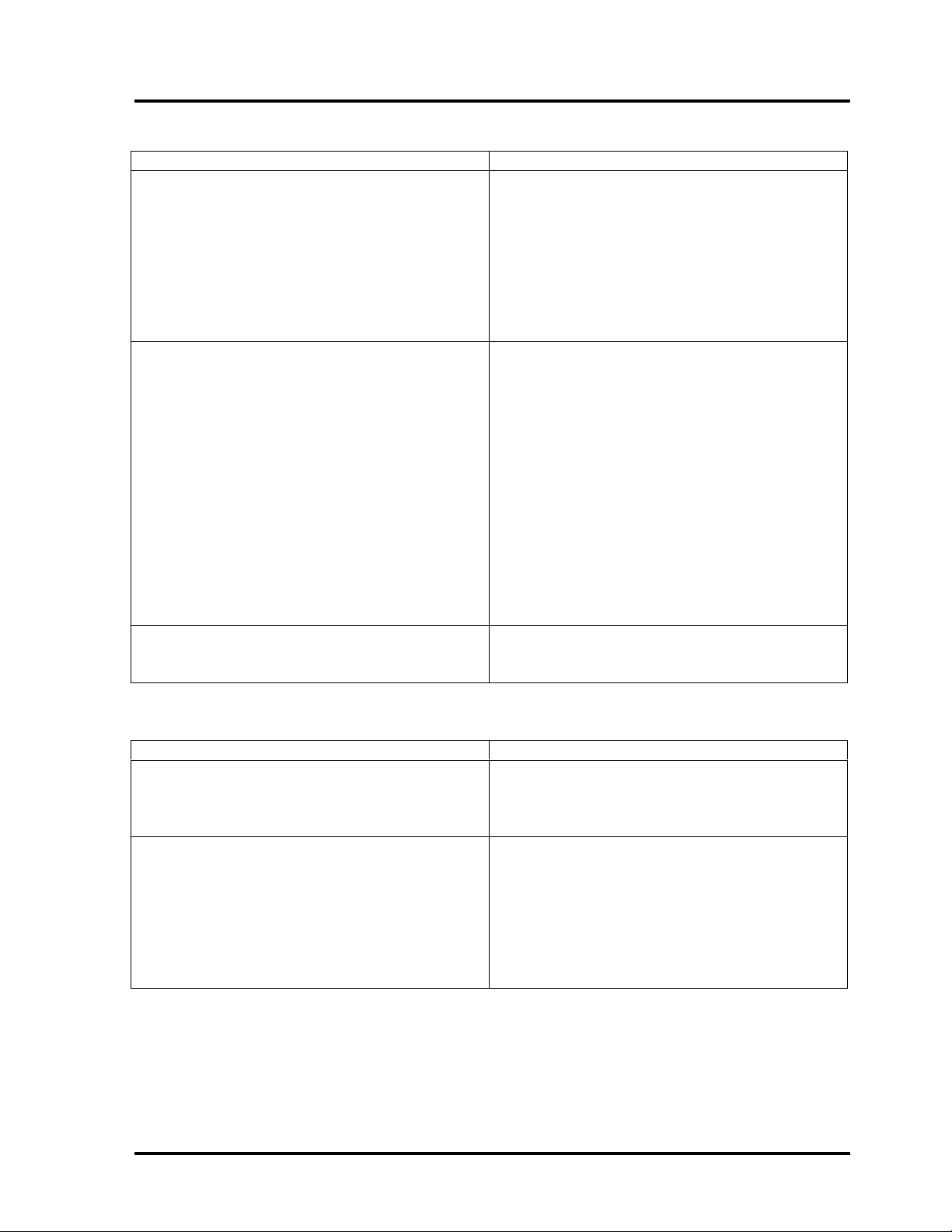

Table 2-2. UHF Exciter Tray Meters

METER FUNCTION

Reads power in terms of a percentage of the calibrated output

power level on the upper scale. The voltage level or frequency

level is read on one of the two bottom scales. A full-scale

reading on the top scale is 120%; 100% is equivalent to the

full-rated 350 watts peak of sync visual. This meter also reads

% Aural Power, % Exciter Power, audio levels, video levels, and

ALC le v e ls .

With Sw itch S3 in

Position

Switch (S3), Meter

Meter (A4-A18)

Audio

ALC

(0 to 10 V)

% Exciter

(0 to 120)

% Aural Power

(0 to 120)

% Visual Power

(0-120)

Video

(0-1V)

2.2 Control and Status

Information on the control and status of

this system is provided by control,

status, and LED indicators and meters on

the front panel of the trays. The functions

of these control and status indicators are

de sc rib e d in the fo llo wing ta b l es .

Display

Selects the desired ALC voltage

reading, % Excit er Pow er, % Visual

Power, % Aural Power, video levels, or

aud io leve ls.

Reads the audio level, ±25 kHz

balanced or ±75 kHz composite, on

the 0 to10 (0 t o1 00 kHz ) scal e.

Indicates baseband audio if it is

connected to the transmitter and even

with the video + 4.5 MHz SCA input

selected.

Reads th e ALC voltage l evel, .85

VDC, on the 0 to10 scale

Reads the % Exciter Output Power

level needed to attain 100% output of

the transmitter on the top scale

Reads the % Aural Output Power of

the excite r/dr iver as sem bly

(100%=45 watts at 10 dB A/V ratio)

on the top scale

Reads the % Output Power of the

exciter/driver assembly (100%=450

watts peak sync) on the top scale

Reads the video level, 1V at white, on

the 0-10 scale

840A, Rev. 0 2-4

Page 5

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

Table 2-3. UHF Exciter Tray Control Switches

SWITCH FUNCTION

The momentary switch (S1) applies a

ground to K1, a latching relay on the

transmitter control board. K1 will switch

Transmitter (S1)

Operate/Standby

Mode Select (S2)

Auto/Manual

Power Adjust (R1)

either to Operate or to Standby, depending

on which direction S1 is pushed. When

switched to Operate, the low Enable

commands are applied to the four UHF

amplifier trays. The opposite occurs when

S1 is switched to Standby.

The momentary switch (S2) applies a

ground to K2, a latching relay on the

transmitter control board. K2 will switch the

transmitter to Automatic or Manual,

depending on which direction S2 is pushed.

In Automatic, the Video Fault command

from the ALC board will control the

operation of the transmi tter. The

transmitter will switch to Standby, a fter a

slig h t de lay , if the vide o input is los t and

will switch back to Operate, quickly, when

the video is restored. In Manual, the

transmitter is controlled by the operator

using the front panel Operate/Standby

switch or by remote control.

The 5 kΩ pot, A20, sets the ALC level on

the ALC board. This sets the output power

for the transmitter.

Table 2-4. UHF Exciter Tray Fault Indicators

FAULT INDICATOR FUNCTION

Indicates that the video input to the

Video L os s (DS9 Red )

VSWR Cutback (DS7 Amber)

transmitter has been lost. The fault is

generated on the ALC board in the UHF

exciter tray.

Indicates that the reflected power level of

the 10-kW transmitter has increased above

15%. This will automatically cut back the

output power level to 15%. T he fault is

generated on the transmitter contro l board

in the UHF exciter tray and is derived from

a peak-detected voltage in the am plifier

cabinet.

840A, Rev. 0 2-5

Page 6

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

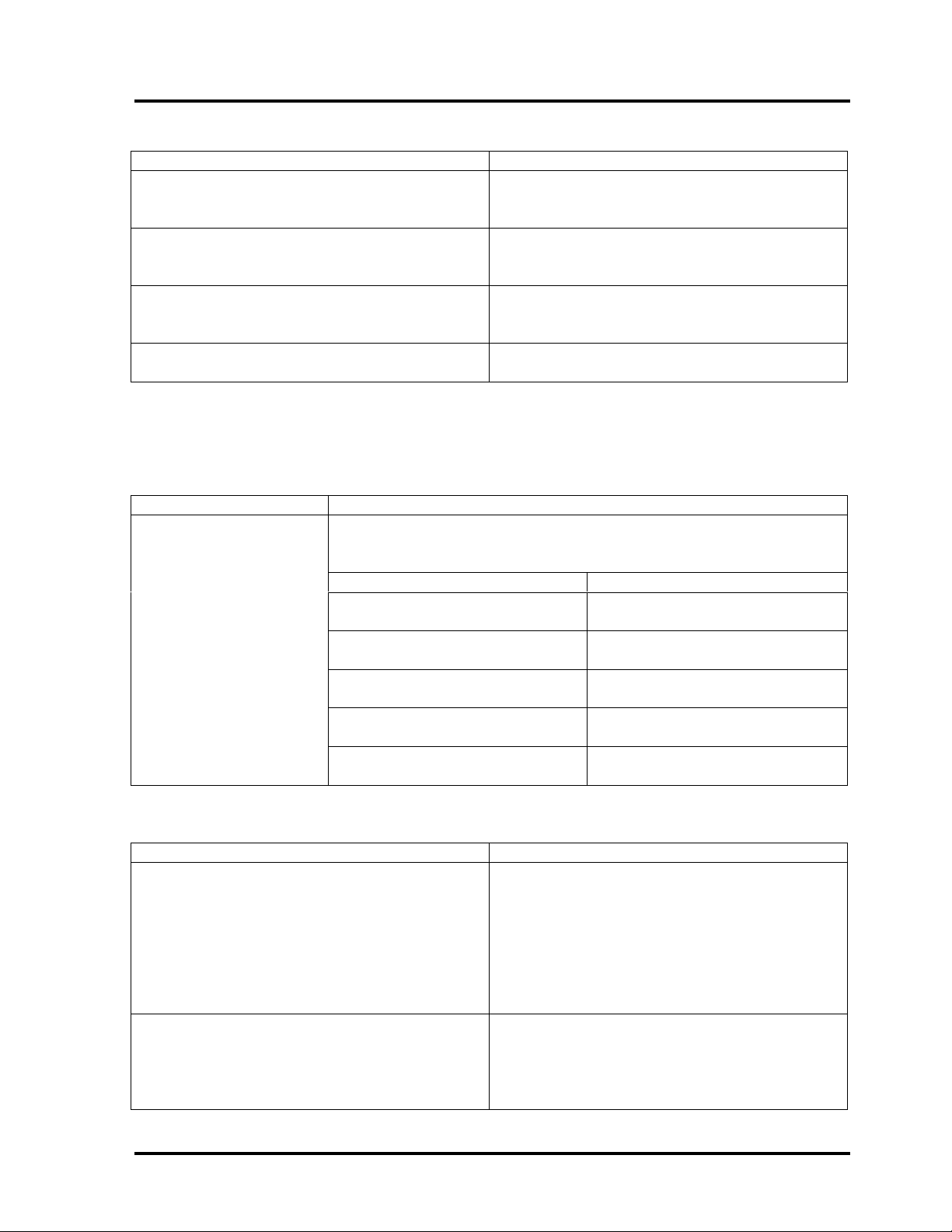

Table 2-5. UHF Exciter Tray Samples

SAMPLE DESCRIPTION

A sample o f the visual IF that is taken from

f(IF)

f(IC)

f(s)

Exciter O/P

2.2.2 3-Watt Amplifier Tray

Table 2-6. 3-Wa tt Amplifier Tray Meter

the sample jack on the IF carrier ove n

oscillator board

A sample of the intercarrier signal that is

taken from the sample jack on the aural IF

synthesizer board

A sample of the channel oscillator output

that is taken from the sample jack of the

channel oscillator assembly

An output power sample of the exciter that

is taken from the UHF upconverter board

METER

Power Meter, Switch

(S1)

Tab l e 2-7. 3-Wa t t Amp l i fi er Tray Fault Indi c ato rs

FAULT INDICATOR FUNCTION

Overtemp (DS1)

AGC Override (DS2)

FUNCTION

Selects whether the % Reflected Power, % Input Power, %

Forward Power, power supply voltage, or AGC voltage is to be

viewed on the meter

With Switch S1 in position Display

Reads the % Reflected O utput

% Refl (Reflected)

% Input

% Forw a rd Pow e r

P.S. Vo lt age

AGC Voltage

Indicates that the temperature of the

heatsink, where the Q1 and Q2 currentpass transistors for the +24 VDC power

supply are mounted, is above 175° F as

sensed by the thermal switch (S2) mounted

to the heatsink. When this fault occurs, the

Enable to t he is o l at io n relay is re m ov e d

immediately.

Indicates tha t the leve l out of the 3-watt

amplifier board has requested the AGC

circuit to exceed the A GC limits. The fault is

generated on the AGC board in the 3-watt

amplifier tray.

Power (<10%)

Reads the % Input Power to

the tray (10%)

Reads the % Forward Power

(100%=3 watts CW)

Reads the power supply

voltage (+24 VDC)

Reads the AGC voltage

(2 VDC)

840A, Rev. 0 2-6

Page 7

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

2.2.3 250-Watt Amplifier Trays

Table 2-8. 250-Watt Amplifier Tray Meters

METER FUNCTION

Reads power in terms of a percent of the calibrated power

output value. A full-scale reading is 100%, which is equivalent

to the full-rated 250 watts peak of sync visual + aural output

power. Also reads % Reflected Power, power supply voltage

levels, and AGC voltage levels.

Meter (A12)

With Sw itch S1 in

Position

Switch (S1), Meter

% Ou tput Pwr

% Refl (Reflected)

Power Supply

Selects the desired % Power or the

voltage readi ng

Reads the % Output Power of the

tra y (100%=250 watts peak of sync

visual with -10 dB aural on the top

scale)

Reads the % Reflected O utput Power

of the tray (<10%)

Reads the power supply voltage,

+26.5 VDC, on the middle scale

Display

Table 2-9. 250-Watt Amplifier Tray Status Indicators

STATUS INDICATOR FUNCTIO N

Indicates that an Enable, Operate,

Enable (DS1 Green)

Overtemp (DS2 Red)

command, is applied to the UHF amplifier

tray from the selected UHF exciter tray

Indicates that the temperature of (A1-A7

and A1-A8), one or both of the two thermal

switches mounted on the heatsink assembly

for the output amplifiers, is above 175° F.

When this fault occurs, the Enable to the

switching power supply in the affected

amplifier tray is removed immediately and

will shut down.

840A, Rev. 0 2-7

Page 8

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

2.2.4 10-kW A mplifier Assembly Metering Control Panel

Table 2-10. 10-kW Amplifier Assembly Meters

METER FUNCTION

Note: A multiplier,

Display

Note: A

Display

Voltage Meter

(M1)

Current Meter

(M2)

Rea ds DC voltage (a full-scale reading is 1 volt)

whose value is d epe nd en t on wh ich posit i on sw itch S1 is in,

must be applied. T he multiplier that is needed is marked in

parentheses near the swi tch.

With Switch S1 in

Position

Selects the desired plate voltage,

Switch (S1) Voltag e Meter

Plate (x10 k) Reads the plate voltage (typical

Screen (x1 k)

Bias (x1 k)

Fila m e nt (x10)

Reads DC current (a full-scale reading is 50 mA)

multiplier, whose value is dependent on which position

switch S2 is in, must be applied. The multiplier that is needed

is marked in parentheses near the switch.

With Switch S2 in

Position

Switch (S2), Current

Meter

Plate (x100)

Screen (x2)

Control Grid (x1)

screen voltage, bias voltage, and

filam ent voltage readings

reading is 5200 vo lts)

Reads the screen voltage (typical

reading is 500 vol t s )

Reads the bias voltage (typical

reading is 85 vo lts)

Reads the filament voltage (typical

reading is 5.2 volts; black heat

voltage is 1.5 volts)

Selects the desired plate current,

screen current, and control grid

current readings

Reads the plate current (a

typical reading is 1.5 amps, no

RF drive, to 4 amps; 100%

power, sync-only)

Reads the screen current (typical

reading is <60 mA)

Reads the control grid current

(typical reading is 0 mA to 5 mA)

Note: The meter reverse

switch (S3) must be switched

down to give an upscale

reading.

840A, Rev. 0 2-8

Page 9

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

METER FUNCTION

Reads power in terms of a percent o f the calibrated power value (a

full-scale rea ding will be 100%)

Power Meter

(M3)

Meter Polarity (S3)

Transmitter (S5)

Mode Select (S6)

With Switch S4 in

Position

Selects the desired visual output

Switch (S4), Power Meter

Visual Output

Aural Output

Reflected

Table 2-11. 10-kW Amplifier Assembly Switches

SWITCH FUNCTION

Changes the polarity of the measured

current applied to the meter. To properly

read the plate I and screen I, the meter

polarity switch must be in the Up (+)

position to give an upscale reading. To read

the control grid I properly, the switch must

be in the Down (-) position. The normal

setting of the meter reverse switch is the

Up position.

The momentary switch (S5) applies a

ground to K3, a latching Operate/Standby

relay on (A7) the transmitter control board.

K3 switches either to Operate or to Standby

depending on which direction S5 is pushed.

When S5 is switched to Operate, a low

Operate (Enable) command is applied to

(A1) the control logic board to start the

automatic turn-on procedure for the 10-kW

transmitter. The opposite occurs when S 5 is

switched to Standby.

The momentary switch (S6) applies a

ground to K1, a latching Auto/Manual relay

on (A7) the transmitte r control board. K1

switches the transmitter to Automatic or

Manual depending on which direction S6 is

pushed. In Automatic, a video fault

command from the upconverter tray

controls the transmitter. The transmitter

sw itc he s to Sta nd b y if th e vid eo input is lo s t

and will switch to Operate when the video is

reapplied. In Manual, the transmitter is

controlled through th e normal automatic

power, aural output

power and the reflected

output power readings

Reads the visual output power of the

10-kW amplifier (1 00%)

Reads the aural output power of the

10-kW amplifier (100%)

Reads the reflected visual output

power from the 10-kW amplifier

(<10%)

Display

840A, Rev. 0 2-9

Page 10

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

SWITCH FUNCTION

turn-on sequence with the operator using

the front panel controls or remote

control.

When the switch is enabled (Up), the

magnetic latching relay (K1) on (A1) the

control logic board will engage. The highvoltage enable indicator will light along with

the High-Voltage Request LED. The High-

HV (H ig h Voltag e) (S 7 )

Enable/Disable

Output Power (S8)

Fault Reset (S9)

Driver Mode (S10)

Normal/Test

Voltage On command to the high-voltage

relay will be applied at the proper time

during the automatic turn-on sequence.

When switched to Disable, the High-Voltage

On command will be removed, disabling the

high voltage and causing the Automatic Off

Cycle sequence to occur.

Adjusts the output power level of the

transmitter by raising or lowering the ALC

level on the visual ALC/AGC board in the

UHF exciter tray. This con trol is used to

compensate for the small, everyday

variations in the output power level. If a

major variation occurs, a problem exists.

After the problem has been repaired, the

output power level adjustment may also

require a re ad jus t m e nt t o t he AG C

voltag e levels (refer to the system setup

procedures in Chapter 3 of this manual).

As a fault occurs in the transmitter, the

Fault LED will flash on and then go off as

the transm itte r autom at ica l ly resets itse lf

to try to eliminate the problem. If the

problem rem a ins, the tr ansm itte r wil l try to

reset itself three times in approximately one

minute. After this, the Three-Fault indicator

will rema in lit and the trans mi tte r will

automatically shut down. When the problem

that caused the fault is found and repa ired,

the Fault Reset switch S9 must be set

be fore the tra nsmitter will recycle.

When the switch is in Normal (Up), the

transm itte r operates norma l ly. When the

sw itc h is in Te s t (Do w n) , t he ma g netic

latching r elay (K4) on (A7) the transmitter

control board supplies the driver Enable to

the exciter/driver assembly. This allows the

operation of the exciter/d river assembly

without requiring the 10-kW amplifier

section to be on. When this function is

being performed, the driver must be

terminat ed in t o a dum m y lo ad a nd the h ig h

voltage must be disabled.

840A, Rev. 0 2-10

Page 11

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

Note: The circuit break ers discussed

in Table 2-12 are on the AC

distributio n panel of the 10-kW

amplifier and the high-voltage power

supply assembly. For the other

circuit breakers on the panel to

operat e, t he m ain AC and the control

circuit breakers must both be

switch ed on

.

Table 2-12. 10-kW Amplifier Assembly Command Status Indicators

STATUS INDICATOR FUNCTIO N

Blower (DS8)

Note: When the preceding command

is completed, the auto matic turn-on

procedure will cycle the transmitter

through the command status and

corresponding operating status steps

from left to right on the front panel

LEDs. The Command Status indicator

shows that a command has been

given and the Operating Status

indicator shows tha t the comm an d

has been carried out .

Indicates that the Blower On command

(Enable) has been given by the control

logic. The blower is controlled by the

filament power supply control board that

sends a low Enable command to the

isolation relay on th e blower assembly. The

relay energizes and the closed contacts

apply 220 VAC to the blower contactor K1.

If the blower circuit breaker is turned on,

the 208/240 VAC 3 phase is applied to (A1)

the blower and the unit will operate.

Fila m e nt (D S9)

Bias (DS10)

High Vo lta g e (D S1 1)

Indicates that the blower is on and that the

Filament On command (Enable) has been

given to the filament power supply

assembly. If the black heat has been

applied to the filament for at least 10

minutes, the Operate co mmand activates

the ramp-up phase of the filament po wer

supply.

Indicates that the filament voltage has been

at 5.2 volts for approximately 20 seconds

and the Bias On comm and (Enable) has

been given t o th e isolation relay (A3) on the

control and bias power supply assembly.

The relay energi zes and, when the bias

circuit breaker is turned on, applies 220

VAC to the bias power supply board.

Indicates that the bias voltage is on and the

High Voltag e On command (Enable) has

been given t o th e isolation relay (A24)

in the high-voltage power supply assembly.

The relay energizes and applies +12 VDC to

the (A18) isolation relay and (K1) the

contactor control relay that control the

840A, Rev. 0 2-11

Page 12

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

STATUS INDICATOR FUNCTIO N

step-start and high-voltage contactors.

When the main AC and HV circuit breakers

are tu rne d on, 20 8/ 240 V AC is app l ied to

the transformer of the high-voltage power

supply.

Indicates that the high volt age (plate

voltage) is on and the Screen On command

(Enable) has been given to the isolat ion

relay (A7) mounted in the screen power

Screen (DS12)

RF Re quest (DS13)

supply assembly. The relay energizes and,

when the screen circuit breaker is switched

on, applies 220 VAC through the Sola 60 Hz

reg u lat o r to the transformer ( T1 ) th a t is

part of the screen power supply.

Indicates that the tube has all of the

voltages applied and that the RF On

command (Enable) has been given to

enable the exci te r/dr iver ass emb ly that

applies the RF drive to the 10-kW amplifier

Table 2-13. 10-kW Amplifier Assembly Operating Status Indicators

STATUS INDICATOR FUNCTIO N

Indicates that the blower is on. The

Blower (DS16)

Fila m e nt (D S1 7 )

Bias (DS18)

High Vo lta g e (D S1 9)

Screen (DS20)

RF Present (DS21)

quantity of air flow through the exhaust

stack is measured by the air pressure

sensor.

Indicates that the above step is complete

and t hat the filament voltage is on. This is

indicated when the filament voltage on

sense at J12-11 of the control logic board is

low.

Indicates that the above steps are complete

and t he bias voltage is on. This is indicated

when the bias on sense at J13-2 of the

co ntrol log ic bo ard is low .

Indicates that the above steps are complete

and t he high voltage is on. This is indicated

when the high voltage on sense at J13-8 of

the control logic board is low.

Indicates that the above steps are complete

and t he screen voltage is on. This is

indicated when the screen voltage on sense

at J13-14 of the control logic boa r d is low.

Indicates that the above steps are complete

and that there is a n RF output from the

transmitter. This is indicated when there is

a forward power sample fed to (J15 - 7 and

6) of the transmitter control board.

840A, Rev. 0 2-12

Page 13

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

Table 2-14. 10-kW Amplifier Assembly Fault Indicators

FAULT INDICATOR FUNCTION

Indicates that the air temperature in the

exhaust stack is above 200° F as sensed

by the thermal switch (A15-S1) mounted

Over Temp (DS22)

VSWR Cutback (DS23)

there. When this fault occurs, the voltages

will be immediately removed from the tube,

but the blower will continue running to

cool the transmitter.

Indicates that the reflected output p owe r

of the transmitter, as sampled at (J15 - 1

and 2) of the transmitter control board, has

exceeded 10%; this causes the 10-kW

amplifier to cut back the output power level

needed to maintain a 10% visual reflected

level. If the reflected output power level

exceeds 15%, a VSWR fault will occur and

cause the transmitter to shut down.

840A, Rev. 0 2-13

Page 14

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

2.3 Remote Control Int er face

Connections

The remote control interface

connections fo r the 840A

transmitter are listed in the

following tables.

Table 2-15. 10-kW Amplifier Assembly Remote Control Interface Connections

FUNCTION REMOTE JACK/PIN

NUMBER

Interlock (Total Shutdown) J1-1

Interlock (Total Shutdown)

Rtn

Interlock (Drv, Scrn, and

high voltage)

Interlock (Drv, Scrn, and

high voltage) R tn

Note: The jumper plug (1176-1019), with jumpers connected between pins 1

and 2 and 3 and 4, must be plugged into jack (J1) for the normal operation of

the transmitter.

Remote Status Indications

Transmitter Operate Ind J4-1 50 mA max current sink

Transm itter Operate Rt n J 4-2

Transmitter Auto Mode Ind J4-3 50 mA max cu rrent sink

Transm itte r Auto Mode Rt n J4-4

High Voltage Enable Ind J4-5 50 mA max current sink

High Voltage Enable Ind Rtn J4-6

J1-2

J1-3

J1-4

IN TERFACE TYPE

May be connected to a

remote interlock

May be connected to a

remote interlock

Fault Ind J4-7 50 mA max current sink

Fault Ind Rtn J4-8

RF Present Ind J4-9 50 mA max current sink

RF Present Ind Rtn J4-10

Overtemp Ind J4-11 50 mA max current sink

Overtemp Ind Rtn J4-12

VSWR Cutback Ind J4-14 50 mA max current sink

VSWR Cutback Ind Rtn J4-15

Video Fault Ind J4-16 50 mA max current sink

Video Fault Ind Rtn J4-17

840A, Rev. 0 2-14

Page 15

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

FUNCTION REMOTE JACK/PIN

NUMBER

Remote Commands

Operate Cmd J5-1 Contact closure

Operate/Standby Cmd Rtn J5-2

Standby Cmd J5-3 Contact closure

Auto Mode Select Cmd J5-4 Contact closure

Auto /Manual Se lec t Cm d Rtn J5-5

Manual Select Cmd J5-6 Contact closure

H.V. Enable Cmd J5-7 Contact closure

H.V. Enable/Disable Cmd

Rtn

H.V. Disable Cmd J5-9 Contact closure

Power Raise Cmd J5-10 Contact closure

Power Raise/Lower Cmd Rtn J5-11

Power Lower Cmd J5-12 Contact closure

Fault Reset Cmd J5-13 Contact closure

Fault Reset Rtn J5-14

J5-8

IN TERFACE TYPE

Remote Metering

Reflected Power Metering J6-1

Reflected Power Rtn J6-2

Visual Forward Power

Metering

Visual Forward Power Rtn J6-4

Plate Current Metering J6-5

Plate Current Rtn J6-6

Screen Current Metering J6-7

Screen Current Rtn J 6-8

Control Grid Current

Metering

Control Grid Current Rtn J6-10

Plate Voltage Metering J6-11

Plate Voltage Rtn J6-12

Scre en Voltage Met e r ing J6-1 3

Scre en Voltage Rtn J6-1 4

J6-3

J6-9

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

Bias Voltage Me t er in g J6-15 1V fu ll sc ale at 1 k Ω source

resistance

840A, Rev. 0 2-15

Page 16

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

FUNCTION REMOTE JACK/PIN

NUMBER

Bias Voltage Rtn J6-1 6

Fila m e nt Vo lt ag e Meteri ng J6-17

Fila m e nt Vo lt ag e Rt n J6- 1 8

Aural Forward Pow e r

Metering

Aural Forward Power Rtn J6-21

Note: T he remote control interface connections for the 10-kW amplifier connect

to jacks J1, J4, J5, and J6 of (A10) the remote c ontrol and cabinet interface

assembly mounted to the rear and at the top of the amplifier cabinet.

The remote connections listed in Table 216 are only made if the (A12) A/V input

and remote inte rfac e assembly are

present in the system. The remote

Table 2-16. UHF Exciter Remote Control Interface Connections

FUNCTION REMOTE CONT ROL/PIN

Transm itte r Enab le Inte rloc k J9-21

Transm itte r Enab le Inte rloc k

Rtn

J6-20

connections are made to jacks J9 and J10

on the assembly. Refer to the

interconnect drawing (1064945) for the

proper pin remote connections.

NUMBER

J9-22

IN TERFACE TYPE

1V full scale at 1 kΩ source

resistance

1V full scale at 1 kΩ source

resistance

IN TERFACE TYPE

J9-21 a nd 22 must be

jumpered together for

normal operation; (1176-

1038) jumper jack should

be used

Remote Control Commands

Transm itte r Stand by

(Disable)

Transmi tter

Standby/Operate Rtn J9-10

Transm itter Operato r

(Enable)

Transmitter Manual J9-15 Contact closure

Transm itte r Auto/ Ma nual

Rtn

Transm itte r Auto J9-17 Contact closu re

Power Level Raise (optional) J9-27 Contact clos ure

Pwr Lvl Raise/Lower Rtn

(optional)

Power Level Lower

(optional)

Modulator Select (optional) J9-31 Contact closure

J9-9

J9-11

J9-16

J9-28

J9-29

Contact closure

Contact closure

Contact closure

840A, Rev. 0 2-16

Page 17

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

FUNCTION REMOTE CONT ROL/PIN

NUMBER

Modulator Select Rtn

(optional)

Remote Status Indications

Transm itter Operate

(Enable) Ind

Operate/Standby Ind Return J9-13

Transm itte r Stand by

(Disable) Ind

Transmitter Auto Indicator J9-18 50 mA max current sink

Auto/Manual Indicator

Return

Transm itte r Man ual

Indicator

VSWR Cutback Indicato r J9-23 50 mA max current sink

VSWR Cutback Indicator

Return

Video Loss (Fault) Indicator J9-25 50 mA max current sink

Video Loss (Fault) Ind Rtn J9-26

J9-32

J9-12

J9-14

J9-19

J9-20

J9-24

IN TERFACE TYPE

50 mA max current sink

50 mA max current sink

50 mA max current sink

Rec ei v e r Fa u lt ( op t io nal) J9-30

Remote Metering

Reflected Power J9-5

Reflected Power Rtn J9-6

Exciter Output Power J9-7

Exciter Output Power Rtn J9-8

1V full scale at 1 kW source

resistance

1V full scale at 1 kW source

resistance

840A, Rev. 0 2-17

Page 18

10-kW UHF Transmitter with Chapter 2, System Description

Feedforward Driver

Table 2-17. UHF Amplifier Tray Remote Control Interface Connections

FUNCTION REMOTE JACK/PIN

NUMBER

Metering

3-watt Fwd Pwr Mtrg J10-16

3-watt Fwd Pwr Mtrg Rtn J10-17 1V at 1KΩ source resistance

250-watt amp A7 Fwd Pwr

Mtrg

250-watt amp A7 Fwd Pwr

Mrtg Rtn

250- wat t am p A7 Refl Pw r

Mtrg

250- wat t am p A7 Refl Pw r

Mtrg Rtn

250-watt amp A6 Fwd Pwr

Mtrg

250-watt amp A6 Fwd Pwr

Mtrg Rtn

250- wat t am p A6 Refl Pw r

Mtrg

250- wat t am p A6 Refl Pw r

Mtrg Rtn

Note: T hese remote co nnections are made only if the optional (A12) A/V input

and remo t e inter face assembly are present in the system. The remote

connections are made to jacks J9 and J10 on the assembly. Refer to the

interconnect drawing (1064945) for the proper pin remote connections.

J10-6

J10-7

J10-8

J10-9

J10-1

J10-2

J10-3

J10-4

IN TERFACE TYPE

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

1V at 1KΩ source resistance

840A, Rev. 0 2-18

Loading...

Loading...